AMC 1222 DUAL

CARBON MONOXIDE AND NITROGEN DIOXIDE

MULTI FUEL EXHAUST SENSING MODULE

WITH COMFORT ZONE TECHNOLOGY

Sensor types: Dual electrochemical CO, NO

Output signal: Standard stepped, common for CO, NO

and “Comfort Zone”

Fail: 0 VDC or 0 mA*

Normal: 1 VDC or 4 mA*

Low: 2 VDC or 8 mA*

High: 3 VDC or 12 mA*

Comfort Zone: 2 VDC or 8 mA*

*Note: Max 250 Ω load on current signal

LED indicators:

Green: Power (steady)/fail (flashing)

Red: CO high (steady)/low (flashing)

Red: NO

Amber: Comfort Zone alarm

Standard alarms/signal trip points:

CO: Low 25 or 35 PPM, high 100 PPM

NO

Range: CO: 0-100 PPM

NO

Time Delays: Minimum run time: five minutes, user selectable

Alarm delay: five minute, user selectable

Delay on power up: 30 seconds

Operating temperature range: -20°C to +40°C

Ambient humidity: 10%-95% RH non-condensing

Sensor life: > five years in air for CO (three year warranty)

> three years in air for NO

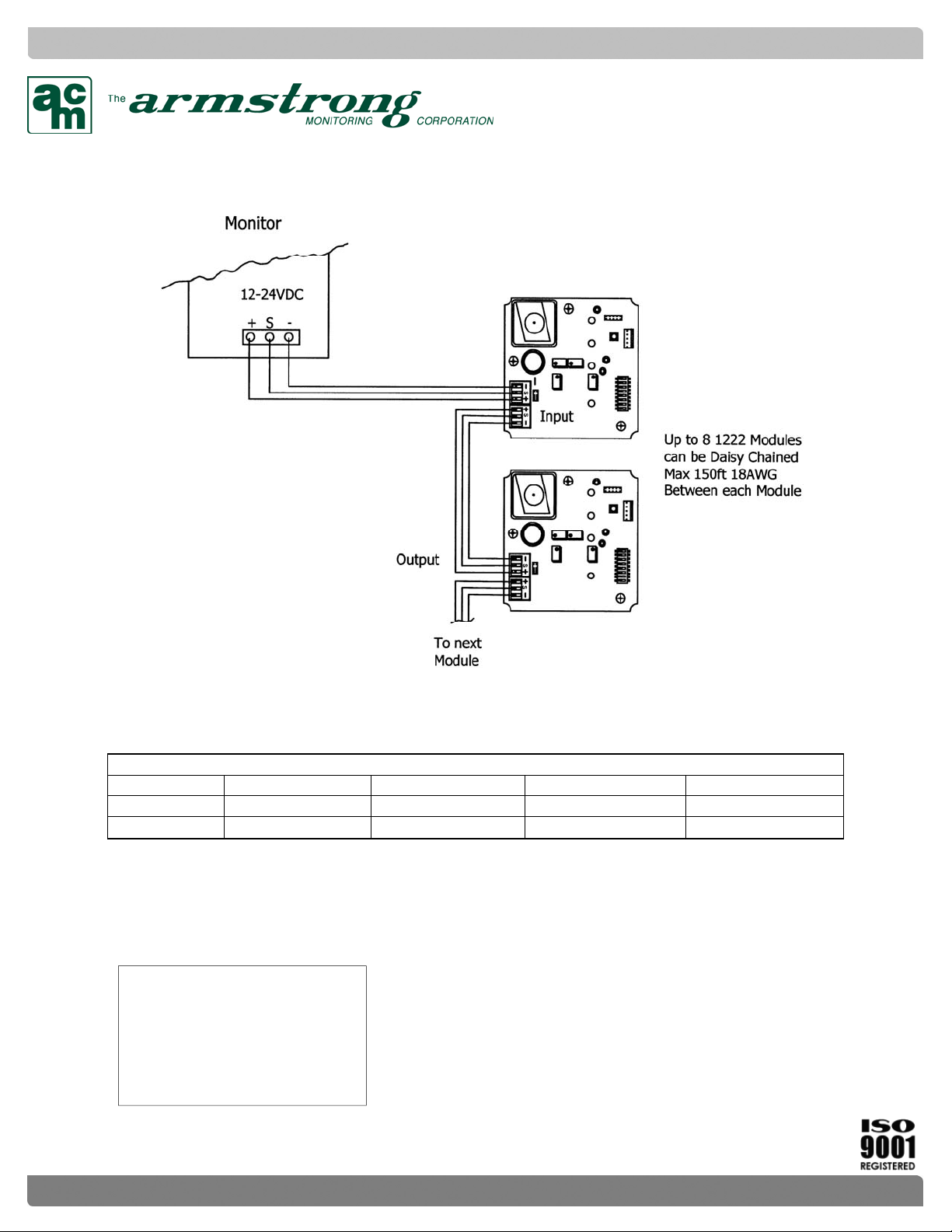

Wiring: Three conductor, shielded cable

Power requirement: 12-24 VDC 35 mA (voltage configuration)

Sensor response time: CO: 90% response in less than two minutes

NO

Central monitor requirement:

Enclosure: PVC, standard venting, optional water resistant venting

: Low 1 PPM, high 3 PPM

2

Comfort Zone:

Alarm trip point is user adjustable at nuisance

concentrations. Active when diesel fumes are present.

: 0-3 PPM

2

Designed for compatibility with existing AMC and most

competitors’ analog, digital or computer interfaced

systems, including a majority of present installations.

high (steady)/low (flashing)

2

55 mA (current configuration)

: 90% response in less than 30 seconds

2

2

2

(one year warranty)

2

The AMC 1222 combines electrochemical carbon monoxide

and nitrogen dioxide sensors to provide the ultimate solution

to any vehicle exhaust monitoring application.

Providing cost effective solutions for single or multi-point

applications, the AMC 1222’s voltage or current output can

be interfaced with standard Armstrong panels, and most

competitors’ equipment for cost effective upgrades. Dual

sensor and multidrop-ready configuration ensure that

wiring and controller requirements are substantially

reduced when compared to standard systems.

COMFORT ZONE TECHNOLOGY:

Diesel exhaust has historically been very difficult to monitor.

Due to the wide variety of pollutants, including carbon

monoxide, oxides of nitrogen, sulfur compounds, as well as

carcinogenic particulates, it is impractical to attempt to

monitor for all possible toxins. Carbon monoxide, nitrogen

dioxide and carbon dioxide have been historically used as

general indicators of air quality in these applications. Because

of the widely varying composition of diesel exhaust, this

method has resulted in inconsistent ventilation control as well

as worker discomfort and complaints.

By applying a combination of carbon monoxide and nitrogen

dioxide sensing, with an interactive logic function, an

effective solution can be provided cost effectively for diesel as

well as varied fuel facilities. Simple user adjustment allows

subjective sensitivity adjustment for control of air quality

issues.

In using this logic, increased sensitivity is engaged only when

trace nitrogen dioxide levels are present, indicating the

presence of diesel vehicles. This acts as an effective energy

saving feature, active only with diesel exhaust.

The Armstrong Monitoring Corporation 215 Colonnade Road South Ottawa, Ontario K2E 7K3

Tel: 613.225.9531 Fax: 613.225.6965 North America: 800.465.5777 www.armstrongmonitoring.com

AMC 1222 WIRING DIAGRAM

AMC 1222 Series Order Code Matrix

Order Code CO Low Trip Point CO High Trip Point NO2 Low Trip Point NO2 High Trip Point

AMC 1222-01 35ppm 100ppm 1ppm 3ppm

AMC 1222-02 25ppm 100ppm 1ppm 3ppm

For more information:

Authorized Distributor

The Armstrong Monitoring Corporation 215 Colonnade Road South Ottawa, Ontario K2E 7K3

Tel: 613.225.9531 Fax: 613.225.6965 North America: 800.465.5777 www.armstrongmonitoring.com

Warranty: All Armstrong equipment is warranted against defects in materials and workmanship for two years

from date of delivery, except sensors. Please contact factory for sensor warranty. During the warranty period,

we will repair or replace components that prove, in our opinion, to be defective. We are not liable for

auxiliary interfaced equipment, or consequential damage. All warranty items must be returned by prepaid

freight.

Note: Due to ongoing product development, the manufacturer reserves the right to change specifications without

prior notice. The information contained herein is based on data considered accurate. However, no warranty is

expressed or implied regarding the accuracy of this data.

Rev. 290605

Loading...

Loading...