Page 1

USE & CARE GUIDE

REFRIGERATORS AND FREEZERS FOR GENERAL PURPOSE STORAGE

PLUS Series

REFRIGERATORS AND FREEZERS FOR MEDICAL STORAGE

MED/MEDDT Series

If you need service or call with a question, please have

this information ready. We advise you to keep this Use &

Care Guide in your possession.

Model: ___________ Serial number: _________________

Options added:

Date of purchase: Dealer:

NOTE: This manual is also

available in French.

Look on our website.

FELIX STORCH, INC.

770 Garrison Avenue

Bronx, New York 10474

www.summitappiance.com

0

Page 2

Model Numbers

*

PLUS Models

• FF6 / FF7 / FF28LWH / FF511L / FF521BL / FFAR2L / FFAR21L /

FFAR24L / FF590SSHH PLUS Series

All-refrigerators with automatic defros t or frost-free operation

• VT65ML PLUS Serie s

Low temperature fr eezers

• FFAR10 PLUS Series

Full-size storage all-refrigerators

• FS20L / FS21L / FS22L / FS24L PLUS Series

Compact all-freezers (-20°C)

• CM411L / CM421BL / CP35LL / CT66 / S19LWH PLUS Series

Compact refrigerator-freezers

• FCL44 / FS30L / FS60ML / FS407 L / FS408 BL PLUS Series

Compact and mid-size storage all-freezers

• SCR450L / SCR500BL / SCR600L / SCR610BL PLUS Series

Glass door all-refrigerators

MED/MEDDT* Models

• FF6 / FF7 / FF28LWH / FF511L / FF521BL / FF590SSHH / FFAR2L / FFAR21L /

FFAR24L MED Series

All-refrigerators wit h automat ic defrost or frost-free operation

• FFAR10 MED Series

Full-size storage all-refrigerators

• SCR450L / SCR500BL / SCR600L / SCR610BL / SP6DS2D7 / SP6DS7 /

SP6DSSTB7 MED Series

Specialty all-refrigerators (drawers or glass doors)

• CP35LL MED Series

Compact refrigerator-freezers

• FCL44 / FS30L / FS60ML / FS407L / FS408BL MED Series

Compact and mid-size storage all-freezers

• VT65ML // SCFF51OSWH MED Series

Low-temperature freezers // Built-in frost-free freezers

• FS20L / FS21L / FS22L / FS24L MED Series

All-freezers (-20°C)

:

:

Model numbers with “DT” indicate units having a Digital Thermostat.

1

Page 3

Table of Contents

Model Numbers ......................................................................... 1

Appliance Safety ....................................................................... 3

Proper disposal of an old appliance ..................................... 3

Installation Instructions ........................................................... 4

Key Eject lock ....................................................................... 4

Location Requirements ...................................................... 5 – 6

Location ................................................................................ 5

Recommended grounding meth od ....................................... 5

Leveling your appliance ....................................................... 6

When using the appliance .................................................... 6

Energy-saving tips ................................................................ 6

Appliance Care .................................................................... 7 – 8

Cleaning a frost-free app li a nc e ............................................ 7

Cleaning a cycle defrost or manual defrost appliance ......... 7

Base grill ............................................................................... 8

Changing the light bulb ........................................................ 8

Loss of power ....................................................................... 8

Moving the appliance ........................................................... 8

Temperature Selection and Monitoring .......................... 9 – 12

Manual (dial) thermostat ...................................................... 9

Digital thermostat ............................................................... 10

Traceable thermometer (PLUS models) ............................. 10

Traceable thermometer/alarm (MED models)............. 11 – 12

Keypad Lock ........................................................................... 12

Operation of Specific Models ................................................ 13

Troubleshooting ..................................................................... 14

Limited Warranty .................................................................... 15

2

Page 4

Appliance Safet

IMPORTANT SAFETY INSTRUCTIONS

y

Your safety and the safety of others are very important to us.

We have provided many important safety messages in this manual and on your

appliance. Always read and obey all safety messages.

You can be seriously injured or even killed if you don’t follow instructions.

Safety messages will tell you what the potential hazard is, how to reduce the

chance of injury, and what can happen if the instructions are not followed.

WARNING: To reduce the risk of fi re, electric shock or injury

when using your appliance, follow these basic precautions:

• Plug into a grounded 3-pr ong outle t.

• Do not remove ground prong, nor use a 3/2 adapter.

• Do not use an extension cord.

• Use care not to plug into outlets controlled by wall switches.

• Disconnect power before servicing.

• After servicing, replace all parts and panels before operating.

• Use nonflammable cleaners.

• Keep flammable materials and vapors, such as gasoline, away from

appliances.

• Use two or more people to move and install appliance.

NOTE: Drawer refrigerators are provided with anti-tip brackets. Always install

prior to use.

Proper disposal of an old appliance

:

Old appliances can represent a suffocation hazard to children.

Remove doors from your old appliance.

Leave shelves in place.

If an old appliance contains refrigerants, it must be recycled by a licensed service

or disposal company.

3

Page 5

Installation Instructions

Excessive Weight Hazard !

Use two or more people to move and install your appl iance.

Failure to do so can result in back or other injury.

ALLOW APPLIANCE TO SIT UPRIGHT FOR 24 HOURS BEFORE TURNING ON, TO

ALLOW THE COMPRESSOR LUBRICANT TO DRAIN.

1. Remove packaging materials.

2. Remove tape and glue residue from surfaces before turning on the appliance.

Rub a small amount of liquid dish soap over the adhesive with your fingers.

Rinse with warm water and dry.

3. Do not use sharp instruments, rubbing alcohol, flammable fluids, or abrasive

cleaners to remove tape or glue. These products can damage the surface of

your appliance.

When Moving Your Appliance

4.

Your appliance is heavy. When moving the appliance for cleaning or service,

be sure to protect the floor. Always pull the appliance straight out when

moving it. Do not wiggle or “walk” the appliance when trying to move it,

because floor damage can occur.

5.

Clean Before Using

After you remove all of the packaging materials, clean the inside of your

appliance before using it. See cleaning instructions in Appliance Care.

6. Some upright models have leveling legs. Level as necessary for best

operation.

7. If your appliance has casters, after moving int o place , lock the bra kes on

those casters supplied with brakes. Always unlock before moving the

appliance for cleaning.

:

:

Key Eject lock (some models)

To lock or unlock the appliance, you must hold the key in the lock while turning.

The lock is spring loaded, so the key cannot be left in the lock.

If the key is lost, contact your dealer or SUMMIT APPLIANCE for a replacement.

Always give the model and serial number of your appliance when requesting a

replacement key. Keys for most models can be ordered online at

www.summitappliance.com/support

:

4

Page 6

Location Requirements

Keep flammable materials and vapors, such as gasoline, away

from appliances. Failure to do so can result in fire, explosion or

death.

Location

IMPORTANT: Do not install the appliance near an oven, radiator, or other heat

source, nor in a location where the temperature will fall below 40°F (5°C). Do not

place in direct sunlight.

Check the strength of the floor before installing your appliance. It should hold the

weight of a fully loaded appliance. Allow at least 4” (10 cm) of airspace at t he top

and on both sides of the appliance and also 4” between the back of the appliance

and the wall. If the appliance is going to be placed next to a wall, leave extra

space on the hinge side so the door can open wider than its width.

NOTE: Allow 4” (10 cm) clearance at the top and sides and a ¼” (0.64 cm)

• Plug into a grounded 3-prong outlet.

• Do not remove ground prong.

• Do not use an adapter.

• Do not use an extension cord.

Failure to follow these instructions can result in fire, electrical shock or

death.

:

clearance between appliances. IF YOUR MODEL HAS THE LETTERS “BI”

IN THE SUFFIX, IT IS DESIGNED FOR BUILT-IN USE AND REQUIRES

ONLY

MINIMAL

LEAST 2” OF CLEARANCE SHOULD BE ALLOWED. ALL FF590 AND

SCFF51OSWH MODELS ARE ALSO BUILT-IN CAPABLE

Electrical Shock Hazard

CLEARANCES EXCEPT AT THE BACK WHERE AT

Recommended grounding method

A 115 Volt (AC only) 60 Hz grounded electrical supply with a 15- or 20- amp fus e

or circuit breaker is required. It is recommended that a separate circuit serving

only your appliance be provided. Use outlets that cannot be turned off by a

switch or pull chain. Do not use an extension cord.

:

5

Page 7

Leveling your appliance

Locate the two front leveling legs that may be taped among the packing materials. (In

many models these legs are already mount ed into the undersi de of the appliance.)

1. Screw these legs into the front holes on the bottom of t he appliance. The back of

the appliance rests on two fixed supports. (Built-in models also have rear level

legs that can provi de more precise leveling).

2. Adjust the f ront legs just enough to lift the cabinet up off the floor.

Note: If your model is equipped with front roll ers, the front legs should be lowered

enough to lift the rollers off the floor to ensure the appliance does not roll

forward when the door is opened.

3. Place a leveling tool on top of the appliance, firs t side to side, then front to back.

Turn leg counter-c lockwise to raise a corner. Turn leg clockwise to lower a corner.

4. Repeat Step 3 unti l appliance is level .

5. After appliance is fully loaded, recheck with level as in Step 3.

6. If your appliance is equipped wit h casters, the two front casters have brakes to

prevent rolli ng. Keep brakes lock ed, and unlock for moving only.

(some upright models):

When using the appliance

In order to ensure proper temperature, you need to permit proper airflow in the

appliance. Do not block off any air vents. If the vents are blocked, airflow will be

hindered, and temperature and moisture problems may occur. Always position

contents to all ow some airflow between shelves or baskets.

Allow the applia nce to cool at least 6 to 8 hour s before adding contents. All ow 24

hours for temperature to stabilize.

NOTE: When the appl ianc e i s fi rs t s tart ed, t he c ompr ess or wi ll run c ons tant l y unt i l t h e

appliance is cooled. It may take 6 to 8 hours (or longer), depending on room

temperature and the number of times the appliance door is opened. After the

appliance has cool ed, the compr essor will tur n on and off as needed t o keep the

appliance at the pro per temperature.

For optimum temperature performance, it is recommended that this unit be at

least 30% full during use. I f you are onl y usin g t his unit t o st ore smal l l oads, w e

recommend adding s ome water bott les or freezer packs to ensure t emperature

stability.

The outside of yo ur appl iance may f eel war m. This i s normal . The ap plianc e’s desi gn

and main function is to remove heat from packages and air space inside the

appliance. The heat is tr ans fer red to t he r oom air , mak ing t he out si de of t he appl ianc e

feel warm. (In s ome models the condenser that get s warm is jus t i nside the side walls,

making these wall s warm to the touch.)

:

ENERGY-SAVING TIPS

• The more airflow provided around an appliance, the less energy it will use.

• If your appliance requires manual defrosting, keep ice build-up to less than 1/2".

• Keep doors open a minimum of time, and shut securely.

6

Page 8

Appliance Care

Cleaning a frost-free appliance

:

Use nonflammable cleaners.

Frost-free means t hat you do not have to defros t your appli ance. Frost is removed by

air moving and collecting any moisture and depositing it on the cooling coil. The

cooling coil per iodically warm s up enough t o melt the fr ost, and the wat er then flows

down to the drain pan (located behind the base grill) wher e it is evaporated.

Complete cleaning should be done at least once a year.

1. Unplug appliance or disconnect power.

2. Remove all stor ed items, plus shelves, trays, etc.

3. Wash the inside wal ls, shelves and tr ays with a solution of mild detergent in warm

water or 2 tbsp (26 g) baking soda to 1 qt (0.95 L) warm water.

• Do not use abrasive or harsh cleaners such as window sprays, scouring

cleansers, fl ammable fluids, cleaning waxes, concentrated detergents,

bleaches or cleansers containing petroleum products on plastic parts , interior

and door liners or gaskets. Do not use paper towels, scouring pads, or other

harsh cleaning tool s. These can scr atch or damage surfaces.

4. Rinse well and wipe dry with a clean soft cloth.

5. Use the appropriate cleaning method for the exterior finish.

Painted metal

detergent in war m water. Do not use abr asive or harsh clean ers, or cleaners

designed for stainless steel. Dry thoroughly with a soft cloth. For additional

protection agai nst damage to p ainted metal exteriors , apply applianc e wax (or

auto paste wax) with a clean, soft cloth. Do not wax plasti c parts.

6. Plug in appliance or reconnect power.

7. Replace all contai ners.

: Wash exteriors with a clean sponge or soft cloth and a mild

Cleaning a cycle defrost or manual defrost refrigerator

Cycle defrost m odels utilize a sys tem where ice bui lds up on the rear wall and melts

when the compressor is off. Manual defrost models continually build ice on inner

walls.

NEVER USE A METAL OBJECT TO REMOVE ICE FROM THE REAR WALL.

IF NEEDED, USE A PLASTIC ICE-SCR APER O R A HAI R DRYER.

Clean surfaces using the same instructions as for frost-free models.

For CSS Models (complet ely s tainl ess steel) , onl y use clean ers espe ciall y made

for stainless steel.

:

7

Page 9

Base grill

To Remove and Replace the Base Grill:

1. Open the appliance door and remove the base grill by pulling down and out

from the top.

2. Replace the base grill by putting the clips in the openings in the appliance

panel. Push in until the base grill snaps into place.

(some models only):

Changing the light

NOTE: Not all appliance bulbs will fit your appliance. Be sure to replace the bulb

with one of the same size, shape, base size and wattage. You can purchase

bulbs fr om www.summitappliance.com/support

1. Unplug appliance or disconnect power.

2. Remove the light shield. Most models do not require tools.

3. Replace the light bulb with an appliance bulb of the same wattage.

4. Replace the light shield.

5. Plug in appliance or reconnect power.

Loss of power

After the power is restored, unplug the appliance for 30 minutes to allow the

refrigeration system to equalize. During this time, keep the door closed as much

as possible.

Remember: A full appliance stays cold longer than a partially filled one.

Moving the appliance

1. Remove stored items and t ape shelv e s, drawers and trays in place.

2. Unplug the appliance.

bulb

(some models only):

:

:

3. Clean it thoroughly.

4. Tape the appliance shut and tape the electrical cord to the cabinet.

When you get the appliance to its new location, refer to the Installation

Instructions and Temperature Selection sections for information on installation

and setting the controls.

8

Page 10

Temperature Selection and Monitoring

YOUR APPLIANCE MAY HAVE A MECHANICAL (DIAL) OR DIGITAL THERMOST AT.

DIAL INSTRUCTIONS ARE BELOW. DIGITAL INSTRUCTIONS ARE ON PAGE 10.

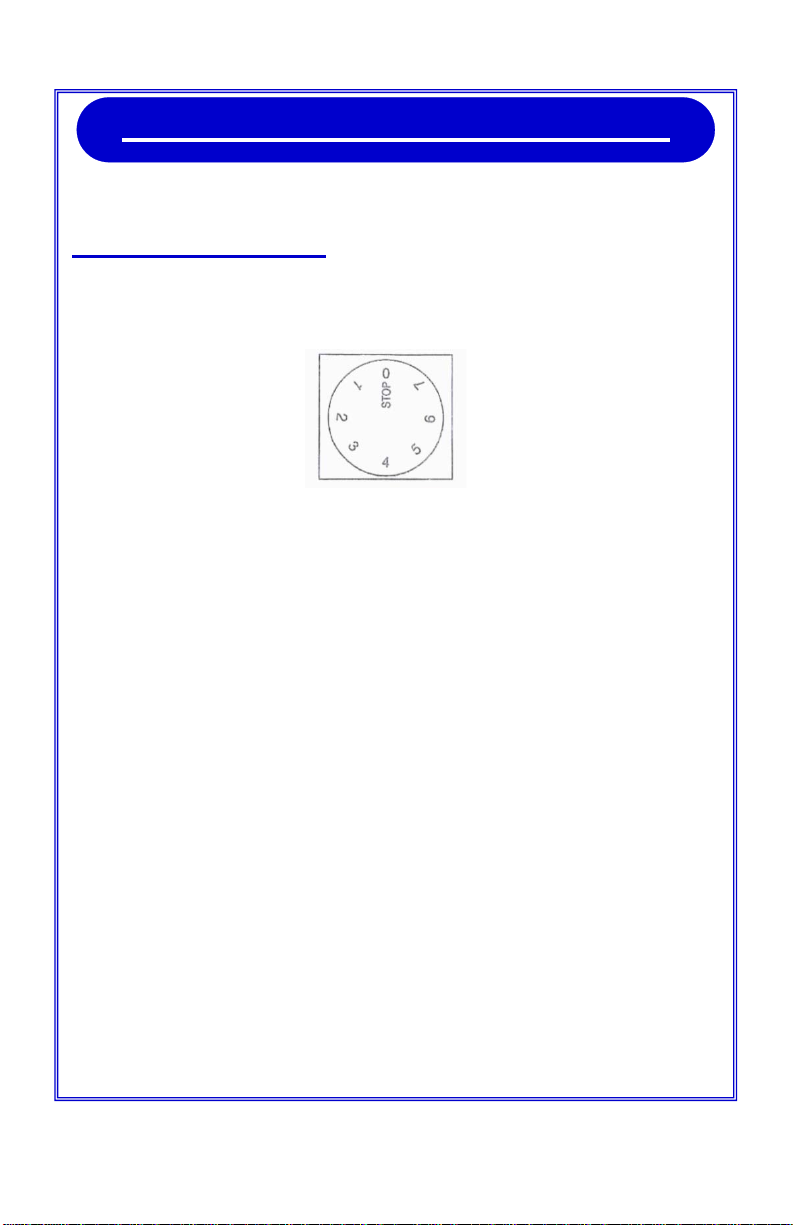

Manual (dial) thermostat

Your refrigerat or may be controlled with a thermostat knob located insi de the unit,

towards the right-hand corner. Turn the knob clockwise from the STOP (0) position

toward the higher numbers for colder t em peratures.

(on most models):

Setting the Temperature:

• Higher settings on the knob (higher numbers) mean lower temperatures

(colder) in all compartments of the appliance. The temperature inside a

refrigerator may even drop below 32°F. Use higher thermostat settings only

when required or recommended. When the ambient temperature is normal,

we recommend a medium setting.

• Changes of the ambient temperature affect temperature in the interior of the

appliance, so keep this in mind when choosing the setting of the thermostat

dial.

• At STOP (0) position, the appliance does not operate (the cooling system is

switched off), but the power supply is not interrupted (the light is on when you

open the refrigerator door).

• The temperatures in the refrigerator and freezer compartments also depend

on how often you open the door.

In all small refrigerators and freezers without interior fans, temperatures are

coldest near the bottom, and occasionally near the rear. Place contents

accordingly.

For optimum temperature performance, it is recom mended that this unit be at

least 30% full during use. If you are onl y using this u nit to stor e small loads,

we recommend adding some water bottles or freezer packs to ensure

temperature stabi lity.

9

Page 11

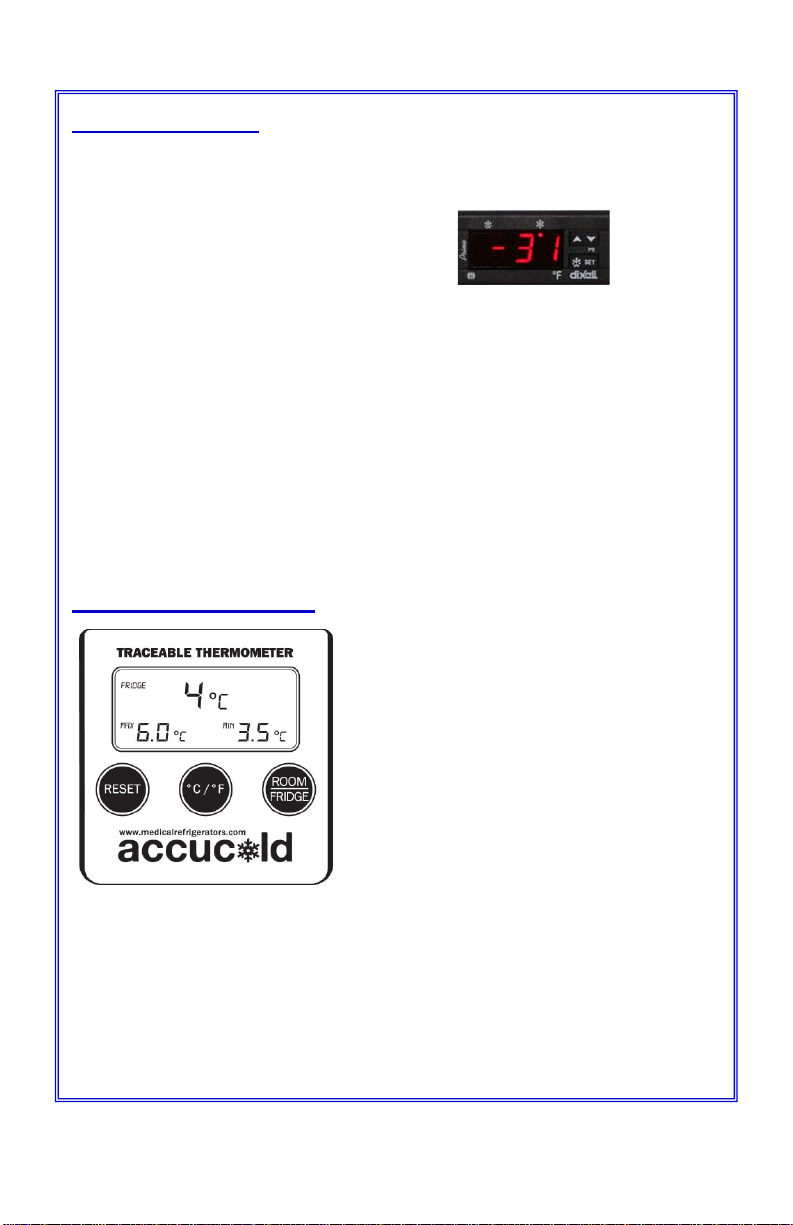

Digital thermostat

melting

snowflake

UP & DOWN arrows

SET key

snowflake

If you find it necessary to cha nge the temperatur e setting for y our digital-thermostat

controlled applianc e, please refer to the following ins tructions. The fr ont panel of the

thermostat is illustrated here:

(on certain models):

To see the SET POINT:

Push and immediatel y release the SET key. The di splay will show the SET POINT

value. Wait 5 seconds and the probe value will display again.

To change the SET POINT:

Push and hold the SET key for more than 3 seconds to chang e the set point value.

The value of the set point will be displayed, and the “snowflake” LED will start

blinking.

To change the SET value:

Push the UP or DOWN arrow to the desired setting. The new setting will be

memorized after 15 s econds, provided no other keys are pushed.

NOTE: The minimum and maximum range of your thermostat is preset and

locked by us, so it cannot easily be accidentally moved bet w een freezer and

refrigerator temperatures. To reset this range lock, either call us or find

information on our website under Troubleshooting.

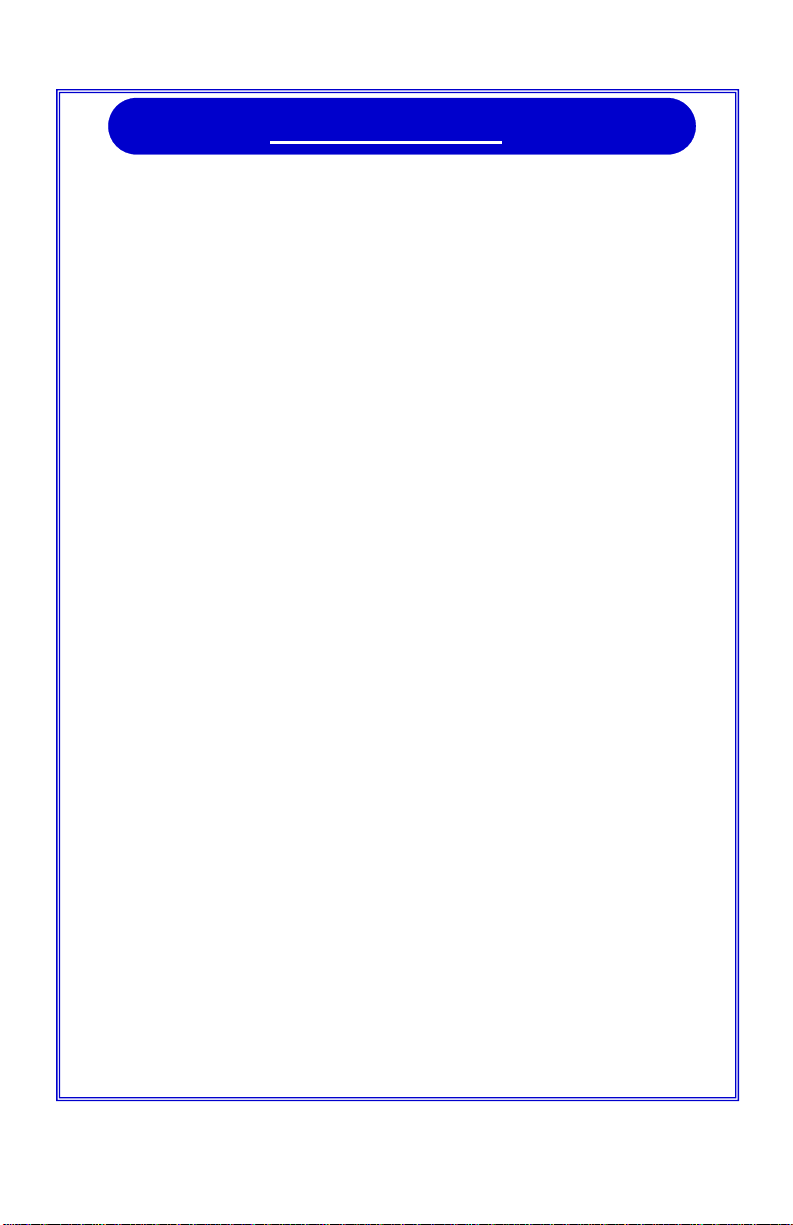

Traceable thermometer

Power to the Traceable Thermometer is supplied with a AAA lithium battery. When it

is inserted correctly, all segments of the LCD displ ay are temporarily activated. When

the battery needs to be replaced, a battery symbol will flash on the display.

The temperature display can be switched between Celsius (°C) and Fahrenheit (°F)

with a push of the

temperature and room temperature when you press the

RESET to clear the Max/Min temperature record.

See instruction pamphlet for more i nformation about the Traceable Thermom eter.

°C/°F button. The display will alternate between refrigerator (probe)

(PLUS models):

This digital t hermometer simult aneously displays

maximum, minimum and current temperatures.

The Max/Min feature monitors and stores the

highest and lowest readings since t he battery

was inserted or since the RESET button was last

pressed.

The temperature s ensor, or probe, is enclosed in

a glycol-fill ed bottle that you insert into the

location to be monit ored, such as inside a

refrigerator or freezer. The thermometer itself

can be attached to the door of the unit with the

magnet on the back, or it can be placed on a

convenient table or shelf.

ROOM/FRIDGE button. Press

10

Page 12

Traceable thermometer/alarm

Power to the Traceable Thermometer/Alarm is supplied w ith a lithium iron disulfide

battery with a 10-year shelf life. When it is inserted c orrectly, the unit will beep and all

segments of the LCD di splay will be temporarily activated. (Note that alarm

temperatures will have to be reset after replacing t he battery.)

The temperature display can be switched between Celsius (°C) and Fahrenheit (°F)

by sliding the

°C/°F button located on the back of the unit.

(MED models):

Every MED unit is equipped with a Trac eable

Thermometer/Alarm that simultaneously displays

minimum, maximum and current interior

temperatures and provides a visual and audible

signal when the temperature inside t he unit falls

outside the set t emperature range.

The temperature s ensor, or probe, i s enclosed in

a glycol-fill ed bottle that you insert into the

location to be monit ored, such as inside a

refrigerator or freezer, once the unit has been

programmed. The thermometer/alarm itself can

be attached to the door of the unit with the

magnet on the back, or it can be placed on a

convenient table or shelf.

Function of Controls:

MODE/RESET Key: Press ONCE to reset Max/Min temperature record. When the unit

is sounding an alarm, press ONCE to tur n off the beeping sound .

HIGH/LOW Key: Press O N C E to display high alarm setting. Press TWICE to display

low alarm setting. Press THREE TIMES to display curr ent temperature readi ng.

ALERT ON/OFF Key

However, the High-Alarm or Low-Alarm will still flash until the temperature goes

back to normal or the Alarm function is turned off.

: When the unit is sounding an alarm, press ONCE to turn of f.

Programming the Alarms:

The thermometer di splays the inter nal temperature of t he unit being monitor ed, as

well as the maximum and minimum temperat ures reached. The maximum and

minimum readings reflect the highest and lowest temperatures since the battery was

inserted or since the MODE/RESET key was last pressed. I f the temperature ri ses

above or falls bel ow the set temperature r ange, the alarm will sound. By default, the

high alarm temperature setting is 8°C (46.4°F) and the low al arm temperature s etting

is 2°C (35.6°F). T o reset these limits, follow these instructions:

High Alarm Temperature Setting: P ress the HIGH/LOW key ON CE, then press

MODE/RESET to enter the High Alarm temperature setting mode. Use the Up and

Down arrows to adjus t the temperature accordingly. Press MODE/RESET once

again to confirm the setting.

Low Alarm Temperature Setting: Pr ess the HIGH/LOW key TWICE, then press

MODE/RESET to enter the Low Alarm temperatur e setting mode. Use the Up and

Down arrows to adjus t the temperature accordingly. Press MODE/RESET ONCE to

confirm the setting.

11

Page 13

Thermometer/alarm instructions

By default, the l ow and high alarms should be audible. To turn alarms on/off:

Audible High Alarm S etting: To make s ure the high alarm is audible, press HIGH/LOW

key ONCE (to activate HI-SET on the sc reen). Then press the ALERT ON/OFF key

ONCE to activate t he H IGH-ALARM beeping sound. Press again to deactivate.

Audible Low Alarm Setting

press the HIGH/LOW k ey TWICE to activat e LOW-SET on the screen. Then press

the ALERT ON/OFF key ON C E to activate t he LOW-ALARM beeping sound. Press

again to deactivat e.

NOTE: For an activated hi gh alarm and low alarm

buzzer, the displ ay should indicate HI-ALARM

and LO-ALARM as shown her e.

More details about the features and usage of the Traceable Thermometer/Alarm can

be found in the User M anual accompanying the unit.

: To make sure t hat the low temperature alarm is audible,

(cont’d):

Keypad Lock

Factory-set default password: The factory-set default password is 0123. If the default

password is lost, press t he key (locat ed inside the battery box) for

seconds, then wait for the warning sound which signif ies the factory-set

default password has been restored.

To set the password

inside the battery box) until it j ingles, enter the 0123 password, then #

within 10 seconds to confirm. Enter your password (1-16 digits), then

press # again to confirm. A total of 10 passwords can be set.

NOTE: Each password starts with a number from 0 to 9 in order. The first password starting

with 0 is the default password. For example, use 1xxx, then 2xxx etc. for 10 users.

Changing password

box) until it jingles, enter the old password and press # within 10 seconds to confirm. Enter

the new password, then press # to confirm.

NOTE: The first digit cannot be changed.

To open the door: While the door is closed, press the START/END key, enter the

password, then press START/END

To lock door manually: Press #.

Function setting of automatic lock: Setting of the auto-lock time: Press the key

(inside the battery box), enter a number (any number between 10-99), then press # to

confirm. The auto-lock time can be set between 10-99 seconds after opening the door. If

the time is set less than 10 seconds, the door will not lock automatically, only manually.

Deleting the door-opening passwords

password followed by 0000, then press # and all the door-opening passwords will be

deleted except for the default password.

NOTE: To access the battery box you need to remove only the two small screws on the top

and bottom of that cover. Do not remove the 4 screws holding the keypad and cover to

the appliance door.

: While the door is open, press the key (located inside the battery

(optional on most models)

: While door is open, press the key (located

again to confirm.

: Press the START/END

key, enter default

30

12

Page 14

Operation of Specific Models

SCFF51OSWH MED Series

These frost-free all-freezers c an be built-in or free-standing. T hey do not require defros ting

and have a digital thermostat, LED lighti ng and a lock. At the top of the unit is a c ooling

system that uses a fan to provide cold air. For best operation, do not block the air flow with

contents.

FF6L, FF7L, FF28LWH, FF511L, FF521BL, FF590SSHH, FFAR2L, FFAR10, FFAR21L,

FFAR24L, SCR450L, SCR500BL, SCR600L, SCR610BL PLUS & MED Series;

SP6DS2D7, SP6D S7, SP6DSSTB7 MED Series only

These models are all-refrigerators (no freezer compartment) with automatic defrost. All

have cold plates on the rear wall, and the coldest s pots in the refri gerator will be in t he rear

and toward the bottom. All have int erior fans to promote even cooling. In t he rear bottom

above the step, t here is a drain line t o allow defrost water to exit the refri gerator. Keep thi s

drain line clear, or icing inside the refrigerator will occur. FF7, FF511L, FF 521BL, and SCR

series models have lights that are not door-activated, and are controll ed by a rocker switch

on the top right. The light generates a small amount of heat, so minimize the use of the light

for best operation and energy savings. FF6 models and FFAR10 models all have dooractivated lights. Smaller models and drawer models do not have interior lights.

NOTE: FF590, models with BI in the model numbe r, and all drawer unit s are designed for

built-in operation and need very little clearance on the sides and above the units.

other models

models operate best when 2 inches is provided between the rear wall and the back of

the unit.

FCL44, FS20L, FS21L, FS22L, FS24L, FS30L, FS60ML, FS407L, FS408BL, VT65ML

PLUS & MED Series

Model FCL44 is a chest freezer; all of the others are upright. These are manual defrost all freezers. No internal fans are present, and ice will build up along the cooling coils.

Periodically defrost the ice (rec ommended when the ice level reach es a thick ness of 1/4 to

1/2 inch). NEVER USE A METAL INSTRUMENT as you can damage the cooling coils,

which will void your warranty and often cannot be repaired. To defrost, disconnect from the

power supply, empty the contents, provide a tray in the bottom to collect water, and use a

hairdryer or other source of warm air to melt the ice (or leave the door open and the power

off for 24 to 48 hours). For built-in (BI) models and clearance information, see NOTE

above.

CP35LL PLUS & MED Series; CT66 PLUS Series only

These models are cycle defrost refri gerator-freezers. The freezers are desi gned to operate

at 0°F (-18°C), suitable for medical or laboratory uses. These models have dual

evaporators to maintain separat e temperatures in the f reezer and refrigerator. Def rost the

freezer carefully, as directed above for manual defrost. The refrigerat or section operates in

the normal range (35 to 45°F, or 2 to 7°C) and defrosts automatically. For built-in (BI)

models and clearance information, see NOTE above.

CM411L, CM421BL, S19LWH PLUS Series

These models are manual defrost ref rigerator-freezers. The freezers in thes e models are

designed to operate at 25°F (-4°C) to keep i ce frozen, and not for medicat ion or products

needing colder temperatures. Defrost c arefully, following directions above. The refrigerator

section will operate in the normal range (35 to 45°F, or 2 to 7°C) and is suitable for most

refrigerated products. For built-in (BI) models and clearance information, see NOTE above.

require at least 1 inch of airflow on the sides and above the units. All

All

13

Page 15

Troubleshootin

g

Try these solutions first to avoid the cost of an unnecessary service call.

Your appliance will not operate:

•

Has a household fuse blown or circuit breaker tri ppe d?

Replace the fuse or reset the circuit breaker.

• I s the fr eeze r de fr os ti ng ( on some model s ) ?

Recheck to see whether the freezer is operating in 30 minutes. Your freezer will regularly run an

automatic defrost cycle.

There is water in the defrost drain pan (on some models):

•

Is the freezer defrosting?

The water will evaporate. It is norm al fo r wat er to dri p int o the defrost pan.

• Is it more humid than normal?

When it is humid, expect that the water in the defrost pan will take longer to evaporate.

The motor seems to run too much:

•

Is there excessive frost or a package preve nti ng t he door fr om closing?

Defrost and clean the freezer, or move the package so the door closes properly.

• I s the room tempe ra t ure hotter than normal?

The motor will run longer under warm conditions. At normal room temperatures, the motor will run

about 40% to 80% of the time. Under warmer conditions, it will run even more.

• Has a large amount of food just been added to the freezer?

Adding a large amount of food warms the freezer. The motor normally will run longer to cool the

freezer back down.

• I s the door cl os e d comple t el y?

Push the door firmly shut. If it will not shut all the way, see The door will not close completely later

in this section.

• Are the condenser coils dirty (on some models)?

This prevents heat transfer and makes the motor work harder. Clean the condenser coils.

• I s the door gasket sealed all the way around?

If not, contact a qualified technician.

NOTE: If the problem is not due to any of the above, remember that the compressor on your new

appliance will operate longer than your old one due to its high-efficiency motor.

Temperature is too warm:

•

Are the air vents blocked?

This prevents cold air movement. Move objects away from the air vents.

• I s the door ope ne d ofte n?

Be aware that the freezer will warm when this occurs. In order to keep the freezer cool, try

to get everything you need out of the freezer at once, keep food organized so it is easy to

find, and close the door as soon as the food is removed.

• Has a large amount of food just been added to the freezer?

Adding a large amount of food warms the freezer. It can take several hou rs for the freez er to

return to the normal temperature.

The door will not close completely or is difficult to open:

•

Are food packages blocking the door?

Rearrange containers so that they fit more tightly and take up less space.

• Ar e the shelves or drawers out of position (on some models)?

Put the shelves and drawers back into their correct positions.

14

Page 16

Limited Warrant y

FELIX STORCH, INC.

For parts and accessory ordering,

January 2015

WARNING! This product may contain chemicals known to the state of

ONE YEAR LIMITED WARRANTY FOR APPLIANCE

Within the 48 co ntiguous Uni ted State s, for one ye ar from th e date of pu rchase, whe n this appli ance is

operated and maintai ned according to instructions attac hed to or furnishe d with the product, warrantor

will pay for factory-specified parts and repair labor to correct defects in materials or workmanship.

Service must be provided by a designated service company. Outside the 48 states, all parts are

warranted for one yea r from m anufa ctu ring def ects. Pl asti c parts , shel ves and cabin ets are warran te d to

be manufactured to commercially acceptable standards, and are not covered from damage during

handling or breakage.

5-YEAR COMPRESSOR WARRANTY

1. The compressor is covered for 5 years.

2. Replacement does not include labor.

ITEMS WARRANTOR WILL NOT PAY FOR:

Service calls to correct the installation of your appliance, to instruct you how to use your appliance, to replace or

1.

repair fuses or to correct wiring or plumbing.

2. Service calls to repair or replace appliance light bulbs or broken glass shelves. Consumable parts (such as filters)

are excluded from warranty coverage.

3. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation, installation

not in accordance with electrical or plumbing codes, or use of products not approved by warrantor.

4. Replacement parts or repair labor costs for units operated outside the United States.

5. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

6. Expenses for travel and transportation for product service in remote locations.

7. The removal and reinstallation of your appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

DISCLAIMER OF IMPLIED WARRAN TIES – LIMITATION OF REMEDIES

CUSTOMER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE

PRODUCT REPAIR AS PROVIDED HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR.

WARRANTOR SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT

APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO

HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE.

California to cause cancer or birth defects or other reproductive harm. For

more information, visit: www.summitappliance.com/prop65

Chemicals known by the manufacturer to be present in this product in

concentrations higher than threshold limits: NONE.

770 Garrison Avenue

Bronx, New York 10474

Phone: (718) 893-3900

Fax: (844) 478-8799

www.summitappliance.com

15

troubleshooting and helpful hints,

visit:www.summitappliance.com/support

Loading...

Loading...