ACDelco 26 SI User Manual

26-SI ALTERNATOR

PRODUCT INFORMATION 1/98

1G/287 4/96

PAGE

1G-287

26 SI

HEAVY DUTY

BRUSHLESS ALTERNATOR

SERVICE MANUAL

©1998 Delco Remy International Inc. All Rights Reserved.

PAGE 1G-287 4/96

SPECIFICATIONS:

MAXIMUM SPEED:

Continuous: 10,000 rpm

Intermittent: 12,000 rpm

AMBIENT TEMPERATURE LIMITS:

-40°C to +85°C

(-40°F to + 185°F)

TRANSIENT VOLTAGE LIMITS:

100V - 300 ms (12-volt)

250V - 300 ms (24-volt)

POLARITY: Negative Ground

ROTATION:

Clockwise or Counterclockwise

26-SI ALTERNATOR

FEATURES

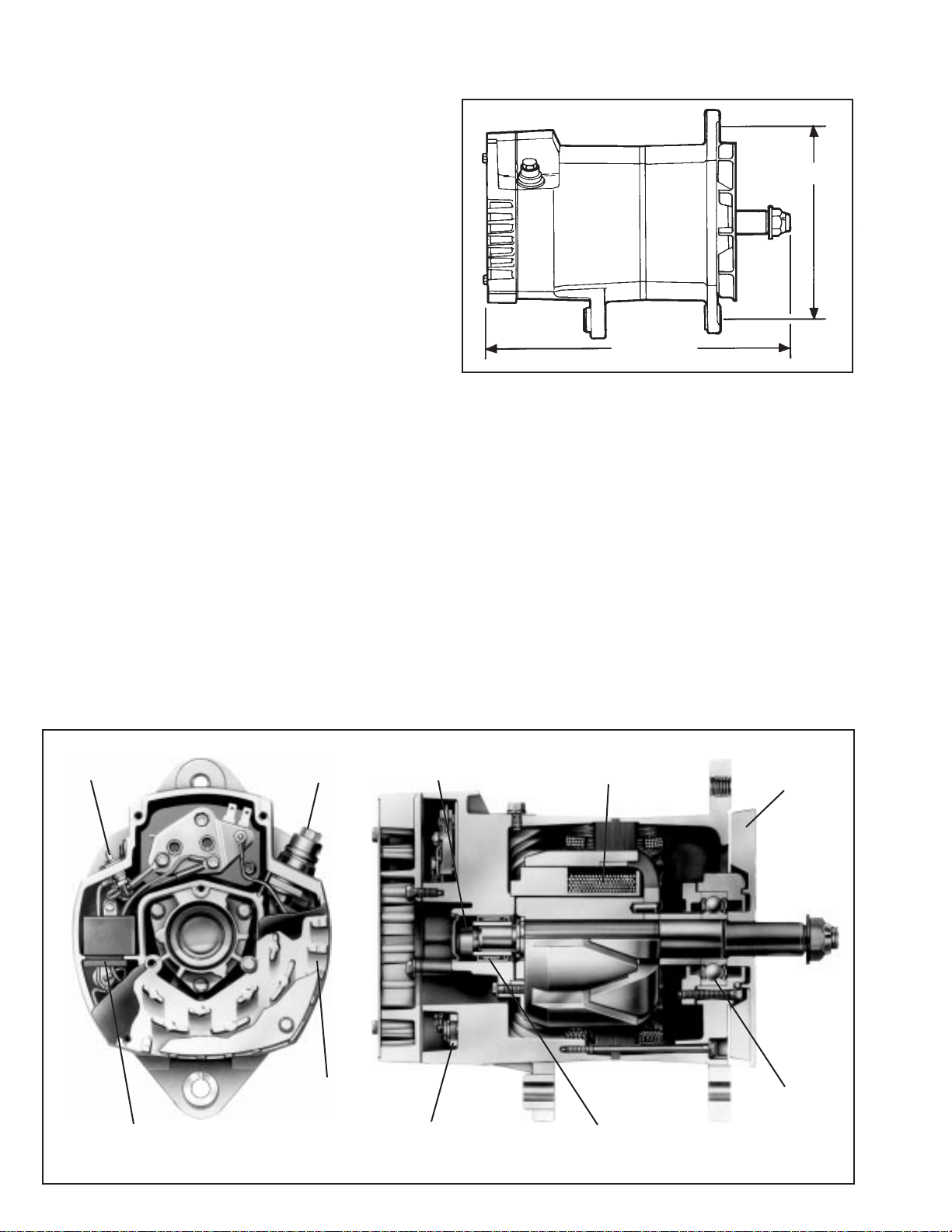

198.0 mm

302.5 mm

26-5010

WEIGHT: 27.6 lbs (12.5 kg)

MOUNTING SPAN: SAE Standard J180

Built-In Voltage Regulator

Solid-State Integrated Circuit

Flat Temperature-Compensated

Low Parasitic Draw

Low Turn-On Speed

Improved RFI Suppression

Load Dump Protection

Brushless Construction

Stationary Field Coil

No Brushes or Slip Rings

Relay

Terminal

Output

Terminal

“Inside-Cooled” System

Baffled Air Inlet

Sealed Live Parts

Prevents entry of large or

foreign material

Corrosion Protection

Sealed Rectifier-End Assembly

Brass Output Terminal Hardware

Applications

Line-Haul Diesel Trucks

Large Commercial Diesel Engines

Harsh Environments

Heavy Belt Loads and Vibrations

Extra-Large

Grease Reservoir

Stationary

Field Coil

Die Cast

Aluminum

Fan

Sealed Regulator and

Rectifier Compartment

Air Inlet

Baffles

Rectifiers

Heavy-Duty

Roller Bearing

Heavy-Duty

Sealed

Ball Bearing

26-5006

26-SI ALTERNATOR

1G/287 4/96

PRODUCT INFORMATION AND SERVICE MANUAL

26-SI HEAVY DUTY BRUSHLESS ALTERNATOR

CONTENTS

Introduction ............................................................... 1

Features ..................................................................... 2

Operating Principles.................................................. 3

Troubleshooting ........................................................ 3

A. All Charging Systems .................................... 4

B. Systems with Indicator Light......................... 4

C. Systems without Indicator Light.................... 5

D. R Terminal Accessory Problems ................... 5

E. No Output ....................................................... 5

F. Rated Output Check ....................................... 6

Alternator Unit Repair............................................... 7

Disassembly and Bench Checks ......................... 7

Final Disassembly............................................... 11

Alternator Assembly ................................................. 12

DE Frame and Rotor ........................................... 13

Rectifier End Housing and Components ............ 13

Final Alternator Assembly ................................. 16

Alternator Bench Test......................................... 19

Alternator Mounting .................................................. 21

Service Parts.............................................................. 25

Alternator Specifications........................................... 26

alternator rpm are also acceptable. The ambient temperature

range for proper operation is -34°C to +85°C (-30°F to

+185°F).

PAGE

1

26-5008

Figure 1. 26-SI Alternator

INTRODUCTION

The 26-SI series alternator is a brushless, heavy-duty

integral charging system with built-in diode rectifier and

voltage regulator, producing DC current for battery

electrical systems. The 26-SI series is designed for use on

large and mid-range diesel and gasoline engines in over

the-road service, as well as for off-road, agricultural, and

construction equipment.

The solid state, integrated circuit voltage regulator built

into the 26-SI alternator limits system voltage by switching

the ground circuit for the rotor field on and off. When the

ground circuit is on, field current passes from a diode trio

through the stationary field coil. Nominal regulated voltages

of 13.8, 14.0, and 14.2 volts are available for 12 volt

systems, and 27.5 volts for 24-volt systems.

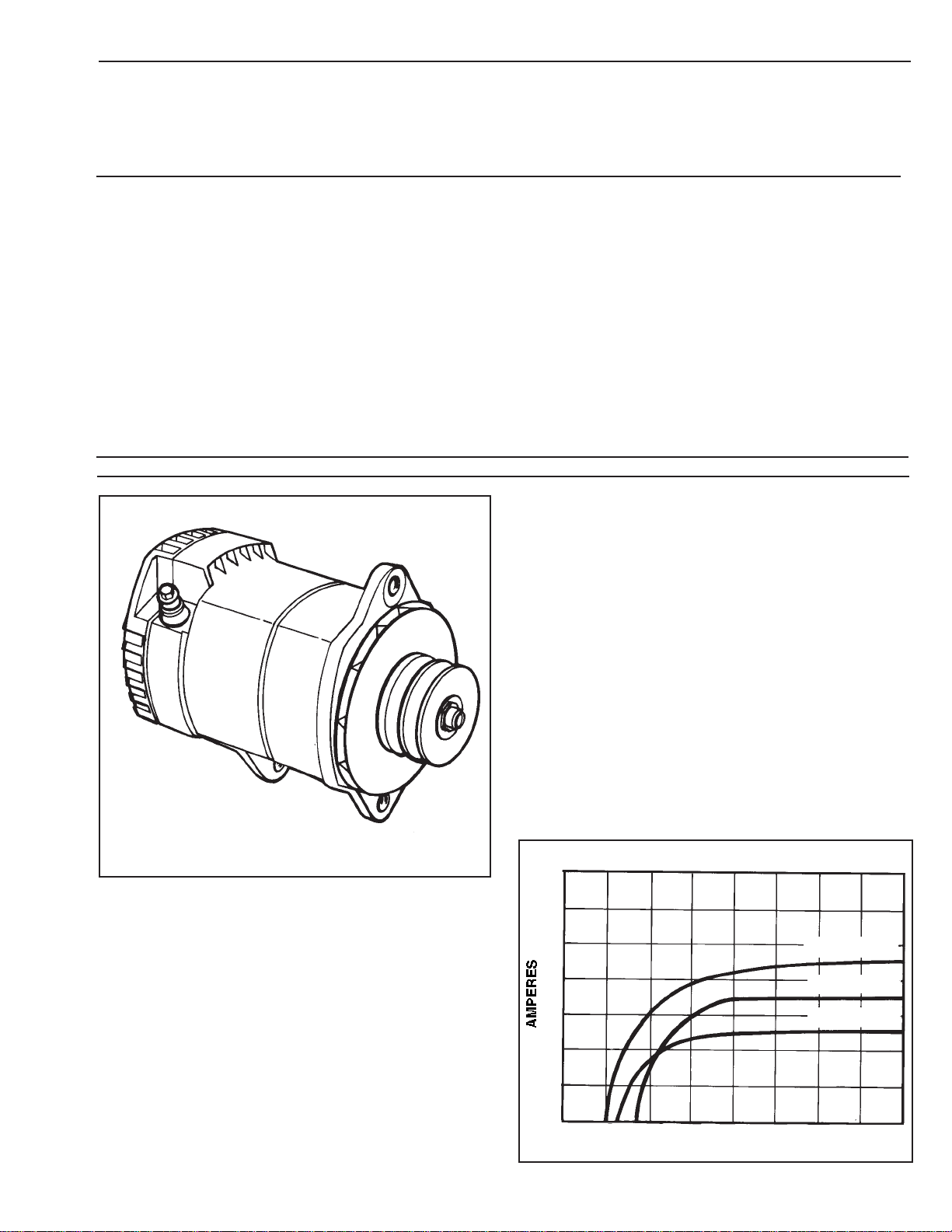

For 12-volt systems, an output rating of 85 amperes is

standard. For 24-volt systems, output ratings of 50 or 75

amperes are available. Refer to Figure 2 for graphs of

typical outputs over a range of alternator speeds. For

output ratings of specific 26-SI models refer to the

Specifications section of this manual.

140

120

100

A

M

P

80

E

R

60

E

40

S

20

85 amp 12V

75 amp 24V

50 amp 24V

The 26-SI alternator may be operated in either clockwise

or counterclockwise directions (external fan may require

changing to reverse rotation) at continuous speeds of up to

10,000 alternator rpm. Intermittent speeds of up to 12,000

1 2 3 4 5 6 7 8

RPM x 1000

26-5009

Figure 2. Typical Output vs. Alternator RPM

PAGE 1G-287 4/96

2

FEATURES

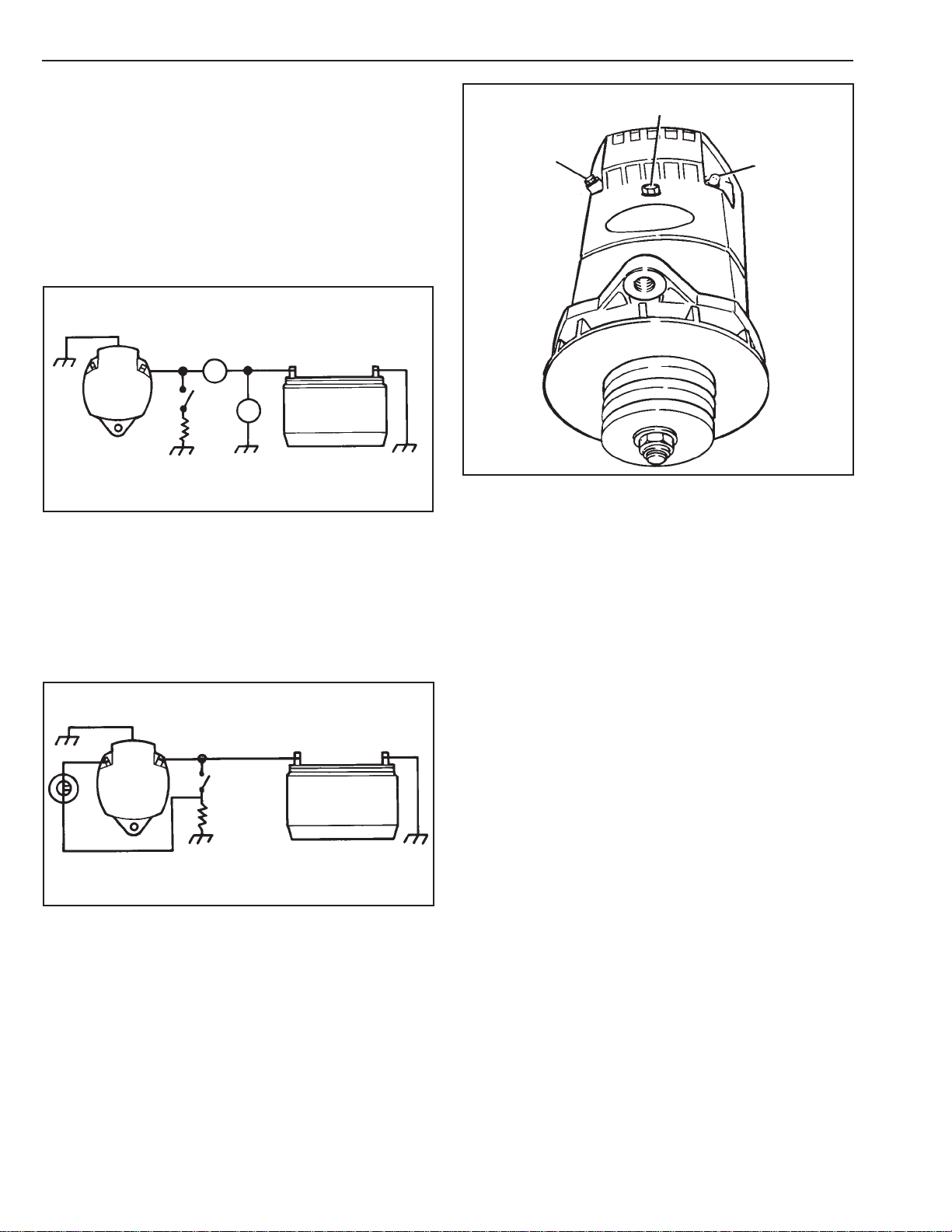

The 26-SI alternator is designed for a “one-wire” charging

system configuration. “One-wire” refers to the minimum

number of lead wire connections necessary at the alternator

for operation and requires only that the alternator output

terminal be connected to the battery insulated (positive for

a negative-ground system) terminal and that a ground

path be provided between the alternator housing and the

battery ground terminal. (See Figure 3)

A

V

OUTPUT

TERMINAL

(B+)

26-SI ALTERNATOR

GROUND

"R" or "I"

TERMINAL

GENERATOR

BATTERY

26-5011

Figure 3. Basic One-Wire System

Some applications use an “I” terminal circuit to power an

indicator light and/or to lower the engine speed (RPM) at

which the alternator will turn on. Typical system wiring

using this type of circuit is shown in Figure 4. This is

commonly referred to as a “one-wire system with I

terminal” or as a “two-wire system.”

GENERATOR

BATTERY

26-5012

Figure 4. One-Wire System with I Terminal

External connections to the 26-SI alternator are made to

terminals shown in Figure 5. The standard output terminal

is a “female” type with insulated connecting bolt and

charge lead cable with a special connector. When installed,

the electrical connection is sealed from moisture and there

are no exposed parts with battery voltage. The connector

bolt head is normally stamped “No Volts” to indicate the

insulated type.

26-5013

Figure 5. 26-SI Electrical Terminals

Some 26-SI models use a 1/4" threaded stud type of output

terminal. With this type of terminal, the exposed metal

parts are not insulated and will have battery voltage when

connected to the battery.

Optional connections to the 26-SI series include either an

“R” (relay) or “I” (indicator light) terminal, and a ground

lead connection to the alternator’s rectifier end housing.

An “R” or relay terminal is located on the side of the

alternator opposite from the output terminal. This terminal

may be used to operate some types of charge indicators, an

ADLO system, a tachometer, or similar device by providing

voltage pulses at a frequency of 8 pulses for each revolution

of the alternator. The current draw of the accessories being

powered through this terminal must not exceed 4 amperes.

“R” terminals are normally of the unthreaded pin type.

When an “I” terminal is present it will be located on the

side of the alternator opposite from the output terminal, in

place of the “R” terminal. An “I” terminal is connected

internally to the field circuit. An indicator light connected

in series with this terminal will glow whenever there is a

voltage difference between the “positive” side of the field

circuit and the system voltage at other side of the indicator

light. During normal alternator operation, the light will be

off since the diode trio output voltage equals the system

voltage. A side benefit of this circuit is that current is

passed through the field winding during engine start-up,

resulting in a lower alternator turn-on speed. A diode or

resistor may be used instead of a light bulb if no indicator

light is needed. (See Fig. 4) Up to 1 ampere of current may

26-SI ALTERNATOR

1G/287 4/96

PAGE

3

be passed through this circuit to aid in alternator turn-on.

An “I” terminal is normally a threaded stud type with a 1024 thread.

A threaded 1/4" hole (with screw and lockwasher) in the

rectifier end housing between the output and “R” or “I”

terminal is provided to connect a ground lead if used;

otherwise, the ground path is through the mounting

hardware and brackets to the engine. On replacement

units, a paper tag is present identifying the “ground

screw”; remove and discard the tag. The screw and

lockwasher should be installed in the housing regardless

of whether a ground lead is connected, to prevent entry of

dirt and water.

All electronic parts of the alternator are sealed in a

compartment to keep out moisture and dirt, and the

alternator is “inside cooled” by air drawn through a

baffled inlet in the rectifier end cover and exiting from the

drive end frame behind the fan.

OPERATING PRINCIPLES

An alternator is a voltage-creating machine. The voltage

regulator limits the maximum voltage that the alternator

will produce at the output terminal by controlling the

induce voltages in the stator windings. The faster the rotor

turns, the higher the induced voltage will be.

The initial voltages at start-up are generated by residual

magnetism in the rotor. On applications with an “I”

terminal in use, this magnetism will be boosted by a small

amount of current flowing through the field from the

indicator light circuit. As speed and output increase,

voltage available at the diode trio becomes sufficient to

supply field current for normal operation. When the

output voltage exceeds the battery voltage, the alternator

begins to drive the system voltage. If the wiring system

includes an indicator light, the presence of system voltage

at the diode trio equalizes the voltage on both sides of the

indicator light and the light goes out.

While the system voltage is below the voltage regulator

setting, the regulator turns on the field current and allows

the alternator to produce as much output as possible for the

alternator speed (rpm), temperature and system voltage.

When the voltage setting is reached, the regulator turns the

field current off. When the field current is turned off, the

magnetic field in the rotor collapses and the alternator

output voltage begins to fall. The falling voltage causes

the regulator to turn the field current back on and the

magnetic field to rebuild. This switching action of the

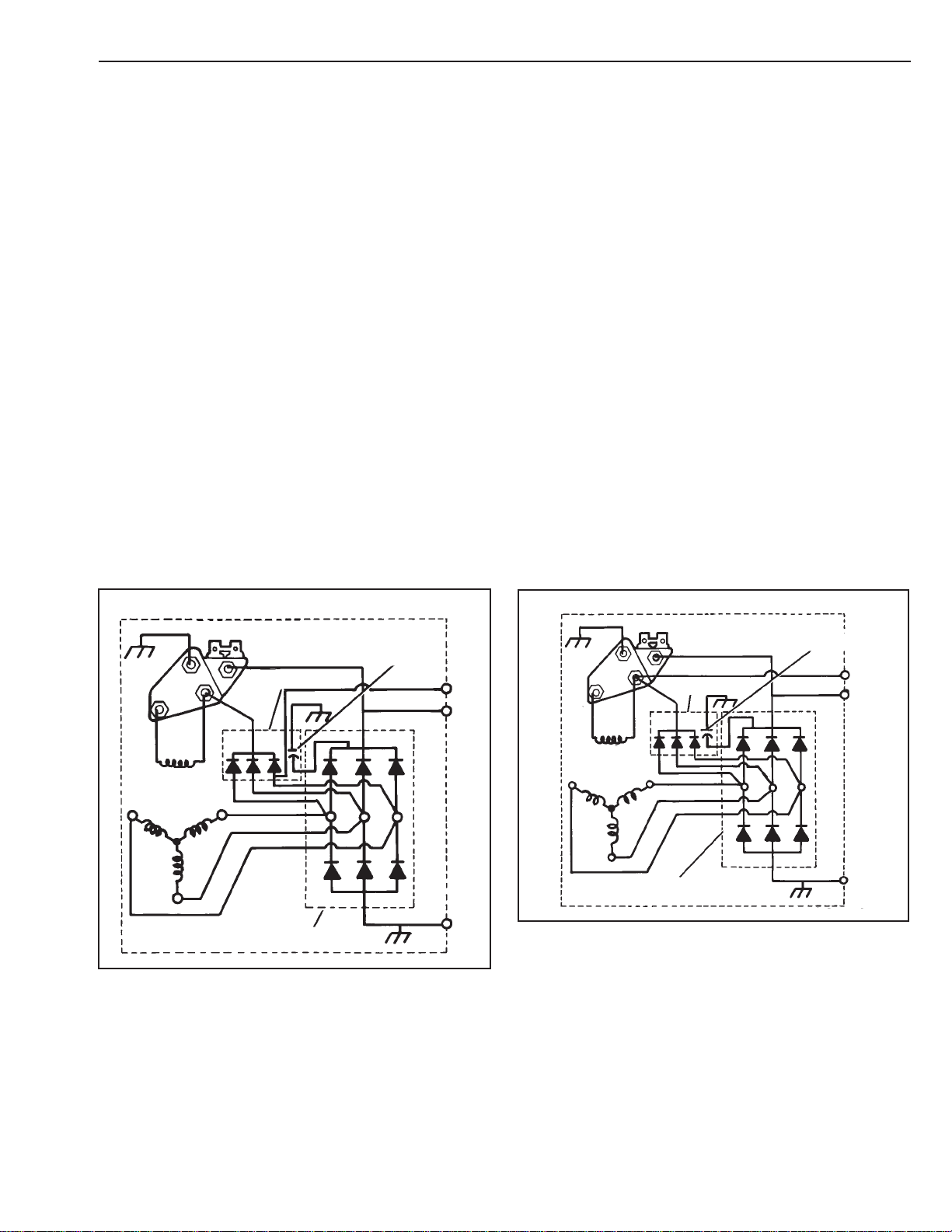

REGULATOR

CAPACITOR

DIODE TRIO

ROTOR

STATOR

RECTIFIER BRIDGE

R

B+

B-

26-5014

Figure 6. Alternator Schematic with R Terminal

magnetic field present in the stationary field. The output

voltage, induced in the stator and rectified by the diodes,

allows current to flow to satisfy the electrical loads placed

on the system, up to a maximum current that is characteristic

of the alternator design.

Schematics of the alternator circuitry are shown in Figure

6 (with “R” terminal) and Figure 7 (with “I” terminal).

With the alternator rotor turning, a magnetic field around

the stationary field coil is conducted by the rotor poles to

REGULATOR

DIODE TRIO

ROTOR

STATOR

RECTIFIER BRIDGE

CAPACITOR

GROUND

I

B+

B-

26-5015

Figure 7. Alternator Schematic with I Terminal

regulator continues rapidly, keeping the output and system

voltage very close to the voltage setting. This will continue

unless the electrical demands of the system cause the

system voltage to fall below the voltage setting. Should

this happen, the regulator will again allow full field

current to flow so that the maximum output of the alternator

at the given speed, temperature and system voltage is

realized.

An internal sense lead installed between the output

terminal/diode heat sink and regulator stud, is used for

voltage control.

PAGE 1G-287 4/96

4

26-SI ALTERNATOR

TROUBLESHOOTING

Trouble in the charging system will normally be indicated

by one of the following:

• Indicator light “on” with engine running.

• Indicator light “off” with key on, engine not running.

• Undercharged or overcharged battery.

• Short life of light bulbs or other electric equipment

caused by abnormally high system voltage.

• System voltmeter readings outside normal range.

• Incorrect or no operation of accessories connected to

alternator “R” terminal.

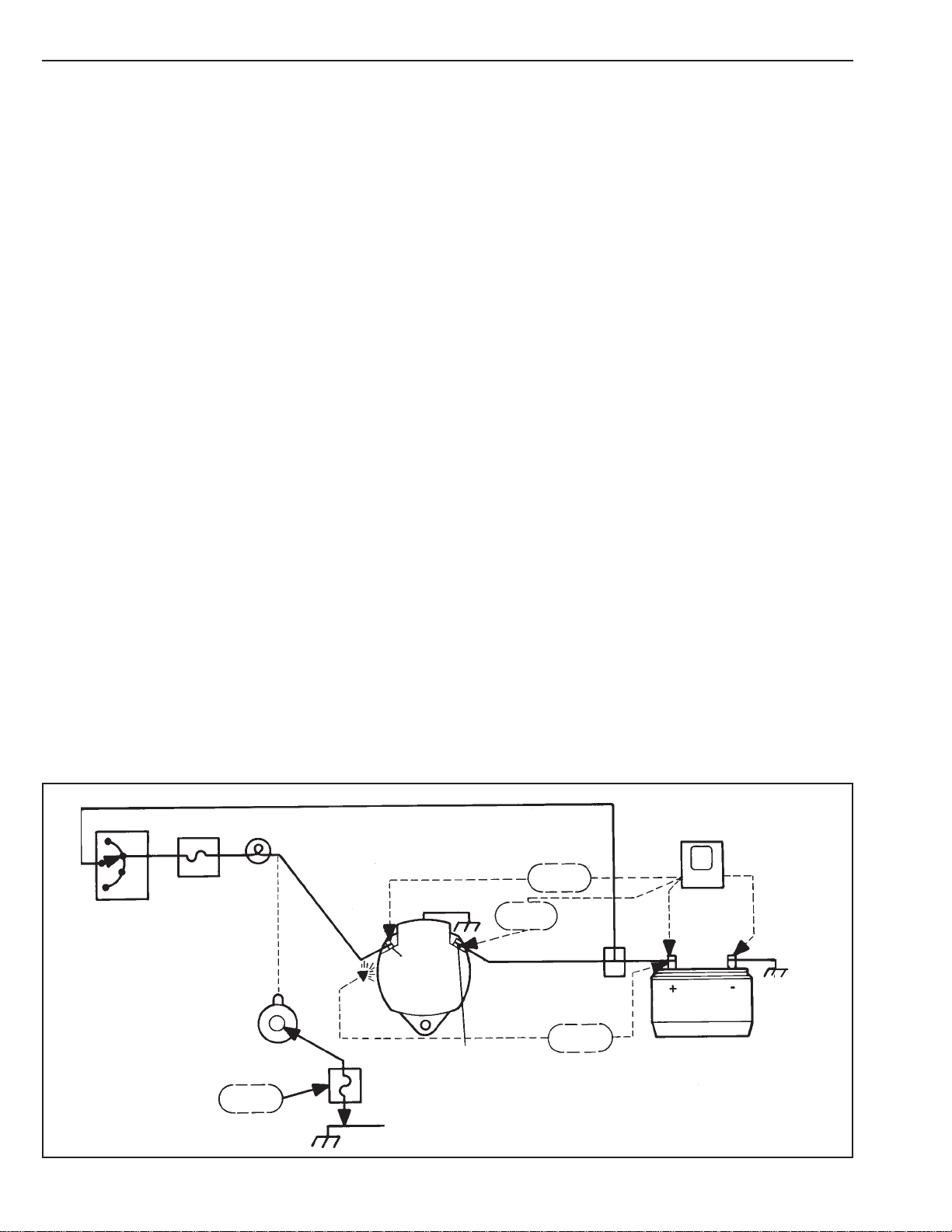

Diagnose system as follows: (See Fig. 8)

A. ALL CHARGING SYSTEMS -

TEST EQUIPMENT NEEDED:

• Belt Tension Gage

• Battery State-of-Charge Indicator

1. Check electrical system wiring and battery terminals

for poor connections or other obvious conditions that

might result in shorts, opens, grounds, or high resistance.

Correct as necessary.

2. Check alternator drive belt for proper tension. Adjust

to manufacturer's specifications.

3. Check battery for state-of-charge. If low, recharge

according to manufacturer’s specifications and load

test to establish serviceability. Further diagnostic tests

require a known good, fully-charged battery for accurate

results.

B. SYSTEMS WITH INDICATOR LIGHT -

TEST EQUIPMENT NEEDED:

• Jumper Lead with 5-Amp Fuse

1. If indicator light is on with engine running:

Stop engine. Turn key switch to “run” position. Indicator

light should be on. If not, go to Step 3.

Disconnect indicator light lead at alternator. This will

be the “I” terminal connector.

If indicator light remains on, locate and correct shorted

or grounded condition in indicator light circuit between

the light and the alternator.

If indicator light goes out, light is working properly.

Proceed to “C.” for check of system with indicator light

working properly.

2. If indicator light does not come on with the key switch

in the “run” position with the engine stopped (“bulb

check” mode):

Leave key in “run” position with engine stopped.

Disconnect indicator light lead from alternator. This

will be at the “I” terminal. Use fused (5-amp) jumper

lead to ground indicator lamp circuit in harness

connector to ground screw or other clean metal ground

on alternator housing.

- If indicator light comes on with jumper lead in place,

repair or replace alternator as described under Unit

Repair.

FUSE

KEY

SWITCH

TERMINAL

CONNECTOR

(DISCONNECTED)

BLOCK

INDICATOR

LIGHT ("I")

CONNECTOR

B2, B3

INDICATOR

LIGHT

INDICATOR

LIGHT

CIRCUIT

FUSE

"R" or "I"

TERMINAL

GENERATOR

OUTPUT

TERMINAL

D3,E2

D2

Figure 8. Troubleshooting a 26-SI System

E1

VOLTMETER

BATTERY

26-5016

26-SI ALTERNATOR

1G/287 4/96

PAGE

5

- If indicator light does not come on with jumper lead in

place, verify that alternator is properly grounded by

touching jumper lead to another ground source. If

lamp still does not light, locate and correct open circuit

in indicator light circuit. Circuit fuse may be open or

light bulb may be burned out. Correct as necessary.

3. If indicator light comes on while engine is running, but

is not on with engine stopped and key switch in “run”

position:

Leave key in “run” position with engine stopped.

Disconnect indicator light lead from alternator. This

will be at the “I” terminal. Use fused (5-amp) jumper

lead to ground indicator lamp circuit to alternator

housing.

- If indicator light comes on with jumper lead in place,

replace internal indicator light lead assembly or

regulator as described under Unit Repair.

- If indicator light does not come on with jumper lead in

place, locate and correct open circuit in indicator light

circuit between battery and light. Circuit fuse may be

open. (With engine running, light is being powered by

alternator and grounded through other circuits

connected in parallel to indicator light circuit.) Correct

as necessary.

4. If indicator light is on with key switch in “off” position:

Disconnect indicator light circuit at alternator.

- If voltage reading at battery terminals is different from

reading showing at system voltmeter (if equipped),

locate and correct cause of incorrect reading.

- If voltage is lower than reading previously recorded

with engine stopped, there is no alternator output.

Proceed to section on No Output.

- If voltage is higher than previous reading with engine

stopped, alternator output is present. Proceed to Rated

Output Check.

2. If battery is overcharged (as evidenced by excessive

water use or electrolyte spewing from battery vents), or

light bulbs or other electrical equipment have shortened

life due to suspected high system voltage, or system

voltmeter reads above normal range:

With fully charged battery, engine running at moderate

speed and all electrical loads off, use voltmeter to

check voltage at battery terminals.

For a 12-volt system, readings should be stable, around

13.5 - 14.5 volts and in no case go above 15 volts. For

a 24-volt system, readings should be stable, around 27

- 28 volts and in no case go above 31 volts.

- One-wire system: If voltage is erratic or goes above 15

volts (31 volts on 24-volt system), check internal sense

circuit and regulator as described under Unit Repair.

- If indicator light remains on, locate and correct shorted

condition between the light and alternator.

- If indicator light goes out, diode is shorted in rectifier.

Locate and replace diode as described under Unit

Repair.

C. SYSTEMS WITH VOLTMETER, NO INDICATOR

LIGHT, OR WITH LIGHT WORKING PROPERLY -

TEST EQUIPMENT NEEDED:

• Voltmeter

1. If battery is undercharged, indicator light remains on

while vehicle is running, or system voltmeter shows

operating voltage is below acceptable range:

With engine stopped and all electrical loads off, use

voltmeter to check system voltage across battery

terminals. Record voltage.

Start engine and run at moderate speed. Check system

voltage across battery terminals with engine running.

D. R TERMINAL ACCESSORY PROBLEMS

1. Disconnect lead from “R” terminal.

2. Start engine and run at moderate speed. Check system

voltage across battery terminals with engine running.

Record voltage.

3. Use voltmeter to check voltage between “R” terminal

and alternator ground screw or other clean metal ground.

- If voltage is near half of system voltage, “R” terminal

output is O.K. Note that this is a pulsating signal, so

some voltmeters may give an unsteady reading.

- If no voltage is present, replace diode trio assembly as

described under Unit Repair.

- If voltage is nearly the same as the alternator output

voltage, disassemble alternator as described under

Unit Repair and check to see if terminal is connected to

diode trio lead. If so, replace diode trio assembly. If

terminal is connected to regulator, it is wired as an “I"

terminal and can’t be used as an “R” terminal.

PAGE 1G-287 4/96

6

26-SI ALTERNATOR

E. NO OUTPUT

TEST EQUIPMENT NEEDED:

• Voltmeter

• Jumper Lead (18 ga. min; no fuse)

Note that 26-SI alternators must be connected to a

battery for the voltage sensing circuit to allow initial

turn on (refer to section on Features). When properly

connected and system checks indicate a “no output”

condition, use the following steps to determine if the

alternator requires repair:

! IMPORTANT

On alternators with insulated output terminal, voltage

in battery cable at output terminal cannot be checked

by touching voltmeter to connecting bolt. Disconnect

output terminal and check voltage at inner ring in

terminal connector of cable.

1. For alternators without an “I” terminal in use,

positive voltage at the output terminal and residual

magnetism in rotor are necessary for alternator to turn

on. With engine stopped, use voltmeter to verify that

battery voltage is present in cable at output terminal. If

not, locate and correct cause of voltage loss.

Residual magnetism in the rotor is sometimes lost

during servicing of the alternator. The rotor can normally

be remagnetized without removing alternator from

application.

CAUTION: Do not allow jumper lead to be

accidentally grounded while connected to battery

insulated terminal. If the free end of this lead is

accidentally touched to the alternator housing or

other grounded areas, the jumper lead may quickly

get hot enough to cause a skin burn or to damage the

jumper lead. Keep jumper lead carefully insulated

from grounding during this procedure.

To remagnetize rotor, make sure the normal

connections are made to the alternator output terminal

and to the ground circuit. Disconnect the wiring harness

from the “R” terminal. Momentarily connect a jumper

lead from battery positive to the alternator “R” (or

unused “I”) terminal. (See Fig. 48) This will cause

field current to momentarily flow through the field

windings in the proper direction and restore magnetism.

Reconnect wiring harness to “R” terminal, then recheck

alternator for output.

battery

voltage present at this terminal. With “I” terminal

connected and indicator lamp on, voltage will be less

than battery voltage. If necessary to disconnect wiring

at “I” terminal to make this check, check for battery

voltage in harness wire. If voltage is present, proceed

to Step 3. If no voltage is present, check “I” terminal

circuit for cause of voltage loss (bulb may be burned

out). Correct as necessary.

3. If no conditions have been found that might prevent the

alternator from turning on (Step 1 or 2), remove

alternator from engine in accordance with engine

manufacturer’s instructions and proceed to Unit Repair.

F. RATED OUTPUT CHECK

TEST EQUIPMENT NEEDED:

• Voltmeter

• Ammeter (current capability at least 15 amperes

higher than alternator rating)

• Variable Carbon Pile Load Test

CAUTION: Failure to disconnect grounded battery

cable at battery before removing or attaching battery

cable at alternator output terminal may result in an

injury. If a tool is shorted to the battery cable

connector at the output terminal, the tool can quickly

heat enough to cause a skin burn or the tool or cable

may be damaged.

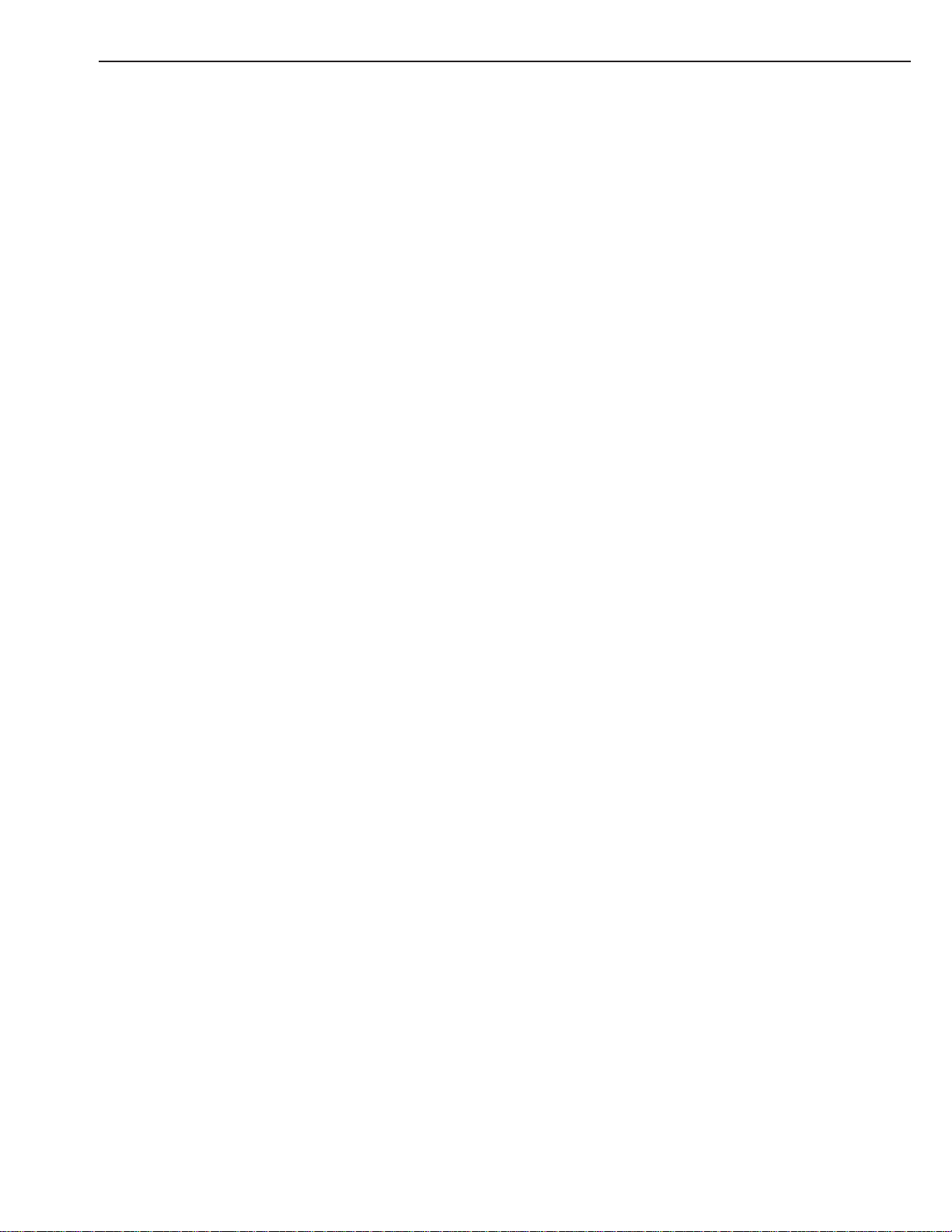

1. Refer to Fig. 9 for test equipment hookups as described

in following steps. If inductive pickup (“clamp on”)

type ammeter is used, place current clamp on alternator

output lead and skip to Step 4. If series ammeter is used,

disconnect grounded battery cable at battery first.

2. Install ammeter in series with alternator output terminal.

3. Reconnect grounded battery cable at battery.

4. NOTICE: When a 12-volt carbon pile load test is used

to diagnose a 24-volt system attach load test only to 12volt potential in battery pack. Attaching a 12-volt load

test to a 24-volt potential will damage the load test.

With load turned off, attach carbon pile load test across

battery.

5. Attach voltmeter lead to grounded battery terminal,

observing proper polarity for system. Leave other

voltmeter lead open for checks at various points.

2. For systems with an “I” terminal in use, the indicator

light current at this terminal will establish normal

magnetism at each engine start-up. Such systems may

depend on this current to help ensure a low turn-on

speed of the alternator. With engine stopped and key

switch in “run” position, use voltmeter to check for

6. Check and record voltage at insulated battery terminal.

For multi-battery systems, check voltage of battery set

connected as if in battery charging mode.

7. With all system electrical loads off, start engine and

run at moderate speed (rpm).

26-SI ALTERNATOR

1G/287 4/96

PAGE

7

CLAMP-ON

AMMETER

A

ALTERNATOR

Figure 9. Rated Output Check

8. Recheck voltage at insulated battery terminal. Voltage

should be higher than previous reading, but below 15

volts on 12-volt system (31 volts on 24 volt system).

- If reading is lower than previous reading (Step 6), refer

to section on No Output.

CARBON

PILE

F9

F6,F8

V

BATTERY

F5

VOLTMETER

Maximum ampere output should be within 15 amps of

output rating stamped on alternator identification plate,

or as listed in Specifications section of this manual.

Voltage drop should be 0.25 volts or less for each

voltage drop test on 12-volt system (0.5 volts or less on

24-volt system).

26-5017

- If reading is higher than 15 volts on 12-volt system (31

volts on 24-volt system), refer to section on High

Voltage Output.

9. Turn carbon pile load on and adjust to obtain maximum

alternator output on ammeter. Record maximum output.

With alternator still running at maximum output, check

and record voltage drop in ground circuit between

alternator housing and grounded battery terminal. Then

check voltage drop from output terminal to battery

positive. Turn carbon pile load off.

- If ground circuit voltage drop is over 0.25 volts on 12

volt system (0.5 volts on 24-volt system), clean and

tighten all ground circuit connections. If this does not

correct excessive voltage drop, check ground circuit

cables for improper sizing or high resistance conditions.

Correct as necessary.

- If within 15 amps of rating, alternator is good. Look

elsewhere for cause of problem.

- If more than 15 amps below rating, repair or replace

alternator.

PAGE 1G-287 4/96

8

26-SI ALTERNATOR

ALTERNATOR UNIT REPAIR

CAUTION: Disconnect grounded cable at battery

before removing or attaching battery cable at

alternator output terminal. Otherwise, a tool

shorted to the battery cable at the output terminal

can quickly heat enough to cause a skin burn or

damage the tool or cable.

NOTICE: Always reinstall fasteners at original

location. If necessary to replace fasteners, use only

correct part number or equivalent.

• If correct part number is not available, use only

equal size and strength. For alternator internal

fasteners, refer to Delco Remy America Standard

Hardware Fasteners section in Service Parts

Catalog.

• Fasteners that are NOT to be reused will be noted

in procedure.

• Fasteners requiring thread locking compound will

be noted in procedure.

• Use specified torque values when shown.

CAUTION: Using or replacing fasteners in any

other manner could result in part or system

damage.

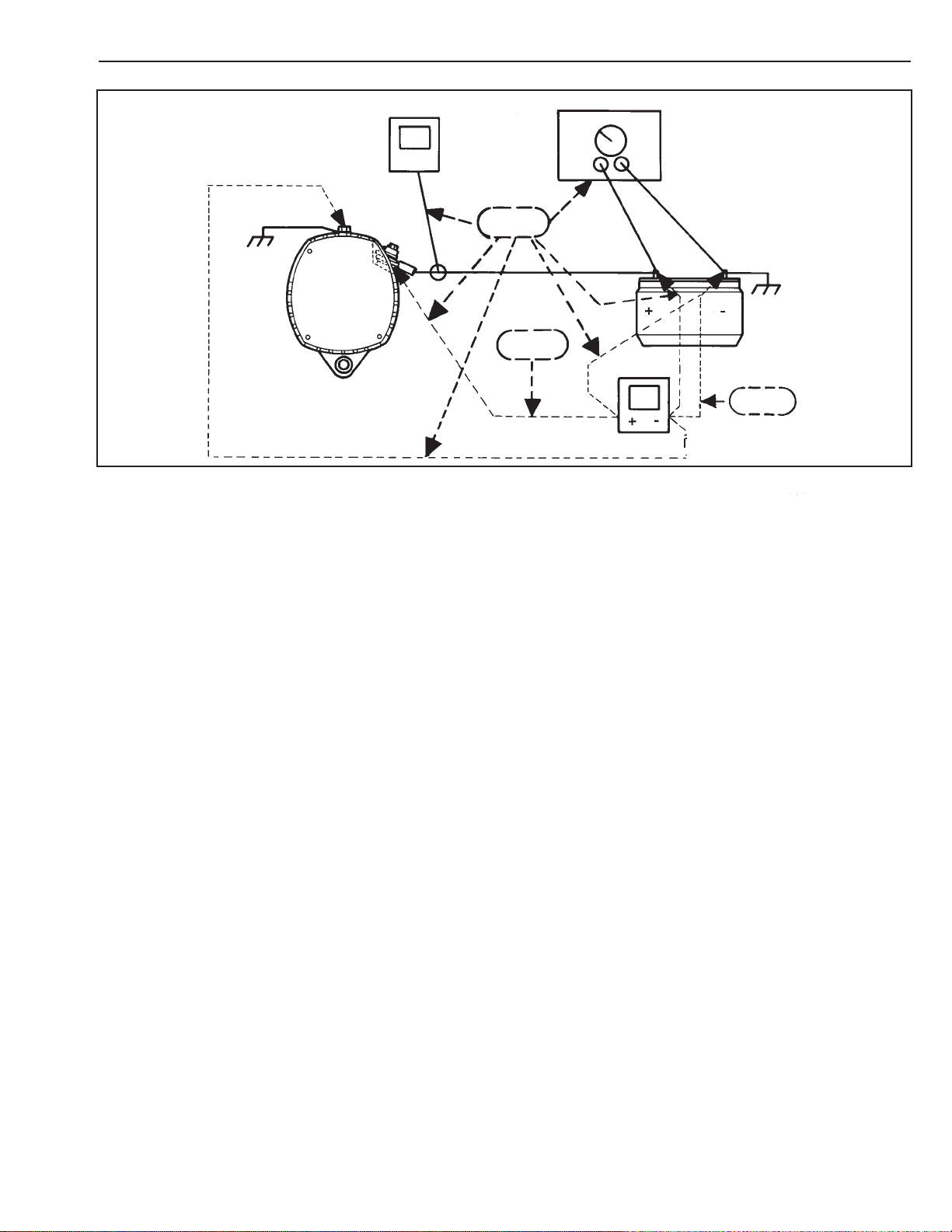

34

1. HOUSING

ASSEMBLY

19. COVER

20. PLATE

20

47

33

1

32

32. SCREW (3)

33. SCREW (4)

34. SCREW (4)

47. GASKET

Figure 10. Removing End Plate and Cover

19

26-5018

If diagnosis determines that alternator repair is

needed, remove alternator from engine according to

manufacturer’s instructions.

DISASSEMBLY AND BENCH CHECKS

TEST EQUIPMENT NEEDED:

• Multimeter

• Regulator Tester

ALTERNATOR

1. Remove rectifier end plate (20), rectifier end cover

(19), and gasket (47). (See Fig. 10)

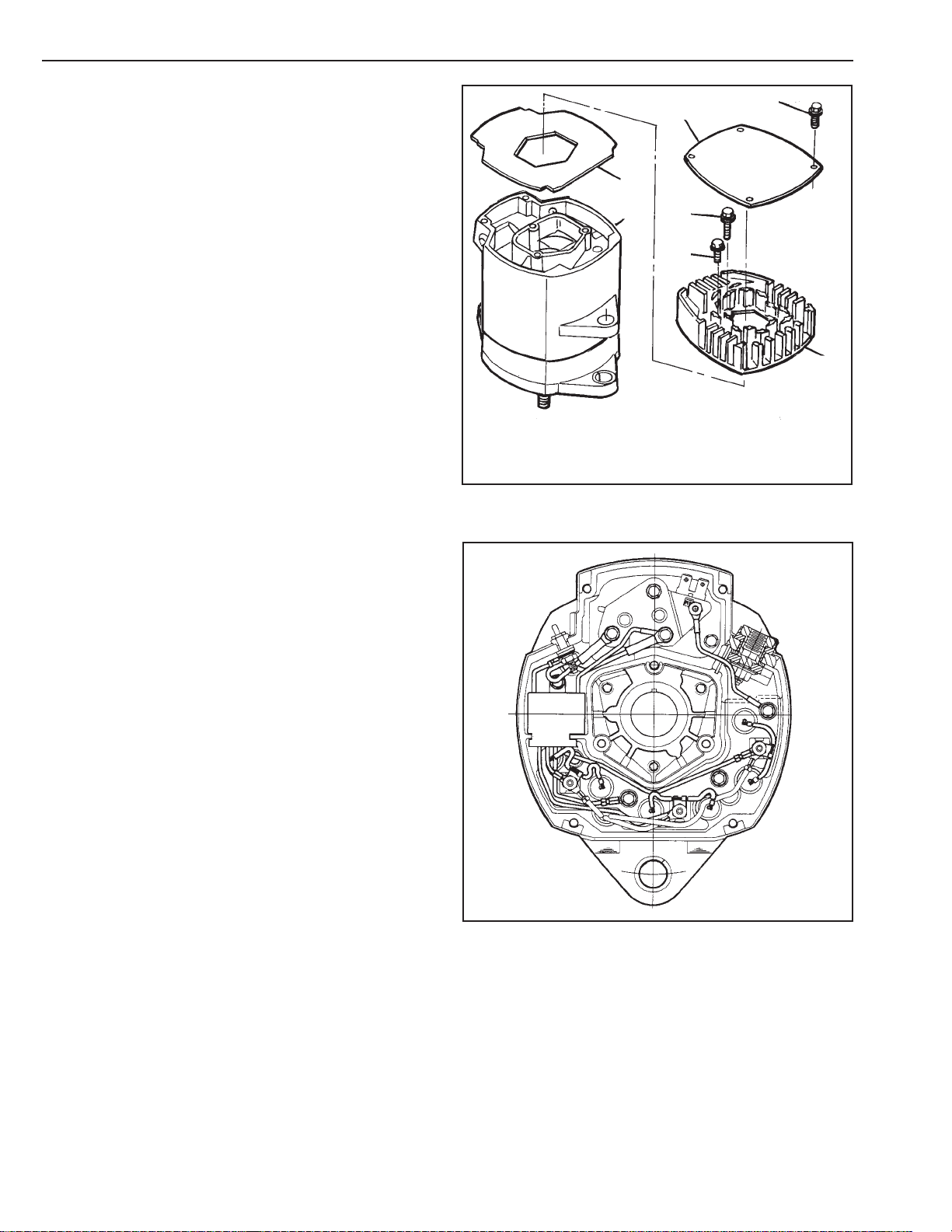

2. Inspect electronics compartment (See Fig. 11) for

contamination, for shorted or grounded wires, and for

loose connections. If contamination is present, clean

and dry compartment before proceeding. Check gasket

for source of entry and replace as necessary.

If indicator light was not operating properly, check

internal indicator light lead assembly for correct

installation and continuity. Correct as necessary.

26-5019

Figure 11. Electronics Compartment

Loading...

Loading...