Page 1

STEAM ‘N’ HOLD

STEAMER

OWNERS MANUAL

IMPORTANT WARRANTY INFORMATION:

For product warranty activation, the Product Registration Form must be submitted to

AccuTemp Products, Inc. after installation of the appliance.

Product Registration Form

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page i

Page 2

TABLE OF CONTENTS

DOCUMENT HISTORY ii

TABLE OF CONTENTS ii

SAFETY WARNINGS 1 – 2

INSTALLATION 3 – 5

INITIAL START-UP 6 – 8

OPERATION 7 – 10

DAILY CLEANING 11

SERVICE AND TROUBLESHOOTING 12 – 14

6 PAN STEAMER ELECTRICAL SCHEMATICS 15 – 20

3 PAN STEAMER ELECTRICAL SCHEMATICS 21 - 29

WARRANTY 30

DOCUMENT HISTORY

Current revision: A Prior revision: Date: 8/24/06 Date: None

Change

Initial release - 6/26/07.

_____________________________________________________________

__________

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page ii

Page 3

SAFETY WARNINGS

DANGER:

CAUTION:

location.

W

ARNING:

Never use wet or damp gloves, as moisture can conduct heat quickly

! !!

1. Only personnel qualified to work with electricity should install this

unit. Improper installation can cause personal injury or damage to

the equipment.

2. This appliance must be properly grounded. Failure to properly

ground the appliance could result in electrocution and/or death.

1. When using a stand that is equipped with casters, the floor surface

must

be level and flat. Failure to do so can result in a “tipping”

situation and could result in serious injury.

2. Direct contact with steam can result in a severe burn.

3. When accessing the cooking chamber, be sure to always stand back

while slowly opening the door, allowing the chamber to vent its

steam. Never look or reach into the cooking chamber before it has

completely vented its steam.

4. Never reach into the cooking chamber or handle hot items without

wearing proper hot gloves.

5.

and could result in a severe burn.

1. Be sure all operators read, understand and follow the information

contained in this manual, including caution warnings, operating

instructions, and safety instructions.

2. Use caution when operating the steamer. Direct contact with steam

can result in a severe burn.

3. Please use caution when emptying the drip pan. The pan’s contents

could cause severe burns.

4. Keep the floor in front of the equipment clean and dry. If spills occur,

clean immediately to avoid the potential injuries.

5. Do not use pressurized water to clean steamer.

6. Use of any replacement parts other then those supplied by AccuTemp

Products, Inc. can cause bodily injury to the operator, damage to the

equipment and will void all warranties.

7. This appliance is extremely heavy. For safe handling, the installer

should obtain help as needed or employ appropriate material handling

equipment to remove unit from it’s packaging and move it into its final

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 1 / 32

Page 4

SAFETY WARNINGS (cont.)

IMPORTANT:

IMPORTANT SERVIC

E INFORMATION

CAUTION (cont.):

! !

8. Do not use the low water warning indicator and buzzer as substitutes

for checking the water level in the cooking chamber periodically.

Failure to properly maintain the water level may result in improperly

cooked product and over time, may result in a premature service issue

that may not be covered under warranty.

1. Never leave a de-liming agent in contact with the stainless steel

longer than 10 minutes before rinsing the cooking chamber

thoroughly with water. Longer contact can cause corrosion.

2. Do not use abrasive materials, such as wire brushes, metal scouring

pads or scrapers to clean the cooking chamber bottom.

3. Service must be performed only by AccuTemp Products, Inc.

authorized service personnel. Service performed by unauthorized

personnel will void all warranties.

4. Any in-field modification made without written authorization from

AccuTemp will void the warranty.

An AccuTemp Products, Inc. Technical & Customer Support Technician is

AT1T-2739-1 Rev. A

1-800-480-0415 or +1-260-469-3040

available Monday thru Sunday, 7:00am to 7:00pm EST.

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 2 / 32

Page 5

INSTALLATION

BUILDING CODES AND STANDARDS

The steamer must be installed in accordance with the following building codes:

USA: National Electric Code, ANSI/NFPA-70, state and local codes.

Canada: Canadian Electric Code, CSA C22.2 and local codes.

UNPACKING

This steamer was inspected before shipment from the factory. The shipping

company accepts full responsibility for safe delivery. Immediately after unpacking,

check the steamer for possible shipping damage. If damage is identified, saving the

packaging material and contact the shipping carrier within 15 days.

LOCATION AND PLACEMENT

To insure maximum benefit of your warranty; location, placement and leveling are

critical. The AccuTemp Steam ‘N’ Hold steamer is designed for installation on either a

commercial kitchen countertop or an AccuTemp Steam ‘N’ Hold stand.

Your Steam ‘N’ Hold steamer is equipped with vents to allow the proper ventilation

of air through the electrical compartments. On current S6 & S3 Steam ‘N’ Hold models,

the vents are located on the bottom and rear panels. To ensure these vents work

properly, a minimum 4 inch (102 mm) clearance from these vents must be allocated.

It is also recommended that the Steam ‘N’ Hold not be placed under other wet

equipment or locations.

Note:

rear face and left side panels. A minimum spacing of 6 inches (152 mm) to the left side

access panel is required between heat sources such as, but not limited too, a range,

griddle or fryer. A minimum spacing of 3 inches (76 mm) to the rear face, between any

object such as a wall, barrier or other piece of equipment, must be allocated as well.

LEVELING

The steamer must be installed in a level condition. An out-of-level condition may

cause improper operation and possible damage. Damage caused by improper leveling

is not covered by warranty. Use a spirit level, resting on the top steamer cabinet

surface, to ensure it is level front-to-back and left-to-right.

If this is a counter-top installation, be sure to install a rubber foot tip

provided with your steamer onto the foot adjuster of each of the steamer leg

as shown. This will keep the steamer from sliding on the counter-top under normal

use. Once the rubber foot tips have been installed, rotate the foot adjusters up or

down as needed to level the steamer.

For S6 models with a serial number lower than 22627, vents are located on the

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 3 / 32

Page 6

INSTALLATION (cont.)

!!

SINGLE STEAMER STAND INSTALLATION

The AccuTemp SNH10 single stand is equipped with adjustable height feet and the

AccuTemp SNH11 single stand is equipped with non-adjustable height casters. Both

can be used with either a one S6 or S3 model Steam ‘N’ Hold steamer. Before

mounting a steamer on the SNH11 stand, engage the brakes on the two front locking

casters, pressing on the “ON” handle of the brake mechanism. To mount the steamer,

carefully lift and place it on the horizontal mounting brackets, ensuring that the (4)

mounting holes on the underside of the Steam ‘N’ Hold are lined up with the mounting

holes on the brackets. Then, using a 7/16” wrench, fasten one pair of the 1/4"-20 hex

bolts and 1/4" split lock washers through the underside of each stand bracket mounting

hole into the Steam ‘N’ Hold and tighten securely.

steamer by adjusting the feet found at the ends of each stand leg, either up or down as

needed.

WARNING

When using a stand that is equipped with casters, the floor surface must be

level and flat. Failure to do so can result in a “tipping” situation that could

result in serious injury.

DOUBLE STEAMER STAND INSTALLATION

The AccuTemp SNH20 double stand is equipped with adjustable height feet and the

AccuTemp SNH21 double stand is equipped with non-adjustable height casters. Both

stands can accommodate either two S6 model Steam ‘N’ Holds, two S3 Model Steam ‘N’

Holds or a one of each steamer model. When ordered as a steamer set, one of the two

steamers will be designated as a “bottom unit” on the outside of its packaging. Before

mounting a steamer on the SNH21 stand, engage the brakes on the two front locking

casters, pressing on the “ON” handle of the brake mechanism. To mount the steamer,

carefully lift and place it on the horizontal mounting brackets, ensuring that the (4)

mounting holes on the underside of the Steam ‘N’ Hold are lined up with the mounting

holes on the brackets. Then, using a 7/16” wrench, fasten one pair of the 1/4"-20 hex

bolts and 1/4" split lock washers through the underside of each stand bracket mounting

hole into the Steam ‘N’ Hold and tighten securely.

Once the “bottom unit” has been installed, carefully lift and place the “top unit”

Steam ‘N’ Hold steamer on the horizontal mounting brackets, ensuring that the (4)

mounting holes on the underside of the Steam ‘N’ Hold are lined up with the mounting

holes on the brackets. Then, using a 7/16” wrench, fasten one pair of the 1/4"-20 hex

bolts and 1/4" split lock washers through the underside of each stand bracket mounting

hole and tighten securely.

With the SNH20 stand, level the steamers by adjusting the feet found at the ends of

each stand leg, either up or down as needed.

With the SNH10 stand, level the

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 4 / 32

Page 7

INSTALLATION (cont.)

WARNING

When using a stand that is equipped with casters, the floor surface must be

level and flat. Failure to do so can result in a “tipping” situation that could

result in serious injury.

ELECTRICAL SUPPLY

The AccuTemp Steam ‘N’ Hold steamer has been designed, manufactured and

tested to meet or exceed the Underwriters Laboratories safety standards. To ensure

safety is maintained in your installation, it is important that the following paragraphs

are understood before attempting to apply power to your Steam ‘N’ Hold. If there is

any doubt as to whether your supply receptacle is of the correct voltage, amperage, or

is properly grounded, consult a qualified electrician or serviceman.

POWER REQUIREMENTS

AC power requirements are listed on the data plate located on the left side access

panel on all steamers. Steamers should never be connected to a circuit operating at

more than 150 VAC to ground and should always be connected to an individual branch

circuit. Make sure the voltage at the supply receptacle is within ±10% of the voltage

listed on the steamer’s data plate. Connection to any other voltage may permanently

damage your Steam ‘N’ Hold or cause premature component failure. Damage of this

type is not covered under the product warranty. Each Steam ‘N’ Hold steamer comes

equipped with a connected 6 foot power cord and plug, rated for the power

requirements of each steamer. Damage caused by removal or modification of factory

standard plug is not covered by product warranty.

GROUNDING

To reduce the risk of serious shock or death in the event of an electrical short

circuit, this appliance must be grounded. The Steam ‘N’ Hold steamer is equipped with

a cord having a grounding wire and plug, which must be plugged into a receptacle that

is properly installed and grounded. Under no circumstance should the grounding plug

be cut or bent to fit a receptacle other than the one specified.

DRAIN CONNECTION

While there are no AccuTemp-supplied drain components, some customers may

desire to construct a drain connection. Any drain connections must include an air gap

between the steamer and the drain to avoid creating a back siphon effect into the

steamer cooking compartment.

HOOD VENTILATION

Some local building codes may require the steamer to be located under an exhaust

hood. Please check local building code requirements before completing installation of

the steamer.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 5 / 32

Page 8

INITIAL START-UP

!

INTRODUCTION

The AccuTemp Steam ‘N’ Hold steamer takes the time-proven method of cooking

with steam and adds the advantage of control. This is accomplished by reducing the

internal atmospheric pressure of the Steam ‘N’ Hold cooking chamber, thereby lowering

the temperature at which the water begins to boil. This allows the operator to control

the temperature of the steam for cooking. Controlling the steam temperature gives the

operator the ability to cook the food to the desired temperature without over-cooking,

resulting in a more tender, juicier, nutritious product and with less shrinkage than was

previously possible. Once the cooking time expires, the steamer automatically enters

the “Hold” mode. In this mode, the thermostat regulates the internal temperature, but

vacuum is released, returning the cooking chamber to normal atmospheric pressure. At

this time, steam is no longer generated and the cooking chamber is held at the desired

temperature at a relative humidity of 100%. This eliminates food from drying out by

suppressing the evaporation of the products’ natural moisture. As a result, most food

products can be held in a ready-to-serve state for several hours after cooking, with no

appreciable loss in taste, appearance or consistency.

DAILY PREPARATION FOR USE

Preparing the Steam ‘N’ Hold for use each day requires very little time and effort:

simply fill the steamer with water and preheat.

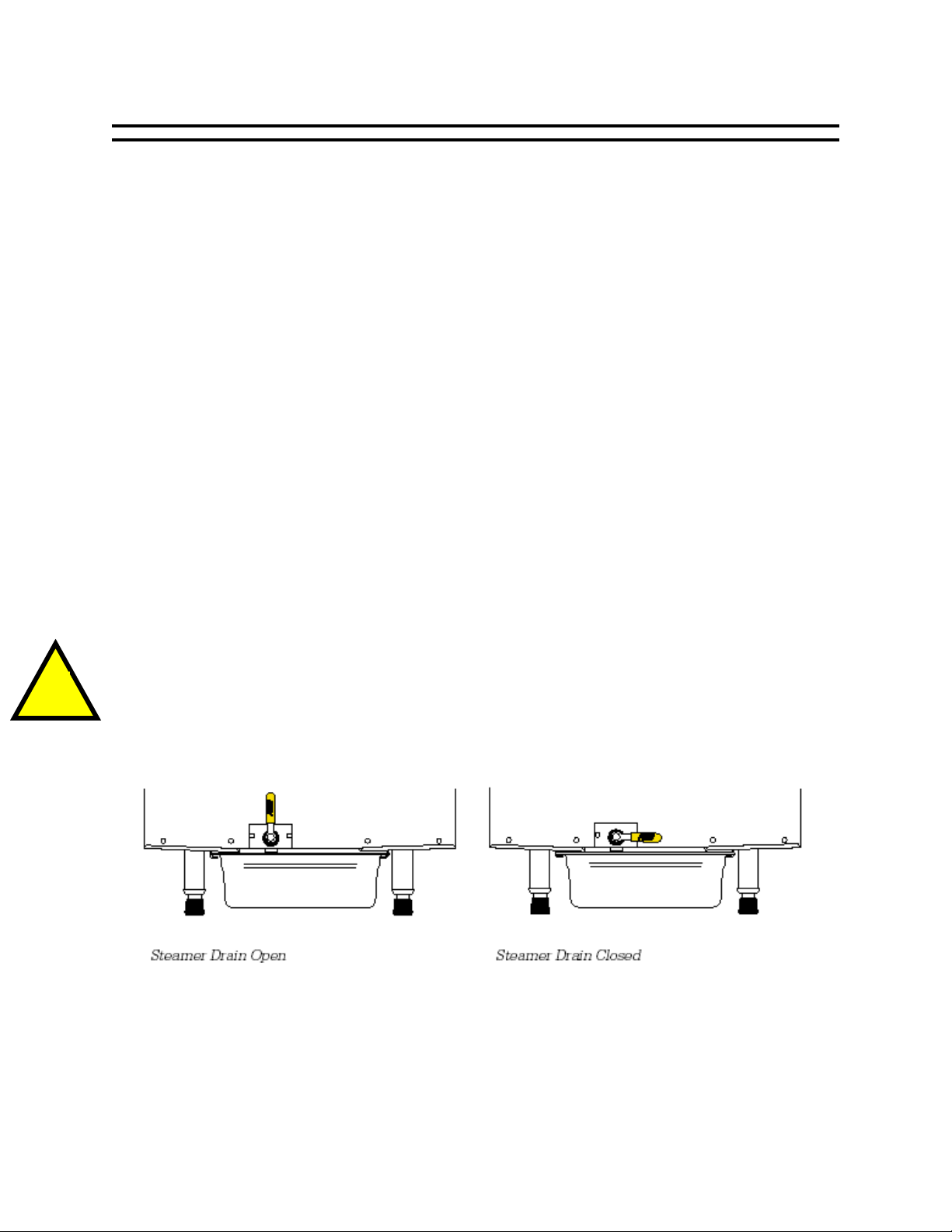

Caution

Before filling the cooking chamber with water, ensure that the drain valve on

the front of the Steam ‘N’ Hold is in the closed position. Ensure that a full

size steam table pan or a 1/1 gastronome pan with a minimum depth of 4

inches, has been positioned on the pan rail brackets under the steamer.

At the beginning of each day, open the door of the Steam ‘N’ Hold and pour 3

gallons (11 liters) of ordinary tap water into the bottom of the cooking chamber.

(Although the mineral content of the water is not that important, the Steam ‘N’ Hold

should always be drained and cleaned at the end of each day to prevent food or

mineral buildup.)

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 6 / 32

Page 9

INITIAL START-UP (cont.)

!

Daily water usage will depend on several factors: cooking temperature, the

products being cooked and the length of time the door is open. In most cases, 3

gallons (11 liters) of water will last several hours or more. However, the level of the

water should be checked periodically to avoid running low and or out. If the Steam ‘N’

Hold does run out of water, the “Low Water” warning indicator light and buzzer will turn

on. Should this occur, simply turn the Steam ‘N’ Hold off, refill it with water and restart

the unit. If the shutdown occurred during cooking, the cycle will resume at the point it

stopped. However, a time adjustment may be necessary, depending on the

temperature of the water the steamer was re-filled with.

CAUTION

Do not use the low water warning indicator light and buzzer as substitutes

for checking the water level in the cooking chamber periodically. Failure to

properly maintain the water level may result in improperly cooked product

and over time may result in a premature service issue that may not be

covered under warranty.

AUTO-FILL MODELS

The Steamer must be connected to the facility water supply via an appliance hose,

preferably a stainless steel braided hose with a ¾” garden hose type connection, from

a water spigot or from a nearby sink faucet.

First time fill (the Steamer water reservoir is empty of water):

1. With the water supply turned on, press the “ON” button. The Steamer will

power up with the pump operating.

2. Both water valves will be turned on.

3. A relay will bypass the low water level sensing to allow for first time filling of the

reservoir.

4. The thermostat will be turned off for the first fill to prevent damage to the heater

elements.

5. Water will rise to the low level probe and reset the low level circuit of the water

control board.

6. The water will continue to rise until it contacts the High Level Probe.

7. A five second delay is initiated when the water touches the High-level probe to

allow for wave action in side the water reservoir.

lower than desired amount of water to be injected in the reservoir by tripping the

control too soon if there were no sequence to ignore the wave action inside the

reservoir.

8. When the five seconds has been satisfied the water level control board shuts off

the water level control relay and the by pass relay.

9. The heater is turned on and normal operation begins.

Wave action would cause a

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 7 / 32

Page 10

INITIAL START-UP (cont.)

PREHEATING

To maximize efficiency, while minimizing cook time, it is always recommended to

preheat the cooking chamber prior to cooking.

S6 Model: With the water reservoir full, close the door, set the thermostat to the

desired cooking temperature, position the toggle switch to the “Thermostat” mode

[160°F (71°C) – 200°F (93°C)] or the “Fast Cook” mode (212°F/100°C), set timer to 15

minutes and press the “ON” button. When the pre-heat cycle is complete, the steamer

will automatically switch to the “Hold” mode, at which time the Steam ‘N’ Hold is ready

for use. Please note, when steamer is in “Hold” mode, the thermostat setting will

regulate the cooking chamber temperature even if the steamer is set in the “Fast Cook”

mode.

S3 Model: With the water reservoir full, close the door, set the thermostat to the

desired cooking temperature, set timer to 15 minutes, turn the rotary selector switch to

“ON” and then select either “Cook” [160°F (71°C) – 200°F (93°C)] or “Fast Cook”

(212°F/100°C). When cycle is complete, the steamer will automatically switch to “Hold”

mode at which time the Steam ‘N’ Hold is ready for use. Please note, when steamer is

in “Hold” mode, the thermostat setting will regulate the cooking chamber temperature

even if the steamer is set in the “Fast Cook” mode.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 8 / 32

Page 11

OPERATION

! !

COOKING

Low Temperature Cooking [160°F (71°C) – 200°F (93°C)]

Did you know that with the AccuTemp Steam ‘N’ Hold steamer, you could

cook and hold food all at the same time? With its patented vacuum cooking

technology, the Steam ‘N’ Hold offers you the versatility of cooking and

holding different types of food product all at the same time when cooking

with low temperature steam.

S6 Model: To begin low temperature cooking, position the toggle switch into

“Thermostat” mode, set the thermostat to the desired cooking temperature, set the

timer to the desired cooking time and press the “ON” button, if the steamer has to be

started.

CAUTION

Maximum recommended food load for the S6 model is 100lbs (45Kg).

S3 Model: To begin low temperature cooking, set the thermostat to the desired

cooking temperature, set the timer to the desired cooking time and turn the selector

switch to “ON”, if the steamer has to be started, and then select “Cook”.

CAUTION

Maximum recommended food load for the S3 model is 50lbs (23Kg).

Try using perforated pans for the best results in cooking! By allowing

steam to penetrate from all directions, perforated pans will maximize heat

transfer and give you the shortest cooking times.

High Temperature Cooking (212°F/100°C)

S6 Model: To begin high temperature cooking, position the toggle switch to “Fast

Cook”, set the timer to the desired cooking time and press the “ON” button, if the

steamer has to be started.

S3 Model: To begin high temperature cooking, set the timer to desired cooking time,

and turn the selector switch to “ON”, if the steamer has to be started, and then select

“Fast Cook”.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 9 / 32

Page 12

OPERATION (cont.)

Continuous Cook

This feature gives you the flexibility of cooking independently of the cooking timer

and can be utilized in either low temperature or high temperature cooking.

S6 & S3 Model: Follow either low temperature or high temperature cooking

guidelines but instead of selecting a time period, rotate the timer knob clockwise until

the white indicator on the timer knob lines up with the yellow “Continuous” position.

Note:

On S6 units with a serial number less than 22627, rotate the timer knob

clockwise until the timer knob rests against the timer “stop pin”.

Checking Food While Cooking

To maximize efficiency, while minimizing cooking time, it is always recommended to

allow food to finish it’s cook cycle before opening the cooking chamber door. However,

if the door is opened during a cooking cycle, a time adjustment may be necessary,

depending on how long and often the chamber door was opened.

S6 Model: Press the “OFF” button, stand back while slowly opening the door, allowing

the cooking chamber to vent its steam. Once steam has vented, carefully check the

food, close the door and press the “ON” button to continue cooking.

S3 Model: Press the “OFF” button, stand back while slowly opening the door, allowing

the cooking chamber to vent its steam. Once steam has vented, carefully check the

food, close the door and turn the selector switch to “ON” and “Cook” or “Fast Cook” to

continue cooking.

HOLDING

The Steam ‘N’ Hold will automatically enter the “Hold” mode once timer cooking

time has expired, where the buzzer will sound, alerting the operator that the food is

ready. A slight counterclockwise manual adjustment to the “Hold” position on the timer

knob is needed to turn off the buzzer. The “Hold” temperature is determined by the

thermostat setting. It is recommended to preheat the cooking chamber to the desired

holding temperature if the cooking chamber is in a cool state.

S6 Model: To hold food independently of cooking, rotate the timer counter clockwise

until the white indicator on the timer knob lines up with the yellow “Hold” position.

Select desired the “Hold” temperature and press the “ON” button.

S3 Model: To hold food independently of cooking, rotate the timer counter clockwise

until the white indicator on the timer knob lines up with the yellow “Hold” position.

Select desired the “Hold” temperature and turn the selector switch to “ON” and “Cook”

or “Fast Cook”.

Note:

On S6 units with a serial number less than 22627, rotate the timer knob

clockwise until the timer knob rests against the timer “stop pin”.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 10 / 32

Page 13

DAILY AND WEEKLY CLEANING

!

DAILY CLEANING

At the end of each day, the Steam ‘N’ Hold should be drained and cleaned.

1) Turn the steamer off.

2) Allow the cooking chamber water to cool. Ensure that a full size steam table pan or

a 1/1 gastronome pan with a minimum depth of 4 inches (101 mm) has been placed

beneath the Steam ‘N’ Hold. Use caution while opening the drain valve. Empty the

water into the drain pan and discard the water.

3) Dry the inside of the cooking chamber, including the two low water sensors, with a

cloth. Failure to follow this cleaning procedure can result in inefficient cooking and

false low water readings with the low water sensors that will shut the steamer down

even though there may be plenty of water in the reservoir.

4)

Do not use a water jet to clean steamer.

5) Leave the door open to allow the cooking chamber to dry overnight.

WEEKLY CLEANING

Once a week, the Steam ‘N’ Hold should be drained and cleaned more thoroughly than

the daily cleaning.

1) Fill the cooking chamber with 2 gallons (7.6 liters) of water and one cup (8 ounces

or 0.24 liters) of white vinegar.

2) Turn the Steamer on and operate for 30 minutes at the maximum temperature in

the THERMOSTAT mode (200ºF/93ºC) or set the Switch to the FAST COOK position.

3) Allow the water and vinegar mixture to cool. Ensure that a full size steam table pan

or a 1/1 gastronome pan with a minimum depth of 4 inches (101 mm) has been

placed beneath the Steam ‘N’ Hold. Use caution while opening the drain valve.

Empty the water into the drain pan and discard the water.

4) Rinse the cooking chamber thoroughly with water. Empty the water and vinegar

mixture into the drain pan and discard the mixture.

5) Remove the pan rails. Dry the inside of the cooking chamber, the two low water

sensors and the pan rails with a cloth. Failure to follow these cleaning procedures

can result in inefficient cooking and false low water readings with the low water

sensors that will shut the steamer down even though there may be plenty of water

in the reservoir.

6) Leave the door open to allow the cooking chamber to dry overnight.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 11 / 32

Page 14

SERVICE AND TROUBLESHOOTING

0415 or

To prevent electrical shock, do not open covers. There are no us

er serviceable

IMPORTANT SERVICE INFORMATION

Service must be performed only by AccuTemp Products, Inc. authorized

service personnel. Service performed by unauthorized personnel will void all

Call AccuTemp Products, Inc. Technical Service Hotline at 1-800-480-

Both high and low voltages are present inside this equipment, even when

turned off. Remove the equipment from all power sources prior to servicing.

An AccuTemp Products, Inc. Technical & Customer Support

Technician is available Monday thru Sunday, 7:00am to 7:00pm EST.

+1-260-469-3040 for the nearest service agent.

WARNING

warranties.

parts inside.

1-800-480-0415 or +1-260-469-3040

GENERAL SERVICE INFORMATION

Conventional steamers require scheduled service (such as boiler maintenance) at

relatively frequent intervals. The Steam ‘N’ Hold steamer however, requires no such

requirements due to its unique design.

Because the Steam ‘N’ Hold has been engineered for the highest reliability, most

problems that arise can be attributed to minor oversights, such an incorrect

temperature or failure to close door securely. These types of situations are addressed in

the following paragraphs.

To ensure continued safe and reliable operation of your Steam ‘N’ Hold, only Factory

Authorized Service Personal should perform any component replacement or major

repair. Please contact the AccuTemp Technical Service Department for help at 800-4800415 or 260-469-3040 if the measures described below fail to correct your problem.

BASIC TROUBLESHOOTING

Steam Will Not Turn On

• Make sure the unit is plugged in (if applicable).

• Check the facility circuit breaker (or fuses) supplying the unit.

• Call AccuTemp Products, Inc. Technical Service toll free at 1-800-480-0415 or at

+1-260-469-3040.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 12 / 32

Page 15

SERVICE AND TROUBLESHOOTING (cont.)

Steamer displays “Low-Water”

• Check level of water in cooking chamber and add accordingly.

• If cooking chamber is full (3 gallons/11 liters), water sensors may have a film

across them. Clean sensors by draining unit of water and wiping sensors off with

a towel and mild detergent and then rinse thoroughly.

• Call AccuTemp Products, Inc. Technical Service toll free at 1-800-480-0415 or at

+1-260-469-3040.

Food Is Over Cooked

• Check that the proper cook temperature is being used. (Excess time will cause

over-cooking only when the temperature setting is moderately higher than the

desired final product temperature).

• Call AccuTemp Products, Inc. Technical Service toll free at 1-800-480-0415 or at

+1-260-469-3040.

Food Is Under Cooked

• Make sure you are using adequate time and temperature settings. Extra time

may be required if pans are covered or if product is left in plastic bags or similar

packaging.

• Try distributing the product more evenly within the steamer and or pans, if

possible.

• Make sure the water drain valve on the front of the Steam ‘N’ Hold is tightly

closed. The steamer may appear to be cooking normally if the valve is slightly

open but efficiency may be compromised.

• Check the door seal for food debris. Food debris on the face of the door seal or

under flap may cause steamer to appear to be cooking normally but efficiency

may be compromised. Nicks or cuts in the door seal may also cause inefficient

cooking.

• Call AccuTemp Products, Inc. Technical Service toll free at 1-800-480-0415 or at

+1-260-469-3040.

Low Vacuum Gauge Readings

• The higher the temperature setting, the lower the vacuum gauge reading. When

operating at 212° (Fast Cook), the gauge will read near or at zero.

• Verify that the door has been closed securely.

• Check to make sure there is no food debris on the face of the door seal or

behind its flap. Also check the door seal for damage such as nicks or cuts.

• Call AccuTemp Products, Inc. Technical Service toll free at 1-800-480-0415 or at

+1-260-469-3040.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 13 / 32

Page 16

SERVICE AND TROUBLESHOOTING (cont.)

Unit Will Not Turn Off

• This symptom, which is extremely rare, indicates a serious control malfunction.

• Turn off the steamer’s electrical supply at the source.

• Call AccuTemp Products, Inc. Technical Service toll free at 1-800-480-0415 or at

+1-260-469-3040.

AUTO-FILL

Failure events and safety control

• The Steamer does not turn on.

i. Check to ensure the Steamer is plugged into the correct receptacle.

ii. Check the branch circuit breaker to insure it is in the “ON” position.

iii. The mechanical over flow level control has been removed. The

Steamer will not start up until the mechanical level control is reinstalled.

iv. Call AccuTemp Products, Inc. Technical Service toll free at 1-800-

480-0415 or at +1-260-469-3040.

• No/low water pressure or no/low flow of water into the reservoir.

i. Check the supply water pressure

ii. Check for dirty inlet screen.

iii. Check for dirty probes.

iv. Call AccuTemp Products, Inc. Technical Service toll free at 1-800-

480-0415 or at +1-260-469-3040.

• The Steamer shuts down during operation.

i. Check conditions listed above for no/low water pressure or no/low

flow of water into the reservoir.

ii. If the water level control valve is stuck “on”, the mechanical over

flow level control will shut down the whole Steamer and the water

supply by turning off the master water control valve.

iii. If the water level sensing control board becomes faulty, the

mechanical over flow level control will shut down the Steamer.

iv. Call AccuTemp Products, Inc. Technical Service toll free at 1-800-

480-0415 or at +1-260-469-3040.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 14 / 32

Page 17

6 PAN ELECTRICAL SCHEMATIC

LOW LIMIT

PRB 2

K2

*DK BRN

PNK

CONTACTOR

L

ZR2

3

WHT

L

2

L

BLK

1

275V

WHT

ORN

J3

J4

L1L2

275V

WHT

BLK

ZR1

BLK

N.O.

LT BLU

RLY2

6

COM

9

BLK

3

TAN

N.C.

N.O.

5

COM

8

2

N.C.

N.O.

DK BRN

4

COM

7

1

N.C

.

ORN

DK BRN

VIO

WHT

WHT

N.O.

RED

RLY1

COM

6

9

RED

3

N.C.

RED

N.O.

PNK

5

COM

8

BLK

BLK

WHT

PNK

2

N.C.

N.O.

4

COM

7

1

N.C

.

BLK

*

AUTO-FILL ONLY

WHT

MASTER

W. VLV.

BLU

BLU

YEL

YEL

ORN

LT BRN

ZR7

ZR6

WHT

FILL

W. VLV.

N.O.

VIO

RLY5

COM

6

VIO

9

3

N.C.

N.O.

5

COM

8

2

YEL

N.C.

N.O.

4

COM

7

1

N.C

DK BRN

.

WHT

BLK

1

2

WHT

3

4

5

HEAT

WHT/RED

WHT/GRY

T1

L1

3

SSR

4

R2

R1BLK

R3

HEATING ELEMENTS

+

-

*RED

*VIO

DK BRN

THERMAL

LIMIT SW3

VIO

OPTIONS

AUTO-FILL

AT1T-2988-1

1 PHASE, 208 - 240V

WHT

THERMOSTAT

VAC SW4

SW5

J TYPE

YEL

WHT/BRN

WHT

RED

o

t

YEL

*YEL

1

3

2

4

*YEL

CONNECTION CHART

WO/ AUTO-FILL

BLK

GRY

BLU

WHT

HOLD

POWER

COOK

WHTWHT

TAN

WHT

DK BRN

RED

WHT

WATER

ON

LOW

SW1

ORN

OFF

SW2

1&2

W/ AUTO-FILL

1&4, 2&3

WHT

YEL

YEL

1 2 3 4 5 6 7

PWR COM OUTPUT + -

J TYPE CONTROLLER CAL OFFSET ADJ

(INTERNATIONAL) - BLU

WHT

(INTERNATIONAL – GRN/YEL

GRN

BLK

(INTERNATIONAL) - BRN

F1

WHT

3A

F2

BLK

COM

9

COM

VIO

8

COM

7

WHT

4

LT BLU

ORN

2

WHT

WHT

WHT/RED

RLY3

N.O.

6

3

N.C.

N.O.

5

2

N.C.

N.O.

4

1

N.C

.

DK GRY

S1

S2

S3

TM

TIMER IN

HOLD

POSITION

BLK

BLK

WHT – GAST

BRN -Thomas

ZR4

WHT/BRN

275V

BLU

F3

WHTWHT

.5 A

WHT

F4

.5 A

RED

HIGH LIMIT

ZR3

275V

GRN

LT BLU

WHT

PRB 1

J1

WHT

J2

GND

*WHT

AUTO-FILL

OPTION ONLY

WATER SENSOR BOARD

N.O. N.C.

K1

COM

J5J6J7J8 J9

*BLU

*YEL

*YEL

WHT

N.O. N.C.

COM

*BLK

*H. W. LIMIT SW7

*LT BRN

VP

GRY

5

BLU

6

TM

PNK

3

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 15 / 32

Page 18

6 PAN ELECTRICAL SCHEMATIC

CONTACTOR

ZR5

275V

L3

GRN

GND

WATER SENSOR BOARD

N.O. N.C.

COM

J5J6 J7J8 J9

*BLK

*YEL

*YEL

*LT BRN

ORN

PRB 2

L1

K2K1

DK BRN

*DK BRN

*H. W. LIMIT SW7

THERMAL

LIMIT SW3

RED

WHT

L2

L1

BLK

WHT

J3

J4

*RED

*VIO

WHT

Y

Z

X

G

GRN

WHT

F1

F3

WHT

BLK

COM

9

VIO

COM

8

COM

7

WHT

.5 A

3A

F2

F4

BLK

.5 A

BLK

WHT/RED

N.O.

RLY3

WHT/BRN

6

3

N.C.

WHT – GAST

BRN -Thomas

N.O.

5

2

VP

N.C.

ZR4

275V

N.O.

BLU

4

1

N.C

.

DK GRY

WHT

WHT

RED

HIGH LIMIT LOW LIMIT

ZR3

275V

LT BLU

PRB 1

J1

WHT

J2

L2

N.O. N.C.

*WHT

COM

*BLU

AUTO-FILL

OPTION ONLY

RED

WHT

ZR2

275V

BLK

ZR1

275V

BLK

N.O.

LT BLU

RLY2

6

COM

9

BLK

3

TAN

N.C.

N.O.

5

COM

8

2

N.C.

N.O.

DK BRN

4

COM

7

1

N.C

.

ORN

DK BRN

VIO

WHT

WHT

VIO

N.O.

RED

RLY1

COM

6

9

RED

3

N.C.

RED

N.O.

5

COM

8

BLK

BLK

WHT

PNK

2

N.C.

N.O.

4

COM

7

1

ORN

N.C

.

BLK

*

AUTO-FILL ONLY

WHT

ZR6

MASTER

W. VLV.

RLY5

BLU

COM

9

BLU

COM

8

YEL

COM

7

LT BRN

WHT

YEL

1

2

WHT

3

BLK

4

RED

ZR7

FILL

WHT

W. VLV.

N.O.

VIO

6

VIO

3

N.C.

N.O.

5

2

YEL

N.C.

N.O.

4

1

N.C

DK BRN

.

BLK

BLK

5

WHT/GRY

WHT/RED

HEAT

3

T1

L1

T1

L1

+

SSR 1

-

4

3

+

SSR 2

-

4

R3

R1

HEATING ELEMENTS

ORN

SW 6

R2

(OPTIONAL)

VAC SW4

YEL

LT BLU

4

ORN

2

WHT

WHT

S1

S2

S3

TM

TIMER IN

HOLD

POSITION

GRY

5

BLU

6

TM

*YEL

ORN

CONNECTION CHART

WO/ AUTO-FILL

1&2

W/ AUTO-FILL

1&4, 2&3

PNK

3

WHT

PNK

BLU

WHT

GRY

HOLD

COOK

WHTWHT

WHT

BLK

POWER

TAN

DK BRN

WHT

LOW

WATER

RED

ON

OFF

SW1

SW2

*YEL

31

2

4

YEL

YEL

1 2 3 4 5 6 7

PWR COM OUTPUT + -

J TYPE CONTROLLER CAL OFFSET ADJ

VIO

SW5

J TYPE

YEL

WHT

WHT

WHT/BRN

WHT

RED

o

t

THERMOSTAT

OPTIONS

AUTO-FILL

OVER-RUN PRESSURE

SWITCH

AT1T-2988-2

3 PHASE, 208 - 240V

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 16 / 32

Page 19

6 PAN ELECTRICAL SCHEMATIC

GRN/YEL

BLU or ORN

L3

N

L2

G

L1

F1

WHT

3A

F2

BLK

WHT/RED

COM

9

VIO

COM

8

COM

7

WHT

LT BLU

4

ORN

2

WHT

WHT

RLY3

N.O.

N.C.

N.O.

N.C.

N.O.

N.C

DK GRY

S1

S2

S3

TM

TIMER IN

HOLD

POSITION

BLK

6

3

5

2

4

1

.

WHT

BLK

WHT/BRN

WHT – GAST

BRN -Thomas

ZR4

F3

.5 A

F4

.5 A

VP

275V

BLU

GRY

5

BLU

6

TM

PNK

3

WHT

WHT

RED

HIGH LIMIT

ZR3

275V

GRN

LT BLU

PRB 1

PRB 2

J1

WHT

J2

GND

L2

WATER SENSOR BOARD

N.O. N.C.

N.O. N.C.

*WHT

K1

COM

COM

J5

J6

*BLU

*BLK

*YEL

AUTO-FILL

*YEL

OPTION ONLY

*H. W. LIMIT SW7

*LT BRN

WHT

LOW LIMIT

L1

K2

J7J8J9

*DK BRN

PNK

ORN

J3

J4

DK BRN

THERMAL

LIMIT SW3

CONTACTOR

ZR5

550V

L3

GRY

BLK

L2

L1

BRN

WHT

RED

WHT

BLK

ZR2

550V

ZR1

275V

BLK

N.O.

LT BLU

RLY2

6

COM

9

BLK

3

TAN

N.C.

N.O.

5

COM

8

2

N.C.

N.O.

DK BRN

DK BRN

4

COM

7

1

N.C

.

ORN

DK BRN

VIO

WHT

WHT

N.O.

RED

RLY1

COM

6

9

RED

3

N.C.

N.O.

RED

5

COM

8

BLK

BLK

WHT

PNK

2

N.C.

N.O.

4

COM

7

1

N.C

.

BLK

*

AUTO-FILL ONLY

WHT

ZR6

MASTER

W. VLV.

BLU

BLU

YEL

YEL

ORN

LT BRN

WHT

ZR7

WHT

FILL

W. VLV.

N.O.

VIO

RLY5

COM

6

VIO

9

3

N.C.

N.O.

YEL

5

COM

8

2

N.C.

N.O.

4

COM

7

1

N.C

DK BRN

.

WHT

RED

WHT/GRY

HEAT

BLK

T1L1

L1

BLK

T1

WHT

1

2

3

BLK

4

5

WHT/RED

SSR 1

SSR 2

3

+

-

4

3

+

-

4

R1

HEATING ELEMENTS

ORN

R2

R3

SW 6

(OPTIONAL)

*RED

*VIO

VIO

OPTIONS

AUTO-FILL

OVER-RUN PRESSURE

SWITCH

AT1T-2988-3

3 PHASE, 380 - 415V

WHT

THERMOSTAT

VAC SW4

VIO

J TYPE

SW5

YEL

o

t

RED

WHT

WHT/BRN

*YEL

YEL

31

2

4

*YEL

CONNECTION CHART

WO/ AUTO-FILL

BLK

WHT

GRY

BLU

WHT

HOLD

POWER

COOK

WHTWHT

TAN

DK BRN

WHT

LOW

WATER

RED

ON

SW1

ORN

OFF

SW2

1&2

W/ AUTO-FILL

1&4, 2&3

WHT

YEL

YEL

1 2 3 4 5 6 7

PWR COM OUTPUT + -

J TYPE CONTROLLER CAL OFFSET ADJ

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 17 / 32

Page 20

6 PAN ELECTRICAL SCHEMATIC

WHT

Y

Z

X

G

GRN

BLK

ORN

WHT

WHT

H4H1X4

BRN

RED

X1

WHT

F1

3A

F2

WHT/RED

COM

9

VIO

COM

8

COM

7

WHT

LT BLU

4

2

F3

WHT

BLK

BLK

N.O.

RLY3

WHT/BRN

6

3

N.C.

WHT – GAST

BRN -Thomas

N.O.

5

2

N.C.

ZR4

N.O.

4

1

N.C

.

DK GRY

S1

S2

S3

TM

TIMER IN

HOLD

POSITION

WHT

.5 A

WHT

F4

.5 A

RED

HIGH LIMIT

ZR3

275V

GRN

LT BLU

J1

PRB 1

PRB 2

J2

WHT

GND

L2

WATER SENSOR BOARD

N.O. N.C.

*WHT

VP

275V

BLU

GRY

5

BLU

6

TM

PNK

3

N.O. N.C.

K1

COM

COM

J5J7J8

J6

*BLU

*BLK

*YEL

AUTO-FILL

*YEL

OPTION ONLY

*H. W. LIMIT SW7

*LT BRN

WHT

LOW LIMIT

L1

K2

*DK BRN

PNK

ORN

J9

DK BRN

THERMAL

LIMIT SW3

CONTACTOR

ZR5

550V

L3

RED

WHT

L2

L1

BLK

WHT

J3

J4

RED

WHT

ZR2

550V

BLK

ZR1

275V

BLK

N.O.

LT BLU

RLY2

6

COM

9

BLK

3

TAN

N.C.

N.O.

5

COM

8

2

N.C.

N.O.

DK BRN

4

COM

7

1

N.C

.

ORN

DK BRN

VIO

WHT

WHT

N.O.

RED

RLY1

COM

6

9

RED

3

N.C.

N.O.

RED

5

COM

8

BLK

BLK

WHT

PNK

2

PNK

N.C.

N.O.

4

COM

7

1

N.C

.

WHT

BLK

*

AUTO-FILL ONLY

WHT

ZR6

MASTER

W. VLV.

BLU

BLU

YEL

ORN

LT BRN

YEL

WHT

ZR7

WHT

FILL

W. VLV.

N.O.

VIO

RLY5

COM

6

VIO

9

3

N.C.

N.O.

5

COM

8

2

YEL

N.C.

N.O.

4

COM

7

1

N.C

DK BRN

.

BLK

BLK

RED

RED

1

2

WHT

3

BLK

4

RED

5

WHT/GRY

WHT/RED

HEAT

T1L1

SSR 1

L1

T1

SSR 2

3

+

-

4

3

+

-

4

R1

HEATING ELEMENTS

ORN

R2

R3

SW 6

(OPTIONAL)

*RED

*VIO

VIO

VAC SW4

YEL

*YEL

31

4

2

WHT

YEL

YEL

*YEL

CONNECTION CHART

WHT

BLU

WHT

POWERCOOKHOLD

BLK

GRY

WHTWHT

TAN

DK BRN

WHT

LOW

WATER

RED

ON

OFF

SW1

SW2

WO/ AUTO-FILL

W/ AUTO-FILL

ORN

1&4, 2&3

1 2 3 4 5 6 7

PWR COM OUTPUT + -

1&2

J TYPE CONTROLLER CAL OFFSET ADJ

VIO

SW5

YEL

WHT

THERMOSTAT

J TYPE

WHT/BRN

WHT

RED

o

t

OPTIONS

AUTO-FILL

OVER-RUN PRESSURE

SWITCH

AT1T-2988-4

3 PHASE, 440/480V

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 18 / 32

Page 21

6 PAN ELECTRICAL SCHEMATIC

WHT

Y

Z

X

G

GRN

WHT

F1

3A

F2

BLK

WHT/RED

F3

WHT

BLK

BLK

N.O.

RLY3

COM

9

N.C.

VIO

N.O.

COM

8

N.C.

N.O.

COM

7

N.C

WHT

6

3

WHT – GAST

BRN -Thomas

5

2

4

1

.

DK GRY

.5 A

F4

.5 A

WHT/BRN

ZR4

275V

BLU

WHT

WHT

RED

HIGH LIMIT

ZR3

275V

GRN

LT BLU

PRB 1

PRB 2

J1

WHT

J2

GND

L2

WATER SENSOR BOARD

N.O. N.C.

*WHT

VP

N.O. N.C.

K1 K2

COM

COM

J5J7J8

J6

*BLU

*BLK

*YEL

AUTO-FILL

*YEL

OPTION ONLY

*H. W. LIMIT SW7

*LT BRN

LOW LIMIT

L1

*DK BRN

ORN

J9

DK BRN

THERMAL

LIMIT SW3

CONTACTOR

ZR5

275V

L3

RED

WHT

BLK

WHT

J3

J4

RED

L2

WHT

ZR2

275V

L1

BLK

ZR1

275V

BLK

N.O.

LT BLU

RLY2

6

COM

9

BLK

3

TAN

N.C.

N.O.

5

COM

8

2

N.C.

N.O.

DK BRN

4

COM

7

1

N.C

.

ORN

DK BRN

VIO

WHT

WHT

N.O.

RED

RLY1

COM

6

9

RED

3

N.C.

N.O.

RED

5

COM

PNK

8

BLK

2

N.C.

BLK

N.O.

4

COM

7

1

N.C

ORN

.

WHT

BLK

*RED

*VIO

VIO

*

AUTO-FILL ONLY

WHT

ZR6

MASTER

W. VLV.

BLU

RLY5

COM

9

BLU

COM

8

YEL

YEL

COM

7

LT BRN

WHT

1

2

3

BLK

R3

R1

HEATING ELEMENTS

3

~

4

~

3

~

4

~

3

~

4

~

R2

ORN

SW6

ORN

WHT/BRN

4

WHT

5

RED

6

BLK

ZR7

FILL

WHT

W. VLV.

N.O.

VIO

6

VIO

3

N.C.

N.O.

5

2

YEL

N.C.

N.O.

4

1

N.C

DK BRN

.

WHT/GRY

WHT/RED

HEAT

T1

SSR 1

BLK

RED

T1 L1

SSR 2

RED

WHT

T1 L1

SSR 3

L1

WHT

*YEL

*YEL

WO/ AUTO-FILL

1&2

W/ AUTO-FILL

1&4, 2&3

YEL

3

412

WHT

YEL

YEL

1 2 3 4 5 6 7

PWR COM OUTPUT + -

J TYPE CONTROLLER CAL OFFSET ADJ

4

LT BLU

ORN

2

WHT

WHT

S1

S2

S3

TM

TIMER IN

HOLD

POSITION

GRY

5

BLU

6

TM

PNK

3

WHT

PNK

BLU

BLK

GRY

WHT

POWER

COOKHOLD

WHTWHT

TAN

WHT

WHT

LOW

WATER

RED

ON

SW1

ORN

OFF

SW2

CONNECTION CHART

VAC SW4

VIO

SW5

YEL

WHT/BRN

WHT

o

t

THERMOSTAT

J TYPE

WHT

RED

WHT/BRN

OPTIONS

AUTO-FILL

AT1T-2988-5

3 PHASE, 208V

17KW

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 19 / 32

Page 22

6 PAN ELECTRICAL SCHEMATIC

1

WHT

GRN/YEL

2

3

WHT

BLK

WHT/BRN

WHT – GAST

BRN -Thomas

ZR4

GRY

4

BLK

5

BRN

F3

.5 A

F4

.5 A

VP

275V

BLU

WHT

WHT

RED

HIGH LIMIT

ZR3

275V

GRN

LT BLU

PRB 1

PRB 2

J1

WHT

J2

GND

L2

WATER SENSOR BOARD

N.O. N.C.

N.O. N.C.

*WHT

K1

COM

COM

J5

J6

*BLU

*BLK

*YEL

AUTO-FILL

*YEL

OPTION ONLY

*H. W. LIMIT SW7

*LT BRN

BLU or ORN

L3

N

L2

G

L1

F1

WHT

3A

F2

BLK

BLK

WHT/RED

N.O.

RLY3

COM

6

9

3

N.C.

N.O.

VIO

5

COM

8

2

N.C.

N.O.

4

COM

7

1

N.C

.

DK GRY

WHT

LOW LIMIT

L1

K2

J7J8J9

*DK BRN

ORN

J3

J4

DK BRN

THERMAL

LIMIT SW3

CONTACTOR

ZR5

550V

L3

GRY

BLK

L2

L1

BRN

WHT

RED

WHT

BLK

ZR2

550V

ZR1

275V

BLK

N.O.

LT BLU

RLY2

6

COM

9

BLK

3

TAN

N.C.

N.O.

5

COM

8

2

N.C.

N.O.

DK BRN

DK BRN

4

COM

7

1

N.C

.

ORN

DK BRN

VIO

WHT

WHT

N.O.

RED

RLY1

COM

6

9

RED

3

N.C.

N.O.

RED

5

COM

8

BLK

BLK

WHT

PNK

2

N.C.

N.O.

4

COM

7

1

N.C

.

BLK

*RED

*VIO

VIO

1

2

WHT

3

*

AUTO-FILL ONLY

WHT

ZR6

MASTER

W. VLV.

BLU

BLU

YEL

YEL

ORN

LT BRN

WHT

ZR7

WHT

FILL

W. VLV.

N.O.

VIO

RLY5

COM

6

VIO

9

3

N.C.

N.O.

YEL

5

COM

8

2

N.C.

N.O.

4

COM

7

1

N.C

DK BRN

.

BLK

4

RED

5

WHT/RED

WHT/GRY

HEAT

BLK

T1L1

SSR 1

L1

BLK

T1

SSR 2

3

+

-

4

3

+

-

4

R1

HEATING ELEMENTS

ORN

R2

R3

SW 6

(OPTIONAL)

LT BLU

4

2

WHT

WHT

S1

S2

S3

TM

TIMER IN

HOLD

POSITION

GRY

5

BLU

6

TM

*YEL

ORN

CONNECTION CHART

WO/ AUTO-FILL

1&2

W/ AUTO-FILL

1&4, 2&3

PNK

3

PNK

WHT

BLU

HOLD

BLK

WHT

GRY

WHT

POWER

COOK

WHTWHT

TAN

DK BRN

WHT

LOW

WATER

RED

ON

OFF

SW1

SW2

*YEL

YEL

31

2

4

WHT

YEL

1 2 3 4 5 6 7

PWR COM - - 28VDC + + -

J TYPE CONTROLLER CAL OFFSET ADJ

VAC SW4

VIO

SW5

VIO

WHT

J TYPE

ORN

RED

WHT

WHT/BRN

o

t

THERMOSTAT

OPTIONS

AUTO-FILL

OVER-RUN PRESSURE

SWITCH

AT1T-2988-7

3 PHASE CE, 380 - 415V

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 20 / 32

Page 23

3 PAN ELECTRICAL SCHEMATIC

WHT

GRN

BLK

F4

WHT

.5A

WHT/BRN

WHT

F3

BLK

.5A

BLK

VP

VAC

SW3

VIO

F1

WHT

3A

F2

BLK

N.O.

6

RLY3

COM

9

3

N.C.

N.O.

WHT

BLK

BRN

5

COM

8

2

ZR6

N.C.

N.O.

BLU

4

COM

7

1

N.C

.

WHT

GRY

VIO

L3

WHT

L2

WHT

BLK

L1

BLK

RLY 4

BRN

ZR4

WHT

WHT

ORNORN

H L

WHT

L2

WATER

SENSOR

L1

BLK

GND

GRN

N.O. N.C.

COM

YEL

BRN

BLK

BLK

BLK

BLK

TAN

WHT

BLK

ZR2

THERMAL

LIMIT SW4

SW5

TAN

SW6

BRN

BRN

N.O.

RLY2

6

COM

9

3

N.C.

YEL

N.O.

YEL

5

COM

8

2

TAN

N.C.

N.O.

TAN

4

COM

7

YEL

1

N.C

.

WHT

VIO

BLK

L3

ZR1

L2

WHT

RED

L1

BLK

N.O.

RLY1

COM

6

9

3

N.C.

N.O.

5

COM

8

2

N.C.

N.O.

4

COM

7

LT BLU

1

N.C

.

BLK

ZR2

WHT/BRN

L1

T1

SSR

3+4

-

BLK

F5

.5A

ORN

F6

.5A

R1 R2 R3

AT1T-2601-1

1 PHASE, 208V - 240V

WITH MINCO HEATER

YEL

S1

4

S2

ZR5

S3

TM

2

WHT

TIMER IN

WHT

HOLD

POSITION

GRY

5

BLU

6

LT BLU

TM

WHT

WHT

PNK

3

GRY

YEL

YEL

VIO

PNK

COOK ON

VIO

FAST

BLK

COOK

SW1

BLK

LT BLU

OFF

SW2

GRY

WHT

1 2 3 4 5 6 7

PWR COM - - 28VDC + + -

WHT/BRN

VIO

J TYPE

WHT

ORN

o

t

RED

TAN

BLK

WHT

5 4 3 2 1

P2

J2

5 4 3 2 1

GRY

PNK

FAST COOK

COOK

POWER

LOW WATER

J TYPE CONTROLLER CAL OFFSET ADJ

LT BLUBLK

RED

4 3 2 1

P1

J1

4 3 2 1

BLU

HOLD

HEAT

CONTINUOUS

N.O.

COM

N.C.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 21 / 32

Page 24

3 PAN ELECTRICAL SCHEMATIC

RED

WHT

Y

XZ

G

GRN

F1

WHT

3A

F2

BLK

RLY3

COM

9

WHT

COM

8

COM

7

BLK

BLK

F4

WHT

.5A

WHT

F3

.5A

N.O.

6

3

WHT/BRN

N.C.

N.O.

BRN

5

2

N.C.

N.O.

4

1

N.C

.

GRY

VP

ZR6

BLU

WHT

VIO VIO

VAC

SW3

BLK

BLK

RED

WHT

WHT

BLK

WHT

RED

L3

WHT

L2

BLK

L1

RLY 4

ZR4

WHT

H L

WHT

L2

L1

BLK

GND

GRN

N.O. N .C.

COM

BRN

BLK

BRN

WHT TAN

ORNORN

WATER

SENSOR

TAN

YEL

BLK

BLK

BLK

ZR2

THERMAL

LIMIT SW4

SW5

SW6

BRN

BRN

N.O.

RLY2

6

COM

9

3

N.C.

YEL

N.O.

YEL

5

COM

8

2

TAN

N.C.

N.O.

TAN

4

COM

7

YEL

1

N.C

.

VIO

RLY1

COM

9

COM

8

COM

7

ZR5

L

RED

3

RED

L

WHT

2

L

BLK

1

N.O.

6

3

N.C.

N.O.

5

2

N.C.

N.O.

4

1

N.C

BLK

.

ZR4

L1

T1 L 1

SSR 2

3+4

-

LT BLU

BLK

WHT/BRN

-

WHT/BRN

T1

SSR 1

3+4

BLK

F5

.5A

ORN

F6

.5A

ZR1

3 PHAS E, 208V - 240V

WITH MI NCO HE ATER

AT1T-26 01-2

R1

WHTR2RED

R3

BLK

YEL

S1

4

S2

ZR3

S3

TM

2

WHT

TIMER IN

HOLD

WHT

POSITION

GRY

5

6

BLU

LT BLU

TM

WHT

PNK

3

GRY

YEL

VIO

GRY

FAST

BLK

COOK

COOK

ON

SW1

PNK

VIO

OFF

BLK

SW2

YEL

LT BLU

WHT

1 2 3 4 5 6 7

PWR COM - - 28 VDC + + -

WHT/BRN

VIO

J TYPE

WHT

ORN

o

t

RED

J TYPE CONTR OLLER CAL OFFSET ADJ

TAN

BLK

WHT

5 4 3 2 1

P2

J2

5 4 3 2 1

GRY

PNK

FAST COOK

COOK

POWER

LOW WATER

LT BLUBLK

RED

4 3 2 1

P1

J1

4 3 2 1

BLU

HOLD

HEAT

CONTINUOUS

N.O.

COM

N.C.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 22 / 32

Page 25

3 PAN ELECTRICAL SCHEMATIC

RED

RED

WHT

RED

Y

Z

X

G

GRN

WHT

H2 H3

BLK

H1 H4

RLY3

COM

9

WHT

COM

8

COM

7

BLK

BLK

F4

F1

3A

F2

WHT/BRN

WHT

VP

VAC

SW3

WHT

X4

X2 X3

X1

BLK

N.O.

6

3

N.C.

N.O.

BRN

5

2

ZR6

N.C.

N.O.

BLU

4

1

N.C

.

WHT

GRY

VIO

WHT

.5A

F3

BLK

.5A

BLK

VIO

L3

WHT

L2

WHT

L1

BLK

BLK

RLY 4

BLK

BLK

WHT TAN

TAN

BLK

BLK

ZR2

THERMAL

LIMIT SW4

SW5

SW6

BRN

BRN

ZR4

WHT

ORNORN

H L

WHT

L2

WATER

SENSOR

L1

BLK

GND

GRN

N.O. N.C .

COM

BRN

YEL

BRN

N.O.

RLY2

6

COM

9

3

N.C.

YEL

N.O.

YEL

5

COM

8

2

TAN

N.C.

N.O.

TAN

4

COM

7

YEL

1

N.C

.

VIO

C

RED

L

RED

3

L

WHT

2

N.O.

RLY1

COM

6

9

3

N.C.

N.O.

5

COM

8

2

N.C.

N.O.

4

COM

7

1

N.C

BLK

.

ZR4

L1

T1 L 1

SSR 2

LT BLU

BLK

3+4

-

WHT/BRN

-

WHT/BRN

T1

SSR 1

3+4

ZR5

L

BLK

1

BLK

F5

.5A

ORN

F6

.5A

R2 R3

ZR1

3 PHASE, 44 0V - 480V

WITH MINCO HEATER

R1

AT1T-2601-3

S1

S2

S3

TM

TIMER IN

HOLD

POSITION

5

6

TM

3

YEL

4

ZR3

2

WHT

WHT

GRY

BLU

LT BLU

WHT

PNK

GRY

VIO

PNK

COOK ON

VIO

FAST

COOK

SW1

GRY

BLK

YEL

BLK

YEL

LT BLU

OFF

SW2

WHT

1 2 3 4 5 6 7

PWR COM - - 28VDC + + -

J TYPE CONTROLLER CAL OF FSET ADJ

WHT/BRN

VIO

J TYPE

WHT

ORN

o

t

RED

TAN

BLK

WHT

5 4 3 2 1

P2

J2

5 4 3 2 1

GRY

PNK

FAST COOK

COOK

POWER

LOW WATER

LT BLUBLK

RED

4 3 2 1

P1

J1

4 3 2 1

BLU

HOLD

HEAT

CONTINUOUS

N.O.

COM

N.C.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 23 / 32

Page 26

3 PAN ELECTRICAL SCHEMATIC

L3

ORN

RED

Z

WHT

Y

N

G X

GRN

F1

WHT

3A

F2

BLK

WHT

BLK

BLK

N.O.

6

RLY3

COM

9

3

N.C.

N.O.

BRN

5

COM

8

2

ZR6

N.C.

N.O.

BLU

4

COM

7

1

N.C

.

WHT

GRY

VIO

WHT

WHT/BRN

BLK

F4

WHT

.5A

WHT

BLK

F3

BLK

.5A

BLK

VP

VAC

SW3

VIO

RED

WHT

WHT

BLK

RED

WHT

L2

L1

BLK

RLY 4

BRN

ZR6

ORNORN

H L

WHT

L2

WATER

SENSOR

L1

BLK

GND

GRN

N.O. N.C.

COM

BRN

YEL

BLK

BLK

BLK

BLK

WHTTAN YEL

ZR2

THERMAL

LIMIT SW4

SW5

TAN

SW6

BRN

BRN

N.O.

RLY2

6

COM

9

3

N.C.

N.O.

YEL

5

COM

8

2

TAN

N.C.

N.O.

TAN

4

COM

7

1

N.C

.

VIO

COM

9

YEL

COM

8

COM

7

BLK

N

C

RED

L

RED

3

L

WHT

2

ZR5

N.O.

RLY1

6

3

N.C.

N.O.

5

2

N.C.

N.O.

4

1

N.C

.

ZR4

L1

T1

L1

T1

SSR 2

LT BLU

-

BLK

3+4

WHT/BRN

SSR 1

-

WHT/BRN

3+4

ORN

L

BLK

1

BLK

F5

.5A

F6

.5A

R2 R3

ZR1

3 PHASE, 380V - 415V

WITH MINCO HEATER

R1

AT1T-2601-4

YEL

S1

4

S2

ZR3

S3

TM

2

TIMER IN

WHT

HOLD

POSITION

WHT

GRY

5

BLU

6

LT BLU

TM

WHT

PNK

3

GRY

YEL

VIO

GRY

FAST

BLK

COOK

COOK ON

SW1

PNK

VIO

OFF

SW2

BLK

YEL

LT BLU

WHT

1 2 3 4 5 6 7

PWR COM - - 28VDC + + -

WHT/BRN

VIO

J TYPE

WHT

ORN

o

t

RED

TAN

WHT

BLK

5 4 3 2 1

P2

J2

5 4 3 2 1

GRY

PNK

FAST COOK

COOK

POWER

LOW WATER

J TYPE CONTROLLER CAL OFFSET ADJ

LT BLUBLK

RED

4 3 2 1

P1

J1

4 3 2 1

BLU

HOLD

HEAT

CONTINUOUS

N.O.

COM

N.C.

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 24 / 32

Page 27

3 PAN ELECTRICAL SCHEMATIC

CONTACTOR

ZR5

275V

L3

GRN

GND

WATER SENSOR BOARD

K1

COM

J5

YEL

*YEL

*

PRB 2

N.O. N.C.

COM

*BLK

*H. W. LIMIT SW7

*LT BRN

*DK BRN

K2

J7J8 J9

RED

WHT

BLK

ORN

J3

J4

L1L2

*VIO

THERMAL

LIMIT SW3, 4, 5

WHT

YEL

WHT

Y

Z

X

G

GRN

WHT

F1

WHT

BLK

3A

F2

BLK

WHT/RED

N.O.

RLY3

COM

6

9

VIO

N.C.

N.O.

5

COM

8

N.C.

N.O.

4

COM

7

1

N.C

.

3

2

BLK

WHT – GAST

BRN -Thomas

VP

ZR6

275V

BLU

WHT/BRN

F4

WHT

.5 A

WHT

F3

BLK

.5 A

BLK

HIGH LIMIT LOW LIMIT

WHT

LT BLU

PRB 1

J1

J2

*WHT

N.O. N.C.

J6

*BLU

AUTO-FILL

OPTION ONLY

RED

L2

WHT

ZR2

275V

L1

BLK

DK BRN

N.O.

RLY2

6

COM

9

ZR4

275V

3

N.C.

N.O.

BLK

YEL

5

COM

YEL

8

2

BLK

BLK

TAN

N.C.

N.O.

4

COM

TAN

7

1

YEL

N.C

.

WHT

VIO

WHT

N.O.

RLY1

COM

6

9

3

N.C.

N.O.

5

COM

8

2

N.C.

N.O.

4

COM

7

1

N.C

.

BLK

BLK

ZR3

275V

ZR1

275V

1

BLK

BLK

2

WHT

3

RED

*

AUTO-FILL ONLY

WHT

ZR7

ZR8

275V

275V

WHT

MASTER

W. VLV.

BLU

BLU

LT BLU

YEL

YEL

LT BRN

FILL

W. VLV.

N.O.

VIO

RLY5

COM

6

VIO

9

3

N.C.

N.O.

5

COM

8

2

YEL

N.C.

N.O.

4

COM

7

1

N.C

DK BRN

.

WHT

RED

ZR5

275V

BLK

T1

L1

BLK

T1

L1

3

+

SSR 1

-

4

3

+

SSR 2

-

4

R3

R1

HEATING ELEMENTS

ORN

ORN

WHT/BRN

R2

DK GRY

VAC SW4

YEL

4

S1

5

BLU

6

S2

TM

S3

3

TM

WHT

2

WHT

TIMER IN

HOLD

POSITION

WHT

PNK

TAN

WATER

WHT

LOW

TAN

WHT

BLK

5 4 3 2 1

P2

J2

5 4 3 2 1

COOKPOWER

BLK

BLU

LT BLU

PNK

GRY

NO NC

COM

FAST

COOK

1 2 3 4

1 2 3 4

HOLD HEATCONTINUOUS

RED

P1

J1

134

A

B

A

6

INT. FAST

COOK SW

GRY

PNK

VIO

COOK ON

B

VIO

YEL

FAST

COOK

SW1

CONNECTION CHART

WO/ AUTO-FILL

W/ AUTO-FILL

LT BLU

BLK

OFF

SW2

1&2

1&4, 2&3

YEL

1

4

*

YEL

F5

.5 A

F6

.5 A

YEL

*

3

WHT

2

WHT

YEL

1 2 3 4 5 6 7

PWR COM - - 28VDC + + -

J TYPE CONTROLLER CAL OFFSET ADJ

THERMOSTAT

J TYPE

WHT/BRN

ORN

WHT

o

t

OPTIONS

AUTO-FILL

OVER-RUN PRESSURE

SWITCH

RED

AT1T-2601-5

3 PHASE, 208V - 240V

AUTO-FILL

WITH MINCO HEATER

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 25 / 32

Page 28

3 PAN ELECTRICAL SCHEMATIC

WHT

BLK

ORN

J3

PRB 2

J4

L1L2

COM

K2

J7J8 J9

DK BRN

*DK BRN

*H. W. LIMIT SW7

THERMAL

LIMIT SW3

TAN

WHT

5 4 3 2 1

5 4 3 2 1

CONTACTOR

L

ZR2

275V

3

WHT

L

2

L

BLK

1

ZR1

275V

WHT

RED

*

*VIO

VIO

VIO

BLK

GRY

P2

J2

FAST

COOKPOWER

COOK

BLK

N.O.

LT BLU

RLY2

6

COM

9

BLK

3

N.C.

TAN

N.O.

5

COM

8

2

N.C.

N.O.

DK BRN

4

COM

7

DK BRN

1

N.C

.

ORN

VIO

WHT

WHT

WHT/GRY

WHT/RED

BLU

LT BLU

1 2 3 4

P1

J1

1 2 3 4

134

A B

NO NC

COM

HOLD HEATCONTINUOUS

INT. FAST

COOK SW

6

RED

A

RED

GRY

VIO

BLK

BLK

WHT

YEL

COOK ON

B

VIO

N.O.

RED

RLY1

COM

6

9

3

N.C.

N.O.

5

COM

8

PNK

PNK

2

N.C.

N.O.

4

COM

7

1

N.C

.

BLK

DK BRN

FAST

COOK

SW1

RED

OFF

SW2

ORN

*

AUTO-FILL ONLY

MASTER

W. VLV.

BLU

BLU

YEL

YEL

LT BRN

*

CONNECTION CHART

WO/ AUTO-FILL

1&2

W/ AUTO-FILL

1&4, 2&3

ORN

WHT

275V

ZR7

ZR6

275V

WHT

FILL

W. VLV.

N.O.

VIO

RLY5

COM

6

VIO

9

3

N.C.

N.O.

5

COM

8

2

YEL

N.C.

N.O.

4

COM

7

1

N.C

DK BRN

.

WHT

YEL

YEL

*

1

3

2

4

YEL

WHT

YEL

YEL

1 2 3 4 5 6 7

PWR COM OUTPUT

J TYPE CONTROLLER CAL OFFSET ADJ

J TYPE

WHT/BRN

+ -

o

t

THERMOSTAT

BLK

WHT

1

2

WHT

WHT/GRY

3

WHT/RED

4

5

T1

SSR

L1

RED

1 PHASE, 208V - 240V

WATLOW FIREBAR

3

+

-

4

OPTIONS

AUTO-FILL

AT1T-2622-1

HEATER

R2

R1BLK

HEATING ELEMENTS

R3

WHT

GRN

BLK

F1

F3

WHT/BRN

275V

BLU

.5 A

F4

.5 A

VP

5

6

TM

PNK

3

BLU

WHTWHT

WHT

RED

RED

HIGH LIMIT LOW LIMIT

ZR3

275V

LT BLU

PRB 1

J1

WHT

J2

WHT

WATER SENSOR BOARD

*WHT

N.O. N.C.

COM

J6

*BLU

AUTO-FILL

OPTION ONLY

WHT

PNK

GRN

GND

N.O. N.C.

K1

J5

*BLK

YEL

*YEL

*

*LT BRN

WHT

LOW

WATER

WHT

3A

F2

BLK

BLK

BLK

WHT/RED

N.O.

RLY3

COM

6

9

3

VIO

N.C.

WHT – GAST

BRN -Thomas

N.O.

5

COM

8

2

N.C.

ZR4

N.O.

4

COM

7

1

N.C

.

WHT

DK GRY

VAC SW4

4

LT BLU

S1

S2

S3

ORN

TM

WHT

2

WHT

TIMER IN

HOLD

POSITION

AT1T-2739-1 Rev. A

STEAM ’N’ HOLD

STEAMER OWNERS MANUAL

Page 26 / 32

Page 29

3 PAN ELECTRICAL SCHEMATIC

CONTACTOR

ZR5

275V

L3

GRN

GND

WATER SENSOR BOARD

K1

J5

*YEL

*YEL

*LT BRN

LOW

WATER

LOW LIMIT

ORN

PRB 2

L1L2

N.O. N.C.

COM

K2

J7J8 J9

*BLK

*DK BRN

*H. W. LIMIT SW 7

WHT

TAN

WHT

5 4 3 2 1

5 4 3 2 1

RED

WHT

BLK

J3

J4

*VIO

DK BRN

THERMAL

LIMIT SW3

P2

J2

L2

WHT

*RED

VIO

BLK

GRY

FAST

COOKPOWER

COOK

WHT

Y

Z

X

G

GRN

WHT

F1

F3

WHTWHT

BLK

COM

VIO

COM

8

COM

7

4

LT BLU

ORN

WHT

2

WHT

.5 A

3A

F2

BLK

BLK

WHT/RED

N.O.

RLY3

6

9

3

N.C.

WHT – GAST

BRN -Thomas

N.O.

5

2

N.C.

ZR4

N.O.

4

1

N.C

.

WHT

DK GRY

VAC SW4

S1

S2

S3

TM

TIMER IN

HOLD

POSITION

WHT/BRN

275V

BLU

WHT

F4

RED

.5 A

RED

HIGH LIMIT

ZR3

275V

LT BLU

PRB 1

J1

WHT

J2

WHT

*WHT

N.O. N.C.

COM

J6

*BLU

AUTO-FILL

OPTION ONLY

VP

5

BLU

6

TM

PNK

3

WHT

PNK

RED

WHT

ZR2

275V

L1

BLK

BLK

N.O.

LT BLU

RLY2

6

COM

9

BLK

ZR1

275V

VIO

3

N.C.

TAN

N.O.

5

COM

8

2

N.C.

N.O.

DK BRN

4

COM

7

DK BRN

1

N.C

.

ORN

VIO

WHT

WHT

WHT/GRY

WHT/RED

BLU

LT BLU

1 2 3 4

P1

J1