AbsolutAire 8800 User Manual

Altivar® 31

Adjustable Speed AC Drives

Catalog

April

05

File 8800

CONTENTS

Description Page

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Altivar® 31 Adjustable Speed AC Drives

Drives Product Support

DRIVES PRODUCT SUPPORT

The Product Support Group is staffed from 8 am to 6 pm Eastern time for

product selection, start-up assistance, or diagnosis of product problems and

advice for the correct course of action. Emergency phone support is

available 24 hours a day, 365 days a year.

Toll-free: 888-Square D (888-778-2733)

Telephone: 919-266-8600

E-mail: drive.products.support@us.schneider-electric.com

Fax: 919-217-6508

2

© 2004–2005 Schneider Electric All Rights Reserved

4/2005

ATV31HU15M3X

ATV31H037M2A

Altivar® 31 Adjustable Speed AC Drives

Product Overview

PRODUCT OVERVIEW

The Altivar 31 (ATV31) adjustable speed AC drive controller incorporates the latest sensorless flux

vector technology into a compact, easy-to-use design for three-phase asynchronous squirrel-cage

motors. This versatile drive controller offers increased performance while maintaining costeffectiveness. The ATV31 drive provides advanced speed control capabilities for motors from

0.25–20 hp (0.18 to 15 kW). The controllers range from:

• 0.25 to 3 hp (0.18 to 2.2 kW), 208/230/240 V, single-phase input

• 0.25 to 20 hp (0.18 to 15 kW), 208/230/240 V, three-phase input

• 0.5 to 20 hp (0.37 to 15 kW), 400/460/480 V, three-phase input

• 1 to 20 hp (0.75 to 15 kW), 525/575/600 V, three-phase input

Industrial users and OEMs who specialize in material handling, pump, fan, packing, packaging, and

general purpose motor control applications will find the features and functions of the ATV31 drive

controller well suited for their use.

Key benefits

• Saves valuable panel space with a compact design and side-by-side mounting capability up to 50 °C

(122 °F)

• Designed as a robust and reliable fourth-generation drive

• Meets international standards

• Integrates Modbus

economical solution for networking mini-drives into an industrial network

• Offers a choice of two integrated interfaces:

— ATV 31 •••••• with display and menu navigation keys

— ATV 31 ••••••A with display, menu navigation keys, and local control via Run/Stop keys and

speed reference potentiometer (not available for 575 V controllers)

• Supplied with a heatsink for normal environments and ventilated enclosures

®

and CANopen protocols as standard into the drive controller, providing an

1

Functions

The ATV31 drive controller has six logic inputs, three analog inputs, one logic/analog output, and two

relay outputs. Integrated into the drive controller are the following main functions:

• Motor and drive protection

• Linear, S, U, and customized acceleration and deceleration ramps

•+/- Speed

• 16 preset speeds

• PI references and regulator

• Two-wire or three-wire control

• Brake sequence

• Automatic catch-on-the-fly with speed detection and automatic restart

• Fault configuration

• Stop type configuration

• Configuration saved in the drive controller

• Assignment of several functions to one logic input

1. A bullet (•) in the catalog number represents a digit that changes based on the drive specifications.

4/2005 © 2004–2005 Schneider Electric All Rights Reserved

3

Altivar® 31 Adjustable Speed AC Drives

d

it

kit

tif

D

B

k

tif

VW3A31101

Field Installed Kits

Options and accessories

The following options and accessories are available for the ATV31 drive controller:

• Braking resistors

• EMC (RFI) input filters

• DIN rail mounting plates

• UL Type 1 conduit entrance kit

• Adapter plate for replacing an Altivar 28 (ATV28) drive controller

• User interface and communication options

1

.

u

con

Conduit entrance kit

ATV18 kit.tif

ATV28 replacement kit

e.

ra

yn

FIELD INSTALLED KITS

Conduit entrance kits

This conduit box, allowing three or more conduit entries, attaches to the bottom of the drive controller.

With the addition of this kit and without removal of the protective vent cover on the top of the drive, the

degree of protection is UL Type 1.

ATV28 replacement kits

These brackets adapt the spacing of the ATV31 mounting holes to match the ATV28 drive controller,

which allows the ATV31 drive to use the panel holes and mounting hardware already in place for the

ATV28 controller.

EMC (RFI) input filter

The EMC input filter allows the drive to comply with European (CE) conducted emissions standard

EN55022 Class B. An EN55011 Class A filter is built into the ATV31 drive controller (ATV31••••N4,

ATV31••••M2 only).

DIN rail kit

This kit allows DIN rail mounting of ATV31 drive controllers, frame sizes 1–6.

Dynamic braking resistor kits

Dynamic braking resistors packaged in UL Type 1 enclosures are available for high-inertia applications

requiring rapid deceleration times. The kits mount separately.

Dynamic braking resistor

Remote keypad display mounting kit

This kit is used to mount a keypad display remotely, such as on the door of a wall-mounted or floorstanding enclosure. The remote keypad display offers the same features as the drive local keypad

display, with the addition of (a) run, stop/reset, and forward/reverse buttons; and (b) an access locking

switch. Up to four complete configurations can be stored in the remote keypad display and transferred

to other drives of the same rating. The kit has an IP65 rating and includes a remote-mount keypad

display, hardware, and a 3 m (10 ft) cable for saving and downloading configuration files.

Remote keypad display

1. EMC = electromagnetic compatibility; RFI = radio frequency interference.

4

© 2004–2005 Schneider Electric All Rights Reserved

4/2005

i

te sw.t

if

i

bl

if

563030

pwrsu

PowerSuite Software

e.t

te ca

pwrsu

Cable and connectors

Ethernet/Modbus bridge

563031563032

Altivar® 31 Adjustable Speed AC Drives

Catalog Numbers

PowerSuite™ commissioning software for PCs and HP® Jornada® Pocket PCs

This Microsoft® Windows®-based software offers the following functionality:

• Display, configure, and adjust the parameters

• Upload and download configurations

• Operate the drive controller

• View the fault history

• Create or modify a configuration in stand-alone mode and transfer it to an ATV31 drive controller

New options have been added for the ATV31 drive, such as an oscilloscope function, parameter name

customization, configuration locking using a password, and creation of a user menu.

Communication options

The ATV31 drive connects directly to Modbus and CANopen networks via an RJ45 connector, which

supports both protocols. The communication function provides access to the drive controller’s

configuration, adjustment, control, and monitoring functions. Various communication options are

available such as cables, junction boxes, and terminators.

Ethernet/Modbus bridge

The ATV31 drive can be connected to an Ethernet network via an Ethernet/Modbus bridge for control

and monitoring. Ethernet communication is primarily intended for the following applications:

• Coordination with PLCs

• Local or centralized supervision

• Communication with production management software

• Communication with remote I/O

• Communication with industrial control products

FIPIO/Modbus gateway

Profibus DP/Modbus

gateway

Communication gateways

The ATV31 drive can connect to other communication networks via the following gateways for control

and monitoring:

• Fipio/Modbus

• DeviceNet/Modbus

• Profibus DP/Modbus

CATALOG NUMBERS

Use the table below as a guide to interpreting ATV31 drive controller catalog numbers. ATV31HU15M2A

is used as an example.

Drive controller

family

ATV31 H U15 M2 A

Type Rating Voltage range Variation

Heatsink

product

0: 0 to 0.99 kW

U: 1 to 9.99 kW

D: 10 to 99.99 kW

M2: 200 V / 240 V, 1 phase

M3X: 200 V / 240 V, 3 phase without filter

N4: 380 V / 500 V, 3 phase

S6X: 525 V / 600 V, 3 phase without filter

A: with local control panel

4/2005 © 2004–2005 Schneider Electric All Rights Reserved

5

Altivar® 31 Adjustable Speed AC Drives

Technical Specifications

TECHNICAL SPECIFICATIONS

Environment

• IP20 without protective vent cover, NEMA 1, UL open type

• IP21 on wiring terminals

Degree of protection

Resistance to vibration

Resistance to shock

Pollution degree

Maximum relative humidity

Maximum ambient temperature

Altitude

Operating position

Maximum permanent angle in relation to the

normal vertical mounting position

Electrical characteristics

Input voltage

Input frequency

Input phases

Output voltage

Output frequency

Output phases

Speed range

Transient overtorque

Maximum transient current

Braking torque

Frequency resolution

Switching frequency

Drive controller protection

Motor protection

• IP31 and IP41 all other areas

• UL Type 1 without removal of the protective vent cover from the top of the controller and with the addition of the

Conduit Entry Kit.

Conforming to IEC/EN 60068-2-6: 1.5 mm peak to peak from 3 to 13 Hz, 1 gn from 13 to 150 Hz

15 g for 11 ms conforming to IEC/EN 60068-2-27

Pollution degree 2 according to UL 840. Protect the drive against dust, corrosive gas, and falling liquid.

96% maximum, non-condensing and without dripping (provide heating system if there is condensation)

Conforms to IEC 60068-2-3

Storage: -13 to +158 °F (-25 to +70 ° C)

Operation: +14 to +122 °F (-10 to +50 °C) without vent cover removed and without derating;

+14 to +140 ° F (-10 to +60 ° C) with vent cover removed and with derating. Refer to derating curves on page 30.

Up to 3,300 ft (1,000 m) without derating; derate by 1% for each additional 330 ft (100 m)

ATV31••••M2 (1 phase): 200 V -15% to 240 V +10%

ATV31••••M3X (3 phase): 200 V -15% to 240 V +10%

ATV31••••N4 (3 phase): 380 V -15% to 460 V +15%

ATV31••••S6X (3 phase): 525 V -15% to 575 V +15%

50/60 Hz ±5%

ATV31••••M2: 1

ATV31••••M3X: 3

ATV31••••N4: 3

ATV31••••S6X: 3

Maximum voltage equal to input voltage

0 to 500 Hz

3

1:50

170–200% nominal motor torque (typical value)

Up to 150% of nominal drive controller current for 60 seconds

With braking resistor: 100% of nominal motor torque continuously and up to 150% for 60 s.

Without braking resistor:

• Drive controllers ≥ ATV31•U22••: 30% of nominal motor torque

• Drive controllers ≤ ATV31•U15••: 50% of nominal motor torque

• Drive controllers ≤ ATV31•075••: 100% of nominal motor torque

• Drive controllers ≤ ATV31•018M2: 150% of nominal motor torque

Display: 0.1 Hz

Analog inputs: 0.1 Hz to 100 Hz maximum [(high speed – low speed)/1024]

Adjustable from 2.0 kHz to 16 kHz. Randomly modulated by default, but this can be disabled.

Galvanic isolation between power and control (power supplies, inputs, outputs)

Protection against short circuits:

• within internal power supplies

• between output phases

• between output phases and ground

Protection against input phase loss

Thermal protection against overheating and overcurrents

Undervoltage and overvoltage faults

Overbraking fault

Thermal protection, integrated into the drive controller, by I2t calculation

Protection against motor phase loss

6

© 2004–2005 Schneider Electric All Rights Reserved

4/2005

Electrical characteristics (continued)

Dielectric strength

Resistance to ground

Communication

Modbus

CANopen

Codes and standards

Electromagnetic immunity

Electromagnetic compatibility

Conducted and radiated

emissions for drive controllers

(Consult page 16 for additional

EMC filters)

Prospective short-circuit current ICC 1

Refer to “Recommended fuses or Powerpact®

circuit breakers” on page 26

Maximum connection capacity and

tightening torque

of the power supply terminals, motor,

braking module, and DC bus

Electrical isolation

Altivar® 31 Adjustable Speed AC Drives

Technical Specifications

Between ground and power terminals:

ATV31••••M2 and M3X: 2040 Vdc

ATV31••••N4: 2410 Vdc

ATV31••••S6X: 2550 Vdc

>500 MΩ (electrical isolation) 500 Vdc for 1 minute

Modbus and CANopen are integrated into the drive controller and available via an RJ45 connector.

RS-485 multidrop serial link characteristics:

• Modbus in RTU mode

• Services supported: decimal function codes 03, 06, 16, 23, and 43

• Broadcasting

• Number of addresses: drive address can be configured via the local keypad display from 1 to 247

• Maximum number of ATV31 drive controllers: 31 (two 470 Ω master pull-down resistors)

• Transmission speed: 4800, 9600, or 19200 bps

• The following devices can be connected to the RS-485 link:

— Remote keypad display

— PowerSuite software workstation

—PLC

— Microprocessor card

—PC

To connect the ATV31 drive controller to a CANopen network, use the VW3CANTAP2 adapter.

The following services are supported:

• Implicit exchange of Process Data Object (PDO):

— Two predefined PDOs conforming to DSP 402 Velocity Mode

— Two configurable PDOs (data and transmission type)

— PDOs can be exchanged between slave devices

• Explicit exchange of Service Data Object (SDO):

— One receive SDO and one transmit SDO

• Boot-up messages, emergency messages, node guarding, and producer and consumer heartbeat

• Number of addresses: drive controller address can be configured via the integrated terminal

from 1 to 127

• Maximum number of drive controllers: 127

• Transmission speed: 10, 20, 50, 125, 250, 500 kbps or 1 Mbps

• UL Listed per UL 508C as incorporating electronic overload protection: UL File E164874 CCN NMMS

• CSA Certified to CSA C22.2 No. 14: CSA File LR96921 Class 3211 06

• CE Marked in accordance with the European low voltage (73/23/EEC and 93/68/EEC) and EMC (89/336/EEC)

directives

• Conforms to applicable NEMA ICS, IEC, NOM, C-TICK, and ISO 9001 standards

ATV31 drives meet IEC and EN requirements, the strictest international standards for electrical industrial control

devices. They conform to EN 50178, governing electromagnetic compatibility and conducted and radiated emissions.

• IEC/EN 61000-4-2 level 3

• IEC/EN 61000-4-3 level 3

• IEC/EN 61000-4-4 level 4

All ratings:

IEC/EN 61800-3, environments 2 (industrial network) and 1 (public utility network) in limited distribution.

ATV31H018M2 to CU40N4:

• EN 55011, Class A, Group 1; EN 61800-3 Category C2 with additional EMC filter

• EN 55022, Class B, Group 1; EN 61800

ATV31HU22M2 to HD15N4:

• EN 55011, Class A, Group 2; EN 61800-3 Category C3 with additional EMC filter

• EN 55022, Class A, Group 1; EN 61800-3 Category C2

• EN 55022, Class B, Group 1; EN 61800-3 Category C1

ATV31H018M3X to HD15M3X with additional EMC filter:

• EN 55011, Class A, Group 1; EN 61800-3 Category C2

• EN 55022, Class B, Group 1; EN 61800-3 Category C1

ATV31••••M2

≤ 1000 A (ICC at connection point) for single phase power supply

ATV31H018M3X...HU40M3X, ATV31•037N4...•U40N4, ATV31H075S6X...HU40S6X

≤ 5000 A (ICC at connection point) for three-phase power supply

ATV31HU55M3X...HD15M3X, ATV31HU55N4...HD15N4, ATV31KU55N4...KD15N4, ATV31HU55S6X...HD15S6X

≤ 22000 A (ICC at connection point) for three-phase power supply

H018M2, H037M2, H055M2, H075M2, H018M3X, H037M3X, H055M3X, H075M3X, HU11M3X, HU15M3X

14 AWG (2.5 mm

HU11M2, HU15M2, HU22M2, HU22M3X, HU30M3X, HU40M3X, H037N4, H055N4, H075N4, HU11N4,HU15N4,

HU22N4, HU30N4, HU40N4, H075S6X, HU15S6X, HU22S6X, HU40S6X

10 AWG (5 mm

HU55M3X, HU75M3X, HU55N4, HU75N4, HU55S6X, HU75S6X

6 AWG (16 mm

HD11M3X, HD15M3X, HD11N4, HD15N4, HD11S6X, HD15S6X

3 AWG (25 mm

Electrical isolation between power and control (inputs, outputs, power supplies)

2

), 7.08 lb-in (0.8 N•m)

2

), 10.62 lb-in (1.2 N•m)

2

), 19.47 lb-in (2.2 N•m)

2

), 35.40 lb-in (4 N•m)

Between control and power terminals:

ATV31••••M2 and M3X: 2880 Vac

ATV31••••N4: 3400 Vac

ATV31••••S6X: 3600 Vac

• IEC/EN 61000-4-5 level 3 (power access)

• IEC/EN 61800-3, environments 1 and 2

4/2005

© 2004–2005 Schneider Electric All Rights Reserved

7

Altivar® 31 Adjustable Speed AC Drives

Technical Specifications

Electrical characteristics (continued)

Short-circuit and overload protection:

Internal supplies available

Configurable analog inputs

Three configurable analog inputs AI1, AI2, AI3.

Analog output configurable for

voltage, current, or logic output

Analog voltage output AOV

or

Analog current output AOC

or

Logic voltage output on AOC

Can assign either AOV or AOC, but not both.

Configurable relay outputs

R1A is a N.O. contact.

R1B is a N.C. contact.

R1C is the common.

R1 is programmable—factory set as a fault

relay (R1A is closed and R1B is open when the

controller is powered with no fault)

R2A, R2C

N.O. contact of programmable relay R2

Logic inputs LI

LI1, LI2, LI3, LI4, LI5, LI6

Maximum I/O connection capacity and

tightening torque

Acceleration and deceleration ramps

DC injection braking

Signaling

on the drive local keypad display

Scan time for reference change

One +10 V (-0 / +8%) supply for setpoint potentiometer (2.2 to 10 kΩ), maximum current 10 mA

One +24 V supply (minimum 19 V, maximum 30 V) for logic inputs, maximum current 100 mA

AI1: Analog input 0 to +10 V (maximum safe voltage is 30 V)

• Impedance: 30 kΩ

• Resolution: 0.01 V, 10-bit converter

• Precision: ± 4.3% of maximum value

AI2: Analog input 0 to +10 V (maximum safe voltage is 30 V)

Bipolar analog input 0 to ±10 V (maximum safe voltage is ±30 V)

The + or - polarity of the voltage on AI2 affects the direction of the setpoint and therefore the direction of rotation.

• Impedance: 30 k

• Resolution: 0.01 V, 10-bit + sign converter

• Precision: ± 4.3% of maximum value

AI3: Analog input X–Y mA; X and Y programmable from 0–20 mA

• Impedance: 250

• Resolution: 0.02 mA, 10-bit converter

• Precision: ± 4.3% of maximum value

Analog output 0 to 10 V, minimum load impedance 470 Ω

or

Analog output X to Y mA; X and Y programmable from 0–20 mA, maximum load impedance 800

• Resolution: 8 bits

• Precision: ± 1%

• Linearity: ± 0.2%

• Sampling time: 8 ms

or

AOC can be configured as a 24 V logic output with a minimum load impedance of 1.2 k

• Minimum switching capacity: 10 mA for 5 Vdc

• Maximum switching capacity on a resistive load (power factor = 1 and L/R time constant = 0 ms):

5 A for 250 Vac and 30 Vdc

• Maximum switching capacity on an inductive load (power factor = 0.4 and L/R time constant = 7 ms):

1.5 A for 250 Vac and 30 Vdc

• Sampling time: 8 ms

• Service life: 100,000 operations at maximum switching power;

1,000,000 operations at minimum switching power

Programmable logic inputs

• +24 V power supply (maximum 30 V)

• Impedance: 3.5 k

• State 0 if the difference between LIx and CLI is < 5 V, State 1 if the difference between LIx and CLI is > 11 V

• Sampling time: 4 ms

14 AWG (2.5 mm2)

0.6 N•m (5.31 lb-in)

Ramp profiles:

• linear, can be adjusted separately from 0.1 to 999.9 s

• S, U, or customized

Automatic adaptation of deceleration ramp time if braking capacities are exceeded,

possible inhibition of this adaptation (use of braking resistor).

DC injection braking can be initiated:

• By a signal on a programmable logic input

• Automatically as soon as the estimated output frequency drops to < 0.5 Hz, period adjustable from 0 to 30 s or

continuous, current adjustable from 0 to 1.2 In

• One red LED indicating the presence of drive voltage

• Four 7-segment displays

• Two CANopen status LEDs (RUN and ERR)

5 ms

Ω

Ω

Ω

• Linearity: ± 0.2% of maximum value

• Sampling time: 8 ms

• Shielded cable length: 100 m (328 ft) maximum

• Linearity: ± 0.2% of maximum value

• Sampling time: 8 ms

• Shielded cable length: 100 m (328 ft) maximum

• Linearity: ± 0.2% of maximum value

• Sampling time: 8 ms

Ω:

Ω.

8

© 2004–2005 Schneider Electric All Rights Reserved

4/2005

Altivar® 31 Adjustable Speed AC Drives

Technical Specifications

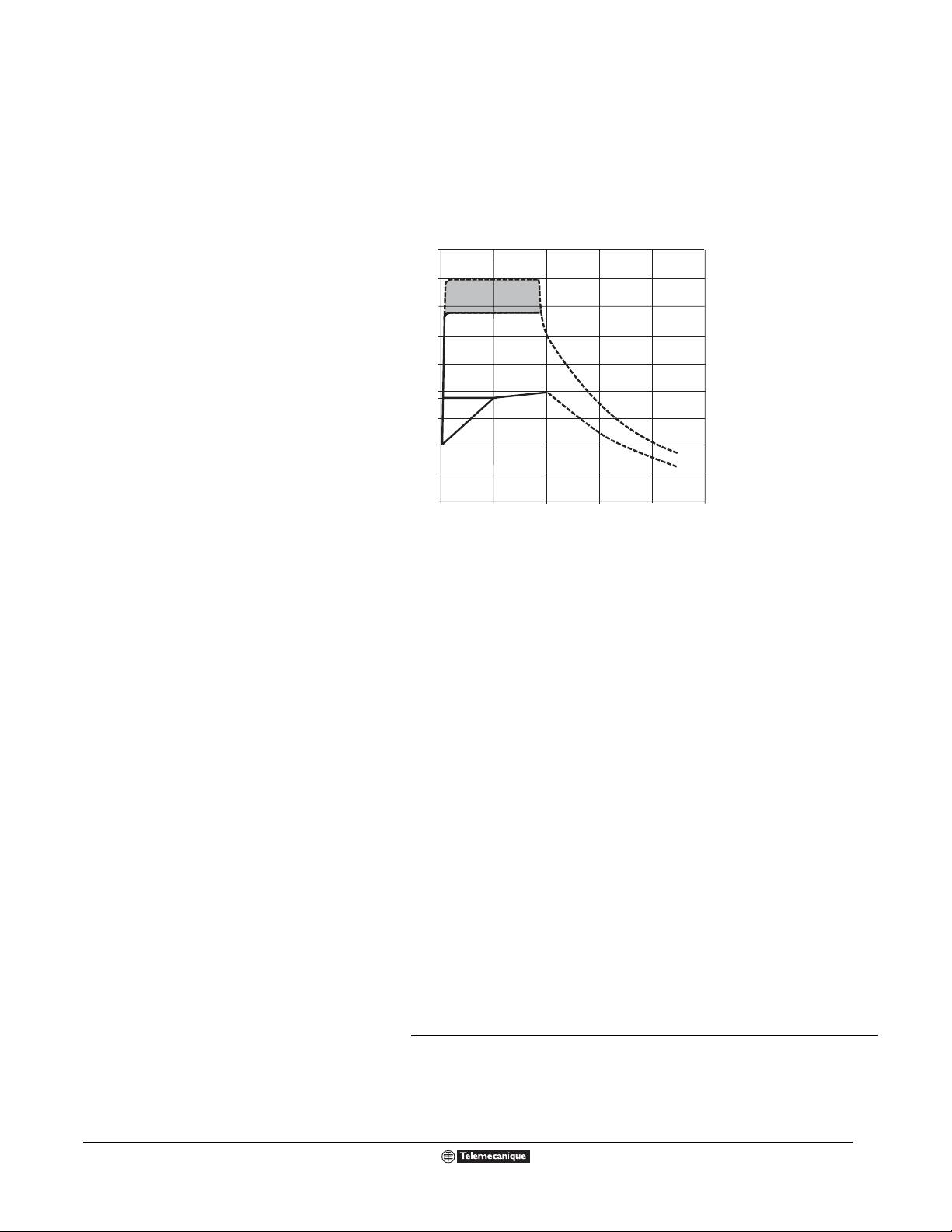

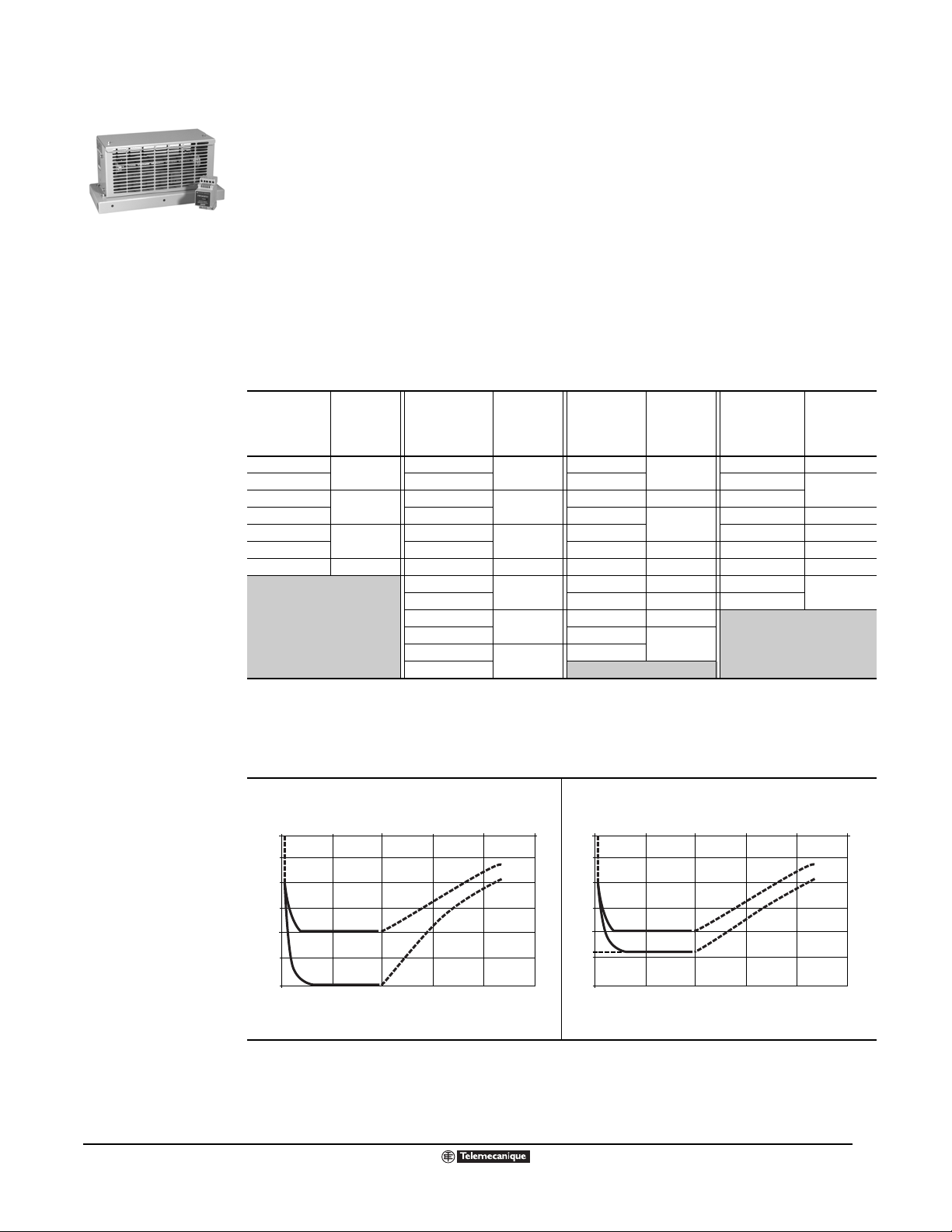

Torque characteristics (typical curves)

The torque characteristics curves below define the available continuous

torque and transient overtorque for both force-cooled and self-cooled motors.

The only difference is in the ability of the motor to provide a high continuous

torque at less than half the nominal speed.

Tn

2.25

563322.eps

Hz

1.75

1.7

1.50

1.25

0.95

0.75

0.50

0.25

2

3

1

2

1

0

0

25/30

50/60

4

75/90

100/120

1. Self-cooled motor: continuous useful torque

2. Force-cooled motor: continuous useful torque

3. Transient overtorque 1.7 to 2 Tn

1

4. Torque in overspeed at constant power

Special uses

Using a motor with a different rating than the drive

The drive can supply any motor with a power rating lower than that for which

it is designed.

For motors rated slightly higher than the drive, ensure that the load does not

exceed the continuous output current of the drive.

4/2005

Testing on a low power motor or without a motor

In a testing or maintenance environment, the drive can be run without

switching to a motor with the same rating as the drive (particularly useful in

the case of high power drives). This requires deactivation of motor phase loss

detection.

Connecting motors in parallel

The rating of the drive must be greater than or equal to the sum of the

currents of the motors connected to the drive.

External thermal protection must be provided for each motor.

If connecting three or more motors in parallel, we recommend installing an

output filter between the drive and the motors.

1. The nominal frequency of the motor and the maximum output frequency are adjustable

between 40 and 500 Hz.

NOTE: Check the mechanical overspeed characteristics of the selected motor with the

manufacturer.

© 2004–2005 Schneider Electric All Rights Reserved

9

Altivar® 31 Adjustable Speed AC Drives

Selection

SELECTION

208 V -15% / 240 V +10% at 50/60 Hz, single-phase input, three-phase output

ATV31 drive Motor Line supply (input) Drive controller (output)

Power

indicated

1

on

nameplate

2

kWhpAAkA A A A W

Power

indicated

1

on

nameplate

2

kWhpAAkA A A A W

ATV31H037M2

ATV31HU40MX3

Catalog

number

ATV31H018M2 0.18 0.25 3.0 2.5 1 10 1.5 2.3 24

ATV31H037M2 0.37 0.5 5.3 4.4 1 10 3.3 5.0 41

531248-10-M.tif

ATV31H055M2 0.55 0.75 6.8 5.8 1 10 3.7 5.6 46

ATV31H075M2 0.75 1 8.9 7.5 1 10 4.8, 4.6, 4.2

ATV31HU11M2 1.1 1.5 12.1 10.2 1 19 6.9 10.4 74

ATV31HU15M2 1.5 2 15.8 13.3 1 19 8.0 12.0 90

ATV31HU22M2 2.2 3 21.9 18.4 1 19 11.0 16.5 123

208 V -15% / 240 V +10% at 50/60 Hz, three-phase input, three-phase output

ATV31 drive Motor Line supply (input) Drive controller (output)

Catalog

number

ATV31H018M3X 0.18 0.25 2.1 1.9 5 10 1.5 2.3 23

ATV31H037M3X 0.37 0.5 3.8 3.3 5 10 3.3 5.0 38

ATV31H055M3X 0.55 0.75 4.9 4.2 5 10 3.7 5.6 43

ATV31H075M3X 0.75 1 6.4 5.6 5 10 4.8 7.2 55

531249-15-M.tif

ATV31HU11M3X 1.1 1.5 8.5 7.4 5 10 6.9 10.4 71

ATV31HU15M3X 1.5 2 11.1 9.6 5 10 8.0 12.0 86

ATV31HU22M3X 2.2 3 14.9 13.0 5 10 11.0 16.5 114

ATV31HU30M3X 3 3 19.1 16.6 5 19 13.7 20.6 146

ATV31HU40M3X 4 5 24.2 21.1 5 19 17.5 26.3 180

ATV31HU55M3X 5.5 7.5 36.8 32.0 22 23 27.5 41.3 292

ATV31HU75M3X 7.5 10 46.8 40.9 22 23 33.0 49.5 388

ATV31HD11M3X 11 15 63.5 55.6 22 93 54.0 81.0 477

ATV31HD15M3X 15 20 82.1 71.9 22 93 66.0 99.0 628

1)

For a drive equipped with a control potentiometer and with run and stop buttons, add an “A” at the end of the catalog number (for

example, ATV31HO37N4A). This option is not available for 575 V controllers.

2)

These power ratings and currents are for a maximum ambient temperature of 50 °C (122 °F) and a switching frequency of 4 kHz

in continuous operation. The switching frequency is adjustable from 2 to 16 kHz. Above 4 kHz, the drive controller reduces the

switching frequency in the event of excessive temperature rise. The temperature rise is controlled by a PTC probe in the power

module. Derate the nominal current if continuous operation above 4 kHz is required. Derating curves are shown on page 30 as a

function of switching frequency, ambient temperature, and mounting conditions.

3)

Current on a line supply with the indicated short-circuit current rating.

4)

Peak current on power-up, for the maximum voltage (240 V +10%).

5)

For 60 seconds.

6)

4.8 A at 200 V, 4.6 A at 208 V, 4.2 A at 240 V.

7

Refer to “Recommended fuses or Powerpact® circuit breakers” on page 26.

Max. line

current

at

208 V

Max. line

current

at

208 V

3

3

at

240 V

at

240 V

Shortcircuit

current

rating

Shortcircuit

current

rating

Max.

inrush

current

7

4

Max.

inrush

current

7

4

Nominal

rated

output

current In

Nominal

rated

output

current In

Transient

output

current

2

2,5

6

7.2 60

Transient

output

current

2

2,5

Total

dissipated

power at

rated load

Total

dissipated

power at

rated load

10

© 2004–2005 Schneider Electric All Rights Reserved

4/2005

ATV31HU75N4

Altivar® 31 Adjustable Speed AC Drives

Selection

400 V -15% / 460 V +15% at 50/60 Hz, three-phase input, three-phase output

ATV31 drive Motor Line supply (input) Drive controller (output)

Catalog

number

2

Power

indicated on

nameplate

3

kWhpAAkA A A A W

ATV31H037N4 0.37 0.5 2.2 1.7 5 10 1.5 2.3 32

531250-20-M.tif

ATV31H055N4 0.55 0.75 2.8 2.2 5 10 1.9 2.9 37

ATV31H075N4 0.75 1 3.6 2.7 5 10 2.3 3.5 41

ATV31HU11N4 1.1 1.5 4.9 3.7 5 10 3.0 4.5 48

ATV31HU15N4 1.5 2 6.4 4.8 5 10 4.1 6.2 61

ATV31HU22N4 2.2 3 8.9 6.7 5 10 5.5 8.3 79

ATV31HU30N4 3 3 10.9 8.3 5 10 7.1 10.7 125

ATV31HU40N4 4 5 13.9 10.6 5 10 9.5 14.3 150

ATV31HU55N4 5.5 7.5 21.9 16.5 22 30 14.3 21.5 232

ATV31HU75N4 7.5 10 27.7 21.0 22 30 17.0 25.5 269

ATV31HD11N4 11 15 37.2 28.4 22 97 27.7 41.6 397

ATV31HD15N4 15 20 48.2 36.8 22 97 33.0 49.5 492

Max. line

current

at

400 V

4

at

460 V

Shortcircuit

current

rating

7

Max.

inrush

current

5

Nominal

rated output

current In

3

Max.

transient

current

3,6

Total

dissipated

power at

rated load

525 V -15% / 575 V +15% at 50/60 Hz, three-phase input, three-phase output

1

ATV31 drive Motor Line supply (input) Drive controller (output)

Catalog

number

2

Power

indicated on

nameplate

3

Max. line

current

at

525 V

4

at

600 V

Shortcircuit

current

rating

7

Max.

inrush

current

5

Nominal

rated output

current In

3,6

Max.

transient

current

3,6

Total

dissipated

power at

rated load

kWhpAAkA A A A W

ATV31H075S6X 0.75 1 2.8 2.4 5 12 1.7 2.6 36

ATV31HU15S6X 1.5 2 4.8 4.2 5 12 2.7 4.1 48

ATV31HU22S6X 2.2 3 6.4 5.6 5 12 3.9 5.9 62

ATV31HU40S6X 4 5 10.7 9.3 5 12 6.1 9.2 94

ATV31HU55S6X 5.5 7.5 16.2 14.1 22 36 9.0 13.5 133

ATV31HU75S6X 7.5 10 21.3 18.5 22 36 11.0 16.5 165

ATV31HD11S6X 11 15 27.8 24.4 22 117 17.0 25.5 257

ATV31HD15S6X 15 20 36.4 31.8 22 117 22.0 33.0 335

1)

A 3% line reactor is required for all 575 V drive controller installations.

2)

For a drive equipped with a control potentiometer and with run and stop buttons, add an “A” at the end of the catalog number (for

example, ATV31HO37N4A). This option is not available for 575 V controllers.

3)

These power ratings and currents are for a maximum ambient temperature of 50 °C (122 °F) and a switching frequency of 4 kHz

in continuous operation. The switching frequency is adjustable from 2 to 16 kHz. Above 4 kHz, the drive controller reduces the

switching frequency in the event of excessive temperature rise. The temperature rise is controlled by a PTC probe in the power

module. Derate the nominal current if continuous operation above 4 kHz is required. Derating curves are shown on page 30 as a

function of switching frequency, ambient temperature, and mounting conditions.

4)

Current on a line supply with the indicated short-circuit current rating.

5)

Peak current on power-up, for the maximum voltage (460 Vac/575 Vac +15%).

6)

For 60 seconds.

7

Refer to “Recommended fuses or Powerpact® circuit breakers” on page 26.

4/2005 © 2004–2005 Schneider Electric All Rights Reserved

11

Altivar® 31 Adjustable Speed AC Drives

VW3A31852

d

it

kit

tif

ATV18

kit

tif

VW3A31101

Accessories

ACCESSORIES

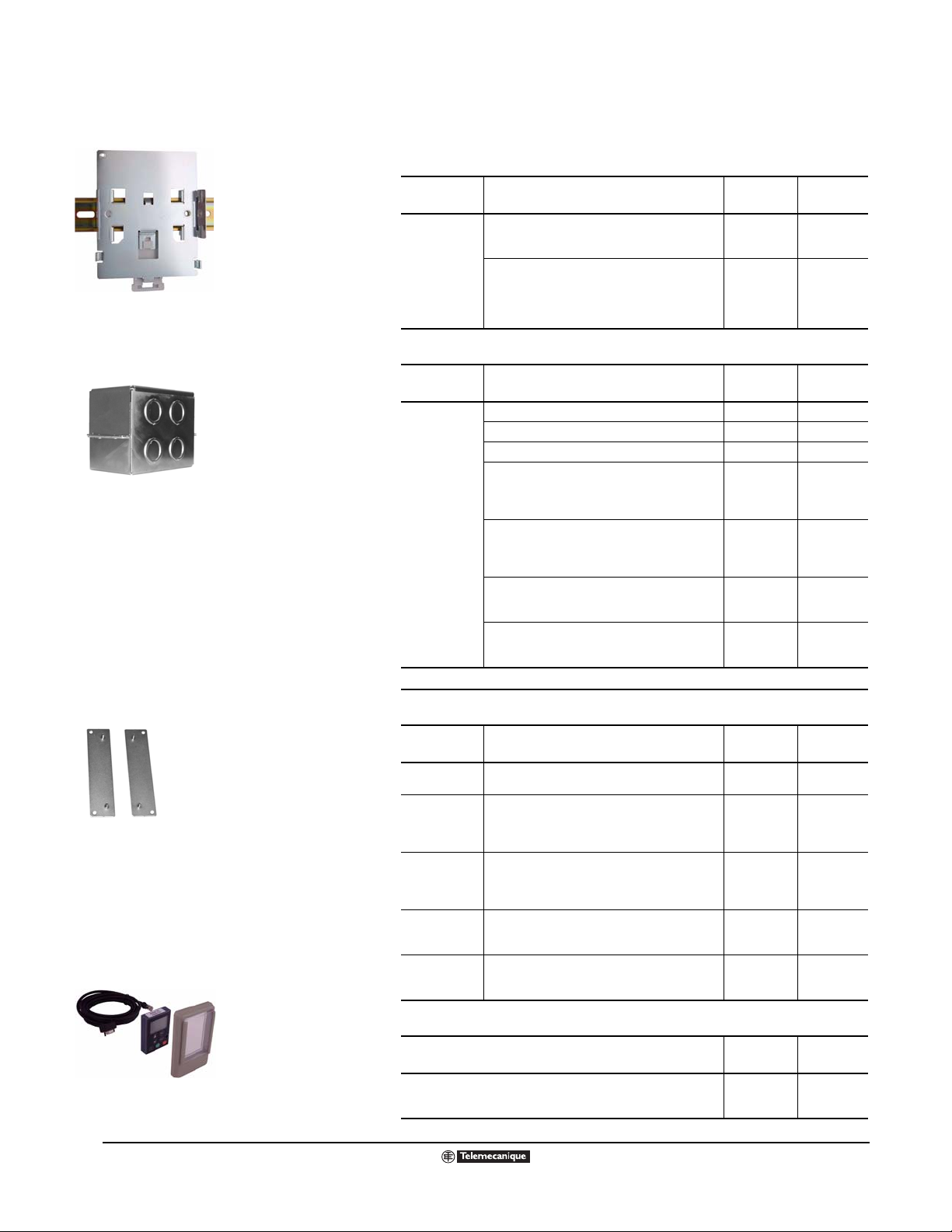

DIN rail mounting plate

Description For drives ATV31•••••••

Plate for

mounting

on DIN rail,

width 35 mm

UL Type 1 conduit entrance kit 1

Description For drives ATV31•••••••

Mechanical

device

attaching to

the bottom of

the ATV31

drive

1)

.

u

con

VW3A31852

VW3A3181•

Frame sizes 1–4

H018M2, H037M2, H055M2, H075M2,

H018M3X, H037M3X, H055M3X, H075M3X

Frame sizes 5–6

HU11M2, HU15M2,

HU11M3X, HU15M3X, HU22M3X,

H037N4, H055N4, H075N4, HU11N4, HU15N4,

H075S6X, HU15S6X

Catalog

number

VW3A11851 0.200 (0.44)

VW3A31852 0.220 (0.49)

Catalog

number

Weight

kg (lb)

Weight

kg (lb)

H018M2, H037M2, H055M2, H075M2 VW3A31812 0.400 (0.88)

H018M3X, H037M3X, H055M3X, H075M3X VW3A31811 0.400 (0.88)

HU11M3X, HU15M3X VW3A31813 0.400 (0.88)

HU11M2, HU15M2,

HU22M3X,

H037N4, H055N4, H075N4, HU11N4, HU15N4,

VW3A31814 0.500 (1.10)

H075S6X, HU15S6X

HU22M2,

HU30M3X, HU40M3X,

HU22N4, HU30N4, HU40N4,

HU22S6X, HU40S6X

HU55M3X, HU75M3X,

HU55N4, HU75N4,

VW3A31815 0.500 (1.10)

VW3A31816 0.900 (1.98)

HU55S6X, HU75S6X

HD11M3X, HD15M3X,

HD11N4, HD15N4,

HD11S6X, HD15S6X

VW3A31817 1.200 (2.65)

This device allows cables to be connected directly to the drive using conduits or cable glands.

.

VW3A31101

12

© 2004–2005 Schneider Electric All Rights Reserved

ATV28 replacement kit

Frame size For Drives ATV31•••••••

1–4

5–6

7

8

9

H018M3X, H037M3X, H055M3X, H075M3X,

H018M2, H037M2, H055M2, H075M2

HU11M2, HU15M2,

HU11M3X, HU15M3X, HU22M3X,

H037N4, H055N4, H075N4, HU11N4, HU15N4,

H075S6X, HU15S6X

HU22M2,

HU30M3X, HU40M3X,

HU22N4, HU30N4, HU40N4,

HU22S6X, HU40S6X

HU55M3X, HU75M3X,

HU55N4, HU75N4,

HU55S6X, HU75S6X

HD11M3X, HD15M3X,

HD11N4, HD15N4,

HD11S6X, HD15S6X

Remote keypad display

Description

For ATV31 drives of all ratings. Assembly includes:

• keypad display, cable fitted with two connectors

• seal and screws for IP65 mounting on an enclosure door

Catalog

number

Weight

kg (lb)

VW3A31821 0.227 (0.50)

VW3A31822 0.255 (0.56)

VW3A31824 0.591 (1.30)

VW3A31823 0.223 (0.49)

VW3A31825 0.445 (0.98)

Catalog

number

Weight

kg (lb)

VW3A31101 0.377 (0.83)

4/2005

Altivar® 31 Adjustable Speed AC Drives

D

B

k

if

Dynamic Braking Resistor Kits

e.t

ra

yn

DYNAMIC BRAKING RESISTOR KITS

The dynamic braking resistor kit allows the ATV31 drive controllers to function in quadrants 2 and 4 of

the four-quadrant speed/torque curve. In these quadrants of motor operation, the motor is essentially a

generator through which energy is transferred from the motor load back to the drive controller. This

results in elevated DC bus voltage to the drive controller, which can cause it to shut down to protect itself.

Dynamic braking resistor kits are commonly used to dissipate the excess energy generated by the motor

operating in this mode. The flow of current to the braking resistor is controlled by the dynamic braking

transistor. Applications include machines with high inertia, overhauling loads, and machines with fast

cycles.

The following table shows the minimum ohmic value of the resistor that can be used with the ATV31 drive

controllers. Using lower than recommended values will cause excessive current flow, exceeding the

rating of the dynamic braking transistor.

Minimum dynamic braking resistance values

240 V

single-phase

drive

catalog no.

ATV31H018M2

ATV31H037M2 ATV31H037M3X ATV31H055N4 ATV31HU15S6X

ATV31H055M2

ATV31H075M2 ATV31H075M3X ATV31HU11N4

ATV31HU11M2

ATV31HU15M2 ATV31HU15M3X ATV31HU22N4 54 ATV31HU55S6X 34

ATV31HU22M2 25 ATV31HU22M3X 25 ATV31HU30N4 55 ATV31HU75S6X 23

PA / PB

minimum

resistance

Ω

40

40

27

240 V

three-phase

drive

catalog no.

ATV31H018M3X

ATV31H055M3X

ATV31HU11M3X

ATV31HU30M3X

ATV31HU40M3X ATV31HU55N4 29 ATV31HU15S6X

ATV31HU55M3X

ATV31HU75M3X ATV31HD11N4

ATV31HU11M3X

ATV31HU15M3X

PA / PB

minimum

resistance

Ω

40

40

27

16

8

5

460 V

three-phase

drive

catalog no.

ATV31H037N4

ATV31H075N4 80 ATV31HU22S6X

ATV31HU15N4 ATV31HU40S6X 44

ATV31HU40N4 36 ATV31HU11S6X

ATV31HU75N4 19

ATV31HD15N4

PA / PB

minimum

resistance

Ω

80

54

20

575 V

three-phase

drive

catalog no.

ATV31H075S6X 96

ATV31HU75S6X 65

PA / PB

minimum

resistance

Ω

64

24

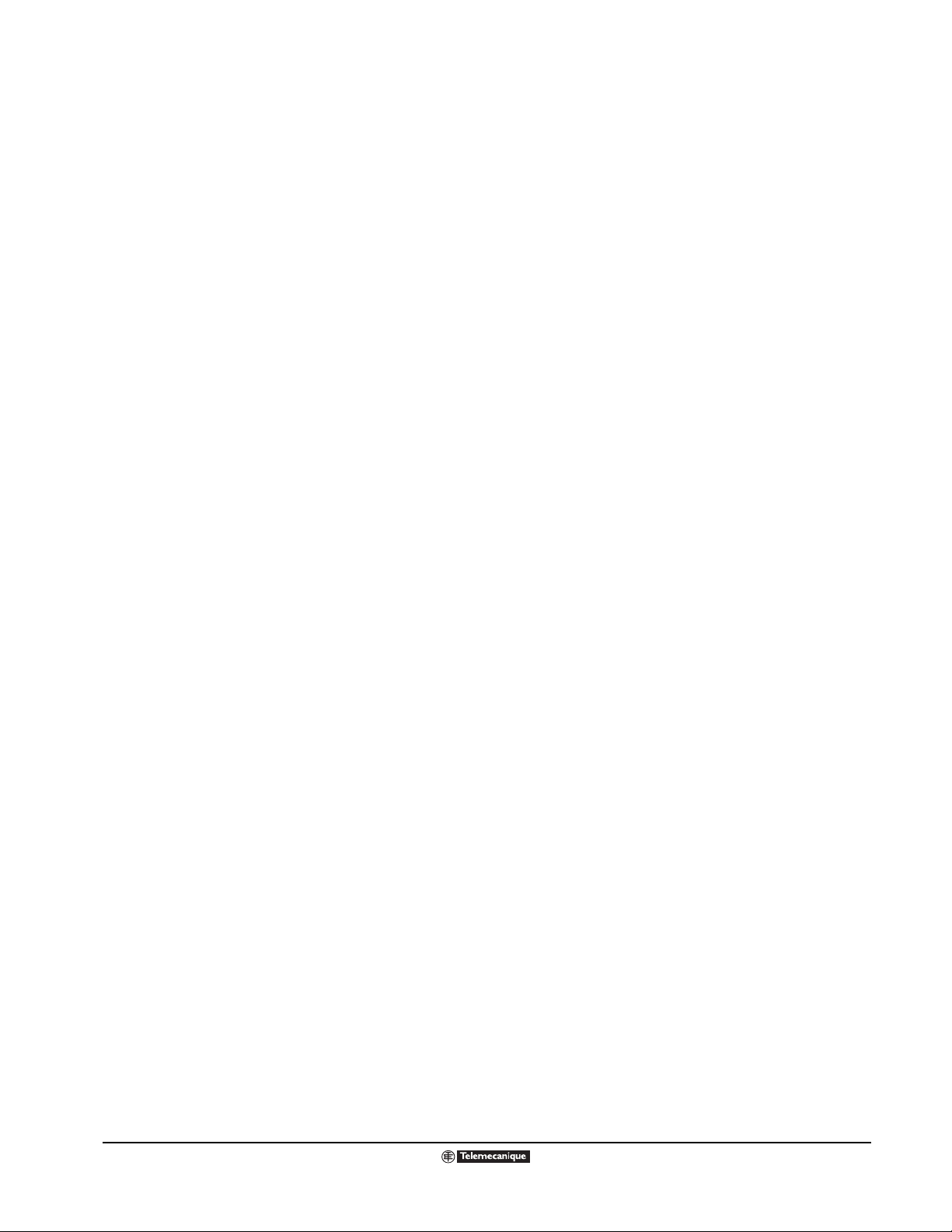

The following charts show the motor braking torque capacity of an ATV31 drive controller with a braking

resistor.

Braking torque with resistor

Constant torque applications Variable torque applications

25/30 50/60 75/90 100/1200N (Hz)

25/30 50/60 75/90 100/1200N (Hz)

1

0.25

0.50

0.75

1.00

1.25

1.50

1. Continuous braking torque (driving load) load factor = 100%.

2. Maximum transient braking torque (for 60 s).

4/2005 © 2004–2005 Schneider Electric All Rights Reserved

1

2

HiTorqGraf.eps

1

0.25

0.50

0.75

1.00

1.20

1.25

1.50

1. Continuous braking torque (driving load) load factor = 100%.

2. Maximum transient braking torque (for 60 s).

1

2

LoTorqGraf.eps

13

Altivar® 31 Adjustable Speed AC Drives

Dynamic Braking Resistor Kits

Calculating resistor size

The standard dynamic braking (DB) resistor assemblies are suited to a wide variety of drive system

stopping applications. However, where the driven machinery can present an overhauling load or large

inertia to the drive system, the suitability of the DB resistor assembly must be verified.

The suitability of a DB resistor assembly is determined by analyzing the mechanical system of the driven

machinery. From the analysis, the following key parameters are computed:

• The peak braking power required during stopping or speed changes (Pi). The value of Pi determines

the maximum allowable ohmic value of the DB resistor.

• The amount of power that must be absorbed (Pd) for a given time (td) by the DB resistors during

stopping or speed changes of the drive. The value of Pd and td determine the required time-current

characteristic of the DB resistor.

• The calculation of dynamic braking power requires Vdb.

— 575 V drives: V

— 460 V drives: V

— 230 V drives: V

• The average power that must be dissipated by the DB resistor during an entire cycle of the machine

(Pa). The value of Pa determines the required continuous current rating of the DB resistor.

The following example illustrates the process.

Given:

The application consists of a 5 hp, 460 Vac, 1740 rpm motor (N

inertia of 0.28 lb-ft2. The motor is being controlled by an ATV31HU40N4 operating in the constant

torque mode. The motor is driving a machine with an inertia 10 times that of the motor with no

interposing gear box. The machine resistive (friction) torque is one-tenth of the rated motor torque

at full speed. The requirement is to stop in 5 seconds from rated speed at a rate of 2 cycles/minute.

= 1020 V

db

= 850 V

db

= 375 V

db

= base speed) with a rotor

base

Mechanical System Parameters:

Rated motor torque: T

Machine cycle time: t

Machine speed change during deceleration: N

Machine deceleration time: t

Mechanical system resistive (friction) torque: T

Mechanical system overhauling torque: T

Mechanical system combined inertia: J

= (hp x 5250)/N

n

= (60 seconds)/(two operations per minute) = 30 seconds

c

= 5 seconds

d

= (5 x 5250)/1740 = 15.1 lb-ft

base

= 1740 rpm – 0 rpm = 1740 rpm

d

= (15.1 lb-ft)/10 = 1.51 lb-ft

r

= 0.00 lb-ft

o

= 0.28 lb-ft2 + (10 x 0.28 lb-ft2) = 3.08 lb-ft2

c

Mechanical system inertial torque for a 5 second deceleration rate (as set by controller

deceleration ramp):

= Jc x [Nd/(308 x td)] = 3.08 x [1740/(308 x 5)] = 3.48 lb-ft

T

j

Required braking torque from motor: T

= Tj + To – Tr = 3.48 + 0.00 – 1.51 = 1.97 lb-ft

b

NOTE: The required braking torque must not exceed the motor’s ability to produce torque. For

inertial loads, including those depicted in the above examples, the required braking torque must

not exceed the torque-producing ability of the dynamic braking unit with the recommended braking

resistor (approximately 1.5 times the motor rated torque for constant torque applications).

For machines that can continuously overhaul the motor, the value of overhauling torque (To) minus

the resistive torque (T

) must not exceed the motor continuous torque rating at any speed.

r

14

© 2004–2005 Schneider Electric All Rights Reserved

4/2005

Altivar® 31 Adjustable Speed AC Drives

Dynamic Braking Resistor Kits

DB resistor requirements:

Peak braking power required to develop braking torque (T

Pi = (Tb x N

)/7.04 = (1.97 x 1740)/7.04 = 487 W

base

The braking power that must be absorbed for a time (t

Pd = 0.5 x Pi = 0.5 x 487 = 243 W for a period of td seconds

The average braking power that must be dissipated during a machine cycle:

= Pd x td/tc = 243 x 5/30 = 40.5 W

P

a

Capability of VW3A66711 DB resistor assembly for ATV31HU40N4 controller:

Peak braking power that can be developed with the VW3A66711 DB resistor assembly with the

controller configured for 460 Vac input line operation: P

The braking power that can be absorbed for t

(based on the DB resistor hot state current-time

d

characteristic curve shown below):

= Rdb x [(Multiple of Ir at td) x Ir]2 = 120 Ω x (3.5 x 1.0)2 = 1470 W

P

d

Since R

limits the peak current that can be drawn from the drive controller DC bus, the value of

db

[(Multiple of Ir) x Ir] must be limited to no greater than (√ Pi/Rdb).

The average braking power that can be dissipated continuously:

P

= Rdb x (Ir)2 = 120 Ω x (1)2 = 120 W

a

For this example, the VW3A66711 DB resistor assembly will work as intended for the application.

) when decelerating from a given speed:

b

) during a stop or speed change operation:

d

= (Vdb)2/Rdb = (850 V)2/120 Ω = 6020 W

i

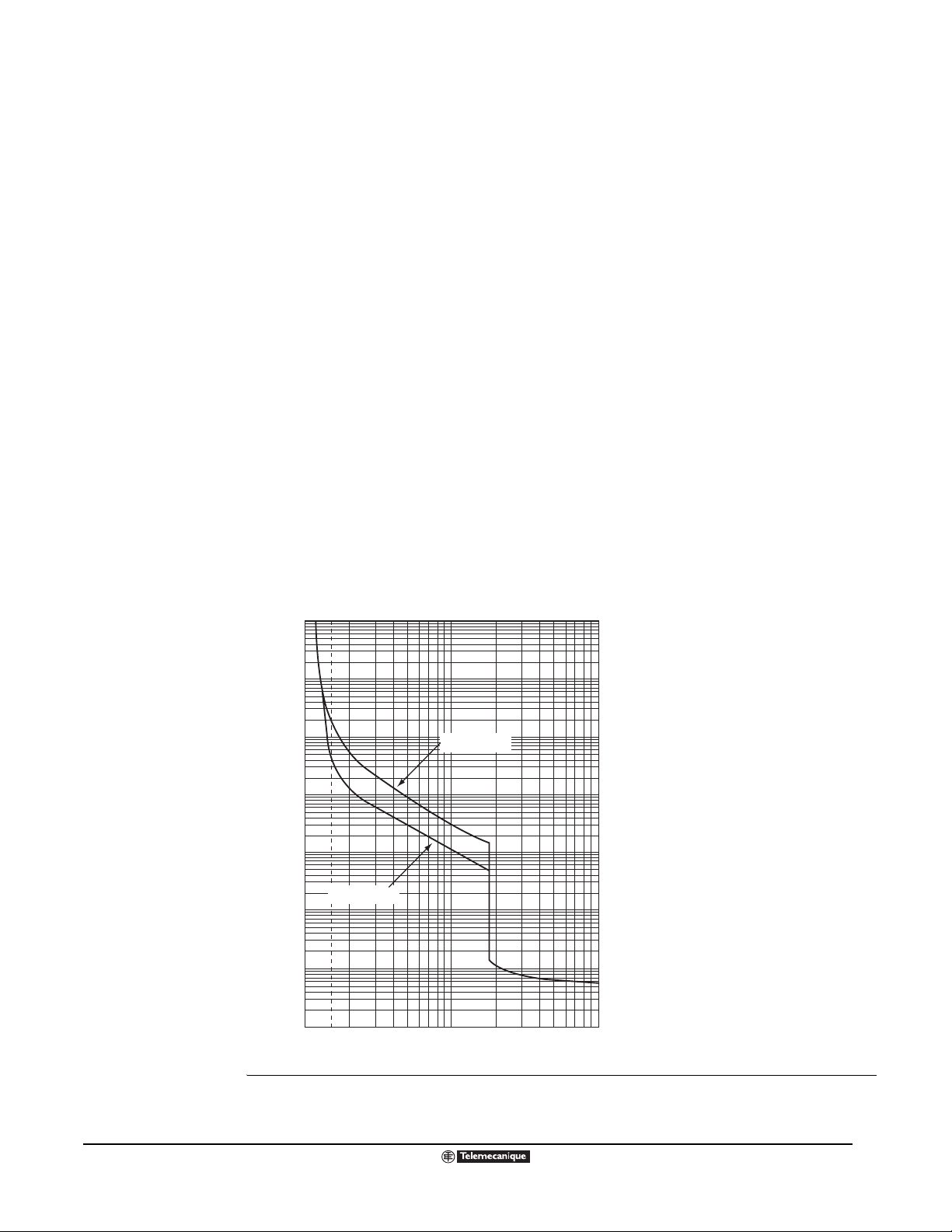

Current/time characteristics for DB resistor assemblies

The figure below shows the allowable trip times1 as a function of current setting multiples with the

dynamic braking resistor assembly located in a 40 °C (104 °F) ambient temperature environment. See

“Calculating resistor size” on page 14 for an example of how to calculate resistor size.

10000

DynBrkCurves.eps

1000

100

10

Time (s)

0.1

0.01

1

Hot State

Cold State

0.001

1

1.5

Multiples of Current Setting (lr)

1. Of the GV2 manual starter; see page 16.

4/2005 © 2004–2005 Schneider Electric All Rights Reserved

10

100

15

Altivar® 31 Adjustable Speed AC Drives

Additional EMC Input Filters

The kits in the following table use the thermal protection of a GV2 manual starter and have a Type 1

rating per UL 50. The insulation system is suitable for use in a Pollution Degree 3 environment (refer to

NEMA ICS-1 Annex A). The package is UL/CSA marked.

Dynamic braking resistor kits technical specifications

Drive controller

catalog number

ATV31H018M2–037M2

ATV31H018M3X–037M3X

ATV31H037N4–U40N4

ATV31H055M2–U22M2

ATV31H055M3X–U22M3X

ATV31HU55N4–U75N4

ATV31HU30M3X–U40M3X

ATV31HD11N4–D15N4

ATV31HU55M3X–U75M3X 14 3.80 202 VW3A66714

ATV31HD11M3X–D15M3X 10 10.00 1000 VW3A66715

Ohmic Value

(Rdb)

Ω

120 1.00 120 VW3A66711

56 1.45 118 VW3A66712

28 2.70 204 VW3A66713

Continuous Current

Rating of Assembly (Ir)

A

Average

Power

W

Kit catalog

number

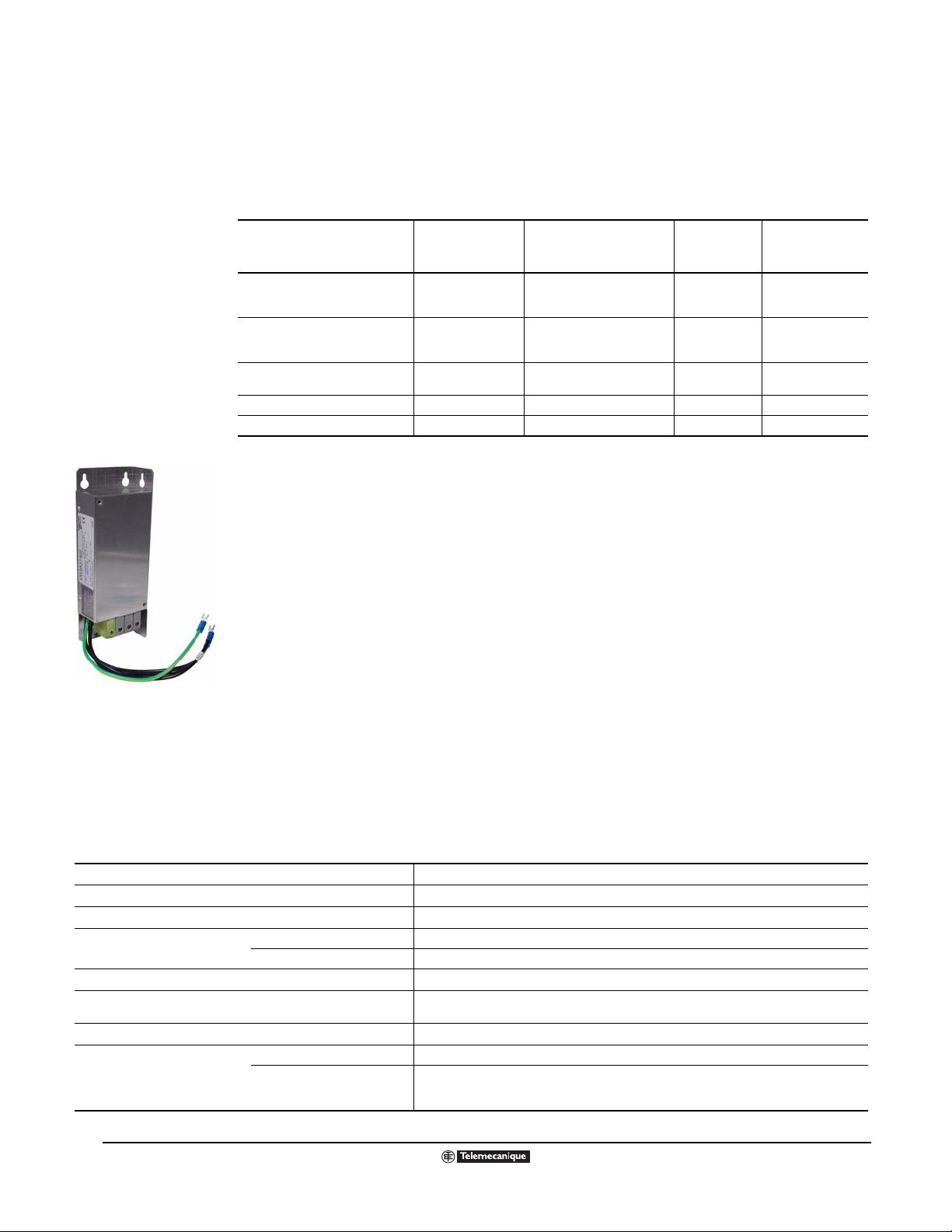

ADDITIONAL EMC INPUT FILTERS

Function

VW3A31402 7A

The ATV31 drive has built-in radio frequency interference (RFI) input filters to meet EMC “product”

standards for adjustable speed drives, IEC/EN 61800-3, and to comply with the European EMC

(electromagnetic compatibility) directive.

The additional filters enable the drives to meet more stringent requirements: they are designed to

reduce conducted emissions on the line supply below the limits of standards EN 55011 class A (1) or

EN 55022 class B. These filters mount beneath ATV31H drives via tapped holes, acting as supports for

the drives.

Characteristics

Conformity to standards

Degree of protection

Maximum relative humidity

Ambient air temperature

around the device

Maximum operating altitude

Vibration resistance

Shock resistance

Maximum nominal voltage

Considerations for isolated or impedance grounded neutral systems

The standard IEC 61800-3, annex D2.1, indicates that on isolated or impedance grounded neutral

systems, the filters can affect the operation of insulation monitors.

The efficiency of additional filters on this type of system also depends on the nature of the impedance

between neutral and earth and is therefore unpredictable.

If installing a machine on an isolated or impedance grounded neutral system, one solution is to insert an

isolation transformer and connect locally to the machine on a neutral connection or neutral-to-earth system.

EN 133200

IP 21 and IP 41 on upper part

93% without condensation or dripping water conforming to IEC 68-2-3

Operation -10 to +60 °C (14 to +140 °F)

Storage -25 to +70 °C (-13 to +158 °F)

Without derating 1000 m (3281 ft). At higher elevations, derate the current by 1% per additional 100 m (328 ft).

Conforming to IEC 60068-2-6

Conforming to IEC 60068-2-27 15 gn for 11 ms

50/60 Hz single phase 240 V +10%

50/60 Hz three-phase

1.5 mm peak to peak from 3 to 13 Hz

1 gn peak from 13 to 150 Hz

240 V +10%

500 V +10%

600 V +10%

16

© 2004–2005 Schneider Electric All Rights Reserved

4/2005

Loading...

Loading...