AccuTemp Steam “n” Hold,

Model 208-D8-300 and 400 Electric Steamers

In-Kitchen Appliance Performance Report

FSTC Report 5011.01.90

Food Service Technology Center Manager

Final Report, December 2001

Prepared by:

Shawn Knapp

Judy Nickel

Todd Bell

Fisher-Nickel, Inc.

Prepared for:

Peter Turnbull, Senior Program Manager

Pacific Gas and Electric Company

Customer Energy Management

123 Mission Street, P.O. Box 770000, Mail Code N6G

San Francisco, California 94177

© 2001 by Pacific Gas and Electric Company. All rights reserved.

The information in this report is based on data generated at Pacific Gas and Electric Company’s Food Service Technology Center.

Acknowledgments

This program is funded by California utility customers and administered by

Pacific Gas and Electric Company under the auspices of the California

Public Utilities Commission.

A National Advisory Group provides guidance to the Food Service

Technology Center Project. Members include:

California Energy Commission (CEC)

California Restaurant Association (CRA)

Carl Karcher Enterprises, Inc.

Darden Restaurants, Inc.

DJ Horton & Associates

Electric Power Research Institute (EPRI)

Enbridge\Consumers Gas

Gas Technology Institute (GTI)

International Facility Management Association (IFMA)

McDonald’s Corporation

M.I.G.A. Restaurant Construction Management

National Restaurant Association

Safeway, Inc.

Underwriters Laboratories (UL)

University of California, Berkeley (UC Berkeley)

University of California, Riverside (CE-CERT)

Specific appreciation is extended to AccuTemp for supplying the Food

Service Technology Center with model Steam “n” Hold, 208-D8-300 and

208-D8-400 electric steamers for controlled testing in the appliance laboratory and subsequent installation and monitoring in the production-test

kitchen.

Policy on the Use of Food Service Technology Center

Test Results and Other Related Information

• The Food Service Technology Center (FSTC) is strongly committed to testing

food service equipment using the most appropriate scientific techniques and instrumentation.

• The FSTC is neutral as to fuel and energy source. It does not, in any way, en-

courage or promote the use of any fuel or energy source nor does it endorse

any of the equipment tested at the FSTC.

• FSTC test results are made available to the general public through Pacific Gas

and Electric Company technical research reports and publications and are protected under U.S. and international copyright laws.

• In the event that FSTC data are to be reported, quoted, or referred to in any way

in publications, papers, brochures, advertising, or any other publicly available

documents, the rules of copyright must be strictly followed, including written

permission from Pacific Gas and Electric Company in advance and proper attribution to Pacific Gas and Electric Company and the Food Service Technology

Center. In any such publication, sufficient text must be excerpted or quoted so

as to give full and fair representation of findings as reported in the original

documentation from FSTC.

Legal Notice

This report was prepared by Pacific Gas and Electric Company for exclusive use by its employees and agents. Neither Pacific Gas and Electric Company

nor any of its employees:

(1) makes any written or oral warranty, expressed or implied, including, but not limited to those concerning merchantability or fitness for a particular

purpose;

(2) assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, process, method, or

policy contained herein; or

(3) represents that its use would not infringe any privately owned rights, including, but not limited to, patents, trademarks, or copyrights.

5011.01.90

Contents

Page

Executive Summary.......................................................................................... iii

1 Introduction ............................................................................................... 1-1

Background.......................................................................................... 1-1

Objective ............................................................................................. 1-2

The Production Test Kitchen................................................................ 1-2

Appliance Description and Operation................................................... 1-2

2 Controlled Energy Tests........................................................................... 2-1

Purpose................................................................................................ 2-1

3 Production Monitoring.............................................................................. 3-1

Energy Performance............................................................................. 3-1

Estimated Annual Energy Cost............................................................. 3-3

Food Production................................................................................... 3-5

Items Cooked................................................................................ 3-5

In-Kitchen Observations................................................................ 3-7

4 Conclusions and Recommendations ...................................................... 4-1

Production............................................................................................ 4-1

Energy Consumption and Conservation Potential................................ 4-2

5 References

Appendix A: Glossary

Appendix B: Manufacturer’s Product Specifications

Appendix C: Energy Monitoring System

Appendix D: Frequency Distribution of Dataset

Methods and Results............................................................................ 2-1

................................................................................................ 5-1

Appendix E: PG&E Energy Rates

Appendix F: Summary of ASTM Test Results

5011.01.90

i

Contents

Figures Page

1-1 Two STEAM “n” HOLD in stacked configuration.................................. 1-4

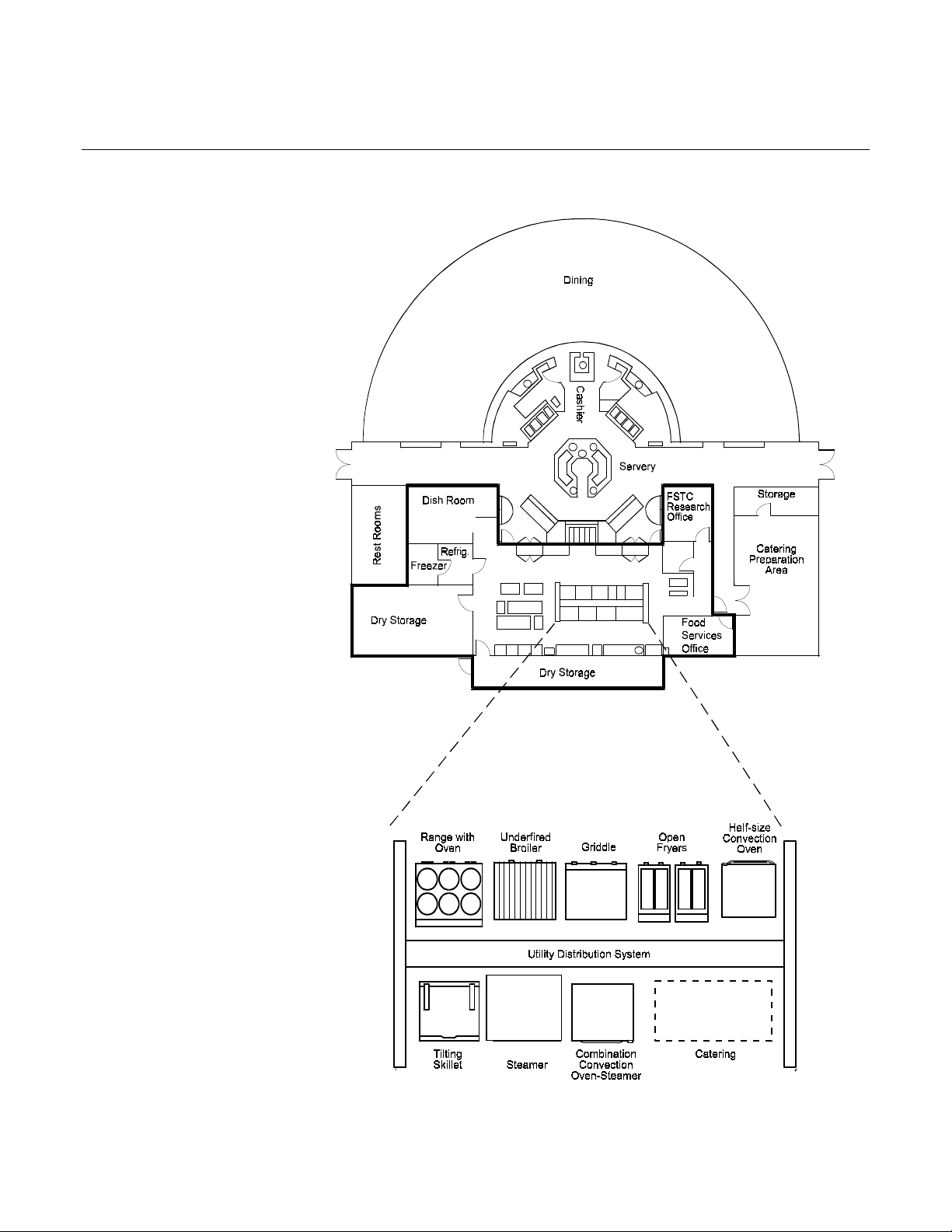

1-2 Pacific Gas and Electric Company Learning Center, Production-test

kitchen and typical appliance layout..................................................... 1-5

2-1 STEAM “n” HOLD instrumented for testing under controlled labora-

tory

conditions............................................................................................. 2-3

2-2 Preheat and idle characteristics ........................................................... 2-3

3-1 Typical daily energy consumption profile of upper steamer................. 3-3

3-2 Typical daily energy consumption profile of lower steamer.................. 3-4

3-3 Typical daily energy consumption profile of combined steamers......... 3-4

3-4 AccuTemp electric steamers in the production-test kitchen................. 3-6

Tables Page

ES-1 Summary of AccuTemp Model 208-D8-300 and 400 Electric

Steamer Performance.......................................................................... iv

1-1 Appliance Specifications ..................................................................... 1-4

2-1 Summary of Controlled Energy Tests of AccuTemp Steam “n” Hold

Electric Steamer................................................................................... 2-2

3-1 Average Daily Energy Performance..................................................... 3-2

3-2 Estimated Annual Energy Cost............................................................. 3-5

5011.01.90

ii

Executive Summary

This Food Service Technology Center (FSTC) research report presents the

results of monitoring two AccuTemp electric steamers, model 208-D8-300

and model 208-D8-400 as they were used for routine menu production in

Pacific Gas and Electric Company’s production-test kitchen and during tests

under controlled laboratory conditions

1

. The manufacturer supplied a cabinet

frame to place the steamers in a double-stacked configuration. Each steamer

could be operated independent of the other.

AccuTemp steamer’s unique vacuum cooking process allows the generation

of steam at a lower temperature than conventional atmospheric steamers.

The boiler-less design eliminates the water feed and condensate drain, leaving a user-friendly and low maintenance machine. The thermostatic controls

maintain food at a desired temperature until ready to serve.

The steamer was monitored in the production-test kitchen over a 6-month

test period. The production energy consumption and appliance operational

hours were recorded. To supplement monitoring information acquired during

actual production conditions, controlled energy tests were also conducted.

1

The measured peak energy input rate for a single steamer was 8.34 kW,

which was 4.25% higher than its 8.00 kW nameplate input. A single steamer

consumed 1.71kWh of energy over the 12.3-minute preheat period. The rate

of idle energy use averaged 1.2 kW. A summary of the test results is presented in Table ES-1.

1

Food Service Technology Center. AccuTemp STEAM “n” HOLD, Model 208-D8-

300. Application of ASTM Standard Test Method Designation F1484-99. Report

5011.99.75. Customer Energy Management Department, San Francisco. California:

Pacific Gas and Electric Company, 1999.

5011.01.90

iii

Executive Summary

Table ES-1. Summary of AccuTemp Model 208-D8-300 and Model 400 Electric

Steamer Performance

Rated Energy Input (kW) a 8.00

Measured Energy Input Rate

Preheat Time (min) 12.3

Preheat Energy (kWh) 1.71

Idle Energy Rate (kW) 1.2

Idle Duty Cycle (%) 14.4

Model 208-D8-300 (upper steamer)

Daily Production Energy Use (kWh/day)

Appliance On-Time (h/d) 9.5

Production Energy Consumption Rate (kW)

Production Duty Cycle (%) 22.6

Model 208-D8-400 (lower steamer)

Daily Production Energy Use (kWh/day)

(kW) a 8.34

b

17.8

c

1.8

b

12.1

Appliance On-Time (h/d) 6.8

Production Energy Consumption Rate (kW)

c

1.9

Production Duty Cycle (%) 22.8

Both Steamers Combined

Daily Production Energy Use (kWh)

b

29.9

Average Appliance On-Time (h/d) 8.2

Production Energy Consumption Rate (kW)

c

3.7

Production Duty Cycle (%) 22.7

a

Per individual steamer.

b

Includes preheat and idle energy over the hours of operation when steamer was in use.

c

Note that the average production energy consumption rate was based on aggregate preheat, idle and

cooking energy for the hours of appliance operation.

5011.01.90

iv

Executive Summary

Energy use data for the six-month test period were reduced to include only

days that reflected typical steamer usage in the production-test kitchen (i.e.,

days when the steamer was used for three-meal periods). The steamers were

on for an average of 8.2 hours, consuming 29.9 kWh per day. This includes

the aggregate preheat, idle, and cooking energy for the entire day of appliance operation. The average rate of production energy use for both steamers

combined was 3.79 kW, resulting in a production duty cycle of 22.7%.

Based on a 5-day per week, 52-week-per-year food service operation, the

steamer would consume 7774 kWh per year. The total yearly cost to operate

the steamer would be $689: consumption accounts for $644, while demand

accounts for $45. This calculation is based on Pacific Gas and Electric Company’s A-10 schedule for commercial electric rates ($0.0824/kWh and

$3.91/kW per month) dated April 2000.

The steamer was one of the most frequently used appliances in the production-test kitchen; it was used heavily to prepare a wide variety of items for

lunch and dinner, including fresh and frozen vegetables, rice, beans, pasta,

potatoes, sauces, and fish. Over a typical day, the operators cooked about

200 pounds of food. Although the daily quantity of food was considered

“light” compared to high volume full-service restaurants, it was considered

representative of many corporate/commercial cafeteria operations offering a

diverse menu mix to a broad customer base.

5011.01.90

v

Introduction

1

Background

AccuTemp’s new

steamer places

the cabinet under

a vacuum to

speed the creation of steam.

Steaming provides a fast-cook option for preparing large quantities of food

while retaining vital nutrients in the cooked product. Beyond the capital cost,

steamers should be evaluated with regard to long-term performance and operational costs characterized by cooking energy efficiency, production

capacity and water consumption.

The Pacific Gas and Electric Company’s Food Service Technology Center

(FSTC) developed a standard testing procedure to evaluate the performance

of gas and electric steam cookers. This test procedure was submitted to the

American Society for Testing and Materials (ASTM) and accepted as a standard test method in December 1993

standard be periodically reviewed, the FSTC revised the steamer test method

in February 1999 under the Designation F 1484-99

F 1484-93). Modifications to the test method included replacing the ice-load

test with frozen green peas to capture real-world application and reducing

the three loading scenarios to two. Pacific Gas & Electric Company’s De-

velopment and Validation of a Uniform Testing Procedure for Steam

Cooker

3

documents the developmental procedures and test results of several

1

. In keeping with ASTM’s policy that a

2

(originally published as

gas and electric steamers.

The Food Service Technology Center monitored the AccuTemp electric

steamers, model 208-D8-300 and model 208-D8-300 under both laboratory

and in-kitchen conditions. They were used for routine menu production in

Pacific Gas and Electric Company’s production-test kitchen over a 6-month

period: June through December 2000. Two other electric steamers have similarly been monitored at the production-test kitchen facility.

5011.01.90

4,5

1-1

Introduction

To supplement production energy monitoring data, controlled energy test

data were also documented. The glossary in Appendix A is provided so that

the reader has a quick reference for the terms used in this report.

Objective

The Production Test

Kitchen

The objective of this appliance performance report was to document the energy consumption characteristics of the AccuTemp electric steamers during

the six months they were in operation at the production-test kitchen. The

report documents steamer usage in relationship to its energy consumption

and cost while in production. Therefore, the reader should bear in mind that

this information is specific to Pacific Gas and Electric Company’s production-test kitchen, a corporate, cafeteria-style operation.

The 1,500-square-foot kitchen is an integral component of the campus-style

dining facility at Pacific Gas and Electric Company’s Learning Center in San

Ramon, California. Typically 10 or more cooking appliances are centrally

located on two sides of a utility distribution system (UDS). The UDS functions as a central “spine” that contains all plumbing, wiring, and natural gas

distribution lines. A 16-foot, double-sided canopy exhaust hood ventilates

the equipment island at a design air flow of 9,600 cfm. Grilles along the

front face of the hood direct conditioned makeup air into the kitchen.

The UDS was designed to accommodate quick connection and disconnection

of the appliances as they are rolled in or out of the “line,” with the flexibility

to accommodate either a gas or an electric model in each appliance slot. Gas

and electric meters interface with a remote data acquisition and processing

system. Appliance monitoring and performance evaluations are conducted by

the FSTC research team, independent of the food service operation.

5011.01.90

1-2

Introduction

Appliance

Description and

Operation

AccuTemp Products, Inc supplied the Food Service Technology Center with

two steamers. The model 208-D8-300 steamer came equipped with a 90minute timer and the model 208-D8-400 steamer was equipped with a 180minute timer. The manufacturer also supplied a stand to house the two

steamers in a double-stacked configuration (Figure 1-1). The model 208-D8300 steamer was placed above model 208-D8-400 steamer in the stand. Each

steamer could be operated independently; the energy consumption of each

steamer was monitored separately.

The STEAM ‘n’ HOLD is a stainless-steel, natural-convection steamer powered by an 8-kW electric heating element. Steam is generated within the

food compartment without a separate boiler. Water is manually added to the

compartment. Elements beneath the compartment bottom heat the water to

produce steam. Water is drained manually using a valve at the front of the

steamer, eliminating the need for water feed and drain hookups. The cooking chamber can accommodate six 12" x 20" x 2½" pans, four 12" x 20" x 4"

pans, or three 12" x 20" x 6" pans. The unique timer/hold feature allows

food to be cooked to the desired temperature and held until it is ready to be

served.

Table 1-1 presents the specifications for the AccuTemp steamers and the

manufacturer’s product literature appears in Appendix B. Figure 1-2 is a

floor plan of the production-test kitchen and appliance lineup.

5011.01.90

1-3

Introduction

Figure 1-1.

Two STEAM ‘n’ HOLDs in

stacked configuration.

Table 1-1. Appliance Specifications.

Manufacturer AccuTemp Products, Inc.

Model 208-D8-300 and 208-D8-400

STEAM ‘n’ HOLD

™

Generic Appliance Type 1-compartment, natural-convection,

electric, vacuum steamer.

Rated Input 8 kW for each compartment.

Technology Boiler-less steamer with natural-convection,

vacuum-sealed chamber.

Construction Double-wall, stainless-steel. Interior

14 Ga. Exterior 22 Ga.

Controls Main ON-OFF buttons. Model 208-D8-300

is equipped with a 90-minute mechanical

timer with continuous steam and hold set-

ting. Model 208-D8-400 is equipped with a

180-minute mechanical timer with continu-

ous steam and hold setting. Thermostat

dial with temperature ranging from 140°F to

212 °F.

Compartment Capacity 6 (12" x 20" x 2½" ) pans

4 (12" x 20" x 4" ) pans

3 (12" x 20" x 6" ) pans

Dimensions 23" x 23

1

/4" x 30"

5011.01.90

1-4

Introduction

Figure 1-2.

PG&E Learning Center,

Production-test kitchen

and typical appliance

layout.

5011.01.90

1-5

Controlled Energy Tests

2

Purpose

The objective of this section of the report is to examine the operation and

performance of the AccuTemp electric steamer, model 208-D8-300, under

the controlled conditions of the ASTM standard test method. The AccuTemp

electric steamer, model 208-D8-300 is equipped with a 90-minute timer. The

AccuTemp electric steamer, model 208-D8-400 steamer, equipped with a

180-minute timer was also monitored in the production-test kitchen, but not

tested under controlled conditions. The model 208-D8-300 and 208-D8-400

steamers differ only by specifications of the timer. The scope of this testing

was as follows:

1. Verify that the appliance is operating at the manufacturer’s

rated energy input.

2. Determine the preheat duration and energy consumption of the

steamer.

3. Determine the steamer’s idle energy rate.

4. Document the cooking energy consumption and efficiency under four different scenarios: full-load frozen green peas (six

pans), light-load frozen green peas (one pan), full-load red potatoes (six pans), and light-load red potatoes (one pan).

5. Determine the production capacity and the water consumption

rate for each loading scenario.

Methods and

Results

5011.01.90

FSTC researchers operated the AccuTemp STEAM “n” Hold electric

steamer under controlled laboratory conditions and in accordance with the

ASTM Standard Test Method for the Performance of Steam Cookers (Designation F1484-99

cedures and test results, refer to Pacific Gas and Electric Company’s Devel-

opment

)2.

For a detailed discussion of the development of the pro-

2-1

Loading...

Loading...