Page 1

AccuTemp STEAM ‘N’ HOLD, Model 208-D12-300

Electric Steamer Performance Test

Application of ASTM Standard

Test Method F 1484-99

FSTC Report # 5011.03.02 (Revised)

Food Service Technology Center

June 2003

Prepared by:

Todd Bell

David Zabrowski

Fisher-Nickel, Inc.

Contributor:

Judy Nickel

Fisher-Nickel, Inc.

2003 by Fisher-Nickel, inc. All rights reserved.

The information in thi s report is based on data generated at the Food Service Technology Center.

Page 2

Acknowledgments

California consumers are not obligated to purchase any full service

or other service not funded by this program. This program is funded

by California utility ratepayers under the auspices of the California

Public Utilities Commission.

Los consumidores en California no estan obligados a comprar servicios completos o

adicionales que no esten cubiertos bajo este programa. Este programa esta financiado

por los usuarios de servicios públicos en California bajo la jurisdiccion de la Comision

de Servicios Públicos de California.

A National Advisory Group provides guidance to the Food Service

Technology Center Project. Members include:

Advantica Restaurant Group

Applebee’s International Group

California Energy Commission (CEC)

California Restaurant Association

Carl Karcher Enterprises, Inc.

DJ Horton & Associates

Electric Power Research Institute (EPRI)

Enbridge Gas Distribution

EPA Energy Star

Gas Technology Institute (GTI)

Lawrence Berkeley National Laboratories

McDonald’s Corporation

National Restaurant Association

Pacific Gas and Electric Company

Safeway, Inc.

Southern California Edison

Underwriters Laboratories (UL)

University of California at Berkeley

University of California at Riverside

US Department of Energy, FEMP

Policy on the Use of Food Service Technology Center

Test Results and Other Related Information

Fisher-Nickel, inc. and the Food Service Technology Center

•

(FSTC) do not endorse particular products or services from any

specific manufacturer or service provider.

The FSTC is

•

using the best available scientific techniques and instrumentation.

The FSTC is neutral as to fuel and energy source. It does not, in

•

any way, encourage or promote the use of any fuel or energy

source nor does it endorse any of the equipment tested at the

FSTC.

FSTC test results are made available to the general public

•

through technical research reports and publications and are protected under U.S. and international copyright laws.

In the event that FSTC data are to be reported, quoted, or referred

•

to in any way in publications, papers, brochures, advertising, or

any other publicly available documents, the rules of copyright

must be strictly followed, including written permission from FisherNickel, inc.

and the Food Service Technology Center. In any such publication,

sufficient text must be excerpted or quoted so as to give full and

fair representation of findings as reported in the original documentation from FSTC.

This report was prepared as a result of work sponsored by the California

Public Utilities Commission (Commission). It does not necessarily represent

the views of the Commission, its employees, or the State of California. The

Commission, the State of California, its employees, contractors, and subcontractors make no warranty, express or implied, and assume no legal liability

for the information in this report; nor does any party represent that the use of

this information will not infringe upon privately owned rights. This report has

not been approved or disapproved by the Commission nor has the Commission passed upon the accuracy or adequacy of the information in this report.

in advance

committed to testing food service equipment

strongly

and proper attribution to Fisher-Nickel, inc.

Legal Notice

Specific appreciation is extended to AccuTemp Products, Inc. for

supplying the FSTC with STEAM ‘N’ HOLD, Model 208-D12-300

connectionless steamer for controlled testing in the appliance laboratory.

Page 3

Contents

Page

Executive Summary

1 Introduction

................................................................................ iii

..................................................................................... 1-1

Background ................................................................................ 1-1

Objectives ................................................................................... 1-2

Appliance Description ................................................................. 1-2

2 Methods

........................................................................................... 2-1

Setup and Instrumentation ......................................................... 2-1

Non-Cooking Tests...................................................................... 2-2

Frozen Green Pea Efficiency Tests............................................. 2-2

Red Potato Efficiency Tests......................................................... 2-2

3 Results

............................................................................................. 3-1

Energy Input Rate........................................................................ 3-1

Preheat and Idle Tests................................................................ 3-1

Cooking Tests ............................................................................. 3-2

4 Conclusions

...................................................................................... 4-1

5 References

....................................................................................... 5-1

Appendix A: Glossary

Appendix B: Appliance Specifications

Appendix C: Results Reporting Sheets

Appendix D: Cooking-Energy Efficiency Data

5011.03.02 (Revised) i

Food Service Technology Center

Page 4

List of Figures and Tables

Figures

Tables

Page

1-1 The AccuTemp D12 steamer in stacked configuration................ 1-3

2-1 The D12 instrumented and ready for testing............................... 2-1

2-2 Frozen green pea load................................................................ 2-2

2-3 Red potato load........................................................................... 2-3

3-1 Preheat and idle characteristics................................................... 3-1

3-2 Comparison of steamer production capacities............................. 3-5

3-3 Comparison of steamer cooking-energy efficiencies................... 3-6

3-4 Steamer part-load cooking-energy efficiency............................... 3-7

3-5 Steamer cooking energy consumption profile.............................. 3-8

Page

1-1 Appliance Specifications.............................................................. 1-3

3-1 Average Input, Preheat and Idle Test Results............................. 3-2

3-2 Frozen Green Pea Cooking Test Results.................................... 3-4

3-3 Red Potato Cooking Test Results................................................ 3-4

5011.03.02 (Revised) ii

Food Service Technology Center

Page 5

Executive Summary

The Food Service Technology Center (FSTC) tested the AccuTemp STEAM

‘N’ HOLD, Model 208-D12-300 connectionless electric steamer under the

controlled conditions of the American Society for Testing and Materials

(ASTM) Standard Test Method for the Performance of Steam Cookers.

Steamer performance is characterized by preheat energy consumption and

duration, idle energy rate, cooking energy rate and efficiency, production

capacity, water consumption and condensate temperature from product

testing. The spectrum of test products includes frozen green peas and red

potatoes. Since the D12 does not employ a condensate drain, condensate

temperature was not monitored during testing.

1

The AccuTemp STEAM ‘N’ HOLD, Model D12 is a productive and energy

efficient connectionless electric steamer. With its 6-pan loading capacity and

fast cook times, the D12 has one of the highest production capacities of any

connectionless steamer tested to date at the FSTC. Researchers established an

average 22.0 minute cook time for a full load (6 pans) of frozen green peas.

When tasked with cooking a “tough” food product, such as red potatoes, the

D12 had an average heavy-load cook time of 22.7 minutes resulting in a

maximum production capacity of 130 lb/h.

Cooking-energy efficiency is a measure of how much of the energy that an

appliance consumes is actually delivered to the food product during the

cooking process. Cooking-energy efficiency is therefore defined by the

following relationship:

EfficiencyEnergy Cooking

=

Food toEnergy

Steamer toEnergy

1

American Society for Testing and Materials, 1999. Standard Test Method for the Performance of Steam Cookers. ASTM Designation F1484-99, in the Annual Book of ASTM Standards, West Conshohocken, PA.

5011.03.02 (Revised) iii

Food Service Technology Center

Page 6

Executive Summary

A summary of the ASTM test results is presented in Table ES-1.

Table ES-1. Summary of D12 Steamer Performance.

Rated Energy Input Rate (kW) 12.0

Measured Energy Input Rate (kW) 12.0

Preheat Time (min) 6.5

Preheat Energy (kWh) 1.3

Idle Energy Rate (kW) (Revised Testing) 0.4

Frozen Green Peas

Light-Load Cooking-Energy Efficiency (%) 64.2 ± 2.5

Heavy-Load Cooking-Energy Efficiency (%) 88.4 ± 0.6

Production Capacity (lb/h) 131 ± 0.0

Red Potatoes

Light-Load Cooking-Energy Efficiency (%) 31.2 ± 2.0

Heavy-Load Cooking-Energy Efficiency (%) 67.5 ± 1.4

Production Capacity (lb/h) 130 ± 4.8

Beyond its respectable productivity and high cooking-energy efficiencies, the

D12 steamer also exhibited low water usage. Typical water consumption

during heavy-load cooking tests was much lower than the unit’s 2.5-gallon

reservoir capacity. Other steam cooking technologies, such as boiler-based or

steam generator-type steamers, typically consume between 20 and 60 gal/h

while cooking.

The D12 is AccuTemp’s latest addition to their family of connectionless

steamers. Earlier STEAM ‘N’ HOLD models, the D6 and the D8, have been

tested under the rigors of the ASTM test method at the FSTC. Testing of the

D12 revealed a marked improvement in cooking performance over the earlier

STEAM ‘N’ HOLD models. The D12 was nearly 20 minutes faster, when

cooking a full load of frozen green peas, than the D6 and almost 10 minutes

5011.03.02 (Revised) iv

Food Service Technology Center

Page 7

Executive Summary

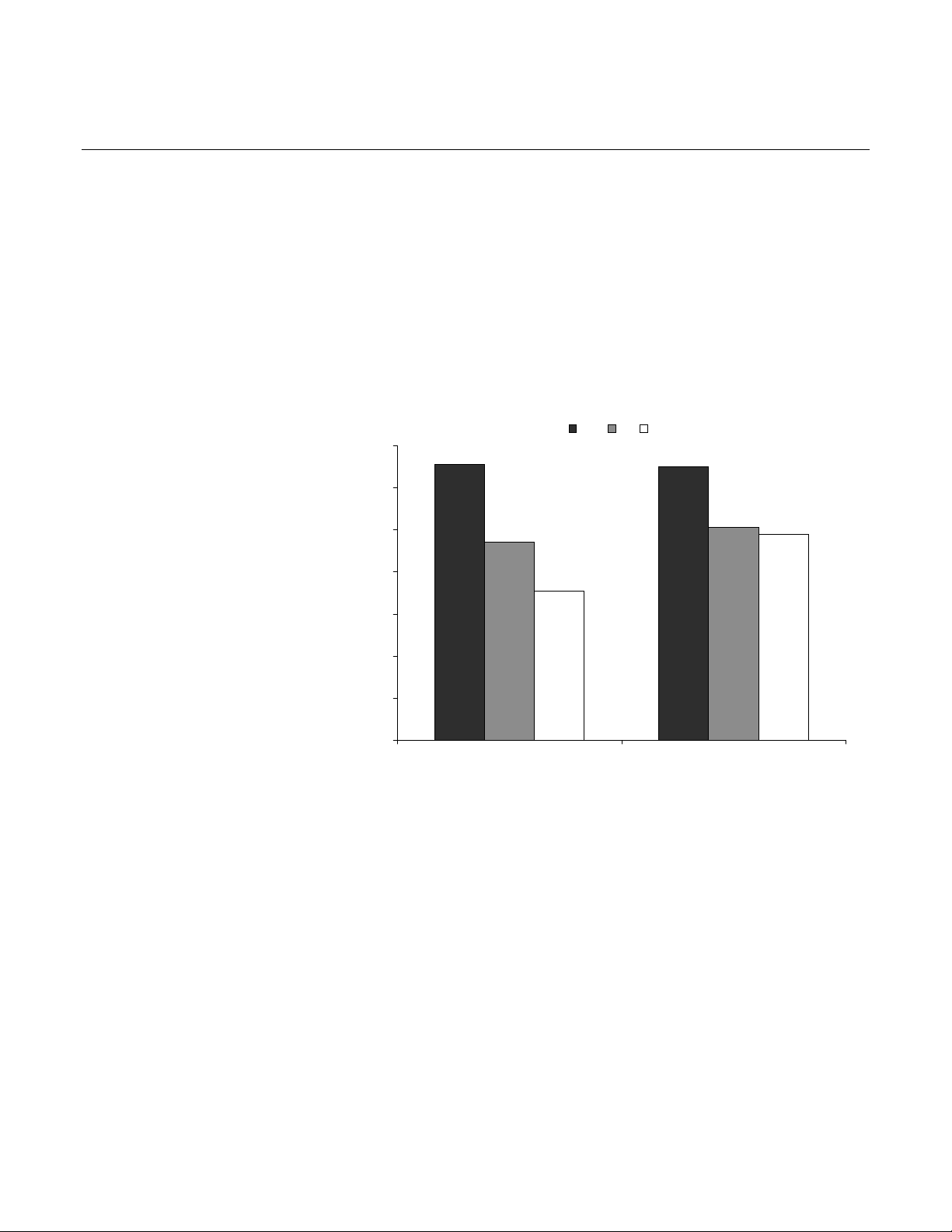

faster than the D8 when cooking the same food product. A full load of red

potatoes required 22.7 minutes to cook in the D12, whereas the D6 and D8

required an additional 6 minutes to cook this “tough” food product to a

temperature of 195°F. Figure ES-1 graphically compares the production

capacities of the D12, D8 and D6 steamers.

D12 D8 D6

140

120

100

80

Figure ES-1.

Comparison of steamer

production capacities.

60

40

Production Capacity (lb/h) .

20

0

Frozen Green Peas Red Potatoes

The additional horsepower was not wasted however, as demonstrated by the

D12’s comparable cooking-energy efficiencies to those of the D6 and D8.

The D12 minimized standby energy losses when the timer was turned to the

“Hold” position. The timer automatically switches to the “Hold” mode after a

preset cooktime has elapsed. Researchers performed tests to characterized the

idle energy rate using the steamer’s two modes of operation, “Fast Cook” and

“Thermostat”. In the “Thermostat” mode the steamer’s thermostat was set to

5011.03.02 (Revised) v

Food Service Technology Center

Page 8

Executive Summary

200°F. In both control settings the D12 exhibited a low idle energy rate of

420 W.

AccuTemp Products, Inc. has markedly increased the maximum production

capacity of its connectionless steamer through the addition of higher input,

12-kW heating elements. The STEAM ‘N’ HOLD, Model 208-D12-300

offers greater productivity in the same platform of earlier models and

maintains the same, high cooking energy efficiencies as well. Operators will

find the D12 a qualified candidate that can satisfy menu demands with its

high productivity, while minimizing utility costs.

5011.03.02 (Revised) vi

Food Service Technology Center

Page 9

1

Introduction

Background

Steaming provides a fast-cooking option for preparing large quantities of

food, while retaining vital nutrients in the cooked product. Steamers are

versatile appliances that can be used to prepare almost any food that does not

require a crust. Delicate vegetables, such as asparagus and broccoli, are

cooked without damage, frozen foods are defrosted and cooked in one step,

and hard-to-cook meats, such as beef ribs, can be par-cooked quickly with

less weight loss than oven roasting.

Dedicated to the advancement of the food service industry, the Food Service

Technology Center (FSTC) has focused on the development of standard test

methods for commercial food service equipment since 1987. The primary

component of the FSTC is a 10,000 square-foot appliance laboratory

equipped with energy monitoring and data acquisition hardware, 60 linear

feet of canopy exhaust hoods integrated with utility distribution systems,

appliance setup and storage areas, and a state-of-the-art demonstration and

training facility.

The test methods, approved and ratified by the American Society for Testing

and Materials (ASTM), allow benchmarking of equipment so that users can

make meaningful comparisons among available equipment choices. By

collaborating with the Electric Power Research Institute (EPRI) and the Gas

Technology Institute (GTI) through matching funding agreements, the test

methods have remained unbiased to fuel choice. End-use customers and

commercial appliance manufacturers consider the FSTC to be the national

leader in commercial food service equipment testing and standards, sparking

alliances with several major chain customers to date.

Since the development of the ASTM test method for steam cookers in 1993,

the FSTC has tested a wide range of gas and electric steamers,

other versions of the AccuTemp STEAM N’ HOLD steamer.

2–14

15,16

including

1

5011.03.02 (Revised) 1-1

Food Service Technology Center

Page 10

Introduction

AccuTemp’s STEAM ‘N’ HOLD Model 208-D12-300 is the newest

generation of connectionless steamers offered by AccuTemp Products, Inc. It

follows in the footsteps of the first unit introduced—the D6 (6 kW input rate)

and its subsequent offspring, the 8-kW input D8. Each model shares a similar

design—the heating element is positioned beneath the water reservoir,

eliminating the need for a separate boiler. Testing of the two earlier units at

the FSTC highlighted the D8’s considerable cooking performance

6

improvements over the D6.

15,1

Testing of the D12 under the ASTM test

method once again allowed for fair and precise comparison of the three

AccuTemp steamers.

The glossary in Appendix A is provided so that the reader has a quick

reference to the terms used in this report.

Objectives

The objective of this report is to examine the operation and performance of

the AccuTemp, Model D12 steamer, under the controlled conditions of the

ASTM Standard Test Method. The scope of this testing is as follows:

1. Verify that the appliance is operating at the manufacturer’s

rated energy input.

2. Determine the time and energy required to preheat the steamer

to an operating condition.

3. Characterize the idle energy use of the steamer while maintaining a ready-to-cook state.

4. Determine the cooking-energy efficiency under 4 scenarios:

heavy-load frozen green peas (6 pans), light-load frozen green

peas (single-pan), heavy-load red potatoes (6 pans) and lightload red potatoes (single-pan).

5. Determine the production capacity, cooking energy rate and

cook time for each loading scenario.

Appliance

Description

5011.03.02(Revised) 1-2

Food Service Technology Center

The AccuTemp STEAM ‘N’ HOLD, Model 208-D12-300 is a 6-pan capacity,

single compartment, electric connectionless steamer. The steamer is powered

Page 11

Introduction

by a 12.0-kW heating element placed beneath the cooking compartment’s

water reservoir (Figure 1-1). Steam is generated within the cooking

compartment without a separate boiler. Water is added and drained manually

at the beginning and end of the day. The cooking chamber accommodates six

standard full-size, 2½-inch deep hotel pans. The D12 has two cooking modes:

timed and continuous. The timed mode allows operators to set a predetermined cooktime of up to 90 minutes. When the cook time has expired,

the unit automatically switches to a hold mode. In the continuous cooking

mode, steam generation is controlled manually by shutting the unit on or off

manually. The unit also has a hold feature that allows the operator to set a

desired cooking compartment temperature between 140°F and 212°F.

Appliance specifications are listed in Table 1-1, and the manufacturer’s

literature is in Appendix B. The appliance is pictured in Figure 1-1.

Figure 1-1.

The AccuTemp D12

steamer in stacked configuration.

Table 1-1. Appliance Specifications.

Manufacturer AccuTemp Products, Inc.

Model Model 208-D12-300

Generic Appliance

Type

Rated Input 12.0 kW

Technology Boiler-less steamer with natural-convection.

Construction Double-wall, stainless-steel.

Interior 14 Ga. stainless-steel

Exterior 33 Ga. stainless-steel

Controls Main ON/OFF buttons. 90 minute mechanical timer with continuous

Compartment Capacity 6 (12" x 20" x 2

Dimensions

Connectionless, 1-compartment, electric, vacuum, connectionless

steamer.

steam and hold setting. Thermostat ranging from 140 °F to 212 °F.

1

/2") pans, 4 (12" x 20" x 4") pans, or

3 (12" x 20" x 6") pans

1

23" x 23

/4" x 30"(w×d×h)

5011.03.02(Revised) 1-3

Food Service Technology Center

Page 12

2

Methods

Setup and

Instrumentation

The steamer was installed in accordance with the manufacturer’s instructions

under a 4-foot-deep canopy hood, with the lower edge of the hood 6 feet, 6

inches above the floor and a minimum of 6 inches inside the vertical front

edge of the hood. The exhaust ventilation operated at a nominal rate of 150

cfm per linear foot of hood with the ambient temperature maintained at 75

±5°F. All test apparatus were installed in accordance with Section 9 of the

1

ASTM test method.

Power and energy were measured with a watt/watt-hour transducer that

generated an analog signal for instantaneous power and a pulse for every

Figure 2-1.

The D12 instrumented

and ready for testing.

10 Wh. The transducer and thermocouples were connected to a computerized

data acquisition unit that recorded data every 5 seconds. A voltage regulator,

connected to the steamer, maintained a constant voltage for all tests. Figure

2-1 shows the D12 instrumented with the data acquisition system.

5011.03.02(Revised) 2-1

Food Service Technology Center

Page 13

Methods

Non-Cooking Tests

Frozen Green Pea

Efficiency Tests

The energy input rate was determined by measuring the energy consumed by

the steamer during a complete preheat cycle. The maximum power draw

during this period was reported as the measured energy input rate. Preheat

tests recorded the time and energy required for the steamer to reach operating

temperature from a cold start, when turned on for the first time in a day. An

hour after the preheat cycle, idle energy consumption was monitored over a 2hour period.

Individually flash-frozen, grade A green peas (Figure 2-2) represented one of

two food products for steamer performance testing. Standard full-size (12" x

20" x 2½"), perforated stainless-steel hotel pans were used for cooking the

green peas. The D12 required 6 pans of green peas for a full load, while a

single pan placed on the center rack of the steamer cavity comprised a light

load. Each pan contained 8.0 ± 0.2 lb of green peas. Pre-weighed green peas

in perforated pans were stored in sealed plastic bags at 0 ± 5°F for at least 24

hours prior to testing. The pans of peas were transferred into an insulated box

and transported to the testing location where the plastic bags were removed,

and the pan(s) of green peas were loaded into the steamer according to the

loading time prescribed in section 10.7.6 of the ASTM test method.

Since probing proves difficult and erroneous in measuring the temperature of

small-sized green peas, a water-bath calorimeter was utilized to determine the

final bulk temperature of the cooked green peas. The time required to cook

Figure 2-2.

Frozen green pea load.

5011.03.02(Revised) 2-2

Food Service Technology Center

the frozen peas to a bulk temperature of 180 ± 2°F was determined through an

iterative process. Once the cook time was determined, the test was replicated

a minimum of three times to minimize the uncertainty in the test results.

1

Page 14

Methods

Red Potato

Efficiency Tests

Figure 2-3.

Red potato load.

Freshly packed, size B, red potatoes (Figure 2-3) served as the second food

product for steamer performance testing. Again, the D12 required 6 pans of

red potatoes for a full load and a single pan for a light load. Each pan

contained 8.0 ± 0.2 pounds of red potatoes.

The red potatoes were loaded into perforated pans prior to the test and

stabilized to a room temperature of 75 ± 5°F. The potatoes were then cooked

to 195 ± 2°F using a predetermined cook time. The final temperature was

determined by randomly probing potatoes, using a hand-held digital

thermocouple meter within 3 minutes after cooking was terminated. Again,

the test was replicated a minimum of three times to minimize the uncertainty

in the test results.

The ASTM results reporting sheets appear in Appendix C.

5011.03.02(Revised) 2-3

Food Service Technology Center

Page 15

3

Results

Energy Input Rate

Measured energy input rate and the manufacturer’s nameplate value were

compared prior to any testing to ensure that the steamer was operating within

its specified parameters. The D12 drew its maximum specified energy input

rating of 12.0 kW.

Preheat and Idle

Tests

Figure 3-1.

Preheat and Idle

Characteristics.

Preheat Energy and Time

The cavity was manually filled with two and a half gallons of water at 70

±5°F. The steamer was placed in its “Fast Cook” mode of operation and the

timer turned to the “Continuous” position. Preheat was judged complete when

the primary elements had cycled off, indicating a ready-to-cook state. Figure

3-1 illustrates the pre-heat and idle characteristics of the D12.

220

200

180

160

140

120

100

80

60

Cabine t Tem pe rature (°F)

40

20

0

020406080100120

Time (min)

14

12

10

8

6

4

2

0

Power (kW)

5011.03.02(Revised) 3-1

Food Service Technology Center

Page 16

Results

Idle Energy Rate

During the original course of testing, researchers performed the idle tests with

the steamer in the “Fast Cook” mode of operation and the timer set to

“Continuous”. The energy consumption was monitored over a 2-hour period

following an one-hour stabalization period and the idle energy rate was

determined to be 1.4 kW. This result was reported in the original version of

this performance report.

In an effort to optimize the D12’s idle energy performance, researchers

changed the control settings used in the above testing. Once again, after

stabilizing for one hour, the steamer remained in the “Fast Cook” mode of

operation but the timer was set to “Hold”. Note: the steamer automatically

enters “Hold” when time has expired if the timer function is used.

Researchers monitored the energy consumption over a 2-hour period and

calculated an idle energy rate of 420 W. The same idle energy rate was

exhibited when the unit was placed in the “Thermostat” mode of operation

and the thermostat set to 200°F with the timer turned to “Hold”.

Test Results

Rated energy input, preheat energy and idle rate test results are summarized

in Table 3-1. The D12 had a preheat time of 6.5 minutes, whereas the D6

required 16.2 minutes to reach full operational capacity. The D8 had a

measured preheat time of 12.3 minutes. The Accutemp line of steamers

utilize identical control features, therefore, both the D6 and D8 have similar

idle rates to the 420 W exhibited by the D12 using the new control setting.

Table 3-1. Average Input, Preheat and Idle Test Results.

Rated Energy Input Rate (kW) 12.0

Measured Energy Input Rate (kW) 12.0

Preheat to Operational Capacity:

Time (min) 6.5

Energy (kWh) 1.30

Idle Energy Rate (kW)

Idle Energy Rate (kW)

a

Original testing data.

5011.03.02(Revised) 3-2

Food Service Technology Center

a

1.40

b

0.42

b

Revised testing data in the “Hold” control setting.

Page 17

Results

Cooking Tests

The steamer was tested using two different food products (green peas and red

potatoes) under two loading scenarios—heavy (6 pans) and light (single pan).

All cooking scenarios were conducted in the unit’s “Fast Cook” mode of

operation with the timer set in the “Continuous” position.

The AccuTemp D12 steamer does not employ a separate boiler, water

connection or drain. Two and a half gallons of water were poured into the

reservior at the bottom of the cooking compartment before testing began. The

steamer was emptied at the end of the day, as directed by the manufacturer’s

instructions. Typical water usage for each cooking scenario was less than the

water reservoir’s 2.5-gallon capacity.

Frozen Green Pea Tests

Moisture content of the frozen green peas was 81% by weight, corresponding

to specific heats (Cp) of 0.44 Btu/lb°F for frozen and 0.84 Btu/lb°F for

thawed peas.

1

The D12 required 22.0 minutes to cook a full load of frozen

green peas and had a cooking-energy efficiency of 88.4% and a production

capacity of 131 lb/h.

The light-load test required an average of 10.6 minutes when cooking a single

pan of frozen green peas. Cooking energy efficiency and productivity during

the light-load tests were determined to be 64.2% and 45 lb/h, respectively.

Red Potato Tests

The red potatoes contained 84% moisture by weight with the specific heat

(Cp) of 0.87 Btu/lb°F.

1

A full load of potatoes averaged 22.7 minutes to reach

a bulk cooked temperature of 195 ± 2°F. The cooking-energy efficiency and

production capacity was 67.5% and 130 lb/h, respectively.

The single pan of red potatoes required 21.7 minutes to achieve an average

bulk temperature of 195 ± 2°F. The light-load potato test exhibited a cookingenergy efficiency of 31.2% and productivity of 23 lb/h.

5011.03.02(Revised) 3-3

Food Service Technology Center

Page 18

Results

Results Discussion

The rate at which steam condenses on food depends on the surface

temperature and area of the food. Therefore, frozen green peas (at 0°F) and

red potatoes (at room temperature) represent two extremities in steam

cooking. Frozen green peas, having a large surface area to volume ratio,

promote condensation. The energy transfer from steam to frozen food is high,

resulting in greater cooking-energy efficiency and productivity. Potatoes are

“tough” to cook, due to low surface to volume ratio and the slower rate of

condensation.

Appendix D lists the physical properties and measured values of each test run.

Using the detailed equations provided in section 11 of the Steamer ASTM

Standard Test Method, the cooking energy efficiencies can readily be

calculated. Tables 3-2 and 3-3 summarize the D12’s cooking performance.

Table 3-2. Frozen Green Pea Cooking Test Results.

Heavy-Load Light-Load

Number of Pans 6 1

Cook Time (min) 22.0 10.6

Cooking Energy Rate (kW) 11.5 5.5

Cooking-Energy Efficiency (%) 88.4 64.2

Production Rate (lb/h) 131 45

Energy Consumption (Btu/lb) 299 312

5011.03.02(Revised) 3-4

Food Service Technology Center

Page 19

Results

Table 3-3. Red Potato Cooking Test Results.

Heavy-Load Light-Load

Number of Pans 6 1

Cook Time (min) 22.7 21.7

Cooking Energy Rate (kW) 6.2 2.4

Cooking-Energy Efficiency (%) 67.5 31.2

Production Rate (lb/h) 130 23

Energy Consumption (Btu/lb) 164 358

Heavy-load cook times and consequent production capacities were greatly

improved in the Model D12 when compared to previous versions of

AccuTemp’s STEAM ‘N’ HOLD steamer. The D12 exhibited a heavy-load

frozen green pea cook time of 22.0 minutes, compared to the 40.7-minute

cook time of the D6 and the 30.7-minute cook time of the D8. A produciton

capacity of 131 lb/h was calculated for the D12 under this cooking scenario.

On the other hand, the D6 and the D8 demonstrated green pea production

capacities of 71 lb/h and 94 lb/h, respectively. The D12 also exhibited faster

cook times when cooking a “tough” food product like red potatoes. A 22.7minute cook time was recorded during the D12’s heavy-load potato tests,

compared to 29.4 minutes for the D6 and 28.6 minutes for the D8. This led to

a 130 lb/h potato production capacity for the D12 versus 98 lb/h for the D6

and 101 lb/h for the D8. Figure 3-2 compares the production capacities for the

three different versions of the AccuTemp steamer.

5011.03.02(Revised) 3-5

Food Service Technology Center

Page 20

Results

D12 D8 D6

140

120

100

80

60

40

Production Capacity (lb/h) .

Figure 3-2.

Comparison of

steamer production

capacities.

20

0

Frozen Green Peas Red Potatoes

Light-load cook times also benefited from the D-12’s increased horsepower.

The D12 required a mere 10.6 minutes to cook a single pan of frozen green

peas, whereas the D6 needed 11.9 minutes and the D8 11.0 minutes under the

same loading conditions. The light-load red potato cook time for the D12 was

21.7 minutes, while the D6 needed 26.2 minutes and the D8 required 26.1

minutes.

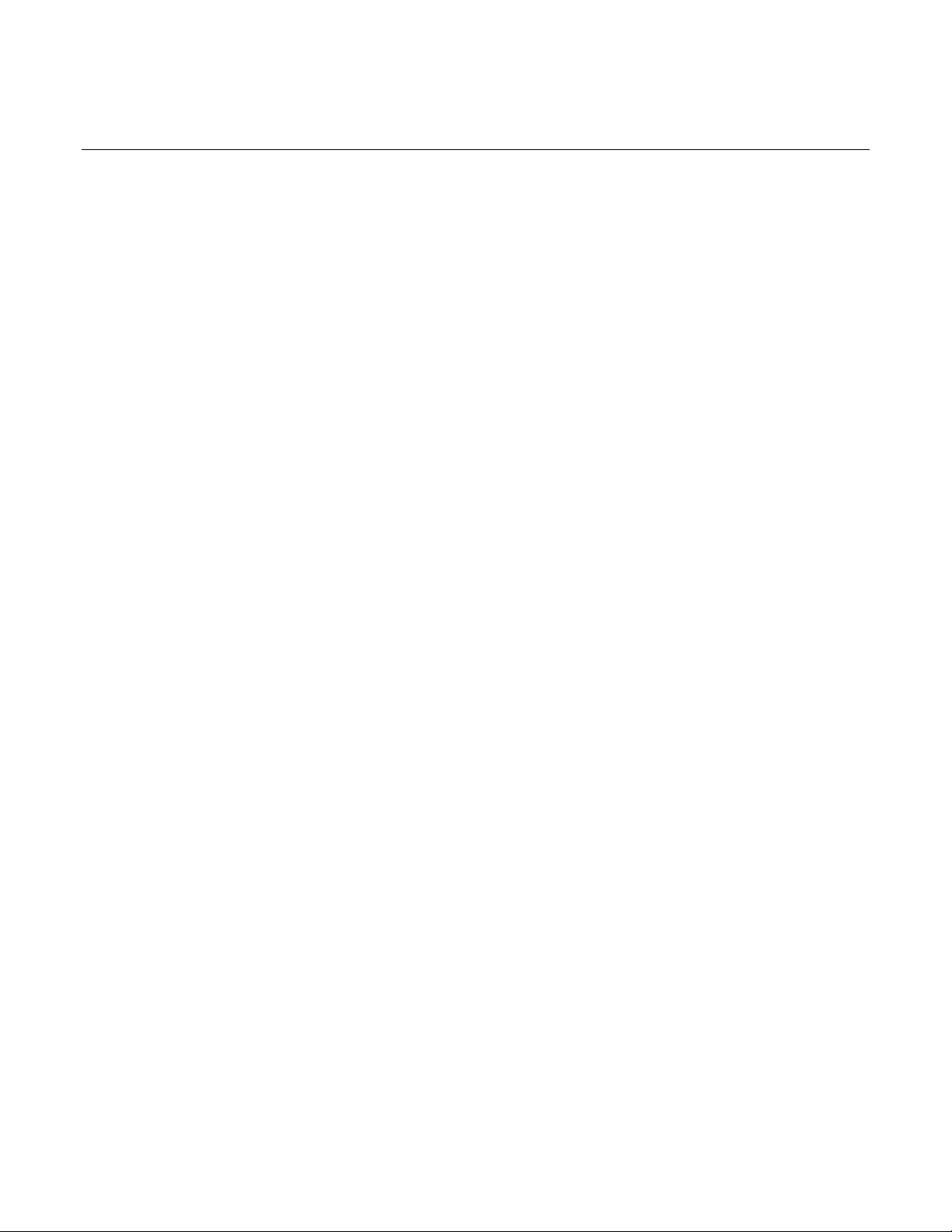

The D12 steamer’s faster cook times were not achieved at the expense of

efficiency. Cooking-energy efficiencies were comparable to the other two

models. Each unit demonstrated an 88% cooking-energy efficiency while

cooking a heavy-load of frozen green peas, and 65% during the light-load pea

test. Red potato cooking-energy efficiency for the three steamers was

approximately 66%, and the light-load potato test yielded a 30% cooking

cooking-energy efficiency for all three steamers. Figure 3-3 graphically

compares the cooking-energy efficiencies of the three AccuTemp STEAM

‘N’ HOLD steamers.

5011.03.02(Revised) 3-6

Food Service Technology Center

Page 21

Results

Figure 3-3.

Comparison of steamer

cooking-energy efficiencies.

100

90

80

70

60

50

40

30

20

Cooking-Energy Efficiency (%) .

10

0

Heavy-Load Peas Light-Load Peas Heavy-Load

D12 D8 D6

Potatoes

Light-Load

Potatoes

Figure 3-4 illustrates the relationship between cooking-energy efficiency and

production rate for this steamer, when cooking two different types of food

product. The upper line represents the part-load efficiency curve for the

steamer when cooking frozen vegetables, while the lower curve represents the

steamer’s part-load efficiency while cooking more stubborn food products.

Steamer production rate is a function of the cook time. Appendix D contains a

synopsis of test data for each replicate of the cooking tests.

5011.03.02(Revised) 3-7

Food Service Technology Center

Page 22

Results

Frozen Green Peas Red Potatoes

100

90

Figure 3-4.

Steamer part-load cooking-energy efficiency.

80

70

60

50

40

30

20

Cooking-Energy Efficiency (%) .

10

0

0 20406080100120140

Light-Load

Production Rate (lb/h)

Heavy-Load

Figure 3-5 illustrates the relationship between the D12 steamer’s average

energy consumption rate and the production rate for different types of food

product. The upper line represents the steamer’s energy consumption rate

when cooking frozen vegetables, while the lower curve represents the

steamer’s energy consumption rate while cooking more stubborn food

products. This graph can be used as a tool to estimate the daily energy

consumption and probable demand for the steamer in a real-world operation,

based on the type of usage. Average energy consumption rates at 15, 30, and

60 pounds per hour of frozen vegetables are 2.8 kW, 4.2 kW, and 6.6 kW,

respectively. For an operation cooking an average of 15 pounds of frozen

vegetables per hour over the course of the day (e.g., 150 pounds of food over

a ten hour day), the probable demand contribution from this steamer would be

2.8 kW.

5011.03.02(Revised) 3-8

Food Service Technology Center

Page 23

Results

14

12

10

Frozen Green Peas Red Potatoes

Heavy-Load

8

Figure 3-5.

Steamer cooking energy

consumption profile.

6

4

Cooking Energy Rate (kW)

2

0

0 20406080100120140

Note: Light-load = single pan/load; Heavy-load = 6 pans/load.

Light-Load

Idle Energy Rate

Production Rate (lb/h)

Production Capacity .

5011.03.02(Revised) 3-9

Food Service Technology Center

Page 24

4

Conclusions

The AccuTemp Model 208-D12-300 is a highly productive and energy

efficient connectionless, electric steamer. With its six-pan loading capacity,

the unit achieved one of the highest frozen green pea production capacities of

any FSTC tested connectionless steamer (131 lb/h). Also, its 130 pounds-perhour red potato production capacity was the highest of any connectionless

steamer tested to date at the FSTC.

productivity was the unit’s ability to transfer the majority of its cooking

energy to both of the test method’s specified food product during heavy-load

cooking conditions, approximately 88% to the frozen green peas and 68% to

the red potatoes.

3–10, 15, 16

Complementing the D12’s high

The AccuTemp steamer also was quick to achieve full operational capacity

from a cold start. Only 6.5 minutes was required to preheat the cooking

compartment to 212°F. With its rapid preheat time, the unit can potentially be

shut off during extended periods of non-use, thus eliminating stand-by energy

losses entirely.

The signature characteristic of the connectionless steamer design was the

D12’s negligible water consumption. For each cooking scenario, the steamer

consumed less than 2.5 gallons per cooking test. On average, researchers

needed only to replenish the water reservoir with a gallon of water after

multiple cooking tests. Steam-generator and boiler-based units typically

consume between 20 and 60 gal/h while cooking.

During the original course of testing, researchers calculated an idle energy

rate of 1.4 kW when the steamer was operated in the “Fast Cook” mode with

the timer set to “Continuous”. The Accutemp D12’s high cooking energy

efficiencies, however, suggested the unit was capable of a much lower idle

energy rate. Consequently, researchers re-evaluated the control settings used

2, 11–14

during the original testing and determined that the idle energy rate could be

5011.03.02(Revised) 4-1

Food Service Technology Center

Page 25

Conclusions

significantly reduced by changing the control settings. Researchers

successfully reduced the idle energy rate to 420 W by taking advantage of the

steamer’s “Hold” feature. Furthermore, the D12’s average cavity temperature

remained above 205°F during the idle period. Through minor changes in the

control panel labeling and clear instructions in the appliance manual,

Accutemp can ensure that end users take full advantage of the D12’s low idle

rate potential.

AccuTemp Products, Inc. has markedly increased the maximum production

capacity of its connectionless steamer through the addition of higher input,

12-kW heating elements. The STEAM ‘N’ HOLD, Model 208-D12-300

offers greater productivity in the same platform of earlier models and

maintains the same, high cooking energy efficiencies as well. Operators will

find the D12 a qualified candidate that can satisfy menu demands with its

high productivity, while minimizing utility costs.

5011.03.02(Revised) 4-2

Food Service Technology Center

Page 26

5

References

1. American Society for Testing and Materials, 1999. Standard Test

Method for the Performance of Steam Cookers. ASTM Designation F

1484–99. In annual book of ASTM Standards, West Conshohocken,

PA.

2. Selden, M., 1995. Development and Validation of a Uniform Testing

Procedure for Steam Cookers. Food Service Technology Center Report

1022.95.19, April.

3. Bell, T., Yap, D., 1999. Southbend Simple Steam, Model EZ-3 Electric

Steamer Performance Test: Application of ASTM Test Method F 1484-

99. Food Service Technology Center Report 5011.99.83, December.

4. Bell, T., Miner, S., Nickel, J., Zabrowski, D., 2001. Stellar Steam

CAPELLA Electric Steamer Performance Test: Application of ASTM

Test Method F 1484-99. Food Service Technology Report 5011.01.94,

January.

5. Bell, T., Miner, S., 2001. Vulcan VPX3 Electric Steamer Performance

Test: Application of ASTM Test Method F 1484-99. Food Service Technology Center Report 5011.01.01, May.

6. Bell, T., Miner, S., 2001. Vulcan VPX5 Electric Steamer Performance

Test: Application of ASTM Test Method F 1484-99. Food Service Technology Center Report 5011.01.02, May.

7. Bell, T., Nickel, J., 2001. Cleveland Range Inc., Electric Steamer Per-

formance Test: Application of ASTM Test Method F 1484-99. Food

Service Technology Center Report 5011.00.84, November.

8. Bell, T., Miner, S., Nickel, J., Zabrowski, D., 2001. Market Forge, ET-

3E Electric Steamer Performance Test: Application of ASTM Test

Method F 1484-99. Food Service Technology Center Report

5011.01.99, April.

5011.03.02(Revised) 5-1

Food Service Technology Center

Page 27

References

9. Bell, T., Miner, S., Nickel, J., Zabrowski, D., 2001. Market Forge, ET-

5E Electric Steamer Performance Test: Application of ASTM Test

Method F 1484-99. Food Service Technology Center Report

5011.01.98, April.

10. Yap, D., Ardley, S., 1998. Groen HyperSteam, Model HY-3E Electric

Steamer Performance Test: Application of ASTM Standard Test Method

F1484-93. Food Service Technology Center Report 5011.98.54, May.

11. Bell, T., Nickel, J., 2001. Market Forge STP-6E Electric Steamer Per-

formance Test: Application of ASTM Test Method F 1484-99. Food

Service Technology Center Report 5011.01.05, December.

12. Bell, T., Nickel, J., 2001. Market Forge STP-6G Gas Steamer Perform-

ance Test: Application of ASTM Test Method F 1484-99. Food Service

Technology Center Report 5011.01.06, December.

13. Bell, T., Miner, S., Nickel, J., Zabrowski, D., 2000. Vulcan-Hart Gas

Steamer Performance Test, Model VL2GSS (Pressure) and Model

VS3616G (Atmospheric) Steamer Performance Test: Application of

ASTM Test Method F 1484-99. Food Service Technology Report

5011.00.85, December.

14. Bell, T., Miner, S., Nickel, J., Zabrowski, D., 2001. Vulcan-Hart Gas

Steamer Performance Test, Model VHX24G-3 Steamer Performance

Test: Application of ASTM Test Method F 1484-99. Food Service Tech-

nology Report 5011.01.97, January.

15. Yap, D., Ardley, S., 1998. AccuTemp Steam “n” Hold, Model 208-D6-

3.0 Electric Steamer Performance Test: Application of ASTM Test

Method F1484-99. Food Service Technology Center Report 5011.98.58,

May.

16. Yap, D., Bell, T., Knapp, S., 1999. AccuTemp Steam ‘n’ Hold, Model

208-D8-300 Electric Steamer Performance Test: Application of ASTM

Test Method F1484-99. Food Service Technology Center Report

5011.99.75, September.

5011.03.02(Revised) 5-2

Food Service Technology Center

Page 28

A

Glossary

Boiler

Cooking-Energy Efficiency

(%)

Self-contained electric, gas, or steam coil

powered vessel wherein water is boiled to

produce steam for the steam cooker. Also

called a steam generator.

Boiler Preheat

Preheat

Process of bringing the boiler water from potable supply temperature to operating temperature (pressure).

Condensate

A mixture of condensed steam and cooling

water, exiting the steam cooker and directed to

the floor drain.

Condensate Temperature

The temperature at which the condensate enters the floor drain.

Cooking Energy

The total energy consumed by an appliance as

it is used to cook a specified food product.

Cooking Energy Consumption Rate

(kW or kBtu/h)

The average rate of energy consumption during the cooking period.

(kWh or kBtu)

(°F)

The quantity of energy input to the food products; expressed as a percentage of the quantity

of energy input to the appliance during the

heavy-, medium-, and light-load tests.

Duty Cycle

Load Factor

The average energy consumption rate (based

on a specified operating period for the appliance) expressed as a percentage of the measured energy input rate.

Duty Cycle =

Energy Input Rate

Energy Consumption Rate

Energy Rate

The peak rate at which an appliance will consume energy, typically reflected during preheat.

Frozen Green Peas Load

12 x 20 x 2½ in. hotel pan filled with 8.0 ± 0.2

lb of frozen, grade A, green peas subsequently

frozen to 0±5°F. One of two food products

used to determine cooking-energy efficiency

and production capacity.

(%)

(kW or kBtu/h)

Rate nConsumptioEnergy Average

RateInput Energy Measured

x 100

5011.03.02(Revised) A-1

Food Service Technology Center

Page 29

Glossary

High-Pressure Steam Cooker

Steam cooker wherein cooking compartment

operates between 10 and 15 psig (ASTM

F1217-92 Classification Type III).

Heating Value

(Btu/ft

3

)

Heating Content

The quantity of heat (energy) generated by the

combustion of fuel. For natural gas, this quantity varies depending on the constituents of the

gas.

Ice Load

12 x 20 x 2½ in. hotel pan filled with 8.0 ± 0.2

lb of water and subsequently frozen to 0±5°F.

This is used to simulate a food product load in

the ice load cooking-energy efficiency and

production capacity test.

Idle Energy Rate

(kW or Btu/h)

Idle Energy Input Rate

Idle Rate

The rate of appliance energy consumption

while it is “holding” or maintaining a stabilized operating condition or temperature.

Idle Temperature

(°F, Setting)

The temperature of the cooking cavity/surface

(selected by the appliance operator or specified for a controlled test) that is maintained by

the appliance under an idle condition.

Idle Duty Cycle

(%)

Idle Energy Factor

The idle energy consumption rate expressed as

a percentage of the measured energy input

rate.

Rate nConsumptioEnergy Idle

Idle Duty Cycle =

x 100

RateInput Energy Measured

Low-Pressure Steam Cooker

Steam cooker wherein the cooking compartment operates between 3 and 9.9 psig (ASTM

F1217-92 Classification Type II).

Measured Input Rate

(kW or Btu/h)

Measured Energy Input Rate

Measured Peak Energy Input Rate

The maximum or peak rate at which an appliance consumes energy, typically reflected during appliance preheat (i.e., the period of operation when all burners or elements are

“on”).

Pilot Energy Rate

(kBtu/h)

Pilot Energy Consumption Rate

The rate of energy consumption by the standing or constant pilot while the appliance is not

being operated (i.e., when the thermostats or

control knobs have been turned off by the

food service operator).

Potato Load

12 x 20 x 2½ in. hotel pan filled with 8.0 ± 0.2

lb of fresh, whole, US No. 1, size B, red potatoes. One of two food products used to determine cooking-energy efficiency and production capacity.

Preheat Energy

(kWh or Btu)

Preheat Energy Consumption

The total amount of energy consumed by an

appliance during the preheat period.

Preheat Rate

(°F/min)

The rate at which the cooking surface heats

during a preheat.

Preheat Time

(minute)

Preheat Period

5011.03.02(Revised) A-2

Food Service Technology Center

Page 30

Glossary

The time required for an appliance to heat

from the ambient room temperature (75 ± 5°F)

to a specified (and calibrated) operating temperature or thermostat set point.

Production Capacity

(lb/h)

The maximum production rate of an appliance

while cooking a specified food product in accordance with the heavy-load cooking test.

Production Rate

(lb/h)

Productivity

The average rate at which an appliance brings

a specified food product to a specified

“cooked” condition.

Rated Energy Input Rate

(kW, W or Btu/h, Btu/h)

Input Rating (ANSI definition)

Nameplate Energy Input Rate

Rated Input

Test Method

A definitive procedure for the identification,

measurement, and evaluation of one or more

qualities, characteristics, or properties of a

material, product, system, or service that produces a test result.

Typical Day

A sampled day of average appliance usage

based on observations and/or operator interviews, used to develop an energy cost model

for the appliance.

Water Consumption

(gal/h)

Water consumed by the steam cooker. Includes both water used in the production of

steam and cooling water (if applicable) for

condensing/cooling unused steam.

The maximum or peak rate at which an appliance consumes energy as rated by the manufacturer and specified on the nameplate.

Steam Cooker

Cooking appliance wherein heat is imparted to

food in a closed compartment by direct contact with steam. The compartment can be at or

above atmospheric pressure. The steam can be

static or circulated.

5011.03.02(Revised) A-3

Food Service Technology Center

Page 31

B

Appliance Specifications

Appendix B includes the product literature for the AccuTemp STEAM ‘N’

HOLD, Model 208-D12-300 steamer.

5011.03.02(Revised) B-1

Food Service Technology Center

Page 32

C

Results Reporting Sheets

Manufacturer: AccuTemp

Model: STEAM ‘N’ HOLD, 208-D12-300

Date: January 2002

Test Steam Cooker

ASTM F 1216 Classification (check one for each classification)

!

______ Type II - Three to 9.9 psig compartment pressure

______ Type III - Ten to 15 psig compartment pressure

!

______ Size 2-6 - Two Compartment, 6 full-size pan capacity

______ Size 2-8 - Two Compartment, 8 full-size pan capacity

______ Size 2-10 - Two Compartment, 10 full-size pan capacity

______ Size 2-12 - Two Compartment, 12 full-size pan capacity

______ Size 2-16 - Two Compartment, 16 full-size pan capacity

______ Size 3-12 - Three Compartment, 12 full-size pan capacity

______ Size 3-15 - Three Compartment, 15 full-size pan capacity

______ Size 3-18 - Three Compartment, 18 full-size pan capacity

______ Size 3-24 - Three Compartment, 24 full-size pan capacity

!

______ Style B - Floor mounted on an open stand

______ Style C - Floor mounted on a cabinet base

______ Style D - Wall Mounted

______ Class A - Direct connection to potable external steam source

______ Class B - Self-contained steam coil steam generator

______ Class C - Self-contained gas fired steam generator

!

Type I - Zero to 2.9 psig compartment pressure

Size 1-3 - One Compartment, 3 full-size pan capacity

Size 1-4 - One Compartment, 4 full-size pan capacity

Size 1-5 - One Compartment, 5 full-size pan capacity

Size 1-6 - One Compartment, 6 full-size pan capacity

Style A - Counter mounted

Class D - Self-contained electric steam generator

5011.03.02(Revised) C-1

Food Service Technology Center

Page 33

Results Reporting Sheets

Description of operational characteristics: Approximately 2.5 gallons of water is manually poured in the

bottom of the cooking compartment. Upon starting the preheat, a pump draws a vacuum within the stainless-

steel chamber to reduce vapor pressure, inducing quicker steam generation. Food is cooked with natural-

convection steam to a desired temperature and held until ready to be served.

Apparatus

The steamer was installed in accordance with the manufacturer’s instructions under a 4-foot-deep canopy

hood, with the lower edge of the hood 6 feet, 6 inches above the floor and a minimum of 6 inches inside the

vertical front edge of the hood. The exhaust ventilation operated at a nominal rate of 150 cfm per linear foot

of hood with the ambient temperature maintained between 75 ±5°F. All test apparatus were installed in

1

accordance with Section 9 of the ASTM test method.

The steamer was instrumented with an electric transducer to measure power and energy; a voltage regulator

was used to maintain constant voltage for all tests. A computerized data acquisition system recorded test

information at 10-seconds intervals for the red potato tests and 5-second intervals for the rest. All test

apparatus were installed in accordance with Section 9 of the ASTM test method.

Energy Input Rate

Test Voltage 208 V

Measured 12.0 kW

Rated 12.0 kW

Percent Difference between Measured and Rated 0.0%

Appliance Preheat Energy Consumption and Duration

Test Voltage 208 V

Energy Consumption 1.3 kWh

Duration 6.53 min

Appliance Idle Energy Rate (Original Testing)

5011.03.02(Revised) C-2

Food Service Technology Center

Page 34

Results Reporting Sheets

Test Voltage 208 V

Idle Energy Rate 1.4 kW

Appliance Idle Energy Rate (Revised Testing)

Test Voltage 208 V

Idle Energy Rate 0.4 kW

Frozen Green Peas

Cooking Time, Energy Efficiency, Energy Rate, Production Capacity, and Water

Consumption Rate

Heavy-Load:

Test Voltage 208 V

Cooking Time 22.0 min

Cooking-Energy Efficiency 88.4 ±0.6%

Cooking Energy Rate 11.5 ± 0.2 kW

Production Capacity 130.9 ±0.0 lb/h

Water Consumption Rate

<

2.5 gal/h

Light-Load:

Test Voltage 208 V

Cooking Time 10.6 min

Cooking-Energy Efficiency 64.2 ±2.5%

Cooking Energy Rate 5.5 ± 0.1 kW

Production Rate 45.1 ± 0.5 lb/h

<

Water Consumption Rate

2.5 gal/h

5011.03.02(Revised) C-3

Food Service Technology Center

Page 35

Results Reporting Sheets

Whole Red Potatoes Cooking Time, Energy Efficiency, Energy Rate, Production Capacity, and Water

Consumption Rate

Test Voltage 208 V

Heavy-Load:

Cooking Time 22.7 min

Cooking-Energy Efficiency 67.5 ±1.4%

Cooking Energy Rate 6.2 ± 0.2 kW

Production Capacity 129.6 ± 4.8 lb/h

Water Consumption Rate

<

2.5 gal/h

Light-Load:

Test Voltage 208 V

Cooking Time 21.7 min

Cooking-Energy Efficiency 31.2 ± 2.0%

Cooking Energy Rate 2.4 ± 0.1kW

Production Capacity 24.1 ± 0.3 lb/h

<

Water Consumption Rate

2.5 gal/h

5011.03.02(Revised) C-4

Food Service Technology Center

Page 36

D

Cooking-Energy Efficiency Data

Table D-1. Preheat and Idle Data (Original Testing)

Replication 1 Replication 2 Replication 3

Measured Values

Preheat Time (min) 6.50 6.67 6.42

Preheat Energy (kWh) 1.28 1.32 1.28

Idle Time (min) 120.00 120.00 120.00

Idle Energy (kWh) 2840.00 2860.00 2880.00

Calculated Values

Preheat Energy Rate (kW) 11.82 11.88 11.97

Idle Energy Rate (kW) 1.42 1.43 1.44

Table D-2. Idle Data (Revised Testing)

Calculated Values

Idle Energy Rate (kW) 0.41 0.41 0.43

Replication 1 Replication 2 Replication 3

5011.03.02(Revised) D-1

Food Service Technology Center

Page 37

Cooking-Energy Efficiency Data

Table D-3. Heavy-Load Peas Data

Replication 1 Replication 2 Replication 3

Measured Values

Number of Pan(s) 6 6 6

Cook Time (min) 22.00 22.00 22.00

Initial Water Temperature (°F) 46.2 45.8 42.7

Final Water Temperature (°F) 100.2 99.7 97.4

Frozen Food Temperature (°F) -4.4 -4.4 -4.4

Weight of Empty Calorimeter (lb) 44.7 44.7 44.8

Weight of Full Calorimeter (lb) 152.3 152.6 152.8

Weight of Calorimeter Water (lb) 60.1 60.0 60.1

Weight of Cooked Food (lb) 47.5 47.9 47.9

Weight of Frozen Food (lb) 48.0 48.0 48.0

Weight of Stainless-Steel Pans (lb) 16.8 15.3 16.4

Moisture Content (%) 81 81 81

Condensate Temperature (°F) n/a n/a n/a

Water Consumption (gal/h) <2.5 <2.5 <2.5

Calculated Values

Moisture Weight in Green Peas (lb) 38.9 38.9 38.9

Final Food Temperature (°F) 180.7 179.3 178.3

Cooking Energy (kWh) 4.24 4.20 4.18

Energy Consumed by Green Peas (Btu) 12,417 12,358 12,318

Energy to Food (Btu/lb) 258.7 257.5 256.6

Energy Consumed by Pans (Btu) 341.6 307.5 329.5

Energy of Boiler Re-init (Btu) n/a n/a n/a

Energy Consumed by the Steamer (Btu) 14,471 14,335 14,266

Energy to Steamer (Btu/lb of food cooked) 301.5 298.6 297.2

Cooking Energy Rate (kW) 11.6 11.5 11.4

Productivity (lb/h) 130.9 130.9 130.9

Energy Efficiency (%) 88.2 88.4 88.7

5011.03.02(Revised) D-2

Food Service Technology Center

Page 38

Cooking-Energy Efficiency Data

Table D-4. Light-Load Peas Data

Replication 1 Replication 2 Replication 3

Measured Values

Number of Pan(s) 1 1 1

Cook Time (min) 11.00 10.92 10.75

Initial Water Temperature (°F) 49.7 47.5 45.4

Final Water Temperature (°F) 84.2 82.4 77.7

Frozen Food Temperature (°F) -4.4 -4.4 -4.4

Weight of Empty Calorimeter (lb) 44.4 44.5 44.2

Weight of Full Calorimeter (lb) 72.4 72.3 72.2

Weight of Calorimeter Water (lb) 20.0 20.0 20.0

Weight of Cooked Food (lb) 8.0 7.8 8.0

Weight of Frozen Food (lb) 8.0 8.0 8.0

Weight of Stainless-Steel Pans (lb) 3.2 2.8 2.4

Moisture Content (%) 81 81 81

Condensate Temperature (°F) n/a n/a n/a

Water Consumption (gal/h) < 2.5 < 2.5 < 2.5

Calculated Values

Moisture Weight in Green Peas (lb) 6.5 6.5 6.5

Final Food Temperature (°F) 179.1 179.8 181.3

Cooking Energy (kWh) 0.98 0.96 0.96

Energy Consumed by Green Peas (Btu) 2,058 2,063 2,074

Energy to Food (Btu/lb) 257.2 257.9 259.3

Energy Consumed by Pans (Btu) 48.4 56.9 49.1

Energy of Boiler Re-init (Btu) n/a n/a n/a

Energy Consumed by the Steamer (Btu) 3,345 3,277 3,277

Energy to Steamer (Btu/lb of food cooked) 418.1 415.9 409.6

Cooking Energy Rate (kW) 5.5 5.4 5.4

Productivity (lb/h) 45.0 45.4 45.0

Energy Efficiency (%) 63.0 64.7 64.8

5011.03.02(Revised) D-3

Food Service Technology Center

Page 39

Cooking-Energy Efficiency Data

Table D-5. Heavy-Load Potatoes Data

Replication 1 Replication 2 Replication 3

Measured Values

Number of Pan(s) 6 6 6

Cook Time (min) 23.00 22.25 22.75

Temperature of Uncooked Potatoes (°F) 73.4 74.0 72.0

Temperature of Cooked Potatoes (°F) 195.0 197.0 195.0

Weight of Stainless-Steel Pans (lb) 17.38 15.88 17.37

Weight of Potatoes (lb) 48.96 48.80 49.06

Total Potato Count 284 283 291

Moisture Content (%) 84 84 84

Condensate Temperature (°F) n/a n/a n/a

Water Consumption (gal/h) <2.5 <2.5 <2.5

Calculated Values

Moisture Weight in Potatoes (lb) 41.16 41.02 41.24

Average Weight of Each Potato (lb) 0.17 0.17 0.17

Cooking Energy (kWh) 2.34 2.36 1.92

Energy Consumed by Potatoes (Btu) 5,257 5,154 5,182

Energy to Food (Btu/lb) 107.4 105.6 105.6

Energy Consumed by Pans (Btu) 235.19 211.36 231.23

Energy of Boiler Re-init (Btu) n/a n/a n/a

Energy Consumed by the Steamer (Btu) 8,055 7,986 8,055

Energy to Steamer (Btu/lb of food cooked) 164.5 163.6 164.2

Cooking Energy Rate (kW) 6.16 6.31 6.22

Productivity (lb/h) 127.7 131.6 129.4

Energy Efficiency (%) 68.2 67.2 67.2

5011.03.02(Revised) D-4

Food Service Technology Center

Page 40

Cooking-Energy Efficiency Data

Table D-6. Light-Load Potatoes Data

Replication 1 Replication 2 Replication 3

Measured Values

Number of Pan(s) 1 1 1

Cook Time (min) 22.00 21.50 21.50

Temperature of Uncooked Potatoes (°F) 72.6 72.0 72.0

Temperature of Cooked Potatoes (°F) 195.0 195.0 195.0

Weight of Stainless-Steel Pans (lb) 2.43 2.82 2.62

Weight of Potatoes (lb) 8.04 8.18 8.18

Total Potato Count 49 49 48

Moisture Content (%) 84 84 84

Condensate Temperature (°F) n/a n/a n/a

Water Consumption (gal/h) <2.5 <2.5 <2.5

Calculated Values

Moisture Weight in Potatoes (lb) 6.76 6.88 6.88

Average Weight of Each Potato (lb) 0.16 0.17 0.17

Cooking Energy (kWh) 0.86 0.88 0.76

Energy Consumed by Potatoes (Btu) 863.33 878.36 878.36

Energy to Food (Btu/lb) 107.4 107.4 107.4

Energy Consumed by Pans (Btu) 32.88 38.15 35.44

Energy of Boiler Re-init (Btu) n/a n/a n/a

Energy Consumed by the Steamer (Btu) 2,799 2,935 3,003

Energy to Steamer (Btu/lb of food cooked) 348.1 358.8 367.1

Cooking Energy Rate (kW) 2.24 2.40 2.46

Productivity (lb/h) 21.9 22.8 22.8

Energy Efficiency (%) 32.0 31.2 30.4

5011.03.02(Revised) D-5

Food Service Technology Center

Page 41

Cooking-Energy Efficiency Data

Table D-7. Frozen Green Pea Cooking-Energy Efficiency and Production Capacity Statistics.

Cooking-Energy Efficiency Production Capacity

Heavy Load Light Load

Replicate #1 88.2 63.0 130.9

Replicate #2 88.4 64.7 130.9

Replicate #3 88.7 64.8 130.9

Average 88.4 64.2 130.9

Standard Deviation 0.25 1.01 0.00

Absolute Uncertainty 0.62 2.51 0.00

Percent Uncertainty 0.71% 3.91% 0.00%

Table D-8. Red Potato Cooking-Energy Efficiency and Production Capacity Statistics.

Cooking-Energy Efficiency Production Capacity

Heavy Load Light Load

Replicate #1 68.2 32.0 127.7

Replicate #2 67.2 31.2 131.6

Replicate #3 67.2 30.4 129.4

Average 67.5 31.2 129.6

Standard Deviation 0.58 0.80 1.96

Absolute Uncertainty 1.43 1.98 4.85

Percent Uncertainty 2.12% 6.36% 3.74%

5011.03.02(Revised) D-6

Food Service Technology Center

Loading...

Loading...