AbsolutAire 243-12 Installation Manual

Model 243

Service Regulators

R-1306

Rev. 10

243 Service Regulators

These large capacity service regulators are designed and built

for commercial, industrial and gas distribution work. They are

right at home in such places as factories and foundries, district

regulator stations, commercial laundries and laundromats,

motels-hotels and apartments, bakeries, restaurants, schools,

churches and hospitals.

The versatile 243 is used for all kinds of gas fueled equipment

. . .boilers, burners, furnaces, ovens, heaters, kilns, engines, air

conditioners, etc.

Remarkable field versatility results from the union connection

between the fully interchangeable bodies and diaphragm-case

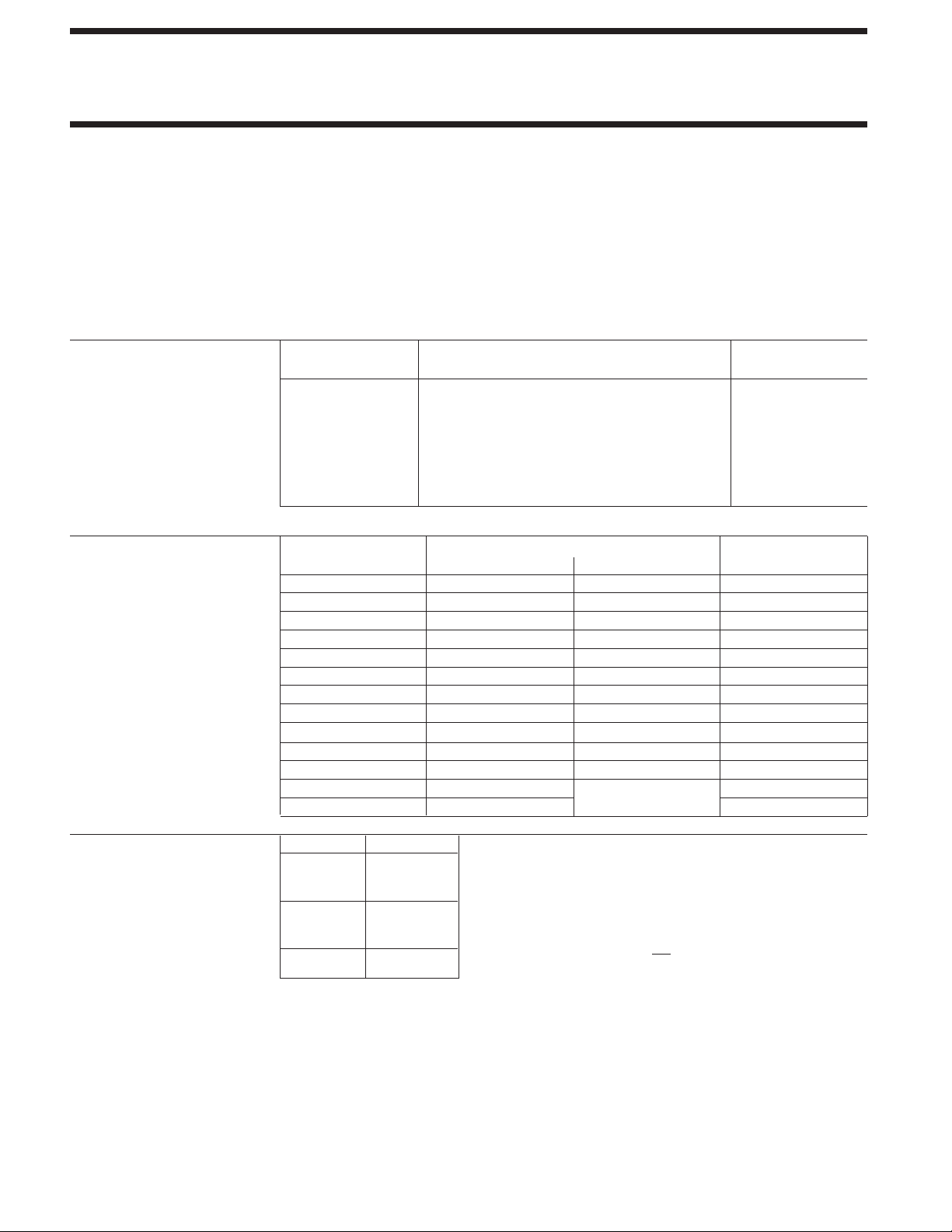

Basic Models

243-12

Model Numbers

243-12-1

243-12-2

243-12-4

243-12-6

Standard* Regulator

Regulator with Internal Relief Valve (IRV)

Regulator with Low Pressure Cut-Off (LPCO)

Regulator with both IRV and LPCO

High Pressure Regulator

Pressure Loaded Regulator

Outlet Pressure

Ranges and Springs

For additional information on IRV refer to page 5. For LPCO refer to page 6

*The term standard refers to non-IR

Spring Color

Red-Black

V configurations.

Blue-Black

Green-Black

Red

Blue

Green

Orange-Black

Orange

Black

Cadmium

Cadmium

Cadmium

t

White

tWhite is nested inside Cadmium *Model 243-8HP only

Model Pipe Size

Pipe Sizes

243-12-1

and

243-12-2

243-8-1

and

243-8-2

243-8HP

1

1

⁄4”,1⁄2”

and 2”

1

⁄4”,11⁄2”

1

and 2”

1

1

⁄4”,11⁄2”

and 2”

assemblies. They are easy to install, adjust, inspect and service in all kinds of piping arrangements.

While used primarily for natural gas services, Model 243 regulators perform equally well on LPG vapor, air, dry CO

, nitrogen

2

and other inert gas applications. Contact your representative

for special construction which may be available for certain corrosive gases.

Variation

243-8

Model Numbers

243-8-1

243-8-2

243-8-4

243-8-6

243-8HP

243-8PL

Outlet Pressure Range

243-12 243-8

---

---

---

31⁄2” to 61⁄2” w.c.

1

5” to 8

⁄2” w.c.

6” to 14” w.c.

10” to 18” w.c.

12” to 28” w.c.

1 to 2 psi

1

⁄2 to 3 psi

1

1

1

⁄2 to 3 psi

---

---

31⁄2” to 61⁄2” w.c.

1

5” to 8

⁄2” w.c.

6” to 14” w.c.

---

---

12” to 28” w.c.

---

1 to 2 psi

1

⁄2 psi

2 to 4

◆

3 to 5 psi

◆

3 to 61⁄2 psi*

6 to 10 psi*

◆

◆

Model 243-8-2 (IRV) only.

Spring Part Number

143-82-021-00

143-82-021-01

143-16-021-02

143-16-021-03

143-16-021-04

143-16-021-05

143-16-021-11

143-16-021-06

143-16-021-07

143-16-021-08

143-16-021-08

143-16-021-08

143-16-021-13

Temperature Limits

The Model 243 Regulator may be used for flowing gas

temperatures from -20

o

F to 150oF.

Buried Service

The Model 243 Regulator is not recommended for buried service.

2

Copyright 2007, Sensus Metering Systems

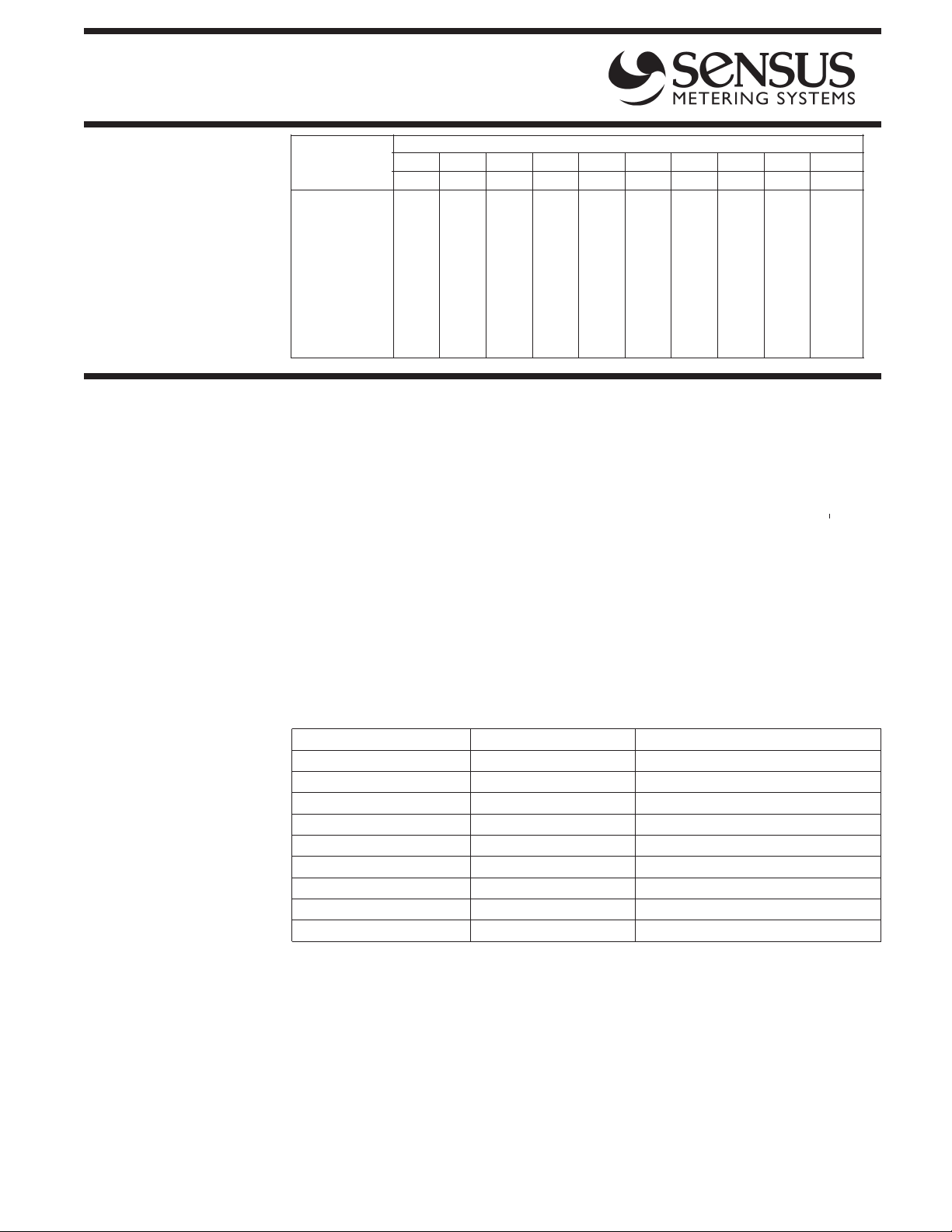

Maximum Inlet

Pressure, psig

*External Control Regulator Only

Regulator

Model

and Size

11⁄4”, 243-12

11⁄2”, 243-12

2”, 243-12

11⁄4”, 243-8

11⁄2”, 243-8

2”, 243-8

11⁄4”, 243-8HP

11⁄2”, 243-8HP

2”, 243-8HP

11⁄4”

30

15

15

15

1

3

3

40

40

3

⁄4”

o

10

-

60

-

60

60

40

40

40

40

-

-

40

⁄2”

⁄4”

o

o

10

100

100

100

80

80

80

80

80

80

10

125

125

125

100

100

100

100

100

*11⁄4”

o

10

-

-

-

-

-

-

25

25

25

1”

25

25

25

25

25

25

25

*1”

o

o

10

30

40

40

40

-

-

-

-

-

-

-

-

o

30

-

-

-

-

-

-

1

⁄8”

⁄4”

10

125

125

125

125

125

125

125

125

125

.207”

o

10

-

-

125

125

-

-

-

-

o

o

Fixed Factor billing

Regulator accuracy is essential to measurement accuracy,

and because the 243 is so

precise, it is ideal for Pressure-Factor Measurement,

Pressure Compensated

Metering, Fixed Factor Billing,

etc.

The table below gives the

pressure accuracies obtainable with 243-12 and 243-8

regulators at the capacities in

the tables on pages 8 to 19.

Set Point

6” w.c.

7” w.c.

11” w.c.

.c.

18” w

1psi

1psi

2psi

3psi

3psi

The 243 will hold outlet pressure within the indicated percentage limits from set flow

(250 scfh) to the flows given in

the capacity tables. Percentages are all based on

absolute pressure using 14.4

psia as atmospheric.

Droop

1” w.c.

1” w.c.

2” w.c.

.c.

3” w

0.3 psi

0.2 psi

0.6 psi

0.3 psi

0.6 psi

As an example, referring to

page 10, a 11⁄2” Model 243-12-

2 with 1” orifice, 30o, valve, 15

psig inlet and 11” w.c. setpoint (green spring) at 2” w.c.

droop has a gas capacity of

9800 scfh. Per the below

table, this regulator at these

conditions will hold outlet

pressure at 11” w.c. = 1⁄2% (2”

w.c.) from 250 to 9800 scfh

(based on absolute pressure).

For higher outlet pressures,

greater capacities, increased

accuracies, and excessive

inlet pressure variations, use

the 243-RPC pilot operated

regulator (see page 7).

Accuracy

+ 1⁄2% and -1⁄2%

1

+

⁄2% and -1⁄2%

+ 1⁄2% and -1⁄2%

+ 1% and -1%

+ 1% and -2%

+ 1% and -11⁄2%

+ 1% and -4%

+ 1% and -2%

+ 1% and -31⁄2%

3

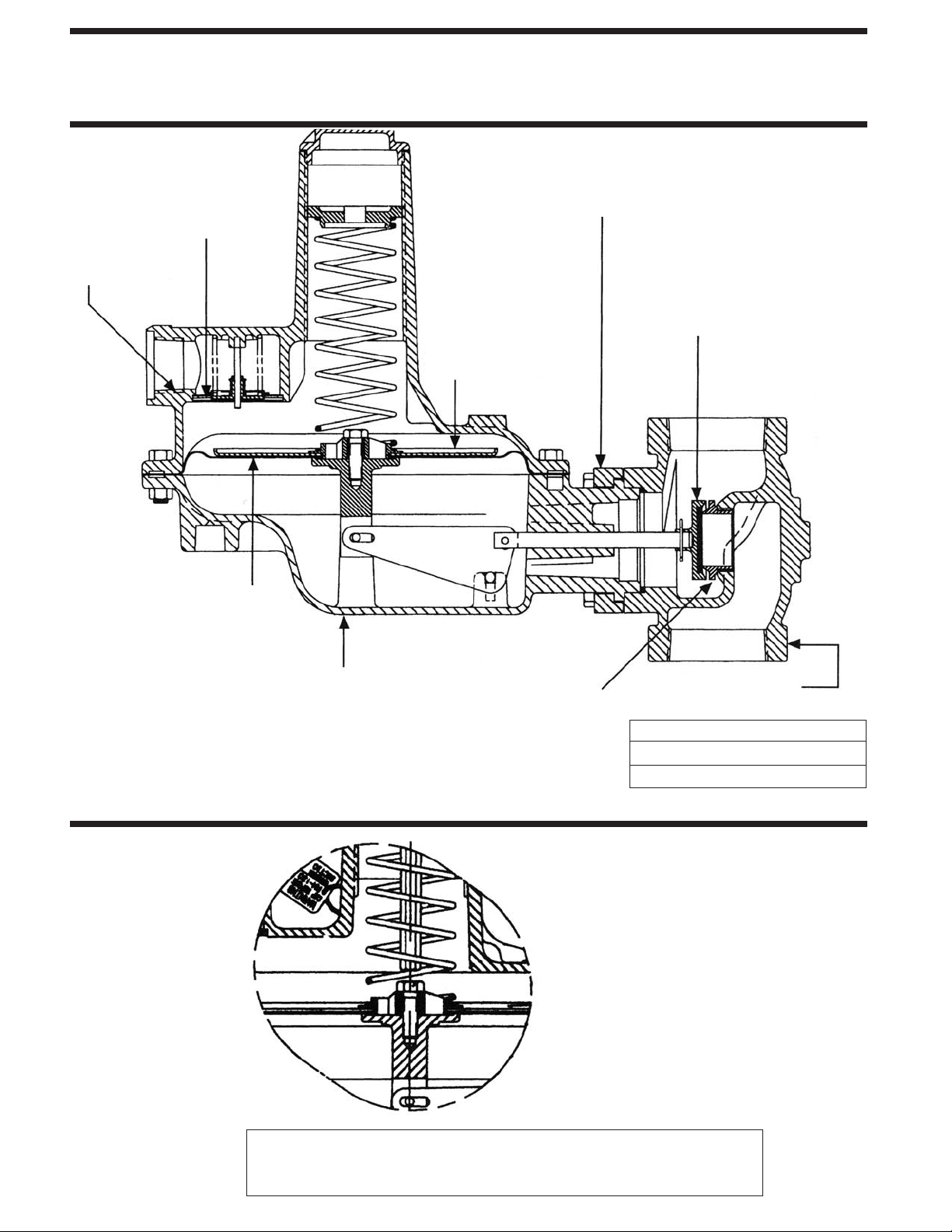

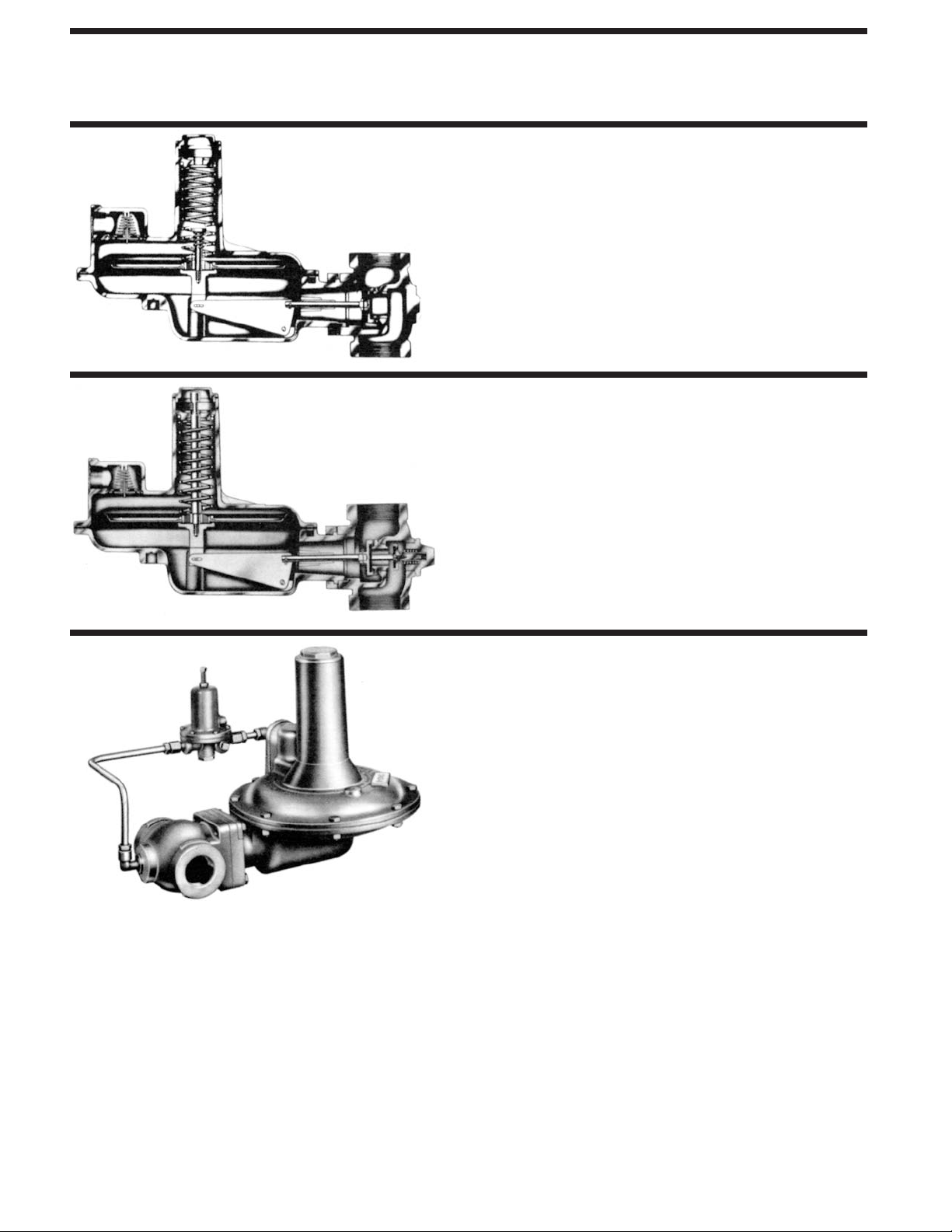

Construction and Design Features

Model 243-8-1

2-Way Vent Valve

• Fast Response on

Rapid Load Change

Vent

1” NPT

•

Interchangeable

Diaphragm

Assemblies

4 Bolt Union Connection

Easily Removable, Fast Off and On

•

Full 360

•

Easy Access for Valve Inspection

•

o

otation for Best

R

iaphragm Assembly Position

D

nd Servicing

a

Molded Valve

Buna-N Disc in

•

luminum Holder

A

Model 243-12-1

Travel Stop

Diaphragm

• Buna-N with

Nylon Fabric

Reinforcement

Die Cast Aluminum Alloy

Diaphragm Case

• Light Weight

• High Strength

• Corrosion Resistant

Interchangeable

Brass Orifices

A travel stop is located in the

243-12-1 and the 243-12-4 to

provide overpressurization

protection.

Cast Iron Bodies

(ASTM A126-81 Class B)

Pipe Sizes

2”, 11⁄2”, 11⁄4” NPT Screwed*

2” Flanged ANSI 125

*Can also be furnished with British Standard Threads (BST)

Caution: Turn gas on slowly. If an outlet stop valve is used, it should be opened first. Do

not overload the diaphragm with a sudden surge of inlet pressure. Monitor the outlet

pressure during start-up to prevent an outlet pressure overload. Refer to RM-1306 for

4

more detailed start-up procedures.

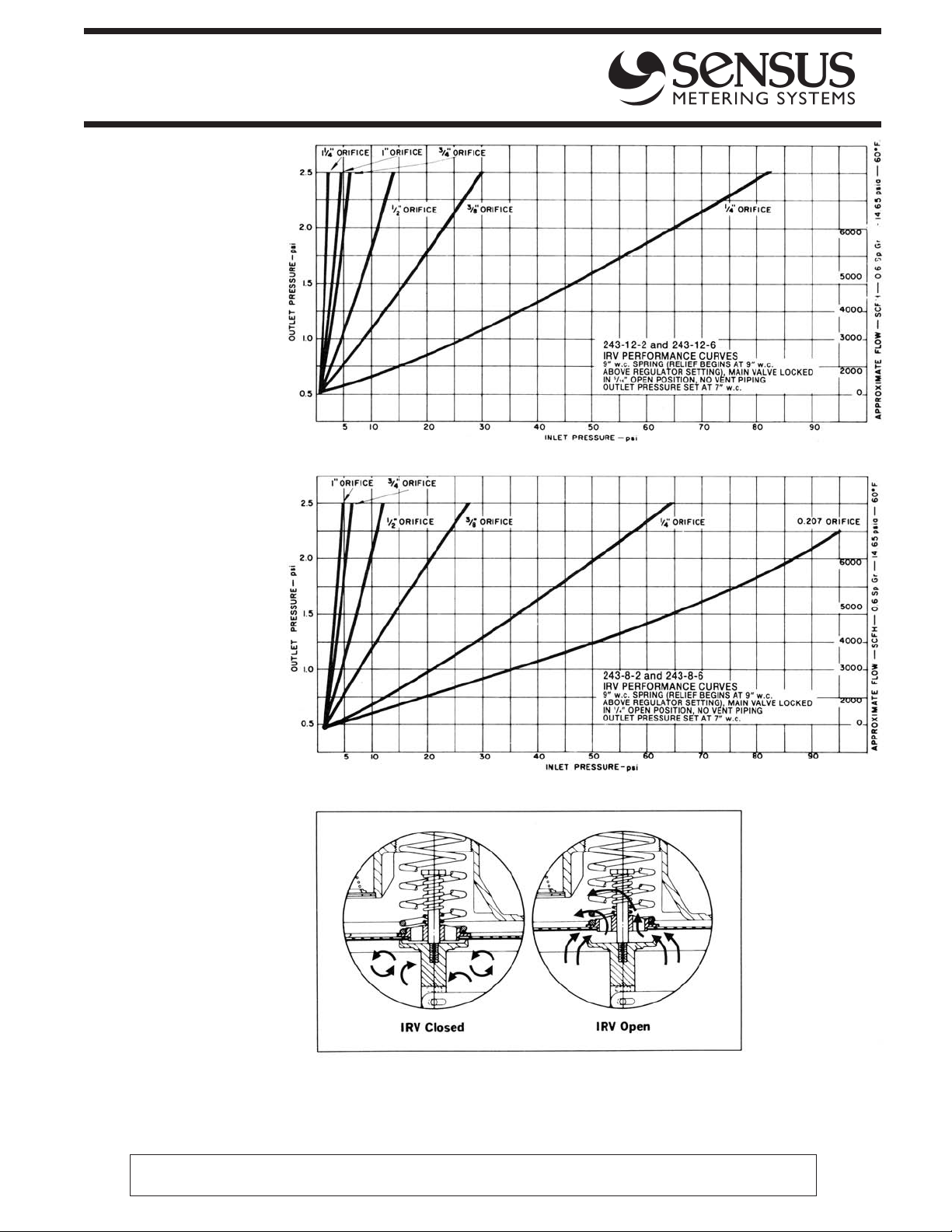

Operation of the

Internal Relief Valve

The internal relief valve is

optional (refer to Basic Models

Table, page 2).

Often called an “IRV”, it is built

into the center of the

diaphragm assembly as

shown in the adjoining sketch

and works in essentially the

same way as standard relief

valves.

It opens when outlet pressure

exceeds the setpoint by

approximately 9” w.c. thereby

allowing excess gas to

escape through the vent to

atmosphere. An optional

spring is available on the 2438-2 for relieving at approximately 20” w.c. above set

point. A cross-section of a

complete 243 with IRV is

shown on page 6.

Performance is given on the

curves at the right. The IRV

will prevent the outlet pressure from exceeding the value

shown by the curves upon

regulator failure at the conditions specified.

The IRV is a proven design of

quality construction. Within its

capacity limits it adds a measure of safety protection to the

outstanding and dependable

performance of the 243.

, like any other relief valve, must be sized carefully

Caution: Note that an IR

exceed the maximum safe limit it is essential to provide an additional relief valve carefully sized to handle the dif

V

. If the curves indicate that outlet pressure can

ference.

5

243 Variations

Internal Relief Valve

The 243 is available with an internal relief valve (IRV). It’s a

built-in safety device for providing a limited level of overpressurization protection.

Like any relief valve, an IRV must be carefully sized.

ore complete description plus performance data is given on

M

page 5. For Basic Models refer to the table on page 2.

Internal Relief valves are not available in the high pressure

Model 243-8HP

Low Pressure Cut-Off

The low pressure cut-off (LPCO) is used for automatic gas shutoff when inlet pressure is too low for the required gas flow. Once

closed, it must be manually reopened and reset.

Basic Models are given in the table at the bottom on page 2.

Note: There is an LPCO version that also includes the internal

relief valve.

Outlet pressures range from 4” w.c. to 30” w.c. and available orifices are

capacities please refer to data bulletin RDS 1306-1.

1

⁄2”, 3⁄4” and 1”. For more complete information and

Pressure Loading

While pressure loading (self-operation) falls short of the remarkable accuracy inherent in the pilot operated regulator (relayoperation) it still does a good job. And the pressure loaded 2438PL has a performance background of many years of dependable, accurate pressure control.

1

Its outlet range is 3 to 35 psig. Pipe sizes are 1

It is available arranged either bleed to atmosphere or bleed to

line. Capacities range to over 50,000 scfh.

⁄4”, 11⁄2” and 2”.

6

Monitoring and

External Control Line

This 243 is used for the first regulator (upstream regulator) in a

monitor set or for other applications requiring an external downstream control line.

A throat block with an o-ring stem seal isolates the lower

iaphragm chamber which has a

d

xternal control line.

e

Use of this regulator for monitoring is shown on page 20.

Capacities with the external control line are provided on pages

12 and 13.

1

FNPT connection for the

⁄2”

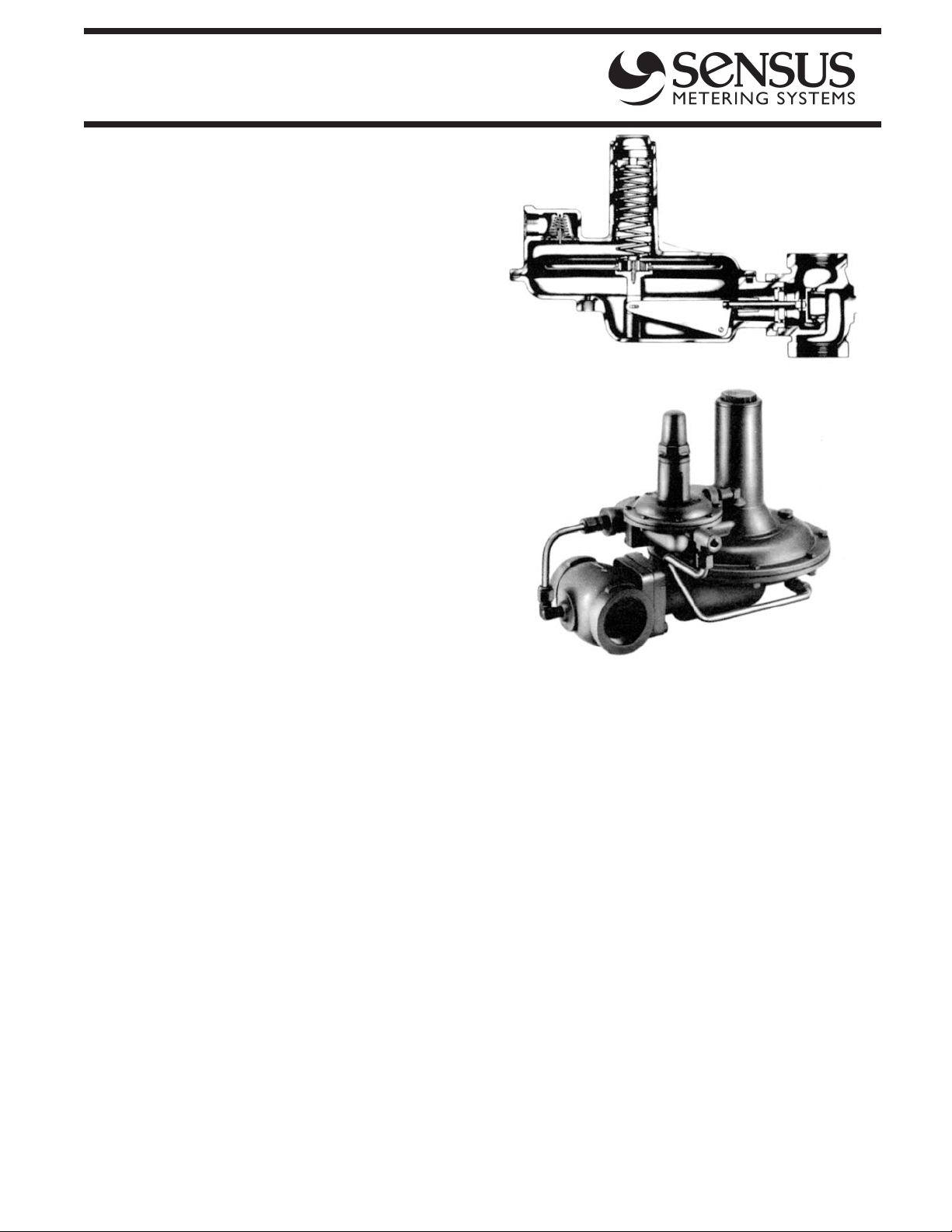

Pilot Operated Regulator

The 243-RPC is a genuine pilot operated regulator. It works on

exactly the same relay-operation principle as the widely used

models 1100 and 1200, and the 441-VPC.

Like its bigger brothers, it not only provides remarkably precise

pressure regulation but it maintains that high level of accuracy

even for wide variations in inlet pressure.

1

The 243-RPC can be used for any outlet pressure from 3

to 35 psig with capacity ranging as high as 75,000 scfh.

For detailed information please refer to Bulletin R-1343.

⁄2” w.c.

7

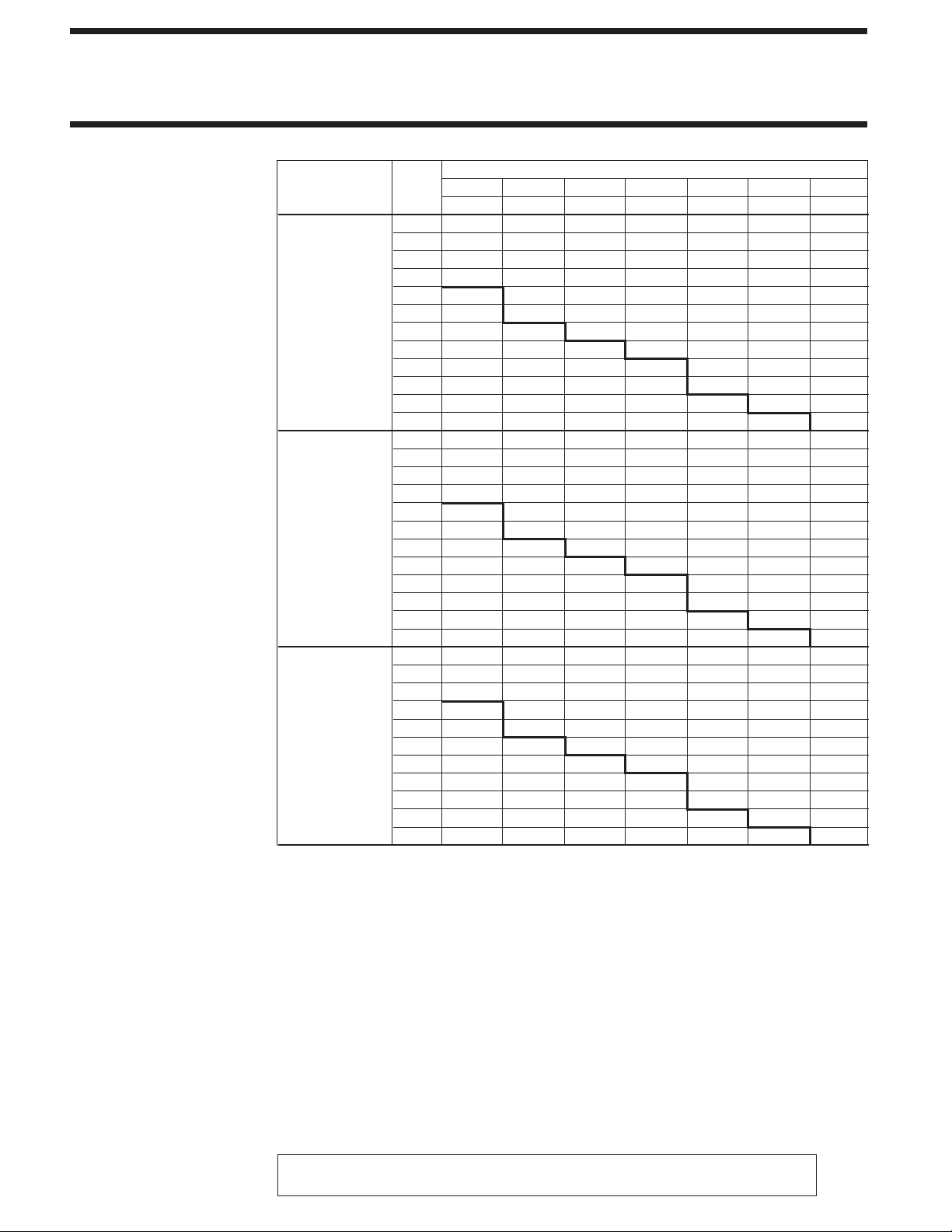

Model 243 Capacity Tables

2” Models 243-12-1 and 243-12-2 in SCFH of Natural Gas

Outlet Pressure

and Spring

Set Point 6” w.c.

1” w.c. Droop

Red Spring

31⁄2” to 61⁄2” w.c.

43-16-021-03

1

Inlet

Pressure

psi

1

⁄2

1

2

5

10

15

1

⁄4”1”3⁄4”

1

o

30

2400

4000

6400

11000

13000

14000

25

40

60

80

100

125

1

2000

10

15

⁄2

3400

1

6000

2

11000

5

12500

14000

Set Point 7” w.c.

1” w.c. Droop

Blue Spring

5” to 81⁄2” w.c.

143-16-021-04

25

40

60

80

100

125

3400

10

15

1

5600

2

10500

5

13000

14000

Set Point 11” w.c.

2” w.c. Droop

Green Spring

6” to 14” w.c.

143-16-021-05

25

40

60

80

100

125

Last capacity figure in each group indicates maximum allowable inlet pressure (except for emergency conditions). Heavy

stepped line indicates the recommended maximum capacity and inlet pressure for each orifice for operation within the

optimum performance

range.

Orifice Size and Valve Angle

o

30

2200

3600

6000

11000

15000

15000

15000

1800

3000

5600

11000

14000

15000

15000

3000

4700

9000

13000

14000

15000

(0.6 Specific Gravity - 14.65 psia - 60ºF)

30

1500

2700

4500

8200

12500

15000

20000

20000

3

o

⁄4”

o

10

1250

2100

3800

6500

9000

10300

11500

13000

15000

1

⁄2”

o

10

800

1300

2200

3800

5700

7100

9500

13000

13000

13000

13000

3

⁄8”

10

500

850

1400

2300

3300

4000

5300

7500

10000

12000

12000

12000

1400

2200

4000

8000

12000

15000

20000

20000

1100

2000

3200

6000

8400

10000

11500

13500

15000

700

1200

2000

3700

5600

7100

9500

12000

13000

13000

13000

500

750

1250

2100

3300

4000

5300

7500

10000

12000

12000

12000

2100

3700

7800

12000

15000

20000

20000

1950

3400

6900

9200

10500

12000

14500

15500

1150

2000

3500

5500

7000

9500

12500

13000

14000

14000

750

1200

2100

3200

4000

5300

7500

10000

12000

12000

12000

1

o

⁄4”

o

10

400

600

1000

1500

1750

2400

3300

4500

5700

7000

8000

400

600

1000

1400

1750

2400

3200

4400

5600

7000

8000

400

600

1000

1600

1800

2400

3200

4400

5600

7000

8000

Note: The performance data is based on normal testing at 70ºF flowing temperature.

8

Changes in performance can occur at extreme low flowing temperatures.

Loading...

Loading...