AbsolutAire 243-8HP Installation Manual

M-1306-1 Rev. 11

R

Regulator Installation and

Maintenance Instructions

243 Service

Regulators

Introduction

The 243 is a large capacity general-purpose gas pressure

regulator.

ts outstanding performance and versatility make it an excellent

I

hoice for use on industrial meter sets, combustion equipment,

c

oilers, burners, unit heaters, furnaces, ovens and other appli-

b

cations.

Use it for natural gas, air, dry CO

nitrogen, and others. Special materials are available for cer-

, propane, butane, L.P.G.,

2

tain corrosive gases.

In addition to the standard models and internal relief models

covered in this bulletin, the 243 is also available with low pressure cut-off, with built-in monitor, and as a pilot operated regulator (outlet pressures to 35 psig), a back pressure valve, a

relief valve, a vacuum regulator and a vacuum breaker. For

information, please contact your Sensus Sales Office or

authorized industrial distributor. The 243 is manufactured in

conformance with Code B31.8.

Note: The term standard refers to Non-IRV configurations.

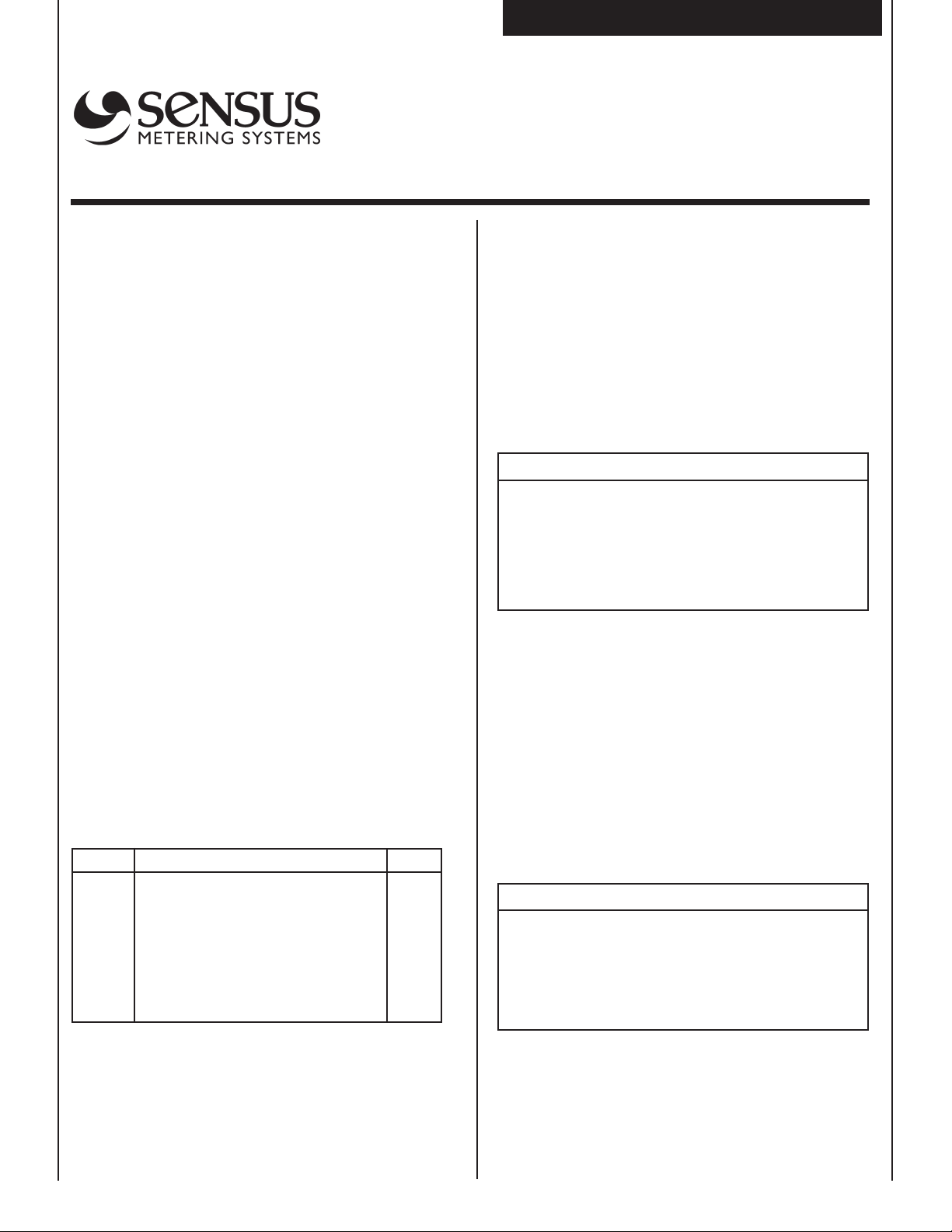

Model Specifications

243-12-1 and 243-12-2

Maximum Inlet Pressure.........................................125 psi

Outlet Pressures......................................3 1⁄2” w.c. to 3 psi

Pipe Sizes................................................ 1 1⁄4”, 1 1⁄2” and 2”

Diaphragm..................................... 12” (nominal diameter)

243-8-1 and 243-8-2

Maximum Inlet Pressure.........................................125 psi

Outlet Pressures..................................3 1⁄2” w.c. to 4 1⁄4” psi

Pipe Sizes................................................ 1 1⁄4”, 1 1⁄2” and 2”

Diaphragm....................................... 8” (nominal diameter)

243-8HP

Maximum Inlet Pressure.........................................125 psi

Outlet Pressures................................................3 to 10 psi

Pipe Sizes................................................ 1 1⁄4”, 1 1⁄2” and 2”

Diaphragm....................................... 8” (nominal diameter)

Maximum Inlet Pressures

243-12

15 psi

*

25 psi

25 psi

*

40 psi

40 psi

60 psi

t

100 psi

125 psi

125 psi

•••

Applies only to 243-12 with external control line.

*

80 psi for 243-12 with external control line

t

ORIFICE SIZE - VALVE

1” - 30

1” - 10

3

⁄4” - 30

3

⁄4” - 10

⁄2” - 10

3

⁄8” - 10

1

⁄4” - 10

O

O

O

O

O

O

O

O

O

O

11⁄4” - 30

11⁄4” - 10

1

.207” - 10

243-8

•••

•••

25 psi

25 psi

40 psi

40 psi

80 psi

100 psi

125 psi

125 psi

Temperature Limits

The Model 243 Service Regulators can be used for flowing

temperatures from -20 F to 150 F

O

O

.

Buried Service

The Model 243 Service Regulators are

buried service.

not

recommended for

Installation and Start Up

(See Illustrations on Page 3.)

1. Make certain that regulator and piping are free of dirt,

moisture, foreign matter and other debris.

2. Be sure all shipping screens or covers are removed and

regulator is installed with flow in correct direction.

3. Regulator may be installed in any position; right-side-up, up-

side down, vertical pipe, horizontal pipe, diagonal pipe, etc.

By loosening union bolts

(16), the diaphragm case assembly

may be rotated to various positions in relation to the body.

Make certain

(16) are re-tightened to hold diaphragm case

assembly in new position and to reseal.

CAUTION

The diaphragm case vent must be positioned

to protect against flooding, drain water, ice

formation, traffic, tampering, etc. The vent

must be protected against nest building

animals, bees, insects, etc. to prevent vent

blockage and minimize the chances for

foreign material from collecting in the vent

side of the regulator diaphragm.

4. Make sure there are no leaks and all connections are firm

and tight. Tighten flange bolts evenly and firmly. On screwed

connections apply pipe dope to male threads only.

5. On regulators arranged for External Control Line, run pipe

or tubing from

trol connection in the outlet piping. This control piping

should not be less than

1

⁄2” NPT connection in lower case to the con-

1

⁄2” in size and should be adequately

protected against breakage (regulators go wide open if the

control line is broken). In general, the control connection

should be at least 8 pipe diameters from the regulator and in

as straight a run of pipe as possible.

The connection itself

must be smooth on the inside of the pipe. Pitch the control

line away from the regulator and avoid moisture pockets.

Keep inside of control line clean. Never install any type of

automatic shut-off device, which closes completely, between

the regulator outlet and the control line connection.

CAUTION

It is the user’s responsibility to assure that all

regulator vents and/or vent lines exhaust to a

non-hazar

used,

that eac

dous location a

ces of ignition.

sour

it is the user’

vice regulator is individuall

h ser

and that common vent lines

6. Adjust outlet pressure (set point) by removing cap (1) or

(1e) and turning adjustment spring button (3). On 243-8 HP

remove cap

(1b).

(1a), loosen locknut and turn adjustment screw

urn clockwise to increase and counter-clockwise to

T

decrease outlet pressure. Only adjust when gas is flowing

through regulator. When adjustment is completed, seal cap

(1) or (1e) must be securely screwed into place.

absence of this seal cap can result in unstable operation.

y from

wa

any potential

Where vent line are

s responsibility to assure

y vented

are not used.

The

Installation and Start Up (Continued)

. On regulators with Internal Relief Valve, there is no

7

adjustment for the internal relief. It is fixed, with relief beginning at approximately 9” w.c. to 20” w.c., above regulator set

oint, depending on relief spring (11k)used.

p

Internal Relief Valves must be carefully sized. For informa-

ion, contact your Sensus Representative.

t

6. Regulators installed indoors must be vented outside. Run

vent pipe from regulator vent connection to safe place outside. Vent piping should be as short and direct as possible.

ent piping for regulators with internal relief valve (Models

V

243-12-2 or 243-8-2) must be large enough to vent all relief

valve discharge to atmosphere without excessive back pressure and resulting excessive pressure in regulator.

Vent pipe outlet must be protected against nest building animals, bees, insects, etc., and positioned to protect against

flooding, drain water, ice formation, etc. but must allow free

and unobstructed passage of air or gas.

AUTION

T

urn gas on very slowly. If an outlet stop valve is used, it should be opened first.

Do not overload the diaphragm with a sudden surge of inlet pressure. Monitor

the outlet pressure during start-up to prevent an outlet pressure overload.

vicing

Ser

1. Make sure the regulator is entirely depressured before

disassembling.

2. Carefully note location and position of all disassembled

parts to be certain reassembly is correct. Inspect each part

and replace those that are worn or damaged or otherwise

unsatisfactory.

3. For access to valve

(16) and remove diaphragm case assembly from body.

bolts

To remove valve

Orifice

(24) unscrews from body. Use 1-5/8” hex socket

(21), first remove hair pin cotter (20b).

“thinwall” type. When replacing orifice use moderate

amount of pipe dope on orifice threads.

4. Before reassembling and tightening union bolts

make certain Tetraseal

5. To replace diaphragm; remove spring

(8) and nuts (9), and disassemble diaphragm assem-

bolts

bly. Remove old diaphragm

(11b). Remove old adhesive from the diaphragm pan using

a solvent such as methyl ethyl ketone (MEK).

To reassemble, apply a thin, even layer of a rubber based

adhesive such as 3M Industrial

cleaned, prepared side of the diaphragm pan.

Attach the diaphragm to the adhesive side of the diaphragm

pan, being careful to align the center hole of the diaphragm

with the corresponsing center hole in the diaphragm pan.

Make certain all parts are reassembled in their correct order

and bolts

(8) are tightened to a torque of 150 in-lbs. Bolts

must be tight enough to prevent leakage but not too tight

that the diaphragm material is crushed or damaged.

Diaphragm must not be twisted or pinched.

6. Upon completion of servicing, make certain that regulator

installation is entirely free of leaks.

s are pressure contr

Regulator

wear that is dependent upon particular operating conditions. To assure continuous

satisfactor

the frequency of inspection determined by the severity of service and applicable

y operation,

a periodic inspection schedule must be adhered to with

C

(21) and orifice (24) loosen union

(17) is in position.

(4), remove flange

(11a) from diaphragm pan

Adhesive #EC-847 to the

CAUTION

vices with numerous moving parts subject to

ol de

laws and regulations.

(16),

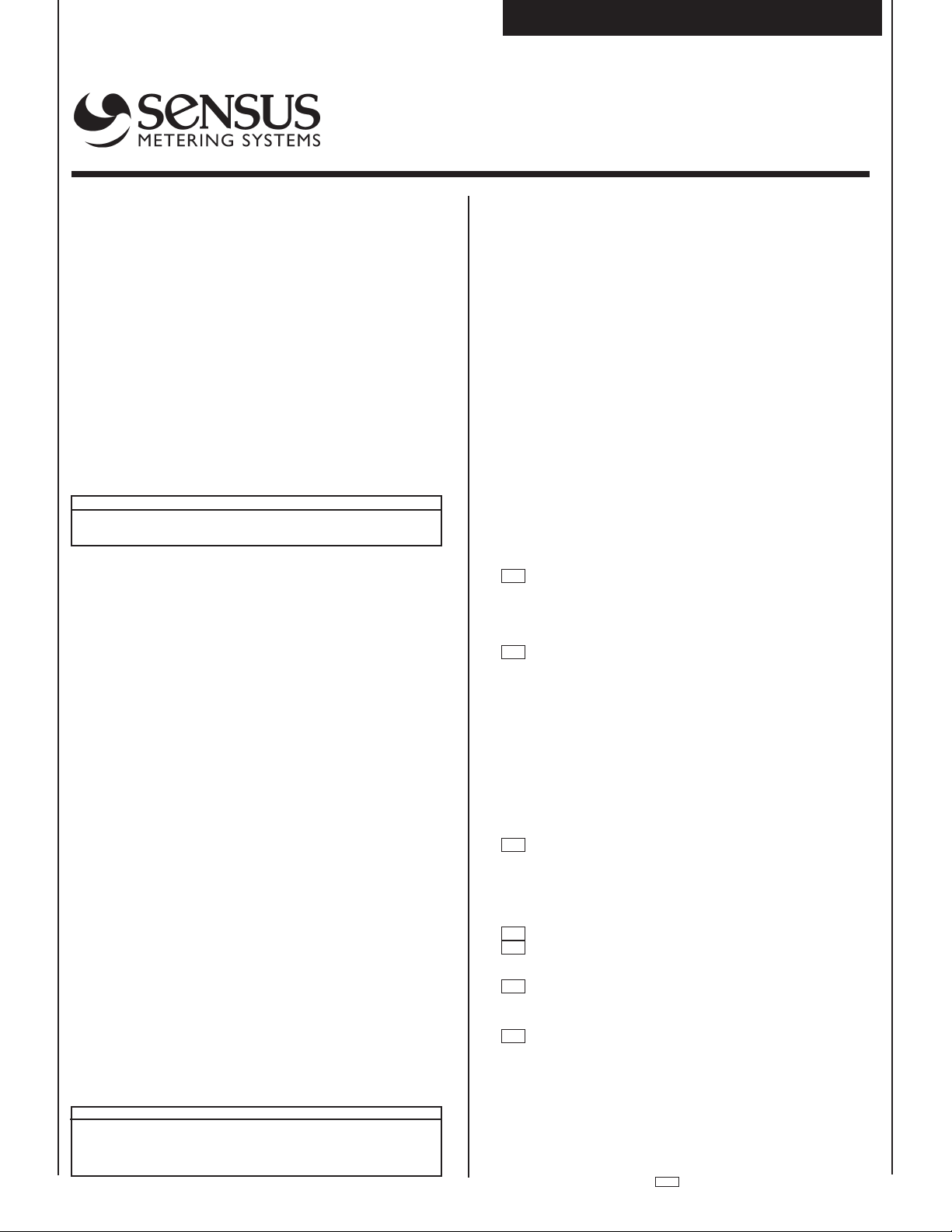

Condensed Parts List

The following are the parts generally required in maintenance and servicing. For a listing of all parts refer to Parts

List RP-1306

LL. Part

I

o. Description Number

N

1

Cover Cap (IRV)

1e

Cover Cap (STD)

1d

Tetraseal 1 1⁄2 x 15⁄8”

2

O-Ring #2-140

2a

O-Ring #2-142

3

Adjustment Spring Button

4

Spring (See Table, 1st page)

5

243-12 Cover Assembly IRV (includes

vent valve and spring)

243-12 Cover Assembly STD (includes

vent valve and spring)

243-8 Cover

valve and spring)

8

Flange Bolt, 5⁄16 x 1” Hex Hd

9

Flange Nut, 5⁄16 - 18 Hex S.F.

10

243-12 Lower Case

243-12 Lower Case (tapped for external control line)

243-08 Lower Case

243-08 Lower Case (tapped for external control line)

11a

243-12 Diaphragm

243-8 Diaphragm

243-8 HP Diaphragm

11b

243-12 Diaphragm Pan

243-8 Diaphragm Pan

243-8 HP Diaphragm Pan

11d

Seal Washer

11e

Emery Cloth Washer (faces against

top side of 243-8 HP diaphragm)

11f

Spring guide

Spring guide (243-8 HP)

11k

Internal Relief Valve Spring,

for 243-8-2 only.

(relief begins at approx. 9” w.c.

11k

11s

13

16

17

18

20b

21

24

25

26

27

28

above regulator set point)

Internal Relief Valve Spring

(relief begins at approx. 9”w

for 243-12-2, and approx.

20” w.c. for 243-8-2

above regulator set point)

243-8 HP

243-12 Coupling-Lever-

Stem

243-8 Coupling-Lever-

Stem Assembly

243-8 (HP) Coupling-Lever-

Stem Assembly

Union Bolts,

etraseal (or O-Ring) 2

T

243-8 Throat Block with O-Ring Seal

243-12 Throat Block with O-Ring Seal

Hair Pin Cotter

Valve Assembly - 10 - Buna N

Valve Assembly - 10 - Viton

alve

V

Valve Assembly - 30 - Viton

1

1

⁄4” Orifice, Brass

1” Orifice, Brass

3

⁄4” Orifice, Brass

1

⁄2” Orifice, Brass

3

⁄8” Orifice, Brass

1

⁄4” Orifice, Brass

.207” Orifice, Brass

ravel Stop Stem

T

Warning Tag-Travel Stop

Warning Tag-Body Interchangeability

Clamping Plate

2

Assembly (includes vent

Diaphragm Plate

Assembly

3

⁄16” x 11⁄4” Hex

Assembly - 30 - Buna N

1

⁄4 x 21⁄2”

o

o

o

o

Denotes recommended spare par

.c.

143-16-005-00

143-16-005-08

906534

951357

951376

143-16-009-00

143-16-503-03

143-16-503-19

143-82-503-04

910030

921002

143-16-002-00

143-16-002-01

143-82-002-00

143-82-002-01

143-16-150-00

143-82-150-00

121-10-150-50

143-16-017-00

143-82-017-00

121-10-017-50

143-16-115-00

143-82-178-00

143-16-018-00

121-10-022-53

143-82-021-03

143-16-021-02

121-10-022-52

143-16-530-00

143-82-530-00

143-82-530-02

910056

904075

143-16-508-00

143-16-508-04

143-62-118-00

143-16-511-09

143-16-511-11

143-16-511-10

143-16-511-12

143-16-023-03

143-16-023-02

143-16-023-01

143-16-023-00

143-16-023-04

143-16-023-10

143-16-023-11

143-16-060-02

143-16-136-05

143-16-136-06

143-16-102-01

ts

Loading...

Loading...