Page 1

Accurate Thermal Systems

Fluidized Temperature Baths

APPL I C A TIO N S

Model FTB

LL12E

PH: 609

-

326

-

3190

Thermal cleaning of

tooling including:

-breaker plates

-dies

-nozzles

-tips

-screens

-metal filters

-flanges

-hardware

-paint hooks

-hardware

-and many more…….

General heat treatment of

devices & materials

Heating of reactors

BEN E F I T S

Large working volume –

8.3”

diameter

in parts basket

4500 watt heat capacity

for fast heat up

Safer to the operator and

tooling versus other

methods

Designed and

manufactured in USA

by 12” depth

Fluidized Temperature Bath

Our most economical system

Easy to operate for quick results

Built rugged for years of reliable

operation

Uses safe and inert aluminum oxide

sand

Fast and efficient cleaning of tooling

and parts

With over 25 years of experience with Fluidized Bath

technology we have developed a range of products that offer

outstanding performance, safety, features and value that are

unmatched. Unlike competing Fluidized baths our systems

have a seam welded tank to eliminate media loss and extend

heater life.

Fluidized Temperature Baths have been the large capacity

heat source of choice for over 40 years by many leading

Fortune 500 companies. The thermal cleaning process

breaks down all polymers and is not abrasive to immersed

objects.

You too can benefit from Fluidized Bath safety, cleaning

efficiency and reduced labor in your extrusion operation and

tool room.

Unique Solutions for Thermal Applications

Page 2

WH A T ’ S I NC L U D ED

Features and

Specifications

4106 Sylon Blvd

MODEL

FTBLL12E

-Fluidized Bath

-100 pounds of bath media

-Instruction manual

WH A T D O I N E E D T O

RU N T H E S Y S T E M

-240 VAC, 50/60hz, 20 amp

supply power

-Clean dry air supply that can

deliver a fixed 40 PSI at a max

flow of 3.5 CFM

-Exhaust hood for ventilation

SERVI C E S AVAILABLE

-Technical support

-Application support

-Installation and setup

-Maintenance

V3 614

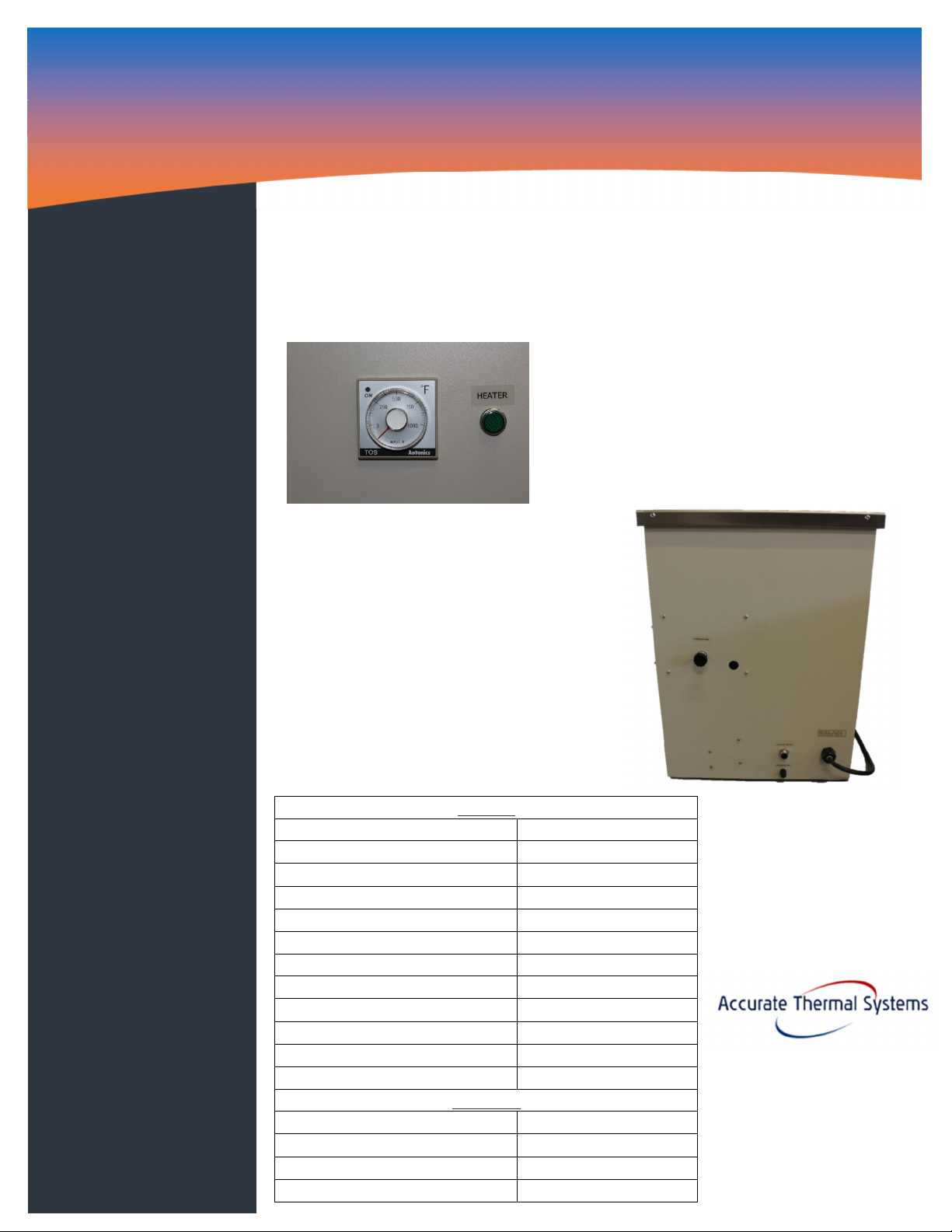

The model FTBLL12E Fluidized Temperature

Bath has an easy to use dial controller for

setting the bath from 100 to 1000°F. The

heater light shows heater status and once

flashing you allow an hour for the system to

fully reach operating temperature.

Fluidizing air is manually controlled by a valve

on the side of the unit. The air will need to be

adjusted a few times when heating from

ambient to higher cleaning temperatures and

vice versa when cooling down. The bath is

well insulated and safe as well as easy to use.

Visit our website for videos and details on how

Fluidized baths operate.

Specifications

FTBLL12E

Temperature range 100 to 1000°F

Working volume, inches in parts basket 8 3/8” diameter x 12 depth

Overall all volume 9 1/2” diameter x 12 depth

Maximum tool cleaning capacity per batch 25 pounds

Heat up time ambient to 1000°F 140 minutes

Cool down time – 1000 to 400°F 180 minutes

Heater Power – 240 VAC 4500 watts

Air pressure & flow required, max 40 PSI, 3.5 CFM

Overall footprint, H x W x D - inches 27 x 21 x 21

Total shipping weight with aluminum oxide 185 lbs

Warranty 1 year

Order code ATS1011

Accessories

Retort lid ATS1020

Parts basket ATS1022

100 pound pail of Aluminum oxide ATS1027

Air filter – regulator ATS1026

Hainesport, NJ 08036 USA

Ph: 609-326-3190

Fax: 609-479-5124

Email: sales@accuthermal.com

Website: www.accuthermal.com

Loading...

Loading...