Accoutrements LO-BOY INSTALLATION INSTRUCTIONS

MANUAL 2100-103B

INSTALLATION INSTRUCTIONS

LO-BOY

HIGH ECONOMY GAS FURNACE

APPLICATION

This is a forced air gas furnace for installation in building

constructed on site. The furnace installation must conform with

local building codes and ordinances or, in their absence with

the National Fuel Cas Code, ANSI Z323.1-19B0, and the

National Electrical Code, ANSI/NFPA 70-1981. It is the

personal responsibility and obligation of the purchaser to

contract a qualified installer to assure that installation is

adequate and is in conformance with governing codes and

ordinances.

HIGH ALTITUDE APPLICATIONS

Ratings of gas utilization equipment are based on зш level

operation and need not be changed for operation at elevations

up to 2, QOQ feet. For operation at elevations above 2,000 feet

and, in the absence of specific recommendations from the local

authority having jurisdiction, equipment ratings shall be

reduced at the rate of 4 percent for each 1,000 feet above sea

level before selecting appropriately sized equipment. (Ref.

ANSI Z223. 1-1980, Par, 8.12).

TRANSPORTATION DAMAGE

All units are packed securely in shipping container. All units

should be carefully inspected upon arrival for damage. In the

event of damage, the consignee should:

1. Note on delivery receipt of any damage to container.

2. Notify carrier promptly and request an inspection.

3. in case of concealed damage, the carrier must be notified

as soon as possible within IS days after delivery.

4. Claims for any damage, apparent or concealed, should be

filed with the carrier, using the following supporting

documents, and within the 9-month statute of limitations.

a) Original Bill of Lading, certified copy, or indemnity

bond.

b) Original paid freight bill of indemnity in lieu thereof.

c) Original invoice or certified copy thereof showing trade

and other discounts or deductions.

d) Copy of the inspection report issued by carrier's

representative at the time damage is reported to

carrier.

The carrier is responsible for making prompt inspection of

damage and for a thorough investigation of each claim.

LOCATING THE FURNACE

When selecting a location for the furnace, observe the

following points:

1. The furnace should be sat on a level floor. The IL-$eries

Lo-Boy furnaces are shipped raised one inch above the

floor to accommodate a damp or wet floor. If greater

amounts of water are present at times, the furnace may be

elevated further using a concrete base, bricks, patio

blocks, etc., nuking sure adequate support is available for

the furnace. Furnaces approved for installation on

combustible flooring shall not be installed directly on

carpeting, tile or other combustible material other than

wood flooring.

figure 1. MINIMUM CLEARANCES (INCHES)

MINIMUM INSTALLATION CLEARANCES

Front

Model

IL8S042A

IL85042C

IL11504aA

IL115048C

IL14506QA

IL14SD60C

* Clearance may be 1 inch when Type B-1 vent is used.

+ Clearance may be 0 inch when Type B-1 vent is used.

C Floor may be combustible material.

Top

1

1

1 6

6 6*

6 6*

Minimum clearance at least one side for access to rear of furnace.

Vent

6*

Back

0

0 0 0

0

2. The furnace should be as centralized as practical with

respect to the air distribution system.

3. Provisions must bo made for venting combustion products

outdoors through an individual venting system.

4. Provide at least the minimum clearances specified in Figure

1 for fire protection, proper operation and service access.

These clearances must be permanently maintained. The

combustion and ventilating air openings in the front of the

furnace must never be obstructed.

5. Minimum service clearances must take precedence over fire

protection clearances (minimum installation clearances).

6. All models are approved for a utility room or closet

installation.

7. A gas-flred furnace installed in a residential garage must

be installed so that the burners and ignition source are

located not less than 18 inches above the floor, and the

furnace must be located or protected to avoid physical

damage by vehicles.

8. For installation in a manufactured building the furnace

should be anchored to the floor and attached to any

adjacent structural members by screwing support brackets

to the back or sides of the furnace with 1/2” sheet metal

screws.

DUCT WORK

The air distribution systrnn should be designed and installed in

conformance with Manuals 7 or 7A published by Air

Conditioning Contractors of America (ACCA), as set forth in

their Manual K.

CAUTION-

When i furnace Is installed so that supply ducts

carry air circulated by the furnace to areas outside

the space containing the furnace, the return atr

must also be handled by a duct(s) sailed to the

furnace casing and terminating outside the space

containing the furnace. This is to prevent drawing

possible hazardous combustion products to the

circulated air.

When the furnace is used in connection with a cooling unit*,

the furnace shall be installed parallel with or on the upstream

side of the cooling unit to avoid condensation in the heating

element. With a parallel flow arrangement, the dampers or

other means used to control flow of air shall be adequate to

prevent chilled air from entering the furnace and, if manually

operated, must be equipped with means to prevent operation of

either unit, unless the damper is in the full heat or cool

position.

*A cooling unit is sn air conditioning coil, heat pump coil or

chilled water coil.

MINIMUM SERVICE CLEARANCE

Left

Side

0 1^ C

0

Right

Side Floor

c

0 c

Front Sides

24

24

24 18 (Î)

ie®

18 Ф

Back

24

24

24

COMBUSTION AND VENTILATION AIR

The furnace and furnace room must have an adequate supply

of air for safe combustion and ventilation. The provisions

necessary to assure an adequate air supply will vary

depending upon differences in the tightness of house

construction and in the location of the furnace. Methods of

providing air from some typical situations are described below.

Consult local codes and ordinances for requirements applicable

to your specific furnace installation conditions and comply with

them. In the absence of local codes and ordinances, comply

with the National Fuat Gas Code, ANSI Z223.1-19B0.

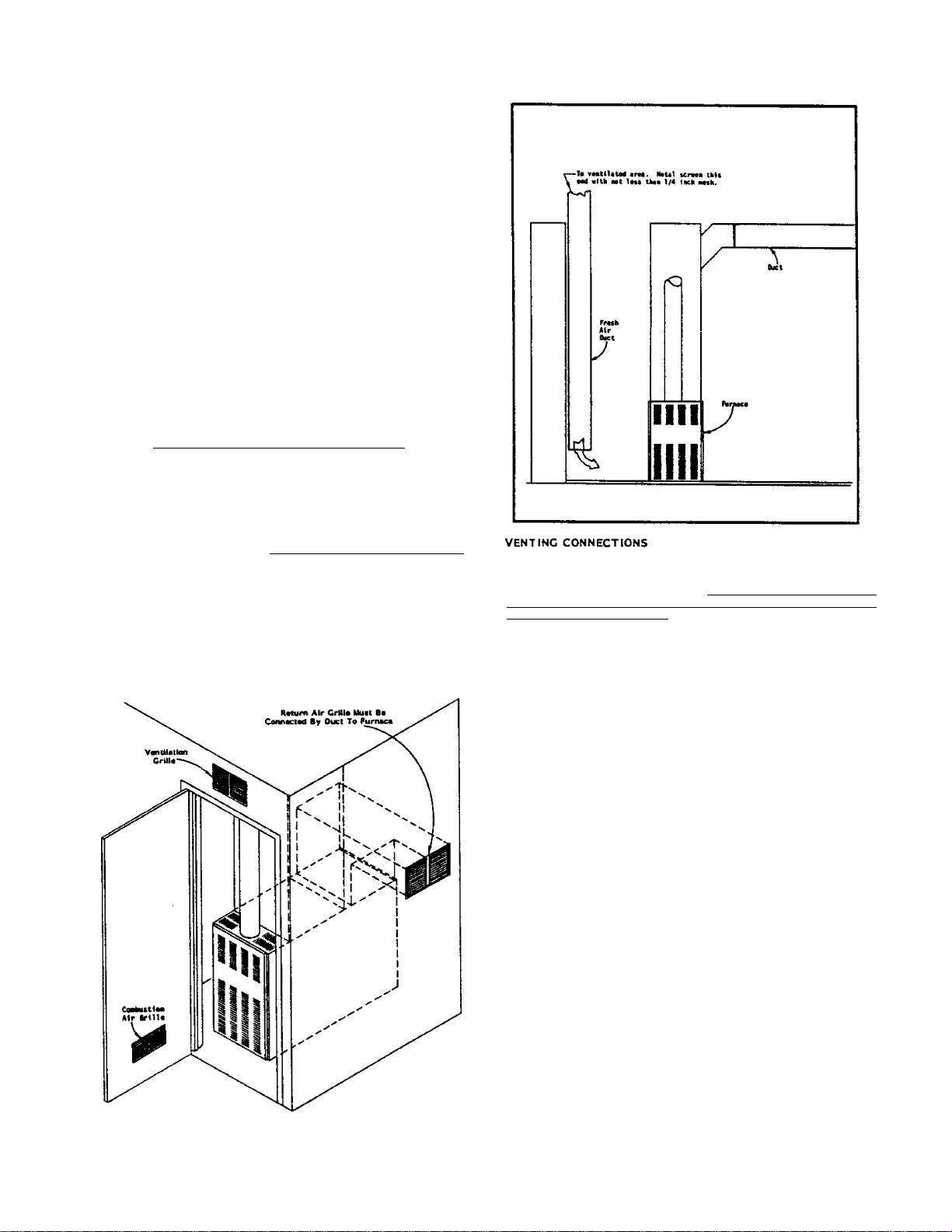

EXAMPLE I - FURNACE LOCATED IN AN UNCONFINED SPACE

A. If the furnace is located in a basement or other large,

open area of a conventionally built house (loose

construction), the air that leaks into the building normally

will provide an adequate air supply.

B. If the furnace is located in a tightly constructed building

(storm windows, weather stripping, cracks caulked, etc.)

an outdoor air intake must be provided. Example 2,

Section B, shows a typical method.

EXAMPLE 2 - FURNACE LOCATED IN A CONFINED SPACE

A. When the furnace is in a closet or utility room, install two

open grilles In a wall or door opening to the rest of the

house. One square inch for each 1000 Btu/h of total input

rating of all gas appliances in the confined space. Refer to

Figure ~T, The grilles must communicate with other open

areas having adequate air infiltration from outdoors.

If the building is tightly constructed, not enough outside

air may enter for safe combustion. Install a fresh air duct

from a point near the burners to the outside or to a

ventilated attic or crawl space. Refer to Figure 3. This

duct must have a free area of at least one square inch for

each 4,000 Btu/h of total Input of aii gas appliances in the

space. The minimum dimension of a rectangular duct must

not be lass than three inches.

CAUTION: WHEN A FURNACE IS INSTALLED IN A CLOSET

FIGURE 2 — FURNACE LOCATED IN CONFINED SPACE

OR UTILITY ROOM, NEVER USE THIS ROOM AS A

RETURN AIR PLENUM.

FIGURE 3 — FRESH AIR DUCT FOR TIGHTLY SEALED

This furnace must be vented directly to the outside through a

suitable chimney. This furnace as shipped from the factory is

suitable for a ^dicated flue only. It should not be vented and

terminated horizontally through a side wall and Is not suitable

for use with plastic pip*- tffth"^'the " addition of optional

field-in stalled Common voting Kit 8620-005 or -006, it is

suitable to common vent thia furnace along with another gas

burning appliance to a single chimney for eese of installation.

Refer to section on Comann Venting beginning on page 11 of

this instruction manual for complete details. The vent must be

installed in compliance with the National Fuel Gas Coda (ANSI

Standard Z223. 1-1980, ] and these instructions.

BUILDING

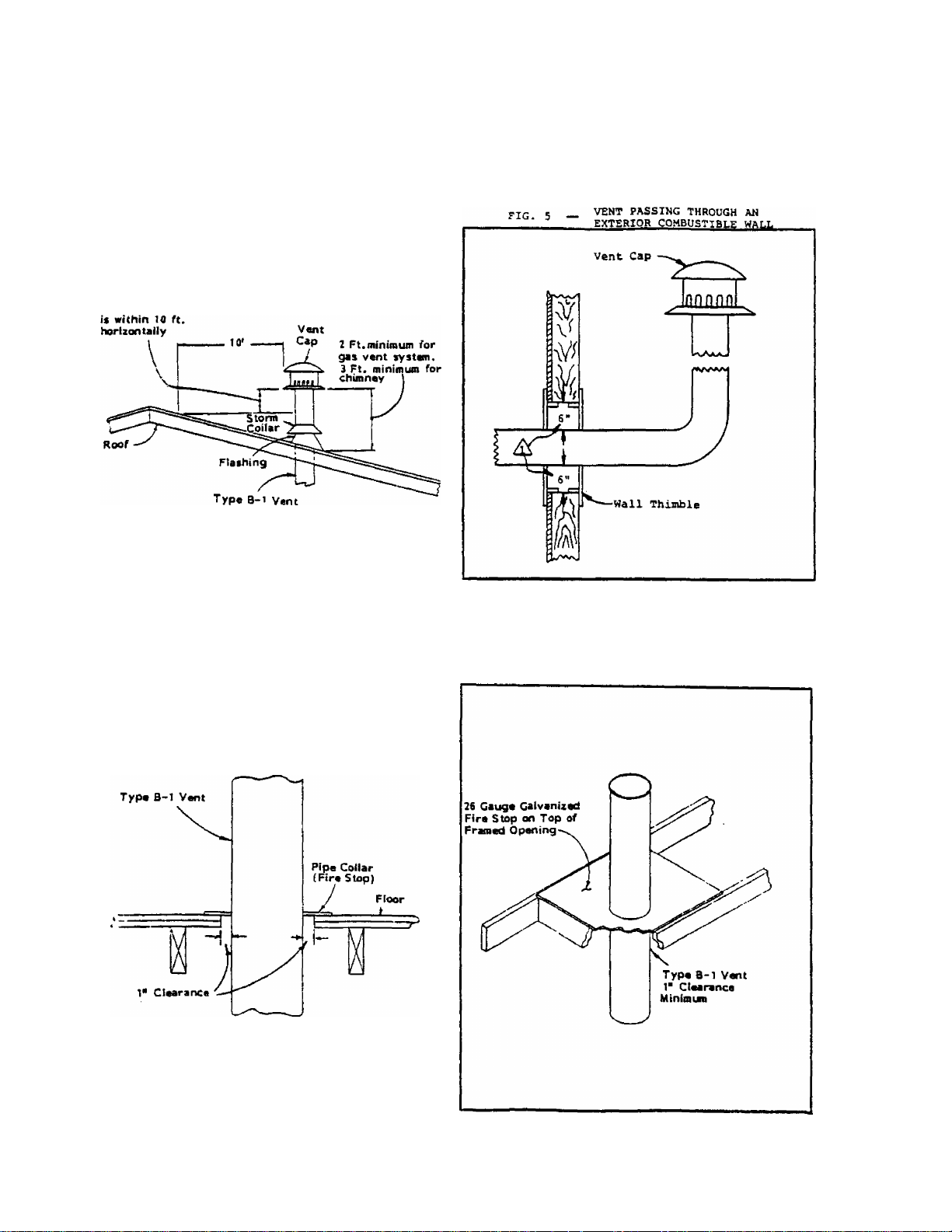

GENERAL INSTRUCTIONS

1. The vent connector must be aluminum pipe and shall be

the same siia as the flue outlet on the furnace. Keep the

vent as short and direct as possible. Type B-1 pipe is

recommended.

2. Maintain a minimum clearance of 6" (1" for B-1) to any

portion of the vent connector from any adjacent

combustible materials. Single wall vent connector is

permitted only within the same space (room or area] at the

furnace. B-1 vent is required whenever the vent is

enclosed or passes through floors, walls, ceilings, roofs or

furred-out spaces. Joists, studs, floors, dry wall,

paneling, sheeting, rafters, roofing and other matcriais

classified as combustibia must not be closer than 1“

clearance to the B-1 vent.

3. If connected into masonry chimney, the vent pipe must be

inserted into, but not beyond the inside wall of the

chimney.

4. The gas vent must extend at least 2 feet above the highest

point where it passes through the roof of a building (3

feet for a chimnay] and at least 1 foot hlghar than any

portion of a building within a horizontal distance of 10

feet. See Figure 4.

5. The vent pipe system shall be installed so as to avoid

excessive turns which create unnecessary resistance to

flow of vent gases.

fi.

Horizontal runs shall be as short and direct as possible.

The maximum length of a single-wall vent pipe shall not

exceed 75 percent of the height of the vent system. The

maximum length of a Type B-1 double wall flue connection

shall not exceed 100 percent of the height of the vent

system.

7.

All horizontal vent pipe shall be pitched upward from the

furnace at least 1/4 inch per foot.

8.

All vent systems shall be adequately supported to maintain

proper clearances, to prevent physical damage, and to

prevent separation to joints.

9.

Vents passing through an exterior combustible wall must

use a ventilated wall thimble. See Figure 5.

10.

Vents passing through floors or ceilings must

fire-stopped. See Figure 6 and Figure 7.

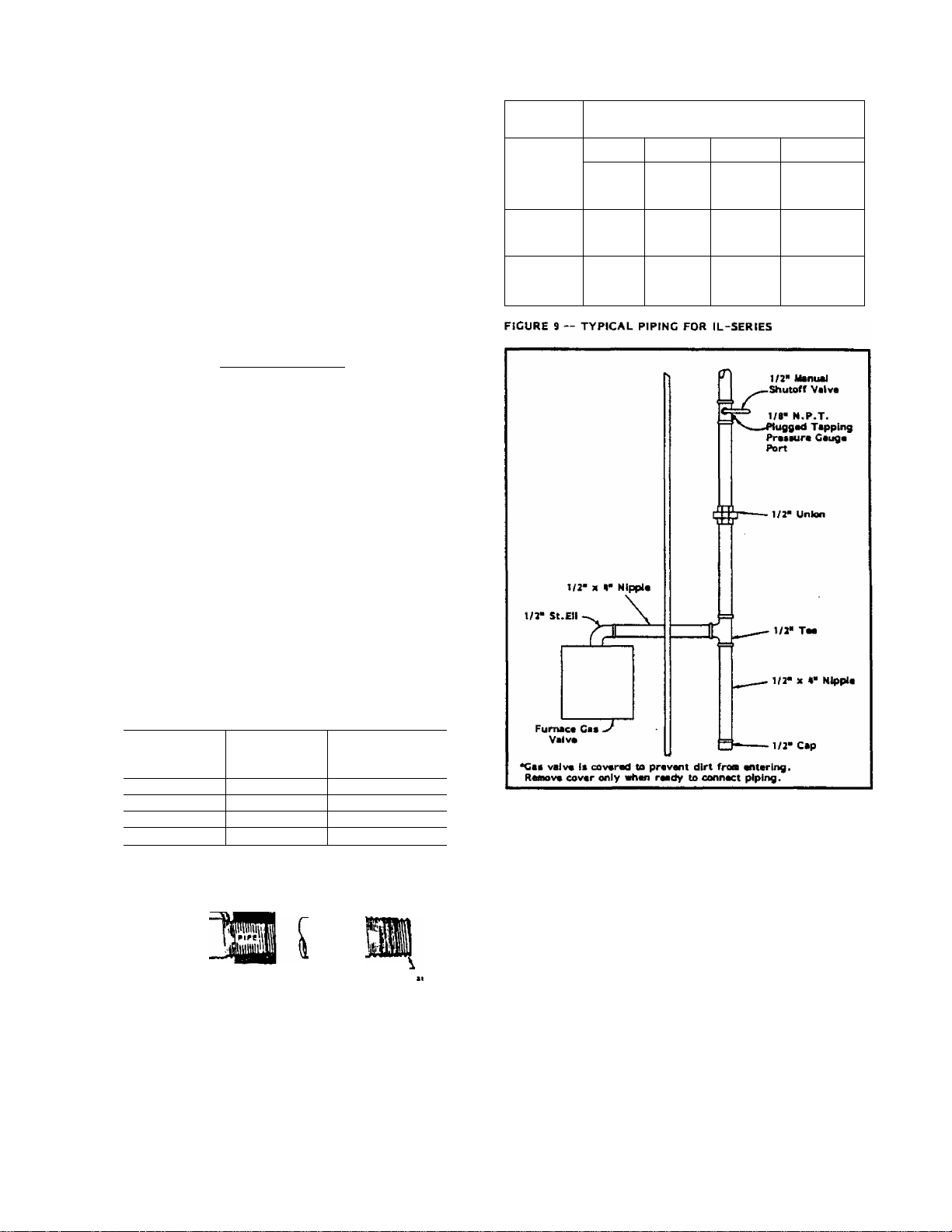

GAS SUPPLY AND PIPING

general recommendations

1. Be sure the gas line complies with the local codes and

ordinances, or in their absence with National Fuel Gas

Code, ANSI Z223.1-1980.

2. A sediment trap or drip leg must be installed in the

supply line to the furnace.

3. A ground joint union shall be installed in the gas line

adjacent to and upstream from the gas valve and

downstream from the manual main shut off valve.

4. A 1/8” N.P.T. plugged tapping accessible for test gauge

connection shall be Installed immediately upstream of the

gas supply connection to the furnace for the purpose of

determining the supply gas pressure.

5. A manual shut-off valve shall be installed in the supply

gas line external to the furnace (see Figure 9 and 10).

6. Use steel or wrought iron pipe and fittings.

7. DO NOT thread pipe too far. Valve distortion or

malfunction may result from excess pipe within the control.

Use pipe joint compound resistant to the action of Liquified

Petroleum gases on male threads only. DO NOT use Teflon

tape. See illustrations below.

FIGURE 8 — GAS PIPE SIZES — NATURAL GAS

Length of

Pipe, Ft.

10 132,000

20

30

40

50

60 50,000

70

80

be

too

Pipe Capacity — Btuh Per Hour

Input Pipe Size

1/2" 3/4“

92,000

73,000

63,000

56,000

46,000 96,000

43,000

38,000

278,000 520, 000

190,000

152,000

130,000

115,000

105,000

90,000

79,000

1"

350,000

285,000

245,000

215,000

195,000

180,000

170,000

150,000 305,000

1-1/4"

1,050,000

730,000

590,000

500,000

440,000

400,000

370,000

350,000

LEKGTH OF STANDARD PIPE THREADS (Indus)

PIPE SIZE

EFFECTIVE

LENGTH

OVERALL

LENGTH

OF THREAD OF THREAD

3/8

1/2

3/4

1

3/8

1/2

1/2-9/18

9/16

9/16

3/4

13/16

1

Ua£UCa!££E±SZ!£l

ThITaOS*^^ COWTgpL use moospats amount or oors

THREAD rirc aiOHT CCNGTH bXAVf I SNO THNSADS SAfIS

8. Refer to Figure 8 for Gas Pipe sizes for natural gas. If

more than one appliance Is supplied from a single line size,

capacity must equal or axcaed the combinad input to all

appliances, and the branch lines feeding the individual

appliances properly sized for eech input.

CHECKING THE GAS PIPING

Before turning gas under pressure into piping, all openings

from which gas can eacape should be closed. IMMEDIATELY

AFTER TURNING ON GAS, the system should be checked for

leaks. This can be done by watching the 1/2 cubic foot test

dial and allowing S minutes to show any movement, and by

soaping each pipe connection and watching for bubbles. If a

leek is found, make the necessary repairs immediately and

repeat the above test. The furnace must be isolated from the

gas supply piping system by closing the manual shutoff valve

on the combination gas control valve during pressure testing

of the gas supply piping system at pressures up to 1/2 psig.

The furnace must be disconnected from supply piping and

supply piping capped during sny pressure testing of supply

piping system at test pressures in excess of 1/2 psig.

Defective pipes or fittings should be replaced and not

repeirad. NEVER USE A FLAME OR FIRE IN ANY FORM TO

LOCATE CAS LEAKS, USE A SOAP SOLUTION.

FIG, A — CHIMNEY OR VENT CAP INSTALLATION

2 Ft. itiintnuin if япу

portion of building

Clearance may be 1 inch when Type B-I vent

A

is used.

FIG, S — VENT THBODGH FLOOR

FIG. 7 — VENT THROUGH CEILING

Loading...

Loading...