Page 1

Page 2

REVISIONS

INDEX P/N REVISION REVISION SECTION DATE

A Creation all 30/03/98

B RAH 581 AA Miscellaneous corrections 1, 3, 4 07/10/98

CONTENTS

1. HYDRAULIC & PNEUMATIC PRINCIPLES

2. ELECTRIC & ELECTRONIC PRINCIPLES

3. MAINTENANCE PROCEDURES

4. OUTPUT FORMAT

5. TRAINING SLIDES

Page 3

1. HYDRAULIC & PNEUMATIC PRINCIPLES

CONTENTS

1. GENERALITIES ..................................................................................................................................... 2

2. MICROS 60 OT HYDRAULIC................................................................................................................. 4

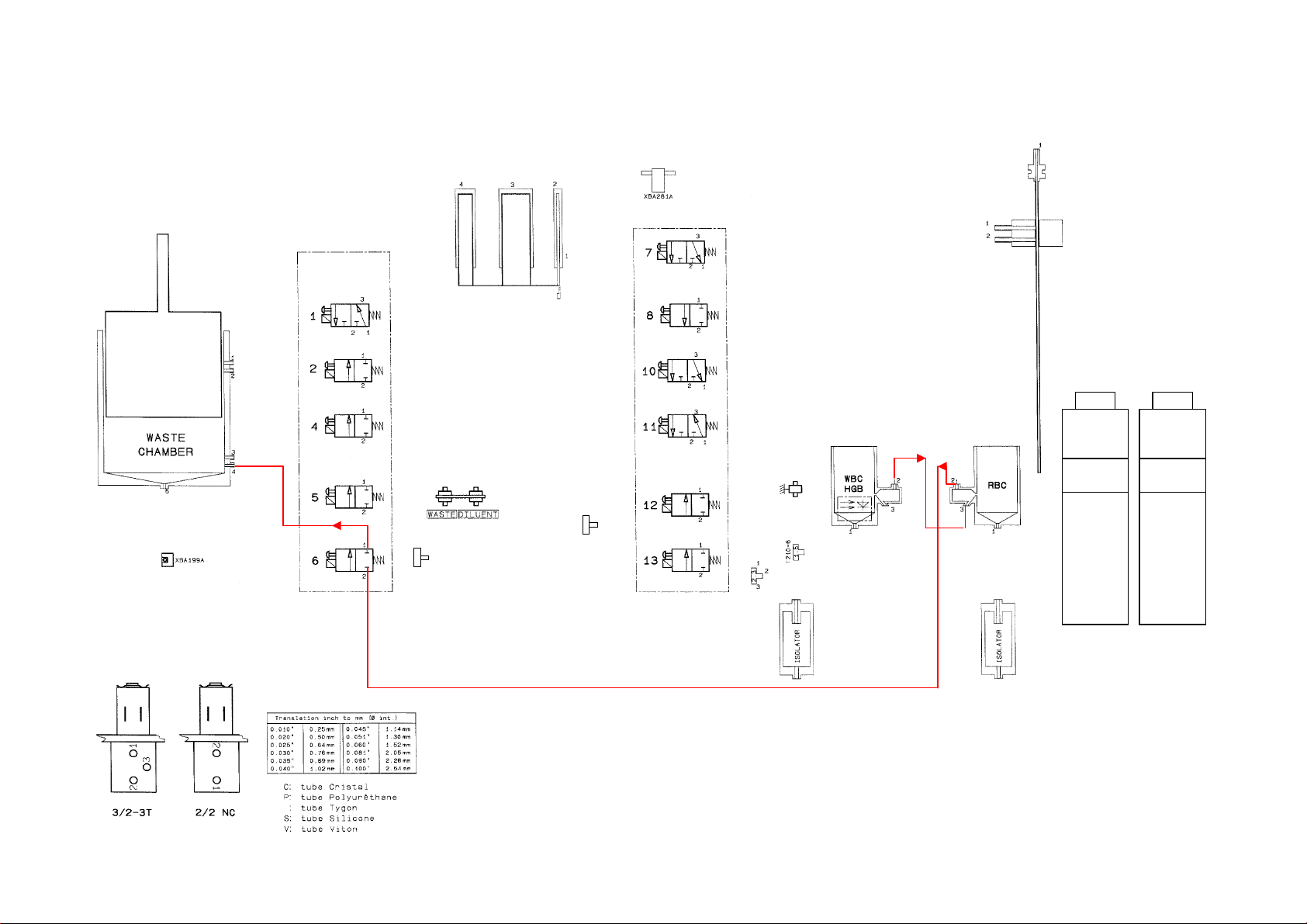

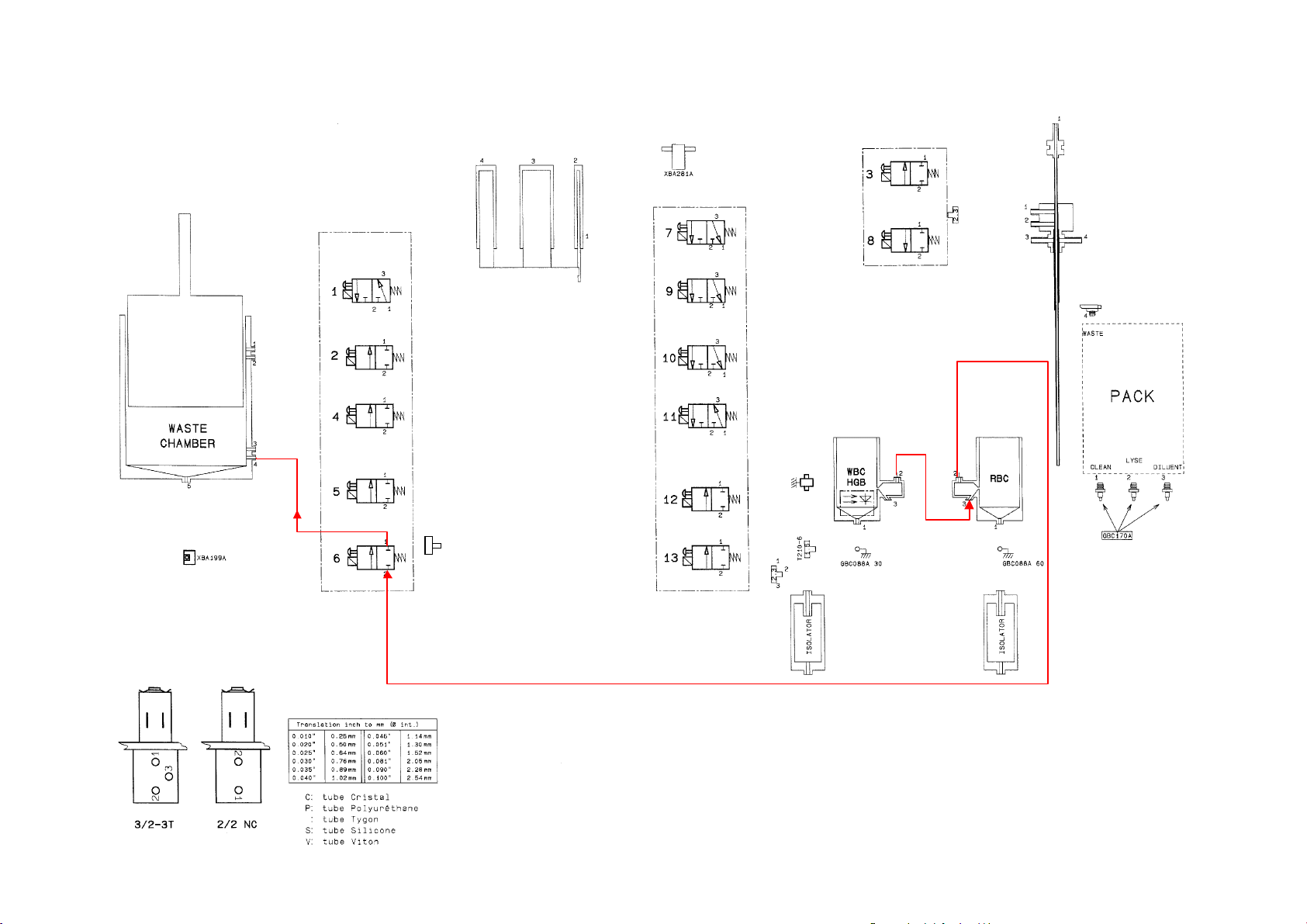

2.1. With bottles..................................................................................................................................... 4

2.1.1. Transmission tubes list ........................................................................................................... 4

2.1.2. Hydropneumatic connections ................................................................................................. 5

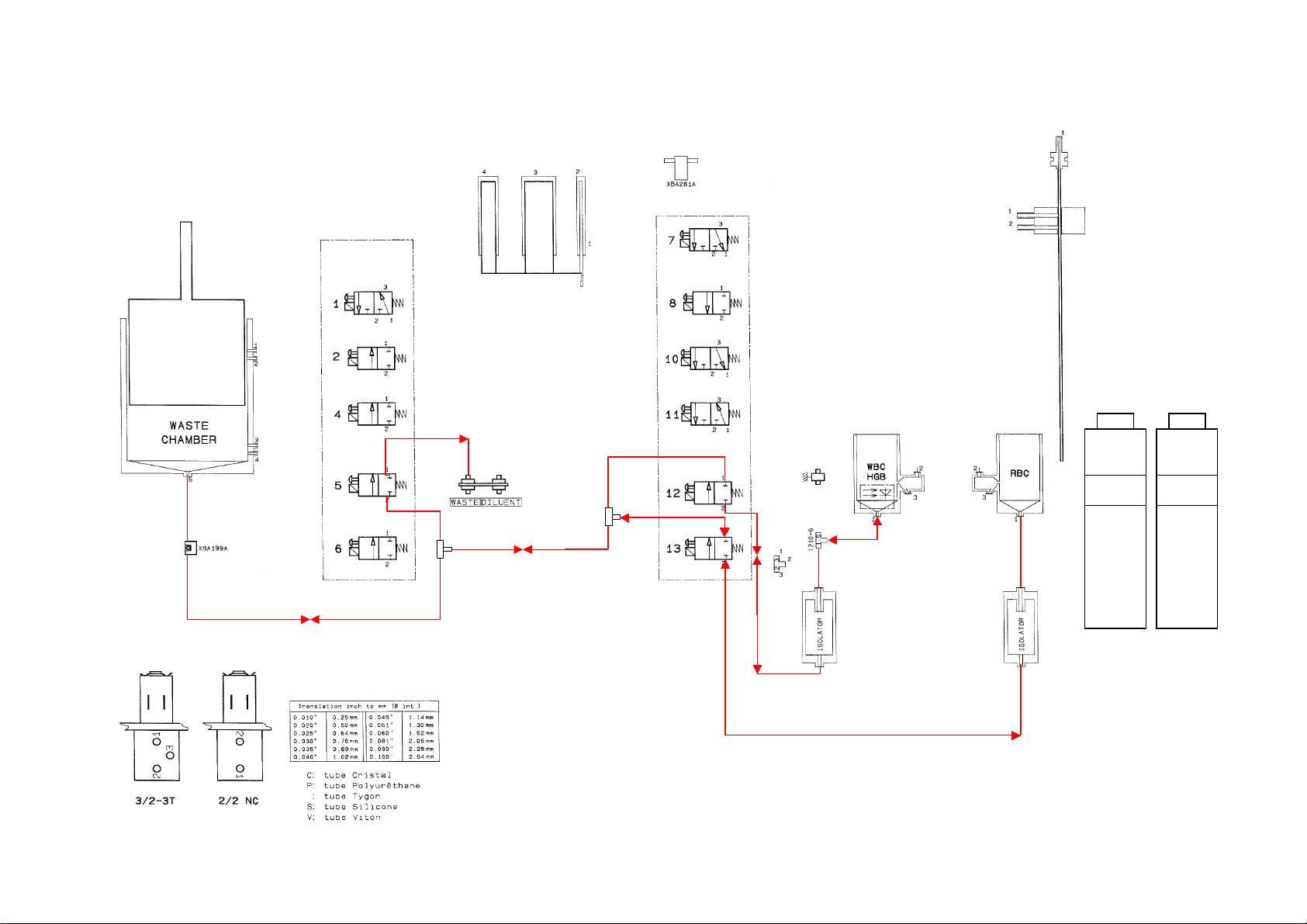

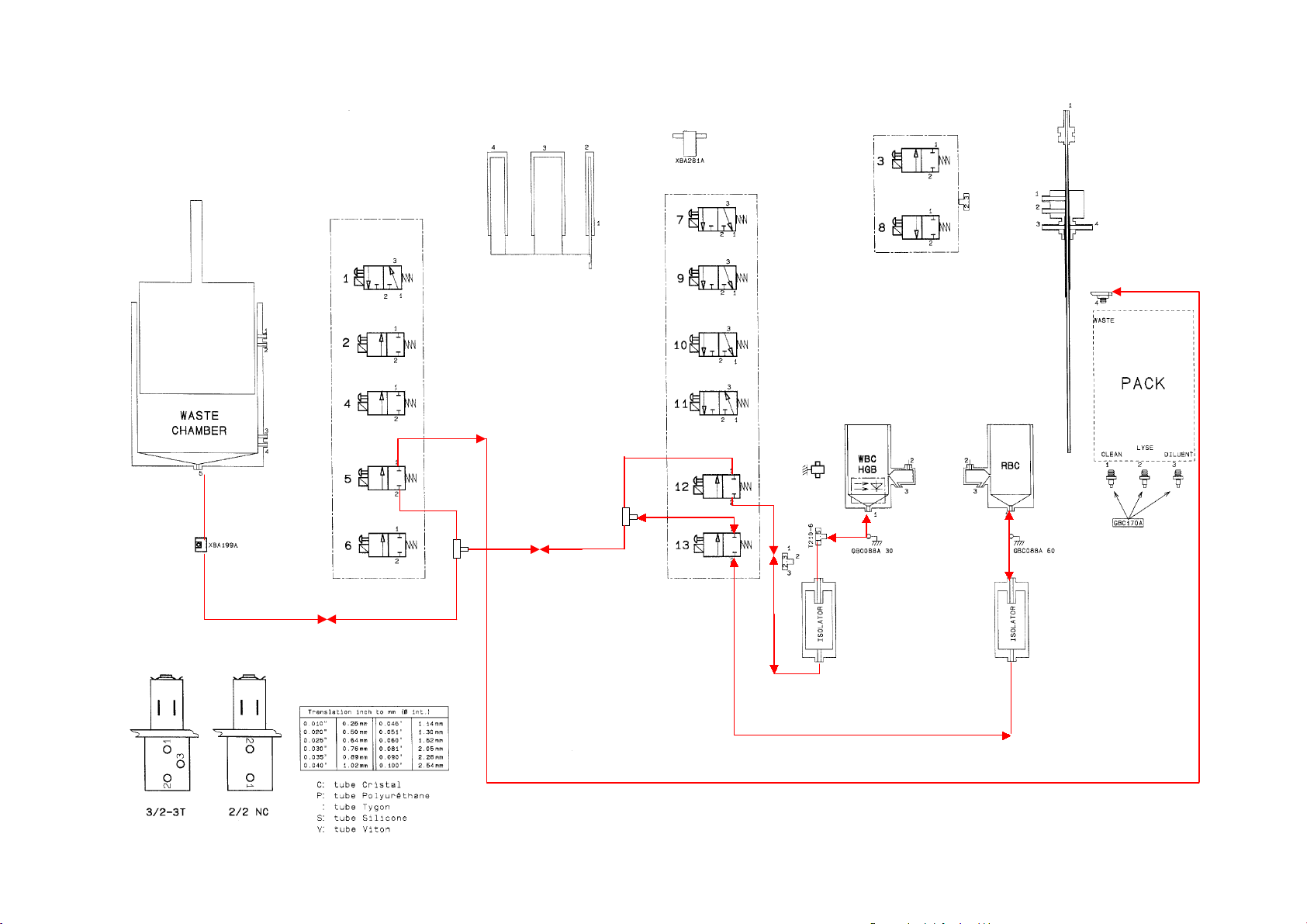

2.2. Pack ............................................................................................................................................... 6

2.2.1. Transmission tubes list ........................................................................................................... 6

2.2.2. Hydropneumatic connections ................................................................................................. 7

2.3. Hydraulic cycle description ............................................................................................................. 8

2.3.1. Atmosphere circuit.................................................................................................................. 8

2.3.2. Diluent circuit .......................................................................................................................... 8

2.3.3. Clean circuit............................................................................................................................ 8

2.3.4. Lyse circuit.............................................................................................................................. 8

2.3.5. WBC/RBC counting circuit...................................................................................................... 8

2.3.6. Drain/bubbling circuit .............................................................................................................. 8

3. MICROS 60 CT HYDRAULIC............................................................................................................... 15

3.1. With bottles................................................................................................................................... 15

3.1.1. Transmission tubes list ......................................................................................................... 15

3.1.2. Hydropneumatic connections ...............................................................................................16

3.2. Pack ............................................................................................................................................. 17

3.2.1. Transmission tubes list ......................................................................................................... 17

3.2.2. Hydropneumatic connections ...............................................................................................18

3.3. Hydraulic cycle description ........................................................................................................... 19

3.3.1. Atmosphere circuit................................................................................................................ 19

3.3.2. Diluent circuit ........................................................................................................................ 19

3.3.3. Clean circuit.......................................................................................................................... 19

3.3.4. Lyse circuit............................................................................................................................ 19

3.3.5. WBC/RBC counting circuit.................................................................................................... 19

3.3.6. Drain/bubbling circuit ............................................................................................................ 19

4. PNEUMA TIC DIAGRAMS..................................................................................................................... 26

4.1. Micros 60 CT bottle version .......................................................................................................... 26

4.2. Micros 60 CT pack version ........................................................................................................... 26

4.3. Micros 60 OT bottle version.......................................................................................................... 26

4.4. Micros 60 OT pack version........................................................................................................... 26

RAA 009 A Ind.A

Page 1/1 18/06/98

Page 4

1. HYDRAULIC & PNEUMATIC PRINCIPLES

1. GENERALITIES

MICROS 60 instrument has been designed for simple mechanical operations.

4 stepper motors provide movements to mechanical assemblies.

Pressure and vacuum are provided by the vacuum/waste syringe up and down movements

(diag 1).

Liquid movements are achieved either by means of mechanical assembly movements (liquid

Diag.1

syringes diag 2) or pressure/vacuum and simultaneous action of specific valves.

• Dilution chambers (Diag .3)

WBC/HGB and RBC chambers are made of GRILAMID TR55 LY injected.

The diode and the cell of the spectrophotometer are glued on the WBC/HGB chamber.

Chamber positions can be modified in order to obtain the best sampling position possible.

Dilutions :

First dilution is carried out in the WBC/HGB chamber (with a bubbling phasis).

The RBC blood sample is aspirated from this dilution.

Lyse is sent from the drain nipple of the WBC/HGB chamber.

Counts have a duration of 2 x 6 seconds.

(see procedures RAS 188 A and RAS 187 A for cycle hydraulic details)

Rinse :

To obtain the best rinse in the counting heads, diluent is sent

from the liquid syringes. This is carried out before, between

and after the two counts.

Diag.2

RAA 009 A Ind.A

Page 1/2

18/06/98

Page 5

1. HYDRAULIC & PNEUMATIC PRINCIPLES

IMPORTANT

A window on the HGB/WBC chamber allows the needle to move down into the chamber

and to inject reagents. As important light or variation of light can cause HGB result

drifts, close instrument cover and door before running blood analyses.

Bubbling

Insulators avoid polluted liquid overflows during bubbling phasis. they also allows an accurate

adjustment of the bubbling volume.

MICROS 60 CT specifics :

- The piercing needle is equipped with two injectors to obtain a homogeneous diluent flow

during needle rinsing phasis (see procedures RAS 188 A and RAS 187 A).

- Atmosphere is provided to sample tubes to allow a correct aspiration of blood.

:

RAA 009 A Ind.A

Page 1/3 18/06/98

Page 6

1. HYDRAULIC & PNEUMATIC PRINCIPLES

2. MICROS 60 OT HYDRAULIC

Liquid circuits, hydropneumatic connections, as well as the transmission tubes used, are

described in the following chart tables.

2.1. With bottles

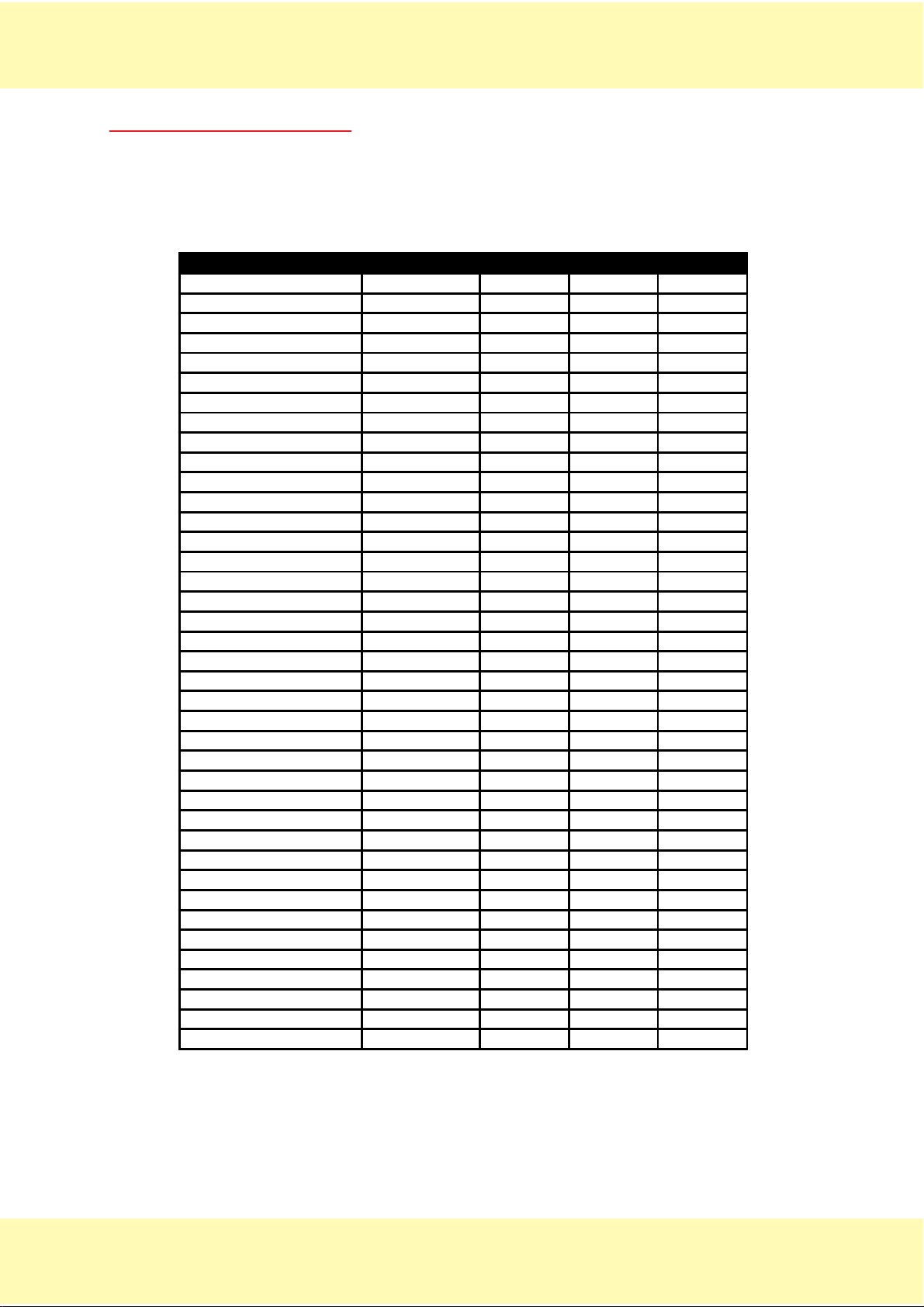

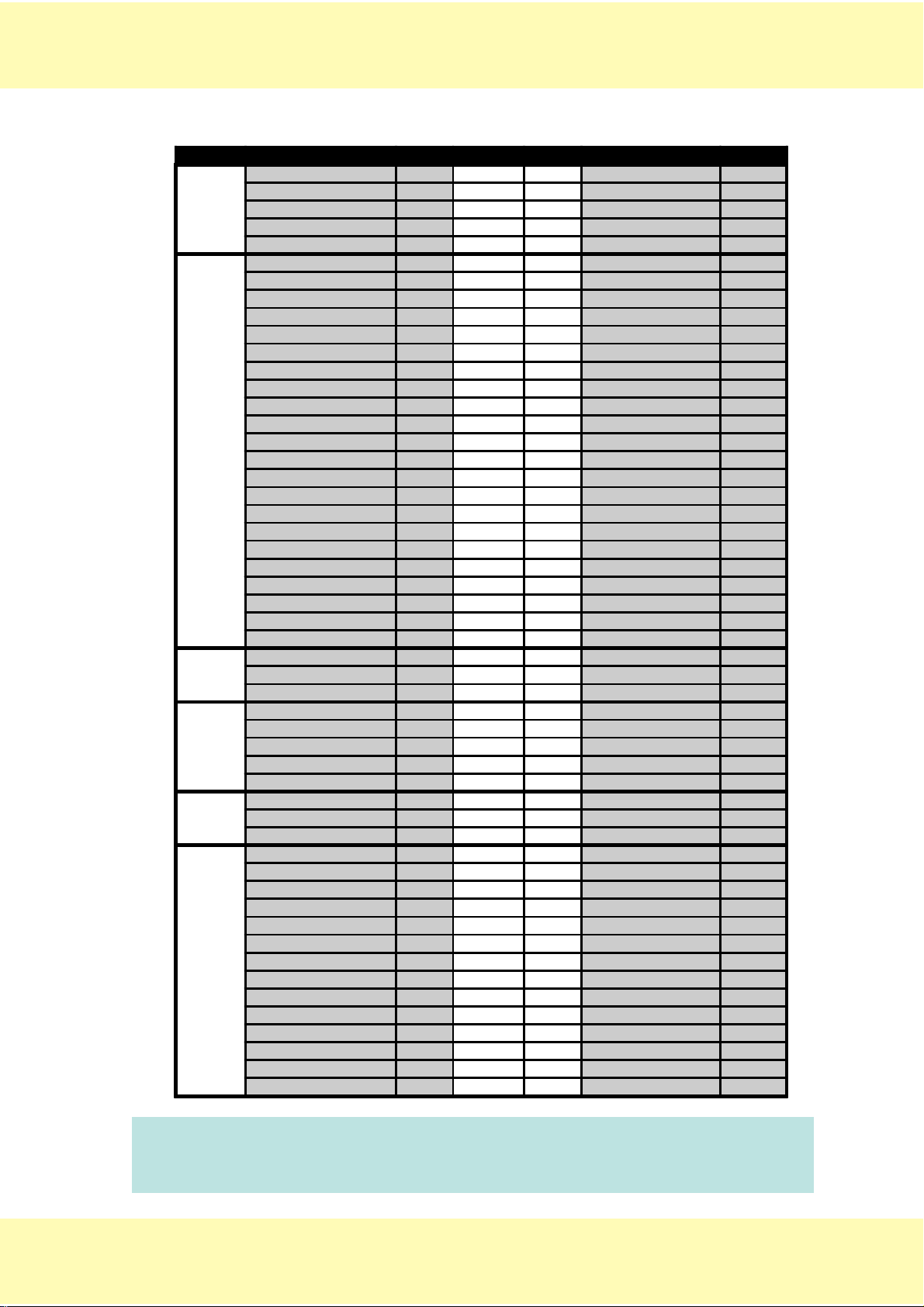

2.1.1. Transmission tubes list

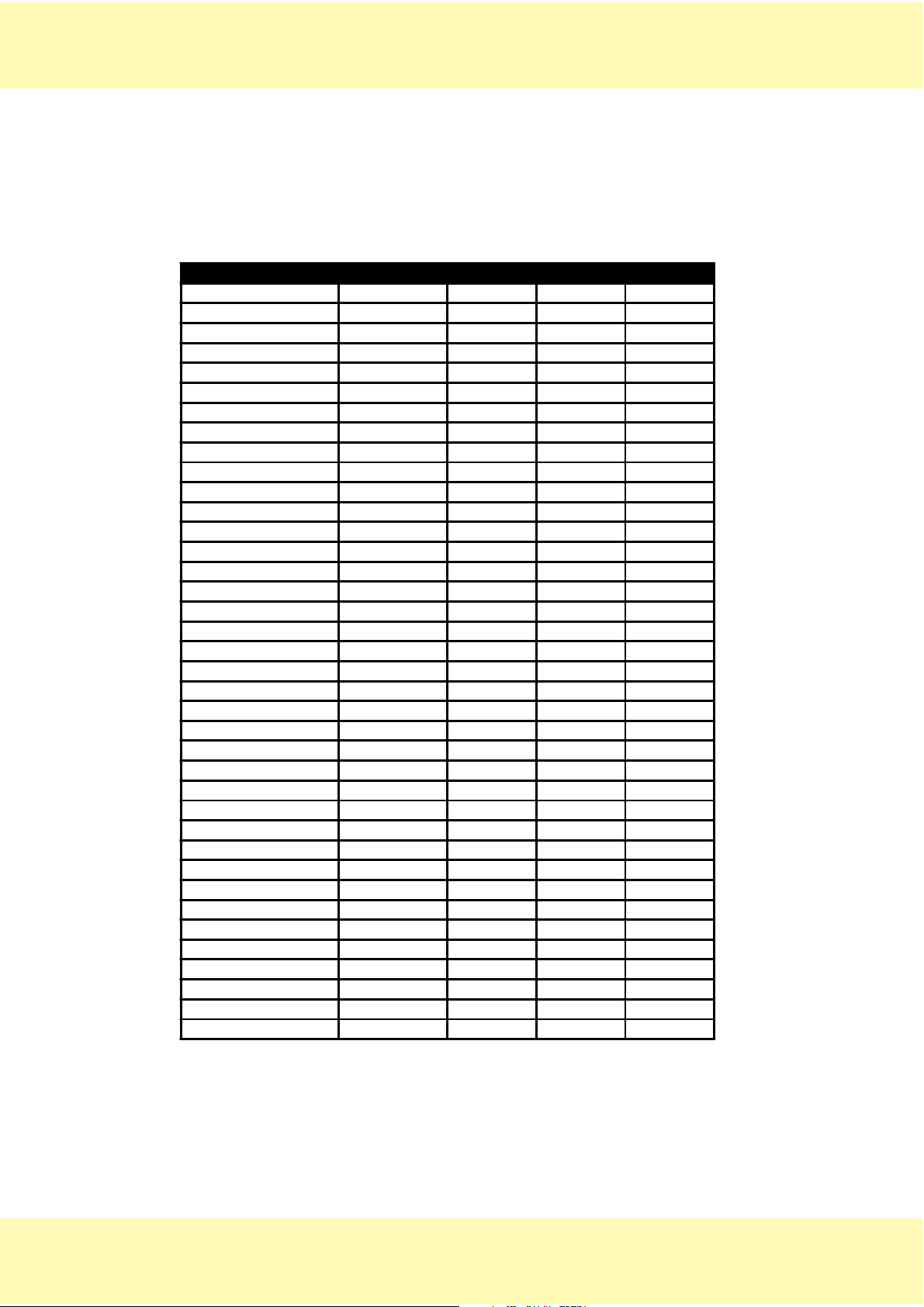

DESIGNATION PART NUMBER DIAMETER LEN GTH QUANTITY

SLEEVE HPS3 DBD005A 5-9 0.5

T CONNECTOR EAB006B 2.3 3

T CONNECTOR EAB032A 1.5 1

TUBE CAP EAC017A 2.5 1

TYGON TUBE 0.051" EAE006A 1.30 140 1

TYGON TUBE 0.051" EAE006A 1.30 350 1

TYGON TUBE 0.060" EAE007A 1.52 20 1

TYGON TUBE 0.060" EAE007A 1.52 40 3

TYGON TUBE 0.060" EAE007A 1.52 50 1

TYGON TUBE 0.060" EAE007A 1.52 60 1

TYGON TUBE 0.060" EAE007A 1.52 70 2

TYGON TUBE 0.060" EAE007A 1.52 80 1

TYGON TUBE 0.060" EAE007A 1.52 150 1

TYGON TUBE 0.060" EAE007A 1.52 170 1

TYGON TUBE 0.060" EAE007A 1.52 220 1

TYGON TUBE 0.060" EAE007A 1.52 240 1

TYGON TUBE 0.060" EAE007A 1.52 300 1

TYGON TUBE 0.060" EAE007A 1.52 370 1

TYGON TUBE 0.060" EAE007A 1.52 410 1

TYGON TUBE 0.060" EAE007A 1.52 450 2

TYGON TUBE 0.060" EAE007A 1.52 480 1

TYGON TUBE 0.081" EAE008A 2.05 20 1

TYGON TUBE 0.081" EAE008A 2.05 35 1

TYGON TUBE 0.081" EAE008A 2.05 200 1

TYGON TUBE 0.081" EAE008A 2.05 330 1

TYGON TUBE 0.081" EAE008A 2.05 1080 1

TYGON TUBE 0.090" EAE009A 2.28 20 2

TYGON TUBE 0.090" EAE009A 2.28 50 1

TYGON TUBE 0.090" EAE009A 2.28 60 2

TYGON TUBE 0.090" EAE009A 2.28 120 1

TYGON TUBE 0.090" EAE009A 2.28 140 1

TYGON TUBE 0.090" EAE009A 2.28 150 1

TYGON TUBE 0.090" EAE009A 2.28 190 1

BLUE TYGON TUBE 0.090" EAE036A 2.28 1100 1

SLEEVE GAL098A 30

TUBE SHIELD GBC088A 4.4 30 1

TUBE SHIELD GBC088A 4.4 60 1

RAA 009 A Ind.A

Page 1/4

18/06/98

Page 7

1. HYDRAULIC & PNEUMATIC PRINCIPLES

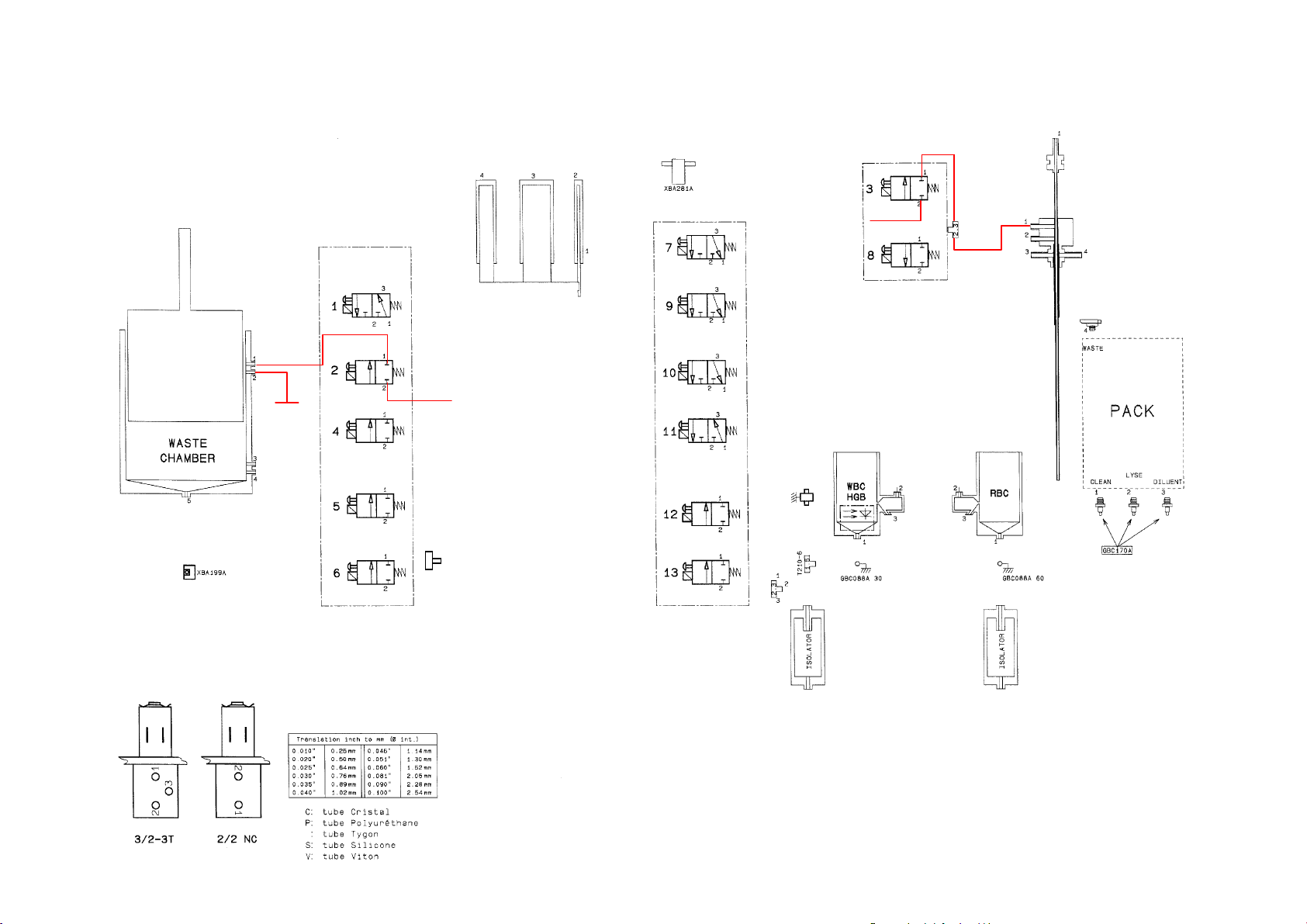

2.1.2. Hydropneumatic connections

CIRCUIT FROM SLEEVE DIAM LENGTH TO SLEEVE

AIR

DILUENT

CLEAN

LYSE

WBC/RBC

COUNTING

DRAIN/BUBBLING

(atmosphere) 2.28 190 Liquid valve 2_2

Liquid valve 2_1 Y2.28 50Waste-chamb._1 Y

Waste-chamb._2 2.28 20 Cap EAC017A

Diluent inpu t 2.05 330 Liquid valve11_1

Liquid valve11_3 Y1.52 220Temp. sensor xba281a Y

Temp. sensor. xba281a Y1.52 40Liquid syringes_3 Y

Liquid valve11_2 Y1.52 40Liquid valve10_3 Y

Liquid valve10_1 Y1.52 70Liquid valve7_3 Y

Liquid valve7_1 Y1.52 370needle rinsing block._2

Needle rinsing block._1 1.52 410 Liquid valve8_1

Liquid valve8_2 Y1.52 300Waste-chamb._3

Liquid valve 7_2 Y1.52 240Té 2.3_1

Té 2.3_2 1.52 50 Bac W BC/HGB_3

Liquid valve10_2 Y1.30 140Liquid syringes_1 Y

Liquid syringes_2 Y1.30 350needle_1

Liquid syringes_2 Y Needle_1 Y

Clean bottle 2.28 1100 blue Liquid valve4_2 Y

Liquid valve4_1 Y1.52 450T connector 2.3_3

Lyse bottle 2.05 1080 liquid valve 1_1

Liquid valve1_3 1.52 150 Liquid syringes _4

Liquid valve1_2 1.52 480 WBC grounding connector

WBC grounding connector 1.52 20 T connector 1.5_1

WBC/HGB_2 chamber 1.52 170 RBC_3 chamber

RBC_2 chamber 1.52 450 liquid valve 6_2 Y

Liquid valve 6_1 Y1.52 60Waste-chamb._4

WBC/HGB_1 chamber 1.52 40 T connector 1.5_2

WBC/HGB_1 chamber gbc088a 30 T connector 1.5_2

T connector 1.5_3 1.52 80 Ins ulator WBC _1

Insulator WB C_2 2.28 120 liquid valve12_2 Y

Liquid valve12_1 Y2.05 35T connector 2.3_1

RBC_1 chamber 1.52 70 In sulator RBC_ 1

RBC_1 chamber gbc088a 60 In sulator RB C_1

Insulator RBC_ 2 2.28 150 liquid valve13_2 Y

Liquid valve13_1 Y2.05 20T connector 2.3_2

T connector 2.3_3 2.05 200 T connector 2.3_2

T connector 2.3_3 2.28 20 Cell xba199a Y

Cell xba199a Y2.28 60Waste-chamb._5 Y

T connector 2.3_1 2.28 60 Liquid valve5_2 Y

Liquid valve5_1 2.28 140 Waste ouput

NOTE

RAA 009 A Ind.A

Read this table as follows in this example :

The Liquid valve 7_2 corresponds to the ouput 2 of the valve number 7 (see

attached pneumatic diagram).

Page 1/5 18/06/98

Page 8

1. HYDRAULIC & PNEUMATIC PRINCIPLES

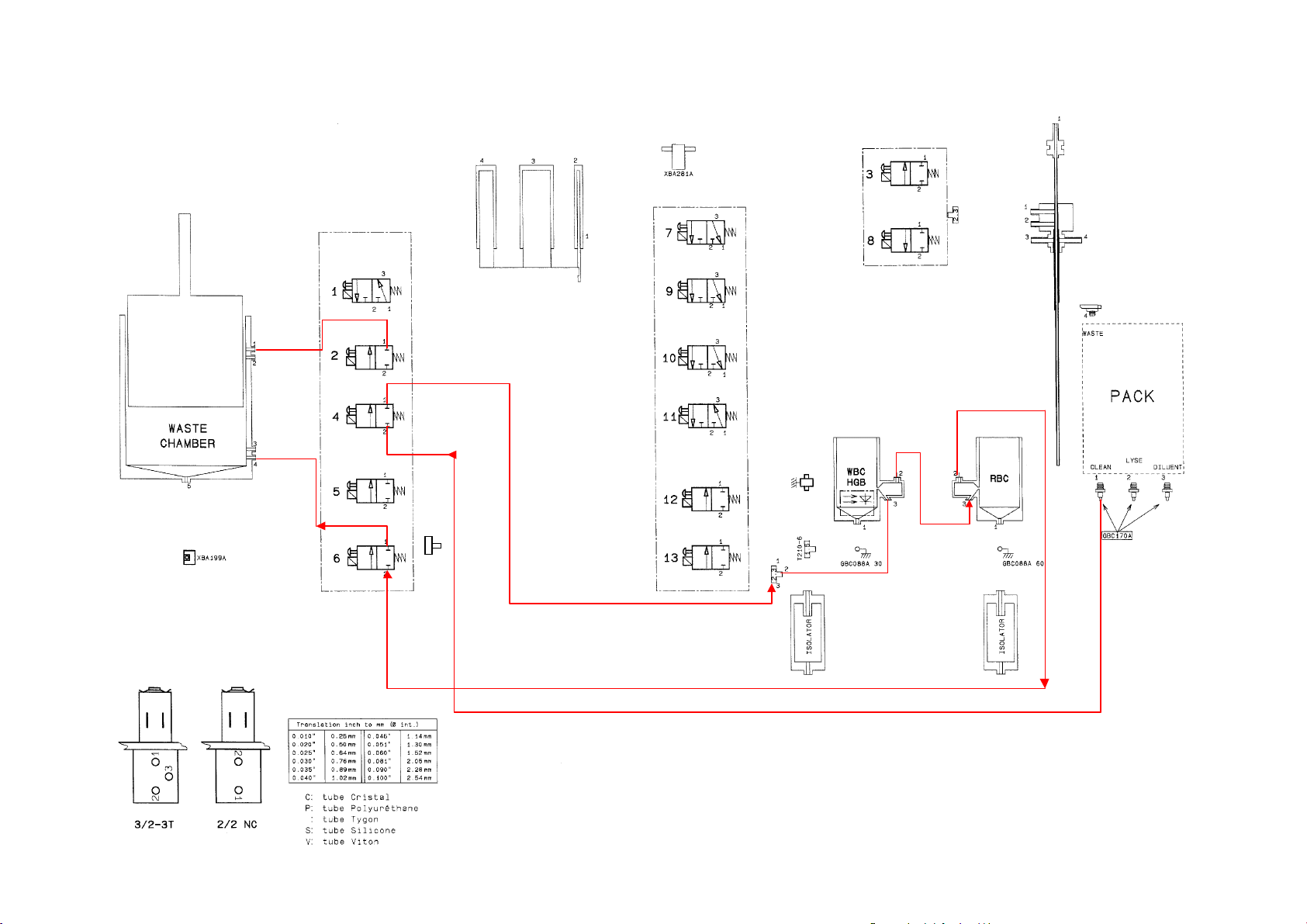

2.2. Pack

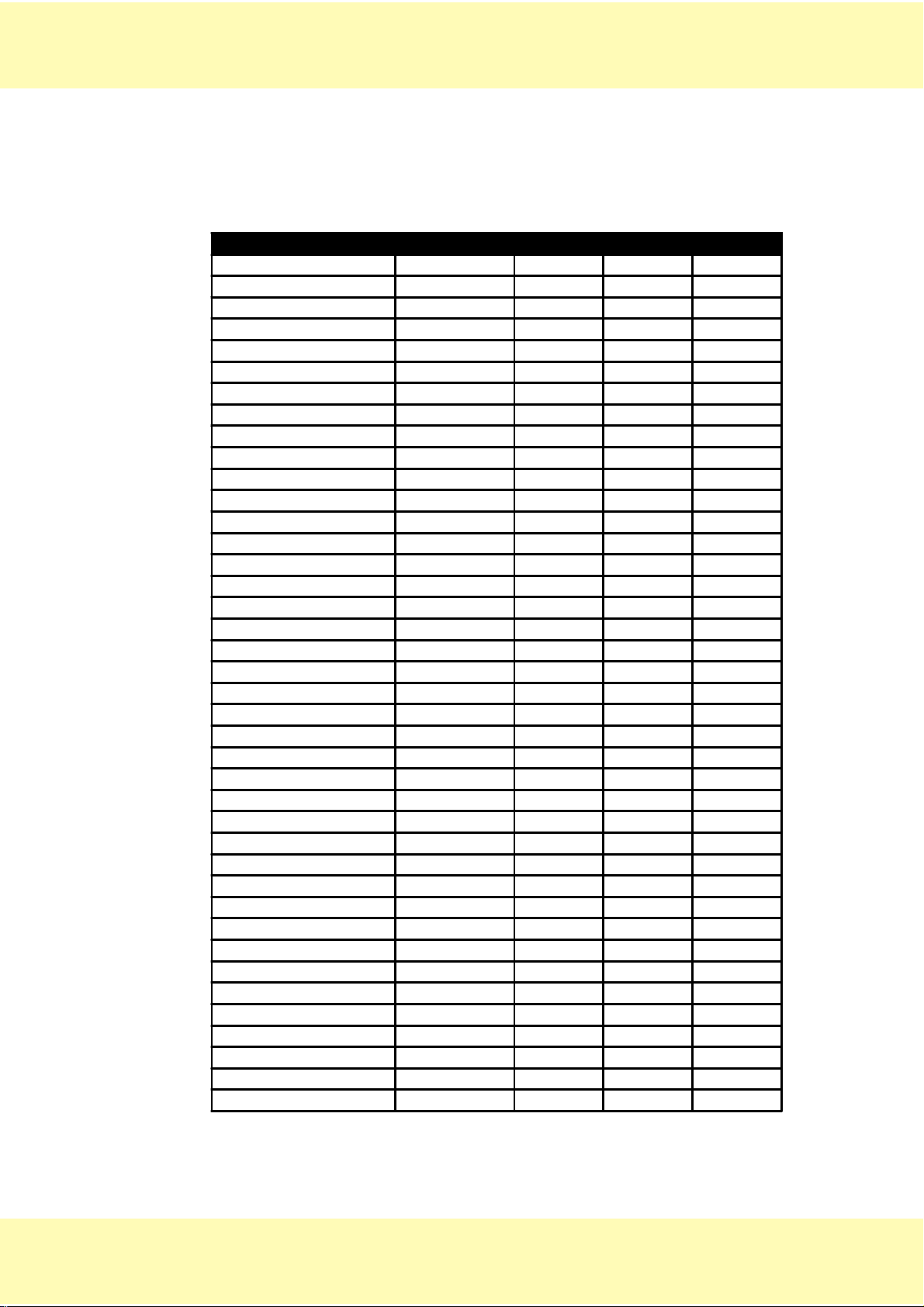

2.2.1. Transmission tubes list

DESIGNATION PART NUMBER DIAMETER LENGTH QUANTITY

SLEEVE HPS3 DBD005A 5-9 0.5

T CONNECTOR EAB006B 2.3 3

T CONNECTOR EAB032A 1.5 1

TUBE CAP EAC017A 2.5 1

TYGON TUBE 0.051" EAE006A 1.30 140 1

TYGON TUBE 0.051" EAE006A 1.30 350 1

TYGON TUBE 0.060" EAE007A 1.52 20 1

TYGON TUBE 0.060" EAE007A 1.52 40 3

TYGON TUBE 0.060" EAE007A 1.52 50 1

TYGON TUBE 0.060" EAE007A 1.52 60 1

TYGON TUBE 0.060" EAE007A 1.52 70 2

TYGON TUBE 0.060" EAE007A 1.52 80 1

TYGON TUBE 0.060" EAE007A 1.52 150 1

TYGON TUBE 0.060" EAE007A 1.52 170 1

TYGON TUBE 0.060" EAE007A 1.52 220 1

TYGON TUBE 0.060" EAE007A 1.52 240 1

TYGON TUBE 0.060" EAE007A 1.52 300 1

TYGON TUBE 0.060" EAE007A 1.52 370 1

TYGON TUBE 0.060" EAE007A 1.52 410 1

TYGON TUBE 0.060" EAE007A 1.52 450 2

TYGON TUBE 0.060" EAE007A 1.52 480 1

TYGON TUBE 0.081" EAE008A 2.05 20 1

TYGON TUBE 0.081" EAE008A 2.05 35 1

TYGON TUBE 0.081" EAE008A 2.05 200 1

TYGON TUBE 0.081" EAE008A 2.05 590 1

TYGON TUBE 0.090" EAE009A 2.28 20 2

TYGON TUBE 0.090" EAE009A 2.28 50 1

TYGON TUBE 0.090" EAE009A 2.28 60 2

TYGON TUBE 0.090" EAE009A 2.28 120 1

TYGON TUBE 0.090" EAE009A 2.28 150 1

TYGON TUBE 0.090" EAE009A 2.28 190 1

TYGON TUBE 0.090" EAE009A 2.28 510 1

TYGON TUBE 0.090" EAE009A 2.28 550 1

TYGON TUBE 0.090" EAE009A 2.28 1100 1

SLEEVE GAL098A 31

TUBE SHIELD GBC088A 4.4 30 1

TUBE SHIELD GBC088A 4.4 60 1

METALLIC SHEATH GBC170A 5.2 35 3

RAA 009 A Ind.A

Page 1/6

18/06/98

Page 9

1. HYDRAULIC & PNEUMATIC PRINCIPLES

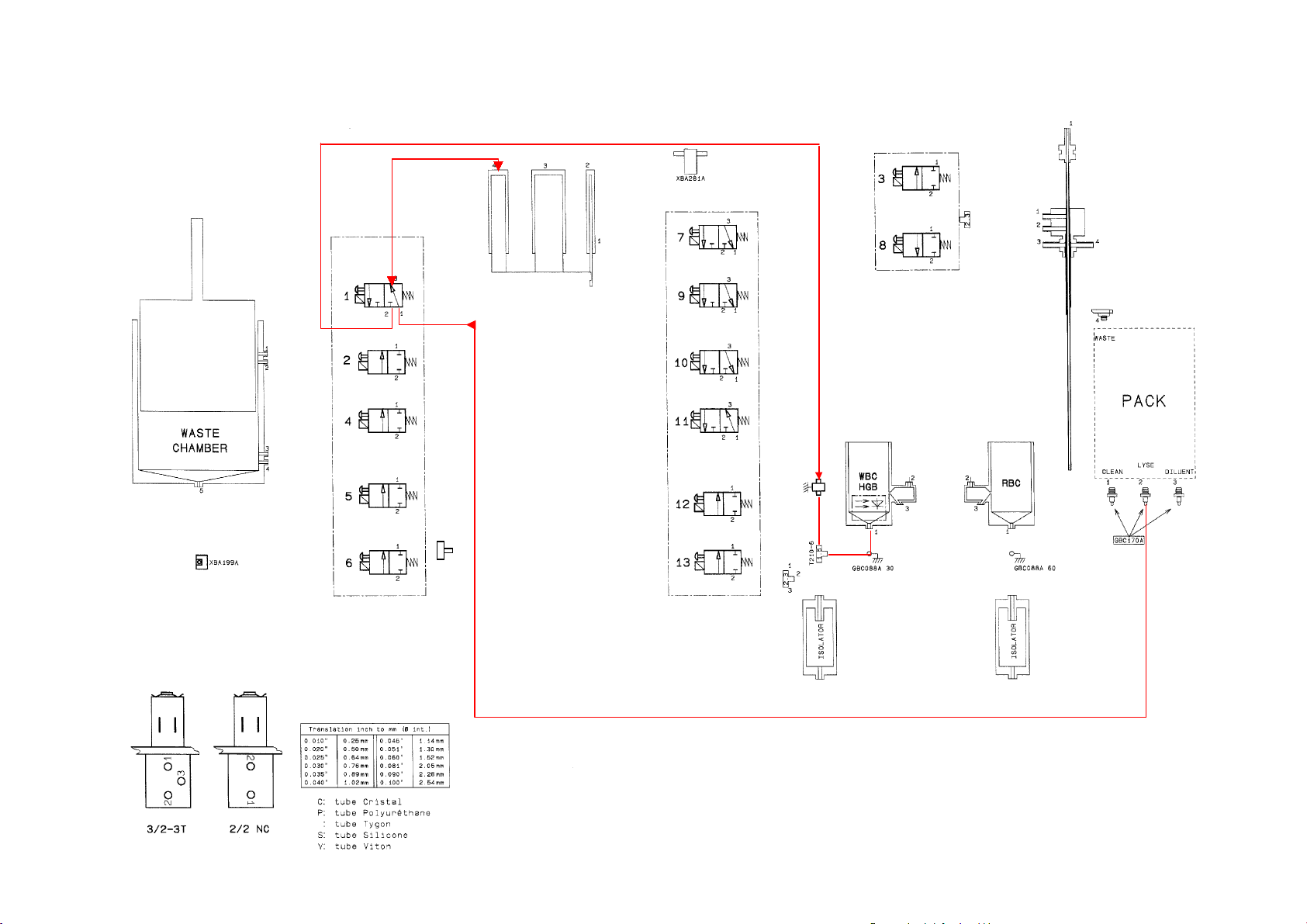

2.2.2. Hydropneumatic connections

CIRCUIT FROM SLEEVE DIAMETER LE NG TH TO SLEEVE

(atmosphere) 2.28 190 Liquid valve 2_2

AIR

DILUENT

CLEAN

LYSE

WBC/RBC

counting

DRAIN /

BUBBLING

Liquid valve 2_1 Y 2.2 8 50 Waste-chamb._1 Y

Waste-chamb._2 2.28 20 cap EAC017A

Pack_3 (Dil uent) 2.28 550 Liquid valve 11_1 Y

Pack_3 (Dil uent) gbc170a

Liquid valve 11_3 Y 1.52 220 temp. sensor xba281a Y

temp. sensor xba281a Y 1.52 40 Liquid syringes _3 Y

Liquid valve 11_2 Y 1.52 40 Liquid valve 10_3 Y

Liquid valve 10_1 Y 1.52 70 Liquid valve 7_3 Y

Liquid valve 7_1 Y 1.5 2 370 Needle rinsing block_2

needle rinsing block._1 1.52 410 Liquid valve 8_1

Liquid valve 8_2 Y 1.5 2 300 Waste-chamb._3

Liquid valve 7_2 Y 1.5 2 240 T connecto r 2.3_1

T connector 2. 3_2 1.52 50 Bac WBC/HGB_3

Liquid valve 10_2 Y 1.30 140 Liquid syringes _1 Y

Liquid syringes _2 Y 1.30 350 NEEDLE_ 1

Liquid syringes _2 Y NEEDLE_1 Y

Pack-1 (Clean ) 2.28 510 Liquid valve 4_2 Y

Pack-1 (Clean ) gbc170a

Liquid valve 4_1 Y 1.5 2 450 T connecto r 2.3_3

Pack_2 (Lyse) 2.05 590 Liquid valve 1_1

Pack_2 (Lyse) gbc170a

Liquid valve 1_3 1.52 150 Liquid syringes _4

Liquid valve 1_2 1.52 480 WBC grounding connector

WBC grounding connector 1.52 20 T connector 1.5_ 1

WBC/HGB ch amber _ 2 1.52 170 RBC chamb er _3

RBC chamber _2 1.52 450 Liquid valve 6_2 Y

Liquid valve 6_1 Y 1.5 2 60 Waste-chamb._4

WBC/HGB cham ber _1 1.52 40 T connector 1. 5_2

WBC/HGB cham ber _1 gbc088a 30 T connector 1. 5_2

T connector 1. 5_3 1.52 80 Insulator WBC_1

Insulator WBC_2 2.28 120 Liquid valve 12_2 Y

Liquid valve 12_1 Y 2.05 35 T connecto r 2.3_1

Bac RBC_1 1.52 70 Insulator RBC_1

Bac RBC_1 gbc 088a 60 Insulator RBC_1

Insulator RBC_2 2.28 150 Liquid valve 13_2 Y

Liquid valve 13_1 Y 2.05 20 T connecto r 2.3_2

T connector 2. 3_3 2.05 200 T connec tor 2.3_2

T connector 2. 3_3 2.28 20 Cellule xba 199a Y

Cell xba199a Y 2.28 60 Waste-chamb._5 Y

T connector 2. 3_1 2.28 60 Liquid valve 5_2 Y

Liquid valve 5_1 2.28 1100 Pack_4 (Waste)

NOTE

RAA 009 A Ind.A

Read this table as follows in this example :

The Liquid valve 7_2 corresponds to ouput 2 of the valve number 7 (see

attached pneumatic diagram).

Page 1/7 18/06/98

Page 10

1. HYDRAULIC & PNEUMATIC PRINCIPLES

2.3. Hydraulic cycle description

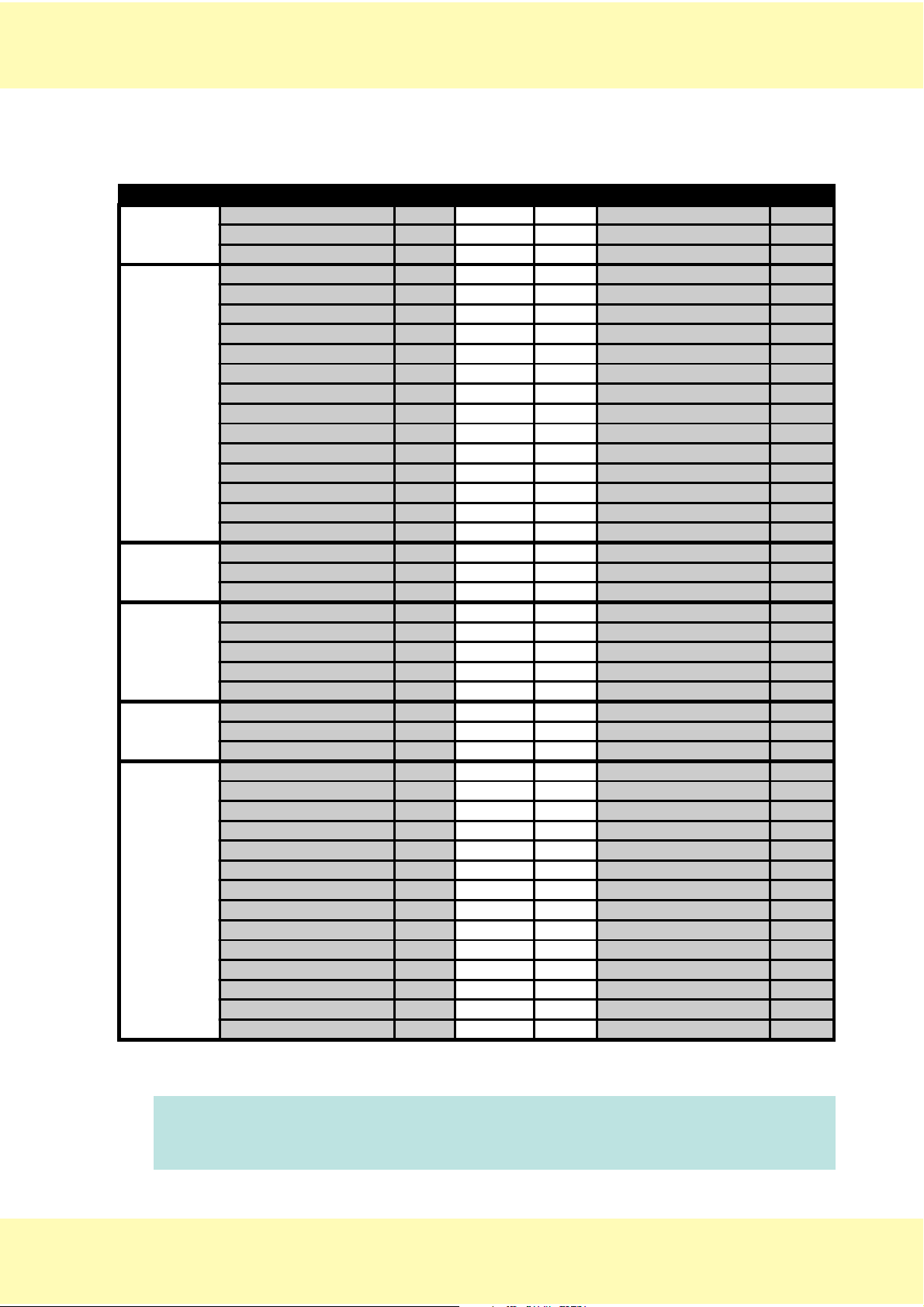

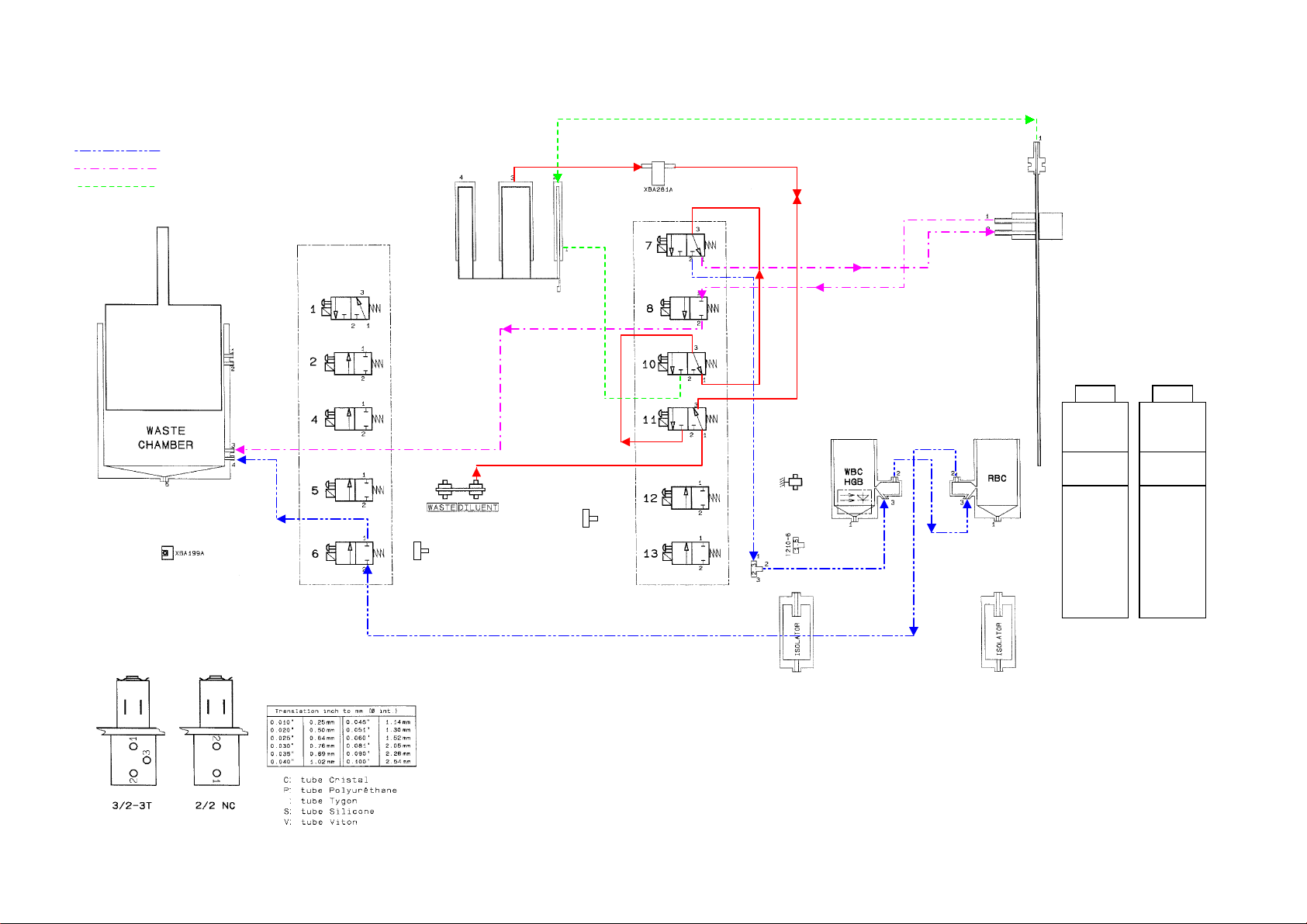

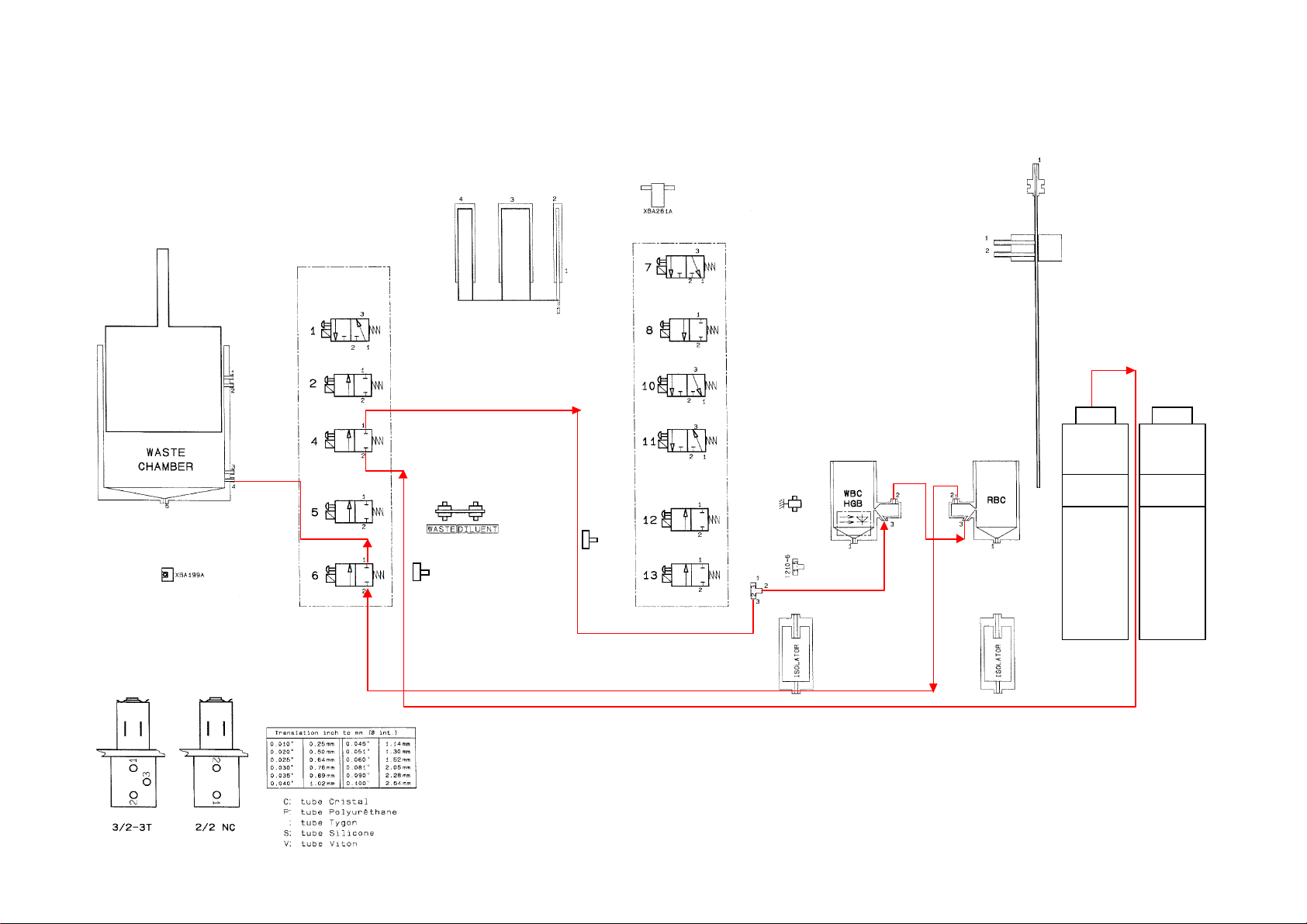

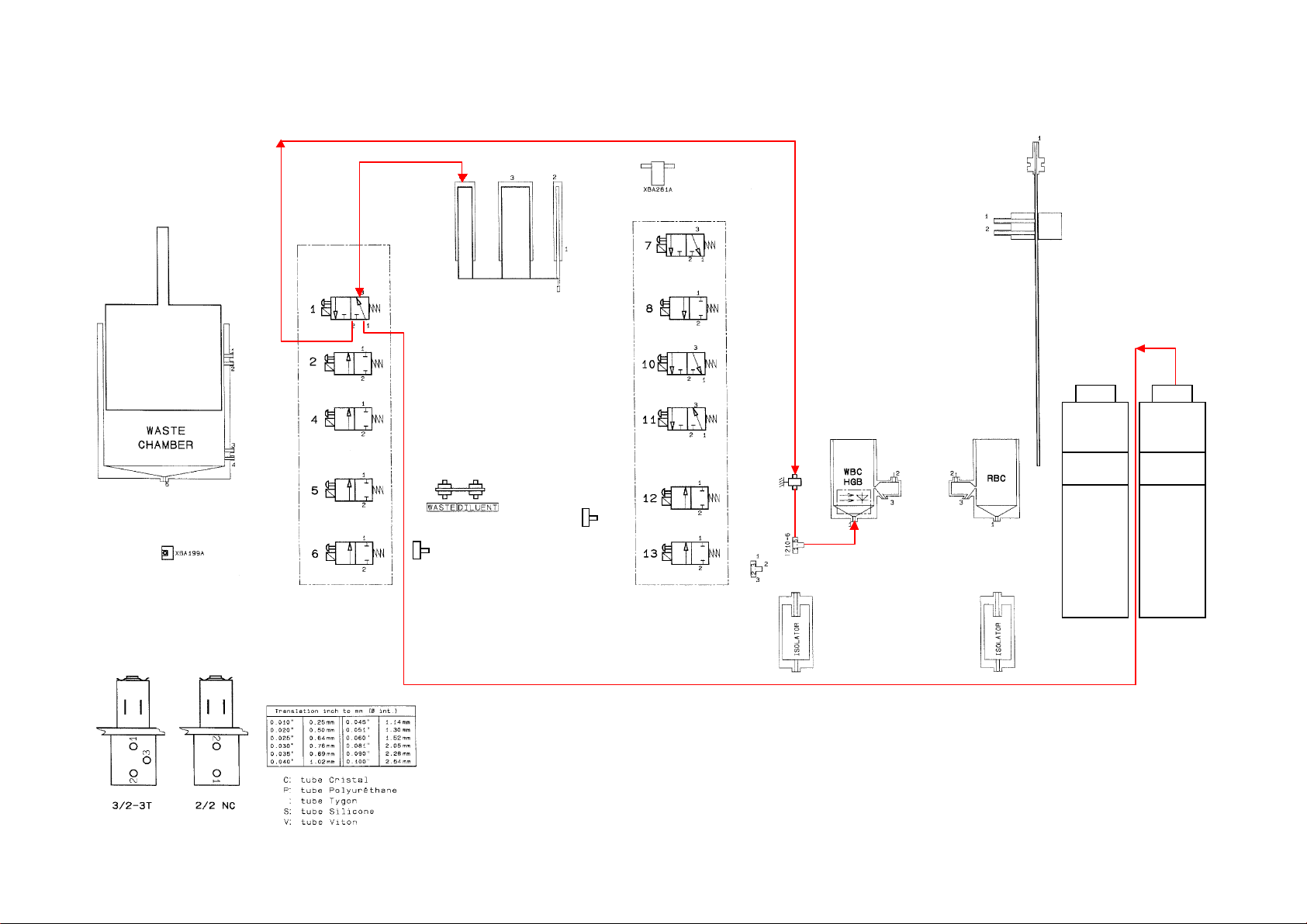

2.3.1. Atmosphere circuit

2.3.2. Diluent circuit

2.3.3. Clean circuit

2.3.4. Lyse circuit

2.3.5. WBC/RBC counting circuit

2.3.6. Drain/bubbling circuit

RAA 009 A Ind.A

Page 1/8

18/06/98

Page 11

RAA 009 A ind B

ATMOSPHERE CIRCUIT

EAC 017 A

CLEAN LYSE

Page 12

RAA 009 A ind B

COUNTING HEAD RINSE CIRCUIT

OUTER NEEDLE RINSE CIRCUIT

DILUENT CIRCUIT

INNER NEEDLE CIRCUIT

CLEAN LYSE

Page 13

RAA 009 A ind B

CLEAN CIRCUIT

CLEAN LYSE

Page 14

RAA 009 A ind B

LYSE CIRCUIT

CLEAN LYSE

Page 15

RAA 009 A ind B

WBC / RBC COUNTING PHASIS

CLEAN LYSE

Page 16

RAA 009 A ind B

DRAIN / BUBBLING CIRCUIT

CLEAN LYSE

Page 17

1. HYDRAULIC & PNEUMATIC PRINCIPLES

3. MICROS 60 CT HYDRAULIC

3.1. With bottles

3.1.1. Transmission tubes list

DESIGNATION PART NUMBER DIAMETER LEN GTH QUANTITY

T CONNECTOR EAB006B 2.3 4

STRAIGHT CONNECTOR EAB015A 1.5/2.5 3

T CONNECTOR EAB032A 1.5 2

TUBE CAP EAC017A 2.5 1

TYGON TUBE 0.040" EAE005A 1.02 110 1

TYGON TUBE 0.040" EAE005A 1.02 335 1

TYGON TUBE 0.060" EAE007A 1.52 15 3

TYGON TUBE 0.060" EAE007A 1.52 20 2

TYGON TUBE 0.060" EAE007A 1.52 40 4

TYGON TUBE 0.060" EAE007A 1.52 50 2

TYGON TUBE 0.060" EAE007A 1.52 60 1

TYGON TUBE 0.060" EAE007A 1.52 70 2

TYGON TUBE 0.060" EAE007A 1.52 80 1

TYGON TUBE 0.060" EAE007A 1.52 100 1

TYGON TUBE 0.060" EAE007A 1.52 150 1

TYGON TUBE 0.060" EAE007A 1.52 170 1

TYGON TUBE 0.060" EAE007A 1.52 220 1

TYGON TUBE 0.060" EAE007A 1.52 240 1

TYGON TUBE 0.060" EAE007A 1.52 420 2

TYGON TUBE 0.060" EAE007A 1.52 450 2

TYGON TUBE 0.060" EAE007A 1.52 480 1

TYGON TUBE 0.081" EAE008A 2.05 20 1

TYGON TUBE 0.081" EAE008A 2.05 35 1

TYGON TUBE 0.081" EAE008A 2.05 200 1

TYGON TUBE 0.081" EAE008A 2.05 330 1

TYGON TUBE 0.081" EAE008A 2.05 650 1

TYGON TUBE 0.081" EAE008A 2.05 1080 1

TYGON TUBE 0.090" EAE009A 2.28 20 2

TYGON TUBE 0.090" EAE009A 2.28 50 1

TYGON TUBE 0.090" EAE009A 2.28 60 3

TYGON TUBE 0.090" EAE009A 2.28 120 1

TYGON TUBE 0.090" EAE009A 2.28 140 1

TYGON TUBE 0.090" EAE009A 2.28 150 1

TYGON TUBE 0.090" EAE009A 2.28 190 1

SILICONE TUBE EAE025A 1.5/3.5 50 2

BLUE TYGON TUBE 0.090" EAE036A 2.28 1100 1

SLEEVE GAL098A 32

TUBE SHIELD GBC088A 4.4 30 1

TUBE SHIELD GBC088A 4.4 60 1

RAA 009 A Ind.A

Page 1/15 18/06/98

Page 18

1. HYDRAULIC & PNEUMATIC PRINCIPLES

3.1.2. Hydropneumatic connections

CIRCUIT FROM SLEEVE DIAMETER LENGTH TO SL EEVE

(atmosphere) 2.28 190 Liqu id valve 2_2

Liquid valve 2_1 Y2.2850Waste-chamb._1 Y

AIR

DILUENT

CLEAN

LYSE

WBC/RBC

counting

DRAIN /

BUBBLING

Waste-chamb._2 2.28 20 cap EAC017A

(atmosphere) 2.28 60 Liquid valve 3_ 2

Liquid valve 3_1 1.52 40 T connector 2.3_1

Diluent input 2.05 330 Liquid va lve 11_1

Liquid valve 11_3 Y1.52220temp sensor. xba281a Y

temp sensor. xba281a Y1.5240liquid syringes_3 Y

Liquid valve 11_2 Y1.5240Liquid valve 10_3 Y

Liquid valve 10_1 Y1.5270Liquid valve 7_3 Y

Liquid valve 7_1 Y1.5250Liquid valve 9_3 Y

Liquid valve 9_1 Y1.52420Needle rinsing block._2

Liquid valve 9_2 Y1.52420T connector 1.5_2

T connector 1.5_1 S 1.5/3.5 50 Needle rinsing block._3

T connector 1.5_3 S 1.5/3.5 50 Needle rinsing block._4

Liquid valve 7_2 Y1.52240T connector 2.3_1

T connector 2.3_2 1.52 50 WBC/HGB chamber_3

Liquid valve 10_2 Y1.5215Connector 1.5/2.5

Connector 1.5/2.5 1.02 110 Co nnector 1.5/2 .5

Connector 1.5/2.5 1.52 15 liquid syrin ges_1 Y

liquid syringe s_2 Y1.5215Connector 1 .5/2.5

Connector 1.5/2.5 1.02 335 needle_1

Connector 1.5/2.5 Y needle_1 Y

Needle rinsing block._1 1.52 100 T connector 2.3_3

T connector 2.3_2 1.52 20 Liqu id valve 8_1

Liquid valve 8_2 2.05 650 Waste-chamb._3

Clean bottle 2.28 1100 blue Liqu id valve 4_2 Y

Liquid valve 4_1 Y1.52450T connector 2.3_3

Lyse bottle 2.05 1080 Liquid valve 1_1

Liquid valve 1_3 1.52 150 liquid syringe s_4

Liquid valve 1_2 1.52 480 WBC grounding connector

WBC grounding connector 1.52 20 T connector 1.5_1

WBC/HGB chamber _2 1.52 170 RBC chamber_3

RBC chamber_2 1.52 450 Liquid valve 6_ 2 Y

Liquid valve 6_1 Y1.5260Waste-chamb._4

WBC/HGB Chamber_1 1.52 40 T connector 1.5_2

WBC/HGB Chamber_1 gbc088a 30 T connector 1.5_2

T connector 1.5_3 1.52 80 insu lator WBC _1

insulator WB C_2 2.28 120 Liqu id valve 12_2 Y

Liquid valve 12_1 Y2.0535T connector 2.3_1

RBC_1 chamber 1.52 70 insu lator RBC_ 1

RBC_1 chamber gbc088a 60 insu lator RBC_ 1

insulator RBC _2 2.28 150 Liquid valve 13_2 Y

Liquid valve 13_1 Y2.0520T connector 2.3_2

T connector 2.3_3 2.05 200 T connector 2.3_2

T connector 2.3_3 2.28 20 Cell x ba199a Y

Cell xba199a Y2.2860Waste-chamb._5 Y

T connector 2.3_1 2.28 60 Liqu id valve 5_2 Y

Liquid valve 5_1 2.28 140 Waste oupu t

NOTE

RAA 009 A Ind.A

Read this table as follows in this example :

The Liquid valve 7_2 corresponds to ouput 2 of the valve number 7 (see

attached pneumatic diagram).

Page 1/16

18/06/98

Page 19

1. HYDRAULIC & PNEUMATIC PRINCIPLES

3.2. Pack

3.2.1. Transmission tubes list

DESIGNATION PART NUMBER DIAMETER LENGTH QUANTITY

T CONNECTOR EAB006B 2.3 4

STRAIGHT CONNECTOR EAB015A 1.5/2.5 3

T CONNECTOR EAB032A 1.5 2

TUBE CAP EAC017A 2.5 1

TYGON TUBE 0.040" EAE005A 1.02 110 1

TYGON TUBE 0.040" EAE005A 1.02 335 1

TYGON TUBE 0.060" EAE007A 1.52 15 3

TYGON TUBE 0.060" EAE007A 1.52 20 2

TYGON TUBE 0.060" EAE007A 1.52 40 4

TYGON TUBE 0.060" EAE007A 1.52 50 2

TYGON TUBE 0.060" EAE007A 1.52 60 1

TYGON TUBE 0.060" EAE007A 1.52 70 2

TYGON TUBE 0.060" EAE007A 1.52 80 1

TYGON TUBE 0.060" EAE007A 1.52 100 1

TYGON TUBE 0.060" EAE007A 1.52 150 1

TYGON TUBE 0.060" EAE007A 1.52 170 1

TYGON TUBE 0.060" EAE007A 1.52 220 1

TYGON TUBE 0.060" EAE007A 1.52 240 1

TYGON TUBE 0.060" EAE007A 1.52 420 2

TYGON TUBE 0.060" EAE007A 1.52 450 2

TYGON TUBE 0.060" EAE007A 1.52 480 1

TYGON TUBE 0.081" EAE008A 2.05 20 1

TYGON TUBE 0.081" EAE008A 2.05 35 1

TYGON TUBE 0.081" EAE008A 2.05 200 1

TYGON TUBE 0.081" EAE008A 2.05 590 1

TYGON TUBE 0.081" EAE008A 2.05 650 1

TYGON TUBE 0.090" EAE009A 2.28 20 2

TYGON TUBE 0.090" EAE009A 2.28 50 1

TYGON TUBE 0.090" EAE009A 2.28 60 3

TYGON TUBE 0.090" EAE009A 2.28 120 1

TYGON TUBE 0.090" EAE009A 2.28 150 1

TYGON TUBE 0.090" EAE009A 2.28 190 1

TYGON TUBE 0.090" EAE009A 2.28 510 1

TYGON TUBE 0.090" EAE009A 2.28 550 1

TYGON TUBE 0.090" EAE009A 2.28 1100 1

SILICONE TUBE EAE025A 1.5/3.5 50 2

SLEEVE GAL098A 33

TUBE SHIELD GBC088A 4.4 30 1

TUBE SHIELD GBC088A 4.4 60 1

METALLIC SHEATH GBC170A 5.2 35 3

RAA 009 A Ind.A

Page 1/17 18/06/98

Page 20

1. HYDRAULIC & PNEUMATIC PRINCIPLES

3.2.2. Hydropneumatic connections

CIRCUIT FROM SLEEVE DIAMETER LENGTH TO SLEEVE

(atmosphere) 2.28 190 Liquid va lve 2_2

Liquid valve 2_1 Y2.2850Waste-chamb._1 Y

AIR

DILUENT

CLEAN

LYSE

Comptage

WBC/RBC

EVACUAT°

/ Bullage

Waste-chamb._2 2.28 20 cap EAC017A

(atmosphere) 2.28 60 Liquid va lve 3_2

Liquid valve 3_1 1.52 40 T Connector 2.3_1

Pack_3 (Diluent) 2.28 550 Liquid valve 11_1 Y

Pack_3 (Diluent) gbc170a

Liquid valve 11_3 Y1.52220Temp. sensor xba281a Y

Temp. sensor xba281a Y1.5240Liqu id syringes_3 Y

Liquid valve 11_2 Y1.5240Liquid valv e 10_3 Y

Liquid valve 10_1 Y1.5270Liquid valv e 7_3 Y

Liquid valve 7_1 Y1.5250Liqu id valve 9_3 Y

Liquid valve 9_1 Y1.52420Needle rinsing block_2

Liquid valve 9_2 Y1.52420T Connector 1.5_2

T Connector 1.5_1 S 1.5/3.5 50 Needle rinsing block_3

T Connector 1.5_3 S 1.5/3.5 50 Needle rinsing block_4

Liquid valve 7_2 Y1.52240T Connector 2.3_1

T Connector 2.3_2 1.52 50 Bac WBC/HGB_3

Liquid valve 10_2 Y1.5215connector1 .5/2.5

connector1.5/2.5 1.02 110 connec tor1.5/2.5

connector 1.5/2.5 1.52 15 Liquid syring es_1 Y

Liquid syringes_2 Y1.5215connector 1.5/2.5

connector 1.5/2.5 1.02 335 Needle_1

connector 1.5/2.5 Y Needle_1 Y

Needle rinsing block_1 1.52 100 T Connector 2.3_3

T Connector 2.3_2 1.52 20 Liquid valve 8_1

Liquid valve 8_2 2.05 650 Waste-chamb._3

Pack_1 (Clean) 2.28 510 Liquid va lve 4_2 Y

Pack_1 (Clean) gbc170a

Liquid valve 4_1 Y1.52450T Connector 2.3_3

Pack_2 (Lyse) 2.05 590 Liquid va lve 1_1

Pack_2 (Lyse) gbc170a

Liquid valve 1_3 1.52 150 Liquid syringes_4

Liquid valve 1_2 1.52 480 WBCgrounding connec.

WBC grounding connect. 1.52 20 T Connector 1.5_1

Bac WBC/HGB_2 1.52 170 RBC chamber_3

RBC chamber_2 1.52 450 Liquid valve 6_2 Y

Liquid valve 6_1 Y1.5260Waste-chamb._4

Bac WBC/HGB_1 1.52 40 T Connector 1.5_2

Bac WBC/HGB_1 gbc088a 30 T Connector 1.5_2

T Connector 1.5_3 1.52 80 insulator WBC_1

insulator WB C_2 2.28 120 Liquid valve 12_2 Y

Liquid valve 12_1 Y2.0535T Connector 2.3_1

RBC chamber_1 1.52 70 insulator RBC_1

RBC chamber_1 gbc088a 60 insulator RB C_1

insulator RBC _2 2.28 150 Liqu id valve 13_2 Y

Liquid valve 13_1 Y2.0520T Connector 2.3_2

T Connector 2.3_3 2.05 200 T Connector 2.3_2

T Connector 2.3_3 2.28 20 CELL xba199a Y

CELL xba199a Y2.2860Waste-chamb._5 Y

T Connector 2.3_1 2.28 60 Liquid valve 5_2 Y

Liquid valve 5_1 2.28 1100 Pack_4 (Waste)

NOTE

RAA 009 A Ind.A

Read this table as follows in this example :

The Liquid valve 7_2 corresponds to ouput 2 of the valve number 7 (see

attached pneumatic diagram)

Page 1/18

18/06/98

Page 21

1. HYDRAULIC & PNEUMATIC PRINCIPLES

3.3. Hydraulic cycle description

3.3.1. Atmosphere circuit

3.3.2. Diluent circuit

3.3.3. Clean circuit

3.3.4. Lyse circuit

3.3.5. WBC/RBC counting circuit

3.3.6. Drain/bubbling circuit

RAA 009 A Ind.A

Page 1/19 18/06/98

Page 22

RAA 009 A ind B

ATMOSPHERE CIRCUIT

ATMOSPHERE

ATMOSPHERE

EAC 017 A

Page 23

RAA 009 A ind B

DILUENT CIRCUIT

COUNTING HEAD RINSE CIRCUIT

OUTER SAMPLING NEEDLE RINSE CIRCUIT

SAMPLING NEEDLE INNER CIRCUIT

PIERCING NEEDLE RINSE CIRCUIT

Page 24

RAA 009 A ind B

CLEAN CIRCUIT

Page 25

RAA 009 A ind B

LYSE CIRCUIT

Page 26

RAA 009 A ind B

WBC / RBC COUNTING CIRCUIT

Page 27

RAA 009 A ind B

DRAIN / BUBBLING CIRCUIT

Page 28

1. HYDRAULIC & PNEUMATIC PRINCIPLES

4. PNEUMATIC DIAGRAMS

4.1. Micros 60 CT bottle version

4.2. Micros 60 CT pack version

4.3. Micros 60 OT bottle version

4.4. Micros 60 OT pack version

RAA 009 A Ind.A

Page 1/26

18/06/98

Page 29

2. ELECTRIC & ELECTRONIC PRINCIPLES

CONTENTS

1. POWER SUPPLY ASSEMBLY .............................................................................................................. 2

1.1. Principle ......................................................................................................................................... 2

1.2. Power supply fan............................................................................................................................ 4

1.3. Secondary supply cable ................................................................................................................. 5

1.4. Main supply filter ............................................................................................................................ 6

2. MOTHER BOARD.................................................................................................................................. 7

2.1. Configuration.................................................................................................................................. 7

3. LCD BOARD .......................................................................................................................................... 8

4. COAXIALS ............................................................................................................................................. 9

4.1. RBC coaxial ................................................................................................................................... 9

4.2. WBC coaxial ................................................................................................................................. 11

5. SENSORS............................................................................................................................................ 12

5.1. Drain detection sensor ................................................................................................................. 12

5.2. Carriage & needle sensors ........................................................................................................... 13

5.3. Syringe sensors............................................................................................................................ 14

6. MISCELLANEOUS............................................................................................................................... 15

6.1. Needle carriage motor.................................................................................................................. 15

6.2. Barcode cable .............................................................................................................................. 16

6.3. Temperature sensor ..................................................................................................................... 17

6.4. HGB Chamber assembly ............................................................................................................. 18

6.5. Chip card reader cable................................................................................................................. 19

6.6. CT Piercing assembly cable......................................................................................................... 20

6.7. CT twin valve cable ...................................................................................................................... 21

7. FLAT CABLES ..................................................................................................................................... 22

8. ELECTRICAL SYNOPTICS ........................................................................................................ ......... 26

RAA 009 A Ind.A

Page 2/1 30/06/98

Page 30

2. ELECTRIC & ELECTRONIC PRINCIPLES

1. POWER SUPPLY ASSEMBLY

1.1. Principle

RAA 009 A Ind.A

Page 2/2

30/06/98

Page 31

2. ELECTRIC & ELECTRONIC PRINCIPLES

RAA 009 A Ind.A

Page 2/3 30/06/98

Page 32

2. ELECTRIC & ELECTRONIC PRINCIPLES

1.2. Power supply fan

RAA 009 A Ind.A

Page 2/4

30/06/98

Page 33

2. ELECTRIC & ELECTRONIC PRINCIPLES

1.3. Secondary supply cable

RAA 009 A Ind.A

Page 2/5 30/06/98

Page 34

2. ELECTRIC & ELECTRONIC PRINCIPLES

1.4. Main supply filter

RAA 009 A Ind.A

Page 2/6

30/06/98

Page 35

2. ELECTRIC & ELECTRONIC PRINCIPLES

2. MOTHER BOARD

2.1. Configuration

RAA 009 A Ind.A

Page 2/7 30/06/98

Page 36

2. ELECTRIC & ELECTRONIC PRINCIPLES

3. LCD BOARD

RAA 009 A Ind.A

Page 2/8

30/06/98

Page 37

2. ELECTRIC & ELECTRONIC PRINCIPLES

4. COAXIALS

4.1. RBC coaxial

RAA 009 A Ind.A

Page 2/9 30/06/98

Page 38

2. ELECTRIC & ELECTRONIC PRINCIPLES

RAA 009 A Ind.A

Page 2/10

30/06/98

Page 39

2. ELECTRIC & ELECTRONIC PRINCIPLES

4.2. WBC coaxial

RAA 009 A Ind.A

Page 2/11 30/06/98

Page 40

2. ELECTRIC & ELECTRONIC PRINCIPLES

5. SENSORS

5.1. Drain detection sensor

RAA 009 A Ind.A

Page 2/12

30/06/98

Page 41

2. ELECTRIC & ELECTRONIC PRINCIPLES

5.2. Carriage & needle sensors

RAA 009 A Ind.A

Page 2/13 30/06/98

Page 42

2. ELECTRIC & ELECTRONIC PRINCIPLES

5.3. Syringe sensors

RAA 009 A Ind.A

Page 2/14

30/06/98

Page 43

2. ELECTRIC & ELECTRONIC PRINCIPLES

6. MISCELLANEOUS

6.1. Needle carriage motor

RAA 009 A Ind.A

Page 2/15 30/06/98

Page 44

2. ELECTRIC & ELECTRONIC PRINCIPLES

6.2. Barcode cable

RAA 009 A Ind.A

Page 2/16

30/06/98

Page 45

2. ELECTRIC & ELECTRONIC PRINCIPLES

6.3. Temperature sensor

RAA 009 A Ind.A

Page 2/17 30/06/98

Page 46

2. ELECTRIC & ELECTRONIC PRINCIPLES

6.4. HGB Chamber assembly

RAA 009 A Ind.A

Page 2/18

30/06/98

Page 47

2. ELECTRIC & ELECTRONIC PRINCIPLES

6.5. Chip card reader cable

RAA 009 A Ind.A

Page 2/19 30/06/98

Page 48

2. ELECTRIC & ELECTRONIC PRINCIPLES

6.6. CT Piercing assembly cable

RAA 009 A Ind.A

Page 2/20

30/06/98

Page 49

2. ELECTRIC & ELECTRONIC PRINCIPLES

6.7. CT twin valve cable

RAA 009 A Ind.A

Page 2/21 30/06/98

Page 50

2. ELECTRIC & ELECTRONIC PRINCIPLES

7. FLAT CABLES

RAA 009 A Ind.A

Page 2/22

30/06/98

Page 51

2. ELECTRIC & ELECTRONIC PRINCIPLES

RAA 009 A Ind.A

Page 2/23 30/06/98

Page 52

2. ELECTRIC & ELECTRONIC PRINCIPLES

RAA 009 A Ind.A

Page 2/24

30/06/98

Page 53

2. ELECTRIC & ELECTRONIC PRINCIPLES

RAA 009 A Ind.A

Page 2/25 30/06/98

Page 54

2. ELECTRIC & ELECTRONIC PRINCIPLES

8. ELECTRICAL SYNOPTICS

RAA 009 A Ind.A

Page 2/26

30/06/98

Page 55

3. MAINTENANCE

CONTENTS

1. MAINTENANCE ..................................................................................................................................... 2

1.1. Introduction .................................................................................................................................... 2

1.2. Daily customer maintenance.......................................................................................................... 2

1.3. Weekly customer maintenance...................................................................................................... 2

2. Maintenance kits .................................................................................................................................... 3

3. PROCEDURES...................................................................................................................................... 4

3.1. Procedure chart tables ................................................................................................................... 5

3.2. Required tools and products .......................................................................................................... 7

RAA 009 A Ind.A

Page 3/1 20/06/98

Page 56

3. MAINTENANCE

1. MAINTENANCE

1.1. Introduction

WARNING !

Customer maintenance has to be carried out according to the recommended

frequency chart table and after having performed an ABX approved customer training course.

The system warranty may be affected if damage occurs after a non trained technician

intervenes or if replaced spare parts and consumables do not come from an ABX

approved origin.

1.2. Daily customer maintenance

No special adjustments or maintenance has to be done on your equipment if the recommended

startup and shutdown procedures are explicitly respected.

See the

ABX MICROS 60

User Manual for the daily rinsing and cleaning of the system.

1.3. Weekly customer maintenance

An overall check for cleanliness of the system is recommended every week.

All traces of blood or reagent have to be wiped off as soon as possible using a piece of cloth

and distilled water.

CAUTION

Never use solvent or abrasive cleaning material to clean the system.

RAA 009 A Ind.A

Page 3/2

20/06/98

Page 57

3. MAINTENANCE

2. MAINTENANCE KITS

O RING KIT : XEA 328 AS

FAA 036 A

FAA 029 A 1 Diluent dispenser O ring

FAA 055 A 2 Sampling syringe O rings

FAA 049 A 2 Aperture O rings

FAA 046 A 2 Coaxial O rings

FAA 054 A 2 Sampling needle O rings (CT)

FAA 053 A 1 Sampling needle O ring (OT)

FAA 017 A 1 Vacuum/waste syringe O ring

KAM 022 A 6 Board holder clips (MICROS 45 only)

FAA 023 A 1 WBC/HGB chamber cap O ring

GBC 030 A 1 Air Syringe piston

Part number

CAE 006 A tube holder detection switch 1

EAE 005 A Tygon tube 1.02mm (0,040") 2

1 Lyse dispenser O ring

1 Piercing needle O ring (MICROS CT only)

SPARE PARTS KIT

XEA 458 AS

Quantity

EAE 007 A Tygon tube 1,52mm (0,060") 2

EAE 008 A Tygon tube 2,05mm (0,081") 2

EAE 009 A Tygon tube 2,29mm (0,090") 2

FAK 001 A Aperture 50µ 1

FAK 003 A Aperture 80µ 1

FBR 002 A N otched belt 290 1

FBR 003 A N otched belt 380 1

GBC 052 A C.T sampling needle 1

GBC 069 A O.T sampling needle 1

GBC 189 A CT Piercing needle 1

GBC 193 A RBC chamber 1

XBA 199 A Drain detection sensor 1

XBA 250 A Carriage/needle sensor 1

XBA 272 B WBC coaxial 1

XDA 472 B WBC/HG B chamber 1

XDA 481 B Liquid valve 2W N C without solenoid 1

XDA 483 B Liquid valve 3W w ithout solenoid 1

RAA 009 A Ind.A

XBA 365 A RBC coaxial 1

XBA 319 A Liquid/air syringe sensor 1

XEA 328 AS Maintenance kit 1

Page 3/3 20/06/98

Page 58

3. MAINTENANCE

3. PROCEDURES

Maintenance and adjustments that need to be done on

NOTE

CONCERNING PARTS :

- Hydraulic maintenance and adjustments.

- Pneumatic maintenance and adjustments.

- Electrical maintenance and adjustments.

- Power supply maintenance and adjustments.

- Electronic maintenance and adjustments.

- Printer maintenance and setup.

are divided into «procedures» according to concerned assemblies. This

should make any updating easier as all interventions can be done with the

corresponding «procedure» on its own.

Each procedure has to be read entirely before beginning the intervention.

NOTE

ABX MICROS 60

WARNING !

When cleaning instruments, disposable gloves should be worn.

RAA 009 A Ind.A

Page 3/4

20/06/98

Page 59

3. MAINTENANCE

3.1. Procedure chart tables

M I C R O S 60 O T

P / N P R O C E D U R E C O N C E R NS

RAS 165 A

RAS 168 A

RAS 169 A CHAMBER MAINTENANCE

RAS 170 A LIQUID VALVE MAINTENANCE Liquid valve assy replacement - Valve body replacement

RAS 171 A

RAS 172 A

RAS 173 A MECHANIC FUNCTIONS

RAS 174 A DR AIN DETECTION ADJUSTM ENT Drain detection sensor adjustment

RAS 175 A PCB VOLTAGE CHECKS

MICROS 60 OT IN STALLATION

AND STARTUP

SAMPLING NEEDLE

MAINTENANCE

POWER SUPPLY

CHECK/REPLACEMENT

TECHNICIAN FUNCTIONS

MICROS 60 OT

MICROS OT

Unpacking - Working conditions - Visual check s - Reagent

connection - Printer & instrument connections - Priming &

Startup

Needle replacement - O ring replacement

RBC, WBC/HGB chamber cleaning - Aperture O ring

replacement - Coaxial O ring replacement

Voltage supply chec k - Pow er supp ly mod ule replac ement

Fan operation check.

Version display. - Adjustments : HGB photometer calibration,

Aperture voltage, pressure check, W BC gain , RBC & PLT

gain, Sensor, Needle heigth and motion , bubbling. Temperature sensor adjustment - Run mode - Reagent pack Serial number - Cycle number - Burning

Sensor replacement - Needle motion check - Carriage motion

check - Liquid syringe motion check - Vac/Waste syringe

motion check - Valve operation check - LCD contrast - Piercing

mechanism check

Voltage supply check/adj. - Aper ture voltage chec k/adj. RBC threshold check/adj. - WBC threshold check/adj. - PLT

threshold check/adj. - HGB blank voltage check - Stepper

motor voltage adjus tment

RAS 177 A LX300 PRINTER

RAS 178 A LIQUID SYRINGE MAINTE NANCE

RAS 179 A

RAS 180 A

RAS 181 A REAGENT PACK Connector O ring rep lacement

RAS 182 A BARCODE READER SETUP Reader configuration

RAS 187 A

RAS 191 A OVERALL MAINTENANCE Instrument maintenance step by step

RAS 192 A DECO NTAMINATION Instrument decontamination

RAS 197 A DRAIN & RINSE Instrument rinse and drain for an extended shutdown

VACUUM/WASTE SYRINGE

MAINTENANCE

CHANGING THE INSTRUMENT

LANGUAGE

HYDRAULIC CYCLE CHECKU P

M

ICROS 60 O T

Configuration - Contro l panel - Control LEds and ke ys Description

Lyse dispenser O ring replacement - Diluent dispenser O ring

replacement - Samplin g needle dispen ser O ring replact. Lubrification

O ring replacement

Changing the instrum ent language

Step by step control of the hy draulic cycle

RAA 009 A Ind.A

Page 3/5 20/06/98

Page 60

3. MAINTENANCE

M I C R O S 60 C T

P / N P R O C E D U R E C O N C E R NS

RAS 166 A

RAS 167 A

RAS 169 A CHAMBER MAINTENANCE

RAS 170 A LIQUID VALVE MAINTENANCE Liquid valve assy replacement - Valve body replacement

RAS 171 A

RAS 176 A

RAS 173 A MECHANIC FUNCTIONS

RAS 174 A DR AIN DETECTION ADJUSTM ENT Drain detection sensor adjustment

RAS 175 A PCB VOLTAGE CHECKS

MICROS 60 CT IN STALLATION

AND STARTUP

SAMPLING NEEDLE

MAINTENANCE

POWER SUPPLY

CHECK/REPLACEMENT

TECHNICIAN FUNCTIONS

MICROS 60 CT

MICROS CT

Unpacking - Working conditions - Visual check s - Reagent

connection - Printer & instrument connections - Priming &

Startup

Needle O ring replacement - Sampling needle replacement

Piercing needle repla cement

RBC, WBC/HGB chamber cleaning - Aperture O ring

replacement - Coaxial O ring replacement

Voltage supply chec k - Pow er supp ly mod ule replac ement

Fan operation check.

Version display. - Adjustments : HGB photometer calibration,

Aperture voltage, pressure check, W BC gain , RBC & PLT

gain, Sensor, Needle heigth and motion , bubbling. Temperature sensor adjustment - Run mode - Reagent pack Serial number - Cycle number - Burning

Sensor replacement - Needle motion check - Carriage motion

check - Liquid syringe motion check - Vac/Waste syringe

motion check - Valve operation check - LCD contrast - Piercing

mechanism check

Voltage supply check/adj. - Aper ture voltage chec k/adj. RBC threshold check/adj. - WBC threshold check/adj. - PLT

threshold check/adj. - HGB blank voltage check - Stepper

motor voltage adjus tment

RAS 177 A LX300 PRINTER

RAS 178 A LIQUID SYRINGE MAINTE NANCE

RAS 179 A

RAS 180 A

RAS 181 A REAGENT PACK Connector O ring rep lacement

RAS 182 A BARCODE READER SETUP Reader configuration

RAS 188 A

RAS 191 A OVERALL MAINTENANCE Instrument maintenance step by step

RAS 192 A DECO NTAMINATION Instrument decontamination

RAS 197 A DRAIN & RINSE Instrument rinse and drain for an extended shutdown

RAS 198 A PIERCING BLOCK Description - Maintenance - Sampling position

VACUUM/WASTE SYRINGE

MAINTENANCE

CHANGING THE INSTRUMENT

LANGUAGE

HYDRAULIC CYCLE CHECKU P

M

ICROS 60 C T

Configuration - Contro l panel - Control LEds and ke ys Description

Lyse dispenser O ring replacement - Diluent dispenser O ring

replacement - Samplin g needle dispen ser O ring replact. Lubrification

O ring replacement

Changing the instrum ent language

Step by step control of the hy draulic cycle

RAA 009 A Ind.A

Page 3/6

20/06/98

Page 61

3. MAINTENANCE

3.2. Required tools and products

TOOLS PRODUCTS

DESIGNATION PART NUMBER DESIGNATION PART NUMBER

HEXAGONAL KEYS

DYNAMOMETRIC

SCREW DRIV ER

A302

DYNAMOMETRIC

SCREW DRIV ER

A301

DYNAMOMETRIC

SCREW DRIV ER

A300

CLAMPS LIQUID SOAP

SCALPEL DISTILLED WATER

CUTTING PLIERS MICROPIPETTE TIP

PAIR OF SCISORS

VOLTMETER LATEX WBC LAD 001 AS

MAG 019 A

MAG 020 A

MAG 013 A

EMPTY SAMPLE

TUBES

SILICONE GREASE LAM 004 A

GREASE FOR

MECHANICAL

ASSEMBLIES

SOFT TISSUE

FLAT PIECE OF

STIFF PLASTIC

XEA 381 AS

FLAT SCREWDRIVER LATEX RBC LAD 002 AS

BARFLEX FELT PEN

THERMOMETER SYRINGE 5ML

TORX KEYS

RAA 009 A Ind.A

Page 3/7 20/06/98

Page 62

INSTALLATION

CONCERNS

1 - Unpacking

2 - Working conditions

3 - Visual checks

4 - Reagent connections

5 - Printer and instrument connections

6 - Priming and startup

REQUIRED TOOLS

Hexagonal keys

01/10/98

REQUIRED PRODUCTS

- MICROS 60 Reagents : Bottles or Pack.

- Waste container (for bottle model).

INTERVENTION TIME

- 30 minutes

FREQUENCY

SPECIFIC KIT OR CONSUMABLES

- PACK installation kit : XEA 314 A

or

- Bottle installation kit : XEA 332 A

MICROS 60 OT

RAS 165 A Ind.B

Page 63

PROCEDURE

1 - Unpacking

INSTALLATION

The instrument is enveloped in a special,

protective foam before being placed in a

cardboard box. Cut the four angles of the box

to unpack the system.

Remove the cardboard box containing the ABX

MICROS 60 installation kit from its location (see

Diag.1).

Diag.1

2 - Working conditions

• Environment

ABX MICROS 60-OT should be operated in an indoor location only. Operation at an altitude

over 2000 meters is not recommended. Instrument is designed to be safe for transient voltages according to INSTALLATION CATEGORY II and POLLUTION DEGREE 2.

• Location

ABX MICROS 60-OT should be placed on a clean and level table or work station. Please note

that ABX MICROS 60-OT, printer and reagents weigh approximately 30 kilograms (66 lbs).

Avoid exposure to sunlight. Proper ventilation requires that a space of at least 20 cm (8 inches)

must be left behind the apparatus.

• Grounding

Proper grounding is required. Check that the wall ground (earth) plug is correctly connected to

the laboratory grounding electricity installation. If there is no ground then use a ground stake.

Current electricity norms must be applied.

• Humidity and temperature conditions

ABX MICROS 60-OT can function between 18 to 32°C (65 to 90°F), with relative humidity,

meaning less than 80% with no condensation. If it is kept at a temperature less than 10°C

(50°F), the instrument should be allowed to sit for an hour at the correct room temperature

before use.

MICROS 60 OT

Page 2/13 RAS 165 A Ind.B

Page 64

INSTALLATION

3 - Visual checks

Diag.2

MICROS 60 OT

Using the key contained into the installation kit, turn

the locker as shown on the Diag. 2 to open the

pneumatic protection door.

Unscrew the 3 cover fixation screws (Diag. 3) and

loosen the 2 tightening screws under the reagent

flap (Diag 4).

Remove the cover : pull it backward and lift it up to

the rear of the instrument .

Diag.3

Diag.5

A

B

Diag.4

Push the black plastic carriage locking clip

(A) as far as possible to the left and place

the sample needle carriage (B) as far

forward as possible to the right-hand side,

as shown in Diag. 5.

Check that the needle is not bent and make

sure it is in its upper position.

RAS 165 A Ind.B Page 3/13

Page 65

INSTALLATION

Unscrew slightly the 2 screws of the WBC/HGB chamber protection cover (diag 6). Remove

the cover and check that both chambers (RBC/PL T, WBC/HGB) are fixed properly in their clips

and the electrode blocks are attached firmly to the chambers (Diag. 7).

Diag.6

Re-install the HGB/WBC chamber cover.

Diag.8

Diag.7

Check that the connectors on the

printed circuit board are securely in

place (Diag. 8).

Re-install the instrument cover.

Remove the fuse holder from its location on

the rear panel pressing on the holder lock

(Diag.9) and check the fuse characteristics :

they should be 1 Ampere, 250 Volts SlowBlow.

MICROS 60 OT

Diag.9

Page 4/13 RAS 165 A Ind.B

Page 66

INSTALLATION

4 - Reagent connections

• Bottle connections

Diag.10

IMPORTANT

MICROS 60 OT

Lyse and cleaning reagents are placed inside the

reagent compartment as shown in the Diag. 10.

Install the reagent straws and the bottle stoppers.

Connect the blue tube to the MINICLEAN bottle

and the white tube to the MINILYSE bottle.

Close the compartment cover.

When the ABX MICROS 60-OT is set up with the 16 or 18 parameters mode, it is mandatory

to use specific MINILYSE LMG and MINIDIL LMG reagents.

CAUTION

The Diluent container will be located on the bench at the same level than the instrument.

• Waste connection

Install the male connectors included in the

installation kit at the liquid input and output located at the bottom of the instrument rear panel (Diag.11).

Connect the diluent container (see CAUTION above) using the diluent straw and

a 3x6 cristal tube (1 meter maximum) on

the diluent input located at the bottom of

the instrument rear panel (Diag.11).

Connect the waste container using the

cristal tube 3 x 6 on the waste output,

and place the waste container below the

instrument level (under the bench).

Diag.11

WARNING !

Always follow the recommended procedures for waste disposal. Never connect

the instrument wastes directly to the laboratory drain pipes. For each waste container, follow the neutralization procedure as described in the user manal.

RAS 165 A Ind.B Page 5/13

Page 67

INSTALLATION

• Reagent pack connection

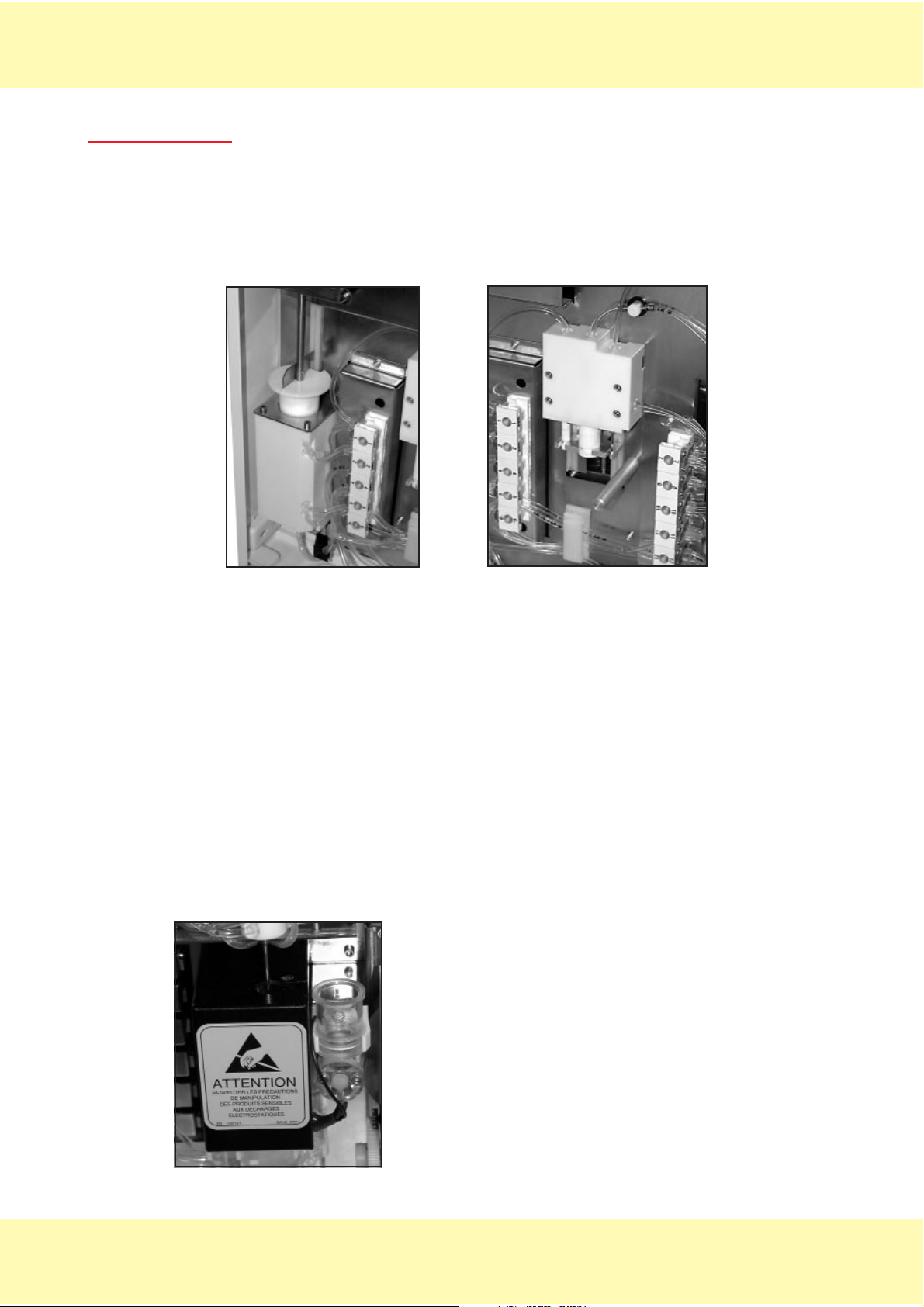

Remove the reagent output protections, as well as the waste input protection (Diag.12 & 13)

Diag.12

Install the pack directly into the compartment of the instrument as shown on the Diag. 14, 15 &

16. Push the pack down in order to plug correctly the pack on the male connectors.

Diag.13

Diag.14 Diag.15

Diag.16

CAUTION

MICROS 60 OT

Page 6/13 RAS 165 A Ind.B

In order to avoid leak problems it is recommended not to unplug several times the

same reagent pack.

The free male connector (see Diags.

14, 15 & 16) must be plugged on the

pack upper valve in order to receive

the waste liquids.

Page 68

INSTALLATION

5 - Printer and instrument connections

• Instrument connection.

If the instrument has to be connected to a

laboratory computer, use the plug RS232.

Connect the power cable to the plug located

on the rear left-hand side of the device (Diag.

17).

• Setting up the printer

- Remove all the package protections

- Install the paper feed-knob

MICROS 60 OT

Diag.17

Diag.19

Diag.18

Open the ink ribbon access door at the top of the printer and install the ribbon as shown in diag

20 & 21 : Slide the printer head to the middle of the printer.

Insert the ribbon cartridge into the printer

Guide the ribbon between the print head and ribbon guide.

Slide the printer head from side to side to make sure it moves smoothly.

Diag.20

Diag.21

RAS 165 A Ind.B Page 7/13

Page 69

INSTALLATION

- Install the paper supports (Diag 22) for single sheets paper use only.

Diag.22

- The printer is connected to ABX MICROS 60-OT with the cable delivered with the instrument.

Lock the connector in place by tightening the 2 screws on each end of the connector to the

ABX MICROS 60-OT. Attach the other end of the cable to the printer and lock the printer

connector in place by the means of the 2 clips located on the connector itself (Diag. 23).

Diag.23

- For continuous paper, introduce it in the slot at the back of the printer and use the sprocket

covers to load paper, or else feed the paper frontward when using single sheets (see printer

user manual).

MICROS 60 OT

Diag.24

Diag.25

Page 8/13 RAS 165 A Ind.B

Page 70

INSTALLATION

• Printer command keys

Diag.26

LED PAUSE : The orange LED PAUSE lights when the printer stops printing. During each

power ON, this LED blinks for few seconds and 4 audible beeps occur. When the printer runs

out of paper, the LED blinks and 3 audible beeps occur. This LED lights also when the paper is

in its tear off position. When a problem occurs, this LED lights ON and 5 audible beeps occur.

LEDS FONT 1 and FONT 2 : These 2 green LEDS indicate the selected font. Refer to the

printer user's manual to select the font.

MICROS 60 OT

Key FONT : During normal operation, the FONT key allows the font selection. For each pressure on this key , the selection is modified. Refer to the printer user's manual to select the font.

When this key is pressed during the printer power ON, the printer setup menu is entered.

Key LF/FF : During normal operation, a quick pressure on this key allows a ligne feed of the

paper. Keep the pressure on this key to feed a whole page. This key can be used to load or

eject the paper.

When this key is pressed during the printer power ON, the printing test starts. Key PAUSE :

When this key is pressed during the printing, the printout stops. Press again on this key to

restart the printout.

PAPER PARK : If Z folded paper is used, the paper can be driven to its parking position when

pressing simultaneously on the keys LF/FF and FONT.

MICRO ADJUST : This function allows to adjust the loading paper position. See the user's

manual for details.

• Printer Configuration

Switch on the printer when pressing the <FONT>. The configuration should be the following :

Diag.29

RAS 165 A Ind.B Page 9/13

Page 71

INSTALLATION

Each parameter can be modified by the corresponding parameter chart.

Each chart is accessible using the keys <PAUSE>, <FONT> and <LF/FF> according to the

control LED combinations (Diag 30).

Diag.30

6 - Instrument startup

• Reagent priming

When the ABX MICROS 60-OT is first installed, it contains no reagents. All the reagents have

to be primed now. Turn ON instrument by pressing the ON/OFF switch located on the rear

panel. When the instrument turns on, the display shows :

PLEASE WAIT FOR 3 MIN

ESCAPE : ESC

This time is required at the startup for the instrument initialization and stabilization, specifically

for the HGB diode to reach its operationnal temperature. Press ESC several times in order to

abort the cycle : the LED of the front panel turns from red to green and the display shows the

following :

STARTUP NOT INITIATED

PRESS A KEY TO CONTINUE...

This message appears when the instrument is setup with the manual startup cycle to prevent

any analysis cycle before running a startup cycle.

Press any key, the main menu is displayed :

MAIN MENU 1 RESULTS

HH : MM 2 QC

MICROS 60 OT

Page 10/13 RAS 165 A Ind.B

Page 72

INSTALLATION

• Bottles and containers set :

Install the reagent bottle and carry out a PRIME cycle to clear the reagent line of air bubbles.

This procedure should be done whenever a new bottle of reagent is installed.

From the MAIN MENU, move the cursor to the function 4 SERVICE and press ENTER. The

service menu is displayed :

SERVICE 1 BACK FLUSH

HH : MM 2 DRAIN CHAMBERS

Move the cursor to function 3 PRIME REAGENTS and press ENTER. The PRIME menu is

displayed :

PRIME 1 ALL REAGENTS

HH : MM 2 DILUENT

MICROS 60 OT

Select either the function 1 prime ALL REAGENTS or move the cursor next to the required

reagent and press ENTER.

The priming cycle starts while the following menu is displayed :

ALL REAGENTS WAIT FOR 2 MN 3 S

******************

IMPORTANT

Before analyzing samples, visually inspect reagent lines and pumps for air bubbles.

Repeat priming if air bubbles are still present. Call the

department

Never initiate two Lyse prime cycles back-to-back. This causes excessive foaming in

the waste chamber. Run a blank cycle between each Lyse prime cycle.

- Run a STARTUP cycle.

if priming does not eliminate air bubbles.

ABX representative service

RAS 165 A Ind.B Page 11/13

Page 73

INSTALLATION

• Reagent pack

From the MAIN MENU, move the cursor to the function 4 SERVICE and press ENTER. The

service menu is displayed :

SERVICE > 2 DRAIN CHAMBER

HH : MM 3 PRIME REAGENTS

Move the cursor to 3 PRIME REAGENTS and press the ENTER key. Select the function

1

CHANGE PACK and follow the instructions given by the LCD in order to install the pack.

REAGENT PACK > 1 CHANGE PACK

HH : MM 2 CBC LEFT < 150>

Once the new PACK is installed a priming cycle will be automatically carried out and the

following menu is displayed.

PRIME WAIT FOR 2 MIN 3 S

* * * * * * * * * *

IMPORTANT

Before analyzing samples, visually inspect reagent lines and pumps for air bubbles.

Repeat priming if air bubbles are still present. Call the

department

From the REAGENT P ACK menu, the function 2 "CBC LEFT" displays the number of analysis

cycles left to run with the same pack.

It is also possible to run a priming cycle at any time using the selection 3 "PRIME REAGENTS"

of the SERVICE menu.

if priming does not eliminate air bubbles.

ABX representative service

IMPORTANT

It is recommended not to remove the pack several times before the reagents are

totally used in order to avoid leak problems.

- Run a STARTUP cycle.

MICROS 60 OT

Page 12/13 RAS 165 A Ind.B

Page 74

INSTALLATION

Once the instrument ready for the analyses, remove the adhesive protection from the front

panel (diag 31)

Diag.31

MICROS 60 OT

RAS 165 A Ind.B Page 13/13

Page 75

INSTALLATION

CONCERNS

1 - Unpacking

2 - Working conditions

3 - Visual checks

4 - Reagent connections

5 - Printer and instrument connections

6 - Priming and startup

REQUIRED TOOLS

Hexagonal keys

01/10/98

REQUIRED PRODUCTS

Reagents : Bottles or Pack.

Waste container (for bottle model).

INTERVENTION TIME

30 minutes

FREQUENCY

SPECIFIC KIT OR CONSUMABLES

MICROS 60 CT

PACK installation kit : XEA 317 A or

Bottle installation kit : XEA 335 A or

RAS 166 A Ind.B

Page 76

PROCEDURE

1 - Unpacking

INSTALLATION

The instrument is enveloped in a special,

protective foam before being placed in a

cardboard box. Cut the four angles of the box

to unpack the system.

Remove the cardboard box containing the instrument installation kit from its location (see

Diag.1).

Diag.1

2 - Working conditions

• Environment

ABX MICROS 60-

over 2000 meters is not recommended. Instrument is designed to be safe for transient voltages according to INSTALLATION CATEGORY II and POLLUTION DEGREE 2.

• Location

ABX MICROS 60-CT should be placed on a clean and level table or work station. Please note

that ABX MICROS 60-CT, printer and reagents weigh approximately 30 kilograms (66 lbs).

Avoid exposure to sunlight. Proper ventilation requires that a space of at least 20 cm (8 inches)

must be left behind the apparatus.

• Grounding

Proper grounding is required. Check that the wall ground (earth) plug is correctly connected to

the laboratory grounding electricity installation. If there is no ground then use a ground stake.

Current electricity norms must be applied.

• Humidity and temperature conditions

ABX MICROS 60-CT can function between 18 to 32°C (65 to 90°F), with relative humidity,

meaning less than 80% with no condensation. If it is kept at a temperature less than 10°C

(50°F), the instrument should be allowed to sit for an hour at the correct room temperature

before use.

CT

should be operated in an indoor location only. Operation at an altitude

MICROS 60 CT

Page 2/13 RAS 166 A Ind.B

Page 77

INSTALLATION

3 - Visual checks

Diag.2

MICROS 60 CT

Using the key contained into the installation kit, turn

the locker as shown on the Diag. 2 to open the

pneumatic protection door.

Unscrew the 3 cover fixation screws (Diag. 3) and

loosen the 2 tightening screws under the reagent

flap (Diag 4).

Remove the cover : pull it backward and lift it up to

the rear of the instrument.

Diag.3

Diag.5

Diag.4

Push the black plastic carriage locking clip

(A) as far as possible to the left and place

the sample needle carriage (B) as far

forward as possible to the right-hand side,

as shown in Diag. 5.

Check that the needle is not bent and make

sure it is in its upper position.

RAS 166 A Ind.B Page 3/13

Page 78

INSTALLATION

Unscrew slightly the 2 screws of the WBC/HGB chamber protection cover (diag 6). Remove

the cover and check that both chambers (RBC/PL T, WBC/HGB) are fixed properly in their clips

and the electrode blocks are attached firmly to the chambers (Diag. 7).

Re-install the HGB/WBC chamber cover.

Diag.8

Diag.7Diag.6

Check that the connectors on the

printed circuit board are securely in

place (Diag. 8).

Re-install the instrument cover.

Remove the fuse holder from its location on

the rear panel pressing on the holder lock

(Diag.9) and check the fuse characteristics :

they should be 1 Ampere, 250 Volts SlowBlow.

MICROS 60 CT

Diag.9

Page 4/13 RAS 166 A Ind.B

Page 79

INSTALLATION

4 - Reagent connections

• Bottle connections

Lyse and cleaning reagents are placed inside the

reagent compartment as shown in the Diag. 10.

Install the reagent straws and the bottle stoppers.

Connect the blue tube to the MINICLEAN bottle

and the white tube to the MINILYSE bottle.

Close the compartment cover.

Diag.10

IMPORTANT

When the ABX MICROS 60-CT is set up with the 16 or 18 parameters mode, it is mandatory

to use specific MINILYSE LMG and MINIDIL LMG reagents.

MICROS 60 CT

CAUTION

The Diluent container will be located on the bench at the same level than the instrument.

• Waste connection

Install the male connectors included in the

installation kit at the liquid input and output located at the bottom of the instrument rear panel (Diag.11).

Connect the diluent container (see CAUTION above) using the diluent straw and

a 3x6 cristal tube (1 meter maximum) on

the diluent input located at the bottom of

the instrument rear panel (Diag.11).

Connect the waste container using the

cristal tube 3 x 6 on the waste output,

and place the waste container below the

instrument level (under the bench).

Diag.11

WARNING !

Always follow the recommended procedures for waste disposal. Never connect

the instrument wastes directly to the laboratory drain pipes. For each waste container, follow the neutralization procedure as described in the user manal.

RAS 166 A Ind.B Page 5/13

Page 80

INSTALLATION

• Reagent pack connection

Remove the reagent output protections, as well as the waste input protection (Diag.12 & 13)

Diag.12

Install the pack directly into the compartment of the instrument as shown on the Diag. 14, 15 &

16. Push the pack down in order to plug correctly the pack on the male connectors.

Diag.13

Diag.14 Diag.15

Diag.16

MICROS 60 CT

Page 6/13 RAS 166 A Ind.B

CAUTION

In order to avoid leak problems it is recommended not to unplug several times the

same reagent pack.

The free male connector (see Diags.

14, 15 & 16) must be plugged on the

pack upper valve in order to receive

the waste liquids.

Page 81

INSTALLATION

5 - Printer and instrument connections

• Instrument connection.

If the instrument has to be connected to a

laboratory computer, use the plug RS232.

Connect the power cable to the plug located

on the rear left-hand side of the device (Diag.

17).

• Setting up the printer

- Remove all the package protections

- Install the paper feed-knob

MICROS 60 CT

Diag.17

Diag.19

Diag.18

Open the ink ribbon access door at the top of the printer and install the ribbon as shown in diag

20 & 21 : Slide the printer head to the middle of the printer.

Insert the ribbon cartridge into the printer

Guide the ribbon between the print head and ribbon guide.

Slide the printer head from side to side to make sure it moves smoothly.

Diag.20

Diag.21

RAS 166 A Ind.B Page 7/13

Page 82

INSTALLATION

- Install the paper supports (Diag 22) for single sheets paper use only.

Diag.22

- The printer is connected to ABX MICROS 60-CT with the cable delivered with the instrument.

Lock the connector in place by tightening the 2 screws on each end of the connector to the

ABX MICROS 60-CT. Attach the other end of the cable to the printer and lock the printer

connector in place by the means of the 2 clips located on the connector itself (Diag. 23).

- For continuous paper, introduce it in the slot at the back of the printer and use the sprocket

covers to load paper, or else feed the paper frontward when using single sheets (see printer

user manual).

MICROS 60 CT

Diag.24

Diag.23

Diag.25

Page 8/13 RAS 166 A Ind.B

Page 83

INSTALLATION

• Printer command keys

Diag.26

LED PAUSE : The orange LED PAUSE lights when the printer stops printing. During each

power ON, this LED blinks for few seconds and 4 audible beeps occur. When the printer runs

out of paper, the LED blinks and 3 audible beeps occur. This LED lights also when the paper is

in its tear off position. When a problem occurs, this LED lights ON and 5 audible beeps occur.

LEDS FONT 1 and FONT 2 : These 2 green LEDS indicate the selected font. Refer to the

printer user's manual to select the font.

Key FONT : During normal operation, the FONT key allows the font selection. For each pressure on this key , the selection is modified. Refer to the printer user's manual to select the font.

When this key is pressed during the printer power ON, the printer setup menu is entered.

MICROS 60 CT

Key LF/FF : During normal operation, a quick pressure on this key allows a ligne feed of the

paper. Keep the pressure on this key to feed a whole page. This key can be used to load or

eject the paper.

When this key is pressed during the printer power ON, the printing test starts. Key PAUSE :

When this key is pressed during the printing, the printout stops. Press again on this key to

restart the printout.

PAPER PARK : If Z folded paper is used, the paper can be driven to its parking position when

pressing simultaneously on the keys LF/FF and FONT.

MICRO ADJUST : This function allows to adjust the loading paper position. See the user's

manual for details.

• Printer Configuration

Switch on the printer when pressing the <FONT>. The configuration should be the following :

Diag.29

RAS 166 A Ind.B Page 9/13

Page 84

INSTALLATION

Each parameter can be modified by the corresponding parameter chart.

Each chart is accessible using the keys <PAUSE>, <FONT> and <LF/FF> according to the

control LED combinations (Diag 30).

Diag.30

6 - Instrument startup

• Reagent priming

When the ABX MICROS 60-CT is first installed, it contains no reagents. All the reagents have

to be primed now. Turn ON instrument by pressing the ON/OFF switch located on the rear

panel. When the instrument turns on, the display shows :

PLEASE WAIT FOR 3 MIN

ESCAPE : ESC

This time is required at the startup for the instrument initialization and stabilization, specifically

for the HGB diode to reach its operational temperature. Press the ESC key in order to abort the

cycle : the LED of the front panel turns from red to green and the display shows :

STARTUP NOT INITIATED

PRESS A KEY TO CONTINUE...

This message appears when the instrument is setup with the manual startup cycle to prevent

any analysis cycle before running a startup cycle.

Press any key, the main menu is displayed :

MAIN MENU 1 RESULTS

HH : MM 2 QC

MICROS 60 CT

Page 10/13 RAS 166 A Ind.B

Page 85

INSTALLATION

Bottles and containers set :

Install the reagent bottle and carry out a PRIME cycle to clear the reagent line of air bubbles.

This procedure should be done whenever a new bottle of reagent is installed.

From the MAIN MENU, move the cursor to the function 4 SERVICE and press ENTER. The

service menu is displayed :

SERVICE 1 BACK FLUSH

HH : MM 2 DRAIN CHAMBERS

Move the cursor to function 3 PRIME REAGENTS and press ENTER. The PRIME menu is

displayed :

PRIME 1 ALL REAGENTS

HH : MM 2 DILUENT

Select either the function 1 prime ALL REAGENTS or move the cursor next to the required

reagent and press ENTER.

The priming cycle starts while the following menu is displayed :

MICROS 60 CT

ALL REAGENTS WAIT FOR 2 MN 3 S

******************

IMPORTANT

Before analyzing samples, visually inspect reagent lines and pumps for air bubbles.

Repeat priming if air bubbles are still present. Call the

department

Never initiate two Lyse prime cycles back-to-back. This causes excessive foaming in the

waste chamber. Run a blank cycle between each Lyse prime cycle.

- Run a STARTUP cycle.

if priming does not eliminate air bubbles.

ABX representative service

RAS 166 A Ind.B Page 11/13

Page 86

INSTALLATION

Reagent pack

From the MAIN MENU, move the cursor to the function 4 SERVICE and press ENTER. The

service menu is displayed :

SERVICE > 2 DRAIN CHAMBER

HH : MM 3 PRIME REAGENTS

Move the cursor to 3 PRIME REAGENTS and press the ENTER key. Select the function

1

CHANGE PACK and follow the instructions given by the LCD in order to install the pack.

REAGENT PACK > 1 CHANGE PACK

HH : MM 2 CBC LEFT < 150>

Once the new PACK is installed a priming cycle will be automatically carried out and the

following menu is displayed.

PRIME WAIT FOR 2 MIN 3 S

* * * * * * * * * *

IMPORTANT

Before analyzing samples, visually inspect reagent lines and pumps for air bubbles.

Repeat priming if air bubbles are still present. Call the

department

From the REAGENT P ACK menu, the function 2 "CBC LEFT" displays the number of analysis

cycles left to run with the same pack.

It is also possible to run a priming cycle at any time using the selection 3 "PRIME REAGENTS"

of the SERVICE menu.

if priming does not eliminate air bubbles.

ABX representative service

IMPORTANT

It is recommended not to remove the pack several times before the reagents are

totally used in order to avoid leak problems.

- Run a STARTUP cycle.

MICROS 60 CT

Page 12/13 RAS 166 A Ind.B

Page 87

INSTALLATION

Once the instrument ready for the analyses, remove the adhesive protection from the front

panel (diag 31)

Diag.31

MICROS 60 CT

RAS 166 A Ind.B Page 13/13

Page 88

CONCERNS

SAMPLING NEEDLE

MAINTENANCE

- Needle O ring replacement

- Sampling needle replacement

- Piercing needle replacement

REQUIRED TOOLS

- Hexagonal keys

- Dynamometric screw driver A302 : MAG 019 A

REQUIRED PRODUCTS

- Silicone grease : LAM 004 A

18/06/98

INTERVENTION TIME

- 15min

FREQUENCY

- See frequency chart table for cleaning.

- O ring replacement : 1/year

- Needle replacement : On request only

SPECIFIC KIT OR CONSUMABLES

- O ring kit : XEA 328 AS

- Sampling needle : GBC 052 A

- Piercing needle : GBC 189 A

MICROS 60 CT

RAS 167 A Ind.A

Page 89

PROCEDURE

SAMPLING NEEDLE MAINTENANCE

A - Needle or O ring replacement

- Disconnect the tube

1

from the

Diag.1

top of the needle

Remove the clip

manually lift up the sampling needle

(Diagram 1).

- Unscrew the 2 screws 3(Diagram

1) in order to freed the needle rinsing

block

- Remove the rinsing block/needle

assy from the carriage taking care not

to bend the needle.

- Lift up the O ring holder

4

from the carriage frame

5

.

2

(diagram 1).

3

(diagram 2) and

1

and re-

Diag.2

Proceed the same way to replace the needle if necessary

- Reassemble in the reverse order. Use a dynamometric screw driver to tighten the screws

(Diag.1) to 700 mN.m (99.4 Ozf.in).

MICROS 60 CT

place the O rings

previously greased. Wipe all excess of

grease away .

- If necessary clean the inner surface

of the rinsing block with a little piece of

paper.

2

by new ones

3

Page 2/3 RAS 167 A Ind.A

Page 90

SAMPLING NEEDLE MAINTENANCE

B - Piercing needle replacement

- Disconnect the tube 1from the piercing needle

4

(Diag.3).

- Lift the needle 2in the upper position.

- Loosen the 2 screws

enough to enable the rinsing block

to be lifted up of about 5 mm.

- Pull the piercing needle

(foreward) and replace it by a new

one if necessary .

- Replace the piercing needle O ring

5

(FAA 036 A) by a new one.

- Reassemble in the reverse order.

Apply the same torque : 700mN.m

(99.4 Ozf.in) to tighten the two

screws 3.

MICROS 60 CT

3

just

4

Diag.3

NOTE

Diag.4

It is recommended to check the correct motion of the needle.

Proceed as follows :

Enter the «SERVICE» menu and then the sub menu «MECHANIC»

and perform a «NEEDLE U/D» cycle.

Blockage problems may occur on some

instruments during the needle or carriage

motions giving some motor error messages.

Before replacing the concerned motor, it is

necessary to check the correct rotation of

the free puley located at the end of the

notched belt.

Remove the axle screw of the puley and

clean its 2 parts and the washer. Reinstall

the puley assy, the rounded edge facing

the puley. Tighten the screw with a torque

of 400mN.m (56.8 Ozf.in).

Check that the puley turns freely after the tightening. Add a drop of oil (LAM 007 A) if necessary .

1 - FAG 011 A : Autolub. axle

2 - GBC 146 A : Free pulley

3 - GBC 147 A : Pulley holder

RAS 167 A Ind.A Page 3/3

Page 91

CONCERNS

SAMPLING NEEDLE

MAINTENANCE

- Needle replacement

- O ring replacement

REQUIRED TOOLS

- Hexagonal keys : 2,5

- Dynamometric screw driver A300 : MAG 013 A

REQUIRED PRODUCTS

- Silicone grease : LAM 004 A

10/04/98

INTERVENTION TIME

- 15 min

FREQUENCY

- Needle replacement : On request only

- O ring replacements : 1/year

SPECIFIC KIT OR CONSUMABLES

- O ring kit : XEA 328 AS

- Spare parts kit : XEA 458 AS

MICROS 60 OT

RAS 168 A Ind.A

Page 92