Operating Manual

A100

1

© 2013 venotec GmbH

GmbH

Am Nordkreuz 36

26180 Rastede

Deutschland

www.venotec.de

Any claims against venotec in relation to the products described in this manual

shall be handled exclusively as per the guarantee conditions of the manufacturer.

The product specifications may deviate from the information in this manual due to

technical improvements and innovations. Abyzz, BOOSTMODE and venotec are

registered trademarks.

Valid as of: 04.02.2014

2

Table of contens

Page

Preface

5

Scope of delivery

6

Function description

7

Abyzz peripheral devices and connection options

8

Warnings

9

Proper use and general information

10

Installation of driver

11

Installation of pump

12

Commissioning

13

Run in phase

13

Description of control elements

14

Operation

15

Maintenance

18

Guarantee

23

Technical changes

24

Troubleshooting

24

Disposal

25

Technical data

25

Materials

26

Appendix

27ff

Test report

29

3

List of figures

Page

Fig. 1a/b

Connector view of driver

12

Fig. 2:

Bearing straight from factory and following run in phase

14

Fig. 3:

Overview of messages

16

Fig. 4:

Abyzz boost mode

17

Fig. 5:

Pump with pump head

18

Fig. 6a/b:

Disassembly of pump head

19

Fig. 7:

Removing impeller group

20

Fig. 8:

O-ring position and assembly

21

Fig. 9:

Assembly of pump head

22

Fig. 10:

Flow charts

27

Fig. 11

Dimension of pump A100

28

4

Preface

Thank you for buying an Abyzz® pump! By buying this powerful product, you have

acquired a highly efficient, fully variable pump that was developed and

manufactured in Germany to meet the most stringent quality and performance

requirements. This manual aims to help you to start using the product and to make

the required settings.

In order to reap the benefits of this product for as long as possible, please read

this manual carefully and observe our recommendations.

Should the quality of the product not meet your expectations, please contact the

dealer who sold you the pump or contact us directly. We recommend that you use

the provided form to register your product with us so that we can provide you with

the best possible service. Please make sure that the serial number on your

product remains legible and be ready to provide us with this number if asked.

Legend

This symbol indicates particularly important information.

5

Scope of delivery

1 Abyzz A100 pump with 2m cable including pump stand

1 Abyzz A100 driver

1 Abyzz connecting cable (for Abyzz peripheral devices)

1 Abyzz mains cable

1 Registration form

1 Owners manual

6

Function description

The core component of the Abyzz® A100 pump is a three-phase synchronous

motor driven by sine waves. The high efficiency of the motor combined with the

low motor voltage makes it ideal for energy saving and safety pump appliances.

Integrated bearing flushing provides optimum protection against calcination and

ensures low-maintenance operations.

The materials used are designed to have a long lifetime and meet the highest

requirements and quality standards. Our products are developed and

manufactured in Germany. Thus, they deserve this label:

"Made in Germany"

The electronic control unit has optimum operating properties. In particular, these

properties include the following:

- Variable speed range (0 - 100%)

- Programmable control unit including Abyzz BOOSTMODE

®

- Dry run protection

- Soft startup

- Bus-enabled interface*

- Lockable plug contacts

- Temperature protection

- Overcurrent protection

- Current limitation

- Low-noise operation

- Long lifetime

- Minimal power loss (especially low loss of heat into water).

7

Abyzz peripheral devices and connection options

The Abyzz connecting cable required for the connection of peripheral devices

forms part of the scope of delivery of the pump*. If you do not use any peripheral

devices, please secure both connections using the provided caps to prevent

corrosion and the penetration of dust.

Abyzz control system (ACS):

The ACS allows you to control several (currently up to 8) Abyzz pumps. You can

program in different profiles to generate waves, tides, or other flow patterns, for

example.

In addition, the ACS allows you to centrally operate and monitor all bus-enabled

Abyzz products. For example, operating data, alarms, temperatures, and so on are

displayed centrally on the ACS display.

There are two D-sub connectors on the bottom of the Abyzz A200 pump driver for

this purpose. The connection labelled "Master" is always connected in the direction

of the ACS and the connection labelled "Slave" is always connected in the

direction of the next Abyzz pump.

Abyzz interface (AInt):

The Abyzz interface allows you to integrate your Abyzz pumps into existing control

systems (PLC, aquarium computer, etc.).

They simply require a 0 - 10 V output. Once the Abyzz interface is connected up,

the internal programming of the driver is deactivated and the speed of the pump is

regulated using the set direct current voltage. The pump's monitoring and

protection functions and the display of operating data remain activated but the

driver keyboard is deactivated.

If you are interested in this component, please contact your specialist dealer.

8

Warnings

- You must disconnect the mains plug before working on the pump!

- Caution - high voltage: It is prohibited to expose the electronic

components of the product. This must only be done by the manufacturer!

- Do not disconnect the motor supply line from the driver at any time

during operations!

- Only connect parts that clearly belong together!

- Make sure that supply lines, connectors, and the driver are kept dry and

protect the components from damage.

- Do not work on cabling or the driver if you have wet hands.

- Do not use the product if any of the people in the vicinity are in the water

or if anyone is in contact with the water.

- Check the product for damage before use. Never use a product that you

know is damaged.

- Connect Abyzz products only to to a suitable, properly installed earthed

wall socket that is fused with a circuit breaker as per DIN VDE

0100T739 (residual current circuit breaker).

9

Proper use and general information

This product is intended for the conveyance of fluids (seawater,

freshwater, brackwater, chlorine water, and other non-aggressive

fluids with a temperature of +2ºC to +40ºC. The appendix includes a

list of parts that come into contact with the medium being conveyed;

in the case of media not specified above, please check the

compatibility of the medium being used with the specified components prior to use.

The product can convey clean water or dirty water with a particle size of up to

1mm. If using dirty water, you must regularly clean the pump and use a preliminary

filter to protect it. In particular, clean the internal flushing channel. Abrasive

components increase the wear rate. Resulting damage is not covered by the

guarantee.

The pump is not a self-priming pump and must therefore always be installed

below the water level.

Please observe all generally valid national and international requirements when

installing the pump.

The maximum working pressure may not exceed 0,8 bar.

Prior to being placed into storage, the product must be thoroughly cleaned with

freshwater and appropriate cleaning agents (e.g. vinegar), since otherwise residue

might settle inside.

During use, please make sure that the intake duct is sufficiently protected to

prevent animals or foreign objects reaching the pump and causing damage.

When laying the piping, make sure that there is sufficient compensation of

temperature fluctuations in the pipes.

Use a sufficiently large pipe diameter (an internal diameter of at least 40 mm on

the intake side and of at least 25 mm on the pressure side).

10

Installation of driver

Moounting:

The product must not be installed outside. The mounting wall must be dry and

protected from splashes of water and damp. A suitable power outlet should be

available at an appropriate distance. Please keep a distance from ceilings of at

least 30cm.

Wiring:

When laying the wires, make sure that no drips of water can reach the electronics

via the wires.

Please note that due to the driver switch-on current, you must not switch on

multiple drivers on the same fuse at the same time. Do not use multi-socket strips

and do not exceed the permitted connected load of your supply line under any

circumstances.

Ambient temperature and cooling:

The product can be used at ambient temperatures of between 2°C and +40°C.

To ensure sufficient cooling, the driver should be at least 30

cm away from any other objects (walls, ceilings, cable

ducts, pipes etc.). The cooling element must not be

covered. We recommend that you do not expose the driver

to any additional heat source (heating system, lighting,

sunlight) and ensure sufficient ventilation if using it in

cupboards or on racks.

11

Electrical connection:

The Abyzz A100 requires a connection of 90...230V/50...60Hz.

The component must be connected to a suitable, properly installed earthed wall

socket that is fused with a circuit breaker as per DIN VDE 0100T739 (residual

current circuit breaker). We recommend that you do not connect more than 4

controllers to a supply line (16A fuse). The product has a mains switch, which is

located on the connector element. The IEC connector on the Abyzz mains cable

has a lock to prevent it from falling out. Press the red lock/unlock button on the IEC

plug (fig. 1b) and then pull out the plug.

Fig. 1: Connector view of driver

Installation of pump

The Abyzz pump can be immersed to a depth of 2 metres or installed in a dry

position, both either horizontally or with outlets down.

On the intake side, make sure that the water can flow in freely and protect the

intake by means of a screen suitable for keeping coarse particles, sand, filter

cotton fibres etc.) away from the impeller wheel. When laying the piping, make

sure that there is at least 20cm of straight pipe on the intake side to allow the

water to enter on a straight course. This measurement optimizes the product's

efficiency and significantly reduces noise. For even more efficiency, use sufficient

pipe diameters for large pipe systems (recommended: 63mm on the intake side,

50mm on the pressure side).

When using adhesive fittings, use an adhesive suitable for ABS and PVC.

12

Installation outside pond:

Find a suitable installation location where there will not be too much of a loss of

power as a result of bends, corners, and the running of cables. Wherever possible,

use bends instead of sharp corners and connect the pump as flexibly as possible

with flexible connection parts (e.g. suitable silicone house from a specialist dealer)

in order to prevent connection line vibrations, which might result in leaks on

screwed or adhesive joints over time.

These measures are optimum precautions for ensuring trouble-free, low-noise

operations.

Installation in pond:

Place the pump in the filter sump and connect it to your piping system as flexibly

as possible to prevent noise and vibrations.

Commissioning

Once it has been properly installed, the Abyzz pump can be placed into operation.

To do so, connect the motor connection cable with the driver. The plug is coded

and can only be connected in one position. The plug used meets the highest

impermeability and safety standards. Screw the plug together to safeguard these

properties. Connect the Abyzz mains cable with the driver, plug the mains cable

into a suitable earth wall socket, and switch on the mains switch (see fig. 1a).

The LED flashes. You can start and stop the pump in any operating mode by

pressing the start/stop button.

If the pump is running dry at more than a third of its output, the dry run protection

function is activated. This function switches the pump off and reports a fault

("DRYRUN!"). After a few seconds, the pump starts up again automatically and,

the dry run fault being rectified, begins working again.

Run-in phase

Despite our best efforts, small production tolerances cannot be avoided when

manufacturing the bearings. Their condition can cause noise during the pump runin phase. However, this is normal, and does not pose a problem in the long term.

During the device test following production, the power, concentricity, and noise

development of all pumps is tested. The run-in phase can last several days

depending on the operating mode. Figure 3 clearly shows the difference between a

bearing that has come straight from the factory (left) and a bearing following the

run-in phase (right): Following the run-in phase, these operating noises practically

disappear.

13

fabrikneu eingelaufen

Fig. 2: Bearing stright from factory and following run-in phase

Description of control elements

Display:

The display tells you about the operating state of the pump. The display switches

to idle mode after 3 minutes of inactivity to ensure the maximum possible lifetime

and the lowest possible current consumption. Simply press a button to switch the

display back on. The overview changes every 2 seconds as follows and displays

the following operating data:

-

Adjusted power in %

-

Driver temperature

-

Driver status and ACS adress, if used

-

Operating mode

-

Actual energy saving

-

BOOSTMODE® adjustment

The text displayed in the first line changes from "Stopped" to "Running" if you

increase the speed and switch on the pump.

LED:

The LED flashes to show that the product is working properly.

Keyboard:

The keyboard enables the direct control of the pump and the programming of the

pump in the menu.

14

Operation

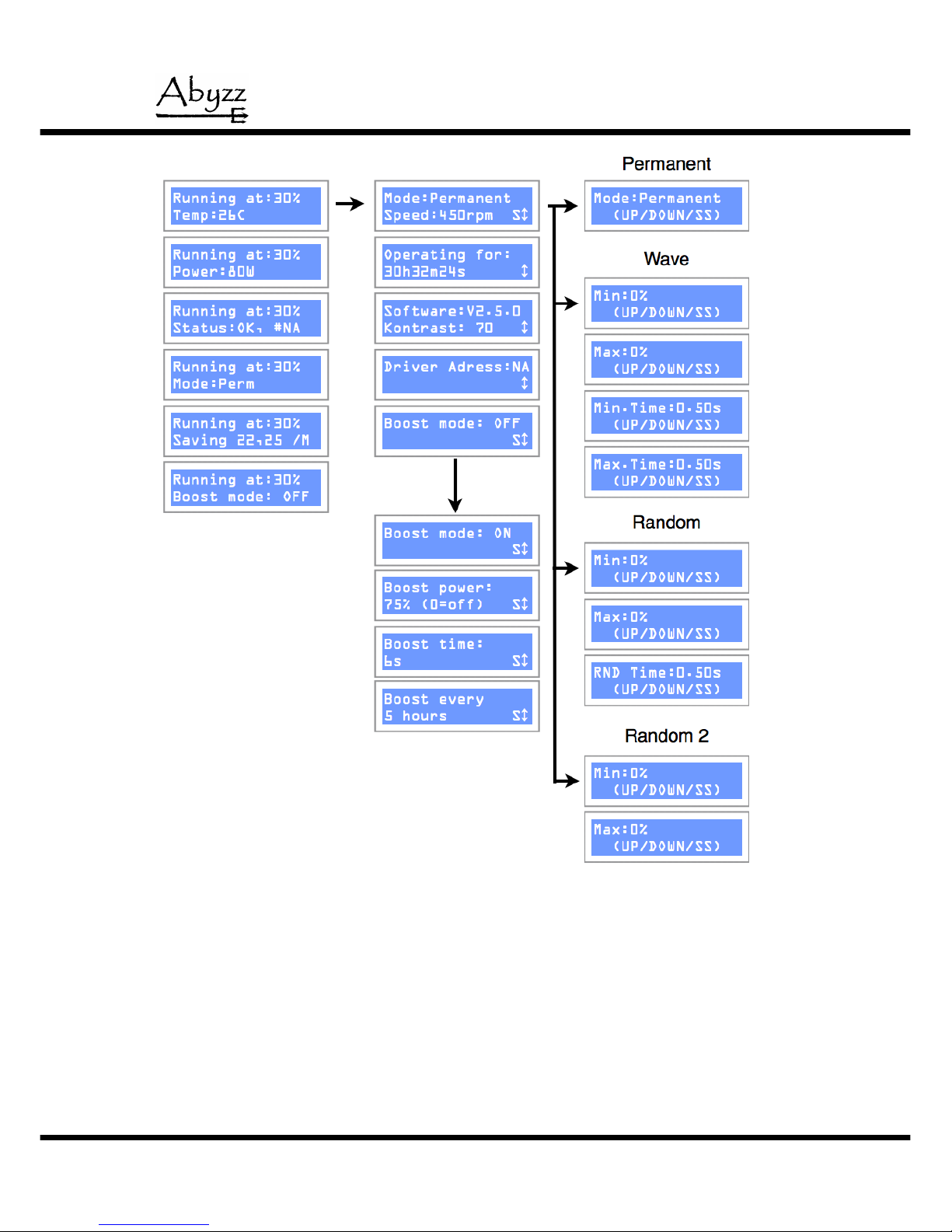

In the "Permanent" operating mode (set when delivered), you can use the start/

stop button to start or stop the motor. You can adjust the speed using the up and

down buttons. If you want to store the new speed permanently, press "M". The set

value is then retained by the system. The start/stop setting is stored automatically

so that the pump automatically starts in its previous operating mode following an

interruption in the operating voltage or if the mains switch is switched off.

If you want to enter the menu to view operating data or to program the pump,

press "M".

The menu appears and the current operating mode is displayed. Use the up and

down buttons to navigate in the menu. The software status, operating hours, and

operating mode are displayed one after the other.

The contrast of the display may be adjusted in the screen „Software & Kontrast“ by

keeping the „Start/Stop“ button pressed and pressing the buttons „up“ or „down“.

If you want to change the operating mode, press the start/stop button on the

operating mode display. You can now use the up and down buttons to change the

operating mode. There are the following operating modes:

a) Permanent: The pump runs continuously at a set speed.

b) Wave: The pump switches between two different set speeds at a set interval.

c) Random: The pump changes speed within a range defined by a minimum and

maximum value at a set time.

d) Random 2: The pump changes speed within a range defined by a minimum

and maximum value at a random time.

Once you have selected the operating mode, press the start/stop button. You are

then asked to enter the required data (minimum and maximum power, time

interval). Confirm each setting by pressing the start/stop button. When you are

finished, the settings are saved automatically and the system returns to the

overview.

15

Fig. 3: Overview of messages

16

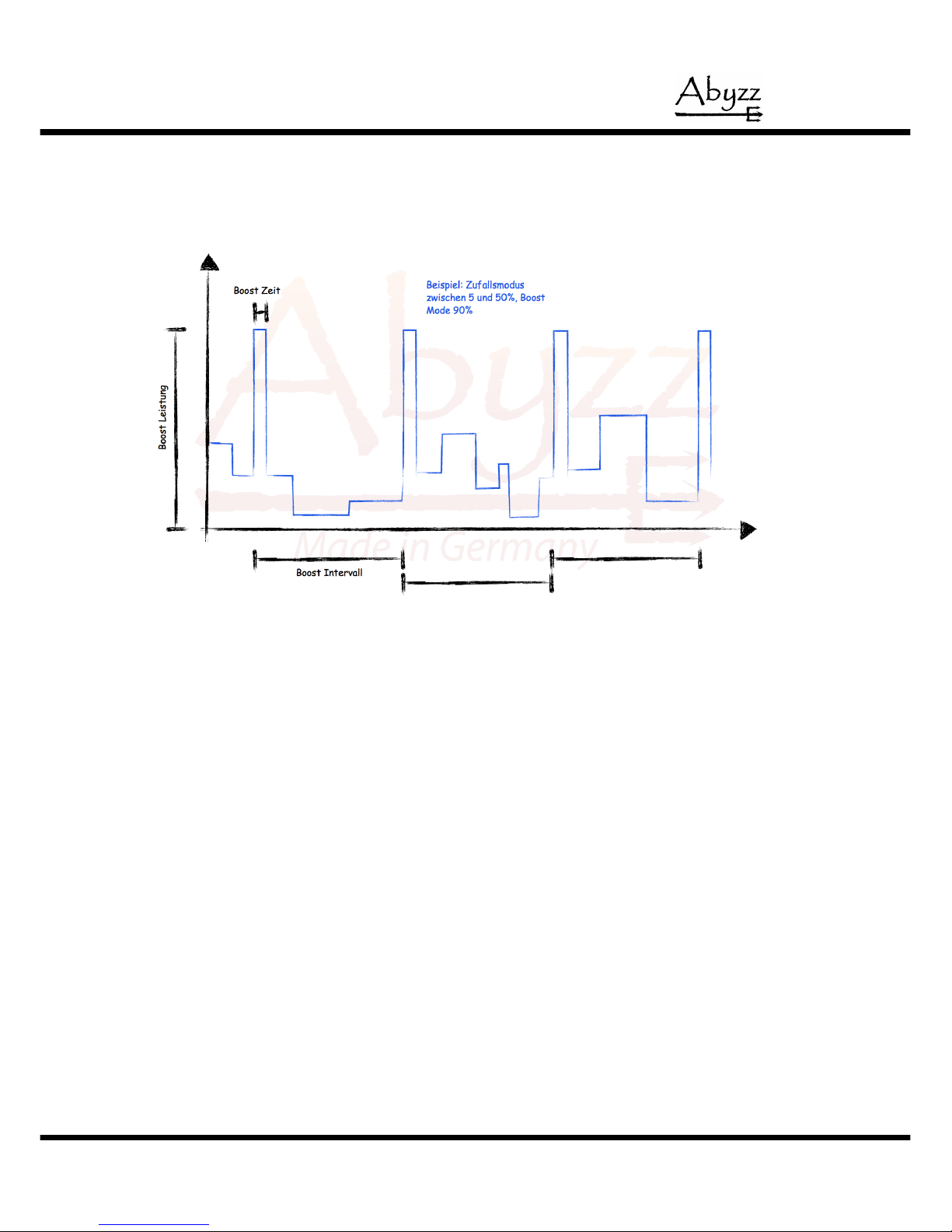

A special new feature is the Abyzz BOOSTMODE®, which makes it possible to set

up a short burst to get rid of debris. This burst can be programmed independently

to the operating mode chosen.

Fig. 4: Abyzz BOOSTMODE

In Fig. 4 you see as an example the burst, which is overriding the control of the

Abyzz random program.

17

Maintenance

Caution - extremely strong magnetic field!

- Risk of death to people with pacemakers!

- Keep the impeller away from pacemakers, credit cards, data carriers, or

similar objects that are sensitive to magnetic fields.

- Risk of injury due to body parts becoming trapped.

- Do not place any metallic parts near to the impeller.

Abyzz pumps are practically maintenance-free if used properly. If the flow rate

drops, there may be particles of dirt that need to be removed in the impeller wheel.

Also, slight vibrations can be an indication that the impeller wheel is dirty.

To clean it, separate the pump head from the motor (bayonet coupling, see Fig. 6)

and pull out the impeller group.

Fig. 5: Pump with pump head

18

Fig. 6a/b: Disassembly of pump head

19

Fig. 7: Removing impeller group

O-rings and rubber parts suffer from unavoidable aging and should be replaced as

required. These parts are listed in the spare parts list and can be ordered from

Abyzz.

Make sure that the rear bearing is in the correct position inside the motor. If

necessary, push the bearing into position with a blunt object (e.g. the handle of a

screwdriver). Make sure that the O-ring for the vibration isolation and sealing is in

the right position before reassembling the pump.

Carefully place the impeller into the motor block and press the assembly into the

bearing seat until the bearing bracket is flush with the flange.

20

Fig. 8: O-ring position and assembly

Place the O-ring on the notch of the pump head and make sure it is properly

placed before closing the bayonet flange again.

21

Fig. 9: Assembly of pump head

In systems that are constantly and intensively subjected to limescale (e.g. hard

coral ponds), the pump must be regularly descaled.

Tip:

We recommend that you use a weak vinegar solution to clean the pump to avoid

damaging it.

22

Guarantee

In accordance with the implied warranty, we provide a 12-month

guarantee. You can also extend the product guarantee period from 12

months to 10 years free of charge within 4 weeks of purchasing the

product (date of invoice) after registering your product successfully.

If you have a complaint, please contact us immediately and if needed,

send the device back - in its original packaging wherever possible and

with proof of purchase - directly to venotec. Please note that we cannot

accept non-prepaid deliveries. Such deliveries will be sent back without

being processed.

The guarantee covers material, functional, and production faults that can

occur when using the product as intended. It does not cover damage of

wearout or abrasive wear, transport damage, claims for compensation

above and beyond compensation for the product itself, or damage

resulting from improper use, negligence, incorrect installation, or

interventions and changes carried out by unauthorized persons. We

expressly exclude such scenarios from our scope of liability. Any

secondary damages such as the loss of coral, fish, or water damage

caused by pump failure or a lack of intake protection are expressly

excluded from guarantee and warranty claims. Calcination inside the

pump and any resulting damage to the product or motor, damage by use

as not intended and any damage to cables (e.g. chafed cables) are

expressly excluded from the warranty. The warranty is invalidated in the

following cases: Removed original plugs, use of non-original spare parts,

impeller wheel damage resulting from parts sucked into the pump, motor

damage caused by the tapering of the intake port or if the pump is

operated with a closed or partially closed ball valve in the intake area,

motor damage caused by persistent dry running, limescale damage

resulting from the improper use of chemicals or the use of unsuitable

chemicals, motor damage resulting from upstream external electronic

components or damage resulting from damp in the driver.

23

Techn i c a l changes

Due to the constant further development of our products and to innovations that, in

particular, serve to improve quality, safety, and technical progress, the

manufacturer reserves the right to make technical changes.

Troubleshooting

If, despite the high standard of quality, faults should occur, please use the

checklist below to rectify or restrict the problem. A number of faults are already

detected and displayed by the electronics.

Malfunction

Cause

Remedy

The display does not light

up and the LED flashes

a) Screensaver on

a) Press a button

The display does not light

up and the LED does not

flash

a) No mains voltage

a) Check the mains

connection

If the fault cannot be rectified,

there is a driver fault. In this

case, please contact the

service team.

Status: COMM FU!

a) Control unit communications

failed

a) Switch off the device and

switch back on after 10

seconds

Status: Imax!

a) Overcurrent fault, motor

overloaded

a) Check motor to make sure

that it can move freely

Status: MOTOR?

a) Motor not detected

a) Check connection to motor,

check plug

Status: TEMP!

a) Driver overheated

a) Let the driver cool down,

lower the ambient

temperature

Status: DRYRUN!

a) Motor has run dry or is drawing

in air

a) Check the water level,

check the pipes for leaks

Status: LOW VOLT!

a) Mains voltage too low

b) Too many devices on one lead

c) Mains lead too long

a) Check the mains voltage

b) Reduce the number of

devices

c) Reduce the length of the

lead, remove multi-socket

strips

Device is working but cannot

reach maximum power

If you cannot rectify the fault by checking the lines (incorrect connections), mains

voltage, and pump (smooth running, blockages), please contact your specialist

dealer. In such cases, please be ready to state the serial number of the driver and

of the motor. The serial numbers are on the blue serial number sticker or on the

packaging.

24

Disposal

As per Directive 2002/96/EC, this product cannot be disposed of in normal

household rubbish.

Within Germany, our customers can send old devices back to us free of charge for

proper recycling or disposal. The WEEE number for reporting to the EAR

(Germany registry of old electrical equipment) is:

DE 16546900

If you do not want to dispose of the product through us, you must bear the costs of

disposing of the product in accordance with legal requirements. In doing so, you

release us from our obligations as per Section 10 Paragraph 2 of the ElektroG

(Electrical and Electronic Equipment Act) and absolve us from all upcoming claims

from third parties.

Technical data:

Maximum flow rate : 8.500 l/h

Rated flow rate : 7.200 l/h

Discharge flow speed

maximum : 4,2 m/s

rated : 3,8 m/s

Delivery height maximum : 6,0 m

rated : 5,5 m

Rated input : 4...100 W

Operating voltage : 90...230V~, 50…60Hz

For details, see the characteristic curves in the appendix (fig. 10 et seq.). The

following calibrated devices were used for the measurement process:

Power test : Zimmer LMG 310

Quantity measurement : Krohne Optiflux 2100C

Discharge flow speed : Dorstmann P670

Pressure test : Kobold 220X1K9 Cl. 0,25

25

Materials

The following components/substances come into contact with the medium being

conveyed:

Housing

Pump head

Impeller wheel : ABS GF 20, PA-6

Flushing line : PVC, PU

Shaft : WCNi

Impeller : Titanium grade 2

Screws : Titanium grade 2

Bearings : SSIC

O-ring

Bearing seat

Device feet : NBR, CR, EPDM

Motor cable : PU

Jointing compound : PU

26

Fig. 10: Flow charts

27

Dimensions and weight

Fig. 11: Dimensions pump A100

28

CE declaration of conformity

GmbH

Am Nordkreuz 36

26180 Rastede

We hereby declare that the design of the pump system

Abyzz A200, A400, A200AS, IPX200, IPX400

complies with the following specifications:

EG-Richtlinie EMV 2004/108/EG

Applied harmonized standards:

DIN EN 61000-6-1

DIN EN 61000-6-2

DIN EN 61000-6-4

DIN EN 61000-3-2

This is a EMI class A product. In some environments it can

cause electromagnetic interference. In this case, it obligates to

the user to perform adequate measures.

29

Test report

Date : ____.____.________

Inspector : ______

Optical inspection : ______

Serial number driver : ____________________

Serial number motor : ____________________

Flow rate on test bench : __________ l/h

(nominal)

Maximum head pressure : __________ bar

Max power consumption : __________ W

Rotation OK : ______

Noise level OK : ______

_________________________

(signature inspector, stamp)

30

Notes

31

www.abyzz.de

www.venotec.de

32

Loading...

Loading...