Installation Instructions for

Indoor AdaptaHorns

Description

The AdaptaHorns are UL listed vibrating horns. They are low

current, high decibel horns designed for heavy-duty use indoors.

The horns are intended for general signaling applications.

PLC Compatibility

The electrical input load requirements for PLC compatible signaling devices are listed in Table 1. Signaling devices may be

directly connected to output cards that meet these input load requirements.

24V DC electromechanical horns such as the 871-G1, 873-G1,

873DPO-G1 and 875-G1 can produce transient spikes and should

only be used on PLC output cards that have inherent transient

spike suppression. The Process Control Engineer should consult

the PLC manufacturer when connecting 24V DC electromechanical devices to PLCs.

Installation

Flush Mounting (870 and 871 Series)

1. Using approved wiring methods, connect black wire leads to

power source wires. Polarity is not important.

2. Ground to wiring system.

3. Insert horn connector into connector receptacle and secure

horn to backbox with (4) oval head screws (supplied).

Surface Mounting (872, 872DPO, 873, 873DPO, 874, and 875

Series)

1. Loosen screw at bottom of horn and remove backplate.

2. Mount plate using one of the following methods:

a. Mount on any outlet box cover having single gang

opening using #6 screws (supplied).

b. Mount on a 3 1/4" (83mm), 3 1/2" (89mm), 4" (102mm)

octagon or 4" (102mm) square box using #8 screws

supplied with backbox.

c. Mount on the wall, for open wiring, using #8 wood screws

(supplied).

3. Using approved wiring methods connect one wire to each

terminal in backplate. Ground to wiring system.

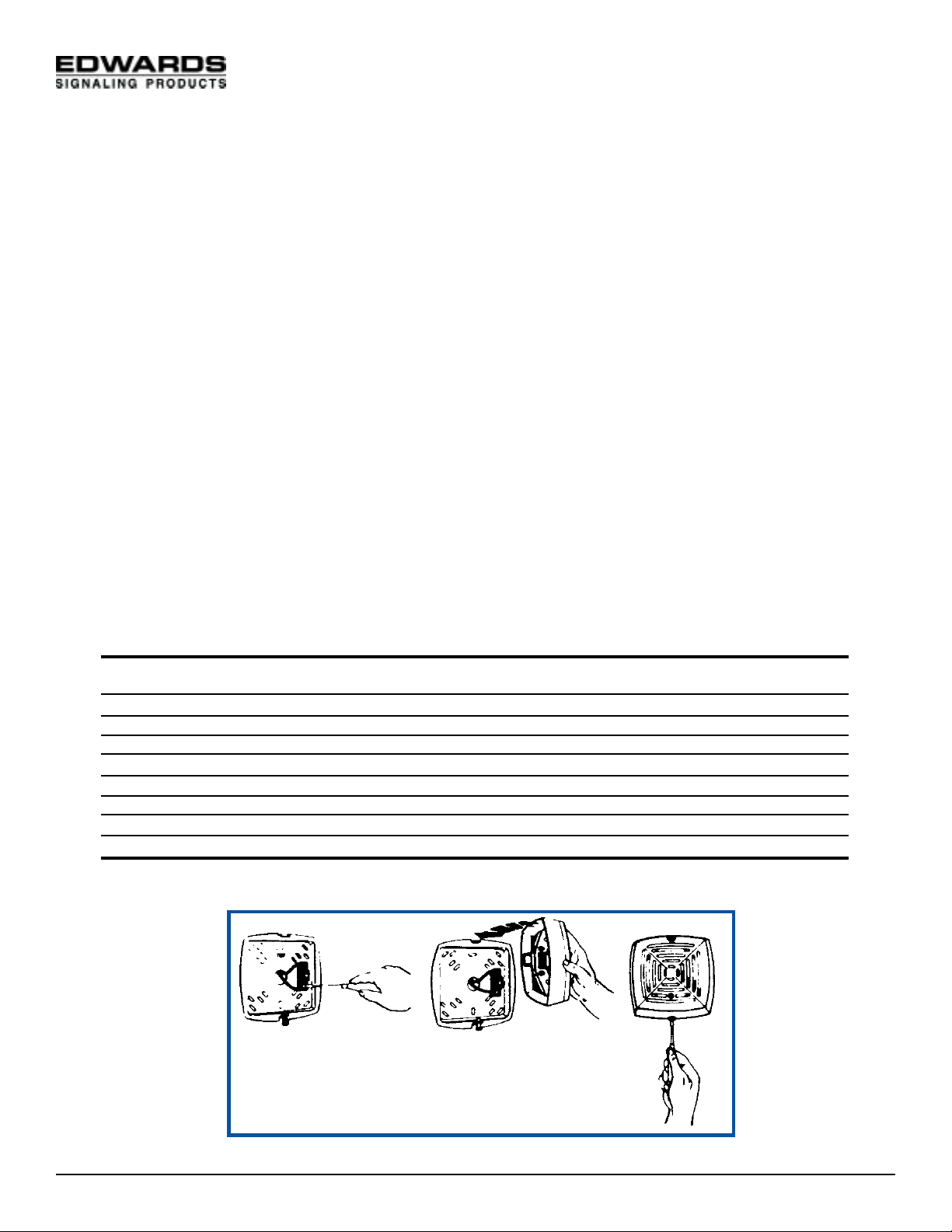

4. Place the horn on the mounting plate so that the tab at the top

seats in slot on horn. Press horn firmly against plate and

tighten screw at bottom of unit. See Figure 1.

Table 1. PLC Compatibility

Operating Maximum off state Continuous on Surge (inrush/duration)

Cat. No. voltage* leakage current (mA) current (mA) (A/ms**)

870-N5 120V AC 25 120 1.02/0.000026

871-G1 24V DC 25 150 1.7/0.000042

872-N5 120V AC 25 120 1.02/0.000026

872DPO-N5 120V AC 25 120 1.02/0.000026

873-G1 24V DC 25 150 1.7/0.000042

873DPO-G1 24V DC 25 150 1.7/0.000042

874-N5 120V AC 25 120 1.02/0.000026

875-G1 24V DC 25 150 1.7/0.000042

*All AC volts at 60 Hz

**Amps/milliseconds

CHESHIRE, CT 203-699-3000 F AX 860-677-7746

Figure 1. Mounting the Horn on the AdaptaPlate

P-047550-1894 ISSUE 1 © 1999

Volume Adjustment

These devices have a volume adjustment screw (located on the

grille front) factory set to maximum. To reduce volume level,

turn set screw clockwise using the supplied 1/16" (1.6mm) allen

wrench.

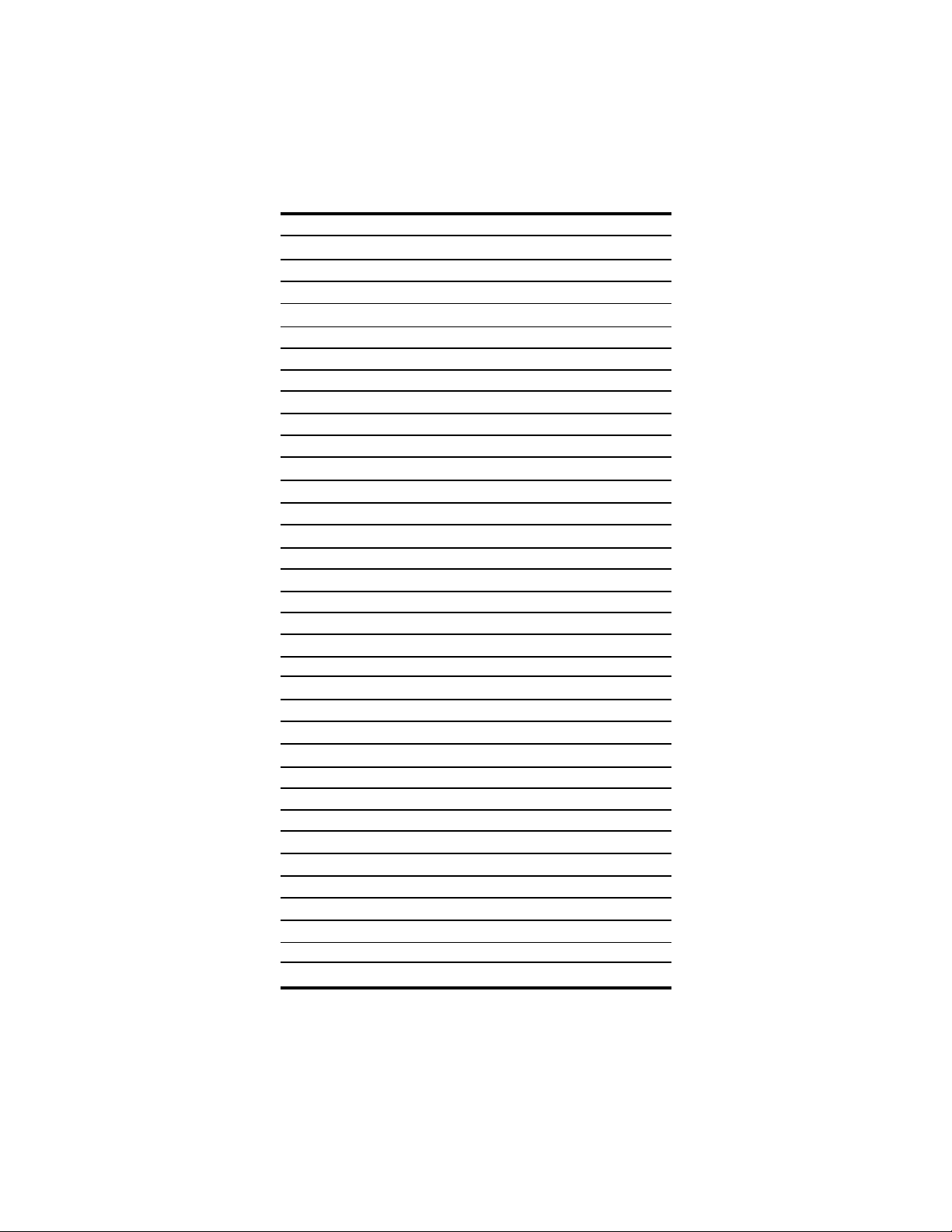

Table 2. Electrical Specifications

Cat. No. Voltage Current

870-G5 24V 50/60 Hz 0.63A

870-N5 120V 50/60 Hz 0.13A

870-R5 240V 50/60 Hz 0.07A

871-E1 12V DC 0.27A

871-G1 24V DC 0.16A

871-K1 48V DC 0.07A

871-P1 125V DC 0.025A

871-S1 250V DC 0.014A

872-E5 12V 50/60 Hz 1.25A

872-G5 24V 50/60 Hz 0.63A

872-N5 120V 50/60 Hz 0.13A

872-R5 240V 50/60 Hz 0.07A

872DPO-G5 24V 50/60 Hz 0.63A

872DPO-N5 120V 50/60 Hz 0.13A

872DPO-R5 240V 50/60 Hz 0.07A

873-G1 24V DC 0.16A

873-K1 48V DC 0.07A

873-P1 125V DC 0.025A

873-S1 250V DC 0.014A

873DPO-E1 12V DC 0.27A

873DPO-G1 24V DC 0.16A

873DPO-J1 32V DC 0.13A

873DPO-P1 125V DC 0.025A

873DPO-S1 250V DC 0.014A

874-E5 12V 50/60 Hz 1.25A

874-G5 24V 50/60 Hz 0.63A

874-N5 120V 50/60 Hz 0.13A

874-R5 240V 50/60 Hz 0.07A

875-C1 6V DC 0.70A

875-E1 12V DC 0.27A

875-G1 24V DC 0.16A

875-J1 32V DC 0.13A

875-P1 125V DC 0.025A

875-S1 250V DC 0.014A

P-047550-1894 ISSUE 1

Loading...

Loading...