Accuenergy ACUVIM-EL-D-RCT-P2V4, ACUVIM-CL-M-333-P2V4, ACUVIM-EL-M-RCT-P2V4, ACUVIM-EL-M-333-P2V4, ACUVIM-EL-M-RCT-P1V4 User manual

...Page 1

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

1

[Cover page]

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

2

Copyright© 2013 V2.02

This manual may not be altered or reproduced in whole or in part by any means

without the expressed written consent of Accuenergy.

The information contained in this document is believed to be accurate at the time of

publication, however, Accuenergy assumes no responsibility for any errors which may

appear here and reserves the right to make changes without notice. Please ask the

local representative for latest product specifications before ordering.

[ Document #1030E2202 Revision Date: October 2018]

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

3

Please read this manual carefully before installation, operation and maintenance of

Acuvim-L power meter.

The following symbols in this manual and on Acuvim-L series meters are used to

provide warning of danger or risk during the installation and operation of the meters.

Electric Shock Symbol: Carries information about procedures which must

be followed to reduce the risk of electric shock and danger to personal

health.

Safety Alert Symbol: Carries information about circumstances which if not

considered may result in injury or death.

This mark indicates that this product is UL listed.

Installation and maintenance of the Acuvim-L power meter should only be performed

by qualified, competent professionals who have received training and should have

experience with high voltage and current device.

Accuenergy shall not be responsible or liable for any damages caused by improper

meter installation and/or operation.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

4

CONTENTS

Chapter 1: Introduction .................................................................................................. 8

1.1 Functionality ................................................................................................................... 8

1.2 Areas of Application ........................................................................................................ 9

1.3 Meter Overview .............................................................................................................. 9

Chapter 2 Installation ................................................................................................... 13

2.1 Appearance and Dimensions ......................................................................................... 14

2.2 Installation Methods ..................................................................................................... 17

2.3 Wiring ........................................................................................................................... 20

2.3.1 Terminal Strips ....................................................................................................... 20

2.3.2 Power Requirement ............................................................................................... 23

2.3.3 Voltage Input Wiring .............................................................................................. 25

2.3.4 Current Input Wiring .............................................................................................. 28

2.3.5 Frequently Used Wiring Method ............................................................................ 30

2.3.6 Digital Output (DO) ................................................................................................. 34

2.3.7 Digital Input (DI) ..................................................................................................... 35

2.3.8 Communication ...................................................................................................... 35

Chapter 3: Meter Display and Parameter Settings ................................................ 38

3.1 Display Panel and Keys .................................................................................................. 38

3.2 Metering Data ............................................................................................................... 40

3.3 Statistics Display ............................................................................................................ 48

3.4 System Parameter Setting ............................................................................................. 53

3.5 DO Parameter Setting and Expansion Module Setting (BL, DL, EL) ................................. 61

3.6 Ethernet Network Module Settings ............................................................................... 68

3.7 DI status Display function .............................................................................................. 72

3.8 TOU Energy and Maximum Demand Display ................................................................. 73

3.9 Acuvim-L Measurement Methods and Parameter Definitions ....................................... 76

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

5

Chapter 4 Communications

4.1 Modbus Protocol Introduction....................................................................................... 90

4.2 Modbus Protocol ........................................................................................................... 91

4.3 Communications Format ............................................................................................... 93

4.4 Ethernet Module (AXM Net) .......................................................................................... 97

4.4.1 Introduction to Ethernet ......................................................................................... 97

4.4.2 Function Description of Ethernet module ............................................................... 98

4.4.3 Appearance and Dimensions................................................................................... 98

4.4.4 Installation Method .............................................................................................. 100

4.4.5 Definition of RJ45 Interface................................................................................... 101

4.4.6 Cable .................................................................................................................... 102

4.4.7 Connection Method .............................................................................................. 102

4.4.8 Initializing Ethernet Module .................................................................................. 102

4.4.9 Searching IP Address of Ethernet Module ............................................................. 107

4.4.10 Description of Modbus-TCP protocol .................................................................. 108

......................................................................................... 90

4.4.11 Webpage Browsing and Parameter Settings ....................................................... 118

4.4.12 Email Function .................................................................................................... 126

4.4.13 SNMP Function ................................................................................................... 126

4.4.14 SNTP Function..................................................................................................... 132

4.5 Data Address Table ...................................................................................................... 133

Appendix ........................................................................................................................ 164

Appendix A Technical Data and Specification .................................................................... 164

Appendix B Ordering Information ...................................................................................... 168

Appendix C Revision History .............................................................................................. 170

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

6

Congratulations!

You have purchased an advanced, versatile and multifunction power meter. This

meter can work as a remote terminal unit (RTU) that contributes to your system’s

stability and reliability by providing real-time power quality monitoring and analysis.

When you open the package, you will find the following items:

1. Acuvim-L power meter 1

2. Terminal Blocks 3 (2 for basic model)

3. [INSERT] Installation Clips 4

4. Product Disk (Manual, Warranty, Software) 1

5. Additional documentation

(Quick Setup Guide, Calibration Certificate) 2

To avoid complications, please read this manual carefully before installation and

operation of the Acuvim-L series meter.

Chapter 1 Chapter 1 Introduction.

Chapter 2 Installation and Wiring.

Chapter 3 Meter Display and Parameter Settings.

Chapter 4 Communication Protocols and Modbus Map.

Appendix Technical Data, Specifications and Ordering Information.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

7

Acuvim-L Series Power Meter

Chapter 1 Introduction

1.2 Areas of Application

1.1 Functionality

1.3 Meter Overview

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

8

Chapter 1: Introduction

1.1 Functionality

Multifunction, high accuracy

Acuvim-L series multifunction power meter is designed with the latest

microprocessor and digital signal process technology. It can measure voltage,

current, active power, reactive power, apparent power, power factor for three

phases, individual harmonics up to the 2nd or 31th order, THD, real and reactive

energy, current and demand and max/min values for real time readings.

The optional Digital Output and RS485 communication can be used for sending

energy pulse output and event alarming signals. The RS485 port also can be used

for remote meter controlling and data collection. Acuvim-L series meter delivers

exceptional metering functionality and provides a cost-effective solution for

customers.

Compact and Easy to Install

Acuvim-L series meter can be installed into a standard ANSI C39.1 (4" round) or an

IEC 92mm DIN (square) slot. With the 51mm depth, the meter can be installed in

a small cabin. Installation clips are used for easy installation and removal.

Easy to use

All metering data and setting parameters can be accessed by using the front panel

keys or via the communication port. Setting parameters are stored in the EEPROM

so that content will be maintained even when the meter is powered off.

Multiple Wiring Modes

The Acuvim-L series meter can be used in high voltage, low voltage, three phase

three wires, three phase four wires and single-phase systems by using different

wiring mode settings.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

9

1.2 Areas of Application

Acuvim-L series meter is the ideal choice for replacing traditional, analog

electric meters. It uses true RMS measuring methods so that nonlinear load can

be monitored. Except providing means of monitoring and measuring power

distribution automation system, it can also be used as a remote terminal unit

(RTU) for monitoring and controlling a SCADA system. Users can access all

measurement parameters via the optional RS485 communication port with

Modbus

TM

protocol. Main application areas Electric Switch Gear and Control

Panels include:

• Power Distribution Automation

• Electric Switch Gear and Control Panels

• Industrial Automation

• Building Automation

• Energy Management Systems

• Marine Applications

• Renewable Energy

1.3 Meter Overview

Multifunction

The Acuvim-L series have six standalone models: Acuvim-AL (basic model),

Acuvim-BL (basic model + 2DO), Acuvim-CL (basic model + RS485), AcuvimDL

(basic model + RS485 + Extend IO), Acuvim-EL(TOU + RS485 + Extend IO) and

Acuvim-KL (Simplified Acuvim-CL). Please see table 1-1 for their functionalities

and details.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

10

Function

Parameters

AL

BL

CL

DL

EL

KL

Real Time

Measuring

Voltage

U1, U2, U3,U12, U23,

U31

= = = = =

Current

I1, I2, I3,In,(AcuvimKL

non-neutral current

measurement)

= = = = =

=

Power

P1, P2, P3, Psum

= = = = =

=

Reactive Power

Q1, Q2, Q3, Qsum

= = = = =

=

Apparent Power

S1, S2, S3, Ssum

= = = = =

=

Power Factor

PF1, PF2, PF3, PF

= = = = =

=

Load Nature

L/C/R

= = = = =

Frequency

F

= = = = =

Energy

Energy

Ep_imp, Ep_exp

= = = = =

Reactive Energy

Eq_imp, Eq_exp

= = = = =

Apparent Energy

Es

= = = = =

Demand

Current Demand

Dmd_I1, Dmd_I2,

Dmd_I3

= = = = =

Power Demand

Dmd_Psum, Dmd_

Qsum, Dmd_Ssum

= = = = =

TOU

E n e r g y / m a x

demand

TOU, 4 Tariffs, 12

Seasons, 14 Schedules

=

Daylight Saving

Time

Daylight saving time

automatically adjust

=

10-year holidays

U p t o d e c a d e

holidays settings

=

Power Quality

Voltage

Unbalance

U_unbl

= = = = =

Current

Unbalance

I_unbl

= = = = =

Voltage THD

THD_V1, THD_V2,

THD_V3

= = = = =

Current THD

THD_I1, THD_I2, THD_I3

= = = = =

Individual

Harmonics

2nd to 31th (Voltage and

Current)

= = = = =

Statistics

Max Current

Demand

Dmd_I1_max, Dmd_I2

_max, Dmd_I3_max

= = = = =

Max Power

Demand

Dmd_Psum_max,

Dmd_Qsum_max,

Dmd_Ssum_max

= = = = =

Max/Min

Voltage

Umax, Umin

= = = = =

Max/Min

Current

Imax, Imin

= = = = =

Hour

Running Hour

Hour

= = = = =

=

Table 1-1 Functions of Acuvim-L series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

11

Load Running

Hour

Hour

= = = = =

=

I/O

Energy Pulse

Output/Alarm

Output

2 DO(Standard)

=

Expansion I/O

module

4DI, 2DO/2RO

8 8

COMMUNICATIONS

RS-485

Modbus®-RTU

Protocol(Standard)

= = =

=

Ethernet

(Extended

communication

module)

Modbus®-TCP, HTTP,

SMTP, SNMP, SNTP

8 8

Second RS-485

Modbus®-RTU Protocol/

8 8

PROFIBUS

(Extended

communication

module)

PROFIBUS-DP (V0)

Protocol, according to

EN50170 standards

8 8

=

Possessed functions; 8 Optional Functions ; Blank NA

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Acuvim-L Series Power Meter

Chapter 1: Introduction

V:2.0 Revised October 2018

12

Acuvim-L Series Power Meter

2.1 Appearance and Dimensions

2.2 Installation Methods

Chapter 2 Installation

2.3 Wiring

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Acuvim-L Series Power Meter

V:2.0 Revised October 2018

13

Chapter 2 Installation

Considerations When Installing Meters

• Installation of the meter must be performed by qualified personnel only, who

follow standard safety precautions through the installation procedures. Those

personnel should have appropriate training and experience with high voltage

devices. Appropriate safety gloves, safety glasses and protective clothing are

recommended.

• During normal operation, dangerous voltage may flow through many parts of

the meter, including: terminals, any connected CTs (Current Transformers) and PTs

(Potential Transformers), all I/O (Inputs and Outputs) modules and their circuits.

All primary and secondary circuits can, at times, produce lethal voltages and

currents. Avoid contact with any current-carrying surfaces.

• The meter and its I/O output channels are NOT designed as primary protection

devices and shall NOT be used for primary circuit protection or in an energy-limiting

capacity. The meter and its I/O output channels can only be used as secondary

protection. AVOID using the meter under situations where failure of the meter may

cause injury or death. AVOID using the meter for any application where risk of fire

may occur.

• All meter terminals should be inaccessible after installation.

• Do NOT perform Dielectric (HIPOT) test to any inputs, outputs or communication

terminals. High voltage testing may damage electronic components of the meter.

• Applying more than the maximum voltage the meter and/or its modules can

withstand will permanently damage the meter and/or its modules. Please refer to

the specifications for all devices before applying voltages.

The installation method is introduced in the chapter. Please read this chapter carefully

before beginning installation.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

14

2.1 Appearance and Dimensions

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

15

Part Name

Description

1. LCD Display

Large bright white backlight LCD display.

2. Front Casing

Visible portion (for display and control)

after mounting onto a panel.

3. Key

Four keys are used to select display and

set.

4. Enclosure

The Acuvim-L series meter enclosures is

made of high strength anti-combustible

engineering plastic.

5. DIN rail

Used for Installation 35mm rail of the DIN

rail Meter.

6. Voltage Input Terminals

Used for voltage input.

7. Current Input Terminals

Used for current input.

8. Power Supply Terminals

Used for control power supply input

9. Communication Terminals

Communication output.

10. Interface

Used for link the remote display unit and

the DIN rail meter.

11. Installation Clip

Used for fixing the meter to the panel.

12. Gasket

Insert the gasket in between the meter

and the cutout to cover up gaps from the

round hole.

Fig.2-1 Appearance and dimensions

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

16

IO module appearance and mechanical dimensions

Fig.2-2 structure configuration of IO modules

PROFIBUS module and Ethernet module appearance and mechanical dimensions

Fig.2-3 structure configuration of PROFIBUS modules

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

17

2.2 Installation Methods

Environmental

Please check the environmental temperature

and humidity according to Acuvim - L’s

requirement to ensure the power meter can

work well.

Temperature

Operation: -25˚C to 70˚C.

Storage: -40˚C to 85˚C

Humidity

5% to 95% non-condensing.

Location

Acuvim-L power meter should be installed in a dry and dust free environment. Avoid exposing

meter to excessive heat, radiation and high electrical noise source.

Installation Steps

Acuvim-L series meter can be installed into a standard ANSI C39.1 (4” round) or an IEC 92mm

DIN (square) form.

1. Cut a square or round hole on the panel of the switch gear. The cutting size shows as Fig.2-

4.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

18

2. Remove the clips from the meter and put Acuvim-L into the square hole from the front

side.

Install the clips to the meter from backside and push the clips tightly so that the meter is

fixed on the panel.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

19

Module Installation

(1) The extend module could be installed from the bottom of the meter.

(2) The extend module is fixed on the meter by the screw.

(3) Please install the PROFIBUS module first if both IO and PROFIBUS module are selected.

(4)Please install the Ethernet module first if both IO and Ethernet module are selected.

Note: Acuvim-DL and Acuvim-EL Power meter can connect at most one IO module, one

PROFIBUS module and one Ethernet module at the same time.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

20

2.3 Wiring

2.3.1 Terminal Strips

There are three or four terminal strips at the back of the Acuvim-L series meter

depending on different models. The terminal strip diagrams are shown in below. The

three phase voltage and current are represented by using 1, 2, and 3 respectively.

These numbers have the same meaning as A, B, and C or R, S, and T used in other

literature.

Current Input Terminal Strip

Voltage Input Terminal Strip

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

21

Communication terminal strips

Digital output terminal strips

Power Supply Terminal Strip

Find Quality Products Online at: sales@GlobalTestSupply.com

Fig.2-8 Terminal diagram of Acuvim-L

www.GlobalTestSupply.com

Page 22

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

22

Before setting up the meter’s wiring, please make

sure that the switch gear has an earth ground

terminal. Connect both the meter and the switch

gear ground terminals together. The following

ground terminal symbol is used in this user’s

manual.

Note: Acuvim-AL does not have digital output and communication terminal strips Acuvim-BL

has digital output terminal strip Acuvim-CL/DL/EL/KL have communication terminal strip

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

23

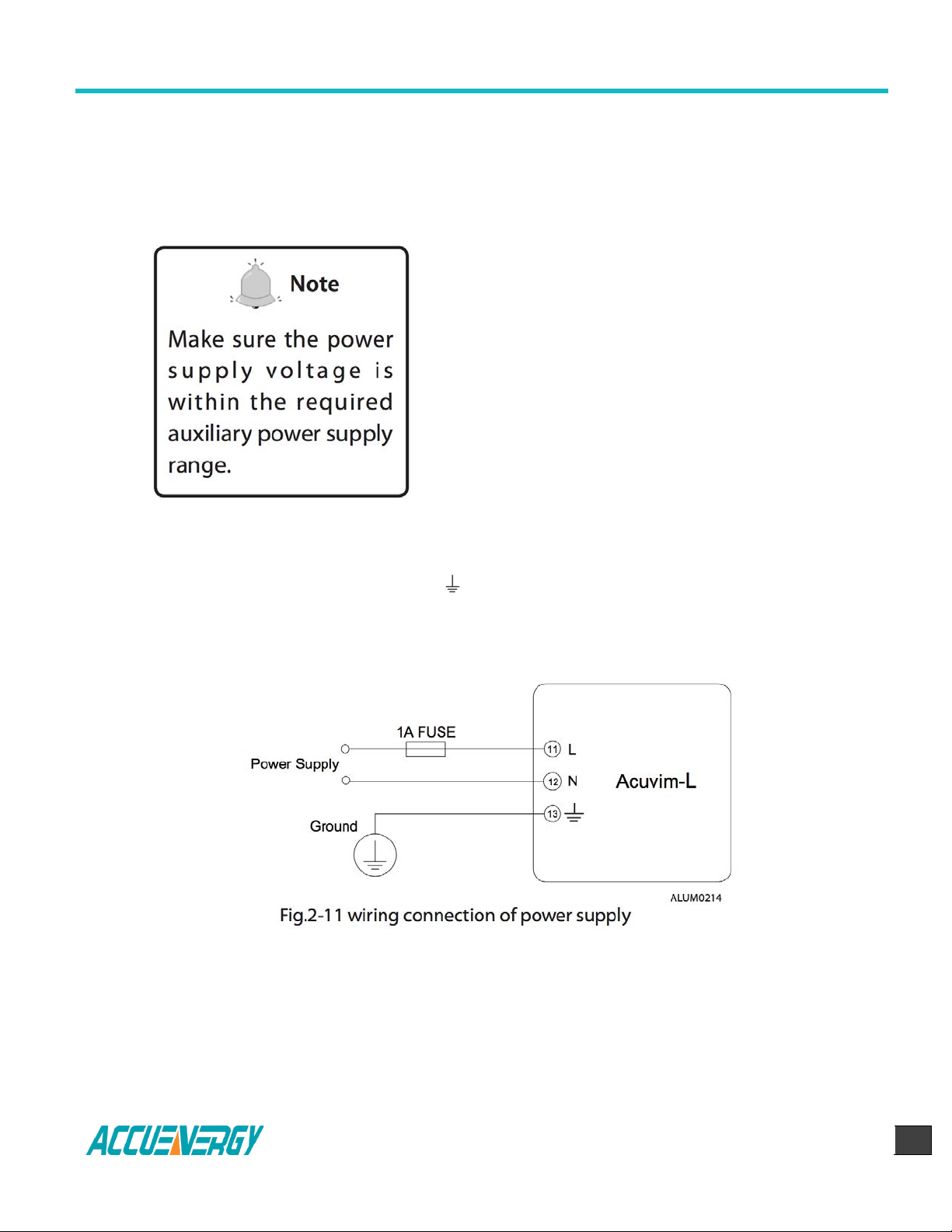

2.3.2 Power Requirement

Auxiliary power

There are two Auxiliary Power Supply options for

the Acuvim-L series meter:

1. Standard: 100~415Vac (50/60Hz) or 100~300Vdc

2. Low Voltage DC Option: 20-60Vdc

Choose the option according to the application.

The meter’s typical power consumption is very low

and can be supplied by an independent source or

by the measured load line. A regulator or an

uninterrupted power supply (UPS) should be used

under high power fluctuation conditions. Terminals

for the auxiliary power supply are 11, 12 , 13 (L, N,

).

The typical wiring connection is shown as Fig.2-11.

Find Quality Products Online at: sales@GlobalTestSupply.com

The wire of power supply should be AWG22-16 or 0.6-1.3mm2 . A fuse (typical 1A/250Vac)

should be used in the auxiliary power supply loop. No.13 terminal must be connected to the

ground terminal of switchgear. An isolated transformer or EMC filter should be used in the

auxiliary power supply loop if there is a power quality problem in the power supply.

www.GlobalTestSupply.com

Page 24

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

24

Voltage Input

Maximum input voltage for the Acuvim-L series meter shall not exceed 400LN/690LL VAC rms

for three phase or 400LN VAC rms for single phase. Potential Transformer (PT) must be used

for high voltage systems. Typical secondary output for PTs shall be less than or equal to 400V.

Please make sure to select an approprate PT to maintain the measurement accuracy of the

meter.

A fuse (typical 1A) should be used in the voltage input

loop. The wire for voltage input could be AWG16-12 or

1.3-2.0mm2.

Note: In no circumstance should the secondary of the

PT be shorted. The secondary the PT should be

grounded at one end.

Please refer to the wiring diagram section for further

details.

Current Input

Current Transformers (CTs) are required in most engineering applications. Typical current

rating for the secondary side of the CT shall be 5A (standard) or 1A (optional, please refer to

the ordering information appendix for further details). CTs must be used if the system rated

current is over 5A. The accuracy of the CT should be better than 0.5% with rating over 3VA is

recommended in order to preserve the meter’s accuracy. The wire between CTs and the

meter shall be as short as possible. The length of the wire may increase the error of the

measurement.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

25

The wire size of current input could be AWG15-16 or 1.5-2.5mm2.

Note: The secondary side of the CT should not be open circuit in any circumstance when the

power is on. There should not be any fuse or switch in the CT loop. One end of the CT loop

should be connected to the ground.

Vn connection

Vn is the reference point of the Acuvim-L voltage input. Low wire resistance helps improve

the measurement accuracy. Different system wiring modes require different Vn connection

method. Please refer to the wiring diagram section for more details.

Three phase wiring diagram

Acuvim-L can satisfy almost all kinds of three phase wiring diagram. Please read this section

carefully before choosing the wiring diagram suitable for your power system.

Voltage and current input wiring mode can be set separately in the meter parameter setting

process. The voltage wiring mode can be set as 3-phase 4-line Wye(3LN), 3-phase 3-line

direct connection mode(3LL), 3-phase 3-line open delta (2LL), single-phase two-line(1LN)

and single-phase three-line(1LL). The current input wiring mode can be set as 3CT, 2CT and

1CT. Any voltage wiring setup can be matched with any one of the current wiring setup.

2.3.3 Voltage Input Wiring

3-Phase 4-Line Wye mode (3LN)

The 3-Phase 4-Line Wye mode is popularly used in low voltage electric distribution power

system. For voltage lower than 400LN/690LL Vac, power line can be connected directly to

the meter’s voltage input port as shown in Fig.2-13a. In the high voltage input system, 3PT

Wye mode is often used as in Fig.2-13b. The meter should be set to 3LN for both voltage

levels.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

26

3-Phase 3-Line Direct Connection Mode (3LL)

In a 3-Phase 3-Line system, power line A, B and C are connected to V1, V2 and V3

directly. Vn is floated. The voltage input mode of the meter should be set to 3LL.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

27

3-Phase 3-Line open Delta Mode (2LL)

Open delta wiring mode is often used in high voltage system. V2 and Vn connected

together in this mode. The voltage input mode of the meter should be set to 2LL for

this voltage input wiring mode.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

28

2.3.4 Current Input Wiring

3CT

The 3CT current wiring configuration can be used when either 3CTs are connected (as

shown in Fig.2-16) or 2CTs are connected (as shown in Fig.2-17) to the system. In either

case, there is current flowing through all three current terminals.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

29

2CT

The difference between Fig.2-17 and Fig.2-18 is that no current flows through current

input terminal I21 and I22. The I2 value is calculated from formula i1+i2+i3=0. The

current input mode of the meter should be set to 2CT .

1CT

The current input mode of the meter should be set to 1CT

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

30

2.3.5 Frequently Used Wiring Method

In this section, most common voltage and current wiring connection combinations are

put together into different diagrams. In order to display measurement readings correctly,

please select the appropriate wiring diagram according your setup and application.

Note: Acuvim-L supports 3LN-3CT (Using the 3CT and a 2CT two wiring), 3LL-3CT, 2LL3CT, 2LL-2CT, 1LL-2CT and 1LN-1CT.

1. 3LN, 3CT with 3 CTs (Wiring mode: 3LN, 3CT)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

31

2. 3LN, 3CT with 2 CTs (Wiring mode: 3LN,3CT)

3. 3LL,3CT (Wiring mode:3LL,3CT)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

32

4. 2LL, 3CT (Wiring mode: 2LL, 3CT)

5. 2LL, 2CT (Wiring mode: 2LL, 2CT)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

33

6. 1LL, 2CT (Wiring mode setting 1LL, 2CT)

7. 1LL, 2CT (Wiring mode setting 1LL, 2CT)

Note: For the 1LL, 2CT, A and B facies of the phase Angle is 1800.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

34

2.3.6 Digital Output (DO)

There are two digital outputs for Acuvim-L. For the Acuvim-BL, the terminals of the

digital output are DO1, DO2 and DOC . For the Acuvim-DL/EL, the terminals

of the digital output respectively is DO11, DO12 and DO21, DO22.These two digital

outputs can be used as energy pulse output or over/under limit alarming output.

Digital output circuit form is Photo-MOS. The simplified circuit is as below:

The max output voltage and current are 250Vac/300Vdc and 100mA. When the digital

output is used as over/under limit alarming output, the upper and lower limit of the

parameter, time interval and output port can be set from the meter front.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

35

2.3.7 Digital Input (DI)

There are 4 dry-contact digital input in extension modules respectively. The digital

input circuit can be used to detect remote signals, or be used as a counter of input

pulses.

The circuit drawing of digital input is simplified as fig.2-28. When K is switched off,

OUT is in high state. When K is switched on, OUT is in low state. The wire of digital

input should be chosen between AWG22~16 or 0.5~1.3mm2.

2.3.8 Communication

Acuvim-L series meter uses RS485 serial communication and the ModbusRTU

protocol. The terminals of communication are A, B, and S (14, 15 and 16). A is

differential signal +, B is differential signal - and S is connected to the shield of twisted

pair cable. Up to 32 devices can be connected on a RS485 bus. Use good quality

shielded twisted pair cable, AWG22 (0.5mm2) or larger. The overall length of the

RS485 cable connecting all devices can not exceed 1200m (4000ft). Acuvim-L series

meter can be used as a slave device of a master device such as PC, PLC, Data Collector

and RTU.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

36

If the master does not have RS485 communication port, a converter (such as a

RS232/RS485 or a USB/RS485 converter) will be required. Typical RS485 network

topologies include line, circle and star (wye).

Data transfer format is start bit + 8 data bits + parity + stop bit. NON1, NON2, odd and

EVEN could be selected in the mode of parity. NON1 represents non-parity, single stop

bit; NON2 represents non-parity, double stop bit; odd represents odd parity, single

stop bit; EVEN represents EVEN-parity, single stop bit.

All meter has been standardized. In order to improve the quality of communications,

now offers the following Suggestions:

The shield of the RS485 cable must be connected to the ground at one end only. Every

A(+) should be connected to A(+), B(-) to B(-), or it will influence the network, even

damage the communication interface.

“T” type connection topology should be avoided. This means no new branches except

from the starting point.

Keep communication cables away as much as possible from sources of electrical noise.

When several devices are connected (daisy chain) to the same long communication

line, an anti signal reflecting resistor (typical value 120Ω- 300Ω/ 0.25W) is often used

at the end of the circuit (the last meter of the chain) if the communication quality is

distorted.

Use RS232/RS485 or USB/RS485 converter with optical isolated output and surge

protection.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

Acuvim-L Series Power Meter

Chapter 2 Installation

V:2.0 Revised October 2018

37

Acuvim-L Series Power Meter

Chapter 3: Meter Operation and Parameter Setting

3.1 Display Panel and Keys

3.2 Metering Data

3.3 Statistics Display

3.4 System Parameter Setting

3.5 DO Parameter Setting and Expansion Module Setting

3.6 Ethernet Network Module Settings

3.7 DI Status Display

3.8 TOU Energy and Maximum Demand Display

3.9 Measurement Methods and Parameters Definitions

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

38

Chapter 3: Meter Display and Parameter Settings

Operational details of the meter will be described in this chapter. This includes viewing realtime metering data and setting parameters using different key combination.

3.1 Display Panel and Keys

The front of the Acuvim-L series meter consists of an LCD screen and four control keys. All

display segments are shown as Fig.3-1 below:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

39

SN

Display

Description

1

Three lines of " " digits in the

metering area

Display metering data Voltage, current, power,

power factor, THD, frequency, demand,

unbalance factor, max, min etc.

2

Status display area One line of " "

digits at the top of display panel

Display current status Meter: metering status;

Max: maximum value; Min: minimum value;

THD: display Har: display individual harmonic

for voltage and current.

3

Item icon

Item icon

U: voltage; I: current, P: active power; q:

reactive power; PF: power factor; when

displaying harmonic content, the little "8" digits

show the harmonic order.

4

3-phase unbalance

Unbalance icon

5

Load nature

: inductive load;

: capacitive load.

6

Energy Icon

Imp: import energy; exp: export energy

7

Communication icon

No icon: no communication

With icon: communication

8

Energy pulse

output indicator

No icon: no pulse output

With icon: pulse output

9

Time icon

With icon: display running time

10

Units

Indicate data unit

Voltage: V, kV, Current: kA, A, Power: kW and

MW, Reactive Power: kvar and Mvar, Apparent

Power: kVA and MVA, Frequency: Hz, Energy:

kWh, Reactive Power: kvarh, Percentage: %

There are four dedicated keys on the front panel, labeled H, P, E and V/A from left to right.

Use these four keys to read metering data and set the parameters.

Note: If the LCD backlight is off, press any key one time to bring the backlight on

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

40

The 1st screen: Voltage for each phase: U1,

U2 and U3. As shown in Fig.3-2, U1=380.2

V, U2=380.0 V, U3=379.8 V.

Load nature is inductive, and

communication status is good.

Note: Since load nature and

communication status belong to system

information, the icons are displayed on

every screen.

3.2 Metering Data

Acuvim-L series meter displays the voltage metering screen (default screen) when first

powered up. Different key combinations show different screen. Press “V/A” to show realtime metering data; press “E” to show energy parameters; press “P” to show power

parameters; press “H” to show power quality information; press “H” and “E” together

simultaneously to show max/min information, unbalance and individual harmonics.

Press “H” and “V/A” together simultaneously to show basic parameter setting.

Press “P” and “V/A” together simultaneously to show DI Status. Press “E” and “V/A”

together simultaneously to show TOU Energy.

Note: No harmonic contents will be displayed in Acuvim-EL and Acuvim-KL.

Press “V/A” to read voltage and current in the metering area. The screen will proceed to

the next display as you press “V/A” each time. It will go back to the first screen if you press

“V/A” at the last screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

41

Press “V/A” to go to the next screen.

The 2nd screen: Line to line voltage: U12,

U23 and U31. As shown in Fig.3-3,

U12=658.5 V, U23=658.0 V, U31=657.8 V.

Press “V/A” to go to the next screen.

The 3rd screen: Current for each phase: I1,

I2 and I3. As shown in Fig. 3-4, I1=2.501 A,

I2=2.500 A, I3=2.499 A.

Press “V/A” to go to the next screen.

The 4th screen: Neutral current. As shown

in Fig.3-5, In=0.000 A.

Press “V/A” to go to the next screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

42

The 5th screen: Current demand of each

phase.

As shown in Fig.3-6, Dmd_I1=2.503 A,

Dmd_I2=2.501 A, Dmd_I3=2.500 A.

Press “V/A” to go back to the 1st screen.

The 5th screen: Current demand of each

phase.

As shown in Fig.3-6, Dmd_I1=2.503 A,

Dmd_I2=2.501 A, Dmd_I3=2.500 A.

Press “V/A” to go back to the 1st screen.

Note: For Acuvim-KL, only the current page is displayed. When the wiring mode is set to 3LL3CT,2LL-3CT or 2LL-2CT, it will not display phase voltage and neutral current, there is no the

1st and 4th screen. When the wiring mode is set to 1LL2CT, it only shows Uab of 2nd screen,

Ia and Ib of 3rd screen. When the wiring is 1LL-1CT, it only shows Ua of 1st screen and Ia of

3rd screen, not display line voltage and neutral current, there is no the 2nd and 4th screen.

Press “P” to display power related parameters.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

43

The 2nd screen: Reactive power of each

phase.

As shown in Fig.3-8, Q1=0.823 kvar,

Q2=0.823 kvar, Q3=0.822 kvar.

Press “P”, go to the next screen.

Go back to the 1st screen.

The 3rd screen: Apparent power of each

phase.

As shown in Fig.3-9, S1=0.950 kVA,

S2=0.951 kVA, S3=0.950 kVA.

Press “P” to go to the next screen.

The 4th screen: System total power,

reactive power and apparent power.

As shown in Fig.3-10, Psum=1.426 kW,

Qsum=2.471 kvar, Ssum=2.853 kVA.

Press “P” to go to the next screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

44

The 5th screen: Power factor of each

phase: PF1,PF2, PF3.

As shown in Fig.3-11, PF1=0.500,

PF2=0.499, PF3=0.500.

Press “P” to go to the next screen.

The 6th screen: System average power

factor PF and system frequency F.

As shown in Fig.3-12, PF=0.500, F=50.01 Hz.

Press “P” to go to the next screen.

The 7th screen: System power demand

Dmd_P, reactive power demand Dmd_Q

and apparent power demand Dmd_S.

As shown in Fig.3-13, Dmd_P=1.425 kW,

Dmd_Q=2.472 kvar, Dmd_S = 2.850 kVA.

Press “P” to go to the next screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

Note: For Acuvim-KL, only display system power, When the wiring is set to 3LL-3CT, 2LL-3CT

and 2LL-2CT, it will not show single-phase active power of 1st, two single-phase reactive

power of 2nd, single-phase apparent power of 3rd and single-phase power factor of 5th.

www.GlobalTestSupply.com

Page 45

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

45

The 1st screen: Import energy

As shown in Fig. 3-14, Ep_imp=50.9 kWh.

Press “E”, go to the next screen.

The 2nd screen: Export energy.

As shown in Fig. 3-15, Ep_exp=1.8 kWh.

Press “E”, go to the next screen.

The 3rd screen: Inductive (import) reactive

energy.

As shown in Fig. 3-16, Eq_imp=3.9 kvarh.

Press “E” to go to the next screen.

For other series meters, if the wiring is set to 2LL, or 3LL, there is no single-phase power and

single-phase power factor displayed, press P to switch between screens only 4,6,7.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

46

The 4th screen: Capactive (export) reactive

energy.

As shown in Fig. 3-17, Eq_exp=1.5 kvarh.

Press “E” to go to the next screen.

The 5th screen: Apparent energy.

As shown in Fig.3-18, Es = 3.0kVAh.

Press “E” to go to the next screen.

The 6th screen: Run hours.

As shown in Fig.3-19, Run_Hour=12.3

hours.

Press “E” to go to the next screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

47

The 7th screen: Load Run hours.

As shown in Fig.3-20, Load Run hour = 1.3

hours.

Press “E” to go to the next screen.

Note: This screen only applies to Acuvim-DL, EL

and KL.

Note: In real-time metering mode, Acuvim-AL, Acuvim-BL, Acuvim-CL, Acuvim-DL and

Acuvim-EL display voltage and current THD when “H” is pressed.

The 1st screen: Voltage THD.

When voltage wiring mode is set to 3LN, display

shows phase voltage THD: THD_U1, THD_U2,

THD_U3.

As shown in Fig. 3-21, THD_U1=2.32%,

THD_U2=2.35%, THD_U3=2.28%.

When voltage wiring mode is set to 2LL or 3LL, display shows line to line voltage THD:

THD_U12, THD_U23, THD_U31.

As shown in Fig.3-22, THD_U12=2.30%,

THD_U23=2.28%, THD_U31=2.25%.

When voltage wiring mode is set 1LN, display

only shows phase voltage THD: THD-U1. When

voltage wiring mode is set 1LL, display only

shows phase voltage THD: THD-U1 and THD-U2.

Press “H” to go to the next screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

48

The 2nd screen: Phase current THD: THD_I1,

THD_I2, THD_I3.

As shown in Fig 3-23, THD of three phase

current, THD_I1=1.89%, THD_I2=1.83%,

THD_I3=1.85%.

Press “H” key, go back to the 1st screen.

Press “V/A” key under the statistics display

mode to display the Min and Max value of

voltage, current and current demand.

The 1st screen: Max value of phase voltage. The

“Max” icon is shown on the top of screen.

As shown in Fig. 3-24, U1_MAX=380.3 V,

U2_MAX=380.2 V, U3_MAX=380.5 V.

Note: When voltage wiring mode is set to 1LN, display only shows phase current THD: THDI1. When voltage wiring mode is set to 1LL, display only shows phase current THD: THD-I1

and THD-I2.

3.3 Statistics Display

For Acuvim-AL,BL,CL,DL,ELPress “H” and “E” simultaneously to enter the statistic display

mode. Maximum and minimum value for metering parameters are

demand, voltage and current unbalance factor, and individual voltage and current harmonic.

Press “H” and “E” simultaneously again to exit to the real-time metering mode.

Note: Acuvim-EL and Acuvim-KL will not show harmonic contents.

3.3.1 Display Max and Min of the voltage and current and Peak Demand of current. (AL,

BL, CL, DL, EL)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 49

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

49

The 2nd screen: MIN value of phase

voltage. The “MIN” icon shown on the top

of screen.

As shown in Fig.3-25, U1_MIN=379.6 V,

U2_MIN=379.8 V, U3_MIN=379.7 V.

Press “V/A” to go to the next screen.

The 3rd screen: Max value of line to line

voltage.

As shown in Fig 3-26, U12_MAX=658.6 V,

U23_MAX=658.3 V, U31_MAX=658.3 V.

Press “V/A” to go to the next screen.

The 4th screen: MIN value of line to line

voltage.

As shown in Fig.3-27, U12_MIN=657.8 V,

U23_MIN=657.7 V, U31_MIN=657.6 V.

Press “V/A” to go to the next screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 50

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

50

The 5th screen: MAX value of current.

As shown in Fig.3-28, I1_MAX=2.502 A ,

I2_MAX=2.503 A, I3_MAX=2.502 A .

Press “V/A” to go to the next screen.

The 6th screen: MIN value of current.

As shown in Fig.3-29, I1_MIN=2.498 A,

I2_MIN=2.496 A, I3_MIN=2.497 A.

Press “V/A” to go to the next screen.

The 7th screen: Peak current demand.

As shown in Fig 3-30, I1_Demand_MAX=2.505

A, I2_Demand_MAX=2.504 A, I3_Demand_

MAX=2.504 A.

When voltage wiring mode is set to1LN, display only shows first line of 1st, 2nd, 5th, 6th and

7th screen. When voltage wiring mode is set to 1LL, display only shows first and second line

line of 1st, 2nd, 5th, 6th and 7th screen, and first line of 3rd and 4th. When voltage wiring

mode is set to 2LL or 3LL, display doesn’t show the 1st and 2nd screen.

Press “V/A” to go back to the first screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 51

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

51

The 7th screen: Peak current demand.

As shown in Fig 3-30, I1_Demand_MAX=2.505

A, I2_Demand_MAX=2.504 A, I3_Demand_

MAX=2.504 A.

The 1st screen: Unbalance factor for voltage

and current.

As shown in Fig.3-32, voltage unbalance

factor=0.3%, current unbalance factor=0.5%.

Press “H” to go to the next screen.

3.3.2 Display the Max value of power and reactive power demand.

Press “P” under the statistics display mode to display the peak value for power, reactive

power and apparent power demand.

3.3.3 Display power quality parameter (AL, BL, CL, DL, EL)

When press “H” under statistic display mode, will display voltage and current unbalance

factor as well as individual voltage and current harmonic content.

Press “H” key to display voltage and current harmonic content. The HAR icon will be shown

on the top of the screen. The sequence will roll starting from the 2nd harmonic of voltage to

the 15th harmonic of current as you press “H” each time. The following shows the display for

phase voltage, line to line voltage and current harmonic contents.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 52

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

52

The 2nd screen: 2nd harmonic content of

voltage.

As shown in Fig.3-33, U1_Hr2=0.12%,

U2_Hr2=0.14%, U3_Hr2=0.12%.

Press H to scroll through the 3rd to the 31th

phase voltage harmonic content

Note: When voltage wiring of the meter is set to 2LL or 3LL, line to line voltage harmonic

contents will be display instead (as shown in Fig. 3-34).

The 2nd screen: 2nd harmonic content of line to

line voltage.

As shown in Fig.3-34, U12_Hr2=0.12%,

U23_Hr2=0.14%, U31_Hr2=0.12%.

Press H to scroll through the 3rd to the 31th line

to line voltage harmonic content.

The 33th screen: 2nd harmonic content of

current.

As shown in Fig.3-35, I1_Hr2=3.08%,

I2_Hr2=3.05%, I3_Hr2=3.01%.

Press “H” key to scroll through the 3rd to the

31th current harmonic content.

In the statistic mode, press “H” and “E”

simultaneously to exit this mode.

Find Quality Products Online at: sales@GlobalTestSupply.com

Note: When voltage wiring mode is set to 1LL, the screen only shows the first line and the

second line; when set to 1LN, this screen only displays the first line.

www.GlobalTestSupply.com

Page 53

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

53

3.4 System Parameter Setting

Press “H” and “V/A” simultaneously in the metering data display mode to enter the system

parameter setting mode. All the settings can be done through the keys on the meter front

panel.

Press “H” to move the flashing cursor to the right, press “P” to increase the number by 1 once

a time, press “E” to decrease the number by 1 once a time, press “V/A” to accept the change

and move to the next screen. Press “H” and “V/A” simultaneously to exit system parameter

setting mode and return to real-time metering mode.

System parameter setting mode is password protected, a four digit password (select from

0000 to 9999) is required every time before accessing the system parameter settings. The

default password is 0000. After entering the password, press “V/A” to accept the password

and proceed. The meter will return to the real-time metering mode if a wrong password is

entered.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 54

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

54

The 1st screen: Communication Address

setting.

The address can be any integer between 1 -

247. As shown in Fig.3-37, the communication

address is 1.

To change the address, press “H” to move the

cursor, press “P” to increase value by 1, press

“E” to decrease value by 1. Press “V/A” to

store the current address and go to the next

setting screen. Press “V/A” to proceed to the

next screen if there is no need to change the

address.

Note: Meters cannot have the same communication address on the same RS485

communication line according to the Modbus-RTU protocol.

The 2nd screen: Baud rate setting.

The asynchronous communication setting of

Acuvim-L is 8-bit, parity, 1 start bit and 1 or 2

stop bits. Baud rate can be set as follows:

1200, 2400, 4800, 9600, 19200, 38400,

57600. Press “P” or “E” to select a suitable

baud rate. Press “V/A” to accept the change

and proceed to the next screen. Same baud

rate should be used for all meter connecting

on the same communication line.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 55

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

55

The 3rd screen: communication check

setting. communication check could be one

of four settings: non1, non2, odd, EVEN. As

shown in Fig.3-39: communication check is

set to non1.

Press “P” or ”E” to select a communication

check mode, press “V/A” to accept the

change and processed to the next page.

The 4th screen: Voltage input wiring setting.

Voltage input could be one of five setting: 3LN,

3LL, 2LL, 1LL, 1LN.

As shown in Fig.3-40: voltage input mode is set

to 3LN.

Press “P” or “E” to select a wiring mode, press

“V/A” to accept the change and proceed to the

next page.

The 5th screen: Current input wiring setting.

Current wiring mode can be one of the three

settings: 3CT, 2CT, 1CT. As shown in Fig.3-41,

current input mode is set to 3CT

Press “P” or “E” to select a wiring mode, press

“V/A” to accept the change and proceed to the

next page.

Note: The page is only shown in Acuvim-EL and KL. “non1” represents non-parity, single

stop bit; “non2” represents non-parity, double stop bit; “odd” represents odd-parity, single

stop-bit; “EVEN” represents even parity, single stop bit. By default, it is set as “EVEN”.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 56

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

56

The 6th screen: PT primary side ratio setting. PT1

ratio can be set from 50.0 to 1,000,000.0 (unit in

V)

As shown in Fig.3-42, PT1=380.0V.

To change PT1 value, press “H” to move the

cursor, press “P” to increase value by 1, press “E”

to decrease value by 1. Press “V/A” to store the

current value and proceed to the next screen.

The 7th screen: PT secondary side ratio setting.

PT2 ratio can be set from 50.0 to 400.0 (unit in

V).

As shown in Fig.3-43, PT2=380.0V.

To change PT2 value, press “H” to move the

cursor, press “P” to increase value by 1, press

“E” to decrease value by 1. Press “V/A” to store

the current value and proceed to the next

screen.

Note: If no PT is installed at the voltage input, PT1 and PT2 should be the same and equal

to the input rated voltage.

The 8th screen: CT primary side ratio setting.

CT1 ratio can be set from 5 to 50000 (unit in A).

For a 1A option meter, CT1 can be set from 1 to

50000 (unit in A).

As shown in Fig.3-44, CT1=5A.

To change CT1 value, press “H” to move the

cursor, press “P” to increase value by 1, press “E”

to decrease value by 1. Press “V/A” to store the

current value and proceed to the next screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 57

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

57

Note: CT1 has two-digit lines representing one figure. For example, if CT primary is 200,

CT1 should be programmed as 0020 for the top line, and 0 for the bottom line, so that it

is read as 200.

The 9th screen: CT secondary side ratio setting.

CT2 can be 1, 5 and 333; user can modify the

CT2 as 1 or 5, if CT2=333mv, it cannot be

modified.

As shown in Fig.3-45, CT1=5A, Press “V/A” to

proceed to the next page.

The 10th screen: Definition of reactive power.

0: sinusoidal reactive power;

1: budeanu’s reactive power.

Please refer to Chapter 3.6 <<Measurement

methods and parameter definitions>> for

details.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 58

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

58

The 11th screen: Backlight “ON” time setting.

The “ON” time can be set from 0 to 120

minute.

The LCD screen backlight will always be “ON” if

the setting value is 0. The backlight will turn

“OFF” after inactive for a period of time if other

value (from 1to 120) is set.

As shown in Fig.3-47, the setting time of the

backlight is 2 minutes. The backlight will

automatically turn “OFF” if no key activation

within 2 minutes.

The 12th screen: Sliding windows time for

demand setting.

Sliding windows time of demand can be set

from

1-30 minute. The window slides once per

minute.

As shown in Fig.3-48, the sliding windows time

is 8 minutes.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 59

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

59

The 13th screen: Clear Max and Min page

setting.

To clear Max and Min values do not mean

writing 0 to all of the registers. Meter’s current

metering values will be copied to the statistic

registers instead and start a new statistic

period.

Press “P” or “E” to select “YES” or “NO”:

“YES”: clear Max and Min;

“NO”: do not clear Max and Min.

Press “V/A” accept selection and proceed to the

next page.

The 14th screen: Clear energy enable setting

page.

This screen enables the energy reset function of

the meter.

1: enable; 0: disable.

The 15th screen: Acknowledgement to

clear energy setting.

This screen appears only when the 14th

screen is set as “enable”.

Press “E” or “P” to select “YES” or “NO”:

“YES”: clear energy;

“NO”: do not clear energy.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 60

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

60

All energy parameters will be set to 0 when “YES” is selected. Press “V/A” to accept

selection and proceed to the next page.

The 16th screen: Clear running time setting.

Press “P” or “E” to select “YES” or “NO”:

“Yes”: clear running time;

“No”: do not clear running time.

Running time will be set to 0 when “YES” is

selected. Press “V/A” to accept selection

and proceed to the next page.

The 17th screen: Clear load running time

setting. the page would display. Press “P”

or “E” to select “YES” or “NO”: “Yes”: clear

running time. “No”: do not clear running

time. Running time will be set

to 0 when “YES” is selected. Press” V/A” to

accept selection and proceed to next page.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 61

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

61

The 18th screen: VAR/PF setting. Press “P” or

“E” to change VAR/PF setting.

As shown in Fig.3-54 is IEC standard.

Note: The page would be show only in

Acuvim-EL.

The 19th screen: Password setting. This is the

last screen in system parameter setting mode.

The password can be changed in this page. It

is important to remember the new password.

As shown in Fig.3-55, the password is 0001.

Press “V/A” to store the new password and

return to the first setting page. Press “H” and

“V/A” together to exit the system setting

mode after finishing all of the settings.

3.5 DO Parameter Setting and Expansion Module Setting (BL, DL, EL)

Acuvim-BL meter has two digital outputs. Each can operate as energy pulse output or alarm

output. All DO parameters can be set from the meter front. To distinguish with system

parameter setting mode, we call this setting mode as DO parameter setting mode.

Press “P” key and “E” key simultaneously under system parameter setting mode to enter DO

parameter setting mode. Press “H” to move the flashing cursor to the right, press “P” to

increase the number by 1 once a time, press “E” to decrease the number by 1 once a time,

press “V/A” to accept the change and move to the next screen. Press “P” and “E”

Find Quality Products Online at: sales@GlobalTestSupply.com

simultaneously to exit DO parameter setting mode and return to system parameter setting

mode.

www.GlobalTestSupply.com

Page 62

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

62

The 1st screen: Extend IO baud rate setting.

Extend IO Baud rate can be set as follows:

1200, 2400,4800, 9600, 19200, 38400,

57600. Press “P” or “E” to select a suitable

baud rate. Press “V/A” to accept the change

and proceed to the next screen. Same baud

rate should be used for all meters

connecting on the same communication

line.

Note: The page would be shown only in

AcuvimDL and Acuvim-EL.

The 2nd screen: Extend IO communication

check setting. Extend IO communication

check could be one of four settings: NON1,

NON2, odd, EVEN. As shown in Fig.3-57:

Extend IO communication

check is set to NON1.

Press “P” or ”E” to select a communication

check mode, press “V/A” to accept the

change and processed to the next page.

Note: The page would be shown only in

AcuvimEL.

If the extend IO module could be added, it contains 2 DO, 4 DI and communication with

Modbus-RTU standard. Press “P” key and “E” key simultaneously under system parameter

setting mode to enter DO parameter setting and Extend IO communication setting mode, the

operation about key is same as Acuvim-BL DO setting. The following steps show how to set

DO items:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 63

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

63

The 3th screen: DO1 output mode setting.

0: pulse output; 1: alarm output. As

shown in Fig.3-58, DO1 is set as pulse

output mode.

Press “V/A” to accept change and

proceed to the next page.

The 4th screen: DO2 output mode

setting.

0: pulse output; 1: alarm output. As

shown in Fig.3-59, DO2 is set as alarm

output mode.

Press “V/A” to accept change and

proceed to the next page

The 5th screen: DO pulse constant rate

setting. Pulse constant can be set from

any integer from 800 to 60000.

As shown in Fig.3-60, pulse constant is

800(meaning 800 pulse for every 1kWh

or 1kvarh).

Press “V/A” to accept change and

proceed to the next page

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 64

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

64

The 6th screen: DO pulse width setting.

DO pulse width can be set from any integer from 1

to 50. Each unit stands for 20ms.

As shown in Fig.3-61, the pulse width is set to 5,

that is 5×20=100ms.

Press “V/A” to accept change and proceed to the

next page.

The7th screen: DO1 output item setting.

The DO1 output can be one of the following

energy items shown in table below:

Press “V/A” to accept change and proceed to the

next page.

Item value

0 1 2 3 4

Energy select

No output

Ep_imp

Ep_exp

Eq_imp

Eq_exp

The 8th screen: DO2 output item setting.

Same as DO1 output item setting, refer to the

energy item selection table shown above.

DO1 and DO2 settings are independent of each

other.

Press V/A key for acknowledgement and go to the

next page.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 65

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

65

The 9th screen: DO delay time for alarm

setting.

If alarm condition lasts for over the pre-set

time period, the alarm signal will be

triggered. The delay time can be set from

any integer from 0 to 255. Each unit stands

for 300ms.

The10th screen: DO1 alarm output item

setting.

The DO1 alarm output can be one of the

following energy items shown in table

below:

As shown in Fig.3-65, DO1 alarm parameter

is 06, tracking object is V31

Press “V/A” to accept change and proceed

to the next page.

Var 0 1 2 3 4 5 6 7

8

Item

Hz

V1

V2

V3

V12

V23

V31

I1

I2

Var 9 10

11

12

13

14

15

16

17

Item

I3

In

P1

P2

P3

Psum

Q1

Q2

Q3

Var

18

19

20

21

22

23

24

25

26

Item

Qsum

Ssum

PF1

PF2

PF3

PFsum

U_unbl

I_unbl

Dmd_P

Var

27

28

29

30

31

32

33

34

Item

Dmd_Q

Dmd_I1

Dmd_I2

Dmd_I3

S1

S2

Dmd_S

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 66

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

66

The 11th screen: DO1 inequality sign setting.

0: < (less than); 1: > (greater than)

As shown in Fig.3-66, the inequality sign is

set to 1, which means when the tracking

value is above the preset limit, an alarm

output will be triggered.

Press “V/A” to accept change and proceed to

the next page.

The 12th screen: DO1 alarm limit setting.

Set the alarming limit value for the tracking

parameter.

As shown in Fig.3-67, the DO1 limit is set to

1800. Refer to Chapter 3.8 << Measurement

Methods and Parameter Definitions >> for

alarm limit value setting details.

Press “V/A” to accept change and proceed to

the next page.

The 13th screen: DO2 alarm output item

setting.

Same as DO1 alarm output item setting,

refer to the alarm output item selection

table shown above.

As shown in Fig.3-68, DO2 alarm parameter

is 08, tracking object is Phase 2 current.

Press “V/A” to accept change and proceed to

the next page.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 67

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

67

The 14th screen: DO2 inequality sign

setting.

0: < (less than); 1: > (greater than)

Press “V/A” to accept change and proceed

to the next page.

The 15th screen: DO2 alarm limit setting.

Set the alarming limit value for the tracking

parameter.

Refer to Chapter 3.8 << Measurement

Methods and Parameter Definitions>> for

alarm limit value setting details.

As shown in Fig.3-70, the DO2 limit is set to

4500. This is the last screen of DO

parameter setting.

The 16th screen: backlight blinking setting.

If the alarm backlight blinking is enabled,

the screen displays “1”. As show in Fig.3-71,

the backlight blinking is enabled. Under this

circumstance, when an alarm is triggered,

the backlight will be blinking at the same

time. Press “P” or “E” to choose between

“0” and “1”.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 68

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

68

The 17th screen: PROFIBUS address setting

page.

PROFIBUS address can be set from 0~126,

this page will display if the power meter

connects a PROFIBUS module.

PROFIBUS address can be set only via key,

and it valid right now after modified.

Only Acuvim-DL/EL display the page.

The 1st screen: Displays the DHCP flag

settings page. When set to 0, the static IP;

set to 1, the dynamic IP.

3.6 Ethernet Network Module Settings

For Acuvim-DL and EL,under any set of system parameters mode page, press the "H" and "P"

key to enter the Network Settings page.Ethernet parameter setting mode key operation is

the same as to system parameter setting mode key operation. Parameters have been set,

simultaneously press the "P" key and the "H" key to exit the Ethernet parameter setting mode

to return to the system parameter setting mode.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 69

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

69

The 2nd screen: Displays the IP address

settings page. IP address: 192.168.3.1

The 3rd screen: Displays the subnet mask

address (SUBMASK) settings page. Such as

the subnet mask address is: 255.255.255.0

The 4th screen: Displays the gateway

address (Gateway) settings page. Such as

the gateway address: 192.168.1.1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 70

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

70

The 5th screen: Displays the IP address of

the domain name server (DNS1) settings

page. Such as server address 1:202.168.0.1

The 6th screen: Displays the domain name

server address (DNS2) Settings page. Such

as server address 2:202.168.0.4

The 7th screen: MODBUS-TCP port setting

page is displayed. Figure MODBUS-TCP

address 5050.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 71

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

71

The 8th screen: Displays the HTTP port

settings page. HTTP port address is 8080.

The 9th screen: Displays network module

reset settings page. Is set to 1, the reset

network module; such as 0, is not reset.

The 10th Screen: Displays the network

module password reset page. Set to 1,

reset network codes 12345678; set to 0 is

not reset.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 72

Acuvim-L Series Power Meter

Chapter 3: Meter Display and Parameter Settings

V:2.0 Revised October 2018

72

The 1st screen: DI1 current status display. if DI1

status is turn on, the screen will display “ON”. if

DI1 status is turn off, the screen will display “OFF”.

As show in Fig.3-83, DI1 status is turn off.

The 2nd screen: DI2 current status display. if DI2

status is turn on, the screen will display “ON”. if

DI2 status is turn off, the screen will display “OFF”.

As show in Fig.3-84, DI2 status is turn off.

The 3th screen: DI3 current status display. if DI3

status is turn on, the screen will display “ON”. if

DI3 status is turn off, the screen will display “OFF”.

As show in Fig.3-85, DI3 ststus is turn off.

3.7 DI status Display function