Page 1

Functional Specifications

Performance Specifications

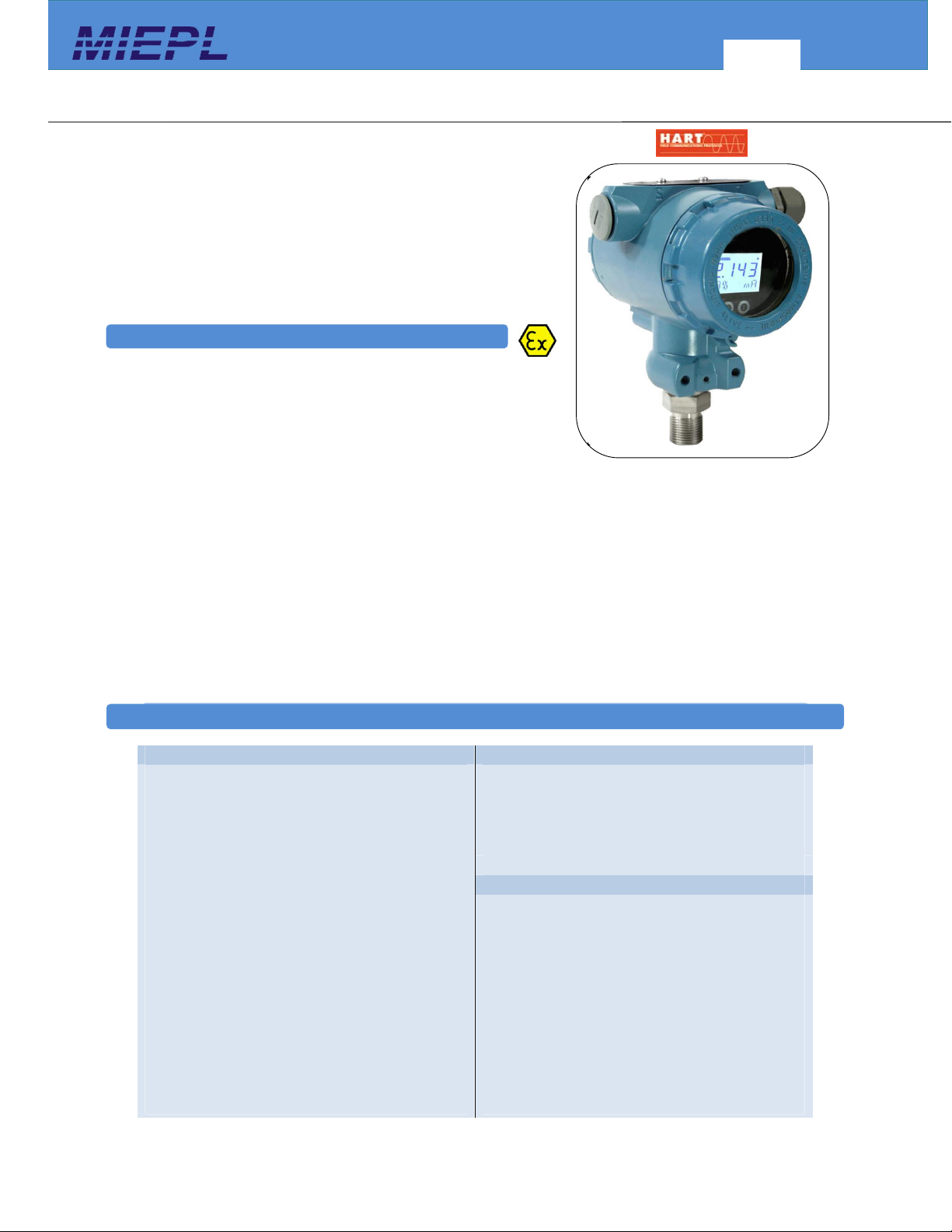

• HART Protocol communication interface

SMART PRESSURE TRANSMITTER

(501P)

501P

• 0.1% inaccuracy and non-linearity

• High Rangeability

• 0 – 0.0016 bar (1. 6kpA) till -1/0 -600 bar

• Automatic temperature compensation

• 4 - 20 mA output

• True non-interactive zero and span

• Local zero and span adjustment

• Totally Field configurable with keypad

• Bright Backlit LCD indicator

• Adjustable damping

• Indication in engineering units

• AISI 316L or Hasteloy C Wetted P

• Robust design

• Small and light weight

• Weather-proof housing

• Intrinsically safe as option

• Explosion Proof as option

DESCRIPTION

MIEPL 501P Smart Pressure Transmitter uses as its measuring principle, the well

known and field proven technique of sensing a crystal silicon chip and a

diaphragm micro-machined into the chip, enhanced by microprocessor based

electronics.

Designed for process control applications, these 2-wire transmitters generate a

4-20 mA signal proportional or characterized to the applied pressure. This signal can be transmitted over a pair of twisted wires

through long distances (limited only by the wire resistance and load). Remarkable features of the transmitters are its 0.075%

inaccuracy and non-linearity(optional), 20:1 rangeability, compactness and light weight.

The pressures are directly applied to the isolating diaphragm that provide isolation and resistance against process fluid corrosion.

Being microprocesor based, the electronic circuit is extremely versatile and accurate. Combined with the sensor precision, it

provides the high accuracy and rangeability.

Transmitter performance is improved by continuous monitoring of the sensor temperature and corresponding auto corrections.

A local display permits easy reading and writing of data and easy configuration of device parameter without requiring Hart

Communicator.

TECHNICAL SPECIFICATIONS

Process Fluid : Liquid, gas or vapor

Range : 0-0,0016 to -1-0-600 bar

Output signal : Two wire 4-20, 20-4 mA and HART

Power supply : 12 -45 VDC

Load limitation : 0-600Ω for 24VDC

Indicator : LCD Indicator

Hazardous area* : IP67 weather-proof, intrinsically safe and

Zero and span : Non-interactive local adjustment

Ambient Temp. : -20 to 80°C display -10 to 70°C

Process Temp. : -20 to 80/130°C, -65 to 150°C, 0 to 200, 0-

Storage Temp. : -40 to 85°C

Turn-on time : Performs within specifications in less than

Overpressure : 400%

Humidity limits : 0 – 100% RH

Damping Adj. : Adjustable

Configuration : By push button on the transmitter or HC,

protocol

explosion proof EEx ia, EExd IIC, T6, T5, to

EN 50.014, EN 50.018 and EN 50.020 for

Zon 0 IIA, IIB, IIC

350°C

120 milliseconds after power is applied

PC using HART

Protocol

Resolution : ±0.01 %

Inaccuracy : ±0.1%

Temperature effect : ±0.1 %/10K Zero and Span

Power Supply effect : Negligible between 12 and 45 VDC

Mounting Effect : Any position, No span effect

EMC : EN 50081-1, EN 50082-2, 89/336/EEC

Physical Specifications

Electrical Connection : ½” – 14 NPT

Process Connection : M G1/2, M20, G½NPT, cassette type

Wetted parts : AISI 316L or Hastelloy

Filling fluid : Silicone oil

Electronic housing : Injected aluminum with polyester

painting (RAL 5014) NEMA 4X, IP66

Identification plate : 304 SS*

Approximate weight : 1.6 kg

Mounting : Directly supported by piping or

optionally with mounting bracket for

2” pipes or with direct or remote

seats

*Optional

Page 2

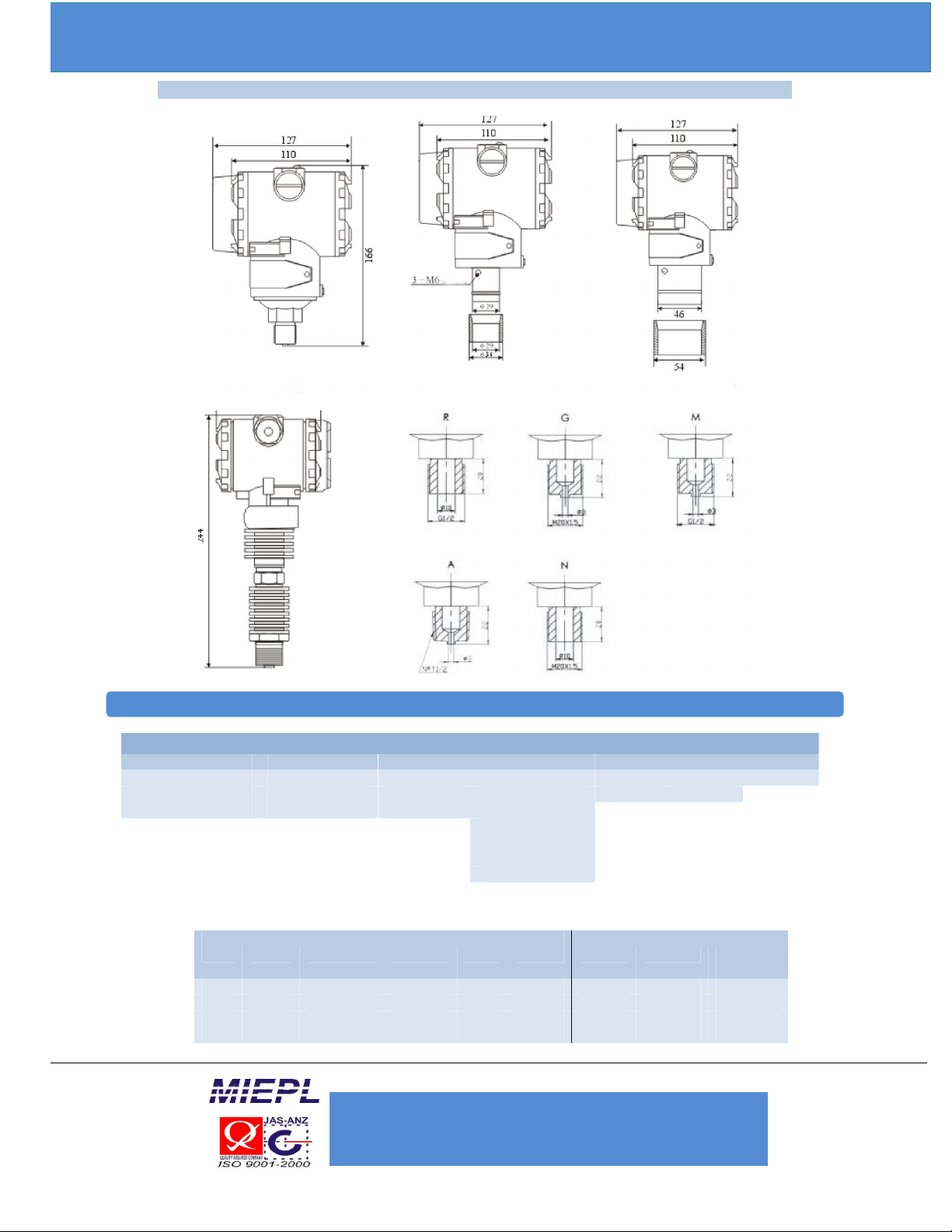

Dimensions

501P

SENSOR

TYPE MATERIAL

CONNECTION

DISPLAY

TYPE RANGE

A1 Standard

W Weather Proof

1 316L

R G ½” hole 10mm

A None

G Gauge

X Specify

A2 With Flanged

P Explosion proof

2 304S

G M20 hole 3mm

B LCD

A Absolute

I Intrinsically safe

4 Hast

e

loy C M G ½” hole 3mm

A ½” 14 NPT

N M20 hole 10mm

P ½” NPT (F)

Y Other

(A2, other)

NOTE:

New

3 PushButton Configurable display available

as option, Add GD to the Code.

FLANGE SIZE (MM)

BOLT HOLE (MM)

Code Size Specification

Diameter

A** B

*** Amount

Diameter

Distribution

A 3” 150lb 190.5 30 66 4 19 152

B 4” 150lb 228.6 30 89 8 19 190

C 3” 300lb 209.6 35 66 8 22.2 168

D 4” 300lb 254 38 89 8 22.2 200

H.O.

: 101, ‘Dwarkashish’, A

-

158, Main Vikas Marg, Shakarpur, Delhi

-92

ORDERING INFORMATION

Diaphragm

* NOTE: Below Code to be used only with Type(A2) Flanged Diaphragm

Flange Thickness *** Effective Diaphragm Area

**

INSTRUMENTS LIMITED

Tel : +91-11-22014325, 22014327, 65094516. Fax : +91-11-22014326

Web : www.miepl.com E-mail : mil@miepl.com, info@miepl.com

Works : F-12, Site-B, UPSIDC, Ind Area, Surajpur, Greater Noida - (UP)

Diameter

Loading...

Loading...