Page 1

Accurate Thermal Systems

Fluidized Temperature Bath

s

AP PL IC A T I O N S

Model FTBSL

6 Laboratory

PH: 609

-

326

-

3190

Thermal cleaning of small

Extrusion tooling and

Polymer Rheometer and

Melt Flow Indexer parts

Nitinol shape setting

Temperature sensor and

system calibration

Reactor Heating

General heat treatment of

devices & materials

BE NE FI T S

Compact working volume –

5.3” diameter by 6” depth

Portable – only 45 lbs with

aluminum oxide

Flexible lid for immersing

parts basket and

temperature probes for

calibration

1900 watt heat capacity

Excellent stability, uniformity

& accuracy

Designed and manufactured

in USA

CE marked

Fluidized Temperature Bath

• Fully automatic Fluidizing

air control

• Cover and lid design that minimizes

media loss

• Independent over-temperature limit

protection

• Fast heat up

• Compact size for placement on

standard lab benches

• RS485 interface for PC connection &

downloadable Windows software

With over 25 years of experience with Fluidized Bath

technology we have developed a range of products that offer

outstanding performance, safety, features and value that are

unmatched. Unlike competing Fluidized baths our systems

have a smaller footprint, include advanced features and cost

thousands of dollars less. They are much safer than salt

baths with thermal response that is 2 to 3 times faster than

ovens.

Fluidized Temperature Baths have been the heat source of

choice for over 20 years by many leading Fortune 500

Plastics and Medical Device manufacturers as well as

companies who require fast heat up of their immersed

devices, sensors and materials with minimal quenching.

Unique Solutions for Thermal Applications

Page 2

shown.

Features and

Specifications

Specification

s

4106 Sylon Blvd

MODEL FTBSL6

FLUIDIZED TEMPERATURE BATH

WH AT ’ S I N C L UD ED

-Fluidized Bath

-20 pounds of media

-Bath cover and Lid

-Instruction manual

WH AT D O I N EE D TO

RU N TH E S YS TE M

-120 VAC mains, 50/60hz 20 amp supply or 240 VAC

mains, 50/60hz 10 amp

supply

-Clean dry air supply at a

fixed 30 PSI, max flow of

1.8 CFM

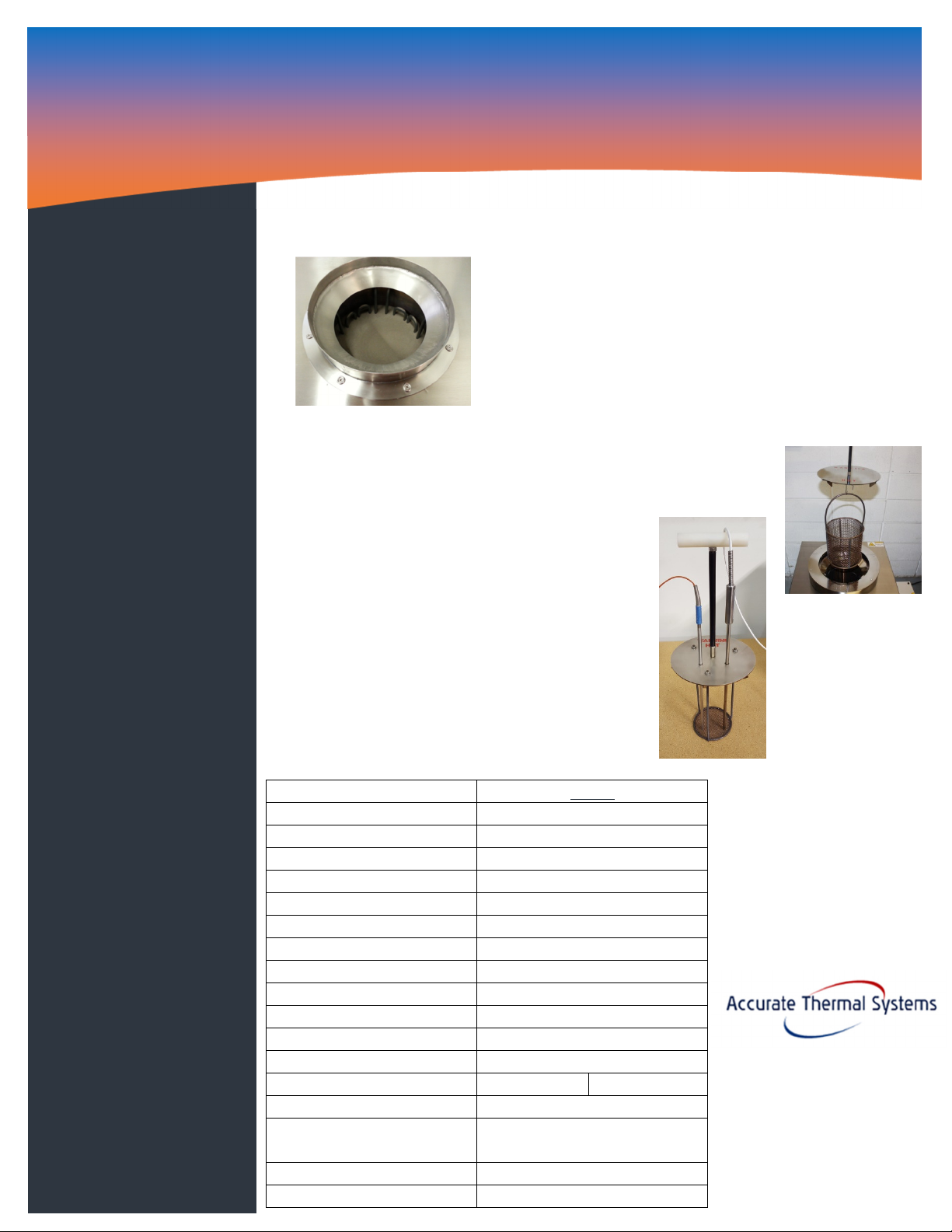

An eyelet is added to the lid for suspending

an optional basket for parts cleaning or device

heat treatment.

The optional probe support will suspend

temperature sensors and thermometers into

the Fluidized Bath for calibration. The probe

holder immersion depth can be adjusted for

added flexibility. Drill holes into the lid for the

diameters you require.

The lid is easily modified for immersing

apparatus, assemblies and small reactors for

heating.

SER VIC E S A VAI LAB LE

-Technical support

-Application support

-Installation and setup

-Maintenance

V3 216

FTBSL6

Temperature range 50 to 605°C

Working volume 5.3” dia x 6” depth

Typical stability thru operating range ±0.3°C

Dead bed stability (5 minute period) ±0.040°C

Calibrated accuracy ±2.0°C

Heat up time to 600°C from ambient 70 minutes

Cool down time – 600 to 200°C 130 minutes

Heater Power – 1 phase, 50/60 hz 1920 watts

Air pressure & max flow required 30 PSI, 1.8 CFM

Overall footprint, H x W x D 15”x17”x13”

Total unit weight with aluminum oxide 45 lbs

Warranty 1 year

Catalog number ATS2016–

Recommended spare lid ATS1078

Parts Basket – 3” ID x 4.5”L

1.5 lbs max capacity

20 pound box of Aluminum oxide ATS1076

Probe support – 4” OD x 6” depth ATS3082

Unique bath cover and lid design that

minimizes media loss. Media is either blocked

by the lid or collected on the cover flange

which then drops back into the system.

The included lid with handle is lowered into

the Fluidized Bath for cleaning parts, heat

treating or calibrating temperature sensors as

Bath Lid with

Probe support

Bath Lid with

Parts Basket

(134mm x 152mm)

(2.1 bar, 50 lpm)

(381mm x 432mm x 330mm)

(20kg) (unit only 32 lbs, 14.5kgs)

120VAC

ATS2018 -

ATS1080

240 VAC

Hainesport, NJ 08036 USA

Ph: 609-326-3190

Fax: 609-479-5124

Email: sales@accuthermal.com

Website: www.accuthermal.com

Loading...

Loading...