Accel TEMPEST 3302 User Manual

T empest® Hot Air Drying System

Installation Instructions

Ryobi 3302

Itek 3985

A.B. Dick 9985

X88-43

01/2001

Rev-B

2740

GENERAL INFORMATION

ATTENTION

TEMPEST® DRYER

OWNER!

Accel Graphic Systems provides parts and service through its

authorized distributors and dealers. Therefore, all requests for

parts and service should be directed to your local dealer.

The philosophy of Accel Graphic Systems is to continually improve

all of its products. Written notices of changes and improvements

are sent to Accel Graphic Systems' Dealers.

If the operating characteristics or the appearance of your product

differs from those described in this manual, please contact your

local Accel Graphic Systems Dealer for updated information and

assistance.

Always update your equipment when improvements are made

available, especially those related to safety.

YOUR AUTHORIZED TEMPEST® DEALER IS:

TECHNICAL

ASSISTANCE

2

THE SERIAL NUMBER OF YOUR

TEMPEST® HOT AIR DRYING SYSTEM IS:

CONTROL BOX

FAN UNIT

For technical assistance during the installation, please contact:

ACCEL GRAPHIC SYSTEMS

11103 INDIAN TRAIL

Dallas, TX 75229

PHONE (972) 484-6808

FAX (800) 365-6510

E-MAIL accel@dallas.net

WEB SITE www. accelgraphicsystems.com

GENERAL INFORMATION

ELECTRICAL

REQUIREMENTS

IMPORTANT

INFORMATION

SAFETY

INFORMATION

220 VAC 50/60 HZ

20 AMP DEDICATED LINE

NEMA L620R RECEPTACLE

The use of heat to accelerate drying may require more frequent

lubrication and/or use of a high temperature lubricant in the delivery of

the press. Please consult your press manufacturer for specific recommendations.

The Tempest® Dryer contains high voltage and hot surfaces. Never

attempt to service or work on the unit unless the power is shut off and

the unit is cool.

Visually inspect the thermistors (Barn housed-shaped objects arranged in a honeycombed pattern on the underside of the unit) weekly.

If a thermistor is damaged or cracked, do not operate the dryer. Contact

Accel immediately for a replacement part.

TERMINOLOGY

The fans should be turned on and set at the lowest speed ("0" on the

dial) when running spray powder only without heat. This prevents

spray powder from accumulating in the thermistors and housings.

OPS = Operator's Side

NOPS= Non Operator's Side

3

GENERAL INFORMATION

HOT AIR

VS INFRARED

WHAT MAKES

TEMPEST

®

WORK

Although the technology behind the Tempest® dryer was significant

enough to be awarded the GATF Intertech Award, it is by no means

new. In fact, thermistors have been in use for many years. They

were originally used in motors and other devices as a heat

controller and later used in refrigeration to turn compressors on and

off. It is only in the last 10 years or so that thermistors have been

used as a heater.

Heat is generated by the thermistor because of the difficulty of

electricity travelling through it when it is a conductor. The thermistor

acts as a conductor until it reaches its set temperature and then it

becomes a resistor. A thermistor is basically a coated

semiconductor designed to switch from a conductor to a resistor at

an established temperature.

When a current is applied to the thermistor it initially uses a large

amount of electricity and heats up very quickly until it reaches its

maximum set temperature. At this point it should not use any more

electricity. However, air that is passed through the holes in the

thermistor causes it to cool. This activates the thermistor to start

using more power again so that can get back to its set temperature.

The thermistor is constantly regenerating itself to stay at a constant

temperature. This process is called autostabilization.

4

Thermistors are also the key element that makes the Tempest

dryer safe. Because the set temperature of the thermistor is lower

than the flash point of paper, you can place even the most easily

burned substrate (such as tissue paper) on top of the thermistor

element without causing a fire. The tissue won't even char, let

alone ignite. If you were to do the same with an IR element, a fire

could start in a matter of seconds. This is particularly important if a

jam occurs in the delivery.

The objective of any drying system is to raise the pile temperature

to accelerate the drying of the ink. However, heating the paper too

much can aggravate problems such as blocking, setoff, mottle, loss

of gloss, and loss of halftone definition. Too much heat can also

cause the paper to shrink which can cause register problems in

multiple pass work. The Tempest® dryer can keep the pile at a

lower temperature than IR and still effectively set the ink film.

®

GENERAL INFORMATION

IR dryers use very high temperatures and a fixed amount of electricity.

One of the drawbacks of using a very hot heat source is that heat wants

to travel from a very high temperature to a very low temperature. In

other words, the heat generated from an IR dryer will travel to the press

wall and attempt to increase its temperature because it is cooler than

the heat produced by the IR dryer. Because the thermistors used in the

Tempest® dryer use lower temperatures, the heated air has had time

to cool by the time it reaches the wall of the press, reducing the chance

of premature wear to press parts.

HOW DRYING IS

ACCOMPLISHED

WITH TEMPEST

KEY FACTORS

TO REMEMBER

ABOUT DRYERS

FOR SMALL

OFFSET

PRESSES.

Tempest® "sets" the surface of the ink to prevent set-off from one sheet

to another and to minimize the use of powder.

®

Tempest® accelerates the final drying of oil based inks by raising the

temperature of the delivery stack.

Do not expect a dryer to "instantly" dry the ink. Only UV inks and

coating dry instantly. The technology and hazards of such systems

make them cost prohibitive on small offset presses.

Some jobs may require spray powder. Because dryers for small offset

presses do not dry ink instantly, powder will be required from time to

time. However, you should expect to see a significant decrease in the

amount of powder needed on a regular basis.

Drying time is dependent upon press speed, paper stock, ink coverage,

type of ink, etc.

Do not expect a dryer to accelerate the drying of rubber based inks.

These inks dry by absorption into the stock, and heat does not

accelerate this process.

5

6

1

2

INSTALLATION

DISCONNECT THE POWER T O THE PRESS BEFORE

BEGINNING INSTALLATION.

Remove the two large side co vers ov er the main frame work of the

press (one at OPS and one at NOPS) and the NOPS cover at the

delivery end of the press.

For an easier installation, you may also want to remove the two

guards on the delivery end of the press.

NOTE: Do not cut the hose if the press is equipped with an

Airtech sprayer .

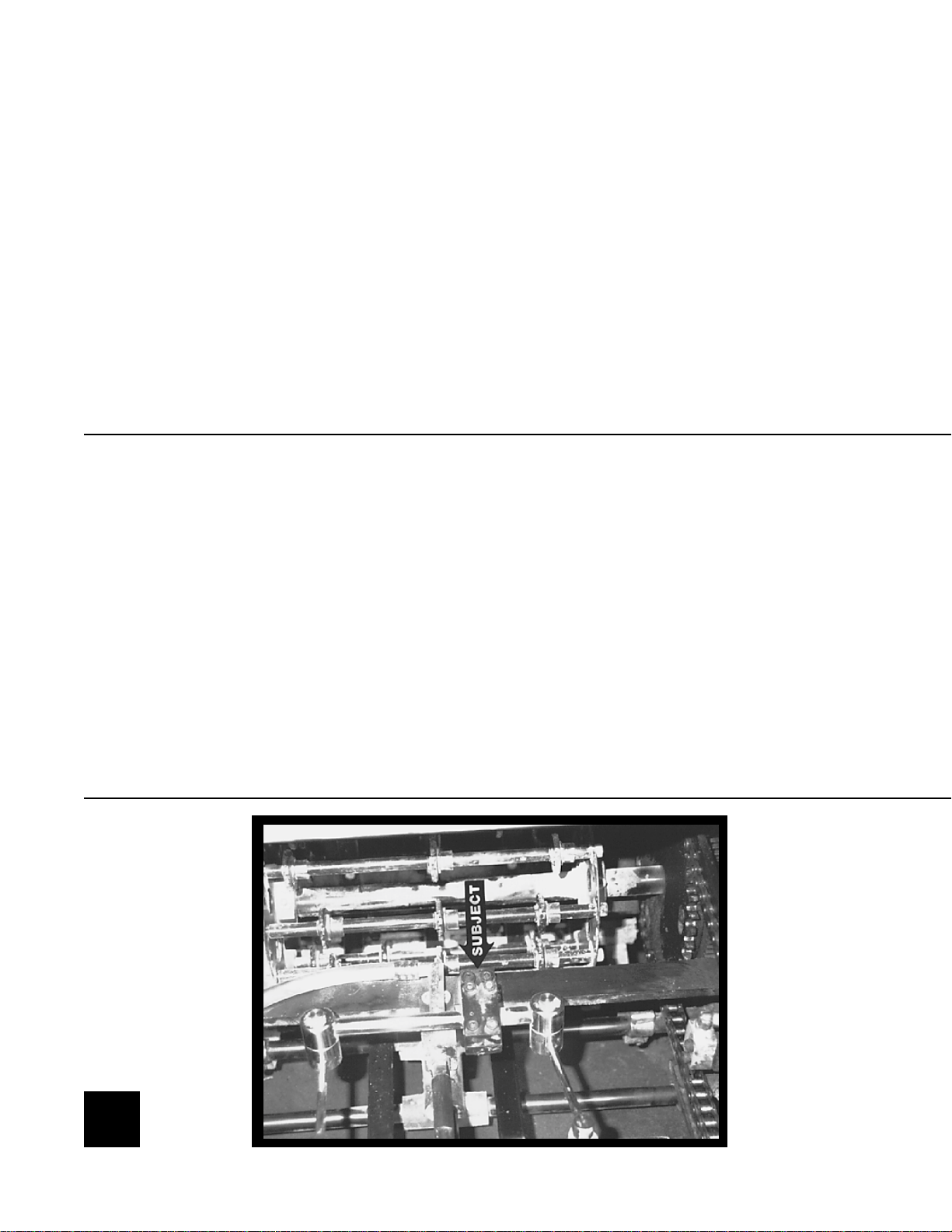

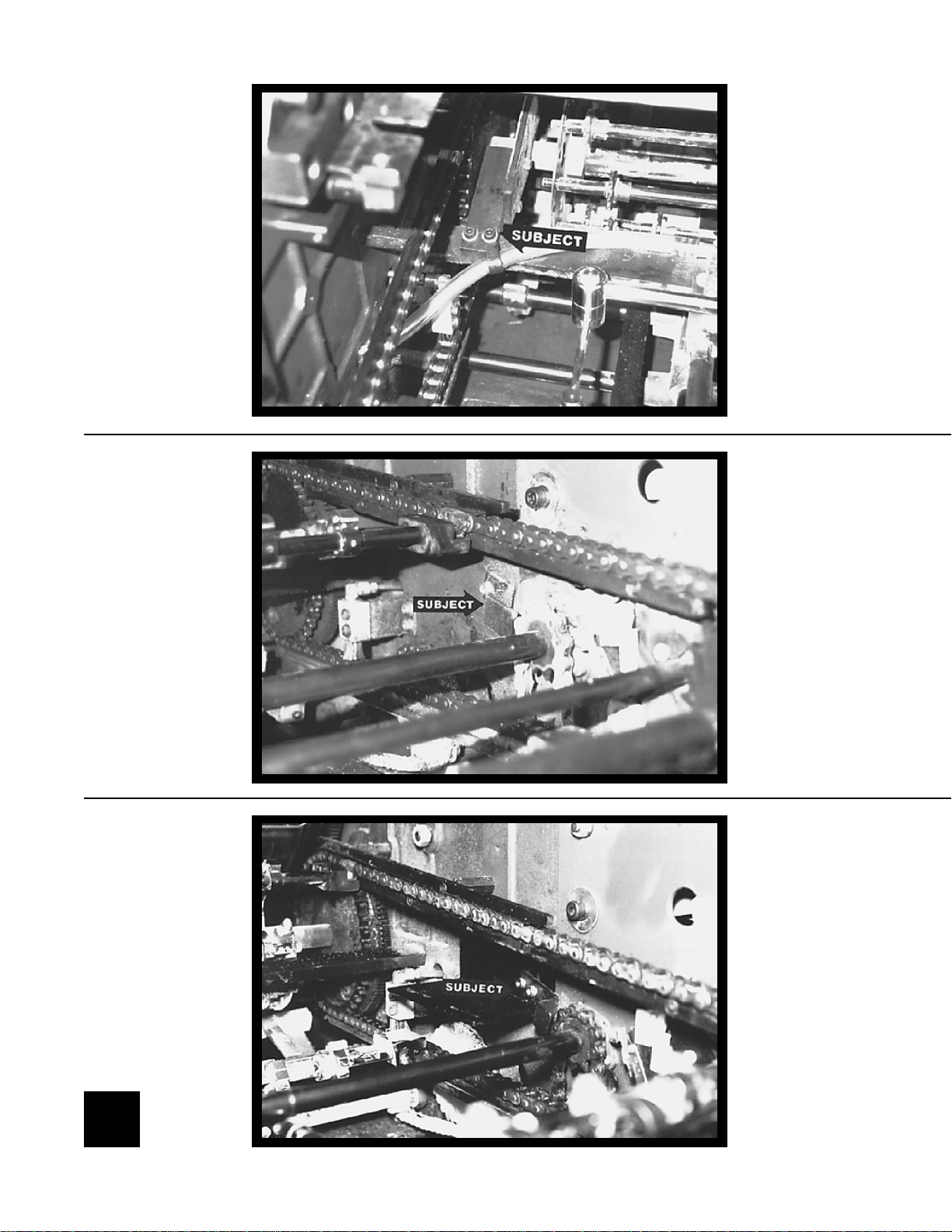

3

Cut the sprayer hose about halfway between the hopper and the

spray bar. A new hose will be attached to the spra y mechanism.

NOTE: Do not remove the spray bar if the press is equipped

with an Airtech sprayer .

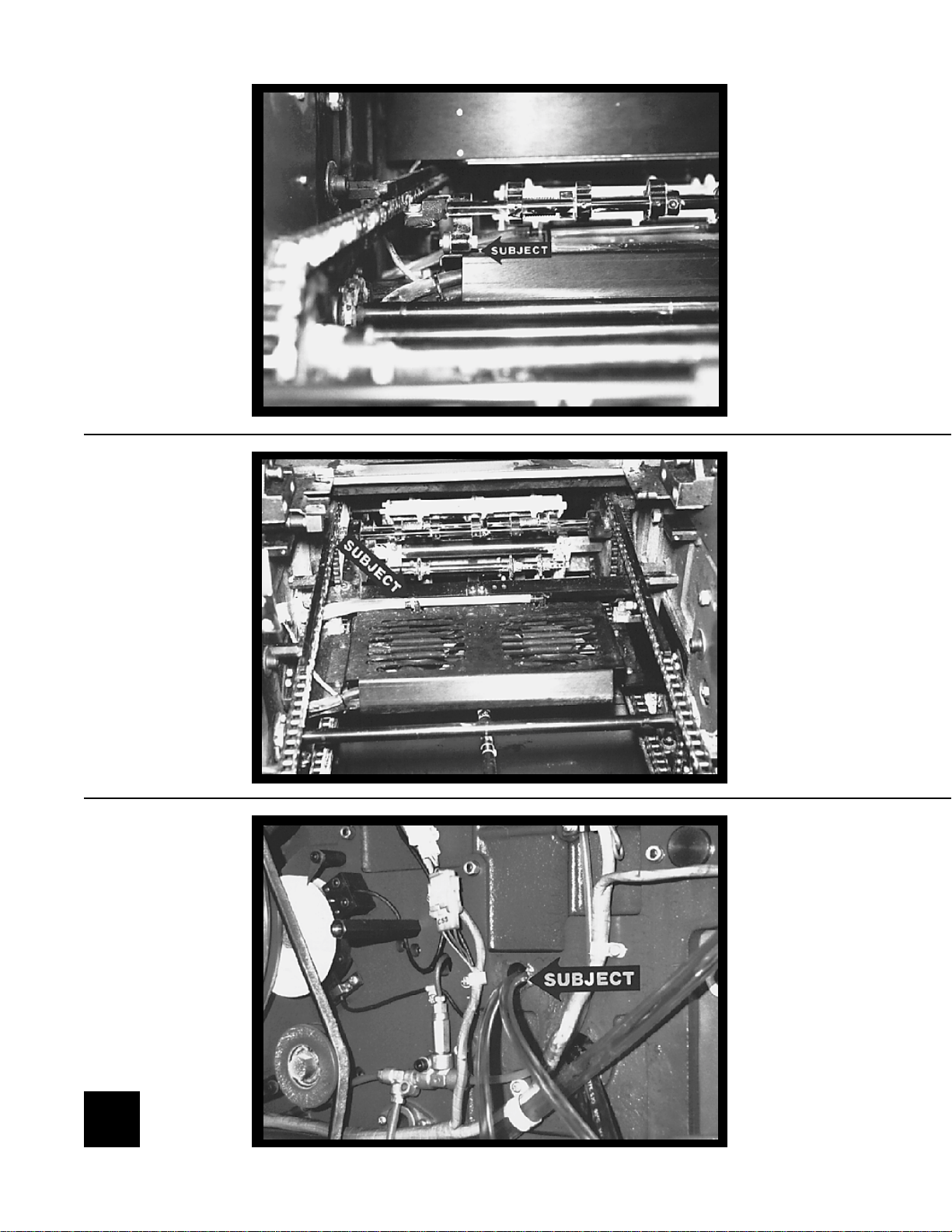

Remove the spray bar by removing the two bolts holding the

bracket (subject arrow). Also remove the clip holding the spray

hose (subject arrow, picture on following page).

7

8

4

INSTALLATION

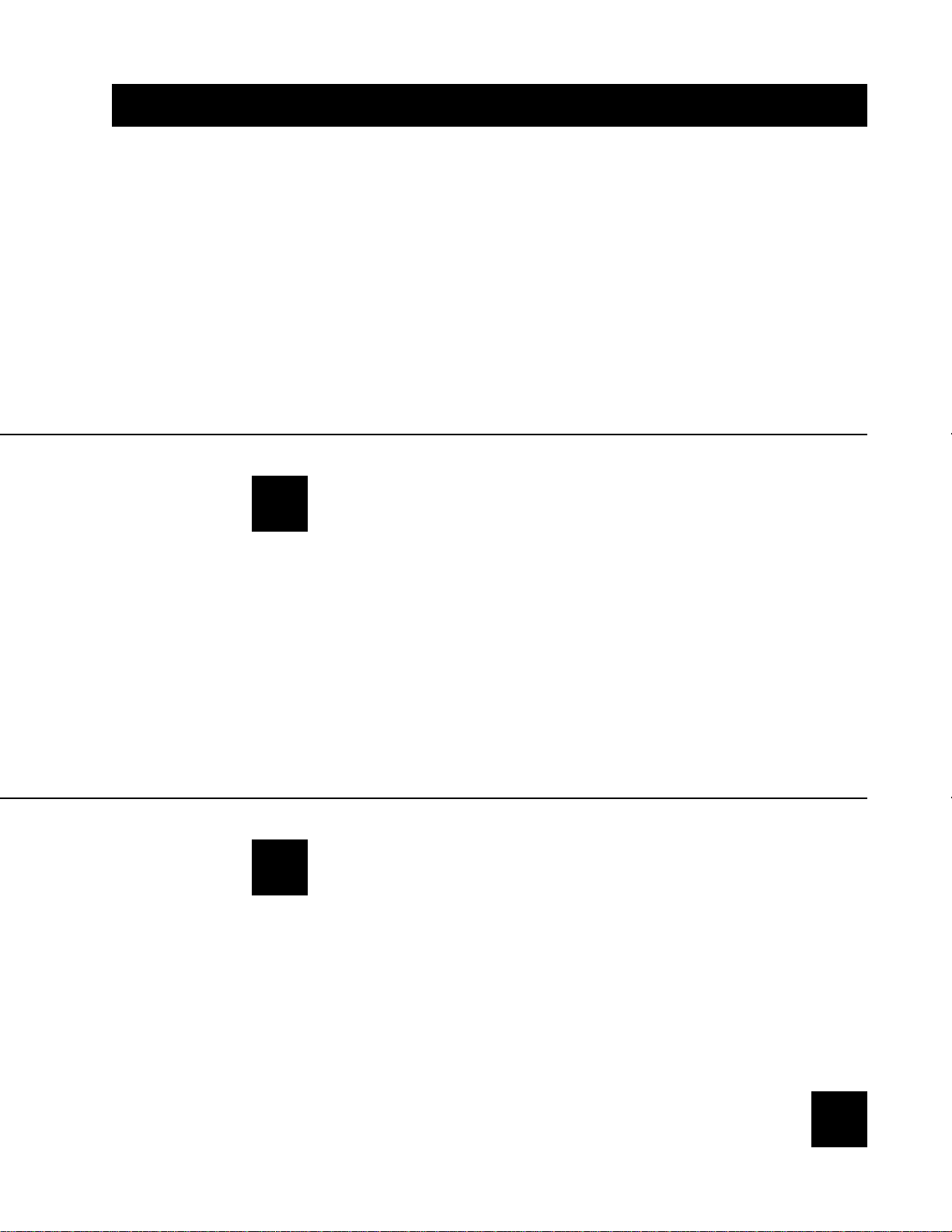

Remove the chain guide (subject arrow) at the OPS & NOPS sides

of the press.

5

Install the mounting bracket and new chain guide using M5 X 16MM

cap head bolts and lock washers (subject arrow) as sho wn at the

OPS & NOPS. Leave the bolts loose so the position of the dryer can

be moved up and down. The bolts thread into the same holes that

held the original chain guides.

9

10

6

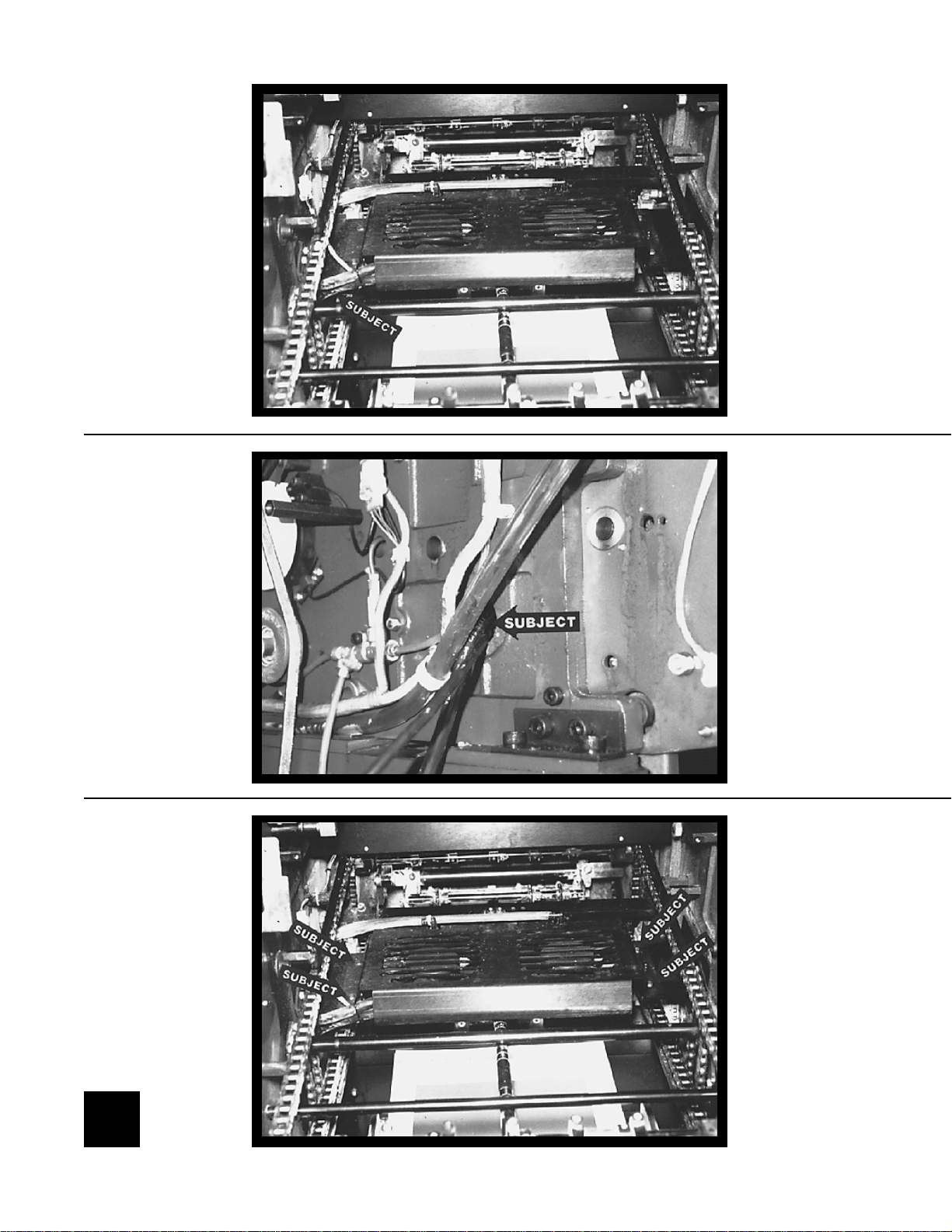

INSTALLATION

Note: If the press is equipped with an Airtech sprayer , you must

remove the spray bar from the dryer before installing it in the

press. To remove the spray bar from the dryer, remove the three

screws on the top of the dryer .

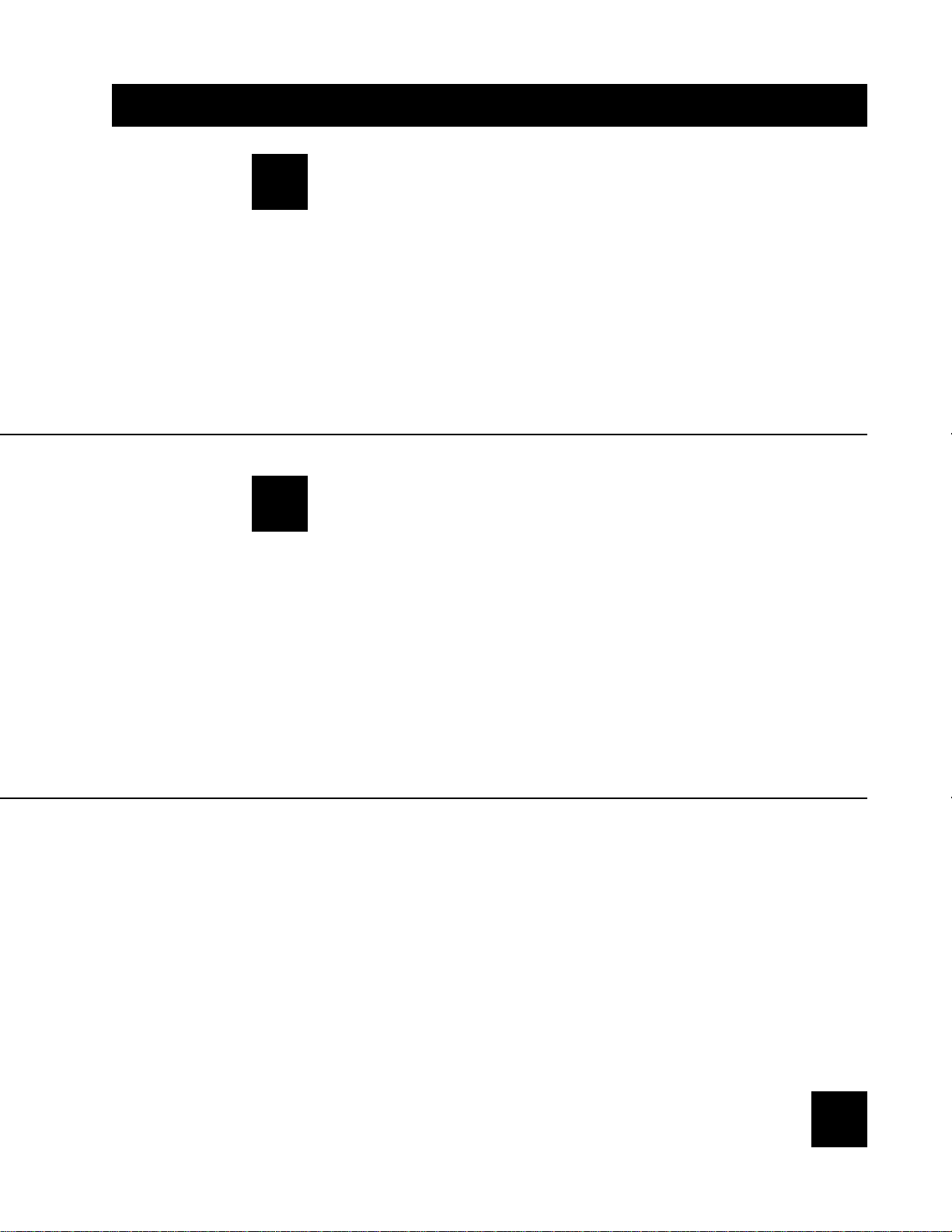

Set the dryer on the brackets with the cable exiting at the NOPS.

Run the cable under the mounting bracket (subject arrow, left

picture) and through the large hole in the side frame (subject arrow ,

lower picture) directly under the mounting bracket.

7

Secure the dryer to the brackets (f our places) using the short button

head bolts, washer , and flanged nut (subject arrows). Leav e the bolt

loose so the dryer can be moved front to back.

11

12

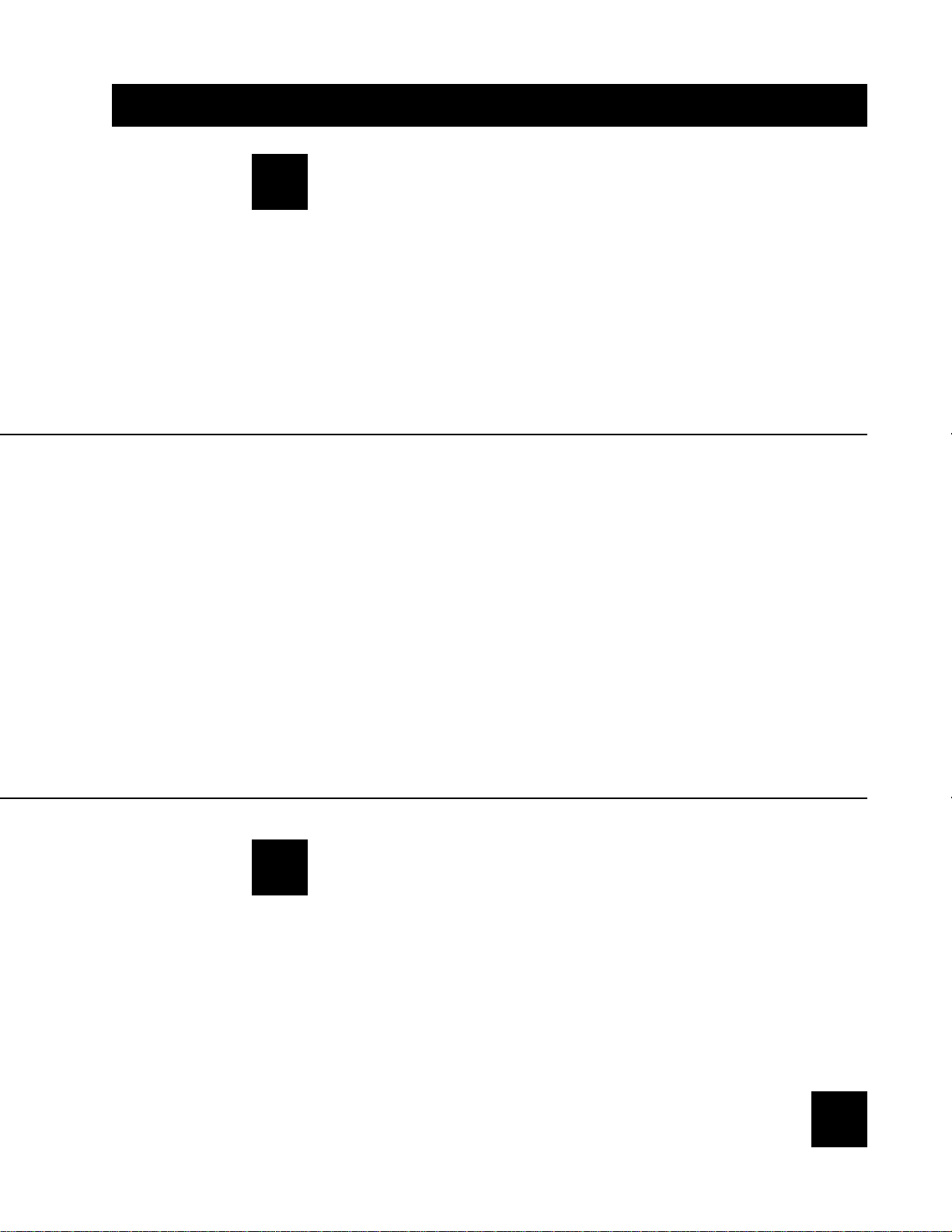

8

9

INSTALLATION

Position the dryer so it clears the gripper opening mechanism on all

three delivery gripper bars. The arm must clear both the top and

bottom of the dryer. The photo shows the arm clearing the top of the

dryer (subject arrow). After positioning the dryer , tighten the bolts

holding the mounting brackets to the press frame and the bolts

holding the dryer to the mounting brackets.

NOTE: If the press is equipped with an Airtech sprayer, proceed to step 11.

Attach two hoses to the elbows in the sprayer housing (subject

arrow , upper picture) and run the hose through the hole in the side

frame (subject arrow, lower picture ). Note how the hoses are tied

together with a zip tie in the upper picture on the left hand side.

13

Loading...

Loading...