Page 1

U

SI

ABUS TECHNOLOGIES INC.

New

Universal Smart Isolator

User Manual

Page 2

WARNING

This manual should be passed on to the end user.

The contents of this manual are subject to change without prior notice.

All rights reserved.

ABUS gives no warranty of any kind with regard to this manual, including, but not limited to, fitness

for a particular purpose.

If any question arises or errors are found, or if any information is missing from this manual, please

USI

inform your supplier or inform at info@abustek.com

The specifications mentioned in this manual are limited to those for the standard type under the

specified model number break-down and do not necessarily apply for customized instruments.

Please note that changes in the specifications, construction, or component parts of the instrument

may not immediately be reflected in this manual at the time of change.

If the customer or any third party is harmed by the use of this product, ABUS assumes no

responsibility for any such harm owing to any defects in the product which were not predictable, or

for any indirect damages.

Although Warning hazards are related to personal injury, and Caution hazards are associated

with equipment or property damage, it must be understood that operation of damaged equipment could,

under certain operational conditions, result in degraded process system performance leading to

personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of

our equipment. Use of this manual for any other purpose is specifically prohibited and its contents are

not to be reproduced in full or part without prior approval of Technical Communications Department,

ABUS Technologies

.

HEALTH AND SAFETY

To ensure that our products are safe and without risk to health, the following points must be

noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained

personnel and in accordance with the information given. Any deviation from these instructions will

transfer the complete liability to the user.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when

operating in conditions of high pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept

dry. Normal safe handling procedures must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant

hazard data sheets (where applicable) may be obtained from the Company address on the back cover,

together with servicing and spares information.

ABUS TECHNOLOGIES INC.

2

Page 3

9

USI

.

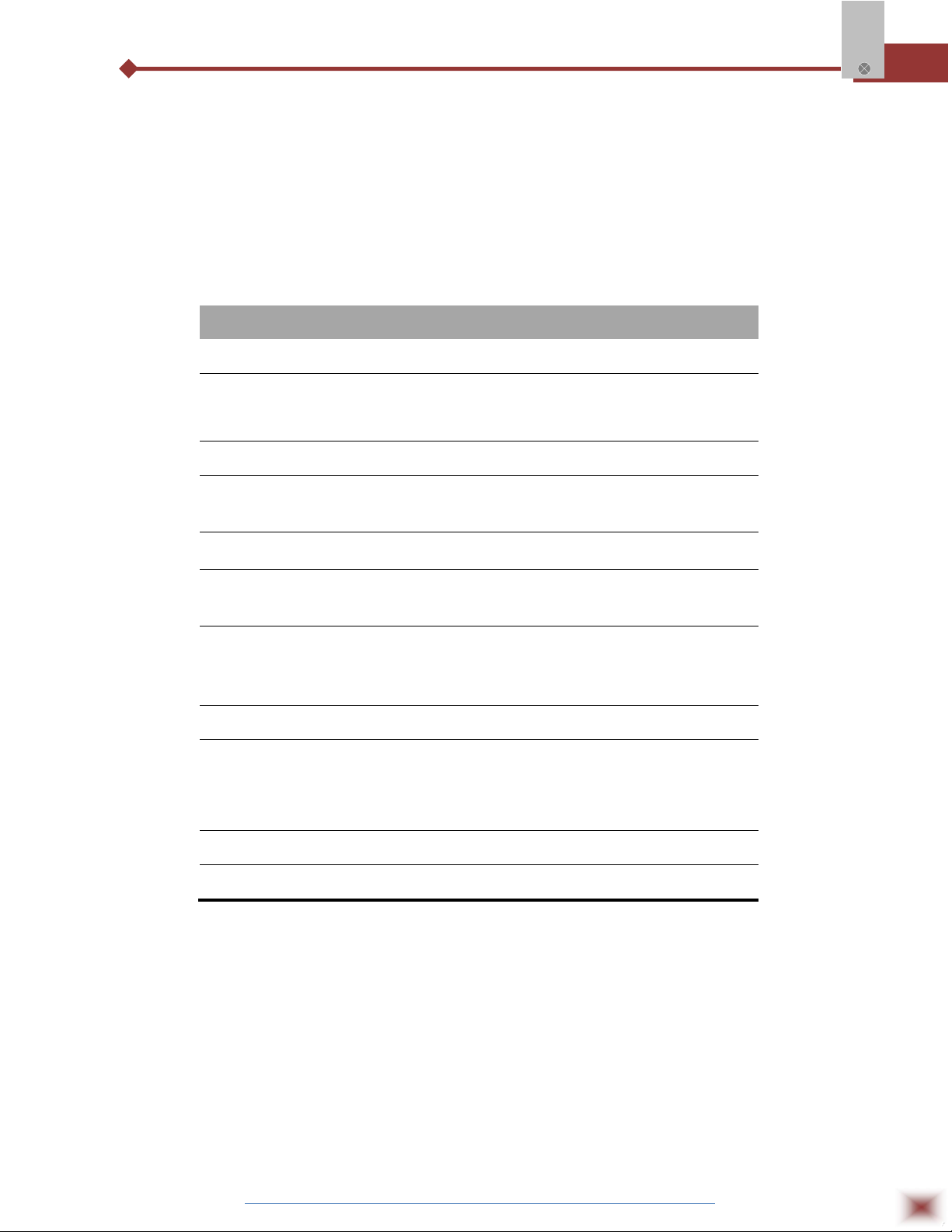

CATALOGUE

Contents Page No.

1. Introduction 4

2. Presentation

1. Features

2. Technical Parameters

3. Dimensions 5

4. Ordering Details

Input Table

5. Connections 8

6. Installation

7. Configuration

8. Operation 9

9. Maintenance

Recommendation

1. Terminal Configuration

2. Single Input Type Configuration

3. Double Input Type Configuration

1. Calibration of Instrument

2. Operation Environment

3. Troubleshooting

4

4

5

6

7

8

9

9

9

10

10

10

10

10. Safety Precautions 11

11. Warranty 11

ABUS TECHNOLOGIES INC.

3

Page 4

1. INTRODUCTION

The ABUS USI Series Universal Smart Isolator being programmable through

Handheld Configurator USI-C can be fit into major of industrial applications operating

with different signals. It can be ordered to accept up to 2 inputs and provide up to 3

outputs. The input signals can be non-linear input such as resistance temperature

detector, thermocouple or linear current or voltage. Signal of one-way, two-way or

three-way current or voltage, isolated by transmitting output provides good electric

isolation between input, output and power. It can be used as a temperature

transmitter, convertor, signal isolator or signal conditioner according to the application.

2. PRESENTATION

2.1 Features

This product uses a special chip. It has many advanced performances which traditional

USI

analogue isolator and many digital isolators don’t possess. This chip provides restrict and process from

software to high/ low-frequency interference signal in input signals. Even in high-power frequency

conversion system it can keep reliable performance. With the help of strong function of this chip

instrument can carry on digitalized automatic/ manual regulation to signal without the help of outside

zero and full-scale potentiometer. Meanwhile it can go on automatic compensation to input signals.

This series of products can also use integrated communication protocol, with the help of the

connection of communicational methods, observing input and output values on line. The integrated

smart isolator using a special chip, besides universal functions, can support the logical process to signal

and set alarm output to condition.

Unique and strong functions of software of the chip and excellent electric performance of

hardware of isolator itself provide firm assurance for stability and reliability of products. And it makes

overall performances of products lead of international advanced standard.

Series of instruments can be used with unit group instruments and DCS, PLC, etc. They are

widely used in all kinds of industries such as oil, chemical, petro-chemical, power, food, steel,

pharmaceutical industries etc...

ABUS TECHNOLOGIES INC.

4

Page 5

2.2 Technical Parameters

Accuracy: ±0.2% FS ± 1 for resistance mVDC VDC and mADC

±0.5% FS ± 1 for thermocouple input.

Output: 0...5 V, 0...10 V, 0.5...4.5 V, 4...20 mA (Customized On

request)

Power Supply: 100~240V AC (50/60Hz, 100~240V AC)

22~26V AC (50/60Hz, 24V AC)

22~26V DC (24V DC).

Isolated Resistance: 10MΩ or more between input and case at DC 550V

10MΩ or more between output and case at DC 550V.

Dielectric Strength: 1000V AC for 1 minute between input terminal and case

1500V AC for 1 minute between output terminal and case.

Load Resistance: DC mA Output

PID O/P: 500Ω

USI

Transmission O/P: 220Ω

VDC Output

Max. Load Current: 20mA

Input Impedance: DC mA Current Input: 200Ω

DC V Voltage Input: 500KΩ

Thermocouple Input: 4.7 KΩ

3. DIMENSIONS

ABUS TECHNOLOGIES INC.

5

Page 6

Linear Signal such as, 4~20mA,

Power

4. ORDERING DETAILS

TYPE DESCRIPTION

USI

Product

Power Supply

Input Type 1

Lower Range 1

Upper Range 1

Input Type 2

Lower Range 2

Upper Range 2

First Output

USI

N AC 90~265V

D DC 24V

C AC 24V

L

0~10V

T Thermocouple or RTD Please Refer Input Table

__

Lower Range : 0 for 0°C

Upper Range : 100 for 100°C

__ Specify Upper Range (Integer value)

N

A Please Refer Input Table

__

__ Specify Upper Range (Integer value)

USI Series Universal Smart Isolator

If None is selected, kindly don’t

specify Range below.

Lower Range : 0 for 0°C

Upper Range : 100 for 100°C

B1

B2 0 – 5 V

B3 0 – 10 mA

Please Refer Input Table

Specify Lower Range (Integer value)

None

Specify Lower Range (Integer value)

4 – 20 mA

Second Output

Third Output

Communication

Auxiliary

Supply

B4 0 – 10 V

Example: USI > D > L > 0 > 100 > N > B1 > C1 > N > M > B

C1

C2 0 – 5 V

C3 0 – 10 mA

C4 0 – 10 V

D1

D2 0 – 5 V

D3 0 – 10 mA

D4 0 – 10 V

N None

N

T RS485

M RS485 (Modbus)

A No AUX power

B AUX 24VDC output

4 – 20 mA

4 – 20 mA

No Communication

ABUS TECHNOLOGIES INC.

6

Page 7

Input Table

SET VALUE INPUT VALUE INPUT RANGE

USI

00

01

02

03

04

05

06

07

10

11

12

13

14

15

K 0~1300 °C

E 0~900 °C

S 0~1600 °C

B 300~1800 °C

J 0 ~ 400 °C

T 0~1300 °C

R 0~1600 °C

N 0~1300 °C

DC 0~20mV -1999~9999 °C

DC 0~75mV -1999~9999 °C

DC 0~200mV -1999~9999 °C

DC 0~10V -1999~9999 °C

DC 2~20V -1999~9999 °C

DC 0~10mA -1999~9999 °C

17

20

21

22

23

24

25

26

27

DC 4~20mA -1999~9999

Pt100 -199.9~600.0 °C

Cu100 -50.0~150.0 °C

Cu50 -50.0~150.0 °C

BA2 -199.9~600 °C

BA1 -199.9~600 °C

G -199.9~600 °C

Pt100X -19.99~99.99 °C

0~400 Ω -1999~9999 °C

ABUS TECHNOLOGIES INC.

7

Page 8

5. CONNECTIONS

USI

1. For thermocouple input, use the specified comenssation wire.

2. For RTD input, use leads with low resistance and having no resistance differences among the 3

leads.

3. Conduct input signal wiring away from instrument power, electric equipment power and loads lines

to avoid noise induction.

4. Conduct instrument power wiring so as not to be influenced by noise from the electric equipment

power. If the instrument is affected by external noise, a noise filter should be used.

a. Shorten the distance between twisted power supply wire pitches. The shorter the distance

between the pitches, more effective is the noise reduction.

b. Install the noise filter on the panel which is always grounded and minimize the wiring distance

between the noise filter output side and the instrument power terminals.

c. Do not install fuses and/or switches on the filter output signal since this may looses filter effect.

5. For wiring, use wires conforming to the domestic standards of the countries.

6. This instruments has no power supply switch for fuses. Therefore, install the fuse close to the

instrument and theswitch, if required.

7. Do not excessively tighten the terminal screws. In addition, use the solderless terminal with respect

to the screw size.

6. INSTALLATION

Recommendation

1. This instrument is intended to be used under the following OVERVOLTAGE CATEGORY II, and

POLLUTION DEGREE 2,

2. Use this instrument within the following ambient temperature and humidity.

a. Temperature: 0~50°C

b. Humidity: 45~85% RH

3. Avoid the following when selecting the mounting location:

a. Rapid changes in ambient temperature which may cause condensation.

b. Corrosive or inflammable gases.

c. Direct vibration or shock to the mainframe,

d. Water, oil, chemicals, vapor or steam splashes.

e. Excessive induction noise, static electricity, magnectic fields or noise

f. Exposure to direct sunlight,

g. Excessive heat accumulation.

ABUS TECHNOLOGIES INC.

8

Page 9

7. CONFIGURATION

7.1 Terminal Configuration

USI

7.2 Single Input Type Configuration

7.3 Double Input Type Configuration

8. OPERATION

For best results, you may use the shielded signal cable to avoid power spikes.

Check all the wires before operating the instrument. Series of instruments can be used

ABUS TECHNOLOGIES INC.

9

Page 10

with instrument for isolation and distribution of signal regarding to your application may

be for recording, controlling through DCS, PLC, etc. They are widely used in all kinds

of industries such as oil, chemical, petro-chemical, power, food, steel, pharmaceutical

industries etc.

S.NO. FUNCTION DESCRIPTION

1 Alarms For indication only.

2 Alarms For indication only

3 Calibration Through Model-1001

9. MAINTENANCE

9.1 Calibration of Instruments

The operation can be realized through ABUS-1001 Operator. The set parameters use the same

USI

calibration way as that of 585 and support automatic calibration.

9.2 Operation Environment

At mounting position strong vibration or strong electromagnetic impact from signal terminal,

power terminal, power terminal and room is not allowed. In operation environment, poisonous or harmful

matters which will corrode metals and plastics are not allowed to exist. Please keep the operation

environment dry for the precise output.

9.3 Troubleshooting

There are two kinds of trouble in input signals: input trouble (open circuit, short circuit) and

beyond span trouble.

Output ways at input trouble: Instruments can select beyond-span gain output and general output.

Gain Output

At the condition of beyond upper limit, output signal has a gain exceeding 5% of normal output

value;

At the condition of beyond lower limit, output signal has an output lower than 5% of lower limit; if

lower limit is zero (i.e.0 ~ 5 V) then output is 0 V.

General Output

At the condition of beyond upper limit, output maximum value or setting value;

At the condition of beyond lower limit, output minimum value or setting value;

At the condition of trouble, keep output value or setting value before output trouble;

Under trouble of input signal, trouble light of instrument flickers to indicate signal trouble.

ABUS TECHNOLOGIES INC.

10

Page 11

10. SAFETY PRECAUTIONS

1. The unit should be powered for 15 minutes before use.

2. Use in ambient temperature of 0-60˚C.

3. Avoid vibrations, shock, excessive dust, corrosive chemical materials or gaseous

environment.

4. Input wire should not be too long. If measured signal have to be far away from the

unit, please use 2-core shielded cable.

5. Use this instrument in the scope of its specifications, otherwise fire or malfunctions

may result.

6. Contact of the instrument, with organic solvents or oils should be avoided.

7. Do not turn on the power supply until all of the wiring is completed. Otherwise

USI

electrical shock, fire or malfunction may result.

8. Do not disassemble, repair or modify the instrument.

9. All connections should be tightened properly.

10. Power supply should be constant, should not be fluctuating.

11. WARRANTY

ABUS provides the original purchaser of this instrument a one (1) year warranty

against defects in material and workmanship under the following terms:

The one year warranty begins on the day of shipment as stated on the sales bill.

During the warranty period all costs of material and labor will be free of charge

provided that the instrument does not show any evidence of misuse.

For maintenance, return the instrument with a copy of the sales bill to our factory.

All transportation and insurance costs should be covered by the owner of the

equipment.

Should any sign of electrical or mechanical shock, abuse, bad handling or misuse

be evident the warranty voids and maintenance costs will be charged.

ABUS TECHNOLOGIES INC.

www.abustek.com, E-M ail: info@abustek.com

ABUS TECHNOLOGIES INC.

11

Loading...

Loading...