Page 1

0

TABLE TOP ICE & WATER DISPENSER

Models AIWD282

SCIWD282

User’s Manual

BEFORE USE, PLEASE READ AND FOLLOW

ALL SAFETY RULES AND OPERATING INSTRUCTIONS

FELIX STORCH, INC.

Summit Appliance Division

An ISO 9001:2015 registered company

770 Garrison Avenue

Bronx, New York 10474

Write Model and Serial Numbers here:

Model No.: _____________________

Ser. No.: _______________________

Page 2

1

Table of Contents

Important Safeguards…………………………………………………………………….. 2-4

Product Specification …….………………………………………………………..………5-7

Product Rating……………………………………………………………………………5

Wiring Diagram…………….……………………………………………………….…….5

Location of Parts…..……..…………..........................................................................6

Unpacking, etc……………….……………………………………………..………………....7

Product Installation…….………………………………………………………..……………7-11

General Instructions……….…………………………………………………….….…….7

Requirements for plumbing..………………………………………………….…….……8

Water Quality……….……….……………………………………………..………….……8

Requirements for Power Supply………………………………………………..….…….9

Panel disassembly method……………………………………………..………………..10

Connection method for water supply and drainage……………………………..……..11

How to start the product………………………………………………………..…………..12-14

Button operation……………..…..…………………………………………..…………..12

Function button description (FND display window)…………………………………..13

Three drainage functions (forced drainage, automatic draining, water drainage)…14

Stop switch……………………………………………………………………………….14

Product Maintenance……………………………………………...………………………..15-19

Water removal in water tank and evaporator ……………………………..……..…..15

Maintenance, repair and disinfection……………………………………….…………15

Maintenance schedule…………………………………………………………………..16

Cautions when cleaning exterior panel (stainless steel)……………………………..17

How to clean and disinfect………..……………………………………………………18-19

Product Troubleshooting ………………………………………………………………….20-21

Product Warranty …………………………………………………………………………...22

Page 3

2

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the Safety Alert Symbol. This symbol alerts you to potential hazards

that can injure or kill you and others.

Safety messages will follow the Safety Alert Symbol and either the words

"DANGER", "WARNING" OR "CAUTION".

DANGER means that failure to heed this safety statement may

result in severe personal injury or death.

WARNING means that failure to heed this safety statement

may result in extensive product damage, serious personal injury

or death.

CAUTION means that failure to heed this safety statement may

result in minor or moderate personal injury, or property or

equipment damage.

What you must obey

Prohibited

Disassembly

Prohibited

No Contact

Remove Power

Plug

Grounding

All safety messages will alert you to what the potential hazard is, tell you how to reduce the

chance of injury, and let you know what can happen if the instructions are not followed.

IMPORTANT SAFEGUARDS

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock or injury when using

your ice maker, follow these basic precautions:

· Plug into grounded 3-prong outlet. Disconnect power before cleaning.

· Do not remove grounding prong. ·Disconnect power before servicing.

· Do not use an adapter. ·Replace all panels before operating.

· Do not use an extension cord. · Use two or more people to move & install ice maker.

SAVE THESE INSTRUCTIONS

Page 4

3

Before the ice/water dispenser is used, it must be properly positioned and installed as

described in this manual, so read the manual carefully. Accucold® by Summit Appliance strongly

recommends that you have a professional install your new machine. The warranty may be affected or

voided by an incorrect installation. To reduce the risk of fire, electrical shock or injury when using the

ice/water dispenser follow basic precautions, including the following:

• Plug into a grounded 3-prong outlet; do not remove

grounding prong, do not use an adapter, and do not use an extension cord.

• It is recommended that a separate circuit, serving only your ice maker, be provided. Use receptacles

that cannot be turned off by a switch or pull chain.

• Do not connect or disconnect the electric plug when your hands are wet.

• Never unplug the dispenser by pulling on the power cord. Always grip the plug firmly and pull straight

out from the outlet.

• Never clean dispenser parts with flammable fluids. Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other appliance. The fumes can create a fire hazard or

explosion.

• Before proceeding with cleaning and maintenance operations, make sure the power line of the unit is

disconnected and the water line is shut off.

• Before operating, put all panels back into place.

• Never allow children to operate, play with the ice dispenser.

• Do not touch the evaporator with your hand when the machine is operating.

• Unplug the ice dispenser or disconnect power before cleaning or servicing. Failure to do

so can result in electrical shock or death.

• Do not attempt to repair or replace any part of your ice dispenser unless it is specifically recommended

in this manual. All other servicing should be referred to a qualified technician.

• Use two or more people to move and install the ice maker.

Failure to do so can result in back or other injury.

• Never install or operate the unit in an enclosed area, such as a closed cabinet. To ensure proper

ventilation for your ice maker, the front of the unit must be completely unobstructed. Choose a wellventilated area with temperatures above 50°F (10°C) and below 100°F (38°C). The optimum supplied

water temperature would be below 50°F. This unit MUST be installed in an area protected from the

elements, such as wind, rain, water spray or drips.

• The dispenser is for indoor use only.

• The dispenser should not be located next to ovens, grills or other sources of high heat.

• The dispenser must be installed with all electrical and water connections in accordance with state and

local codes. A standard electrical supply (115 V AC, 60 Hz, 15 A), properly grounded in accordance with

the National Electrical Code and local codes and ordinances, is required.

• Do not kink or pinch the power supply cord between the dispenser and cabinet.

• The fuse (or circuit breaker) size should be 15 amperes.

• It is important for the dispenser to be leveled in order to work properly. Otherwise water may not flow

properly through the evaporator (ice mold). The ice production will be less than normal. You may need

to make several adjustments to level it.

• All installations must be in accordance with local plumbing code requirements.

Page 5

4

• Make certain that hoses are not pinched, kinked or damaged during installation.

• Check for leaks after water line is connected.

• Although the unit has been tested and cleaned at the factory, due to long-term transit and storage, the

first batch of cubes must be discarded.

• Remove the packing materials and clean the dispenser before using.

• Turn on the water supply tap before switching on the ice maker. Never turn the water supply tap off

when the dispenser is working.

• Except to take ice from the unit, keep the door closed in order to reduce ice melting and to promote

proper ice formation.

• If the dispenser will not be used for a long time, before the next use it must be thoroughly cleaned.

Follow carefully any instructions provided for cleaning or use of sanitizing solution. Do not leave any

solution inside the dispenser after cleaning.

• Do not touch the condenser fins. They are sharp and can be easily damaged.

• DO NOT use solvent-based cleaning agents or abrasives on the interior. These cleaners may transmit

taste to the ice cubes, or damage or discolor the interior.

• The ice machine cleaner contains acids. Do not use or mix with any other solvent-based cleaning

products. Use rubber gloves to protect hands. Carefully read the safety instructions on the container of

the ice machine cleaner.

• Do not use the apparatus other than for its intended purpose.

• Do not place heavy objects or containers containing water on the ice maker. The objects or

containers may fall and cause water to leak and the insulation may be weakened, resulting in a fire

due to a short circuit.

• Do not install the product in a humid place or where there is a risk of water splashing. Insulation may

be weakened, resulting in short circuit, electric shock, or fire.

• Do not use: If the product malfunctions, such as smoke or burning smell, unplug the power cord to

stop operation. If you continue operating in abnormal conditions, there is a risk of fire or electric

shock.

• Do not use: Do not use if the outlet is loose or has a problem. There is a risk of fire due to electric

shock or short circuit.

• Do not modify or repair the product yourself. Ignition or abnormal operation is dangerous and may

cause more trouble.

• Do not allow electrical cords or plugs to be pinched or twisted. The cord or plug may be peeled and

there is a risk of fire or electric shock. If the cord or plug is peeled or damaged, be sure to ask the

service to replace it.

• Do not damage the inside of the dispenser with a sharp tool. The ice reservoir may break or become

damaged.

• When not in use for a long time, remove ice and water (to prevent winter frost), and unplug the power

cord from the outlet.

• If there is a risk of slippery water or oil on the floor near the ice maker, please wipe it. There is a risk of

injury if you slip on the dispenser or get hands or feet in the bottom of the side.

• When transferring this dispenser to another person, please hand it along with the instruction manual.

New users need a manual for safe use.

• Do not put your hands or feet on the bottom of the ice maker. The bottom of the dispenser has iron

plates and various parts which may cause injury.

• If you unplug the power plug from the wall outlet and plug it back in again, wait at least 5 minutes

before reinserting. If it is plugged in immediately, it may cause a trouble in operation of the freezer and

it may cause malfunction of the ice maker.

• In areas where there is a lot of lime content in the water, please install a lime removal filter at the

entrance of the product water supply (the product life may be shortened by calcareous).

Do not let children hang on the product. There is a danger of the

dispenser twitching or falling, resulting in injury. In particular, do

not let children hang on the reservoir not fixed to the product.

Never allow children to operate, play with, or crawl inside the dispenser.

Page 6

5

Product Specifications

WATER/ICE DISPENSER

Model

AIWD282/SCIWD282

AC Supply Voltage:

115 V 60 Hz, 1 PH

Refrigerant:

R404A

Amount of refrigerant:

11.29 oz

Design Pressure: High Side

360 psig

Design Pressure: Low Side

190 psig

Compressor

LRA 40 A

Fan Motor

115 V, 0.7 A

Geared Motor

115V, 1.6A

Maximum Fuse Size

20 A

Max. HACR Breaker (USA Only)

20A

Max. HACR Breaker (Canada Only)

20A

Min. Circuit Ampacity

5.8A (570W)

FCC Identifier

ICTR-TR-E191162-OA

Condensation Method

Air-cooled

Ice Shape

Nugget

Discharging method

Solenoid

SAVE THESE INSTRUCTIONS

Page 7

6

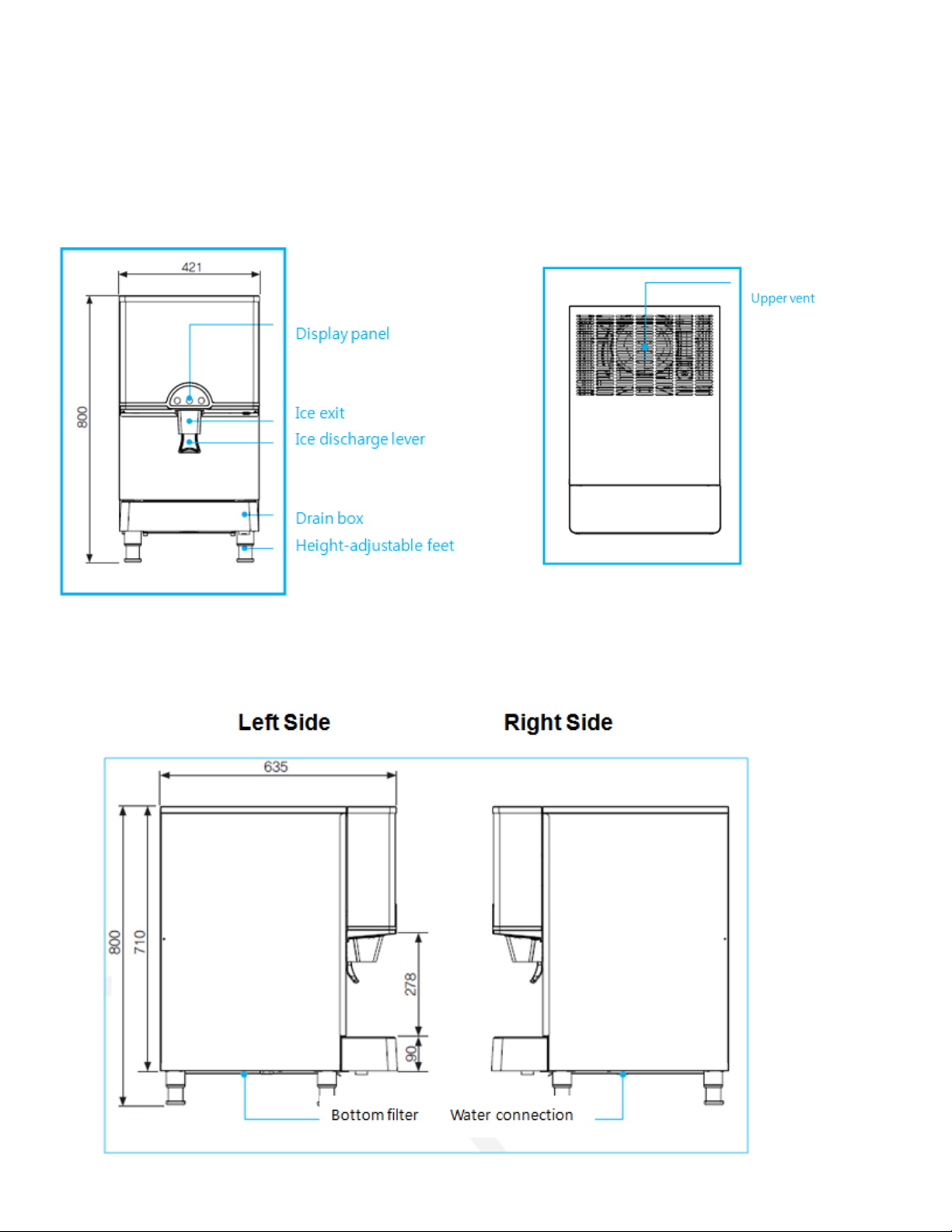

Location of Parts

Front Top/Bottom

Page 8

7

Unpacking, etc.

• After removing the packing materials, check the appearance of the dispenser for possible defects or

irregularity. If the product shows any irregularity in its appearance, contact the distributor.

• All the packing materials (straps, box, Styrofoam, wood, etc.) should never be left within the reach of

children and should be disposed of according to local regulations.

• For safety, the product should be installed and used with caution in accordance with the User’s

manual.

• Incorrect installation or careless use of the product may damage or injure the environment, humans,

animals, and/or materials and property. The manufacturer does not bear any responsibility for the

aforesaid damage or injury.

• The dispenser performs best at room temperature of 50~75°F and a supply of water at 50°F.

• The dispenser should only be installed indoor and should NOT be installed near heat generators such

as heaters, stoves, or dish washers.

Installation

Where there is no heat source.

※ Install in a place where there is no heating device

such as a fireplace or a gas range, and do not install in an

area outside the range of 10 ~ 38 ℃/50 ~100oF.

Allow enough ventilation

• For normal operation, install the dispenser at least 4

inches away from the back wall and 6 inches above the top

of the dispenser.

※ Never block the upper vents and do not place any

load on it.

• Poor ventilation will decrease the unit’s ability to

make ice.

Install on a flat surface

※ Unstable installation may cause vibration and noise.

The recommended angle of installation is 1o

• A flat surface is recommended because there is a

possibility that the product will fall and cause injury when

the installation is made in a sloping place.

• Installation should be indoors in a clean place

• The drain hose should be installed at an angle so that drainage is good.

• During installation and use, water leakage may occur due to various reasons. It must be used at a

place where drainage facilities are fully equipped

• When installing the product indoors (places such as living room, store, floor where damage may

occur due to leakage), please install natural drainage facilities and waterproof the floor.

• Even when installing in the kitchen, a drain hole must be provided, and a drain hose must be

connected.

• The manufacturer shall not be held responsible for the spreading damage caused by insufficient

drainage facilities in case of above mentioned problems and problems due to water supply hose

deviation or breakage.

Page 9

8

Requirements for plumbing

Plan the arrangement of the water supply pipes.

Connect a 1/4" diameter copper cable with the tap water pipe.

Install a shutoff valve between the tap water pipe and the product so that the user can operate the valve.

Do not install the shutoff valve at the back of the product. Do not use a self-piercing valve. If the tap water

has a high level of minerals, a pipeline filter will be required.

The pressure of the tap water should be maintained at a level between 20psi (1.4bar) and 80psi (5.5bar).

The tap water and drain pipeline should be planned and prepared at the place of installation. If an electric

outlet is available just at the back of the ice maker, installation may be easier. The electric power, tap

water pipeline and drain pipeline should satisfy all the provisions under local laws and regulations. For the

position of the tap water, refer to the installation specifications and drawings on pages 10 and 11.

Important Information:

The dispenser is designed for use in a fixed position but it

may be necessary to

pull the unit forward for service. Therefore, do not install any material at the front, upper or lower end of

the product which may act as an obstacle when moving the ice maker.

Water quality

• There is no such thing as “perfectly pure” water. All kinds of water including tap water contain some

impurities. Rainwater absorbs impurities from the atmosphere or when it passes through soil. Some

impurities consist of solid particles called suspended solids and are filtered through micro filters. Any

remaining impurities cannot be filtered because they are chemically combined with water molecules.

These impurities are called dissolved solids.

• The mineral content of the ice produced by the dispenser is reduced compared to the content in the

water before conversion into ice. Water containing a low level of impurities is rapidly frozen. The

reason for this is that the impurities elevate the temperature of the water. Through such action, most

of the impurities condensed in the water-tank of the dispenser form a hard precipitation called scale.

• This dispenser reduces the mineral level by circulating water during the harvest cycle (the excessive

quantity is removed through the outlet tube). Each cycle requires about 0.64 quart (0.6ℓ) of water. For

each quart, about 0.5 quart is used in rinsing the water tank and the remaining quantity is removed

through the outlet pipe. In this process, some impurities unavoidably remain and may accumulate on

the internal parts of the ice maker, forming abnormally-shaped ice cubes. If a large quantity of mineral

scale accumulates, the lifespan of the dispenser may be reduced.

• For best operation of the ice maker, impurities and minerals should be decomposed by washing

periodically. The method of cleaning the dispenser is described on pages 18 -19.

• In general, it is best to use filtered water. Filters may remove not only bad odor but also particles.

Neutral water is not recommended.

• Water softener is not recommended because it exchanges minerals. If the hardness of the water is

very high, softening may lead to the formation of opaque pieces of ice.

• If you have any questions about the purity of your water, address your inquiry about water treatment

to an expert in water quality.

• This product was thoroughly washed at the factory. However, check the cleanness of the inside before

use and keep it clean during use.

Page 10

9

Warning!

Do not use extension cords or 2-prong adapters. The product must be grounded.

Never cut off the grounding terminal of the 3-prong grounding plug.

Requirements for power supply

120VAC, 60Hz, 15-amp circuit breaker and electric power are required. A separate circuit is required for

grounding.

The power cord of the product should be inserted into a suitable 3-prong grounding-type socket.

Important Information:

A Ground Fault Circuit Interrupter

(GFCI) is not recommended because it could

cause the operation of the product to stop.

Important Information: The provisions of the National Electric Code as well as any local laws and

instructions should be observed when installing the product.

Electrical Connection

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. For

personal safety, this appliance must be properly grounded. The power cord of this appliance is equipped

with a 3-prong grounding plug that mates with a standard 3-prong grounding wall outlet to minimize the

possibility of electric shock hazard from the appliance. Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet is properly grounded. When a standard 2-prong wall outlet is

encountered, it is your responsibility and obligation to have it replaced with a properly grounded 3-prong

wall outlet. The dispenser should always be plugged into its own individual electrical outlet which has a

voltage rating that matches the rating label on the appliance. This provides the best performance and also

prevents overloading house wiring circuits which could cause a fire hazard from overheated wires. Never

unplug your dispenser by pulling on the power cord. Always grip the plug firmly and pull straight out from

the outlet. Repair or replace immediately all power cords that have become frayed or otherwise damaged.

Do not use a cord that shows cracks or abrasion damage along its length or at either end. When moving

the ice maker, be careful not to damage the power cord.

Extension Cord

Because of potential safety hazards under certain conditions, it is strongly recommended that you do not

use an extension cord with this dispenser.

Page 11

10

Panel Disassembly Method

1. Upper panel: Open the front door and lift the upper panel, then the back magnets will be separated and

disassembled.

2. Front panel: Remove the lower set screws of the drain box, then loosen the set screws on the top of

the front panel and pull out the front panel taking both sides.

3. Side panel: Open the door, loosen the screws on the top of the front panel, push the front panel

forward, and slide the side panel forward to remove it.

• Precede the assembly work in the reverse order of disassembly.

Side Panel

Page 12

11

Connection to water supply and drainage [Connection of

water and drainage hoses]

Division

Proper water temperature

Water pressure

Hose to be used

ICE MAKING water supply

50 ~ 90

o

F

14.22 ~ 71.12 psi

OD ø6.35

PE TUBE

ICE MAKING drainage

-

-

ID ø20 hose

• If the temperature of the ICE MAKING water supply is too high, the amount of ICE MAKING may

be reduced,

• If the water pressure is too low, it may not be possible to freeze. In this case, an auxiliary

hydraulic pump should be installed.

• Connect the ø6.35 PE TUBE to the bottom right of the product as shown in the picture and

secure the clip to prevent hose detachment.

After the installation is complete, please operate the product and check whether there is leakage in the water

supply and drainage parts.

• Please connect a hose with an inner diameter of Φ20mm or more for the ice making drain hose and the drain

outlet should be 5cm above the drain floor level. If the drain outlet dips in the drainage, the drainage may flow

back into the dispenser and damage the product and the floor.

Be careful not to bend the drainage hose during

the installation and also confirm that the hose is

not exposed to fire or sharpness which may

result in the hose burst (This will become the

cause of the PL accident and the manufacturer

shall not be held responsible)

Page 13

12

STARTING THE PRODUCT

1) Water supply hose protection --Do not place heavy objects on the water supply hose leading to the

water supply, or keep the hose from treading.

2) Proper water pressure, water temperature, ambient temperature

3) Please connect only the water you can drink.

Power connection - connect the dispenser to a dedicated outlet.

4) Water supply - open the faucet and let the water supply.

5) Ice making operation - Turn the ICE MAKING-OFF-WASH switch to ICE MAKING

6) Start ice production -There is a slight difference depending on the ambient temperature and water

temperature, ice starts to be generated from about 3 minutes after starting the ice making operation.

After about 70 minutes, the reservoir will be full of ice. (You can use ice after about 10 minutes.)

BUTTON OPERATION

When ERROR occurs

- ICE-WATER-ICE & WATER button will flicker in order and will disappear when restarting after the action against

the ERROR.

Service cycle setting notification (parts check / replacement cycle notification)

- If the motor is running for more than 10,000 hours, the corresponding lamp blinks for 5 seconds in the initial stage

of the ice maker.

- If the motor is operated for more than 11,000 hours, all the buttons will blink for 5 seconds in 1 hour cycle.

※ If all the buttons are flashing, it is a signal to check / replace regular replacement parts and you should contact

the customer service center (paid service).

Failure to check / replace parts may result in higher repair costs.

ICE

- If you turn on the power, this will always come in first. The initial

water subtraction is done three times and then the ICE MAKING

operation is preceded. If you put the cup in the ice exit, you can

discharge the ice for the time set in F1.

WATER

Press the button to light up. If you put the cup on the ice exit, you

can discharge the water for the time set in F1.

ICE &

WATER

Press the button to light up. If you put the cup on the ice exit, you

can simultaneously discharge ice and water for the time set in F1.

Water pressure: 14.22 ~ 71.12 psi

Water temperature: 50 ~ 90

o

F

Ambient temperature: 50 ~ 100

o

F

ICE MAKING-

OFF-WASH

switch

Page 14

13

Function Button Description (FND Display Window)

F. 1

Maximum Discharge

Time

① SOLENOID Maximum operating time adjustment function.

②3rd, 4thdigits: 20 seconds (5 seconds ~ 30 seconds, Set Unit of one

second)

F. 2

Complete removal of

ice in the reservoir

①This function can be entered in "OFF" state of ICE MAKING-OFF-WASH

switch.

②Press two buttons (WATER, ICE) simultaneously for 3 seconds and Button

part LED lights up.

③ Press the discharge lever for continuous operation of SOLENOID and the

motor. Keep 'ON' state.

F. 3

Automatic ice

discharge function

① When ICE, WATER &ICE button is selected, ice is automatically emitted

for the set time.

② Automatic operation is not possible when OFF is set. (Manual operation)

③ Automatic discharge is performed for the set time of At01 ~ 99.

F. 4

Initial water

subtraction function

① It operates first when "ICE MAKING" switch is operated.

② FND 1st, 2nddigits (drain time) 30 seconds (oF ~ 99 seconds, Set Unit of

one second)

③ Water supply operation after drainage to high water level.

④ FND 3rd, 4thdigits (number of repetitions) Standard: 3 times (1 ~ 9 times)

F. 5

Automatic drain

function

It operates when "ICE MAKING" switch is operated.

② FND 1st, 2nddigits (drain time): 2 seconds (oF ~ 9 seconds, Set Unit of one

second)

③ FND 3rd, 4thdigits (drain interval): 1.0 hour (0.5 ~ 9.5 hours, every 30

minutes)

F. 6

ICE + WATER

volume control

①1st, 2nddigits Ice time Default 5 seconds (up to 99 seconds)

②3rd, 4thdigits Water time Default 5 seconds (up to 99 seconds)

F. 7

UV LAMP time

adjustment

①1st, 2nddigit lighting time Default 3minutes (99 minutes possible)

②3rd, 4thdigits off time Default 1 hour (9 hours available)

F. 8

Notify service period

setting

① A.1.0 After using 10,000 hours, the corresponding mode LED blinks for 5

seconds (for the first 5 seconds during ice making)

② A.1.1 After using 11,000 hours, all LEDs blink for 5 seconds (1 hour cycle)

F. 9

Cumulative uptime

① The FND display is displayed in year, month, day, and hour, and is

displayed in order from right to left.

② Cumulative operation time of product is expressed in hour unit.

③ Calculation example: 12 months for 1 year, 30 days for 1 month, 24 hours

for 1 day.

F. 10

Change temperature

unit

Function of setting the unit of temperature in degrees Celsius or Fahrenheit

F. 11

Evaporation inlet

temperature display

F. 12

Evaporation outlet

temperature display

Page 15

14

Three Draining Functions

(Forced Draining, Automatic Draining, Water Draining)

Forced drainage

function

Must be implemented to prevent freezing in winter storage. Use this function for

cleaning the inside.

- Turn on the power switch and press the "DOWN + SET" button simultaneously for 3

seconds with any signal on the FND display. (30 seconds)

Automatic drain

function (F. 5)

Turn on the power switch and turn the ice making switch to "ICE MAKING" to start the

operation.

① FND 1st, 2nddigits (drain time): 2 seconds (oF ~ 99 seconds, Set Unit of one

second).

② FND 3rd, 4th digits (drain interval): 1.0 hour.

(0.5 to 9.5 hours, every 30 minutes)

Initial water draining

function (F. 4)

Turn the power switch off and then on again (the ICE MAKING-OFF-WASH switch at

"ICE MAKING" position) to operate the function.

① Clean the water line and ice making cylinder thoroughly.

② FND 1st, 2nd(drain time) 30 seconds (oF ~ 99 seconds, Set Unit of one second).

③ Water supply operation to high water level after drainage.

④ FND 3rd, 4thdigits (number of repetition) Reference: 3 times (1 ~ 9 times).

Stop switch

• With the power switch turned on, turn the "ICE MAKING-OFF-WASH" switch to center OFF, then the

ice making stops and the motor runs for another 60 seconds.

• This function protects the motor by removing the ice remaining in the product.

• If you sell the remaining ice even when it is OFF, ice discharging will be done.

Page 16

15

Required Actions to prevent frost

(Water Removal in Water Tank and Evaporator)

• If the ambient temperature falls below 0°C/32oF, water will freeze inside the machine and machine

operation will be impossible.

• If you do not use for a long period of time in winter, be sure to completely remove the ice making

water inside the body by following the instructions below. If you do not remove the ice making water

or if it is insufficient, it will cause serious damage to the product. This shall not be guaranteed by the

manufacturer and may result in a lot of repair costs. Please observe the following points.

1. Turn on the power switch and press the DOWN + SET

button at the same time for 3 seconds with any signal

on the FND window. Forced drainage will be done for

30 seconds.

2. Turn off the power switch and disconnect the power

plug from the outlet.

3. Remove the upper panel → the front panel.

4. Remove the evaporator cylinder drain hose clamp and

remove the hose, and wait until the ice in the

evaporator cylinder completely melts down. It is

possible to remove internal water quickly by using

compressed air gun etc.

5. Reassemble the evaporator cylinder drain hose and tighten the clamp.

6. Assemble in the order of left panel → upper panel → front panel.

Maintenance, repair and disinfection

※ Please keep the product according to the instruction manual and label provided.

● Be sure to have a qualified service technician service the product.

● To reduce the risk of electric shock, do not touch or disassemble the parts of the ice maker.

● Before service

- Turn off the power switch of the dispenser and the earth leakage breaker, and disconnect the power

plug from the outlet.

● Choking hazard - After performing maintenance and repair, make sure that all components (such as

fixtures, screws, bolts, etc.) are completely assembled.

- Be careful not to let any components fall into the ice making compartment and ice reservoir.

Page 17

16

Maintenance Schedule

※ The following maintenance schedule is guideline.

※ Maintenance and repair should be done more frequently according to water quality, equipment usage

environment and local hygiene regulations.

Inspection

Schedule

Area

Contents

Daily

Chute

1. Clean the ice scoops with a neutral detergent.

2. Rinse thoroughly after cleaning.

Weekly

Air Filters (air-cooled)

1. Inspect for dust and wash dirt with warm water and neutral detergent.

Monthly

External water filter

1. Make sure that the pressure is adequate and make changes if needed.

Outside of the icemaker

1. Wipe it with a clean, soft cloth, and use a cloth dampened with a neutral

detergent to wipe away any accumulated dust or grease.

2. Clean the chlorine dye (green spots) with non-abrasive detergent.

The bottom of the ice

maker

1. Wipe clean with clean cloth and warm water.

Every six

months

Dispenser and reservoir

1. Clean and disinfect according to the disinfection instructions given in the

instruction manual.

Evaporator condensate

drain pan and Geared

motor drain pan

1. Wipe clean with clean cloths and warm water, and slowly pour a cup of

disinfectant solution (prepared as described in the instructions for disinfection

in the manual) into the evaporator condensate drain pan.

2. Take care not to overflow the drain pan.

3. This disinfectant solution will flow out through the geared motor drain pan and

drain passage.

4. Rinse repeatedly with a glass of clean water.

Ice maker and reservoir

1. Always check that it is kept clean.

Ice exit fixing

seal bolt

1. Check for leaks around the seal bolt. Tighten if necessary and replace O-rings.

2. Always replace the O-ring when loosening the seal bolt and tighten it again. If

there is no O-ring, apply Loctite 243 or equivalent fixing agent so that it does not

leak.

Every year

Water supply valve and

Drain valve

1. Close the shutoff valve to shut off the water supply line and drain the water.

2. Clean the inlet of the water supply valve and check the water supply valve and

drain valve for leakage and operation.

Water hose

1. Check the water hose and clean it if necessary.

Condenser (air-cooled)

1. Inspect for cleaning. If necessary, clean with a brush or vacuum cleaner

2. If the dust adhesion is severe, spray the pin cleaning agent, clean the dust,

spray it with clean water, rinse and dry with air gun.

Ice maker

1. Inspect for oil marks, loose components, tightening parts and wires.

Upper bearing

(Ice exit head)

1. Check that 0.5mm round bar or pin gauge (or clearance gauge) is inserted into

auger and bearing clearance, and replace all upper and lower bearings (ice exit

head and lower housing) (Paid service)

Mechanical seal

1. Check for leaks in the bottom housing, and if there is a leak, disassemble the

auger to replace the mechanical seal. (Paid service) (Water with a lot of calcium

will shorten the life of replacement parts.)

Every three

years

Upper and lower

bearings,

Housing O-ring,

Mechanical seals,

Evaporator cylinder,

Auger

1. Please check if the auger and bearing clearance exceeds the factory

recommended value (0.5mm or less), replace both the upper and lower bearings.

If the contact surface of the mechanical seal is worn, cracked, or scratched,

replace it.

Page 18

17

Caution when cleaning exterior panel

(stainless steel)

How to clean the rust state

Stain type initial rust

Since the initial rusted stainless steel surface itself is only slightly affected by the

stain, it can be returned to almost the original surface by selecting the neutral

detergent or a commercially available cleaning solution. If it is regularly cleaned at

a proper frequency, the state of the rust can stop at this stage and you can remove

the rust easily and cheaply.

Red Rust

If the initial rust is left for a long time, it will result in a thick brown rust that can

damage the stainless steel surface. In this condition, it is not easy to remove the

rust and the surface cannot be restored. Therefore it is important to remove the

rust in the early stage of the rusting.

If the rust is not removed by a commercial cleaning agent, it can be easily removed

by using a cleaning agent after removing some rust in advance with sandpaper or

a stainless steel brush. In this case, it is necessary to fix the surface by cleaning

and regrinding the surface.

Rust by iron powder

Rust by iron powder can occur due to welding spatter at the time of construction,

rust water flowing down from steel in the upper part of stainless steel, and rust

generated in contact with stainless steel and ordinary iron products during storage.

It should be removed with neutral detergent at the first sign of rusting. If the rusting

state is further developed, it should be removed with 15% nitric acid solution or

commercially available stainless steel cleaner.

Rust due to exhaust gas or acid

rain

Exhaust gas or acid rain, sometimes found in high traffic cities, may affect this unit.

Relatively light rusts can be cleaned with a neutral detergent or soapy water, but if

they get worse, they should be removed with 15% nitric acid solution or a

commercially available stainless steel cleaner.

Rust due to salt deposition

When exposed to sea breezes like a window frame or a verandah railway pipe that

faces the ocean, the icemaker may experience red rust in a short time. To avoid

red rest, ensure regular cleaning according to this manual.

Rust by disinfection and cleaning

agent

Chlorine-based disinfectants are used to disinfect water in places such as

swimming pools and bathrooms. In the case of chlorine-based cleaning agents

such as ROX used for cleaning toilets, etc., many chlorine compounds are

attached to the surface of stainless steel and can result in rusting. When chlorinebased disinfectants are used, it is important to thoroughly wash them with water to

ensure that no residue remains. They must be removed with 15% nitric acid

solution or stainless steel cleaner.

Page 19

18

How to Clean and Disinfect

The dispenser should be cleaned and disinfected at least twice a year. More frequent cleaning and

disinfection may be required.

Washing

solution

Use a scale remover that is not harmful to human body by diluting with water, and use more

amount if necessary.

It is important to use the diluted cleaning solution immediately for safety and maximum

effect.

Washing

procedure

1) Shut off the water supply by locking the valve of the water line of the ice maker.

2) Switch the ICE MAKING-OFF-WASH switch to the "WASH" position.

3) The water in the water tank is drained through the evaporator cylinder and washing is

done by this (max. 5 minutes).

4) Turn the ICE MAKING-OFF-WASH switch to "OFF" position.

5) Remove all ice from the ice maker and reservoir.

6) Pour the wash solution into the wash solution inlet until the evaporator assembly and the

water tank are full.

7) (Until the wash solution overflows to the drain box)

8) Leave the ice maker for 10 minutes before starting operation. If the water supply hose is

clogged in step 7, remove it before operation.

9) As described below, please disassemble and clean the water level sensor (high and low)

if it is in bad water condition.

10) If not, proceed to step 9.

Ⓐ Remove the water level sensor from the water tank cover.

Ⓐ Clean the level sensor with washing solution.

Ⓐ Wash the water level sensor thoroughly with clean water.

Ⓐ Fix the level sensor to the correct position.

9) Switch the ICE MAKING-OFF-WASH switch to the " ICE MAKING" position to start

the ice maker. Keep it running until ice making stops.(※ Water supply valve should be

locked so that water is not supplied.)

11) 10) Switch the front ICE MAKING-OFF-WASH switch to the "WASH" position, and drain

the remaining water in the water tank and evaporator cylinders for 5 minutes.

12) 11) Switch the ICE MAKING-OFF-WASH switch to the "OFF" position.

13) 12) Open the water supply valve of the ice maker, and switch the ICE MAKING-OFFWASH switch to the " ICE MAKING" position so that water can be supplied to the water

tank.

14) 13) When the geared motor is activated, switch the ICE MAKING-OFF-WASH switch to

the "WASH" position and drain the water (drain is possible for 5 minutes).

14) Turn OFF the power switch and disconnect the power cord from the outlet.

Please observe the following points.

• Do not use ammonia-type detergents to prevent personal injury or damage to the ice maker.

• Disinfection and cleaning should be handled according to the instructions provided.

• Always wear protective eyewear and waterproof gloves to prevent skin or eye contact with water and

disinfectant.

• After cleaning and disinfection, do not use ice made from cleaning agent and disinfectant. Be careful that no

disinfectant remains in the dispenser and any parts in the reservoir.

Page 20

19

Disinfection

wash

Dilute 10 L of warm water and 400 mL of 5.25% sodium hypochlorite solution (bleach).

(※ Dilution ratio may vary depending on the solution manufacturer, please refer to the solution

manual).

If this is the minimum amount to be used, use more washing solution.

※ To ensure safety and maximum effect, please use the washing solution immediately after

dilution.

Disinfection

procedure initial

1) Shut off the water supply by closing the valve of the water supply line and make sure

that the power switch is turned to “OFF” position and the power plug is disconnected from

the outlet, and then remove the front panel and the upper panel.

2) Pour the disinfectant solution over the water inlet until the evaporator assembly and the

water tank are full.(Until the disinfecting solution overflows to the drain box)

3) Open the top cover and disassemble the ice reservoir lid.

4) Disassemble packing, bush, etc. inside the lid.

5) Turn the Agitator to the left to disassemble it.

6) Remove the Ice Base Plate.

7) Disinfect the inside of the reservoir and the removed parts for 10 minutes and wipe

them.

8) Remove Spout, clean for 10 minutes and wipe.

9) Please thoroughly rinse all parts with clean water. (※ If there is residual washing

solution, it will cause corrosion.)

10) Assemble all parts in the correct position.

11) Connect the power plug to the outlet, turn the power switch to “ON”, turn the ICE

MAKING-OFF-WASH switch to “ICE MAKING” and keep the operation until the

disinfectant solution is exhausted and the ice production stops.

12) Switch the ICE MAKING-OFF-WASH switch to the "WASH" position and let the

remaining water drain out for 5 minutes.

13) Turn the power switch to “OFF” and disconnect the power plug from the outlet.

Disinfection

procedure final

1) Mix the disinfection solution in a new bowl.

2) Check that the water valve is closed, the power switch is turned off and the power plug

is disconnected from the outlet, and then remove the front panel and the upper panel.

3) Pour the disinfectant solution over the water inlet until the evaporator assembly and the

water tank are full.

(Until the disinfecting solution overflows to the drain box)

4) Leave the ice maker for 10 minutes before operating the ice maker.

5) Connect the power plug to the outlet, turn on the power switch, and turn the ICE

MAKING-OFF-WASH switch to 'ICE MAKING' until the disinfectant solution is exhausted

and the ice stops generating.

6) Switch the ICE MAKING-OFF-WASH switch to 'WASH' and drain the remaining water

for 5 minutes.

7) Switch the ICE MAKING-OFF-WASH switch to "ICE MAKING" and open the valve of

the ice-maker water supply line so that water can be supplied to the water tank.

8) When the geared motor starts to operate, switch the ICE MAKING-OFF-WASH switch

to the 'OFF' position.

9) Switch the ICE MAKING-OFF-WASH switch to 'WASH' and discharge the remaining

water for 5 minutes.

10) Turn the ICE MAKING-OFF-WASH switch to 'ICE MAKING' position to generate ice for

30 minutes, then turn off the power switch.

11) Pour warm water into the ice reservoir to dissolve the ice and drain it. Use a neutral

detergent to wash the reservoir. After washing, rinse thoroughly with clean water.

Page 21

20

Troubleshooting

① When Error occurs, the front use button (ICE-WATER-ICE & WATER) of the door lights alternately to

the left and right. Restart after action.

② When the button is lit alternately to the left and right, open the door and press the bottom setting

button of the control buttons, Error display will appear.

Display

Error type

Causes

Action

Release

Operation

Er01

Evaporator

temperature

error

When the Evaporator

temperature is 0 ° C or more

after 30 minutes passed

during the ice making

Check refrigerant

leakage

Check sensor and

attachment

abnormality

Resupply

power after

resolving

cooling

problem

Stop ice making

Er03

Evaporator

temperature

error

When the Evaporator

temperature is over -5 ° C

after 30 minutes passed

Check refrigerant

leakage

Check sensor and

attachment

abnormality

Resupply

power after

resolving

cooling

problem

Keep on ice

making

Er06

Temperature

sensor error

Displayed when temperature

sensor is open or shorted.

Check sensor and

attachment

abnormality

Start operation

after sensor

part repair

Stop ice making

Er13

High

pressure

switch error

Condenser dust, fan motor

failure, cold cycle

abnormality, etc.

Remove dust,

Check Fan motor

Check for

abnormal cold

cycle

Automatic

return after

action

Stop

compressor.

Stop motor after

operating 10

seconds.

Er14

High

pressure

switch error

Occurs when High pressure

switch is OPEN 3 times or

more

Contact service

representative

Start operation

after action

Stop

compressor.

Stop motor after

operating 10

seconds.

Er15

Water

supply error

When water level is not

detected by the water level

sensor due to no water

supply for 120 seconds.

Water supply

pressure check

Water level

sensor check

Start operation

after action

Stop ice making

Er16

Water level

sensor

defect

At the start of ice making,

when the upper and lower

limits are not detected by the

water level sensor for 60

seconds

Replacement of

Water Level

Sensor

Start operation

after action

Stop ice making

Er25

Motor

restraint

Occurs when Evaporator inlet

/ outlet temperature is -18 ℃

or less for 10 minutes.

Poor water supply, Agitator

restraint,

Ice jams due to scale

Unlock ice jams

Check water

supply line

Check motor

restraint fault

Start operation

after action.

Machine stops

after 3

repetitions

Stop ice making

Page 22

21

Before Requesting Service

If the operating condition of the machine is not good, please refer to the table below to identify the issue.

If you still require assistance, contact your dealer or service center. For expedited service, it is best to

have the following information on hand: model name, serial number, name of dealer, and date of

purchase.

Operating

status

Things to check

Action

1. Machine does

not work

1. Is power supplied?

Please plug in the power cord.

2. Is the circuit breaker switch

disconnected?

After removing the cause, please raise (turn on) the

earth leakage breaker located on the back of the

unit.

3. Is power supplied to 220V ±

10%?

Please check the power and use a dedicated outlet.

4. Is the front power switch on?

Set the front power switch on the front display to the

on ('ICE') position

2. No water

supply.

1. Is the water valve locked?

Please open the water supply valve.

2. Is the water supply hose

properly installed?

Check and take action.

3. Has the water supply stopped?

Wait until water supply is confirmed.

4. Is the water supply valve

operating?

After confirming, contact A / S center.

3. Ice freezes too

late

1. Machine is too dirty (lots of dust)

(Air-cooled)

After removing the front cover, remove the dust net

to the side and remove the dust using the vacuum

cleaner. If a lot of dust accumulates, the

performance of the machine may deteriorate and a

lot of electricity bill may be charged.

2. Is the ambient temperature too

high or too low?

The operating temperature of the product is within

10 ℃ ~ 38 ℃. Control the ambient temperature

according to the operating temperature.

3. Is there accumulation of debris

inside the water supply valve?

Disassemble the water supply valve, and then

remove any foreign matter from the sieve. Be sure

to lock the faucet at this time.

4. The noise is

too big and

abnormal

1. Is the installation floor unstable

or weak?

Fit the floor flat

2. Is the front and rear of the

dispenser not touching the wall?

Please keep more than 50cm on the front and back.

3. Is the water supply temperature

too low?

Use water with a supply water temperature of 10 ° C

to 32 ° C.

4. Does the ice generator produce

loud noise?

Turn the power switch to 'OFF' to completely

dissolve the ice, then switch back to 'ICE'.

Please contact A / S center

Page 23

22

LIMITED WARRANTY

ONE-YEAR LIMITED WARRANTY

Within the 48 contiguous United States, for one year from the date of purchase, when this appliance is operated

and maintained according to instructions attached to or furnished with the product, warrantor will pay for factoryspecified parts and repair labor to correct defects in materials or workmanship. Service must be provided by a

designated service company. Outside the 48 states, all parts are warranted for one year from manufacturing

defects. Plastic parts, shelves and cabinets are warranted to be manufactured to commercially acceptable

standards, and are not covered from damage during handling or breakage.

5-YEARS COMPRESSOR WARRANTY

1. The compressor is covered for 5 years.

2. Replacement does not include labor.

ITEMS WARRANTOR WILL NOT PAY FOR:

1. Service calls to correct the installation of your appliance, to instruct you how to use your appliance, to replace

or repair fuses or to correct wiring or plumbing.

2. Service calls to repair or replace appliance light bulbs or broken shelves. Consumable parts (such as filters)

are excluded from warranty coverage.

3. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

installation not in accordance with electrical or plumbing codes, or use of products not approved by warrantor.

4. Replacement parts or repair labor costs for units operated outside the United States.

5. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

6. The removal and reinstallation of your appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE

PRODUCT REPAIRAS PROVIDED HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR.

WARRANTOR SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO

YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER

RIGHTS, WHICH VARY FROM STATE TO STATE.

WARNING: This product can expose you to chemicals including Nickel (Metallic) which

is known to the State of California to cause cancer. For more information go to

www.P65Warnings.ca.gov

Note: Nickel is a component in all stainless steel and some other metal components.

FELIX STORCH, INC.

770 Garrison Avenue

Bronx, NY10474

Phone: (718) 893-3900

Fax: (844) 478-8799

www.accucold.com

For parts and accessory ordering,

troubleshooting and helpful hints,

visit:www.summitappliance.com/support

Printed in Korea

Loading...

Loading...