ACDelco 34113, 34131, 34135 Operating lnstructions

TM

Hydraulic

34113

34131

341

35

Trolley

Jack

GAUTION:

ACDelco,

Genenal

Pr

Motons

oducts

Operating

and

Before

using this

and Openational

ACDelco

Conporation,

Emblems,

conponation,

Lifting

product,

lnstr-uctions.

and

used under

19OO

So.

lnstructions

Cautions

nead this

ACDelco

Burgundy

related

license

Place

manual

gr.aphics

to and

Ontar io,

and follow

ane Trademar.ks

distr-ibuted

gt

Ca.

all safety

by Test

ZOi

U.S.n.

Rules

of

Rite

.

Study,

Do

not exceed

Use

only on

Lifting

understand,

devise

o

r

o

with appropriate

Failure

'

r

o

r

to heed

Lift

only

on areas

No alterations

0nly attachments

shall

be used.

and follow

rated

capacity.

hard, level

only .

lmmediately

means.

these

of

the vehicle

shall

be made

and/or

surface.

markings

adapters

all

instructions

after lifting,

may result

as

specified

to

this

supplied by

I

product.

wnnrurruo

before

operating this

supporr

the vehicle

personal

in

bythe vehicle

the manufacturer

injury

manufacturer.

and/or

devise.

property

damage.

BEFORE

During

jack

to

To release

1. Turn

2. Remove

3. Pump

4. Repeat

USE

shipment

malfunction.

air

from

release

valve

oil fill

jack

handle

above

steps as

or

handling,

the hydraulic

counter-clockwise

plug.

quickly

INSTRUCTIONS

TO RAISE:

valve

tightly

Ioad

proper

for

down

continuing.

height

procedure

MOVE

DAMAGE

(in

so that

1. Place

vehicle

2.

Close release

Center

Owner's

handle

correctly

load

jack

stands

Reverse

SLEEVE.

jack

IVanual

before

above

3.

4. Pump

5. Raise

6.

IMPORTANT:

VALVE

in PARK

under

up and

to desired

and remove

NEVER

air in

system:

in several

needed.

FOR

gear

0n

by turning

saddle

Iifting

until

lf not,

and

jack.

t0 remove

JACK

TO

THE PUMPING

jack

can

become trapped

with handle

full

strokes.

Bemember

no more

to replace

USE

standard transmissions)

handle

clockwise.

contacts load

points.)

saddle

recenter

place

jack

WHEN

contacts load.

jack

stands.

THE HANDLE

and

continue.

stands

UNIT MAY

f irmly

in correct

in the

hydraulic

than two

plug.

oil fill

and apply

and will not

Check to insure

position.

IS IN

OPERATING

OCCUR.

system

full turns.

emergency

slip.

that

SL0WLY transfer

brake.

(Refer

saddle is

LEVEL

causing

to vehicle

centered

load to

OR

THE

TO TOWEB:

1. 0pen

the release

release

valve is

valve

open,

VEBY

SLOWLY

the saddle

can

be lowered

by turning

the handle

easily

2

counter-clockwise.

hand

by

or foot.

When the

JACK

OIt

MAINTENANCE

LEVEL

:

IMPORTANT:

transmission

Never

use

brake fluid,

lmproper

ADDING

level

is

more

oil usage

0!L: With

REPLAGING

plate,

oil f iller

matter

into

the

LUBRICATION:

3 months.

BUsr

PBEVENTION:

every

3 months

the

saddle

and

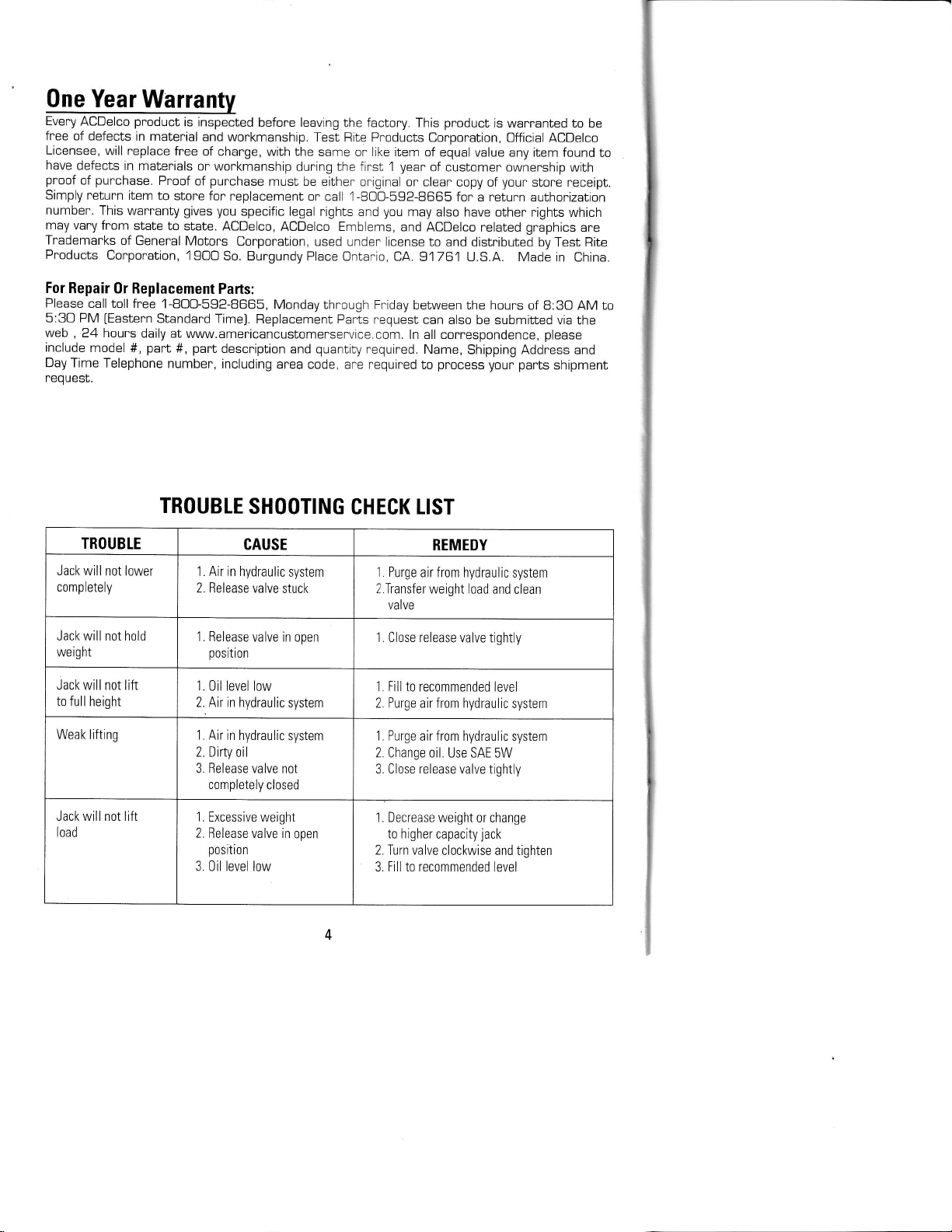

PARTS

HANDLE

2

HYDRAULIC

OIL FILL Pt UG

4

HANDLE

RELEASE

OVERLOAD VALVE

7

NIJT IVI12

SNAP RING'C'

SPRI NG

11

COVFB PI ATF

12

CARRING HANNI F

LIFTING ARIM

SADDI F

WHEEL

FLAT WASHFR

17

CASTER

SPRING

10

NUT I\iI8

when

oil or

turbine

will

ram

lhan112"

0l[:

0il should

plug

and

system.

grease

Put

orwhen

pump

LIST

RAM

BRACKET

VALVE

WASHEB IVI8

10

adding

alcohol,

cause

fully

below

release

clean

signs

piston

or replacing

oil and

always

glycerine,

serious

lowered

hole

be replaced

valve.

in

fitting

and

wipe

of rust

in the

completely

o

internal

and

replace

Be

on base

with

or

corrosion

offi-

oil,

always

avoid

mixing

detergent

damage

jack

on level

cover

at least

vEBy

CAREFUL

and

an

oiry croth,

down

1

19

L-18

17

use

diffeient

motor

to

plate.

once

everyyear.

lubricate

appear.

position.

13

@

3

o

7

good

a

oil

or dirty

jack.

ground,

to not

lifting

piston

the

when

12

@

I

grade

types

remove

To

allow

arm

not

14

4

of hydraulic

of oii.

oil of

oil fill

drain

dirt

or any

spindle

ram

and

in

use,

jack

any kind.

plug.

oil, remove

foreign

with

oil,

pump

piston

aiways

leave

15

I

@

3

2

Add

6

@

oil,

oil if

cover

every

L&

o

D0 N0T

Sometimes

0VERL0AD

during

JACK

shipment

BEYoND

trs

and handling,

1

RATED

air may

IMPORTANT

cApAcrry

become

rurvrR

trapped

3

5

uovrise

in the hydraulic

lAcK

wHtLE lr

system

?@

7;

ts

supponlNG

causing

poor

or

no lifting.

@

LoAD.

One Year

Eveny ACDelco

ft ee of defects

Licensee,

have

proof

Simply retunn

numben.

may

Tnademarks

Pt

For

Please

5:30 PIV

web

include

Day Time

nequest.

will neplace

defects

purchase.

of

in matenials

This wannanty gives

vany fnom

of

oducts

Conponation,

Bepair

0r Replacement

call toll

(Eastenn

24 houns

,

model

Telephone

Warranty

product

in material

item

state to

General lVotot

fnee 1-800-5S2-8665,

#,

is inspected

and

fnee of

wonkmanship. Test

charge, with the

or wonkmanship

Proof

to store fon

purchase

of

you

neplacement

specific legal

state. ACDelco,

s Conponation,

19oo

So. Burgundy

Parts:

Standand Timel.

daily at

www.amenicancustomenservice.com.

part

part

#,

number,

descr.iption

including

before leaving

the factory. This

Bite Products Conponation,

same or like item of

duning

must be

the first

eithen original or clean

'1

or call

-BOG592-8665

nights and

ACDelco Emblems,

used under

Place ontario, cA.

Mondaythnough Friday

Beplacement

anea code, are required

and

Parts nequest

quantity

pnoduct

'1

equal value any item

yean

of customen owner.ship

copy of

for a netunn

you

may

also have

and ACDelco

license to and

distnibuted by Test Rite

9176'1 u.s.A. IVlade

between the hour.s

can also be submitLed via

ln all cor.nespondence, please

requir-ed. Name,

to

Shipping Address

pnocess

is wanr.anted to be

Official ACDelco

youn

stone neceipt.

author.ization

othen rights which

gr

nelated

aphics ane

in China.

of B:30 AIV ro

youn pants

shipment

found to

with

the

and

TROUBTE

Jack

will not lower

completely

Jack will not hold

weight

Jack will not lift

to full

height

Weak lifting

Jack will not

load

lift

TROUBLE

1. Air

in hydraulic

2. Helease valve

1. Belease

positi

1. 0il level low

2. Air in hydraulic

1. Air

in hydraulic

2. Dirty

3. Belease valve

completely

1. Excessive weight

2. Release valve in

position

3. 0il level low

SHOOTING

CAUSE

system

stuck

valve in open

on

system

system

oil

not

closed

open

CHECK LIST

1 Purge

2.Transfer weight load

valve

1. Close release

l Fill to recommended level

2. Purge air from hydraulic

1. Purge

2. Change oil. Use

3. Close release valve

1. Decrease weight

to higher

2. Turn valve

Fill to recommended

3.

4

REMEDY

air from hydraulic

valve tightly

air from hydraulic system

capacity

clockwise and tighten

system

and clean

system

SAE 5W

tightly

or change

jack

level

TM

V6rin

34113

34131

34'135

Bouleur

Hydraulique

Mode

Attention:

ACDelco

corporation,

Buena Pank,

est I'embleme

d'emploi

Avant

d'utiliser

consignes

utilisees

CA 90621-18O8.

de secur

ACDelco

sous

de

pr.oduit,

ce

licence

line ce

ite et instructions

sont des

et distnibuees

et Pr6cautions

leuage

manuel et nespecten

d'emplol.

marques

5

de commerce

par-

Test

Bite Pr-oducts

toutes

les

de Gener-al

corpor-ation,

Motons

Loading...

Loading...