Accuenergy AcuDC 243-300V-A0-P2-C-D, AcuDC 243-1000V-A2-P1-X5-C, AcuDC 243-1000V-A0-P1-C-D, AcuDC 243-1000V-A2-P1-X5-C-D, AcuDC 243-1000V-A0-P1-C User manual

...Page 1

User's Manual

ACUDC 240

DC POWER & ENERGY METER

AcuDC 240 Series Power and Energy Meter

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

ABOUT ACCUENERGY

Formed in 1998, Accuenergy is a leading producer of power and energy metering

products for the distribution, control and management of electrical energy and other

dynamic processes. Accuenergy’s vision is to make energy usage more dependable and

efficient, and to make energy management more convenient and intelligent. Accuenergy

products are easily integrated into new and existing energy management, automation

and building control systems for intelligent and user-friendly energy systems and are

backed by an industry-leading pre and post sale technical support and manufacturer’s

warranty.

With an emphasis on continuous improvement, innovation and high performance and

cost-effective solutions, Accuenergy has developed a growing global footprint with offices

in Toronto Canada (Headquarter), Los Angeles and Beijing.

WARNINGS GLOSSARY

The following symbols in this manual and on AcuDC 240 series meters are used to provide

warning of danger or risk during the installation and operation of the meters.

Electric Shock Symbol: Carries information about procedures which

must be followed to reduce the risk of electric shock and danger to

personal health.

When this symbol is seen on the meter, consult this user manual. Refer

to Chapter 2 for important safety information regarding mounting and

wiring of the AcuDC meter.

Safety Alert Symbol: Carries information about circumstances which if

not considered may result in injury or death.

Note: Please read this manual carefully before installation, operation and maintenance of

an AcuDC 240 series meter.

Installation and maintenance of the AcuDC 240 meter should only be performed

by qualified, competent professionals who have received training and should have

experience with high voltage and current devices.

ACCUENERGY shall not be responsible or liable for any damages caused by improper

meter installation and/or operation.

IV

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

TABLE OF CONTENTS

CUSTOMER SERVICE AND SUPPORT .....................................................................II

PRODUCT WARRANTY .................................................................................................III

CHAPTER 1: Introduction to the AcuDC ................................................................1

1.1 Package Contents & Available Accessories ..............................................1

1.2 Introduction and Compliance ......................................................................1

1.2.1 Introduction ........................................................................................................................1

1.2.2 Compliance ........................................................................................................................2

1.3 Applications & Industries ................................................................................2

1.4 Features & Specifications ...............................................................................3

1.4.1 Features .................................................................................................................................3

1.4.2 Specifications ....................................................................................................................3

CHAPTER 2: Installation - Physical Setup............................................................7

2.1 Tools .........................................................................................................................7

2.1.1 Tools for Mounting ..........................................................................................................7

2.1.2 Tools for Wiring ................................................................................................................7

2.2 Mounting ..............................................................................................................7

2.2.1 Tools for Mounting..........................................................................................................8

2.2.2 Mounting I/O Modules Onto Meter ......................................................................9

2.3 Wiring .......................................................................................................................................12

2.3.1 Wiring Control Power ....................................................................................................13

2.3.2 Current Input Wiring ....................................................................................................14

2.3.3 Voltage Input Wiring ....................................................................................................16

2.3.4 Current & Voltage Wiring at the Same Time ...................................................17

2.3.5 Communications Wiring .............................................................................................20

2.4 Removing meter for servicing or maintenance ...................................21

CHAPTER 3: Installation - Configuration Parameter Set-up via display .............24

3.1 Display Panel and Keys ....................................................................................24

3.2 General Parameter Setup ...............................................................................25

3.2.1 Key’s Function in parameters setup .....................................................................26

3.2.2 Configure AcuDC to work with Shunt.................................................................26

3.2.3 Configure AcuDC to work with Current Hall Effect Sensor .....................27

3.2.4 Configure AcuDC to work with Current and Voltage Hall Effect Sensor

28

3.2.5 Clear Energy, Ah and DI Counter ...........................................................................29

V

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

3.2.6 Set Backlight Brightness ............................................................................................30

3.2.7 Meter Clock Setting ......................................................................................................30

3.2.8 Password Setting ............................................................................................................31

3.3 AcuDC Communication Setup .....................................................................31

3.4 I/O Parameter Setup.........................................................................................32

3.4.1 Meter Clock Setting .......................................................................................................32

3.4.2 RO parameter setting ..................................................................................................34

CHAPTER 4: Viewing Metering Parameters – VIA Display ............................40

4.1 General Display on the AcuDC ......................................................................40

4.2 View the Meter and Load Running Time .................................................43

4.3 View the serial number from the meter ..................................................44

CHAPTER 5: Viewing Real-time Readings Via AcuView Software ...........46

5.1 Connection Setup ..............................................................................................46

5.1.1 Wiring .....................................................................................................................................46

5.1.2 Acuview Software Setup .............................................................................................46

5.2 Configuration Parameters Setup ................................................................49

5.2.1 General Meter Parameter Setting ..........................................................................49

5.2.2 Configure the Data Log using the meter’s onboard memory ...............51

5.2.3 Configure the data log to log the readings on the computer’s memory

53

5.3 Viewing Metering Parameters ......................................................................56

5.3.1 Real-Time Metering .......................................................................................................56

5.3.2 Reading Data Log on Meter’s Onboard Memory ..........................................57

5.3.3 Reading Data Log on the computer’s memory .............................................58

APPENDIX ..........................................................................................................................60

A. Troubleshooting ..................................................................................................60

B. Modbus Register Map ........................................................................................63

B.1 MODBUS-RTU Protocol ...................................................................................................63

B.2 Communication Format ................................................................................................66

B.3 AcuDC240 Communication Address Table .........................................................71

C. Ordering Information ........................................................................................83

D. Glossary of Definitions ......................................................................................84

VI

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

AcuDC 240 Series

DC Power and Energy Meters

Chapter 1: Introduction to AcuDC

1.1 Package Contents + Available

Accessories

1.2 Introduction and Compliance

1.2.1 Introduction

1.2.2 Compliance

1.3 Applications & Industries

1.4 Features & Specifications

1.4.1 Features

1.4.2 Specifications

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

Chapter 1: Introduction to AcuDC

CHAPTER 1: INTRODUCTION TO THE ACUDC

1.1 Package Contents & Available Accessories

When you open the package, you will find the following items:

1. AcuDC 240 Meter X1

2. Terminal Blocks X1 - X3 (Depending on model)

3. Installation Clips X4 (Already assembled to the meter)

Available Accessories:

I/O modules (Combinations of digital I/O, analog I/O and relay output)

Current transformers

USB to Serial Converters

1.2 Introduction and Compliance

1.2.1 Introduction

Powerful Yet Cost-Effective

AcuDC 240 series monitors DC voltage, current, power and energy. It supports bidirectional current measurement, and also displays meter running hour and load running

hour. Analog Output applies to DCS system, industrial monitoring and control. AcuDC

240 has a combination of accurate measurement, intelligent multifunction and simple

human machine interface. The cost-effective meter fulfills the requirements of monitoring

and controlling the DC circuit.

Compact and Easy to Install

The dimensions of AcuDC 240 series meet DIN 72X72 requirements. With a mounting

depth of 65mm, the meter can even fit in small drawer type cabinets. It utilizes a self-lock

installation mechanism, eliminating the necessary of fix bolts, which makes installation or

removal quick and convenient.

User Friendly Interface

AcuDC 240 series utilizes a clear high-definition LCD screen with large characters. The

LCD screen comes with a brightness adjustable backlight, which ensures easy observation

of metering data in any environment. With a large LCD screen display, the two keys on the

meter from allow users to observe multiple parameter data at the same time. The meter

parameter settings can be set either via front panel keys or the communication port. The

Parameter settings are saved in the non-volatile EEPROM, which remains when power is

off.

V: 1.0 Revised: Jan. 2018

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

1

Page 7

AcuDC 240 Series

V: 1.0 Revised: Jan. 2018

DC Energy & Power meters

High Safety and Reliability

AcuDC 240 series meter was designed according to industrial standards. It can run

reliably under high power disturbance conditions. This meter has been fully tested for

EMC and safety compliance in accordance with multiple international standards. The

casing is highly fire resistant due to high quality, durable engineering plastics.

1.2.2 Compliance

The following table lists the compliances this meter meets:

Safety

Quality Control

Environmental

1.3 Applications & Industries

Conforms to UL Std 61010-1

Certified to CSA Std C22/2 No. 61010-1

CE certified.

Certified to ISO 9001:2008 standard

IEC 60068-2; Nema3 Certified

IP54 Certified

Applications:

• DC meter & metering

Metering of DC consumption and generation of different DC electrical systems

• DC transducer

Installed transducer reads power, energy, voltage, current and amp hour data and

outputs digital pulse and/or analog signals

• DC data logger / data logging

Installed meter reads, records and stores power, energy, voltage, current and amp

hour data for subsequent download, reporting and analysis

Industries:

• Renewable energy & green systems

Generation by solar photovoltaic (PV) arrays, wind turbines, inverter & battery

monitoring, DC consumption of electric vehicle (EV) charging stations

• Transportation Systems

Consumption of rail / railway, subway and trains and transit systems and related DC

equipment

• Telecommunications

Consumption on cell / cellular towers and equipment

• Datacenters

Consumption of data centers and equipment

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Chapter 1: Introduction to AcuDC

1.4 Features & Specifications

1.4.1 Features

DC power system metering;

Monitor and control power switches;

Alarming and analog output;

Standard 72x72mm, allows for drawer type panel installation;

Three line high-definition LCD display;

Accessible with SCADA, PLC systems;

Easy installation, simple wiring;

Data Logging: Offers 3 configurable historical logs where the all of the metering

parameters can be recorded. The onboard memory is up to 4 MB and each log size is

adjustable.

1.4.2 Specifications

The following tables list the specifications of AcuDC 240 meter.

Parameter Accuracy Resolution Range

Voltage 0.2% 0.001 V 0~1200 V

Current 0.2% 0.001 A 0~±50000 A

Power 0.5% 0.001 kW 0~±60000 kW

Energy 0.5% 0.01 kWh 0~9999999.99 kWh

Drift with

Temperature

Stability 0.5‰/year

Voltage

Input Range

Voltage Direct Input0~1000V; Via Hall Effect Sensor0~1200V

Input Impedance 2MΩ

Load <0.6W

Accuracy 0.2%

<100ppm / °C

V: 1.0 Revised: Jan. 2018

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

3

Page 9

AcuDC 240 Series

V: 1.0 Revised: Jan. 2018

DC Energy & Power meters

Voltage

Current

Input Range

Shunt 50~100mV(programmable)

Hall Effect Sensor 0~±5V/0-±4V, 4~20mA/12mA±8mA

Power Consumption 2W(MAX)

Accuracy 0.2%

Digital Input

Type Dry Contact

Isolation Voltage 2500Vac

Environment

Operation Temperature -25°C ~ +70°C

Storage Temperature -40°C ~ +85°C

Humidity 5%~95%Non-condensing

0~±10A(Direct Input, pick up current 0.01A)

0~±50000A(Via Shunt or Hall Effect Sensor, program-

mable range)

Output

Relay Output (RO)

Type Mechanical contact, Form A

Max Load Voltage 250Vac/30Vdc

Max Load Current 3A

On Resistance 100mΩ (Max)

Isolation Voltage 4000Vac

Mechanical Life 5 × 106 times

Digital Output (Photo-Mos)

Load Voltage Range 0~250Vac/dc

Load Current 100mA(Max)

Max Output Frequency 25Hz, 50% duty cycle

Isolation Voltage 2500Vac

Analog Output (AO)

Load Voltage Range 4-20mA/0~20mA; 0~5V/1-5V

Load Current 0.5%

Max Output Frequency

Current type, max load resistance: 750 Ohm Voltage

type, max load current: 20 mA

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Chapter 1: Introduction to AcuDC

Communication

Type RS485, half duplex, Optical Isolated

Protocol Modbus-RTU

Baud Rate 1200~38400bps

Isolation Voltage 2500VAC

Power Relay Supply

Input

Consumption 3W (typical value)

72 x 72 mm Panel mounted

Table 1-3 lists the functions of AcuDC240 series.

Table 1-3 AcuDC 240 Series

Function AcuDC 241 AcuDC 242 AcuDC 243

Voltage V

Current I

Metering

I/O

Power P

Energy E

Ampere

-Hour

2DI+2AO

2DI+2RO

2DI+2DO

2DI+ ±15Vdc

Ah

Support DI

Count

(P1)100-240Vac, 50/60Hz, 100-300Vdc

(P2) 20-60Vdc

Installation

• •

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

• •

•

•

•

All metering parameters can

be recorded (Voltage, Current,

Data Logging

Communication RS485, Modbus RTU

Display LCD

Dimensions

Find Quality Products Online at: sales@GlobalTestSupply.com

Power, Energy, Ampere-hour, DI

Count); Interval 1 minute; Can

record 4 months

○

○ ○ ○

• • •

72×72×64.5mm (Cutout: 68x68 mm) / 2.835 x 2.835 x 2.539 inch (Cutout:

www.GlobalTestSupply.com

2.677 x 2.677 inch)

V: 1.0 Revised: Jan. 2018

5

Page 11

AcuDC 240 Series

DC Power and Energy Meters

Chapter 2: Installation - Physical Setup

2.1 Tools

2.1.1 Tools for Mounting

2.1.2 Tools for Wiring

2.2 Mounting

2.2.1 How to choose installation place

2.2.2 Mounting I/O modules onto meter

2.2.3 Mounting meter onto switchboard panel

2.3 Wiring

2.3.1 Wiring Control Power

2.3.2 Current input wiring

2.3.3 Voltage input wiring

2.3.4 Current & Voltage wiring at the same time

2.3.5 I/O Module wiring

2.3.6 Communications wiring

2.4 Removing meter for servicing or

maintenance

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

V: 1.0 Revised: Jan. 2018

Chapter 2: Installation - Physical Setup

CHAPTER 2: INSTALLATION - PHYSICAL SETUP

2.1 Tools

2.1.1 Tools for Mounting

• #2 Flathead Screwdriver

• Wire Cutters

2.1.2 Tools for Wiring

• A 1A/250Vac circuit breaker for the auxiliary power supply loopWire Cutters

• A 1A/250Vac circuit breaker should be used in the voltage input loop.

• Choice of wire of power supply is AWG22-16 or 0.6-1.5mm

• The wire for voltage input is AWG16-12 or 1.3-2.0mm

• The wire size of current input is AWG15-10 or 1.5-2.5mm

The following may be required:

• If using RS485 for communication, use a good quality shielded twisted pair cable,

AWG22 (0.5mm2) or higher

• The wire of digital input should be chosen between AWG22~16 or 0.5~ 1.3mm

• The wire of relay output should be chosen between AWG22~16 or 0.5~1.3mm

• The wire of the digital output circuit should be chosen between AWG22~16 or 0.5~1.3

2

mm

2

2

2

2

2

2.2 Mounting

Considerations When Installing Meters

• Installation of the meter must be performed by qualified personnel only, and should

follow standard safety precautions through the installation procedures. Those

personnel should have appropriate training and experience with high voltage devices.

Appropriate safety gloves, safety glasses and protective clothing are recommended.

• During normal operation, dangerous voltage may be present in many parts of the

meter, including terminals, and any connected I/O (Inputs and Outputs) modules and

their circuits. All primary and secondary circuits can, at times, produce lethal voltages.

AVOID contact with any current-carrying surfaces.

• The meter and its I/O output channels are NOT designed as primary protection

devices and shall NOT be used as primary circuit protection or in an energy limiting

capacity. The meter and its I/O output channels can only be used as secondary

protection. AVOID using the meter under situations where failure of the meter may

cause injury or death. AVOID using the meter for any application where risk of fire

may occur.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

• All meter terminals should be inaccessible after installation.

• Applying more than the maximum voltage the meter and/or its modules can

withstand will permanently damage the meter and/or its modules. Please refer to the

specifications in section 1.4.1 for all devices before applying voltages.

DC Energy & Power meters

NOTE: If the equipment is used in a manner not specified by the

Alert

Alert

Alert

manufacturer, the protection provided by the equipment may be

impaired.

NOTE: There is no required preventive maintenance or inspection

necessary for safety. However, any repair or maintenance should be

performed by the factory.

DISCONNECT DEVICE: The following part is considered the equipment

disconnect device.

A switch or circuit- breaker shall be included in the installation.

The switch shall be in close proximity to the equipment and within

easy reach of the operator. The switch shall be marked as the

disconnecting device for the equipment.

2.2.1 Tools for Mounting

Note: Before installation, please check the environment, temperature and humidity to

ensure the AcuDC 240 series meter is being placed in a proper place.

1. Temperature

AcuDC 240 operation temperature is -25°C ~ 70°C, which will accommodate most user

Please Note: It can influence the meter life negatively if the meter operates under

extremely high or extremely low temperature environments. AcuDC 240 storage

temperature is -40°C ~ 85°C.

2. Humidity

5% to 95% non-condensing

3. Location

AcuDC 240 series meter should be installed in a dry and dust free environment. Avoid

exposing meter to excessive heat, radiation and high electrical noise sources.

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

V: 1.0 Revised: Jan. 2018

Chapter 2: Installation - Physical Setup

2.2.2 Mounting I/O Modules Onto Meter

If the meter is equipped with an I/O module, you need to mount the module onto meter

before installing the meter.

Installation Method

With the link pins, I/O module is linked to the meter.

1. Insert the mounting clips to the counterpart of AcuDC 240 meter, and then press the

I/O module lightly, so linking is established, as shown in Fig 2-2.

(A)

(B)

(C)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

(D)

9

Page 15

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

2. Tighten the installation screws.

Note: Install I/O Module carefully to avoid damage; under no circumstances should any

installation be done with the meter powered on. Failure to do so may result in injury or

death.

2.2.3 Mounting Meter Onto Switchboard Panel

Appearance and Dimensions

DC Energy & Power meters

Fig 2-3 AcuDC 240 Appearance

Table 2-1 Part Name of AcuDC 240

Part Description

1. Casing High intensity fire resistant engineering plastics

2. Front Casing Visible portion after mounting onto a panel

3. Display Large LCD display

4. Key Two keys are used to select display and set

5. Voltage and Current Input Terminals Used for voltage and current input

6. Communication Terminals Communication output

7. I/O Module Optional I/O module

8. I/O Terminal Optional I/O terminals, including 2DI, 2AO/2RO

9. Power Supply Terminal Power supply terminal

10. Installation Clips Used for securing the meter to the panel

Fig 2-4 AcuDC 240 Dimensions

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

V: 1.0 Revised: Jan. 2018

Chapter 2: Installation - Physical Setup

Installation Steps

AcuDC 240 series meter is generally installed into the switchboard panel.

1. Cut a square hole (Standard DIN). See figure 2-5 for dimensions. Unit:mm

Fig 2-5 Panel Cutout

2. Remove the clips (10) from the meter, and insert the meter into the square hole from

the front side, as shown in following figures.

a. Panel Cutout

c. Putting back the Clips at the back

of the Panel

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

b. Inserting the Meter to the Panel

Square Hole

d. Installation Completed

11

Page 17

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

2.3 Wiring

Terminal Strips

There are 3 groups of current terminal strips. There will be another terminal strip if the

meter is connected with the I/O module.

DC Energy & Power meters

a. Voltage and Current Terminal Strip

c. I/O Terminal Strip (2DI+2AO)

e. I/O Terminal Strip (2DI+±15V)

Fig 2-7 AcuDC 240 Terminal Strip

Safety Earth Connection

b. Power Supply Terminal Strip

d. I/O Terminal Strip(2DI+2RO/2DO)

f. Communication Terminal Strip

Before setting up the meter’s wiring, please make sure that the

switchgear has an earth ground terminal. Connect both the

meters and the switchgear’s ground terminal together.

This ground terminal symbol is used in this user’s manual.

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

V: 1.0 Revised: Jan. 2018

Chapter 2: Installation - Physical Setup

2.3.1 Wiring Control Power

CAUTION: Make sure you check the power supply option you have before energizing the

meter. Check the silver sticker on the side of the meter to confirm what power supply

option you have.

The silver sticker on the side of the meter contains information such as the model

number, power supply, voltage/current inputs and serial number.

To power the meter, you need to connect the power supply terminal as shown below.

This will be connected based on the two power supply options available, that is:

1A FUSE

Power Supply

L/+

11

12

N/-

AcuDC 240

13

G

Fig 2-9 Power Supply Wiring

1. The Standard option: 100-240Vac, 50/60Hz or 100-300Vdc

2. The Low Voltage DC option: 20-60Vdc

The independent power supply circuit loop must have a fuse or air circuit breaker. The

fuse could be 1A/250Vac, time delay type. If circuit breaker is used, a CE certified product

with compliance of IEC947 is recommended.

Terminal G (13) must be connected to the ground for the safety.

An isolated transformer or EMC filter should be used in the auxiliary power supply loop if

power quality problem exists in the power supply, as shown in following figure.

Power Supply

1A FUSE

L

L

N

N

G

G

11

12

13

L/+

N/-

AcuDC 240

G

EMC lter

2-10 Power Supply Wiring with EMC Filter

Choice of wire power supply is AWG16-22 or 0.6-1.5 mm

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

2

.

13

Page 19

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

2.3.2 Current Input Wiring

AcuDC 240 meter current can be wired in three different ways: direct wiring, wiring using

a shunt and wiring using a current Hall Effect sensor.

NOTE: When wiring using a shunt or Hall Effect Sensor these must be wired on the

negative terminal of the load that is being measured.

Choice of wire current input is AWG15-16 or 1.5-2.5 mm2 or equivalent resistance wire.

DC Energy & Power meters

Vdc+Vdc-

Meter

I/O terminal strip

2423222120191817

V+GNDV-NCDI22DI21DI12DI11

shunt

Voltage, Current, Terminal Strip

Fig 2-11a Wiring using a Shunt

Meter

I/O terminal strip

Voltage, Current, Terminal Strip

123456

U+NCU-NCI+I-

Load

Vdc-

2423222120191817

V+GNDV-NCDI22DI21DI12DI11

123456

U+NCU-NCI+I-

Vdc+

Load

Fig 2-11b Direct Wiring

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

V: 1.0 Revised: Jan. 2018

Meter

I/O terminal strip

Voltage, Current, Terminal Strip

Fig 2-11 C Wiring using a Hall Effect Sensor

Chapter 2: Installation - Physical Setup

Hall Eect Sensor

2423222120191817

V+GNDV-NCDI22DI21DI12DI11

123456

U+NCU-NCI+I-

Fig 2-11 Current Input Wiring

Hall Eect Sensor Terminal

Vdc+Vdc-

Current

1

2

3

4

Load

Table 2-2 Accuenergy Line of Shunts/Hall Effect Sensors for Measuring Current

(Works with AcuDC 243 A1 Current Input Option)

Shunt

Rated Input: 50A

Output: 75mV

Rated Input: 100A

Output: 75mV

Rated Input: 200A

Output: 75mV

Rated Input: 500A

Output: 75mV

Rated Input: 1000A

Output: 75mV

Rated Input: 1500A

Output: 75mV

Rated Input: 2000A

Output: 75mV

(Works with AcuDC 243 A2 Current Input Option)

Hall Effect Sensor

Rated Input: 50A

Output: 4-20mA

Window Size: 21mm

Rated Input: 100A

Output: 4-20mA

Window Size: 21mm

Rated Input: 200A

Output: 4-20mA

Window Size: 21mm

Rated Input: 400A

Output: 4-20mA

Window Size: 40mm

Rated Input: 600A

Output: 4-20mA

Window Size: 40mm

Rated Input: 1000A

Output: 4-20mA

Window Size: 40mm

NOTE: For measuring higher currents or larger window size openings, please

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

Vdc+

2.3.3 Voltage Input Wiring

AcuDC 240 series meter Voltage can be wired in two different ways: direct wiring and

wiring using a voltage Hall Effect sensor. Choice of wire for the voltage input is AWG16-22

or 0.6~1.5 mm

DC Energy & Power meters

2

. Please see the wiring diagrams for details as shown in fig 2-12.

Meter

Vdc-

I/O terminal strip

Voltage, Current, Terminal Strip

Fig 2-12a Wiring using a Voltage Hall Effect Sensor

Meter

I/O terminal strip

Hall Eect Sensor

2423222120191817

V+GNDV-NCDI22DI21DI12DI11

+

IN-

M

123456

U+NCU-NCI+I-

IN+

T

Vdc+Vdc-

2423222120191817

V+GNDV-NCDI22DI21DI12DI11

Voltage, Current, Terminal Strip

123456

U+NCU-NCI+I-

Load

Fig2-12b-Direct Wiring

Fig2-12-Voltage Input Wiring

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

V: 1.0 Revised: Jan. 2018

Chapter 2: Installation - Physical Setup

2.3.4 Current & Voltage Wiring at the Same Time

You can wire the voltage and current for different systems based on the different

methods above. Here are the common wiring methods used:

1. Direct voltage connection and a direct current connection see 2-13a.

2. Direct voltage connection and a current connection using a shunt see 2-13b.

3. Direct voltage connection and a current connection using a current Hall Effect sensor

see 2-13c.

The different wiring diagrams are shown below:

Meter

I/O terminal strip

Voltage, Current, Terminal Strip

Fig 2-13a Direct Wiring

Meter

I/O terminal strip

Vdc+Vdc-

2423222120191817

V+GNDV-NCDI22DI21DI12DI11

123456

U+NCU-NCI+I-

Load

Vdc+Vdc-

2423222120191817

V+GNDV-NCDI22DI21DI12DI11

shunt

Voltage, Current, Terminal Strip

123456

U+NCU-NCI+I-

Load

Fig 2-13b Voltage and Current Wiring Using a Shunt

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

Voltage, Current, Terminal Strip

DC Energy & Power meters

Meter

Hall Eect Sensor

I/O terminal strip

2423222120191817

V+GNDV-NCDI22DI21DI12DI11

1

2

3

123456

U+NCU-NCI+I-

Fig 2-13c Voltage and Current Wiring Using Current Hall Effect Sensor

4

Load

Vdc+Vdc-

Meter

I/O terminal strip

Voltage, Current, Terminal Strip

Fig 2-13 d Voltage and Current Wiring Using Hall Effect Sensors

Fig 2-13-Typical Voltage and Current wiring diagram for systems

Hall Eect Sensor

Voltage

Hall Eect Sensors

+

IN-

M

2423222120191817

IN+

T

Vdc+Vdc-

V+GNDV-NCDI22DI21DI12DI11

1

2

3

123456

U+NCU-NCI+I-

4

Current

Hall Eect Sensors

Load

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

V: 1.0 Revised: Jan. 2018

Chapter 2: Installation - Physical Setup

Digital Input

AcuDC 240 optional I/O module is equipped with two dry contact digital inputs. The

terminals are (17), (18), (19) and (20), as shown in figure 2-7. The Circuit is simplified as:

When the switch is open, there is no current flowing into the diode side of the optical

coupler, the triode is off, OUT is in low state. When the switch is closed, there is current

flowing into the diode side, the triode is on, OUT is in high state. In this way, the ‘high’ and

‘low’ state of OUT corresponding to ‘closed’ and ‘’open’ state of the switch.

The I/O module has built in power supply therefore the digital input does not require an

external power supply.

2

DI wire may choose AWG22-16 or 0.5-1.5 mm

Analog Output

AcuDC 240 I/O module offers two Analog Output modes, which are the current output

0-20mA/4-20mA(max 24mA) mode, and the voltage output 0-5V/1-5V(max 6V) mode, as

shown in figure 2-15.

NOTE: Each module can only has one type of output, please specify when ordering.

.

Fig 2-15 Analog Output Wiring

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

Relay Output

The AcuDC 240 series I/O option has two relay outputs, which are terminal (21), (22) and

(23), (24) as shown in Fig 2-7. They can be used to remotely control circuit breakers.

The relay outputs are form A (normally open) electromagnetic relay. The nodal capacity is

3A/250 Vac or 3A/30Vdc. If the coil current is high, a medium relay is recommended.

DC Energy & Power meters

2.3.5 Communications Wiring

AcuDC 240 series meter uses RS485 serial communication and the Modbus RTU protocol.

The terminals of communication are A, B and S (14, 15 and 16). A is differential signal +, B is

differential -, and S is connected to the shield of twisted pair cable. The overall length of

the RS485 cable connecting all devices cannot exceed 1200m (4000ft). Utilizing a large

number of RS485 devices and utilizing a high baud rate will make the communication

range shorter. AcuDC 240 works as a Slave device. Master device can be PC, PLC, Data

Acquisition Device, or RTU.

Suggestions to improve communication quality:

A high-quality Shielded Twisted Pair cable, AWG22(0.6mm2) or larger diameter cable, is

recommended. Two cables should be in different colors.

• Pay attention to ‘single point earthling’. Make sure that there is only one point of the

shielding connected to ground in a single communication link.

• Every terminal A(+) should be connected to terminal A(+), terminal B(-) to terminal B(-

), or it will influence the network, or even damage the communication interface.

• The connection topology should avoid ‘T’ type which means there is a new branch

and it does not begin from the beginning point.

• Keep communication cables away from sources of electrical noise whenever possible.

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

V: 1.0 Revised: Jan. 2018

Chapter 2: Installation - Physical Setup

When using a long communication cable to connect several devices, an anti signal

reflecting resistor (typical value 120Ω-300 Ω/0.25W) is normally added to the end of the

cable beside the last meter if the communication quality is distorted.

Use RS485 converter with optical isolated output and surge protection.

RS485 Converter

VCCGNDRDX-RDX+T/R-T/R+

Fig 2-17 Communications Wiring

Communication

Terminal Block

S

Meter

16

15

14

2.4 Removing meter for servicing or maintenance

Power Supply Inputs

The wires carrying power into the AcuDC 240 meter must be de-energized regardless of

whether the meter is powered by an independent source or by the measured load line.

De-energize the wires by turning off the switchgear (disconnect switch, breaker or fuse)

leading to the terminal block for pins 11 through 13. The terminal block can then be safely

removed.

NOTE: Removing the terminal block without turning off the

switchgear switch may expose the operator to visible/bare wires

that are still connected to dangerously high voltage levels. This

may cause injury or death.

Voltage Inputs

1. Preparing for Safe Removal

De-energize the leads into the voltage pins by turning off the switchgear.

NOTE: Removing the voltage leads without turning off the

switchgear will expose the operator to dangerously high voltage

levels. This may cause injury or death.

2. Disconnecting the Voltage Inputs

Using a #2 flathead screw driver, turn each of the screws on pins 1 and 3 counterclock wise. Stop turning when the wires can be easily removed from their

housing.

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

Current Inputs

1. Preparing for Safe Removal

If the meter was wired directly in series to the current carrying lines without the use of a

shunt/Hall effect sensor then the operator must de-energize the circuit before removing

the circuit wires from the AcuDC meter.

2. Disconnecting the current inputs

Using a #2 flat head screw driver, screw driver, turn the screws on pins 5 and pin 6

counter-clock wise. Stop turning when the wire can be easily removed from its housing.

Cleaning the Meter

ACCUENERGY recommends using a dry cloth to wipe the meter.

DC Energy & Power meters

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

AcuDC 240 Series

DC Power and Energy Meters

Chapter 3: Installation - Configuration

parameter set-up via display

3.1 Display panel and keys

3.2 General parameter setup

3.2.1 Key’s function in parameters setup

3.2.2 Configure AcuDC to work with shunt

3.2.3 Configure AcuDC for current

hall effect sensor

3.2.4 Configure AcuDC for current and

hall effect sensor

3.2.5 Clear energy Ah and DI counter

3.2.6 Set backlight brightness

3.2.7 Meter clock setting

3.2.8 Password setting

3.3 AcuDC Communication Setup

3.4 I/O Parameter Setup

3.4.1 AO parameter setting

3.4.2 RO parameter setting

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

CHAPTER 3: INSTALLATION - CONFIGURATION PARAMETER

SET-UP VIA DISPLAY

3.1 Display Panel and Keys

The front of the AcuDC 240 series meter consists of an LCD screen and two control keys.

All the display segments are illustrated in Fig 3-1. Users should note that all the segments

will not display in a single page under normal conditions.

There are two keys on the front panel, marked as ‘F’ key and ‘V/A’ key, which are used to

display different parameter data and parameter settings.

DC Energy & Power meters

4

SET

1

2

1

kV

kA

kW

MW

2

3

Number Display Description

1

2

3

kV, kA, kW, MW, Hz, kvar, Mvar, kVA, MVA,

3

Fig 3-1 All Display Segments

kWh, kvarh, kVAh

kWh

Display data of voltage, current, power and

energy

Data Unit

No Icon: no communication

One icon: query sent

Two icons: query sent and response received

4

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Setting mode: Indicates the meter is in

Setting Mode

Page 30

V: 1.0 Revised: Jan. 2018

Chapter 3: Installation - Conguration Parameter Set-up

3.2 General Parameter Setup

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering display mode to get to the

system parameter setting mode. In parameter setting mode, pressing ‘F’ and ‘V/A’

simultaneously will exit the system parameter setting mode and return to the metering

data mode.

General parameter setup will define the general operating characteristics, such as current

range setting, shunt current output range setting, rated voltage of voltage Hall Effect

sensor, reset energy, Ah and DI counter, meter clock setting, and password reset etc., as

shown in table 3-2.

NOTE: Some of these settings will vary depending on the model number and firmware

version of the meter.

Label Paramters Default Options Description Note

Communication

parameter setup

Shunt/Hall Effect

Sensor Parameter

Setup

Hall Effect Sensor

Setup

Energy, Ah and

DI counter clear

setup

Communica-

tion address

Baud Rate 19200

Parity Non1

Current input

of the shunt

/ hall effect

sensor

Current

output of the

shunt

output range

of the current

Hall Effect

Sensor

rated voltage

of the Voltage

Hall Effect

Sensor

output range

of the voltage

Hall Effect

Sensor

Energy

delete(energy

clear)

1 1 ~ 247

1200;

2400;

4800;

9600;

19200;

38400

even;

odd;

non1;

non2

20

100

0 0; 1

0 0; 1

NO

20 ~

50000A

50 ~

100mV

0 ~ 3000V

NO;

Yes

The address can

be any integer

between 1~247

Data Transmission

Rate

0: 4~20mA/0~±5V

1:

4~12-20mA/0~±4V

0: 0 ~ ±5V;

1: 0 ~ ±4V

No: energy not

cleared;

Yes: clear energy

to 0

Assign different ad-

dresses to meters on

same bus

All devices on the

same communica-

tion bus must use the

same baud rate

All devices on the

same communica-

tion bus must use the

same parity

Only indirect current

measurement has this

screen

Corresponds to the

output range of the

shunt

Only meter with indi-

rect voltage measure-

ment has this screen.

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

DC Energy & Power meters

Label Paramters Default Options Description Note

Energy, Ah

and DI counter clear setup

Brightness

Setup

Meter Clock

Setup

Password

Setup

DI counter

delete(DI

counter clear)

Backlight

brightness

Date 1 ~ 31

Time 0 ~ 59 24-hour clock

Password 0000

NO

5 1 ~ 5

NO;

Yes

4

Digitals

No: means DI

counter not

cleared DI;

Yes: clear DI

counter to 0

1: minimum light

level;

5: maximum light

level

Year/month/ date

3.2.1 Key’s Function in parameters setup

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering display mode to get to the

system parameter setting mode. In parameter setting mode, pressing ‘F’ and ‘V/A’

simultaneously will exit the system parameter setting mode and return to the metering

data mode.

In the setting mode:

• ‘V/A’ can be used to confirm changes or go to the next screen

• ‘F’ can be used to change a setting or enter edit mode. A digit

When in edit mode:

• Press ‘F’ to increase the number of the flashing digit

• Press ‘V/A’ to switch the flashing digit

• Press ‘V/A’ on the last digit to confirm the change; the cursor should stop flashing.

Once you are in the settings mode, you will be required to type in a password on the

‘PASS’ screen.

• Enter your password or leave it as default ‘0000’ if it wasn’t changed.

• Press ‘V/A’ to enter the system parameter settings mode.

3.2.2 Configure AcuDC to work with Shunt

If the meter is wired to use a shunt to measure the current, you need to configure the full

range current setting and shunt output range in the AcuDC so that it can read accurately

from the shunt.

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

V: 1.0 Revised: Jan. 2018

Chapter 3: Installation - Conguration Parameter Set-up

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering display mode to get to the

system parameter setting mode. In the parameter setting mode, Press ‘V/A’ until you get

to the ‘I In’ screen. Enter the rated current input of the shunt in this screen.

SET

Press ‘F’ to change this setting. A digit will begin to flash and you

will enter the edit mode. Press ‘F’ to increase the value of the

flashing digit and press ‘V/A’ to switch the flashing digit. Press

‘V/A’ when on the last digit to confirm the change; the cursor will

Fig 3-2 Full range

current setting

NOTE: The setting can be configured in the range of 20-50000A.

NOTE: Only indirect current wiring has this screen.

stop flashing at this point

SET

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering display

mode to get to the system parameter setting mode. In the

parameter setting mode, press ‘V/A’ until the screen ‘I o’ displays.

This setting corresponds to the output range of the shunt. Press

‘F’ to change this setting. The first digit will begin to flash. Press

Fig 3-3 Full range

shunt setting

‘F’ to increase the value of the flashing digit. Use ‘V/A’ to switch

the flashing digit. Press ‘V/A’ to confirm the change on the last

flashing digit to go to the next screen.

NOTE: The setting can be configured in the range of 50-100mV.

3.2.3 Configure AcuDC to work with Current Hall Effect Sensor

If the meter is wired to measure current using a Hall Effect sensor, you will have to

configure the full range current setting and Current Hall Effect sensor output range in the

AcuDC, so that it can read accurately from the Hall Effect Sensor. To change the settings

from the meter’s display, first get to the parameter setting mode.

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

DC Energy & Power meters

SET

Refer to section 3.2.2 configure AcuDC to work with Hall Effect

Sensor, first set the full range current setting as shown in Fig

3-2. Press ‘F’ and ‘V/A’ simultaneously whiles in the metering

display mode to get to the system parameter setting mode. In

the parameter setting mode, Press ‘V/A’ until you get to the ‘I In’

Fig 3-4 Current Hall

Effect sensor setting

screen as shown in Fig 3-2. Enter the rated current input of the

shunt in this screen. After setting up the current range, press

‘V/A’ until the screen ‘I P’ displays. This setting corresponds to the

output range of the Hall Effect Sensor. Press ‘F’ to change this

setting and to select required output. Press ‘V/A’ to confirm this

setting; the cursor will stop flashing at this point.

NOTE: The default setting is ‘0’ for 4~20mA/0~±5V. The other mode is ‘1’ for

4-12~20mA/0~±4V.

3.2.4 Configure AcuDC to work with Current and Voltage Hall Effect Sensor

If the meter is wired to measure current and voltage using a current hall effect sensor and

voltage hall effect sensor respectively, You need to configure the settings in the AcuDC so

that it can read accurately from both Hall Effect Sensors.

Refer to section 3.2.2 configure AcuDC to work with shunt, first set up the current input

range as shown in Fig 3-2 full range current setting.

SET

After setting up the current range, press ‘V/A’ to go to the next

screen, as shown in Fig 3-5. This will be the ‘I P’ screen. This

setting corresponds to the output range of the current Hall

Effect Sensor. Press ‘F’ to change this setting and to select

required output. Press ‘V/A’ to confirm this setting; the cursor will

Fig 3-5 Current Hall

stop flashing at this point.

Effect sensor setting

NOTE: The default setting is ‘0’ for 4~20mA/0~±5V. The other mode is ‘1’ for

4-12~20mA/0~±4V.

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

V: 1.0 Revised: Jan. 2018

Chapter 3: Installation - Conguration Parameter Set-up

SET

Fig3-6 Range

Voltage setting

After setting up the output range of the Current Hall Effect

Sensor, as shown in Fig 3-5, press ‘V/A’ to go to the next screen.

This will be the ‘U In’ screen, as shown in Fig 3-6. Enter the

rated voltage of the Voltage Hall Effect Sensor. Press ‘F’ to

change this setting. A digit will begin to flash and you will

enter edit mode. Press ‘F’ to increase the value of the flashing

digit. Press ‘V/A’ to switch the flashing digit. Press ‘V/A’ when

on the last digit to confirm the change; the cursor will stop

flashing at this point.

SET

After setting up the rated voltage of the voltage Hall Effect

Sensor, as shown in Fig 3-6, press ‘V/A’ to go to the next screen.

This will be the ‘U P’ screen. This setting corresponds to the

output range of the voltage Hall Effect Sensor. Press ‘F’ to

change this setting and to select required output. Press ‘V/A’

Fig 3-7 Voltage Hall

Effect Sensor setting

to confirm this setting; the cursor will stop flashing at this

point.

NOTE: The default setting is ‘0’: 0~±5V. The other mode is ‘1’: for 0~±4V.

3.2.5 Clear Energy, Ah and DI Counter

SET

To clear the readings from the meter display mode, first get

to the Setting mode. Press ‘F’ and ‘V/A’ simultaneously whiles

in the metering display mode to get to the system parameter

setting mode. In parameter setting mode, press ‘V/A’ until

you get to the ‘EdEL’ screen, as shown in Fig 3-8. The screen

Fig 3-8 Clear Energy

displays ‘No’, which means energy not cleared. Press ‘F’ twice

and it will show ‘YES’, which means ‘clear energy’, and the

energy will be cleared to 0. After you choose ‘YES’ or ‘NO’,

press ‘V/A’ to confirm and go to the next screen.

SET

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering

display mode to get to the system parameter setting mode. In

parameter setting mode, press ‘V/A’ until you get to the ‘AdEL’

screen, as shown in Fig 3-9. The screen displays ‘No’, which

means charge not cleared. Press ‘F’ twice and it will show

Fig 3-9 Clear Ah

‘YES’, which means clear charge Ah, and the charge Ah will

be cleared to 0. After you choose ‘YES’ or ‘NO’, press ‘V/A’ to

confirm and go to the next screen.

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

DC Energy & Power meters

SET

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering

display mode to get to the system parameter setting mode. In

parameter setting mode, press ‘V/A’ until you get to the ‘ddEL’

screen, as shown in Fig 3-10. The screen displays ‘No’, which

means DI counter not cleared’. Press ‘F’ twice and it will show

Fig 3-10 DI Counter

Reset

‘YES’, which means clear Di counter , and DI counter will be

cleared to 0. After you choose ‘YES’ or ‘NO’, press ‘V/A’ to confirm

and go to the next screen.

3.2.6 Set Backlight Brightness

To set the backlight brightness from the meter display mode, first get to the Setting

mode.

SET

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering

display mode to get to the system parameter setting mode.

In the parameter setting mode, press ‘V/A’ until you get to the

‘bL’ screen, as shown in Fig 3-11. There are 5 levels backlight

brightness. ‘1’ is minimum light level and ‘5’ is maximum light

Fig 3-11 Backlight

Brightness Setting

level. Press ‘F’ to select and press ‘V/A’ to confirm and go to the

next screen.

3.2.7 Meter Clock Setting

SET

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering

display mode to get to the system parameter setting mode. In

parameter setting mode, press ‘V/A’ until you get to the ‘dATE’

screen, as shown in Fig 3-12. Press ‘F’ to change this setting. A

digit will begin to flash and you can change the number. Press

Fig 3-12 Date

Adjustment

‘F’ to increase the value of the flashing digit. Press ‘V/A’ to switch

the flashing digit. Press ‘V/A’ when on the last digit to confirm

the change; the cursor will stop flashing at this point. Press ‘V/A’

to confirm and go to the time setting screen.

SET

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering display

mode to get to the system parameter setting mode. In the

parameter setting mode, press ‘V/A’ until you get to the ‘TinE’

screen, as shown in Fig 3-13. The meter uses the 24-hour clock

system. The time shown in Fig 3-15 is 14:19:52. Press ‘F’ to change

Fig 3-13 Time

Adjustment

this setting. A digit will begin to flash and you can change the

number. Press ‘F’ to increase the value of the flashing digit. Press

‘V/A’ to switch the flashing digit. Pressing ‘V/A’ when on the last

digit will confirm the change; the cursor will stop flashing at this

point. Press ‘V/A’ to confirm and go to the next screen.

30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

V: 1.0 Revised: Jan. 2018

Chapter 3: Installation - Conguration Parameter Set-up

3.2.8 Password Setting

SET

Press ‘F’ and ‘V/A’ simultaneously whiles in the metering

display mode to get to the system parameter setting mode. In

parameter setting mode, press ‘V/A’ until you get to the ‘PASS’

screen, as shown in Fig 3-14. Press ‘F’ to change this setting. A

digit will begin to flash and you can change the number. Press

Fig 3-14 Password

Setting

‘F’ to increase the value of the flashing digit. Press ‘V/A’ to switch

the flashing digit. Press ‘V/A’ when on the last digit to confirm

the change; the cursor will stop flashing at this point. Press ‘V/A’

to confirm and go to the next screen.

By now the parameter settings are almost completed, except for the I/O module setting.

Pressing ‘F’ and ‘V/A’ simultaneously will exit system parameter settings mode and return

to the metering data mode.

3.3 AcuDC Communication Setup

NOTE: Only meters with communication options have device address, baud rate and

parity setting screens.

To set communication parameters from the meter display mode, you must first press

the ‘F’ and ‘V/A’ buttons simultaneously to get to the parameter setting mode. The

communication parameter setup includes address setup, Baud rate setup, and parity

setting, as shown in table 3-3.

SET

Communication address can be any integer 1 ~ 247. Fig 3-15

shows the address number is 1. Press ‘F’ to change this setting.

The first digit will begin to flash and you can change the edit

mode. Press ‘F’ to increase the value of the flashing digit. Press

‘V/A’ to switch the flashing digit. Press ‘V/A’ when on the last

Fig 3-15

Communication

digit to confirm the change; the cursor will stop flashing at this

point. Press ‘V/A’ to confirm and scroll to the next screen.

Address Setup

NOTE: Modbus-RTU communication protocol requires that all meters on the same

communication bus should have different addresses.

SET

After address setup, the second screen is Baud rate setting

page, or in parameter setting mode, press ‘V/A’ until see ‘bPS’

on the screen. Baud rate can be set as 1200, 2400, 4800, 9600,

19200 and 38400. Fig 3-18 shows the baud rate is 19200 bps.

Press ‘F’ to select the desired baud rate, and then press ‘V/A’ to

Fig 3-16 Baud Rate

confirm and go to the next screen.

Setting

31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

DC Energy & Power meters

SET

Fig 3-17 Parity

Setting

NOTE: All devices on the same communication bus should use the same baud rate and

parity settings.

After Baud rate setup, the next screen is the Parity setting page,

or in parameter setting mode, press the ‘V/A’ button until you see

‘CHEC’ on the screen. Parity can be set as EVEN: even parity, 1 stop

bit; ODD: odd parity, 1 stop bit; 1: no parity, 1 stop bit; 2: no parity, 2

stop bits. Fig 3-17 shows no parity, and 1 stop bit. Press ‘F’ to select

the desired baud rate, and then press ‘V/A’ to confirm and go to

the next screen.

3.4 I/O Parameter Setup

I/O module has two optional types: AO(Analog Output) type and RO(Relay Output) type.

In the system parameter setting operation, hold the ’F” key for 3 seconds to enter the AO

parameter setting mode, or hold the ‘V/A’ key for 3 seconds to enter the RO parameter

setting mode. In the AO or RO setting mode, key functions are the same as in system

parameter settings mode. ‘F’ key is used to increase value by 1 for the flashing digit.

‘V/A’ key is used to confirm the flashing digit and move to the cursor. At the last digit of

the parameter, pressing ‘V/A’ key will confirm and go to the next screen. On ant screen,

pressing ‘F’ and ‘V/A’ simultaneously will exit AO or RO parameter settings mode and

return to the system parameter settings mode.

Note: only the meters have AO or RO functions have the valid operations for the

corresponding AO or RO parameter setting .

3.4.1 Meter Clock Setting

For the module that supports the Analog Output function, it offers two AO channels. The

AO parameter can be voltage, current and power. AO upper and lower limits include ‘sign’

and ‘percentage’ digit. The sign digit has three options”:

represents (±). The range of the percentage digit is ‘0.00~1.00’, representing ‘0%~100%’

of the full range value. When the AO parameter is set as voltage, the upper and lower

limit setting is ‘0%~100%’. When AO parameter is set as current or power, there are four

modes:’ 0%~ +100%’; 0%~ -100%’;’-100%~ +100%’ and ‘0%~ ±100%’.

NOTE:

1. There is no ‘sign’ digit when AO is set as voltage. ‘sign’ digit is invisible when percentage is 0.

2. For limit setting, 1.00 is 100%, 0 is 0%, and 0.25 is 25%.

represents (+), represents (-),

32

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

V: 1.0 Revised: Jan. 2018

Chapter 3: Installation - Conguration Parameter Set-up

SET

In parameter setting mode, hold ‘F’ for 3 seconds until the screen

‘AotP’ displays (as shown in Fig 3-18), the meter is in AO parameter

setting mode. It is the AO output setting. There are four AO

output modes: 0: 0 ~ 5V; 1: 1 ~ 5V; 2: 0 ~ 20mA; 3: 4 ~ 20mA. Press

‘F’ key to select the type number (0, 1, 2 or 3), and then press

Fig 3-18 AO Output

Setting

‘V/A’ key to confirm and scroll to the next screen setting page.

For example, Fig 3-18 shows the output type is 3, it means its AO

output type is 4~20mA mode.

NOTE: AO output type is determined by the equipped I/O module you ordered; incorrect

parameter setting will result in invalid AO output value.

SET

In AO parameter setting mode, press ‘V/A’ until the screen ‘Ao 1P’

displays (as shown in Fig 3-19). It is AO1 parameter setting. There

are three options: 0: voltage; 1: current; 2: power. Press ‘F’ key to

select the parameter number (0, 1, or 2), and then press ‘V/A’ key

to confirm and scroll to the next screen setting page. Fig 3-19

Fig 3-19 AO1

shows the AO1 is se t as current.

Parameter Setting

NOTE: AcuDC 241 and 242 do not have this screen. AO1 is set as what is being measured.

SET

Fig 3-20 AO1 Lower

Limit Setting

SET

Fig 3-21 AO1 Up Limit

Setting

In AO parameter setting mode, press ‘V/A’ until the screen ‘Ao 1L’

displays (as shown in Fig 3-20). It is AO1 lower limit setting, range

is ‘0.00 ~ 1.00’. There is no ‘sign’ digit when the limit is 0. When

the limit is not 0, the ‘sign’ digit will be visible, the sign can be

adjusted by moving the cursor to the digit. Press ‘F’ and ‘V/A’ to

edit the value, and then press ‘V/A’ key to confirm and scroll to the

next screen setting page. Fig 3-20 shows the AO1 lower limit is set

as 0.

In AO parameter setting mode, press ‘V/A’ until the screen ‘Ao 1H’

displays (as shown in Fig 3-21). It is AO1 upper limit setting, range

is ‘-100% ~ +100%’. The entire upper limit’s absolute value cannot

be smaller or equal to the lower limit’. Under no circumstance

can the upper limit be 0. Press ‘F’ to edit the value, and then press

‘V/A’ key to confirm and scroll to the next screen setting page. Fig

3-21 shows the AO1 up limit is set as +100%.

33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

DC Energy & Power meters

SET

In AO parameter setting mode, press ‘V/A’ until the screen ‘Ao 2P’

displays (as shown in Fig 3-22). It is AO2 parameter setting. There

are three options: 0: voltage; 1: current; 2: power. Press ‘F’ key to

select the parameter number (0, 1, or 2), and then press ‘V/A’ key

to confirm and scroll to the next screen setting page. Fig 3-22

Fig 3-22 AO2

shows the AO2 is set as voltage.

Parameter Setting

NOTE: 241 and 242 do not have this screen. AO1 is set as what is being measured.

SET

In AO parameter setting mode, press ‘V/A’ until the screen ‘Ao 2L’

displays (as shown in Fig 3-23). It is AO1 lower limit setting, range

is ‘0.00 ~ 1.00’. There is no ‘sign’ digit when the limit is 0. When

the limit is not 0, the ‘sign’ digit will be visible, the sign can be

adjusted by moving the cursor to the digit. Press ‘F’ to edit the

Fig 3-23 AO2 Lower

Limit Setting

value, and then press ‘V/A’ key to confirm and scroll to the next

screen setting page. Fig 3-23 shows the AO1 lower limit is set as 0.

SET

In AO parameter setting mode, press ‘V/A’ until the screen ‘Ao

2H’ displays (as shown in Fig 3-22). It is the AO2 upper limit

setting, range is ‘-100% ~ +100%’. The entire upper limit’s absolute

value cannot be smaller or equal to the lower limit’. Under no

circumstance can the upper limit be 0. Press ‘F’ to edit the value,

Fig 3-24 AO2 Up

Limit Setting

and then press ‘V/A’ key to confirm and scroll to the next screen

setting page. Fig 3-24 shows the AO1 up limit is set as +100%.

3.4.2 RO parameter setting

In the system parameter setting operation page after successfully entering the password,

hold the ‘V/A’ key for 3 seconds to enter the RO parameter setting page. The I/O module

that contains the Relay Output function offers two RO channels. There are three

modes for RO: Latch, Momentary and alarm. The mode setting depends on the object

requirement i.e. A circuit breaker use Momentary. The momentary delay time is 300-5000

ms. Due to the relay action time error, this delay time has up to 3ms error.

34

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

V: 1.0 Revised: Jan. 2018

Chapter 3: Installation - Conguration Parameter Set-up

SET

Fig 3-25 RO1 Mode

Setting

SET

Fig 3-26 RO1

Momentary Delay

Time

SET

Fig 3-27 RO1 Alarm

Parameter Setting

RO1 mode setting: In the parameter setting mode, hold ‘V/A’ for 3

seconds until the screen ‘Ro1F’ displays (as shown in Fig 3-23), the

meter is in RO parameter setting mode. There are 3 RO1 modes:

0: Latch; 1: Momentary; 2: Alarm. Press ‘F’ key to select the mode

number (0, 1 or 2), and then press ‘V/A’ key to confirm and scroll

to the next screen setting page. For example, Fig 3-25 shows the

RO1 mode is Latch.

RO1 momentary delay time setting: In RO parameter setting

mode, if RO1 mode is set as 1, Momentary, press ‘V/A’ key until the

screen ‘Ro1d’ displays. The delay range in 300 ~ 5000 ms. Press

‘F’ to set the delay time. And then press ‘V/A’ key to confirm and

scroll to the next screen setting page. Fig 3-26 shows the RO1

momentary delay time is 500ms, or 0.5s.

RO1 alarm parameter setting: In RO parameter setting mode, if

RO1 mode is set as 2, Alarm, press ‘V/A’ key until the screen ‘Ro1P’

displays. There are 4 options: 0: no alarm; 1: voltage; 2: current; 3:

power. Press ‘F’ to select setting and press ‘V/A’ key to confirm

and scroll to the next screen setting page. Fig 3-27 shows the RO1

alarm is ‘no alarm’.

SET

RO1 alarm inequality setting: In RO parameter setting mode, if

RO1 mode is set as 2, Alarm, press ‘V/A’ key until the screen ‘Ro1S’

displays. There are 2 options: 0: smaller than; 1: larger than. Press

‘F’ to select and press ‘V/A’ key to confirm and scroll to the next

screen setting page.

Fig 3-28 RO1 Alarm

Inequality Setting

SET

RO1 alarm threshold range setting: In RO parameter setting

mode, if RO1 mode is set as 2, Alarm, press ‘V/A’ key until the

screen ‘Ro1u’ displays. The threshold setting range is the same as

measurement range. Voltage: 0 ~ 3000V; Current: 0 ~ 50000A;

Power: 0- 60000kW. Press ‘F’ to edit the value, and press ‘V/A’ key

Fig 3-29 RO1 Alarm

to confirm and scroll to the next screen setting page.

Threshold Range

Setting

35

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

SET

DC Energy & Power meters

SET

Fig 3-30 RO1 Alarm

Delay Setting

SET

Fig 3-31 RO2 Mode

Setting

SET

Fig 3-32 RO2

Momentary Delay

Time

RO1 alarm delay setting: In RO parameter setting mode, if RO1

mode is set as 2, Alarm, press ‘V/A’ key until the screen ‘Ro1t’

displays. The alarm delay time range is 0 ~ 255 s. In Fig 3-30,

the alarm delay time is 15 seconds. If the alarm condition is

met, after 15 second, the alarm will be triggered; or if the alarm

condition is no longer met, after 15 seconds, the alarm will be

restored. Press ‘F’ to edit the value, and press ‘V/A’ key to confirm

and scroll to the next screen setting page.

RO2 mode setting: In RO parameter setting mode, press ‘V/A’

until the screen ‘Ro2F’ displays (as shown in Fig 3-31). There are

3 RO2 modes: 0: Latch; 1: Momentary; 2: Alarm. Press ‘F’ key to

select the mode number (0, 1 or 2), and then press ‘V/A’ key to

confirm and scroll to the next screen setting page. For example,

Fig 3-29 shows the RO2 mode is Latch.

RO2 momentary: In RO parameter setting mode, if RO1 mode

is set as 1, Momentary, press ‘V/A’ key until the screen ‘Ro2d’

displays. The delay range in 300 ~ 5000 ms. Press ‘F’ to set the

delay time and then press ‘V/A’ key to confirm and scroll to the

next screen setting page. Fig 3-30 shows the R21 momentary

delay time is 500ms, or 0.5s.

SET

RO2 alarm parameter setting : In RO parameter setting mode,

if RO2 mode is set as 2, Alarm, press ‘V/A’ key until the screen

‘Ro2P’ displays. There are 4 options: 0: no alarm; 1: voltage; 2:

current; 3: power. Press ‘F’ to select and press ‘V/A’ key to confirm

and scroll to the next screen setting page. Fig 3-33 shows the

Fig 3-33 RO2 Alarm

RO2 alarm parameter is set as ‘voltage’.

Parameter Setting

RO2 alarm inequality setting: In RO parameter setting mode,

if RO2 mode is set as 2, Alarm, press ‘V/A’ key until the screen

‘Ro2S’ displays. There are 2 options: 0: smaller than; 1: larger than.

Press ‘F’ to select and press ‘V/A’ key to confirm and scroll to the

next screen setting page.

Fig 3-34 RO2 Alarm

Inequality Setting

36

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

V: 1.0 Revised: Jan. 2018

Chapter 3: Installation - Conguration Parameter Set-up

SET

RO2 alarm threshold range setting: In RO parameter setting

mode, if RO2 mode is set as 2, Alarm, press ‘V/A’ key until the

screen ‘Ro2u’ displays. The threshold setting range is the same as

measurement range. Voltage: 0 ~ 3000 V; Current: 0 ~ 50000A;

Power: 0~ 60000kW. Press ‘F’ to edit the value and press ‘V/A’ key

Fig 3-35 RO2 Alarm

to confirm and scroll to the next screen setting page.

Threshold Range

Setting

SET

RO2 alarm delay setting: In RO parameter setting mode, if RO2

mode is set as 2, Alarm, press ‘V/A’ key until the screen ‘Ro2t’

displays. The alarm delay time range is 0 ~ 255, unit: second. In

Fig 3-36, the alarm delay time is 15 second. If the alarm condition

is met, after 15 second, alarm will be triggered; or if the alarm

Fig 3-36 RO2 Alarm

Delay Setting

condition is no longer met, after 15 seconds, the alarm will be

restored. Press ‘F’ to edit the value, and press ‘V/A’ key to confirm

and scroll to the next screen setting page.

Table 3-3 I/O Parameter Setting

Label Paramters Options Description

AO (Analogy

Output)

RO

AO Output 0; 1; 2; 3

AO1 Parameter 0; 1; 2 0: voltage; 1: current; 2: power

AO1 lower limit 0.00 ~ 1.00 0%-100%

AO1 up limit -1.00 ~ +1.00

AO2 parameter 0; 1; 2 0: voltage; 1: current; 2: power

AO2 lower limit 0.00 ~ 1.00 0%~100%

AO2 up limit -1.00 ~ +1.00

RO1 mode 0; 1; 2

RO1 momentary delay

time

RO1 alarm parameter 0; 1; 2; 3 0: no alarm; 1: voltage; 2: current; 3: power

300 ~ 5000 Unit: ms

The entire upper limit’s absolute value

should be larger than the lower limit.

The entire upper limit’s absolute value

should be larger than the lower limit.

0: 0 ~ 5V; 1: 1 ~ 5V;

2: 0 ~ 20mA; 3: 4 ~ 20mA

-100%~100%

-100%~100%

0: Latch;

1:Momentary;

2: Alarm

37

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

DC Energy & Power meters

Label Paramters Options Description

RO

RO1 alarm inequality 0; 1

RO1 alarm threshold

range

RO1 alarm delay 0 ~ 255 unit: second

RO2 mode 0; 1; 2

RO2 momentary delay

time

RO2 alarm parameter 0; 1; 2; 3

RO2 alarm inequality 0; 1

RO2 alarm threshold

range

RO2 alarm delay 0 ~ 255 unit: second

Voltage: 0 ~ 3000 V;

Current: 0 ~ 50000A;

Power: 0~ 60000kW.

300 ~ 5000 Unit: ms

0: no alarm; 1: voltage; 2: current;

Voltage: 0 ~ 1200V;

Current: 0 ~ 50000A;

Power: 0~ 6000kW

0: smaller than;

1: larger than

0: Latch;

1:Momentary;

2: Alarm

3: power

0: smaller than;

1: larger than

38

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

AcuDC 240 Series

DC Power and Energy Meters

Chapter 4: Viewing Metering Parameters via Display

4.1 General Display on the AcuDC

4.2 View the Meter and Load Running Time

4.3 View the Serial Number from the Meter

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

V: 1.0 Revised: Jan. 2018

AcuDC 240 Series

CHAPTER 4: VIEWING METERING PARAMETERS – VIA

DISPLAY

You can view different information from the metering screen. For example, you can view voltage,

current, power, energy, electric charge and clock information.

In the metering screen, press ‘F’ to go to next screen, press ‘V/A’ to go to the different windows to

view different information.

4.1 General Display on the AcuDC

AcuDC 240 normally displays the metering screen, which shows real-time measured

data, such as voltage, current, power, energy, meter clock, DI counter etc., as shown in

table 4-1.

DC Energy & Power meters

The first screen on the metering screen shows voltage, current and power. Please note

that AcuDC241 only shows voltage and AcuDC242 only shows current. Only AcuDC243

shows voltage, current and power at the same time.

40

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

V: 1.0 Revised: Jan. 2018

Chapter 4: Viewing Metering Parameters via Display

V

Fig 4-1 Voltage

Display (AcuDC 241)

k

Fig 4-2 Current

Display (AcuDC 242)

1

2

3

V

A

kW

Fig 4-3Multifunction

Display (AcuDC 243)

For the AcuDC 241, it only displays voltage, and there is a unit ‘V’

shown at the top right corner. For example, the screen in Fig. 4-1

shows it is AcuDC 241, and the voltage is 220.2V.

For the AcuDC 242, it only displays current, and there is a unit ‘A’

shown at the top right corner. For example, the screen in Fig. 4-2

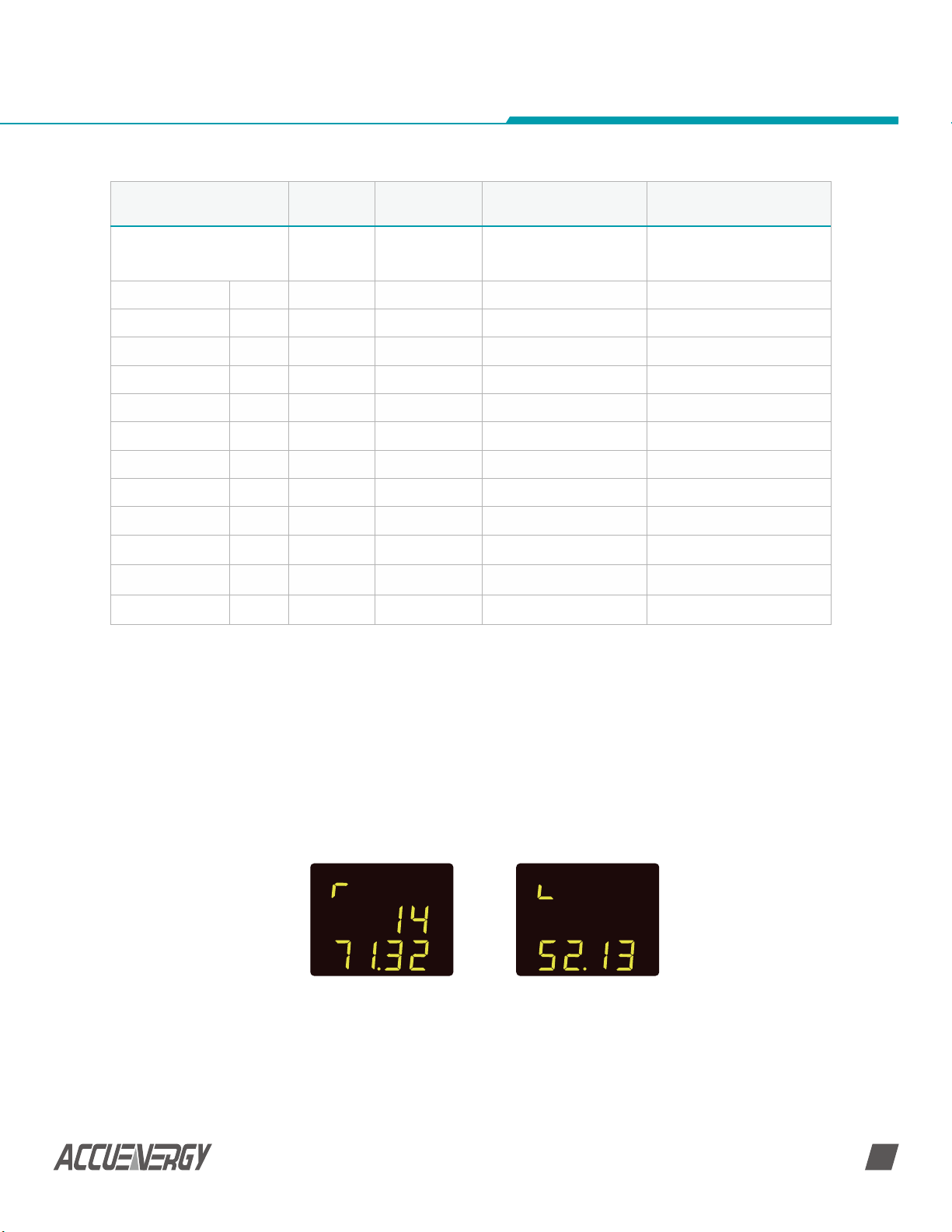

Shows it is AcuDC 242, and the current is 49.99A.