Page 1

m Powerful 6-parallel push-pull output stage deliv ers linear

power into ultra-low impedance loads m Current feedback

guarantees great sound and stable operation m Bridged

connection mode allows upgrading to true monophonic

amplifier m Printed circuit boards made from T eflon material

m Massive Super Ring toroidal transformer rated for 1 kV A

Page 2

Astounding energy emerging from perfect poise – witness a stereo po wer

amplifier capable of delivering 720 watts (actual measurement) into 1ohm loads. Massive power supply with 1000 VA toroidal transformer

and wide-band high-power transistors in 6-parallel push-pull

configuration ensure constant-voltage drive. Teflon printed circuit

boards feature low dielectric constant and low loss. Current feedback

topology guarantees stable operation up to ultra high frequencies.

Accuphase power amplifiers are designed to

realize two major goals: very low output

impedance (Note 1), and constant drive voltage

(Note 2). As a result, Accuphase amplifiers are

capable of driving any kind of speaker load with

optimum results, which is one of the reasons

behind the high praise that these products

invariably receive. The low impedance not only

ensures accurate speaker driv e b ut also absorbs

the counterelectromotive force generated by the

voice coil, thereby eliminating a major source of

intermodulation distortion. The ove rall result is a

significant improvement in sound quality.

The P-650 is a stereo power amplifier which fully

implements these advanced circuit design

principles. Using only strictly selected high-quality

parts, this product was designed with a full

mastery of all aspects of amplifier performance.

The output uses six pairs of high-power transistors

in each channel, arranged in a parallel push-pull

configuration. These devices are mounted to

massive heat sinks located on both sides of the

unit, for efficient dissipation of thermal energy.

Power linearity is maintained down to extremely

low load impedances. This allows the amplifier to

easily drive even speakers with very low

impedance or uneven impedance curves . By using

the P-650 in bridged mode, you can create a mono

amplifier with even more impressive power

reserves.

Current feedback topology combines total

operation stability with excellent frequency

response, while requiring only minimal amounts

of negative feedback. The printed circuit boards

of the P-650 are made of a Teflon material with

extremely low dielectric constant and low loss,

resulting in more transparent sound. The front

panel in traditional champagne gold features two

large analog power meters. The elegant and

sophisticated appearance of the amplifier will

enhance every listening room.

BIAS STABILIZER

CIRCUIT

Q

–

+

INPUT

INPUT

Q

Q

1

2

BIAS STABILIZER

CIRCUIT

3

Q

4

–

Q

+

+

–

5

Q

6

Figure 1 Circuit diagram of amplifier section (one channel)

Note 1: Low amplifier output impedance

The load of a power amplifier, namely the loudspeaker generates a

counterelectromotive force that can flow back into the amplifier via the NF

loop. This phenomenon is influenced by fluctuations in speaker impedance,

and interferes with the drive perfo rmance of the amplifier. The output impedance

of a power amplifier should therefore be made as low as possible by using

output devices with high current capability.

Note 2: Constant drive voltage principle

Even in the presence of a load with wildly fluctuating impedance, the ideal

power amplifier should deliver a constant voltage signal to the load. When the

supplied voltage remains constant for any impedance, output power will be

inversely proportional to the impedance of the load. A conventional amplifier

can be easily made to operate in this way down to a load impedance of about

4 ohms. Howe ver , at 2 ohms and below , much more substantial output reserves

are needed, which can only be sustained by an extremely well designed and

capable output stage and a highly robust and powerful power supply section.

To build such an amplifier is a task that requires not only considerable

experience and resources but also a thorough reappraisal of basic tenets.

Power units with 6-parallel push-pull

configuration deliver ample linear power: 400

watts into 2 ohms, 200 watts into 4 ohms, or

100 watts into 8 ohms

The output stage uses high power transistors with

excellent linearity and switching characteristics,

rated for a collector dissipation of 130 watts and

collector current of 15 amperes. These transistors

are arranged in a 6-parallel push-pull configuration

(Figure 1) and mounted on massive heat sinks

made from diecast aluminum, for efficient heat

dissipation. This enables the P-650 to eff ortlessly

drive even speakers with e xtremely low impedance

or with reactive loads.

Figure 2 shows the output/voltage characteristics

at various load impedances. It can be seen that

output voltage remains nearly constant regardless

Q

7

Q

9

BIAS STABILIZER CIRCUIT

Q

10

Q

8

REGULATOR

–

B

1

Figure 2 Load impedance vs. output power

(output voltage/output current) of P-650

of load, which means that output current increases

linearly. The actually measured clipping power is

an impressive 720 watts into 1 ohm, 518 watts

into 2 ohms, 320 watts into 4 ohms, or 178 watts

into 8 ohms.

Current feedback circuit topology prevents

phase shifts

The P-650 employs the so-called current feedbac k

principle. Figure 3 shows the operating principle

of this circuit. At the sensing point of the f eedback

loop, the impedance is kept low and current

detection is performed. An impedance-conv erting

amplifier then converts the current into a voltage

to be used as the feedback signal. Since the

impedance at the current feedback point (current

adder in Figure 3) is very low, there is

almost no phase shift. Phase

compensation can be kept to a minimum,

resulting in excellent transient response

and superb sonic transparency.

Figure 4 shows frequency response for

different gain settings of the current

feedback amplifier. The graphs

demonstrate that response remains

uniform over a wide range.

OUTPUT

Page 3

Bridged mode creates a true monophonic

amplifier with 800 watts into 4 ohms or 400

watts into 8 ohms

Bridged operation means that two amplifiers are

driven by the same signal voltage but with opposite

phase. The P-650 pro vides a switch arrangement

for bridged operation of its two channels, which

turns the unit into a high-grade monaural amplifier

with even higher output capability.

Easy switching between dual mono operation

and bridged connection

A mode selector on the rear panel makes it simple

to switch between dual

mono, stereo, or

bridged operation. The

dual mono position is

useful for example to

drive a center woofer in

mono, or to obtain the

same signal from both

speaker outputs for driving a bi-amped speaker

setup.

minimizes leak currents between patterns and

results in more speedy signal propagation. Low

losses mean further enhanced signal purity. S/N

ratio also is excellent.

* Teflon is a registered trademark of DuPont USA.

Balanced connection reliably blocks induced

noise

Balanced signal transmission means that two

signal lines are

used which carry

the same signal

with opposite

phase. On the

receiving side,

the signals are

mixed. Since any

noise interference that has

arisen during

transmission will

be present in

both lines with identical phase, such noise is

canceled out, leaving only the pure original signal.

Balanced connection therefore keeps the signal

transfer free from an y kind of interference.

All major signal paths gold-plated

The P-650 uses gold-plating for the copper traces

on printed

circuit boards

as well as for

ground bars

carrying large

ripple currents, bus

bars providing current to the power transistors,

input jacks, and speaker terminals. This thorough

approach results in a distinct sonic improvement.

Robust power supply with "Super Ring"

toroidal transformer and high filtering capacity

The P-650 features a large toroidal power

transformer with a rating of about 1 kVA. Toroidal

Printed circuit boards made from Teflon

material (glass cloth fluorocarbon resin) with

low dielectric constant and low loss

The power amplification circuit boards are made

of a glass cloth fluorocarbon resin material which

has a stable, low dielectric constant as well as

superior heat resistance and high-frequency

characteristics. The low dielectr ic constant

n 6-parallel push-pull output stage

with transistors mounted directly

to large aluminum diecast heat

sinks. Power amplifier assembly

with Teflon PCBs and current

feedback amplifier circuitry.

Page 4

power transf ormers

use heavy-gauge

copper wiring on a

doughnut-shaped

core. This results in

circular coil windings with high packing density.

Two ultra-large aluminum electrolytic capacitors

rated for 47,000 µF each serve to smooth the

pulsating direct current from the rectifier, providing

more than ample filtering capacity.

low impedance and

high efficiency,

Extra large speaker terminals

while allowing

compact

dimensions. In

particular, the

"Super Ring"

transformer used in

the P-650 has

various

advantages, such

as the near-circular

core caliber,

allowing near-

nn

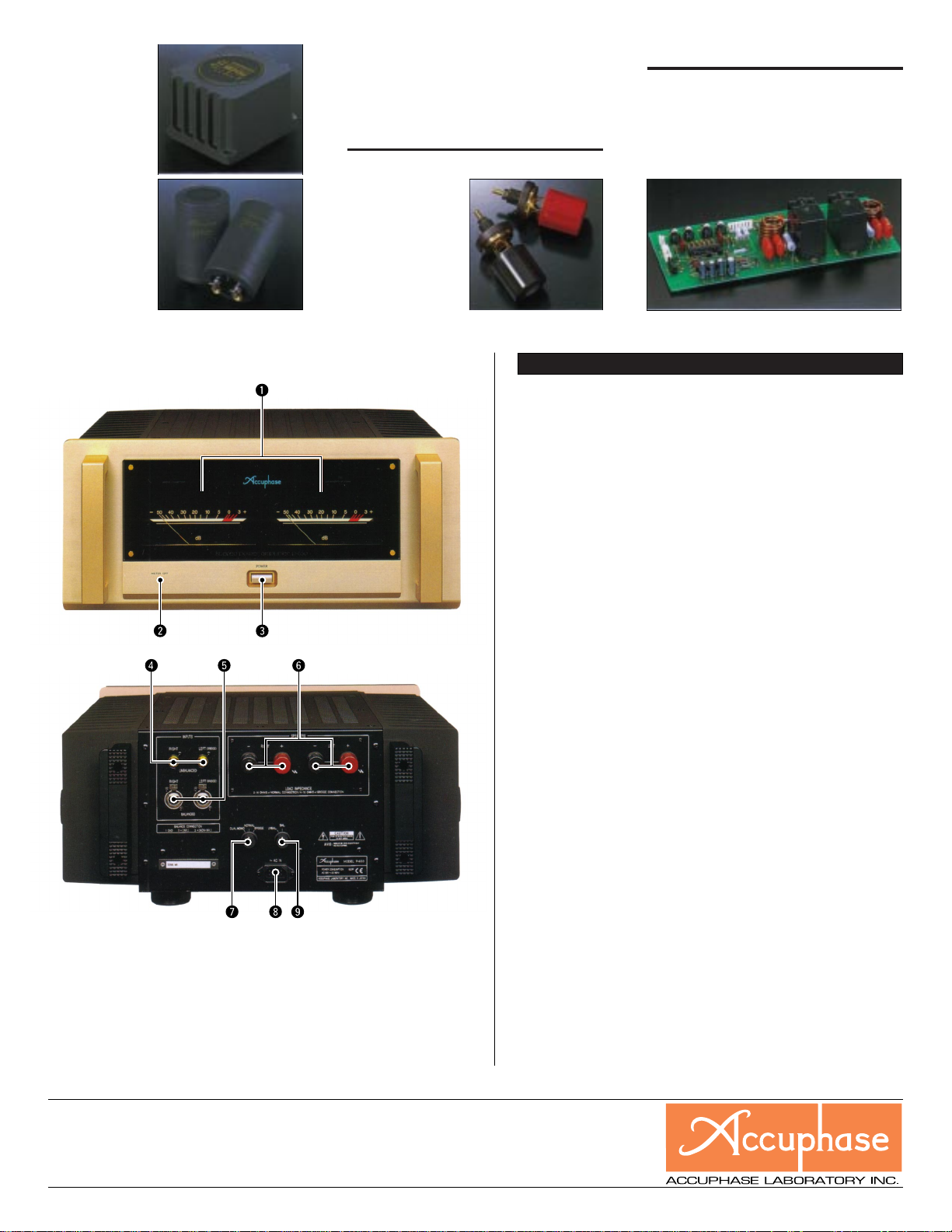

n FRONT PANEL

nn

nn

n REAR PANEL

nn

H

1 P ower meters f or left aand right channel

(dB scale)

2 Meter operation/illumination switch

ON OFF

3 P ower switch

4 Unbalanced inputs

5 Balanced input connectors

a Ground b Inverted (–)

c Non-inverted (+)

Remarks

H

This product is available in versions for 120/230 V AC. Make sure that the voltage shown on the rear panel matches the AC line voltage in your area.

H

The shape of the AC inlet and plug of the supplied power cord depends on the voltage rating and destination country.

❇ Specifications and design subject to change without notice for improvements.

6 Speaker output terminals for left and right

channel

7 Mode selector

DUAL MONO NORMAL BRIDGE

8 AC input connector

(for supplied power cord)

9 Input selector

UNBAL BAL

The oversize speaker terminals accept also very

heavy-gauge speaker

cable. The terminals

are made of extruded

high-purity brass

material and are gold-

plated for utmost

reliability and minimum

contact resistance.

Molded caps provide

proper insulation.

(Guaranteed specifications are measured according to EIA standard RS-490.)

mm

m Continuous Average Output (20 to 20,000 Hz)

mm

Stereo mode ,0650 watts per channel into 1 ohms*

(both channels driven) ,0400 watts per channel into 2 ohms

Monophonic mode 1,300 watts into 2 ohms*

(bridge connection) ,0800 watts into 4 ohms

mm

m Total Harmonic Distortion

mm

Stereo mode (both channels driven)

Monophonic operation (bridged connection)

mm

m Intermodulation Distortion 0.003%

mm

mm

m Frequency Response At rated output: 20 - 20,000 Hz +0, –0.2 dB

mm

mm

m Gain 28.0 dB (in stereo and monophonic operation)

mm

mm

m Output Load Impedance Stereo operation: 2 to 16 ohms

mm

mm

m Damping Factor 270 (stereo/monophonic operation)

mm

mm

m Input Sensitivity (with an 8-ohm load) Stereo mode 1.12 V for rated output

mm

mm

m Input Impedance Balanced: 40 kilohms

mm

mm

m Signal-to-Noise Ratio 120 dB (rated continuous average output)

mm

(A-weighted, input shorted)

mm

m Output Level Meters –50 dB to +3 dB, logarithmic scale,

mm

mm

m Power Requirements 120V/230V (Voltage as indicated on rear panel)

mm

mm

m Power Consumption 80 watts idle

mm

mm

m Maximum Dimensions Width: 475 mm (18-11/16")

H

mm

mm

m Weight 38 kg (83.8 lbs.) net

mm

Large direct-reading analog power meters

The large analog power meters cover a wide

dynamic range and provide direct readings.

Switches for meter on/off and illumination control

are also provided.

Assembly with protection circuitry, etc.

P-650 Guaranteed Specifications

,0200 watts per channel into 4 ohms

,0100 watts per channel into 8 ohms

Note: Ratings marked

,0400 watts into 8 ohms

Note: Ratings marked

0.05% with 2-ohm load

0.02% with 4- to 16-ohm load

0.02% with 4- to 16-ohm load

At 1 watt output: 0.5 - 160,000 Hz +0, –3.0 dB

Monophonic operation: 4 to 16 ohms

H

With music signals, load impedance of 1 ohm (stereo)

or 2 ohms (mono) can be driven.

Monophonic mode

Unbalanced: 20 kilohms

OFF switch provided

AC, 50/60Hz

625 watts in accordance with IEC-65

Height: 223 mm (8-3/4")

Depth: 491 mm (16-1/2")

48 kg (105.8 lbs.) in shipping carton.

H

are for music signals only.

H

are for music signals only.

0.11 V for 1 watt output

2.25 V for rated output

0.11 V for 1 watt output

http://www.accuphase.com/

PRINTED IN JAPAN F0010 851-0168-00 (AD1)

Loading...

Loading...