Page 1

Elcold Frysere Hobro ApS

Løgstørvej 81 Hørby 9500 Hobro Denmark

Phone +45 9657 2222 Fax +45 9852 4685

Email elcold@elcold.com www.elcold.com

i.c. graphics cph

Page 2

User Instructions

Low Temperature Freezers Model UNI/LT

Page 3

USER INSTRUCTIONS

Congratulations on your new low temperature

freezer. We trust that it will serve you for many years

to come. In order to gain optimum benefit from

your freezer, please read the following instructions

thoroughly and act accordingly. The low-temperature freezers are used for freezing and long-term

storing of food products, medical preparations (

vaccines, blood plasm, ect.) and other biological

products.

1. Environmental protection and disposal.

The packaging is designed to protect the

appliance and its components during

transportation, and it is made of recyclable

materials.

• Please return the packaging to an

official collection point for recycling.

• Old appliances contain reusable

materials and should not be disposed

of together with household refuse.

• Remove the spring-action hinges from

the appliance, in order to prevent

children from being entrapped in the

appliance.

• Ensure that no part of the refrigeration

tubing is damaged as the refrigerant

in the appliance risks escaping to the

environment.

• Information about refrigerant type

and amount will be found on the type

plate on the rear of the appliance

(Fig. 1).

2. Safety instructions.

• In order to prevent injuries and or

damage to the appliance, it should

be unpacked and set up by min. two

people.

• If upon unpacking the appliance is

found damaged, do not connect to

the mains, but contact the supplier.

• Interference with or repair to the

appliance should only be carried out

by authorized personnel, in order to

avoid any injuries. (contact the sup plier for further information).

• Never put naked flames or other igni tion sources inside the appliance.

• Never touch the freezers interior or

products in the freezer when the

GB

freezer is operating. Use gloves or alike

in order to avoid injuries (frost-bite).

• Keep the key to the appliance away

from the appliance and out of the

reach of children.

3. Connection to the mains.

• For safety reasons the appliance must

be earthed. If you are in any doubt,

please contact an authorized electri

cian.

• The appliance should be left for 5

hours before it is connected to the

mains. If the appliance is connected

before that, there is a risk of damaging

the compressor.

• If for any reason the appliance is

disconnected from the mains, please

wait 10 minutes before re-connecting.

The electronic starting device needs

this time to cool down, before a safe

re-start can be made.

4. Before use.

• Before use, the interior of the appli ance should be cleaned with a mild

soap solution, and wiped off with a dry

clean cloth. Never use any kind of

solvent or other chemicals.

5. Setting up the freezer.

The freezer should not be placed where it

might be splashed with water, in extreme

high humidity or in direct sunlight. Any of

these factors may lead to a reduction in

performance and shorten the life span of

the components. The freezer should be

placed on a horizontal level, and should

not be placed close to a heating appliance

or heating tubes. Allow a minimum of 50mm

(2”) clearance on the side and the back.

The side with the ventilation grill should have

a clearance of at least 100 mm (4”) in order

to allow the heat from the compressor

motor to dissipate. Underneath the appliance there should be a gap of 15 mm approx. (1⁄2”). On a soft surface, e.g. carpet,

it may be necessary to ensure the correct

distance by means of spacers.

User Instructions Low Temperature Freezers Model UNI/LT

2

Page 4

6. Electrical supply.

The electrical supply should always be in

accordance with the rating plate on the

back of the freezer.

The supply must always be in accordance

with the law and regulations regarding

electrical safety, if any doubts contact your

supplier.

7. Starting Up.

In case the compressor does not start when

the freezer has been plugged in, the electrical supply may not be in order. Check if

there is an electricity supply to the plug or if

the fuse is blown. If not please go to trouble

shooting page 6. 18.

The ice layer is easily removed with a plastic

or wooden scraper. Never use a sharp metal

object which might will cause damage to

the inner liner.

The defrosting frequency is determined

mainly by two factors the usage pattern

(number of lid openings) and the relative

humidity. Excess water can be drained out

by using the drain water outlet on the front

of the freezer.

10.Cleaning.

Cleaning should be done when needed.

When used in a dirty environment it might

be necessary to remove the compressor

compartment grill, and clean the compressor compartment eventually with a vacuum

cleaner.

If the cleaning process is neglected there

is a risk that the performance of the freezer

will be effected, and even damage to the

compressor could occur due to overheating.

8.Operating the freezer

The empty freezer should be switched on

for at least 5-6 hours prior to loading of the

freezer. The freezer should not be loaded

above the inside walls which is also the load

line limit.

Please note: After the lid has been opened,

there will be a vacuum created inside the

freezer due to the low temperatures. Wait a

few minutes before trying to reopen the lid

otherwise the handle could be damaged.

Fig. 1

9.Defrosting.

In order for the freezer to work to its maximum efficiency the cabinet should be defrosted when a approx. 2mm thick ice layer

has formed inside the cabinet.

11. Storage.

If the freezer is stored for a period of time,

the lid should be kept open for free circulation of air inside the cabinet in order to

avoid corrosion of the inner liner.

12. Temperature control UNI/LT- freezers.

The temperature inside the freezer is controlled by the electronic controller in the

front grill. The controller has a digital readout

of the temperature inside the cabinet. and

3

User Instructions Low Temperature Freezers Model UNI/LT

Page 5

the option of changing the temperature

inside the cabinet.

13. External voltage and temperature alarm.

Optionally the freezer can be equipped with

a battery operated alarm box with connections for external alarm for voltage failure

and temperature alarm. The battery should

be exchanged every two years.

Please note! When commissioning the

freezer, the battery must be turned into its

correct position. More details on page 17.

14.Dixell controller.

15. Functions.

How to see the set point:

1.Press and immediately release the SET key,

the display will now show the set point value.

2.Press and immediately release the SET key

or wait for 5 seconds to display the probe

value again.

How to lock and unlock the keyboard

1.Press the up and down keys simultaneously

for more than 3.seconds.

How to change the set point

1.Press the SET key for more than 3.seconds

to change the set point value.

2.The set point value will be displayed and

the LED starts flashing.

3.To change the set point value, push the up

or down arrow.

4. To memorise the new setting press the SET

key again or wait 15 seconds for the controller to return to normal display of the probe

temperature.

16. Setting the controllers offset value

The UNI/LT freezer is designed for long time

and safe storage of sensitive products.

In some situations the UNI/LT freezer is also

used for other applications like in laboratories for different low temperature test.

Depending on the actual situation it might

be necessary to change the controllers offset value in order to get a correspondence

between the reading on the display and the

actual temperature inside the cabinet.

The factory setting is an offset of 0 dgr:C.

The offset can be adjusted in the following

way.

Unlock the keyboard.

Enter the programming mode by pressing

the SET and arrow down keys for 3 seconds.

Select the parameter “Ot” by pressing arrow

up or down key.

Press the SET key to display its value.

Use arrow up or down to change its value.

The offset can be adjusted to +/- 12 dgr .C

Press SET to store the new value.

Press SET + arrow up or wait 15 seconds

without pressing any key. The new value will

now be stored.

For more detailed information about

programming the Dixell controllers please

consult the attached manuals.

17. Trouble shooting.

The appliance is not operating. Please

check:

Is the electrical plug connected to the

mains (wall socket)? Has the fuse blown?

The temperature inside the appliance is too

high. Please check:

Is the Dixell controller set to the correct

temperature?

Has an excess amount of ice formed inside

the appliance?

The appliance is operating continuously.

Please check:

Is the ambient temperature very high?

Has the appliance recently been loaded

with a large amount of warm products?

If you have checked the above points and the appliance is still not working as expected, please contact

your local dealer for further advice.

User Instructions Low Temperature Freezers Model UNI/LT

4

Page 6

INSTALLING AND OPERATING INSTRUCTIONS

Digital controller with off cycle

defrost

XR30C

GENERAL WARNING

Please read before using this

manual

• This manual is part of the product and

should be kept near the instrument for

easy and quick reference.

• The instrument shall not be used for

purposes different from those de

scribed hereunder. It cannot be used

as a safety device.

• Check the application limits before

proceeding.

Safety Precautions

• Check the supply voltage is correct

before connecting the instrument.

• Do not expose to water or moisture:

use the controller only within the

operating limits avoiding sudden

temperature changes with high at-

mospheric humidity to prevent forma tion of condensation

• Warning: disconnect all electrical con nections before any kind of mainte nance

• Fit the probe where it is not accessible

by the End User. The instrument must

not be opened.

• In case of failure or faulty operation

send the instrument back to the dis tributor with a detailed description of

the fault.

• Consider the maximum current which

can be applied to each relay (see

Technical Data).

• Ensure that the wires for probes, loads

and the power supply are separated

and far enough from each other,

without crossing or intertwining.

• In case of applications in industrial

environments, the use of mains filters

(our mod. FT1) in parallel with

inductive loads could be useful.

GENERAL DESCRIPTION

Model XR30C, format 32 x 74 mm, is a digital

termostat with off cycle defrost designed for

refrigeration applications at normal temperature. It provides two relay outputs, one for

the compressor, the other one can be used

for alarm signalling or as auxiliary output. The

probe input can be selected between PTC

or NTC. The instrument has a digital input, for

alarm signalling, for switching the auxiliary

output or for start a defrost cycle. The instrument is fully configurable through special

parameters that can be easily programmed

through the keyboard.

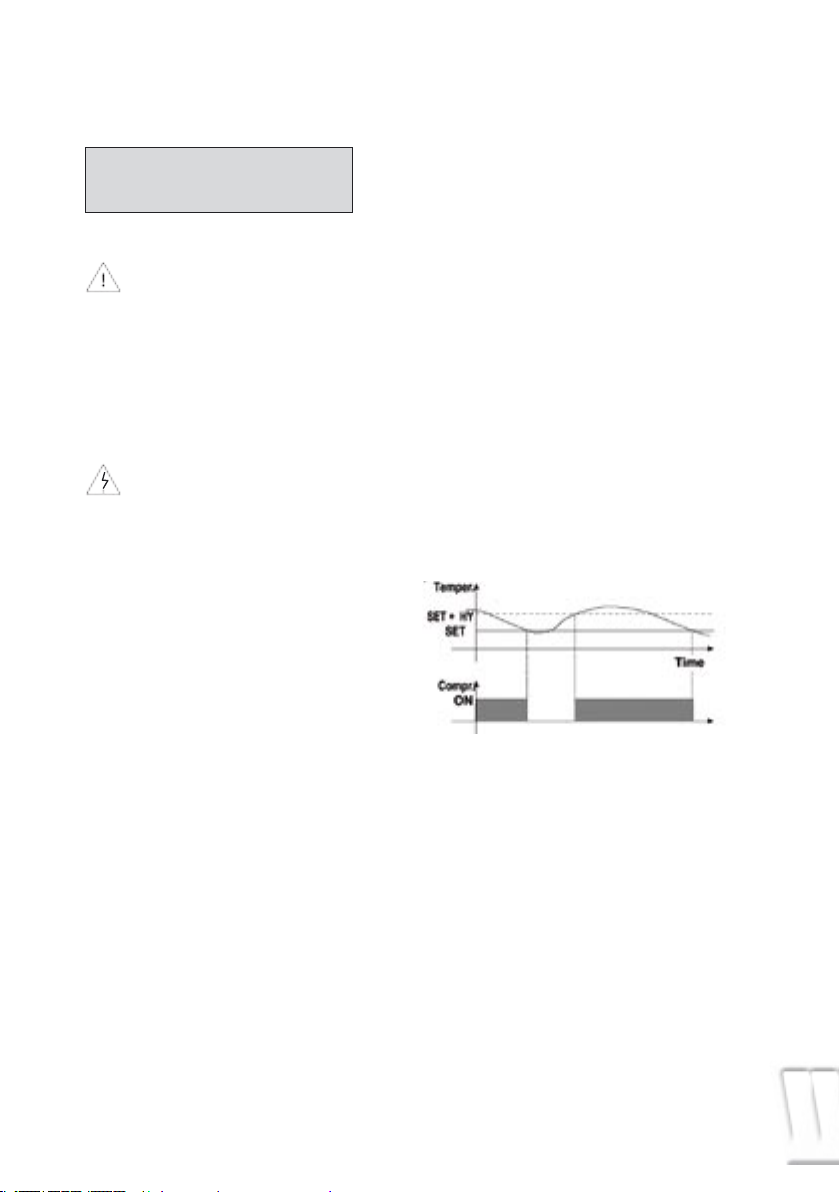

CONTROLLER LOADS

COMPRESSOR

The regulation is performed according to

the temperature measured by the thermostat probe with a positive differential from

the set point: if the temperature increases

and reaches set point plus differential the

compressor is started and then turned off

when the temperature reaches the set point

value again.

In case of fault in the thermostat probe the

start and stop of the compressor are timed

through parameters “COn” and “COF”.

DEFROST

Defrost is performed through a simple stop

of the compressor. Parameter “IdF” controls

the interval between defrost cycles, while its

length is controlled by parameter “MdF”.

5

User Instructions Low Temperature Freezers Model UNI/LT

Page 7

FRONT PANEL COMMANDS

SET: To display target set point; in pro

gramming mode it selects a

parameter or confirm an opera

tion.

(DEF) To start a manual defrost

(UP) To see the last temperature

alarm happened; in program

ming mode it browses the para meter codes or increases the

displayed value.

(DOWN) To see the last temp erature alarm happened; hold

pressed it switches the auxiliary

output; in programming mode it

browses the parameter codes or

decreases the displayed value.

KEY COMBINATIONS:

+ To lock & unlock the keyboard.

SET + To enter in programming mode.

SET + To return to the room temperature

display.

HOW TO SEE THE ALARM DURATION AND MAX

(MIN) TEMPERATURE

If the alarm LED is on, an alarm has taken

place.

To see the kind of alarm, the max (min)

reached temperature and alarm duration

do as follows:

1. Push the Up or Down key.

2. On the display the following mes

sage is shown::

“HAL” for high temperature alarm

(“LAL” fot the minimum allarm),

followed by the Maximum (mini-

mum) temperature.

Then the “tiM” (tiMe) message is

displayed, followed by the “Dura-

tion” in h.mm.

3. Then the instrument displays the

temperature once again.

NOTE1: if an alarm is still occurring the “tim”

shows the partial duration.

NOTE2: the alarm is recorded when the temperature come back to normal values

HOW TO RESET A RECORDED ALARM OR ONE

THAT IS STILL OCCURRING

1. Hold the SET key pressed for more

than 3s, while the recorded alarm

is displayed. (the rSt message will

be displayed)

2. To confirm the operation, the “rSt”

message starts blinking and the

normal temperature will be dis

played.

TEMPERATURE ALARM AND ITS DURATION

RECORDING (HACCP)

XR30C signals and records temperature

alarms, together with their duration and

max value reached. See drawing:

User Instructions Low Temperature Freezers Model UNI/LT

MAIN FUNCTIONS

HOW TO SEE THE SETPOINT

1. Push and immediately release

SET

the SET key: the display will show

the Set point value;

2. Push and immediately release

the SET key or wait for 5 sec-

onds to display the probe value

again.

HOW TO CHANGE THE SETPOINT

1. Push the SET key for more than 2

seconds to change the Set point

value;

2. The value of the set point will be

6

Page 8

displayed and the LED starts

blinking;

3. To change the Set value push the

o or n arrows within 10s.

4. To memorise the new set point

value push the SET key again or

wait 10s.

HOW TO START A MANUAL DEFROST

Push the DEF key for more than

2 seconds and a manual defrost

will start.

HOW TO SWITCH ON OR OFF THE SECOND

RELAY(OAC= LHt)

Hold pressed the n key for some

AUX

seconds, till the AUX LED is turned

ON or OFF

HOW TO CHANGE A PARAMETER VALUE

To change the parameter’s value operate

as follows:

1. Enter the Programming mode

by pressing the Set and

DOWN key for 3s ( and

SET

start blinking).

2. Select the required parameter.

3. Press the “SET” key to display its value

(now only the LED is blinking).

4. Use “UP” or “DOWN” to change its value.

5. Press “SET” to store the new value and

move to the following parameter.

To exit: Press SET + UP or wait 15s without

pressing a key.

NOTE: the set value is stored even when the

procedure is exited by waiting the time-out

to expire.

THE HIDDEN MENU

The hidden menu Includes all the parameters of the instrument.

HOW TO ENTER THE HIDDEN MENU

1. Enter the Programming mode

by pressing the Set + n key for

3s (LED 1 and start blinking).

SET

2. When a parameter is displayed

keep pressed the Set+ n for

more than 7s. The Pr2 label will

be displayed immediately fol lowed from the HY parameter.

NOW YOU ARE IN THE HIDDEN

MENU.

3. Select the required parameter.

4. Press the “SET” key to display its value

(Now only the LED is blinking).

5. Use o or n to change its value.

6. Press “SET” to store the new value and

move to the following parameter.

To exit: Press SET + o or wait 15s without

pressing a key.

NOTE: the set value is stored even when the

procedure is exited by waiting the time-out

to expire.

HOW TO MOVE A PARAMETER FROM THE

HIDDEN MENU TO THE FIRST LEVEL AND VICEVERSA.

Each parameter present in the HIDDEN

MENU can be removed or put into “ THE

FIRST LEVEL” (user level) by pressing “SET+ n”

In HIDDEN MENU when a parameter is present in First Level the decimal point is on.

HOW TO LOCK THE KEYBOARD

1. Keep pressed for more than 3 s the o and

n keys.

2. The “POF” message will be displayed and

the keyboard will be locked. At this point

it will be possible only to see the set point

or the MAX o Min temperature stored

3. If a key is pressed more than 3s the “POF”

message will be displayed.

TO UNLOCK THE KEYBOARD

Keep pressed together for more than 3s the

and keys, till the “Pon” message will be

displayed.

THE CONTINUOUS CYCLE

When defrost is not in progress,

it can be activated by holding

the “o” key pressed for about 3

seconds.

The compressor operates in continuous

mode for the time set through the “CCt”

parameter. The cycle can be terminated

before the end of the set time using the

same activation key “o” for 3 seconds.

7

User Instructions Low Temperature Freezers Model UNI/LT

Page 9

PARAMETERS

NOTE: the parameters preceded by dots are

in the Hidden Menu.

REGULATION

Hy Differential: (0,1 ÷ 25,5°C / 1÷255 °F) Intervention differential for set point. Compressor

Cut IN is Set Point Plus Differential (Hy). Compressor Cut OUT is when the temperature

reaches the set point.

• LS Minimum set point: (- 50°C÷SET-58°F÷

SET): Sets the minimum acceptable value

for the set point.

• US Maximum set point: (SET÷110°C/ SET÷

230°F). Set the maximum acceptable

value for set point.

Ot Thermostat probe calibration: (-12.0÷

12.0°C; -120÷120°F) allows to adjust possible

offset of the thermostat probe.

• OdS Outputs activation delay at start up:

(0÷255min) This function is enabled at the

initial start up of the instrument and inhibits

any output activation for the period of

time set in the parameter.

AC Anti-short cycle delay: (0÷50 min) minimum interval between the compressor stop

and the following restart.

• CCt Compressor ON time during continu

ous cycle: (0.0÷24.0h; res. 10min) Allows

to set the length of the continuous cycle:

compressor stays on without interruption

for the CCt time. Can be used, for in-

stance, when the room is filled with new

products.

• COn Compressor ON time with faulty

probe: (0÷255 min) time during which

the compressor is active in case of fauly

thermostat probe. With COn=0 compressor

is always OFF.

• COF Compressor OFF time with faulty

probe: (0÷255 min) time during which the

compressor is OFF in case of faulty thermo

stat probe. With COF=0 compressor is

always active.

CH Type of action: CL = cooling; Ht = heating.

DISPLAY

• CF Temperature measurement unit:

°C=Celsius; °F=Fahrenheit. WARNING: When

the measurement unit is changed the SET

point and the values of the parameters Hy,

LS, US, Ot, ALU and ALL have to be checked

and modified if necessary).

rES Resolution (for °C): (in = 1°C; dE = 0.1 °C)

allows decimal point display.

DEFROST

IdF Interval between defrost cycles: (0÷120h)

Determines the time interval between the

beginning of two defrost cycles.

MdF (Maximum) length for defrost: (0÷255min)

When P2P = n, (not evaporator probe: timed

defrost) it sets the defrost duration, when P2P

= y (defrost end based on temperature) it sets

the maximum length for defrost.

• dFd Temperature displayed during defrost: (rt

= real temperature; it = temperature at de

frost start; SEt = set point; dEF = “dEF” label)

• dAd MAX display delay after defrost:

(0÷255min). Sets the maximum time

between the end of defrost and the restart

ing of the real room temperature display.

ALARMS

• ALC Temperature alarms configuration:

(Ab; rE) Ab= absolute temperature: alarm

temperature is given by the ALL or ALU

values. rE = temperature alarms are re

ferred to the set point. Temperature

alarm is enabled when the temperature

exceeds the “SET+ALU” or “SET-ALL”

values.

ALU MAXIMUM temperature alarm:

(SET÷110°C; SET÷230°F) when this temperature is reached the alarm is enabled, after

the “ALd” delay time.

ALL Minimum temperature alarm: (-50.0 ÷

SET°C; -58÷230°F when this temperature is

reached the alarm is enabled, after the

“ALd” delay time.

• ALd Temperature alarm delay: (0÷255 min)

time interval between the detection of an

alarm condition and alarm signalling.

• dAO Exclusion of temperature alarm at

startup: (from 0.0 min to 23.5h) time interval

between the detection of the tempera-

ture alarm condition after instrument

power on and alarm signalling.

SECOND RELAY AND DIGITAL INPUT

• tbA Alarm relay silencing (with oAC=ALr):

(n= silencing disabled: alarm relay stays

on till alarm condition lasts, y =silencing

enabled: alarm relay is switched OFF by

pressing a key during an alarm).

User Instructions Low Temperature Freezers Model UNI/LT

8

Page 10

OA1 Second relay configuration: ALr: alarm;

LHt: auxiliary; onF: always on;

dEF: do not select it!.; FAn: do not select it!.;

AoP Alarm relay polarity: it set if the alarm

relay is open or closed when an alarm happens. CL= the relay is closed; oP = the relay

is open

i1P Digital input polarity: oP: the digital input

is activated by opening the contact; CL:

the digital input is activated by closing the

contact.

i1F Digital input configuration:

EAL = external alarm: “EA” message is dis-

played; bAL = serious alarm “CA” message is

displayed. PAL = pressure switch alarm, “CA”

message is displayed; dor = door switch

function; dEF = activation of a defrost cycle;

LHt =switch on the second relay if oA1=LHt;

Htr = kind of action inversion (cooling – heat-

ing).

did: (0÷255 min)

with i1F= EAL or i1F = bAL digital input alarm

delay: delay between the detection of the

external alarm condition and its signalling.

with i1F= dor: door open signalling delay

with i1F = PAL: time for pressure switch function: time interval to

calculate the number of the pressure switch

activation.

nPS Pressure switch number: (0 ÷15) Number

of activation of the pressure switch, during

the “did” interval, before signalling the

alarm event (I2F= PAL). If the nPS activation

in the did time is reached, switch off and on

the instrument to restart normal regulation.

• odc Compressor status when open door:

no, Fan = normal; CPr, F_C = Compressor

OFF

OTHER

PbC Type of probe: it allows to set the kind

of probe used by the instrument: PbC = PBC

probe, ntC = NTC probe.

• rEL Software release for internal use.

• Ptb Parameter table code: readable only.

DIGITAL INPUT

The free contact digital input is programmable in five different configurations by the

“i1F” parameter.

DOOR SWITCH INPUT (i1F = dor)

It signals the door status and the corre-

sponding relay output status through the

“odc” parameter:

no, Fan = normal (any change);

CPr, F_C = Compressor OFF;

Since the door is opened, after the delay

time set through parameter “did”, the door

alarm is enabled, the display shows the message “dA” and the regulation restarts. The

alarm stops as soon as the external digital

input is disabled again. With the door open,

the high and low temperature alarms are

disabled.

GENERIC ALARM (i1F = EAL)

As soon as the digital input is activated the

unit will wait for “did” time delay before

signalling the “EAL” alarm message. The

outputs status don’t change. The alarm

stops just after the digital input is de-activated.

SERIOUS ALARM MODE (i1F = bAL)

When the digital input is activated, the unit

will wait for “did” delay before signalling the

“CA” alarm message. The relay outputs are

switched OFF. The alarm will stop as soon as

the digital input is de-activated.

PRESSURE SWITCH (i1F = PAL)

If during the interval time set by “did” parameter, the pressure switch has reached

the number of activation of the “nPS” parameter, the “CA” pressure alarm message

will be displayed. The compressor and the

regulation are stopped. When the digital

input is ON the compressor is always OFF.

If the nPS activation in the did time is reached, switch off and on the instrument

to restart normal regulation.

SWITCHING SECOND RELAY ON (i1F = LHt)

With oA1= LHt it switches on and off the

second relay.

START DEFROST (i1F = dFr)

It starts a defrost if there are the right conditions. After the defrost is finished, the normal

regulation will restart only if the digital input

is disabled otherwise the instrument will wait

until the “MdF” safety time is expired.

INVERSION OF THE KIND OF ACTION: HEATINGCOOLING (i1F = Htr)

This function allows to invert the regulation of

the controller: from cooling to heating and

viceversa.

9

User Instructions Low Temperature Freezers Model UNI/LT

Page 11

DIGITAL INPUTS POLARITY

The digital input polarity depends on the

“i1P” parameter.

i1P=CL: the input is activated by closing the

contact.

i1P=OP: the input is activated by opening

the contact

INSTALLATION AND MOUNTING

Instrument XR30C shall be mounted on

vertical panel, in a 29x71 mm hole, and fixed

using the special bracket supplied.

To obtain an IP65 protection grade use the

front panel rubber gasket (mod. RG-C) as

shown in figure.

PANEL

BRACKET

(PUSH TO RELEASE)

The temperature range allowed for correct

operation is 0÷60 °C. Avoid places subject to

strong vibrations, corrosive gases, excessive

dirt or humidity. The same recommendations apply to probes. Let air circulate by the

cooling holes.

ELECTRICAL CONNECTIONS

The instrument is provided with screw

terminal block to connect cables with a

cross section up to 2,5 mm2. Before con-

necting cables make sure the power supply

complies with the instrument’s requirements.

Separate the probe cables from the power

supply cables, from the outputs and the

power connections. Do not exceed the

maximum current allowed on each relay, in

case of heavier loads use a suitable external

relay.

PROBE CONNECTION

The probes shall be mounted with the bulb

upwards to prevent damages due to casual

liquid infiltration. It is recommended to place

the thermostat probe away from air streams

to correctly measure the average room

temperature. Place the defrost termination

probe among the evaporator fins in the

coldest place, where most ice is formed,

far from heaters or from the warmest place

during defrost, to prevent premature defrost

termination.

HOW TO USE THE HOT KEY

HOW TO PROGRAM A HOT KEY FROM THE

INSTRUMENT (UPLOAD)

1. Program one controller with the front

keypad.

2. When the controller is ON, insert the “Hot

key” and push o key; the “uPL” message

appears followed a by flashing “End”

3. Push “SET” key and the End will stop flash

ing.

4. Turn OFF the instrument remove the “Hot

Key”, then turn it ON again.

NOTE: the “Err” message is displayed for

failed programming. In this case push again

key if you want to restart the upload again

or remove the “Hot key” to abort the operation.

HOW TO PROGRAM AN INSTRUMENT USING

A HOT KEY (DOWNLOAD)

1. Turn OFF the instrument.

2. Insert a programmed “Hot Key” into the

5 PIN receptacle and then turn the Con

troller ON.

3. Automatically the parameter list of the

“Hot Key” is downloaded into the

Controller memory, the “doL” message is

blinking followed a by flashing “End”.

4. After 10 seconds the instrument will restart

working with the new parameters.

5. Remove the “Hot Key”..

User Instructions Low Temperature Freezers Model UNI/LT

10

Page 12

NOTE: the message “Err” is displayed for

Alarm signals;

Message

EE

P1

HA

LA

Cause

Date or memory failure

Probe failure

Max. temp. alarm

Min. temp. alarm

failed programming. In this case turn the

unit off and then on if you want to restart the

download again or remove the “Hot key” to

abort the operation.

ALARM SIGNALS

ALARM RECOVERY

Probe alarm “P1” starts some seconds after

the fault in the related probe; it automatically stops some seconds after the probe

restarts normal operation. Check connections before replacing the probe.

Temperature alarms “HA” and “LA” automatically stop as soon as the thermostat

temperature returns to normal values and

when defrost starts.

Alarms “EA” and “CA” (with i1F=bAL) recover as soon as the digital input is

disabled.

Alarm “CA” (with i1F=PAL) recovers only by

switching off and on the instrument.

Inputs: 1 NTC or PTC probe.

Digital input: free contact

Relay outputs:

compressor: SPST relay 8(3) A, 250Vac or

SPST relay 20(8)A; 250Vac

second relay: SPDT relay 8(3) A, 250Vac or

Data storing: on the non-volatile memory

(EEPROM).

Kind of action: 1B; Pollution grade: normal;

Software class: A.

Operating temperature: 0÷60 °C.

Storage temperature: -30÷85 °C.

Relative humidity: 20÷85% (no condensing)

Measuring and regulation range:

NTC probe: -40÷110°C (-40÷230°F)

PTC probe: -50÷150°C (-58÷302°F)

Resolution: 0,1 °C or 1°C or 1 °F (selectable).

Accuracy (ambient temp. 25°C): ±0,7 °C ±1

digit

CONNECTIONS

XR30C: 8A compressor

TECHNICAL DATA

Housing: self extinguishing ABS.

Case: XR30C frontal 32x74 mm; depth 60mm;

Mounting: XR30C panel mounting in a

71x29mm panel cut-out

Protection: IP20.

Frontal protection: IP65 with frontal gasket

RG-C (optional).

Connections: Screw terminal block ≤ 2,5

mm2 wiring.

Power supply: according to the model:

12Vac/dc, ±10%; 24Vac/dc, ±10%;

230Vac ±10%, 50/60Hz, 110Vac ±10%,

50/60Hz

Power absorption: 3VA max

Display: 3 digits, red LED, 14,2 mm high.

11

User Instructions Low Temperature Freezers Model UNI/LT

Page 13

DEFAULT SETTING VALUES

Set

HY

LS

US

Ot

Ods

AC

CCt

COn

COF

CH

CF

rES

IdF

MdF

dFd

dAd

ALc

ALU

ALL

ALd

dAO

tbA

oA1

AoP

i1P

i1F

did

NpS

odc

PbC

rEL

Ptb

Set point

Differential

Minimum set point

Maximum setpoint

Thermostat probe calibration

Outputs delay at start up

Anti-short cycle delay

Continuos cycle duration

Compressor ON time with faulty probe

Compressor OFF time with faulty probe

Kind of action

Temperature measurement

Resolution

Interval between defrost cycles

(Maximum) length for defrost

Displaying during defrost

MAX display delay after defrost

Temp. alarmsconfiguration

MAXIMUM temp. alarm

Mimimum temp. alarm

Temperature alarm delay

Delay of temp. alarm at start up

Alarm relay silencing

2nd relay configuration

Second relay polarity (oA1=ALr)

Digital input polarity

Digital input configuration

Digital input delay

Number of activation of pressure switch

Compressor status with open door:

Kind of probe

Software release

Map code

Label Name Range °C/°F

3,0/37

2,0/4

-50,0/-58

110/230

0,0

0

1

0,0

15

30

CL

ºC/ºF

dE/-

8

20

it

30

Ab

LS+US

0,1-25,5ºC/ 1-255ºF

-50ºC-SET/ -58ºF-SET

SET-110ºC/ SET-230ºF

-12-12ºC/ -120-120ºF

0-255 min

0-50 min

0,0-24,0 h

0-255 min

0-255 min

CL=cooling Ht=heating

ºC - ºF

in=integer dE=dec. point

1-120 ore

0-255 min

rt, it, SEt, DEF

0-255 min

rE=related to set;

Ab=absolute

Set-110,0ºC; Set-230ºF

-50,0ºC-Set/ -58ºF-Set

0-255 min

0-23 h e 50´

n=no y=yes

ALr=alarm; dEF=no select it;

LHt=auxiliary; onF=always on:

Fan=no select it

oP; cL

oP=opening; CL=closing

EAL=extern alarm; bAL=lock

regulation; PAL=press switch;

dor=door switch; dEF=defrost

LHt=switch on 2nd relay;

Htr=cooling - heating

0-255 min

0-15

no, Fan=normal;

CPr; F_C=Compr. OFF

Ptc; ntc

--

--

110/230

-50/-58

15

1,3

Y

LHt

cL

cL

LHt

5

15

no

ntc/Ptc

4,0

-

Hidden parameters

User Instructions Low Temperature Freezers Model UNI/LT

12

Page 14

Factory settings UNI/LT models.

Description

Set point

Different (Hysteresis)

Minimum set point

Maximum set point

Offset

Output delay start up

Anti-short cycle delay

Continious cycle delay

Compressor ON time with probe failure

Compressor OFF time with probe failure

Type of action (cooling, heating)

Temperature measurement unit

Interval between defrost cycles

Maximum lenght for defrost

Displaying during defrost

Max. display delay after defrost

Temp. alarms configuration

Maximum temp. alarm

Minimum temp. alarm

Temp. alarm delay

Delay of temp. alarm start up

Probe selection

N/A

N/A

Label

Set

Hy

LS

US

Ot

Ods

AC

CCt

COn

COF

CH

CF

ldF

Mdf

dFd

dAd

Alc

ALU

ALL

Ald

dAo

PbC

Rel

Ptb

Dixell XR30C 115 volt

Setting Celcius

-45

3

-50

0

0

1

3

0

60

5

CL

C

120

0

Set

1

Ab

-36

-50

120

24

Ptc

3

84

Setting Farenheit

-45

3

-58

0

0

1

3

0

60

5

CL

F

120

0

Set

0

Ab

-33

-58

120

24

Ptc

3

84

230 volt

Ambient temperature

Gross volume

Gross volume

Height on feet

Height with open lid

Width

Insulation thickness

Depth excl. handle and hinges

Power consumption UNI/LT at +25˚ C

Fuse

Temeprature range UNI/LT

Noise level UNI/LT

Weight

˚C

litres

cu. ft.

mm

mm

mm

mm

mm

Watts

A

˚C

dBa

kg

+10˚ to +30˚

130

4,6

860

1560

720

100

730

210

10

-30˚ to -45˚

< 51

50

+10˚ to +30˚

227

8,0

860

1560

1055

100

730

360

10

-30˚ to -45˚

< 51

63

+10˚ to +30˚

301

10,6

860

1560

1300

100

730

360

10

-30˚ to -45˚

< 51

75

11 21 31

UNI/LT

5141

+10˚ to +30˚

360

12,7

860

1560

1500

100

730

400

10

-30˚ to -45˚

< 51

80

+10˚ to +30˚

418

14,8

860

1560

1700

100

730

420

10

-30˚ to -45˚

< 51

92

(230V 50Hz)

Technical specifications:

13

User Instructions Low Temperature Freezers Model UNI/LT

Page 15

Wiring diagrams

Censor

Power supply

230V

50/60 HZ

User Instructions Low Temperature Freezers Model UNI/LT

Censor

Power supply

230V

50/60 HZ

14

Page 16

Wiring diagrams

Censor

Power

supply

115V 60 HZ

Censor

Power

supply

115V

60 HZ

15

User Instructions Low Temperature Freezers Model UNI/LT

Page 17

Wiring diagrams

Censor

Power

supply

115V

60 HZ

User Instructions Low Temperature Freezers Model UNI/LT

16

Page 18

17

User Instructions Low Temperature Freezers Model UNI/LT

Loading...

Loading...