Page 1

23435 Industrial Park Drive

Farmington Hills, Michigan 48335

tel: 248.476.0213

fax: 248.476.2470

Air-Oil Tank Installation Instructions

CAA & CSA Self-Compensating and

AA & SA Adjustable 2” & 3” Bore Series

Maximum efficiency of operation can be obtained by

carefully following these instructions:

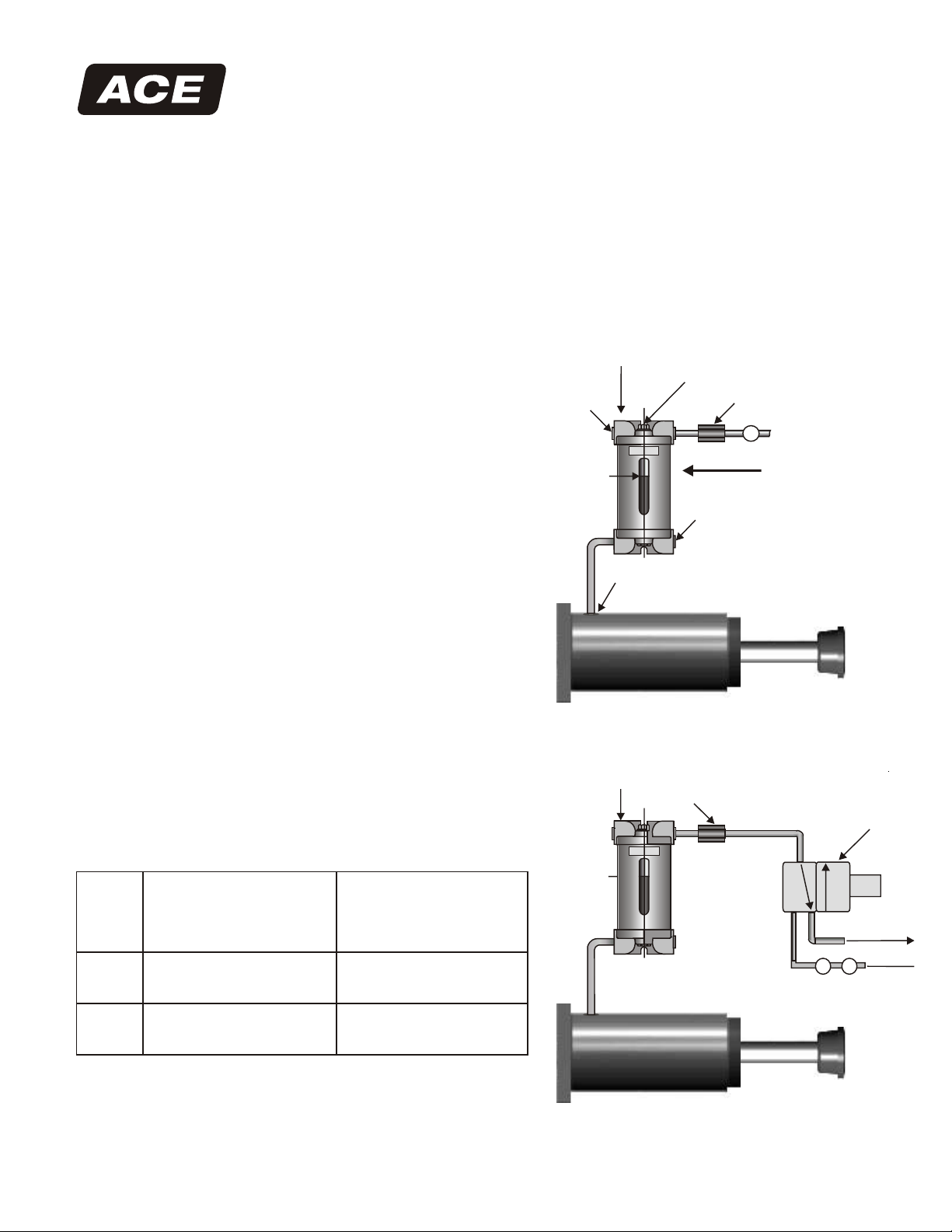

Figure 1

AIR-OIL TANK INSTALLATION (Figure 1)

Self-compensating models CAA and CSA as well as

adjustable models AA and SA are pre-filled with ATF

but must be connected to an air-oil tank before use.

Install the proper ACE air-oil tank as close as possible to,

and physically higher than the shock absorber. The line

connecting the shock absorber to the air-oil tank must

be free of kinks and loops. The inside diameter of this

line must be equal to, or greater than, that of the port

in the shock absorber.

Do not put a shut-off valve between the shock

absorber and the air-oil tank. Install a check valve in

the air line to the air-oil tank and plug the extra ports of

the tank. Fill the tank with ATF to the fill mark and charge

the system to between 50 - 100 psi (3.4 - 6.8 bar).

Air-Oil Tank

Plug

Do not fill

above this line

Inlet Port

WARNING

Do not use near open flame

contents may be flammable

www.acecontrols.com

Fill Plug

Check Valve

R

Free

Flow

Plug

AIR EXHAUST CIRCUIT FOR MODELS CAA and

AA SHOCK ABSORBERS (Figure 2)

If the rod is to remain in the shock absorber after

decelerating the load, this type of installation is

necessary. Avoid overfilling the air-oil tank. If not built in,

a special ACE check valve should be used to eliminate

misting of oil out of the air-oil tank.

PROPER AIR-OIL TANK SIZE

Refer to the chart below for proper air-oil tank size.

Bore

2”

3”

Air-Oil

Tank

AO-6-91

AO-6-91

Air-Oil Tank

(Re-circulating Circuit)

AO-6-91

AO-6-91

Figure 2

Air-Oil Tank

Do not fill

above this line

WARNING

Do not use near open flame

contents may be flammable

CV 3/4-F

TRT

3-Way Normal

Closed Valve

SOL

Exhaust

Supply

F

ACE Controls Inc.

World leader in deceleration technology

ISO 9001:2000 Certified

Page 2

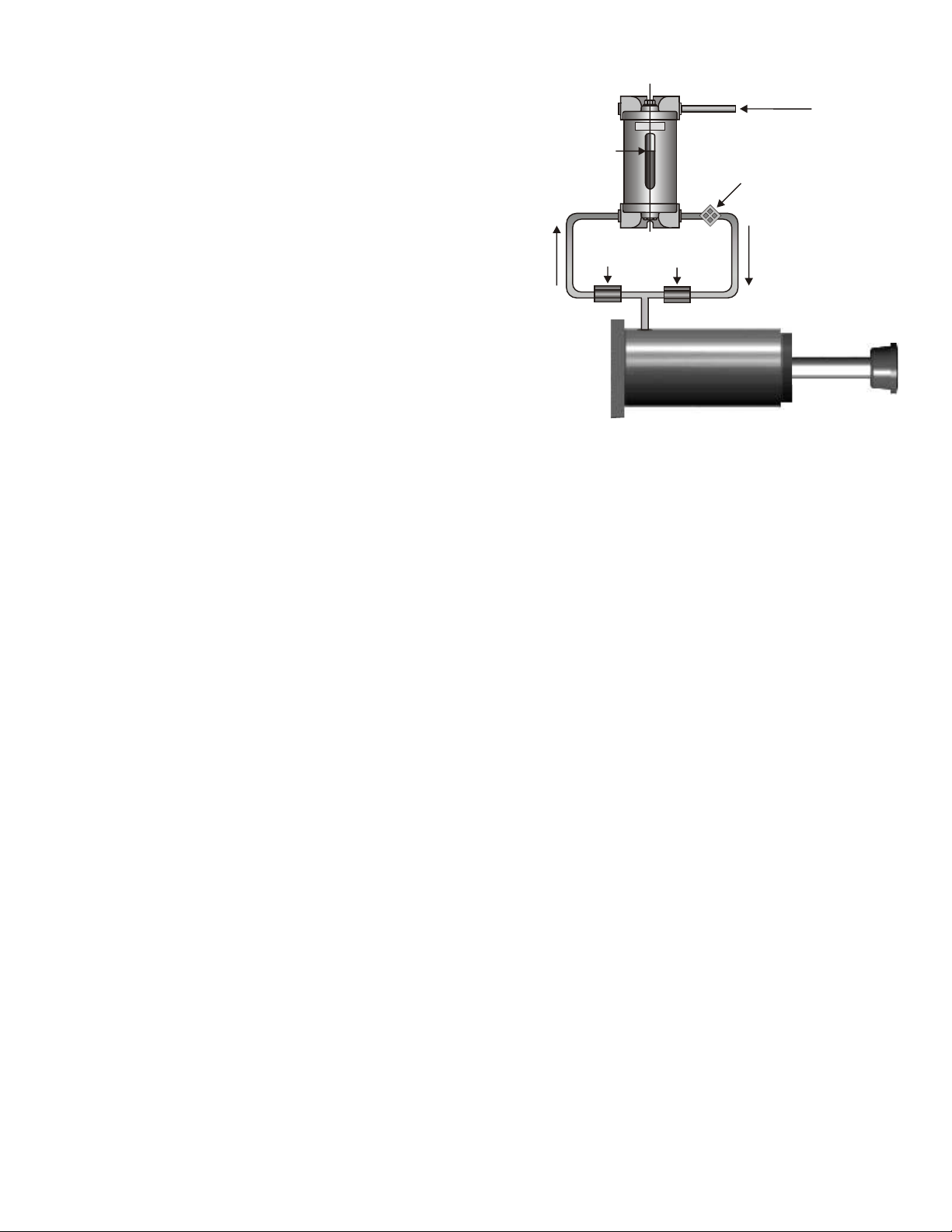

RE-CIRCULATING COOLING CIRCUIT FOR

MODELS CAA, CSA, AA and SA (Figure 3)

This type of installation may be required when ambient

temperatures and/or cycle rates cause the shock absorber

to heat up beyond 200 F (93 C).

0 0

Use 250 psi (17 bar) check valves with a low cracking

pressure of 5 psi (0.34 bar). If a filter is to be used in this

circuit, a 30 to 40 micron filter element with a 5 psi (0.34 bar)

by-pass is recommended. Consult factory for assistance.

Figure 3

Check Valve (2)

Do not fill

above this line

WARNING

Do not use near open flame

contents may be flammable

Air Supply

Optional Filter

ACE Controls Inc.

World leader in deceleration technology

ISO 9001:2000 Certified

ACE Form 19, Air-Oil Tank, 2” & 3” Bore Series

11/01/04

Loading...

Loading...