Page 1

SERVICE MANUAL

SERIAL NUMBERS 25384 AND UP

ACCUTEMP PRODUCTS, INC.

8415 NORTH CLINTON PARK - FORT WAYNE, IN 46825 - 800.480.0415 - www.accutemp.net

Page 2

2

MP5006-1001 Rev A

TABLE OF CONTENTS

CONNECTIONLESS MODELS

Introduction____________________________________________________ 4

Sequence of Operation___________________________________________ 4

Trouble Shooting Guide__________________________________________ 5-7

Removal and Installation – 6 Pan Models

Removal from Stand________________________________________ 8

Removal of Legs___________________________________________ 8

Gast Vacuum Pump________________________________________ 8

Thermostat________________________________________________ 9

Temperature Probe_________________________________________ 9

Timer_____________________________________________________ 9

Vacuum and Temperature Gauges_____________________________ 10

Contactor__________________________________________________ 10

Vacuum Hoses and Tees_____________________________________ 10

Solid State Relays___________________________________________ 11

Lamps_____________________________________________________11

Fuses_____________________________________________________ 11

Water Sensor Control Board__________________________________ 12

Water Sensors______________________________________________ 12

Control Relays______________________________________________12

Fast Cook / Thermostat Toggle Switch__________________________ 12

On/Off Switches_____________________________________________13

Cord and Plug Assy._________________________________________ 13

Drain Valve_________________________________________________13

Gutters____________________________________________________ 13

Pressure Switch____________________________________________ 14

Dual Pressure Switch________________________________________ 14

Firebar Heater Replacement___________________________________14-15

Cast Heater________________________________________________ 15

Door Removal______________________________________________ 16

Inner Door Removal_________________________________________ 16

Floating Inner Door Removal__________________________________ 16

Gasket Replacement_________________________________________16

Inner Door Valve Cup Replacement_____________________________16

Door Latch Replacement______________________________________17

Removal and Installation – 3 Pan Model

Light Board_________________________________________________17

Page 3

3

MP5006-1001 Rev A

AUTOFILL MODELS

Introduction & Sequence of Events– 3 & 6 Pan Models________________ 18

Trouble Shooting Guide___________________________________________ 19

Removal and Installation

Water Fill / Sensor Control Board______________________________ 20

Water Fill Valve_____________________________________________ 20

Overfill Sensor Switch_______________________________________ 21

Schematics – 6 Pan Models________________________________________ 22-28

Schematics – 3 Pan Models________________________________________ 29-35

Parts___________________________________________________________ 36 - 39

Page 4

4

MP5006-1001 Rev A

INTRODUCTION-CONNECTIONLESS 3 & 6 PAN MODELS

The AccuTemp Steam ‘N’ Hold steamer takes time-proven method of cooking with steam

and adds the advantage of control. This is accomplished by reducing the internal

atmospheric pressure of the Steam ‘N’ Hold cooking chamber, thereby lowering the

temperature at which water begins to boil. This allows the operator to control the temperature

of the steam for cooking. Controlling the steam temperature gives the operator the ability to

cook the food to the desired temperature without over-cooking, resulting in a more tender,

juicier, nutritious product with less shrinkage than was previously possible. Once the cooking

time expires, the steamer automatically enters the “Hold” mode. In this mode, the thermostat

regulates the internal temperature, but vacuum is released, returning the cooking chamber to

normal atmospheric pressure. At this time, steam is no longer generated and the cooking

chamber is held at the desired temperature at a relative humidity of 100%. This eliminates

food from drying out by suppressing the evaporation of the products’ natural moisture. As a

result, most food products can be held in a ready to serve state for several hours after

cooking, with no appreciable loss in taste, appearance or consistency.

SEQUENCE OF OPERATION

MAIN ON / OFF SWITCHES

Power is supplied through the power cord to the main contactor. Power comes off the back

side of the contactor to the water board. While power is supplied to the water board, current

is conducted thru the water sensors in the cooking chamber which must sense that water is

in the unit to allow it to come on. The over-temp and water board are in series. Both must be

satisfied before the unit can turn on. When the ON button is pressed it completes the circuit.

The main contactor will pull in and will send power to the solid state heater relays at the

same time latching the CR1 and CR2 control relays. Power is also sent to the timer and

thermostat. The timer has 3 settings: HOLD, TIME and CONTINUOUS. When the timer is

engaged power will be sent to the control relay on the top of the pump and the pump will

start.

Page 5

5

MP5006-1001 Rev A

TROUBLE SHOOTING GUIDE

STEAMER TROUBLE SHOOTING GUIDE

SYMPTOM

POSSIBLE CAUSE

EVALUATION

Unit will not power up

No water in the steamer

Fill with up to 3 gallons of water. Make sure

the water level is above the sensors.

Water Sensors

Scrub and clean with a scotch brite pad.

Incoming power supply

Check breakers, reset if required. Check the

power plug to be sure it is firmly in the

receptacle. Measure incoming power, call

the Power Co., if necessary.

Steamer fuses

Check and or replace

Fuse holder

Check and or replace

On switch and contacts

Check for continuity

Control Relays

Check continuity of the coil. Check for

power to relay coil. Visually check for

contact pull in and contact condition. Check

for voltage across relay terminals.

Water Board

Check to see if the LED on the water board

is on when the unit is powered up. Clean the

sensors and re-inspect. Check for incoming

power and check to make sure the ground is

correct. If the LED light does not come on,

replace the board. Boards with a 10 second

delay is just the opposite

Hi Limit

NOTE

: Serial No. 3865 to 19117 have a

resetable Hi-Limit.

Unplug

the unit and

locate the access panel on the rear of the

unit. Push the button in until it clicks. If this

fails to start the unit after plugging back in,

check the control relay and/or the off

contact. These units also have a auto- reset

hi-limit (purple and brown wires). If this is

open while the unit goes to low water it

needs to be replaced.

Unit is cooking slow

Low vacuum pressure, Vacuum

pump.

Remove the top left pan rail in the steaming

chamber. There will be 1 or two holes. If

there are two holes, the one towards the

front is for the pressure switch and does not

need to be plugged. There may be a third

hole located on the lower left side of the

chamber and this must be plugged in

addition to the top hole. From a cold start,

plug all the holes with your fingers, turn the

unit on and observe the reading on the

vacuum gauge. The correct reading should

be between 20 to 25 inches of pressure.

0 to 5 inches of pressure denotes a faulty

pump.

Check all the hoses and connections for any

leaks. If the pump does not run at all, give

the fan blade a push start through the grill. If

the pump starts, it has a bad run capacitor.

Replace as needed.

Page 6

6

MP5006-1001 Rev A

Unit is cooking slow (cont)

Pressure switch

In the FAST cook mode, the pressure switch

will close once the steam chamber reaches

the thermostat setting. As the temperature

rises, the vacuum pressure falls. Once the

unit reaches 210 to 212 degrees, the

pressure will be at zero. Cycle times when

the unit is calling for heat should be around

8 to 10 seconds on and 60 to 90 seconds

off. Replace the pressure switch if the cycle

times are off or if you can suck air through

the switch.

Unit is cooking slow (cont)

Door Gasket

Check for cuts or cracks. Replace as

needed

Door Alignment

With the unit on and the pump running,

perform the Dollar Bill test on the door.

Close the door on a Dollar Bill. (all four

sides of the door) There should be

resistance when pulling the bill out. If the

bills comes out easily, remove the hinge

covers. Loosen all of the screws, turn the

thermostat to150 degrees, enable the timer,

shut the door and turn the unit on so it

creates a vacuum and draws the door in

and then retighten the screws.

Door Sealing

If the door alignment process does not fix

the problem, remove the inner door and

place it on a flat surface and check for any

warpage. Also check that the suctions cups

are sealing. If they have turned gray or

white then replace. Use one of the pan rails

as a straight edge. Straighten and re-bend

the inner door until it is flat and re-install

using the door alignment procedure.

Quick Release Door

On the inner door, check that the four

suction cups are sealing and that the spring

is functioning properly. Replace as needed.

Unit is over-temping

Solid State Relay

Check the cycle times as stated above.

Check the voltage between T1 and L1. If the

LED light is on, there should be 0 voltage. If

the unit does not cycle, and the LED stays

on, replace the relay.

Over-temp

Ohm out the Hi-limit to see if it is good.

Clean the sensors and check the water

board. If the low water light comes on while

the unit is heating up, refer to the Hi-limit

procedure.

Thermocouple (type J)

Check that the thermocouple is wired

correctly to the thermostat. White is positive

(Terminal 6) and Red is negative (terminal

7). Reversing the terminals will result in a

run-away condition. See attached chart for

DC-milli volt readings.

Page 7

7

MP5006-1001 Rev A

Unit is over-temping (cont)

Thermostat

When a unit is at an altitude of 2,500ft+

water boils at this altitude at about 207

degree's. In thermostat mode unit starts

blowing steam out the door just after heat

light goes out. (It will do this because of

extra heat in the element when it shuts off

at about 205 degree's, drift point is at least 2

degree's). If you have the tech set

thermostat at 190 degree's and put in fast

cook it will run at the point customer wants

to cook at

Thermostat

Check resistance between terminals 4 & 5.

AC thermostats should read line voltage and

DC thermostats should be between 3 to 34

DC volts.

Thermocouple (type J)

See above

Unit is not coming up to

proper temperature

Heating elements

Check for resistance between the two

outside double white wires on the terminal

block. On 17kW units check to terminals 1 &

6, 2 & 5, and 3 & 4 on the terminal block.

See attached chart for resistance readings.

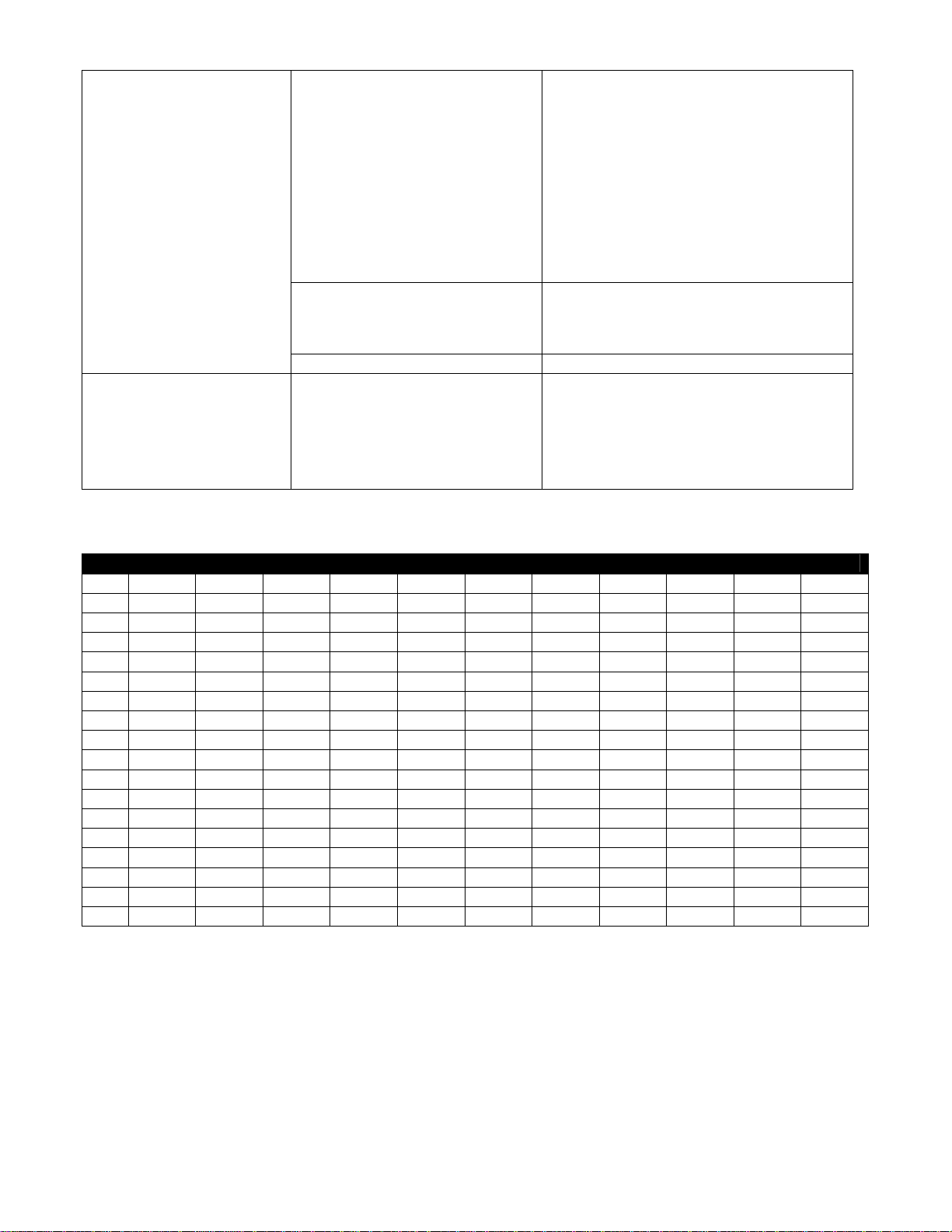

TYPE J THERMOCOUPLE READINGS - THERMOELECTRIC VOLTAGE IN DC MILLIVOLTS

F°0123456789

10

70

1.076

1.105

1.134

1.162

1.191

1.22

1.249

1.277

1.306

1.335

1.364

80

1.364

1.392

1.421

1.45

1.479

1.508

1.537

1.566

1.594

1.623

1.652

90

1.652

1.681

1.71

1.739

1.768

1.797

1.826

1.855

1.884

1.913

1.942

100

1.942

1.972

2.001

2.03

2.059

2.088

2.117

2.146

2.175

2.205

2.234

110

2.234

2.263

2.292

2.322

2.351

2.38

2.409

2.439

2.468

2.497

2.527

120

2.527

2.556

2.585

2.615

2.644

2.673

2.703

2.732

2.762

2.791

2.821

130

2.821

2.85

2.88

2.909

2.938

2.968

2.997

3.027

3.057

3.086

3.116

140

3.116

3.145

3.175

3.204

3.234

3.264

3.293

3.323

3.353

3.382

3.412

150

3.412

3.442

3.471

3.501

3.531

3.56

3.59

3.62

3.65

3.679

3.709

160

3.709

3.739

3.769

3.798

3.828

3.858

3.888

3.918

3.948

3.977

4.007

170

4.007

4.037

4.067

4.097

4.127

4.157

4.187

4.217

4.246

4.276

4.306

180

4.306

4.336

4.366

4.396

4.426

4.456

4.486

4.516

4.546

4.576

4.606

190

4.606

4.636

4.666

4.696

4.726

4.757

4.787

4.817

4.847

4.877

4.907

200

4.907

4.937

4.967

4.997

5.028

5.058

5.088

5.118

5.148

5.178

5.209

210

5.209

5.239

5.269

5.299

5.329

5.36

5.39

5.42

5.45

5.48

5.511

Page 8

8

MP5006-1001 Rev A

REMOVAL AND INSTALLATION 6 PAN MODEL

REMOVAL FROM STAND

Using a 7/16” wrench, remove the 4 ¼’-20 x ½” bolts and lock washers located on the

mounting brackets going into the bottom of the unit. When reinstalling, make sure the “L”

brackets that hold the drip pan are facing inward.

REMOVAL OF LEGS

Units with legs use the same “L” brackets used on the stand but are held on by 8 ¼”-20 X ½”

bolts and lock washers. Use a 7/16” wrench to remove these to access the bottom panel.

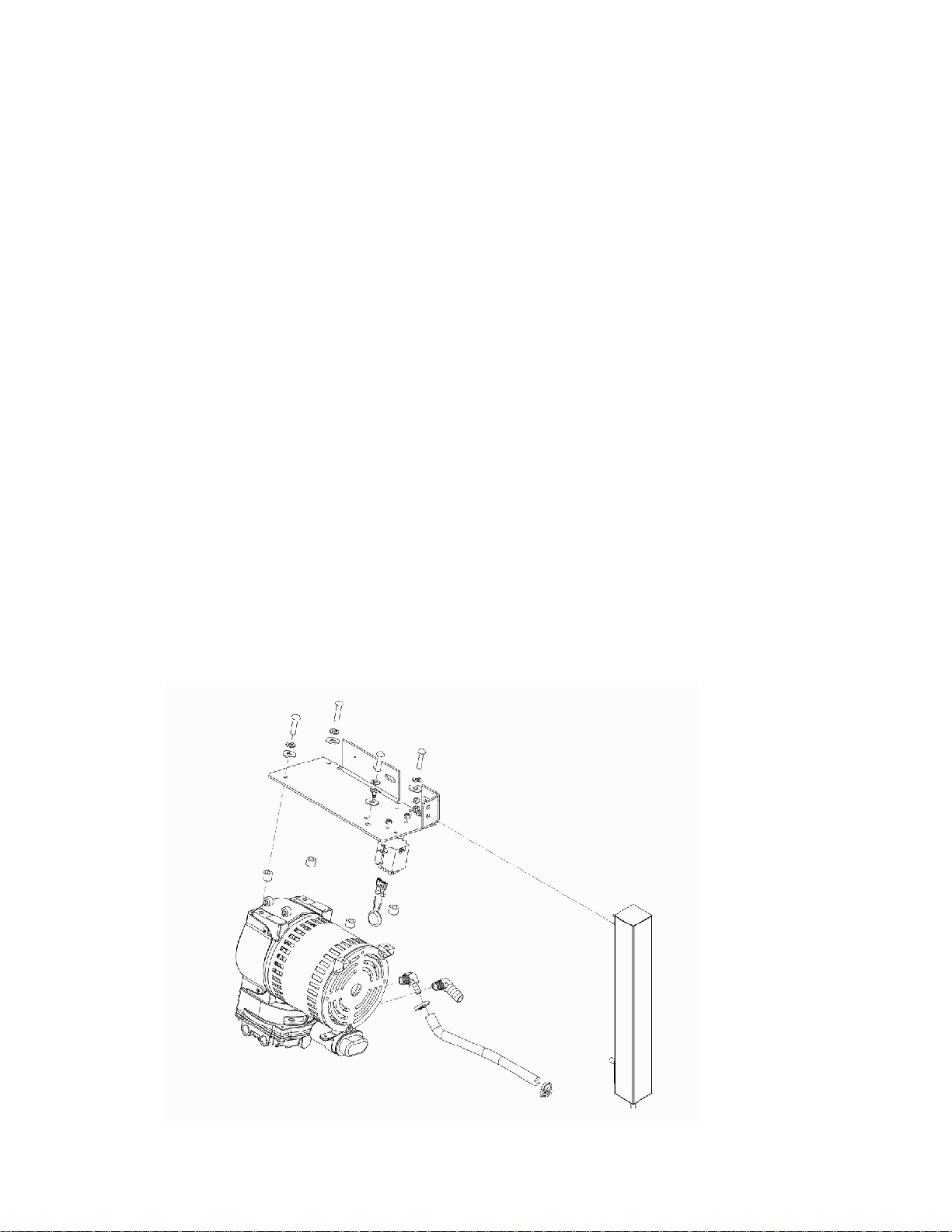

GAST VACUUM PUMP

1. Unplug the unit.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Disconnect the wires to the relay and mark the locations.

4. Remove the hoses from the pump head.

5. Remove the two 3/8” nuts holding the muffler on and pull out of the way.

6. Remove the bolts on the pump bracket and pull the whole assembly out.

7. Remove the 4 Phillips screws washers and spacers on the bracket.

8. Remove the brass fittings on the head of the pump.

9. Reassemble in reverse order.

Page 9

9

MP5006-1001 Rev A

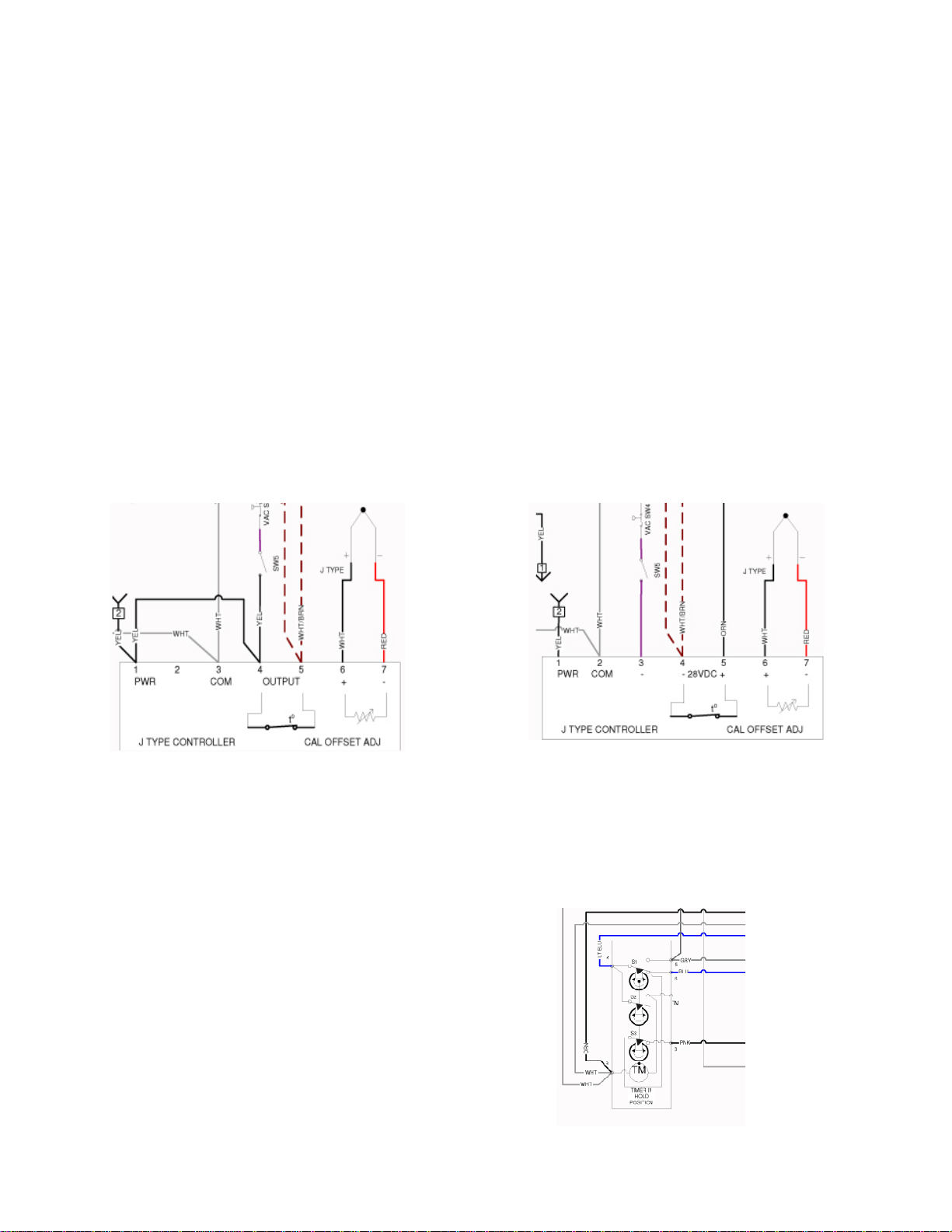

THERMOSTAT

1. Unplug the unit

2. Remove the sheet metal screws on the left side panel of the unit.

3. Remove the knob and the seal nut with a ½” nut driver on the front of the unit.

4. Disconnect the wires and mark the pin locations.

5. Reassemble in reverse order.

Note: AC thermostats have 6 pins and DC thermostats have 7 pins.

TEMPERATURE PROBE

1. Unplug the unit.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Remove the white wire from terminal # 6 and the red wire from terminal # 7.

4. Follow the red and white wire down to the bottom of the unit.

5. Peel the insulation aside and remove the retaining nut with a 3/8” nut driver.

6. Reassemble in reverse order.

TIMER

1. Unplug the unit

2. Remove the sheet metal screws on the left side panel of the unit.

3. Remove the knob and retaining nut with a ½” nut driver on the front of the unit.

4. Disconnect the wires and mark the pin locations.

5. Reassemble in reverse order.

Note: Don’t remove jumper wires.

AC Thermostat

DC Thermostat

Page 10

10

MP5006-1001 Rev A

VACUUM AND TEMPERATURE GAUGES

1. Unplug the unit

2. Remove the sheet metal screws on the left side panel of the unit.

3. On the vacuum gauge, remove the hose form the inlet connection.

4. Remove the two 10/24 nuts.

5. On the temperature gauge, remove the retaining nut on the inlet connection.

6. Follow the capillary leads down to where the probe is mounted to the unit.

7. Remove the two 3/8” nuts.

8. Reassemble in reverse order.

CONTACTOR

1. Unplug the unit.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Remove the red, black and white leads on both sides of the contactor.

4. Remove coil wires.

5. Remove the 6/32” nyloc nuts that secure the contactor.

6. Reassemble in reverse order.

VACUUM HOSES AND TEES

1. Unplug the unit.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Check all hoses and Tees for cracks or leakage.

4. Remove clamps and replace.

Page 11

11

MP5006-1001 Rev A

SOLID STATE RELAYS

1. Unplug the unit.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Remove the wires attached to the relay and mark their locations.

4. Remove the two mounting screws.

5. Reassemble in reverse order.

Note. Relays not mounted on a heat sink should use a heat pad or thermal paste.

LAMPS

1. Unplug the unit

2. Remove the sheet metal screws on the left side panel of the unit.

3. Remove the two wires on the lamp terminals.

4. With a pair of pliers, depress the locking ears on the switch and push the lamp thru

the front.

5. Push new lamp in the mounting hole. Make sure locking ears engage.

6. Reattach the wires.

FUSES

1. Unplug the unit

2. Remove the sheet metal screws on the left side panel of the unit.

3. Pry the fuses out of the fuse block with a pocket screw driver.

Page 12

12

MP5006-1001 Rev A

WATER SENSOR CONTROL BOARD

1. Unplug the unit

2. Remove the sheet metal screws on the left side panel of the unit

3. Disconnect the wires and mark the pin locations.

4. Remove the nylon mounting pins.

5. Reassemble in reverse order.

WATER SENSORS

1. Unplug the unit.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Open the door and drain all the water from the chamber.

4. Remove the 8/32” hex nut from the back side of the sensor with an 11/32” wrench and

remove the sensor lead.

5. Use a ¾” wrench to remove the nut on the sensor.

6. Push the sensor thru the hole from the backside.

7. Reassemble in reverse order.

Note: Do not exceed 15 inch pounds when tightening the sensor mounting nut.

CONTROL RELAYS

1. Unplug the unit

.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Disconnect the wires and mark the pin connections.

4. Remove the 6/32” nyloc nuts.

5. Reassemble in reverse order.

Page 13

13

MP5006-1001 Rev A

FAST COOK / THERMOSTAT TOGGLE SWITCH

1. Unplug the unit

2. Remove the sheet metal screws on the left side panel of the unit.

3. Remove the retaining nut with an open end 1/2” wrench.

4. Disconnect the wires.

5. Reassemble in reverse order.

ON/OFF SWITCHES

1. Unplug the unit

2. Remove the sheet metal screws on the left side panel of the unit.

3. On the inside of the unit, push the tension spring on the locking ring and then pull the

switch out from the front.

4. Reassemble in reverse order

CORD AND PLUG ASSY

1. Unplug the unit.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Disconnect the red, black and white leads form the contactor.

4. Remove the strain relief retaining nut on the inside of the unit and pull the cord out.

5. Reassemble in reverse order.

DRAIN VALVE

1. Unplug the unit.

2. Drain all of the water from the chamber.

3. Turn the unit upside down and remove the legs and bottom panel.

4. Use a strap wrench to remove the valve.

5. Reassemble in reverse order.

GUTTERS

1. Remove the sheet metal screws on the bottom front of the unit. Two on the right and

two on the left.

2. There are right and left oriented gutters. The right gutter will have a hole *5/8” from the

left side and the left gutter will have a 5/8” from the right side. Gutters need to angle

down towards the drip pan.

Page 14

14

MP5006-1001 Rev A

PRESSURE SWITCH

1. Unplug the unit.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Remove the wires from the top and bottom leads of the switch.

4. Use Teflon tape on the barrel of the new switch and reinstall.

DUAL PRESSURE SWITCH

1. Unplug the unit.

2. Remove the sheet metal screws on the left side panel of the unit.

3. Remove the wires from the top and bottom leads off of the switches.

4. Remove the brass elbow attached to the “J” tube going into the chamber. Make sure it

is not plugged up.

5. Use Teflon tape on the barrel of the new switch and reinstall.

Note: The 5” W/C pressure switch is rated at 1/3 HP and the 60” WC switch is rated

at ½ HP.

FIREBAR HEATER REPLACEMENT

1. Turn unit up side down.

2. Remove legs and bottom panel.

3. Remove all brackets, nuts, washers, spacers, over-temp nuts, over-temp plate, overtemp, center heater mount, element and the isolator plate.

4. Remove any old anti-seize from the isolator plate and clean thoroughly.

5. Apply new anti-seize to both sides of the isolator plate. ( silver grade rated @ 1600 to

1800 degrees F)

6. Apply anti-seize to both sides of the new element.

Keep 2” away from the wire

leads.

7. Re-install in order: isolator plate, element, center heater mount, over-temp, over-temp

plate and nuts, spacers, Belleville washers

( dome side up),

plain washers,

new

lock nuts. ( torque to 30 inch pounds)

, and front and back “Z” brackets. Tighten in a

circular pattern from the inside to the outside.

8. Reinstall bottom plate and legs.

P/N AT1E-2647-2

60” W/C

P/N AT1E-2647-1

5” W/C

Page 15

15

MP5006-1001 Rev A

CAST HEATER REPLACEMENT

1. Turn unit upside down

2. Remove legs and bottom panel.

3. Remove all nuts, Belleville washers, fender washers, heater mount bracket, and

heater element.

4. Thoroughly clean old thermal paste from the studs and bottom of the unit.

5. Apply thermal paste to bottom side of the new element and install over studs.

6. Apply thermal paste to the screw-in over-temp and install.

7. Install in order: heater mount bracket, fender washers, Belleville washers

(dome side

up) and new lock nut. ( torque to 25 inch pounds)

Page 16

16

MP5006-1001 Rev A

DOOR REMOVAL

1. Leave the door shut.

2. Remove the hinge covers.

3. Remove the Phillips head screws going into the cabinet and remove door.

INNER DOOR REMOVAL

1. Remove hinge covers.

2. Remove the long top screw in the top hinge and the long bottom screw in the bottom

hinge (if equipped)

3. Insert a flat head screw driver into the slot located on the bottom of the outer door and

pry the inner door out.

FLOATING INNER DOOR REMOVAL ( SERIAL NUMBERS 29783 AND ABOVE)

1. Remove the long top screw in top hinge and the long bottom screw in the bottom

hinge (if equipped).

2. Pull inner door out. Angle the rod that is inserted in the spring on the bottom side of

the handle out last.

GASKET REPLACEMENT

1. Remove the inner door as stated above.

2. Make sure the gasket is untangled, then starting at a corner, stretch the gasket to the

opposite corner. Repeat this sequence on the other corners until all four corners are

seated. Push the gasket along the edges to firmly seat onto the inner door.

INNER DOOR VALVE CUP REPLACEMENT

1. Remove inner door as stated above.

2. Locate the valve plate assembly and remove the 10/24 nyloc nut and discard.

Remove cone spring.

3. Remove the valve plate assembly from the inner door.

4. Remove the (4) 8-32 nyloc nuts holding the seals and discard both.

5. On each valve, first place a flat washer and then a “wave” washer on the threaded

stem of the seal.

6. Place each seal assembly back into the valve plate and fasten with the 8/32 nyloc

nuts. Tighten down until the space between the seal and the valve plate is about the

thickness of the flat washer. Make sure each seal is free to pivot and rotate.

7. Reinstall the valve plate and cone spring. Tighten the nyloc nut so that one or two

threads protrude through the nylon material

8. Reinstall inner door.

Page 17

17

MP5006-1001 Rev A

DOOR LATCH REPLACEMENT

1. Remove the inner door as stated above.

2. Use a Phillips screw driver and a 3/8” nut driver to remove the handle from the outer

door

3. Reinstall the new handle.

REMOVAL AND INSTALLATION - 3 PAN MODEL

LIGHT BOARD

1. Remove the cover panel to gain access to the components.

2. Remove the mounting nuts and molex connections on the board.

3. Reinstall in reverse order.

ALL OTHER COMPONENTS, REFER TO THE 6 PAN SECTION

Page 18

18

MP5006-1001 Rev A

INTRODUCTION & SEQUENCE OF EVENTS

AUTOFILL – 3 & 6 PAN MODELS

Simple connection to water source via a garden hose style connection.

Electronic water level control for normal operation.

A master control valve

Multiple level safety controls, electronic and mechanical float.

Operates on city water supply and water pressures (40-60psi)

Easy to clean and care for.

Theory of operation

The Steamer is connected to the facility water supply via a washing machine or garden hose

type supply line from a water spigot or from a nearby sink faucet.

First time fill

1. With the water supply turned on, press the “

ON”

button. The Steamer will power up with the

pump operating.

2. The water fill valve will turn on, via the K5 relay on the water sense PCB. The status LED

on the water sensing PCB will flash rapidly about 2-3 times a second.

3. Water Fill/Sensor PCB mounted K2 relay (low water level sensing) is bypassed to allow for

first time filling of thereservoir.

4. The thermostat will be turned off, via Water Fill/Sensor PCB mounted K1 relay and CR4

bypass relay, for the first fill to preventdamage to the heater elements.

5. Water will rise to the low level probe and reset the low level circuit of the water control

board and reset relay CR4.

6. When the water level reaches the High Level Probe, a 30 second delay is initiated to

allow for wave action and rapid boiling inside to subside. Wave action and rapid boiling

would cause a lower than desired amount of water to be injected in the reservoir by

tripping the control too soon.

7. When the 30 seconds and water level have been satisfied, the water level control

board shuts off the water level control relay and the by pass relay. The status LED

will change to a slower flash rate of about 1 time per second.

8. The heater is turned on and normal operation begins.

Normal operation (the Steamer water reservoir has water in it).

1. On a full reservoir, the Steamer will heat up as normal for normal operation.

2. As the water is used up and the water level drops below the High-Level Probe, the water

valve is turned on with no delay period.

3. After the water has reached the high water level probe and stays in constant

contact, a thirty-second timing sequence is started. (Thisis done to prevent short

cycling of the water valve increasing the life and thereliability of the water level control

valve.)

Page 19

19

MP5006-1001 Rev A

4. When the thirty seconds have been satisfied, the water level control board shuts

off the water level control K2 relay.

5. This process is repeated until the Steamer is shut off.

TROUBLE SHOOTING GUIDE

1. No water pressure.

On a first time fill the unit will not fill up with water and the Steamer will not turn

the heaters on to prevent damage.

Check water pressure

Check for dirty inlet screen.

Check for dirty probes.

Check for power to control board

Check for operation of the control valves

2. During operation of the Steamer, after successful initial water fill.

The steamer shuts down after the water level drops below the low water sensor and a 10

second delay has passed for wave and boiling action

Check the conditions listed above for reasons of non-operation

3. Water level sensing fails

If the water level control valve becomes stuck on, a mechanical float will shut

down the whole Steamer and the water supply by turning off the master watercontrol

valve.

4. If the water level sensing control board becomes faulty the mechanical float will shut

down the Steamer.

5. If the float has been removed

The Steamer will not start up until the float is re-installed.

Cleaning the chamber is still easy by just lifting out the mechanical float and wipingdown

as normal each night.

Page 20

20

MP5006-1001 Rev A

REMOVAL AND INSTALLATION

WATER FILL / SENSOR CONTROL BOARD

1. Unplug the unit

2. Remove the sheet metal screws on the left side panel of the unit

3. Disconnect the wires and mark the pin locations.

4. Remove the nylon mounting pins.

5. Reassemble in reverse order.

WATER FILL VALVE

1. Unplug the unit.

2. Serial numbers 27604 and below have two plastic bodied water valves. These are

discontinued and are being replaced with a heavier duty brass valve.

3. Remove the plastic body water valves and all of the plastic water lines.

4. Remove the water line brass fitting from the water inlet fitting.

5. Install the brass water valve kit into the water inlet fitting which is mounted on the back

wall of the steamer enclosure, using thread sealant.

6. Connect the brass water valve kit water line to the steam chamber water inlet fitting.

7. Connect the blue and white control harness (part of the brass valve kit) to the blue and

white connectors originally connected to the plastic water valve terminals.

8. Neatly bundle the non-connected ends of the yellow and white harnesses that were

originally connected to the plastic water valves together with the remaining existing

loose wire harnesses and wire tie them together.

9. Reconnect the steamer to the power outlet and slowly turn on the water supply while

checking for leaks.

Page 21

21

MP5006-1001 Rev A

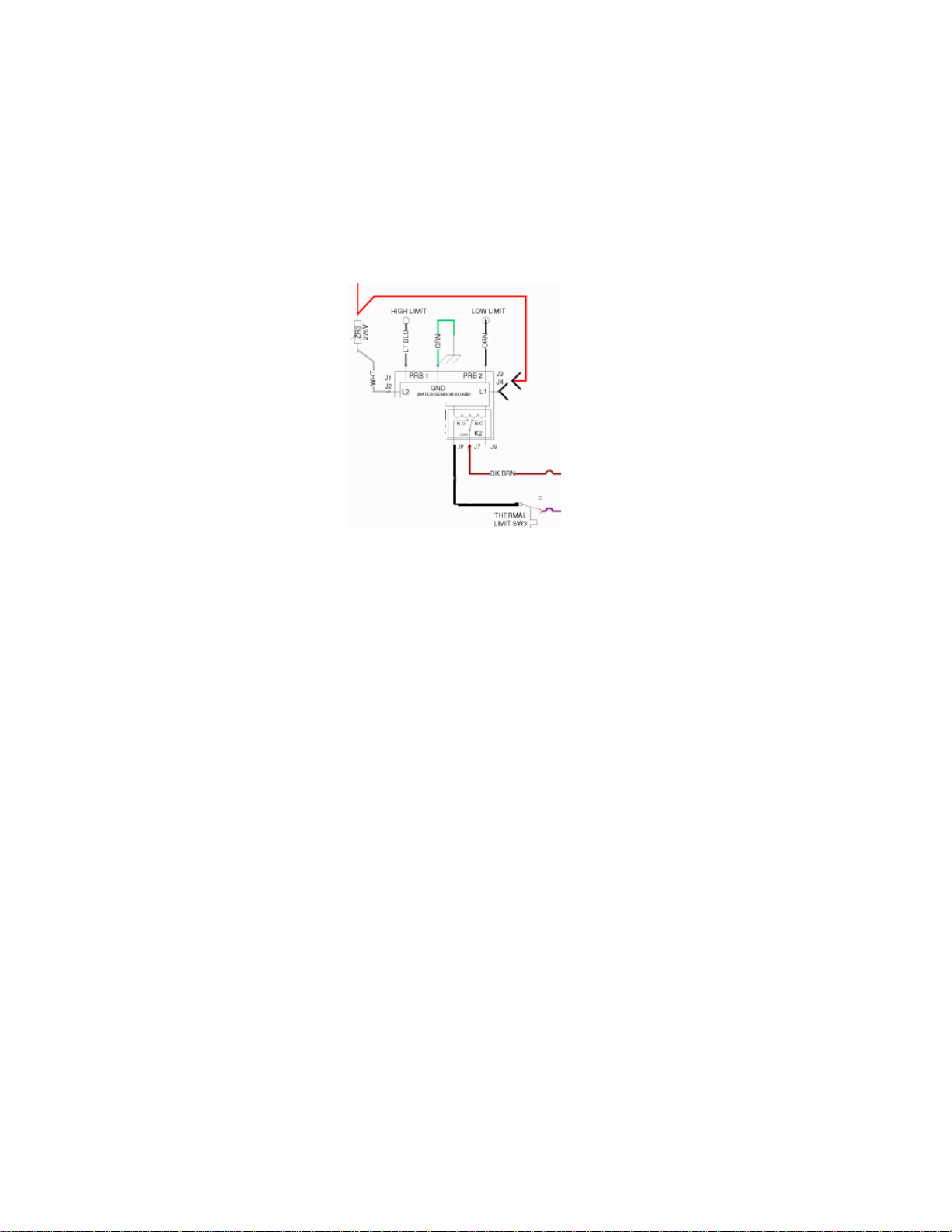

OVERFILL SENSOR SWITCH

1. Unplug the unit

2. Remove the left side panel.

3. Remove leads J7 & J8 from the water board

4. Turn the unit up side down.

5. Remove the brass nut for the weep hole drain line.

6. Remove the legs and bottom panel.

7. Remove the retaining screw from the switch mounting tab and remove the switch.

8. Reinstall in reverse order.

Note: Make sure the wires are not close to the heater element.

DRAIN SYSTEM

1. Remove the drain pan which is inserted in the pan rails on the bottom of the unit.

2. Remove the hose clamps from the drain hose connections.

Page 22

22

MP5006-1001 Rev A

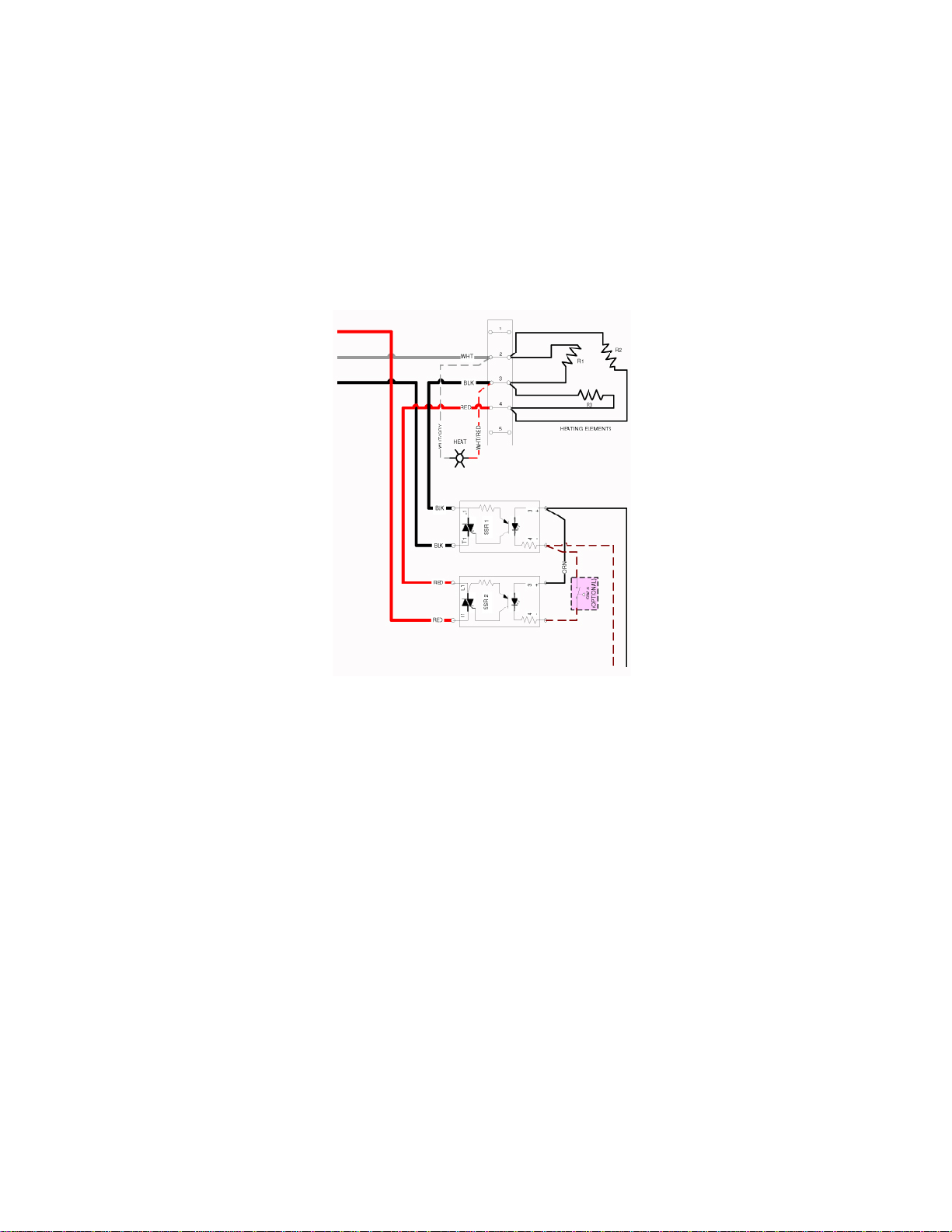

SCHEMATIC – 6 PAN – 208V & 240V – SINGLE PHASE

Page 23

23

MP5006-1001 Rev A

SCHEMATIC – 6 PAN – 208V & 240V – THREE PHASE

Page 24

24

MP5006-1001 Rev A

SCHEMATIC – 6 PAN – 380V-415V- 3 PHASE

Page 25

25

MP5006-1001 Rev A

SCHEMATIC – 6 PAN – 440V-480V – 3 PHASE

Page 26

26

MP5006-1001 Rev A

SCHEMATIC – 6 PAN – 208V – 3 PHASE – 17kW

Page 27

27

MP5006-1001 Rev A

SCHEMATIC – 6 PAN – 230V – 1 PHASE – CE

Page 28

28

MP5006-1001 Rev A

SCHEMATIC – 6 PAN – 380V -415V – 3 PHASE - CE

Page 29

29

MP5006-1001 Rev A

SCHEMATIC – 3 PAN – 208V – 240V – 1 PHASE

Page 30

30

MP5006-1001 Rev A

SCHEMATIC – 3 PAN – 208V – 240V – 3 PHASE

Page 31

31

MP5006-1001 Rev A

SCHEMATIC – 3 PAN – 380V – 415V – 3 PHASE

Page 32

32

MP5006-1001 Rev A

SCHEMATIC – 3 PAN – 440V – 480V – 3 PHASE

Page 33

33

MP5006-1001 Rev A

SCHEMATIC – 3 PAN – 208V – 3 PHASE – 17kW

Page 34

34

MP5006-1001 Rev A

SCHEMATIC – 3 PAN – 230V – 1 PHASE

Page 35

35

MP5006-1001 Rev A

SCHEMATIC – 3 PAN – 380V – 415V – 3 PHASE – CE

Page 36

36

MP5006-1001 Rev A

PARTS

Part #

Description -

Prices are subject to change without notice

Buzzers

AT0E-2807-1

Buzzer, Timer/Low Water

Door - Quick Release Door - Current Production

AT1A-2912-1

QR Door Replacement - Right Hinged, (Floating Inner door)

AT1A-2912-3

QR Door Replacement - Left Hand (Floating Inner door)

AT1A-2426-5

Floating Inner Door - Right hand

AT1A-2426-6

Floating Inner door - Left Hand

AT1A-2427-1

Valve Bracket Assy- (w/cups & rod)

AT1A-2426-1

Inner Door Assy, Right 6 pan

AT1A-2426-3

Inner Door Assy, Left 6 pan

AT1A-2644-2

Quick Release Door handle

RAT1K-1830

QRD Valve Plate Seal Kit

AT1H-2046-1

QRD, Spring Compression

AT1M-3045-1

QRD Valve Cover

AT1M-3046-1

QRD Latch Backer Plate -RH

AT1M-3046-2

QRD Latch Backer Plate -LH

AT1M-3466-1

Bracket, Right steamer door

AT1M-3466-2

Bracket, Left steamer door

AT1H-2058-3

Door Hinge (Pair)

Door - Standard Door

AT1H-3609-1

Door Latch, Ceramic Magnet, Chrome -Standard & Evolution

AT1M-2689-1

Plate, Hinge Backer

Door Gasket

AT1G-2633-1

Gasket, Door S6 - Six Pan

Fittings/Scre

ws

AT0F-206141060

Screw, 10-24 x 3/4 slot flat, (hinge plate)

AT0F-2061-

41140

Screw, 10-24 x 1 3/4 fhms (qrd handle)

AT0F-2061-

41160

Screw, Slot Flat 10-24X2

AT0F-2691-

41011

Nyloc Nut, Serrated hex #10-24

AT0F-1046-

31030

Screw, Phillips Truss #8-32x3/8, Control panel

AT0F-3371-1

Nut, Rotary Shaft Seal, (for thermostats)

AT0P-2849-2

Street Elbow 1/8"x1/8" Extra Long

AT0P-2849-3

Street Elbow 1/8"x1/8"

AT0P-2987-2

Nylon Tee - Barbed 1/2 x 1/2 x 1/2

AT0P-3430-1

Garden Hose fitting- Autofill

AT1P-222P-88

Adapter 1/2"x1/2"

AT1P-

CMASSY

Copper Manifold Assembly-External Muffler

AT1P-2239

Ball Valve (drain)

Fuses

AT0E-3162-1

Fuse, Slo-Blo 1/2 Amp

AT0E-2731-1

Fuse, Slo-Blo 3 Amp

AT1E-FU5

Fuse, 5 Amp

ATR-FU30

Fuse, 30A 250V, Time Delay

AT1E-FB2P

Fuse Block, Two Position 250V

Gauges

AT1A-3303-1

Thermometer, Assembly 2"

AT1A-THME

Thermometer, Assembly 1-1/2"

AT0H-2614-1

Vacuum Gauge 2"

AT-VG

Vacuum Gauge 1-1/2"

Page 37

37

MP5006-1001 Rev A

AT0H-3544-1

Lens, 2" gauge

Heaters

AT1A-3530-1

Cast Heater Kit; 208v 6kw, 230/7.3, 240/8, 380/6.7, 400/7.4,

415/8, 440/9, 480/10.7

AT1A-3530-2

Cast Heater Kit; 240k/6kw

AT1A-3530-3

Cast Heater Kit; 208v/8kw, 240/10.7, 380/9, 400/10, 415/10.7,

480/14

AT1A-3530-4

Cast Heater Kit; 208v/12.0kw, 240/16, 380/13, 400/14.8, 415/16,

440/18

AT1A-3530-6

Cast Heater Kit; 208v 10.0kw

AT1A-3530-7

Cast Heater Kit; 208v 17.0kw

Hoses

AT0P-2714-1

Hose Clamp 1/4

AT0P-2714-2

Hose Clamp 1/2

AT1P-255532000

1/4" Silicone Hose - per ft'

AT1P-2555-

62000

1/2" Silicone Hose - per ft'

AT1P-2558-1

Hose 1/2 - 14"

AT1P-2558-2

Hose 1/4" Cut to Length 9'

AT1P-2558-3

Hose 1/4" x 15"

AT1P-2558-4

Hose, 1/4" X 22" (drain valve)

Lamps

AT0E-1800-5

Pilot Lamp Unit, 208/240V (Red)

AT0E-1800-4

Pilot Lamp Unit, 208/240V (Green)

AT0E-1800-6

Pilot Lamp Unit, 208/240V (Amber)

AT0E-1800-9

Pilot Lamp Unit, 208/240V (Clear)

Legs

AT1H-FTA

Foot Adjustment (Cookers)

AT1A-3030-1

Leg Assembly Kit, Steamer

AT0H-3040-1

Rubber Foot Tip (Cooker)

AT0H-2479-7

Stand Caster, Non-Break

AT0H-2479-8

Stand Caster, Break

Misc.

Electronic

AT0E-2717-1

MOV Transient Suppressor, 275V

Misc.

Hardware

AT1M-2573-1

Drip Edge, Left

AT1M-2573-2

Drip Edge, Right

AT1M-2590-1

Bracket, Interior Tray Left

AT1M-2590-2

Bracket, Interior Tray Right

Overlay Graphics

AT1L-2804-1

Overlay, 300 90m timer 2"

AT1L-2804-2

Overlay, 100- 90M Timer 2"

AT1L-2804-3

Overlay, 400 180M Timer 2"

AT1L-OPSUM

Operator Summary (D Model)

Overtemps

AT1E-OTT

Overtemp

ATR-OT

Overtemp w/pigtail

AT1E-OTHLX

Overtemp Switch, Ultimate

AT1A-2613-1

Overtemp (Super Duty) 6 pan

AT1E-2653-3

Overtemp switch, Cast htr-watts

up to incl/14KW

AT1E-2653-4

Overtemp switch, Cast htr-watts

over 14KW

PCB

AT1E-2593-1

Light Control Board (3 PAN Only))

Plugs/Power Cords

AT0E-1051-5

L16-20P Steamer plug

AT1E-

Plug, Power Cord 250V/30A, Locking

Page 38

38

MP5006-1001 Rev A

PSC310-PG

AT1EPSC310-SR

Strain Relief, Power Supply Cord

Relays

AT0E-2059-3

Solid State Relay, (D & A2450)

AT0E-2996-1

Heat Pad - SSR (if no heatsink comp)

AT0E-1587-1

Contactor, 208/240 3pole

AT0E-2825-2

Control Relay, 240V 3PDT

AT0E-2825

-4

Control Relay, 208/240V 3PDT ( Replaces -1 or -2)

AT2E-1220

Relay, Mercury Disp 240V (12KW)

AT0A-2876-2

Relay, Mercury Disp. 208V SP-1269-2

Shell

AT1M-2979-1

Shell Exterior

AT0F-277731030

Truss Screws#8 x 3/8 SS

AT1M-2981-2

Left Side Panel

Solenoids

AT1ESOL208

Solenoid, (Air) 208V Coil

AT1E-

SOL240

Solenoid, (Air) 240V Coil

ATR-S208C

208V Replacement Coil

ATR-S240C

240V Replacement Coil

ATR-SKIT

Solenoid Rebuild Kit

ATR-SKIT2

Sol. Rebuild Kit-new style D803045

Switches

AT0E-2874-2

Switch, Toggle

AT1E-2647-1

Pressure Switch - Single Pressure Switch

AT1E-2647-2

Pressure Switch - Dual Pressure Switch -Above 14KW units

only

AT0E-3337-1

On Pushbutton, Steamer - must use new assy, not

interchangeable with old style

AT0E-3337-2

Off Pushbutton, Steamer -(Must use all new assy)

AT0E-3338-1

On Contact, Steamer

AT0E-3338-2

Off Contact, Steamer

AT0E-3339-1

Pushbutton Lock Ring

Timers

ATR-TI60

Timer, 60 Minute (Cooker Ready)

AT0E-2297-2

Timer, 180 Minute (Cooker Ready)

AT0E-2297-1

Timer, 90 Minute (Cooker Ready)

ATR-WH-C

Conversion Wire Harness (Crammer)

AT0H-1455-2

Thermostat/Timer Repl. Knob-soft grip

Thermocoupl

es

AT0E-3661-1

Thermocouple

Thermostats

AT0E-2559-1

DC Thermostat, Calibrated (100-200 F)

AT0E-2559-2

AC Thermostat, Calibrated (100-200 F)

Transformers

AT0E-2662-1

Transformer

Terminal

Block

AT0E-1134-2

Terminal Block, 2 Position

AT1EH-TB3

Terminal Block, 3 Position, 8000W

AT0E-1134-5

Terminal Block, 5 Position

Vacuum

Pumps

AT1E-2991-1

Vacuum Pump, Gast (new style)

RK935

Gast vacuum pump rebuild kit

AT1E-2703-1

Vacuum Pump, Thomas

Page 39

39

MP5006-1001 Rev A

ATR-CAP

Capacitor - Thomas Pump Only

ATR-VP2RA

Thomas Rod & Diaphragm Assy

ATR-THA2

Thomas Head

ATR-VPLV

Vacuum Pump, Leaf Valves (Pair) Thomas Pump Only

ATR-VPHS

Vacuum Pump Head Replmnt. Screws

Valves

ATR-BVRK

Auto Fill Brass Valve Replace

AT0P-3268-1

Water Fill Solenoid 208V - Autofill only

Water Sensor

AT1E-2652

Probe Water Sensor

AT1E-2654-1

PCB, Water Board Sensor

AT0E-3230-1

PCB, Autofill Water Board Sensor

AT0P-3509-1

Water Valve Control, Autofill only

AT0E-3234-1

Sensor Magnetic Reed Switch-Autofill

Loading...

Loading...