Page 1

Pico™ Controller

Bulletin 1760

Getting Results

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may

be present.

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be

dangerous temperatures.

Page 3

Table of Contents

Preface

Pico Controller

Drawing a Circuit with Pico

Who Should Use this Manual. . . . . . . . . . . . . . . . . . . Preface-i

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . Preface-ii

Common Techniques Used in this Manual . . . . . . . . . Preface-ii

Rockwell Automation Support . . . . . . . . . . . . . . . . . Preface-iii

Chapter 1

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Simply Pico. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Mount Pico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Connect Pico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Pico Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Chapter 2

Operation of Pico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Set the Menu Language . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Set the Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Choose Pico Operating Mode . . . . . . . . . . . . . . . . . . . . . . 2-4

Pico Circuit Diagram Elements. . . . . . . . . . . . . . . . . . . . . . 2-5

Example: Creating a Circuit Diagram . . . . . . . . . . . . . . . . . 2-9

Function Relay Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Example: Use a Function Relay . . . . . . . . . . . . . . . . . . . . . 2-20

Basic Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Pico Interface Socket

Specifications

Chapter 3

Appendix A

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Product Selection Table. . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Index

i Publication 1760-GR001C-EN-P - April 2005

Page 4

Table of Contents ii

Publication 1760-GR001C-EN-P - April 2005

Page 5

Preface

Read this preface to familiarize yourself with the rest of the manual. It

provides information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

• Rockwell Automation support

Who Should Use this Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use Pico

controllers.

You should have a basic understanding of electrical circuitry and

familiarity with relay logic. If you do not, obtain the proper training

before using this product.

i Publication 1760-GR001C-EN-P - April 2005

Page 6

Preface ii

Purpose of This Manual

This manual provides a basic overview of Pico and an introduction to

Pico programming. For a more detailed description of how to install

and use your Pico Controller, refer to publication 1760-UM001, Pico

Controller User Manual.

Related Documentation

The following documents contain additional information concerning

Rockwell Automation products. To obtain a copy, contact your local

Rockwell Automation office or distributor.

For Read this Document Document Number

A more detailed description of how to install and use your Pico

controller.

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

A description of important differences between solid-state

programmable controller products and hard-wired electromechanical

devices

Pico Controller User Manual 1760-UM001

Allen-Bradley Programmable

Controller Grounding and Wiring

Guidelines

Application Considerations for

Solid-State Controls

1770-4.1

SGI-1.1

An article on wire sizes and types for grounding electrical equipment National Electrical Code - Published by the National Fire

Protection Association of Boston, MA.

A complete listing of current documentation, including ordering

instructions. Also indicates whether the documents are available on

CD-ROM or in multi-languages.

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not

Allen-Bradley Publication Index SD499

AG-7.1

Glossary

procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Italic type is used for emphasis.

Publication 1760-GR001C-EN-P - April 2005

Page 7

Preface iii

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the

world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

please review the Troubleshooting chapter in the Pico Controller User

Manual first. Then call your local Rockwell Automation representative.

You can also contact Rockwell Automation Technical Support. To

reach our Technical Support, go to the following website to find the

support site for your region.

• http://support.automation.rockwell.com/contactinformation/

Your Questions or Comments on this Manual

If you find a problem with this manual, or you have any suggestions

for how this manual could be made more useful to you, please

contact us at the address below:

Rockwell Automation

Control and Information Group

Technical Communication, Dept. A602V

P.O. Box 2086

Milwaukee, WI 53201-2086

or visit our internet page at:

http://www.ab.com/pico or http://www.rockwellautomation.com

Publication 1760-GR001C-EN-P - April 2005

Page 8

Preface iv

Publication 1760-GR001C-EN-P - April 2005

Page 9

Safety Information

Pico Controller

ATTENTION

Electrical Shock Hazard

The electrical installation and commissioning work

must only be carried out by suitably qualified

personnel.

Do not work on the device when the power is turned

on.

Observe the relevant safety regulations:

• Turn off the power

• Make sure that the device cannot be powered on

again inadvertently

• Check to make sure that no dangerous voltages

are present before working on the device

Chapter

1

Simply Pico

Clever Switching and Controlling

Pico is a compact, user-friendly and low-cost controller for simple

control applications. Applications range from building and domestic

automation to machine and plant control. Pico has built-in

user-friendly operating elements and an LCD display.

Connect Pico and draw a circuit diagram on the display by pressing

the buttons on the device. Pico works with make contacts, break

contacts, and relays.

Enter a circuit diagram in Pico just like it is sketched on paper. Pico

has basic and advanced functions for relays, time switches and

contactors, among other functions. Make changes to the circuit by

pressing the buttons on the device. Time consuming rewiring is not

necessary.

1 Publication 1760-GR001C-EN-P - April 2005

Page 10

1-2 Pico Controller

Applications Everywhere

• Building and domestic automation, controllers for lighting,

doors, window shutters

• Control ventilators, rotating doors, greenhouses, exterior

lighting, window controllers, shop display lighting

• Create controllers for temperature, ventilation and brightness

levels

• Control machines and plant, presses, conveyor belts, oscillating

conveyors, sorters, pumps

Overview of Pico

7

8

7

8

8

Item Description

1 Incoming Power

1

D

2

e

l

A

lt

3

4

E

s

c

O

D

e

l

A

lt

E

s

c

O

k

k

5

6

5

3

5

Publication 1760-GR001C-EN-P - April 2005

2 Inputs

3 Power/Run LED

4 Keypad

5 Socket for memory module or PC interface cable

6 Outputs

7 LCD display

8 Write-On Surface

Page 11

Pico Controller 1-3

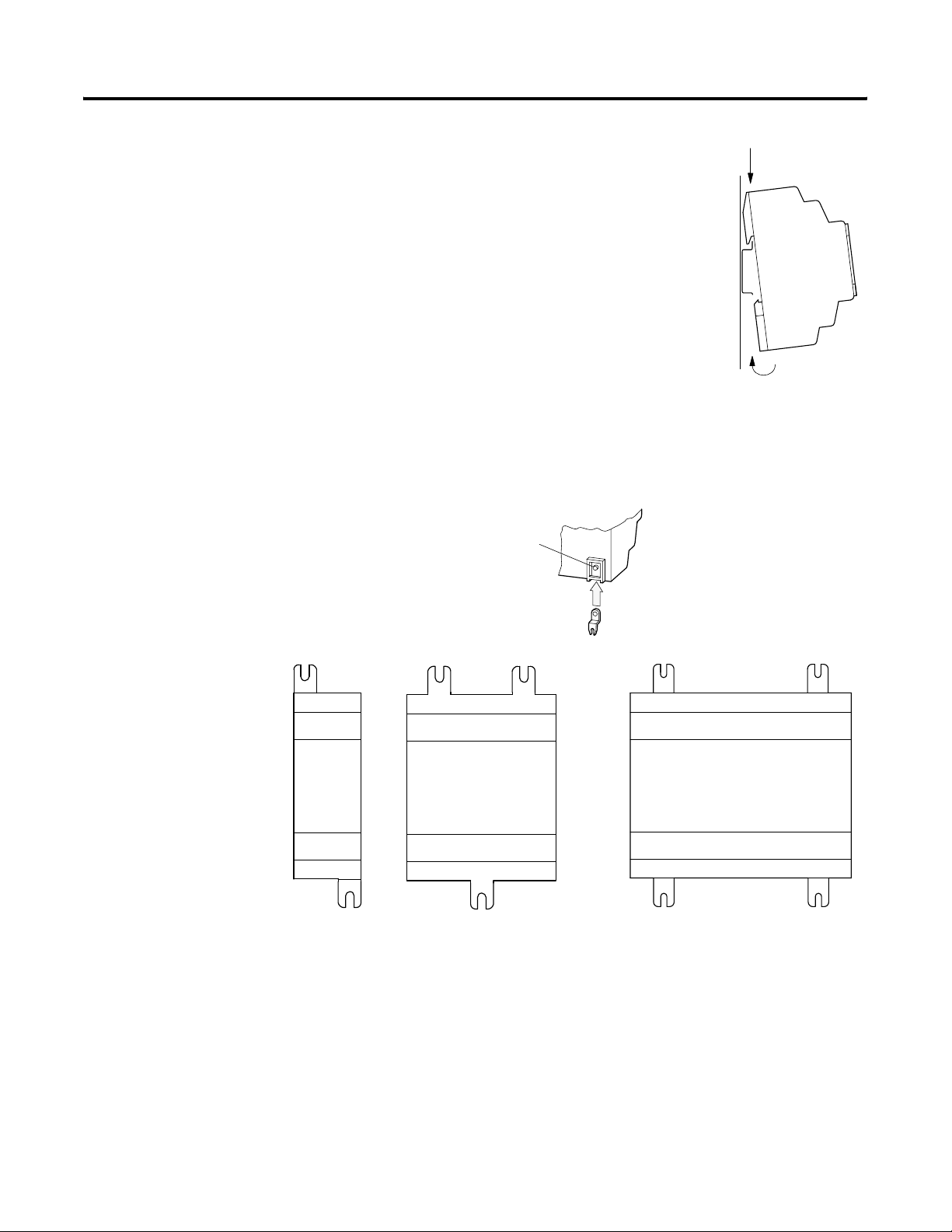

Mount Pico

Mount on DIN Rail

1. Hook Pico to the top edge of the DIN rail

and rotate into place while pressing down

slightly as shown by the arrow.

2. Pico will clip into place and is secured by

the built-in spring mechanism.

Mount on a Mounting Plate

Pico can be screwed to a mounting plate with the three or four feet

which are included.

Click

1

2

Publication 1760-GR001C-EN-P - April 2005

Page 12

1-4 Pico Controller

Connect Pico

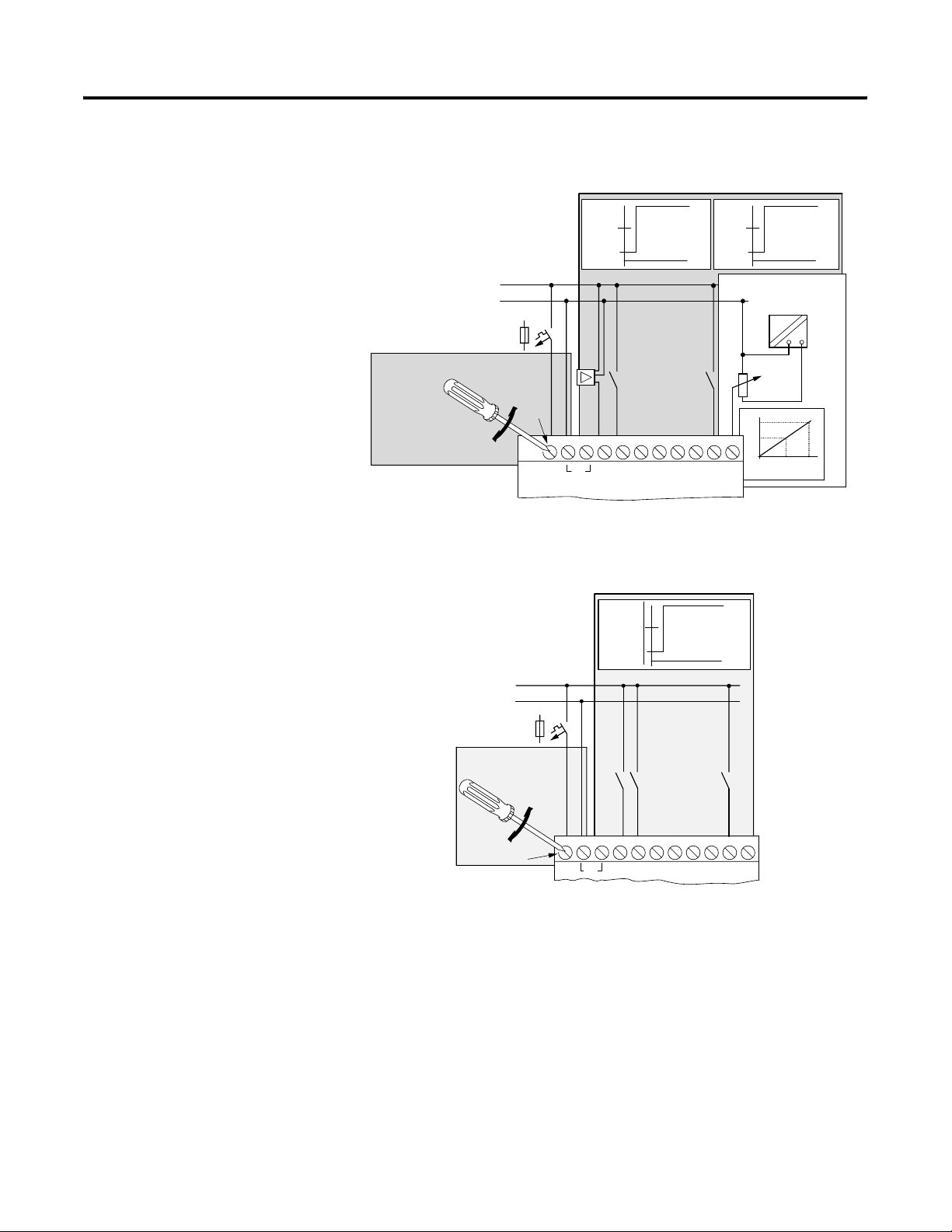

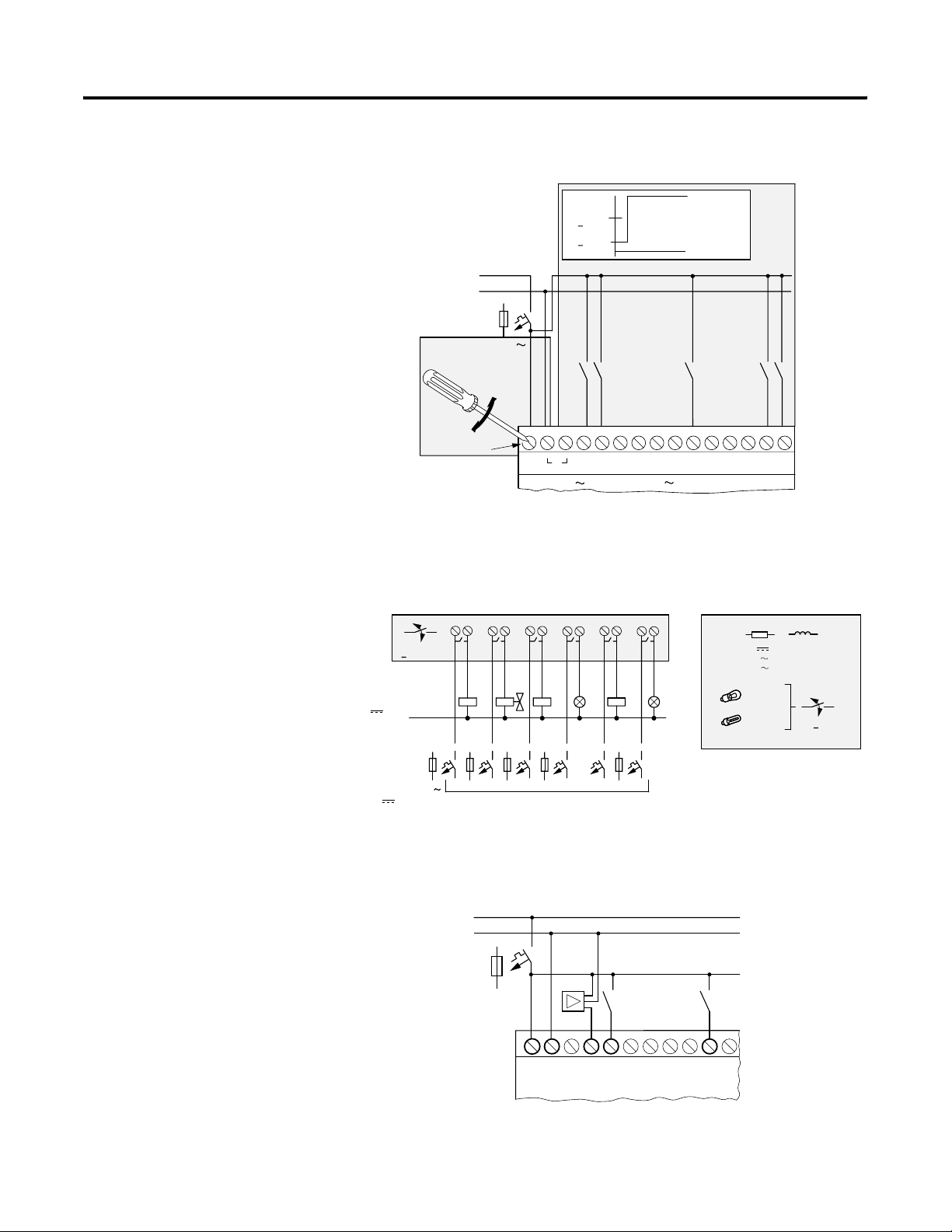

Pico Inputs1760-L12BBB-xx, 1760-L12BWB-xx and 1760-L12DWD-xx

BWB

I6

15.6 V

1 ≥ 8 V

0 ≤ 4 V

10 V

I7 I8

BWB:

= 24 V

U

e

(20.4 - 28.8 V)

= 80 mA

I

e

DWD:

= 12 V

U

e

(10.2 - 15.6 V)

= 140 mA

I

e

BWB: +24 V

DWD: +12 V

0 V

> 1 A

5 - 7 lb-in

3.5 mm

BWB: +24 V

DWD: +12 V

+.. V

COM

28.8 V

1 ≥ 15 V

0 ≤ 5 V

l1I2I3

l = 3.3 mA/24 V

I7, I8 = 2.2 mA/24 V

I4 I5

Pico Inputs 1760-L12AWA-xx and 1760-L12NWA-xx

l = 3.3 mA/12 V

I7, I8 = 1.1 mA/12 V

l7, l8

~

0 V

5 V

0 V

0

510

DWD

+10 V

5-7 lb-in.

L1

L2

>1A

Ue = 120/240 V

50/60 Hz

(90 to 264V)

le = 40 mA 120V

20 mA 240V

3.5 mm

264V

1 ≥ 79V

0 ≤ 40V

L2

L1

l1

I3

I2

l1–I6 = 0.5 mA 240 V

l1–I6 = 0.25 mA 120 V

I7, I8

l = 6 mA 240 V

l = 4 mA 120V

I4 I5

I6

I7 I8

Publication 1760-GR001C-EN-P - April 2005

Page 13

Pico Controller 1-5

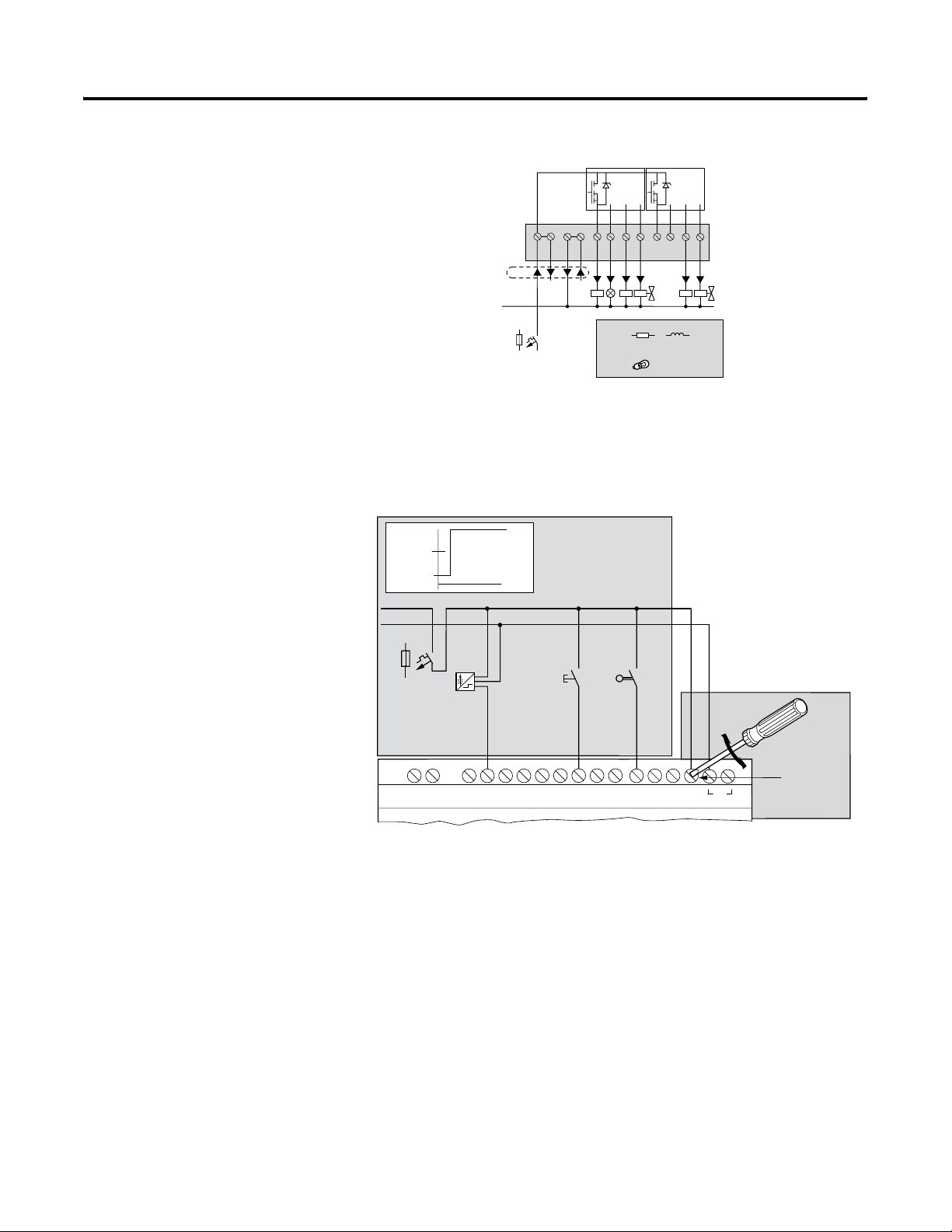

Pico Outputs 1760-L12AWA-xx, 1760-L12BWB-xx, 1760-L12DWD-xx, 1760-L12BBB-xx and 1760-L12NWA-xx

10 000 000

0 V , N

8 A / B 16

L1, L2, L3 (120/240 V )

+ 24 V

1

2

Q1

1

2

2

1

Q3 Q4

Q2

2

1

R

24 V 8 A

120 V 8 A

240 V 8 A

1000 W

10 x 58 W

L

2 A

2 A

2 A

25.000

Pico Inputs 1760-L18BWB-EX and 1760-L18BWB-EXND

I1–I6, I9–I12 = 3.3 mA

28.8 V

Input 24 V

24 V

I7, I8 = 2.2 mA

24 V

I4 I5

l7, I8

I6

I7 I8

10 V

z

0V

+10 V

5V

0V

0

10

5

I9

I10

I11 I12

5–7 lb-in

+24 V

> 1 A

Ue = 24 V

(20.4–28.8 V )

= 140 mA

I

e

3.5 mm

1 ≥ 15 V

0 ≤ 5 V

0V

COM

+24 V

24 V

l1I2I3

-

G '1D %

B

Publication 1760-GR001C-EN-P - April 2005

Page 14

1-6 Pico Controller

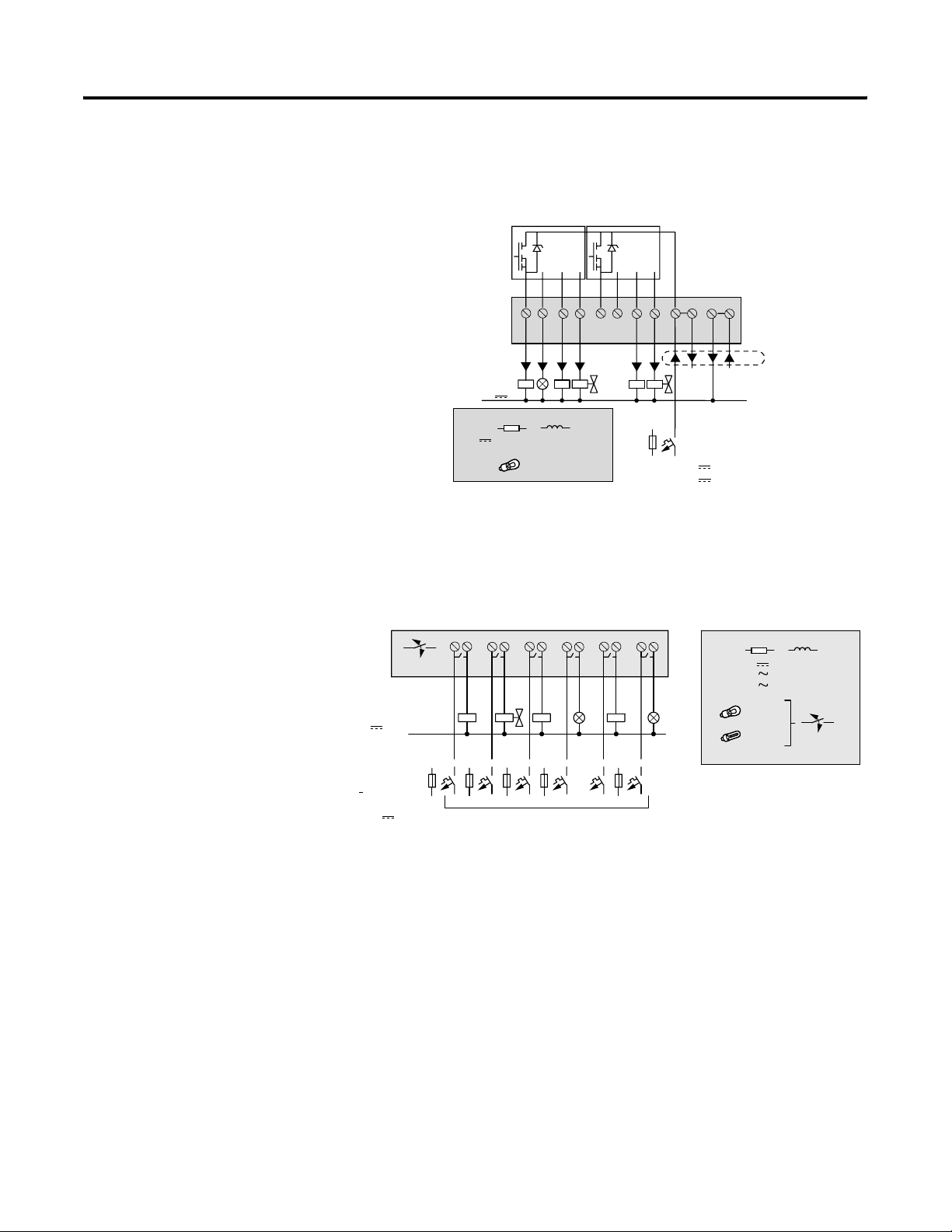

Pico Inputs 1760-L18AWA-xx and 1760-L18NWA-xx

L1

L2

> 1 A

Ue = 120/240 V

50/60 Hz

(85–264 V)

le = 70 mA 120 V

35 mA 240 V

5-7 lb-in.

3.5 mm

L1

100/240 V Input 100/240 V

Pico Outputs 1760-L18xxx

0 V , N

< 10 000 000

12 2 2 2 2 2

Q1

Q2

1

1

264 V

1 > 79 V

0 < 40 V

l1

L2

1

l1–I6, I9 –I12 = 0.5 mA 240 V

l1–I6, I9 –I12 = 0.25 mA 120 V

I7, I8

l = 6 mA 240 V

l = 4 mA 120 V

I4 I5

I3

I2

1

1

Q6Q5Q4Q3

I7 I8

I9

I10

24 V

120 V 8 A

240 V 8A

10 x 58 W

I11 I12

R

1000 W

8A

2A

2A

2A

< 25.000

I6

Publication 1760-GR001C-EN-P - April 2005

8 A / B 16

L1, L2, L3 (120/240 V )

+ 24 V

Pico Inputs 1760-L20xxx

L011

L012

F1

+...V

DC : +24 V

DA : +12 V

0 V l1 I2 I7

Page 15

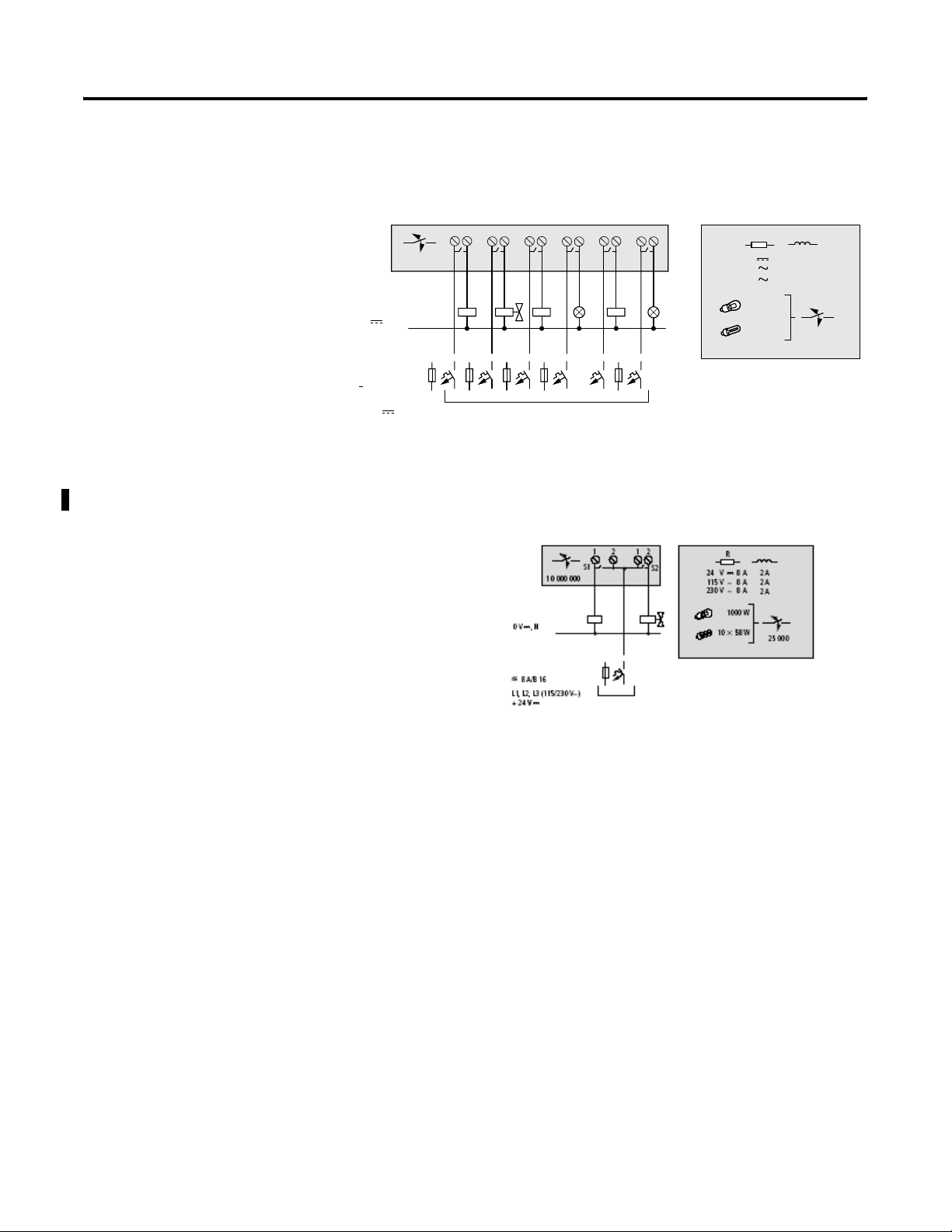

Pico Outputs 1760-L20xxx

Pico Controller 1-7

+24 V 0 V Q1 Q2 Q3Q4Q5Q6Q7

F 10 A

0 V H

f 2.5 A

(20.4 – 28.8 V H)

Pico Inputs 1760-IB12XOB8

28.8 V

1 ≥ 15 V

0 ≤ 5 V

+24 V

0V

> 1 A

R1–R12 = 3.3 mA; 24 V

Q

+ 24 V H

Q

R

24 V H

0.5 A

Q8

0.5 A

5 W/24 V

R10R9R8R7R6R5R4R3R2R1NC NC

R11

R12 +24V

Input 24 V 24 V

5–7 lb-in

COM

Ue = 24 V

(20.4 –28.8 V )

= 140 mA

I

e

3.5 mm

Publication 1760-GR001C-EN-P - April 2005

Page 16

1-8 Pico Controller

Pico Outputs 1760-IB12XOB8

S1 S2 S3 S4 S5 S6 S7 S8

0V

R

24V 0.5A 0.5A

5W/24V

2.5A

≤

(20.4-28.8V dc )

+24V dc

+ 24V dc

COM

Pico Inputs 1760-IA12XOW6I and 1760-IB12XOW6I

1

1

1

S6S5S4S3

0 V , N

10 000 000

12 2 2 2 2 2

S1

S2

1

1

10A

R

24 V

120 V 8 A

240 V 8 A

1000 W

10 x 58 W

8A

2A

2A

2A

25.000

Publication 1760-GR001C-EN-P - April 2005

< 8 A / B 16

L1, L2, L3 (120/240 V)

+ 24 V

Page 17

Pico Outputs 1760-IA12XOW6I and 1760-IB12XOW6I

Pico Controller 1-9

12 2 2 2 2 2

1

S1

10 000 000

0 V , N

< 8 A / B 16

L1, L2, L3 (120/240 V)

+ 24 V

S2

Pico Outputs 1760-OW8

1

1

1

1

S6S5S4S3

R

24 V

120 V 8 A

240 V 8 A

1000 W

10 x 58 W

8A

2A

2A

2A

25.000

Publication 1760-GR001C-EN-P - April 2005

Page 18

1-10 Pico Controller

Pico Operating Principle

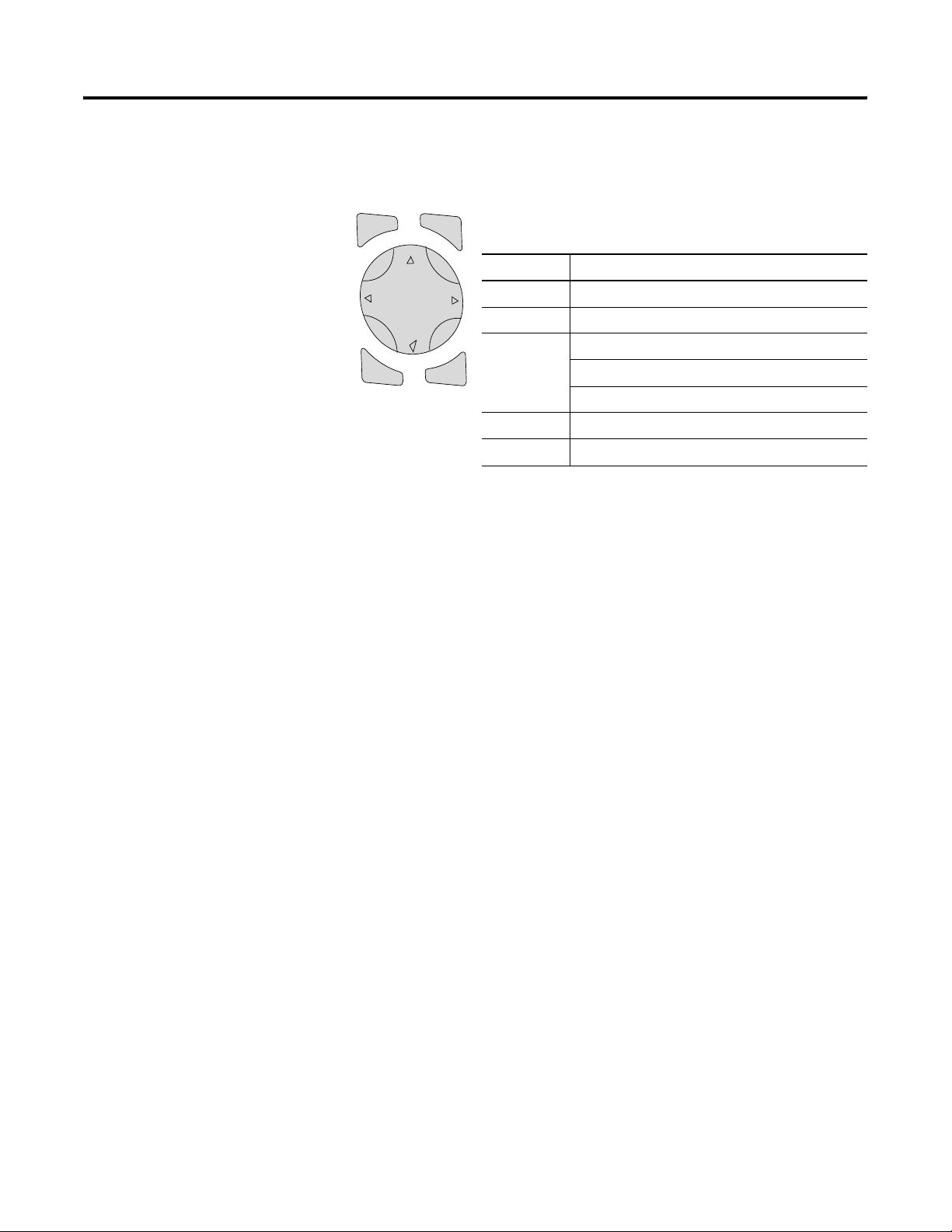

Pico Operating Buttons

Del

Esc

Alt

Button Function

Del Delete object in the circuit diagram

Alt Special functions in the circuit diagram

Cursor

Buttons

Ok

Ok Next menu level, store your entry

Esc Previous menu level, cancel your entry

Move cursor

Select menu item

Choose contact numbers, values, times, etc.

Publication 1760-GR001C-EN-P - April 2005

Page 19

Move Through Menus to Choose Values

Press To

Show system menu (press both keys at the same time).

Pico Controller 1-11

Del

and

Alt

Ok

Cancel your entry since the last Ok.

Esc

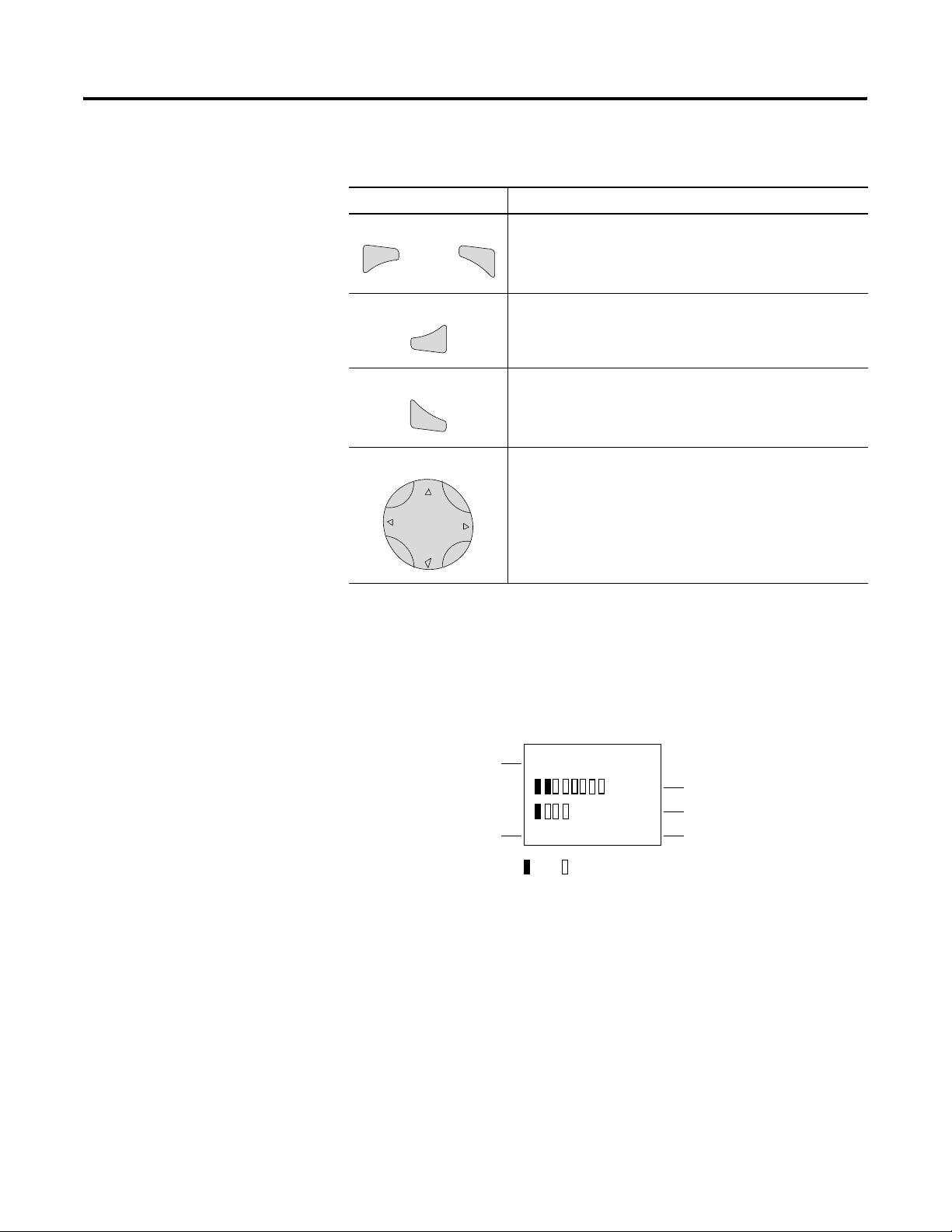

12-Point Status Display

• Go to next menu level.

• Select menu item.

• Store your entry.

• Change menu item.

• Change value.

• Change position.

Inputs

Outputs

I12345678

MO

12:50

Q1234 RUN

On/ Off

Weekday

Time

RUN/STOP mode

Publication 1760-GR001C-EN-P - April 2005

Page 20

1-12 Pico Controller

18-Point and 20-Point Status Display

Inputs

Retention Enabled

Day, Time

Outputs

Menu Display

Current choice

blinks in the Pico

menu

1...5..8....

IP

RE

MO 02:00 ST

.2..5..8 RUN

Inputs 1, 5, 8 ON

Outputs 2, 5, 8 ON

PROGRAM...

RUN...

PARAMETER

SET CLOCK..

Main menu with and without password enabled

Debounce Enabled/P-Buttons Enabled

Start-up Mode

Mode

PASSWORD..

RUN...

PARAMETER

SET CLOCK..

Publication 1760-GR001C-EN-P - April 2005

Page 21

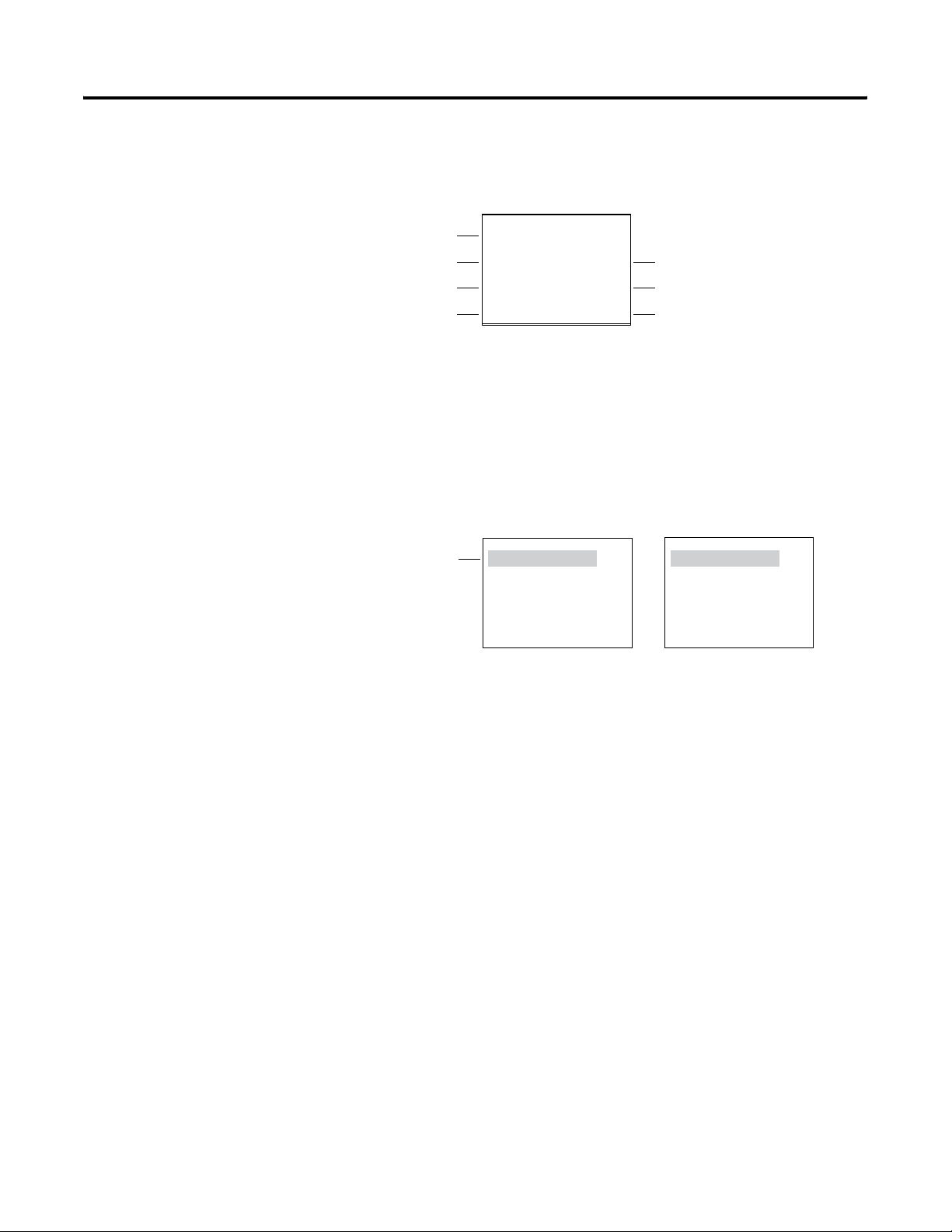

Cursor Display

Pico Controller 1-13

There are two different cursor types:

Full block navigation is shown as a flashing

block:

• Move cursor with the left/right arrows

• When in circuit diagram, also use

up/down arrows

Parameter change cursor flashes the selected

parameter:

• Change position with left/right arrows

• Change values with up/down arrows

Flashing values/menus are highlighted in grey

in this manual.

Circuit Diagram Menu

WINTER TIME

DAY : MO

TIME :

WINTER TIME

DAY :

TIME : 01:25

01 25

MO

Circuit

Connections/Rungs

Input

Contacts

I1 -I2 -T1 -{Q1

1

I2 -

Branch Connections

Output

Coil Field

Each rung can hold four instructions, three input instructions

(contacts) and one output instruction (coil or relay). Rungs are

connected together through branches at the three positions between

instructions. All programming of Pico can be done using the display

and keypad.

Publication 1760-GR001C-EN-P - April 2005

Page 22

1-14 Pico Controller

Circuit Diagram Symbols

P

I

Q

M

T

C

A

D

:

R

S

I1 -M2 -T1 -{Q1

I2 -Q1

I3-M2-T2----{Q2

Cursor button as input

Contact for input

Contact for output

Contact for internal marker bits

Contact for timer relay

Contact for counter relay

Contact for real time clock switch

Analog comparator contact

Contact for text display (1)

Contact for jump

Expansion Inputs

Contact for internal marker relay or

Expansion Output

(1)

(1)

(1)

Coil Field

1st circuit connection

2nd circuit connection

3rd circuit connection

…

41st circuit connection

…

Last circuit connection

Publication 1760-GR001C-EN-P - April 2005

(1) For 1760-L18xxx only

Page 23

Pico Controller 1-15

Menu Structure

PROGRAM...

STOP RUN

PARAMETER

INFO...

SET CLOCK

PROGRAM...

STOP RUN

PARAMETER

INFO...

SET CLOCK

Main Menu Without Optional Password Protection

STOP: Circuit diagram menu

RUN: Power flow display

RUN

å

STOP

PROGRAM

DELETE PROG

CARD ...

PROGRAM

DELETE PROG

CARD ...

PROGRAM

DELETE PROG

CARD ...

RUN

STOP

Circuit Diagram

Parameters

DELETE ?

DEVICE->CARD

CARD->DEVICE

DELETE CARD

DEVICE->CARD

CARD->DEVICE

DELETE CARD

DEVICE->CARD

CARD->DEVICE

DELETE CARD

Parameter

Display

REPLACE ?

REPLACE ?

DELETE ?

PROGRAM...

STOP RUN

PARAMETER

INFO...

SET CLOCK

PROGRAM...

RUN

PARAMETER

INFO...

SET CLOCK

PROGRAM...

RUN

PARAMETER

INFO...

SET CLOCK

T1 X

T2

Ü

C1 N

Parameter Display

O1

Information Display of Device

DC TC LCD

OS: 1.00.027

CRC: 02752

SET CLOCK

SUMMER TIME

S

M:S++

+

+

Display for

Setting Clock

HH:MM --:--

DD.MM

YEAR

T1 X

S1 10.000

S2 +0

T:

--.--

----

+S

HH:MM 14:23

DD.MM

YEAR

17.03

2004

Publication 1760-GR001C-EN-P - April 2005

Page 24

1-16 Pico Controller

Main Menu Setting Summer Time

PROGRAM...

RUN

PARAMETER

INFO...

SET CLOCK

SET CLOCK

SUMMER TIME

SET CLOCK

SUMMER TIME

SET CLOCK

SUMMER TIME

SET CLOCK

SUMMER TIME

NONE

RULE...

EU

GB

US

NONE

RULE...

EU

GB

US

NONE

RULE...

EU

GB

US

NONE

RULE...

EU

GB

US

å

SUMMER START

SUMMER END

AM -HH:MM --

--

DD.MM:00.00

HH.MM:00:00

DIFF: 0:00

SUMMER START

SUMMER END

SUMMER START

SUMMER END

AM -HH:MM --

--

DD.MM:00.00

HH.MM:00:00

DIFF: 0:00

Publication 1760-GR001C-EN-P - April 2005

Page 25

Main Menu with Password Protection

Pico Controller 1-17

Main Menu

PASSWORD...

RUN

PARAMETER

INFO...

SET CLOCK

PASSWORD...

RUN

TIP

Unlock

Password Entry

Password

Status Display

Four Wrong

Entries

Correct Entry

DELETE ALL

If you do not know the password, you can delete the

old password, but the circuit diagram and data will

also be deleted. To delete the password, press Ok to

DELETE ALL after entering four incorrect passwords.

(Pressing Esc retains the circuit diagram and data.

You can then make another four attempts to enter

the password.)

Publication 1760-GR001C-EN-P - April 2005

Page 26

1-18 Pico Controller

System Menu

System

sECURITY...

SYSTEM...

LANGUAGE ...

CONFIGURATOR

SECURITY...

SYSTEM...

LANGUAGE...

CONFIGURATOR

SECURITY...

SYSTEM...

LANGUAGE...

CONFIGURATOR

SECURITY...

SYSTEM...

LANGUAGE...

CONFIGURATOR

Set Password

Change Password

DEBOUNCE OFF

P ON

STOP MODE

DEBOUNCE OFF

P ON

STOP MODE

DEBOUNCE OFF

P ON

STOP MODE

DEBOUNCE OFF

P ON

STOP MODE

RETENTION ON

ENGLISH

DEUTSCH

FRANCAIS

ESPANOL

ITALIANO

PORTUGUES

NEDERLANDS

SVENSKA

POLSKI

TURKCE

CESKY

MAGYAR

Password Entry

Password

RANGE...

ACTIVATE PW

CHANGE PW

Password

RANGE...

DEBOUNCE OFF

DEBOUNCE ON

P ON

P OFF

MODE: STOP

MODE: RUN

(2)

RETENTION ON

RETENTION OFF

ENTER PASSW:

XXXX

ENTER PASSW:

XXXX

PROGRAM å

PARAMETER

CLOCK

OPRTNG MODE

INTERFACE

DELETE FUNCT

(2)

(2)

(1) Only for Pico 1760-L18xxx

(2) Only for Pico 1760-L12BWB-xx,

-L12DWD and -L18xxx.

CHANGE PW

ACTIVATE PW

CHANGE PW

ACTIVATE PW

PROGRAM å

PARAMETER å

CLOCK å

OPRTNG MODE å

INTERFACE å

DELETE FUNCT å

Publication 1760-GR001C-EN-P - April 2005

Page 27

Drawing a Circuit with Pico

Chapter

2

Operation of Pico

Buttons for Drawing Circuit Diagrams

Button Function

Del

Alt

Esc

Ok

Delete branch, contact, relay, or empty rung in the

circuit diagram

• Toggle between break and make contact

• Connect contacts and relays

• Add circuit connections

Up/down arrows:

• Change value

• Move cursor up and down

Left/right arrows:

• Move cursor to left and right

• Change between parameters

• Go to previous menu level

• Undo settings from previous Ok

• Exit current display

• Go to next menu level

• Change, add contact/relay

• Save setting

1 Publication 1760-GR001C-EN-P - April 2005

Page 28

2-2 Drawing a Circuit with Pico

Set the Menu Language

Power Up Pico for the First Time

TIP

When you power-up Pico for the first time, you are asked to select the

menu language.

Use the up and down cursor buttons to select a language. Definitions

of the language abbreviations are shown below.

Language LCD display Abbreviaton

English ENGLISH GB

German DEUTSCH D

French FRANCAIS F

Spanish ESPANOL E

A brief current surge is produced when powering on

the unit for the first time. Do not switch the unit

using reed contacts, since these may burn or melt.

ENGLISH

DEUTSCH

FRANCAIS

ESPANOL

ITALIANO

PORTUGUES

NEDERLANDS

SVENSKA

POLSKI

TURKCE

CESKY

MAGYAR

Italian ITALIANO I

Portuguese PORTUGUES –

Dutch NEDERLANDS –

Swedish SVENSKA –

Polish POLSKI –

Turkish TURKCE –

Czexh CESKY –

Hungarian MAGYAR –

Press Ok to confirm your choice or press Esc to exit the menu. The

unit then switches to the status display. You can also change the

language setting at a later date.

If you do not set the language, Pico displays this menu and waits for

you to select a language every time the unit is powered up.

Publication 1760-GR001C-EN-P - April 2005

Page 29

Drawing a Circuit with Pico 2-3

Set the Time

Controllers with the “-NC” designation do not have real time clocks.

Set the Real Time Clock

12 3 4 5 6 7

I

Q1234

8

MO

14:15

STOP

12-I/O Pico 18-I/O Pico

1 ...5 ..8 ....

RE

or

MO

.2 ..5 ..8 RUN

IP

02:00

ST

PROGRAM ...

Ok

PARAMETER

Ok

RUN

PROGRAM ...

RUN

PARAMETER

SET CLOCK

SET CLOCK

SUMMER TIME

Set Week Day and Time

SET CLOCK

SUMMER TIME

Esc

Esc

WINTER TIME

Ok

DAY : MO

TIME : 14:15

left/right arrows: Move cursor

up/down arrows:

Change values

Save setting

Ok

Keep previous value

Exit Menu

Publication 1760-GR001C-EN-P - April 2005

Page 30

2-4 Drawing a Circuit with Pico

Winter/Summer Time (Daylight Savings Time)

Display: SUMMER TIME

SET CLOCK

SUMMER TIME

Winter time is set

Display: WINTER TIME

Summer time is set

Ok

Toggle Settings

Choose Pico Operating Mode

Esc

Exit Menu

The two Pico operating modes are RUN and STOP.

• RUN: Pico processes the circuit diagram.

• STOP: Create and modify the circuit diagram.

The alternating RUN/STOP menu shows either

RUN or STOP as follows:

• STOP mode active: RUN is shown

• RUN mode active: STOP is shown

PROGRAM ...

RUN

PARAMETER

SET CLOCK ..

Selectable Start-up Behavior

It is possible to select the operating mode to be activated when Pico is

powered up. You can choose start-up in “RUN” mode or in “STOP”

mode through the System Menu.

Publication 1760-GR001C-EN-P - April 2005

Page 31

Drawing a Circuit with Pico 2-5

Pico Circuit Diagram Elements

Contacts

Contacts are used to modify the flow of current in the circuit diagram.

Contacts in the circuit diagram are either make or break contacts.

Make contacts are open when off (de-energized) and closed when on.

Break contacts are closed when off and open when on.

Contact Pico Representation

Make contact; Open when off I, Q, M, A, C, T, P, D, S, :, R

Break contact; Closed when off I

Pico works with different contacts, which can be used in any order in

the contact fields of the circuit diagram.

Contact Type Make

Contact

Controller Inputs I I

, Q, M, A, C, T, P, D, S, R

Break

Contact

1760-L12xxx 1760-L18xxx

I1 to I8 I1 to I12

1760-L20xxx

0 signal I13 I13

Expansion Status –

Short-circuit/overload I16 I15 to I16

Soft Inputs - Keypad P P

Controller Outputs Q Q

Internal Marker Bits M M

Internal Marker Bits N N

Counters C C

Timers T T

Real Time Clock

Analog Setpoint

Compare

Text D i s p l a y D D

Expansion Outputs or

Internal Marker Bits

Jump to Label : – :1 to :8 :1 to :8

Expansion Inputs R R

Expansion Overload

Detection

(1)

AAA1 to A16 A1 to A16

(2)

SS

RR

P1 to P4 P1 to P4

Q1 to Q4 Q1 to Q8

M1 to M16 M1 to M16

N1 to N16 N1 to N16

C1 to C16 C1 to C16

T1 to T16 T1 to T16

1 to 8 1 to 8

D1 to D16 D1 to D16

S1 to S8 S1 to S8

–R1 to R12

–

(3)

I14

R15 and R16

(3)

Publication 1760-GR001C-EN-P - April 2005

Page 32

2-6 Drawing a Circuit with Pico

Contact Type Make

Contact

Break

Contact

1760-L12xxx 1760-L18xxx

1760-L20xxx

Operating Hours Counter O O O1 to O4 O1 to O4

Year Time Switch Y Y

Master Reset Z Z

(1) Not available on “-NC” models.

(2) This applies only to the 1760-LxxBWB-xx and 1760-L12DWD.

(3) This applies only to 1760-L18xxx-EX models. R15 and R16 are used for expansion overload detection for the

transistor expansion module, 1760-IB12XOB8, as described on page 9-4.

Y1 to Y8 Y1 to Y8

Z1 to Z3 Z1 to Z3

Relays

Pico has thirteen different types of relay for use in a circuit diagram.

Relay type Pico Symbol 1760-L12xxx 1760-L18xxx

1760-L20xxx

Controller Outputs Q Q1 to Q8 Q1 to Q8 X –

Coil

Function

Parameter

Internal Marker Bits M M1 to M16 M1 to M16 X –

Internal Marker Bits N N1 to N16 N1 to N16 X –

Counters C C1 to C16 C1 to C16 X X

Timers T T1 to T16 T1 to T16 X X

Real Time Clock

(1)

1 to 8 1 to 8

–X

Operating Hours Counters O O1 to O4 O1 to O4 X X

Analog Setpoint Compare

(2)

A A1 to A16 A1 to A16 – X

Text Display D D1 to D16 D1 to D16 X X

Jump to Label : :1 to :8 :1 to :8 X –

Expansion Outputs or Internal Marker

S S1 to S8 (as marker) S1 to S8 X –

Bits

Year Time Switch Y Y1 to Y8 Y1 to Y8 – X

Master Reset Z Z1 to Z3 Z1 to Z3 X –

(1) Not available on “-NC” models.

(2) This applies only to the 1760-LxxBWB-xx and 1760-L12DWD.

The switching behavior of these relays is set using coil functions and

parameters. The coil functions and parameters are listed with the

description of each function relay type.

Publication 1760-GR001C-EN-P - April 2005

Page 33

Drawing a Circuit with Pico 2-7

The options for setting output and marker relays are listed with the

description of each coil function.

Retentive Actual Values

With Pico 1760-L12BWB-xx, 1760-L12DWD, and 1760-L18xxx, it is

possible to save the actual values of markers, timers and counters in

the event of a power failure. The quantities and values that may be

retained are found in the following table.

For further information see the Pico Controller User Manual,

publication number 1760-UM001B-EN-P.

Retentive Relays

Relay Type Pico

Symbol

Internal Marker Bits M 4 (M13 to M16) 4 (M13 to M16)

Counters C 1 (C8) 4 (C5, C6, C7, C8)

Timers T 1 (T8) 2 (T7, T8)

Text Display D – 8 (D1 to D8)

1760-L12BWB-xx

1760-L12DWD

1760-L18xxx

Publication 1760-GR001C-EN-P - April 2005

Page 34

2-8 Drawing a Circuit with Pico

Basic Output Energize

{

Instruction

Output

Instruction

Output

S,R

On

On

Maintained/Flip-Flop Output

On

On

Latching Output

Publication 1760-GR001C-EN-P - April 2005

Set Instruction

Reset Instruction

Output

On

On

On

Page 35

Drawing a Circuit with Pico 2-9

Example: Creating a Circuit Diagram

S1 S2

CR1

12 3 4 5 6 7

I

Q1234

12-I/O Pico 18-I/O Pico

Interconnect Contacts and Relays

Connecting Pico

CR1

Pico circuit diagram

M1

I1-I2----{Q1

Draw Circuit in Circuit Diagram Menu

Start Status Display

8

MO

14:15

STOP

1 ...5 ..8 ....

RE I P

or

MO 02:00 ST

.2 ..5 ..8 RUN

1. Connect S1 to Pico input terminal I1

2. Connect S2 to Pico input I2

3. Connect load M1 to Pico output Q1

PROGRAM...

Ok

RUN

PROGRAM...

OkOk

DELETE PROG

Insert Contact “I1”

Circuit Diagram Display

Ok

Ok

Ok

OkOk

I1

I1

I1

Publication 1760-GR001C-EN-P - April 2005

Page 36

2-10 Drawing a Circuit with Pico

Insert Contact “I2”

I1

Ok

Ok

I1 I1

I1 I1

Ok

I1 I2

I1 I2

Draw Connection Between Contact and Relay Coil

I1-I2

I1-I2

Alt

I1-I2---

Choose Relay Coil “Q1”

I1-I2---

I1-I2------{Q1

Ok

I1-I2------{Q1

Ok

Ok

I1-I2---

I1-I2------{Q1

Publication 1760-GR001C-EN-P - April 2005

Page 37

Change Operating Mode

Drawing a Circuit with Pico 2-11

I1-I1----{Q1

Test Circuit Diagram

PROGRAM

Esc

Esc

Ok

Pico now in RUN mode

DELETE PROG

PROGRAM...

RUN

PROGRAM...

RUN

PARAMETER

SET CLOCK..

PROGRAM...

STOP

PARAMETER

SET CLOCK...

PROGRAM...

STOP

PARAMETER

SET CLOCK...

Power flow display

I1-I2----{Q1

Ok

Publication 1760-GR001C-EN-P - April 2005

Page 38

2-12 Drawing a Circuit with Pico

Operate Switch “S1” and “S2”

“S1” on

“S2” on

Relay “Q1” picks up

I1-I2----{Q1

I1-I2----{Q1

Return to Status Display with ESC

I1-I2----{Q1

I1-I2----{Q1

Esc

Esc

12 3 4 5 6 7

I

Q1234

12-I/O Pico 18-I/O Pico

8

MO

13:34

STOP

or

12............

RE I P

MO 02:00 ST

1.........RUN

In the next example, a timing relay will be added to the circuit.

Status display is activated.

Ok

Choose STOP mode.

PROGRAM...

RUN

Ok

PARAMETER

SET CLOCK..

Publication 1760-GR001C-EN-P - April 2005

Page 39

Function Relay Types

Drawing a Circuit with Pico 2-13

Circuit Diagram

Symbol

Function Relay Type

Timing relay with on-delay, with and without random switching

Timing relay with off-delay, with and without random switching

Timing relay, single pulse

Timing relay, flashing

Counter relay, up/down counter

Time switch, weekday/time (only in Pico models with clock)

Analog comparator relay (only in Pico models with 24V dc)

Timing Relay

X?X

Tri gg er

Reset

Timer Output

Timing Relay with on delay, with and

without random switching

on

on

on

ttt

Publication 1760-GR001C-EN-P - April 2005

Page 40

2-14 Drawing a Circuit with Pico

?

Timing Relay with Off-Delay, with and without

Random Switching

Trigger

Reset

Timer Output

on

on

on

tt

With random switching, the relay contact switches randomly at any

time up to the specified time value (shown shaded in figure).

Timing Relay, Single Pulse

Tri gg er

on

Reset

Output

on

on

tt

Publication 1760-GR001C-EN-P - April 2005

Page 41

Timing Relay, Flashing

Flash Frequency = 1/2 x setpoint

Drawing a Circuit with Pico 2-15

Trigger

Reset

Tim er O utput

on

on

on

ttt

Parameter Display for Timing Relays

Switch Function

Tim e Un its

Trigger (Connected)

Reset (Not Connected)

00.00

S 30.00

{ TRG

RES

T1

+

Accumulated Time

Setpoint

Timer Number

Parameter Display

(Access Control)

Publication 1760-GR001C-EN-P - April 2005

Page 42

2-16 Drawing a Circuit with Pico

Counter Relay

Count Input

on

Direction

Reset

Accumulated Value

(setpoint = 6)

Counter Output

on

on

8

7

6

5

4

3

2

1

0

on

Parameter Display for Counter Relays

Counter Number

Setpoint

C1 N +

S

AAAAA

Parameter Display

(Access Control)

Accumulated Value

Publication 1760-GR001C-EN-P - April 2005

Page 43

Drawing a Circuit with Pico 2-17

Real Time Switch

Example: Real Time Switch 1 switches on Monday through Friday

between 6:30 and 9:00 and again between 17:00 and 22:30 (5:00 pm

and 10:30 pm).

1A

D MO-FR

ON

OFF

on

on

on

06:30

09:00

+

ON

OFF

1B

D MO-FR

17:00

22:30

Parameter Display for Real Time Switches

Real Time Switch Number

Week Day(s) from - to

On Time

Off Time

1A +

D SU

ON --:--

OFF --:--

Parameter Display

(Access Control)

+

Publication 1760-GR001C-EN-P - April 2005

Page 44

2-18 Drawing a Circuit with Pico

Analog Comparator

Available functions:

• I7 ≥ I8, I7 ≤ I8

• I7 ≥ Setpoint, I7 ≤ Setpoint

• I8 ≥ Setpoint, I8 ≤ Setpoint

The analog comparator can compare voltages from 0V to 10V

(setpoints “0.0” to “10.0”).

TIP

Analog signals of sensors typically fluctuate by

several millivolts. For stable switching the setpoints

should differ by at least 0.2V (switching hysteresis).

Do not use any relay with output energize or

impulse relay coil functions.

Parameter Displays for Analog Comparators

Compare inputs I7 and I8.

ANALOG

Input I7

Compare Function

Input I8

I7 8.0 V

A1

I8 4.2 V +

Current Value

Analog Compare Number

Parameter Display

(Access Control)

Current Value

Publication 1760-GR001C-EN-P - April 2005

Input I7/I8

Compare Function

Setpoint

Compare input “I7” to a setpoint.

ANALOG

I7 8.0 V

A1

3.2

+

Current Value

Relay Number

Parameter Display

(Access Control)

Page 45

Drawing a Circuit with Pico 2-19

Text Displ ay

The Text Display is used to display eight freely definable messages on

the Pico screen. Each text block displays up to 48 characters from the

Pico display character set (ASCII + Pico special characters). If the Text

Display is enabled, the text entered via PicoSoft is displayed. If several

Text Displays are enabled, the next screen is displayed every 4

seconds. When Text Display D1 is enabled it stays displayed (fault

indication).

Press Ok to switch to the menus at any time.

Current values or parameters of function relays can be displayed in

lines 2 and 3.

Examples:

Fault Signals Time with Text Display

CAUTION!

PUMP 1

MOTOR

MALFUNCTION

Display Counter Value

QUANTITY

ACTV 0042

PCS

SETP0100

THE TIME

IS

14:42

Display Current Value and

Parameter of Timing Relay

TIME RELAY 1

SETP99.00 S

ACTV 42.00 S

Publication 1760-GR001C-EN-P - April 2005

Page 46

2-20 Drawing a Circuit with Pico

Example: Use a Function Relay

Conventional Circuit

S1 S2

CR1

T1

CR1

T1

10.0 sec

M1

Select an Internal Marker Relay

Start Circuit from first example

Pico switches M1 with

10 seconds delay.

I1-I2----{M1

M1-------TT1

T1-------{Q1

Pico Circuit Diagram

Position cursor on “Q”

I1-I2----{Q1

2 X

I1-I2----{Q1

Ok

Ok

I1-I2----{M1

I1-I2----{M1

Select Marker Contact and Connect to New Output Relay

I1-I2----{M1

2 X

2 X

Ok

3 X

Alt

I1-I2----{M1

Ok

I1

Ok

I1-I2----{M1

M1------ {Q1

Publication 1760-GR001C-EN-P - April 2005

Page 47

Select Trigger Relay for Time

Drawing a Circuit with Pico 2-21

I1-I2----{M1

M1-------{Q1

Insert Timing Relay Contact

I1-I2----{M1

M1-------TT1

2 X

I1-I2----{M1

M1-------TT1

Ok

Ok

2 X

I1-I2----{M1

M1-------TT1

I1-I2----{M1

M1-------TT1

I1

I1-I2----{M1

M1-------TT1

T1

Select Parameter Access

I1-I2----{M1

M1-------TT1

T1

2 X

X

S 00.00

{ TRG T1

Ok

Publication 1760-GR001C-EN-P - April 2005

RES +

Page 48

2-22 Drawing a Circuit with Pico

Set “10 Seconds”

T1 X

S 00.00

TRG

RES

+

2 X

2 X

Ok

T1 X

S 00.00

TRG

RES

T1 X

S 10.00

TRG

RES

back to circuit diagram

Connect Timing Relay Contact to New Output Relay

I1-I2----{M1

M1-------TT1

T1

I1-I2----{M1

Alt

M1-------TT1

T1

+

+

Publication 1760-GR001C-EN-P - April 2005

3 X

3 X

I1-I2----{M1

M1-------TT1

Ok

T1-------{Q1

Change Pico to RUN to test the program. Test the circuit as shown for

the first example. To display and access the parameters for the timing

relay and change the time value in RUN mode, position the cursor in

the circuit diagram on the “T” of “T1” and press Ok.

Page 49

Drawing a Circuit with Pico 2-23

I1---------

Basic Circuits

Significance of Logic Values

Value Function

“0” Make contact open, break contact closed, relay coil not energized

“1” Make contact closed, break contact open, relay coil energized

Negation (NOR)

I1 Q1

10

01

Permanent Contact (Unconditional Rung)

--- Q1

11

I1---------{Q1

-----------{Q1

Flip-Flop Output

I1 State Q1 Q1

00 0

0 to 101

01 1

0 to 110

Q1

Publication 1760-GR001C-EN-P - April 2005

Page 50

2-24 Drawing a Circuit with Pico

Series Connection (AND)

I1 I2 I3 Q1 Q2

00001

10000

01000

11000

00100

10100

01100

11110

Parallel Connection (OR)

I1 I2 I3 Q1 Q2

00001

10011

I1-I2-I3-{Q1

I1-I2-I3-{Q2

I1--------{Q1

I2

I3

01011

11011

00111

10111

01111

11110

Exclusive OR Circuit (XOR)

I1 I2 Q1

000

101

011

110

I1--------{Q2

I2

I3

I1-I2------{Q1

I1-I2

Publication 1760-GR001C-EN-P - April 2005

Page 51

Motor Start/Stop Circuit

I1 I2 Contact Q1Coil

Q1

000 0

101 1

001 1

010 0

110 0

Drawing a Circuit with Pico 2-25

I1--I2-----{Q1

Q1

Alternatively:

I1--------SQ1

I2--------RQ1

Publication 1760-GR001C-EN-P - April 2005

Page 52

2-26 Drawing a Circuit with Pico

Publication 1760-GR001C-EN-P - April 2005

Page 53

Chapter

3

Pico Interface Socket

The Pico interface socket, which is beneath a protective cap, accepts

the optional Pico memory module, or connects Pico to a PC using the

optional PC interface cable and the PicoSoft software. This allows you

to copy the circuit diagrams to and from the PC and/or memory

module.

Memory Module

Memory modules are available as an optional accessory. Each memory

module can store a single Pico circuit diagram. Information stored on

the memory module is non-volatile (the information is not lost when

the power is turned off). The memory module can be used to make a

backup copy of a program and/or to transfer it to another Pico

controller.

Each memory module can hold one Pico program, up to 32K.

Each memory module stores:

• the circuit diagram

• all parameter settings of the circuit diagram

• system settings

1760-MM1 for all 1760-L12xxx

controllers

1760-MM2 for the 1760-L18xxx

controllers

1 Publication 1760-GR001C-EN-P - April 2005

Page 54

3-2 Pico Interface Socket

ATTENTION

ELECTRICAL SHOCK HAZARD

The memory module and PC-cable socket are at the

potential of L2. There is a danger of electric shock if

L2 is not grounded. Do not make contact with

electrical components under the socket cover.

Load or Store the Circuit Diagram

You can only transfer the program from Pico to the memory module

or vice versa in the STOP mode.

DEVICE - CARD: Transfer circuit diagram and

parameter settings from Pico to the memory

module.

CARD - DEVICE: Transfer circuit diagram and

parameter settings from the memory module to

Pico.

DELETE CARD: Delete the contents of the memory module.

DEVICE -> CARD

CARD -> DEVICE

DELETE CARD

Available Memory Modules

The following memory modules are available as Pico accessories.

Pico Controller Memory Module

1760-L12xxx 1760-MM1 (Series A only)

1760-L18xxx 1760-MM2 (Series A only)

Series B Pico Controllers 1760-MM2B

Programs including all relevant data can be transferred from the

1760-MM2B memory module to the Series B Pico Controllers. The

existing 1760-MM1 and 1760-MM2 memory modules are Read-Only

when used with Series B Pico Controllers. The 1760-MM2B memory

module will not work with Series A Pico Controllers.

Publication 1760-GR001C-EN-P - April 2005

Page 55

Pico Interface Socket 3-3

PicoSoft

PicoSoft is an optional PC program that creates, stores, and manages

Pico circuit diagrams. It transfers the circuit diagrams from the PC to

Pico or vice versa using a special PC interface cable.

ATTENTION

The PicoSoft software also includes extensive on-line Help.

To use the on-line Help, start PicoSoft and choose Contents in the

Help menu. Context sensitive help is also available. Choose a menu

item with the mouse and press F1 while keeping the mouse button

pressed.

The PC interface cable is catalog number

1760-CBL-PM02 and is available as an accessory

item. Only use the Pico interface cable. Do not

attempt to make your own cable as this can cause

damage to the unit or present a shock hazard.

Software Compatibility

If you are using programming software to program the Pico controller,

be sure that you are using the correct software version.

IMPORTANT

PicoSoft version 6.1 or higher must be used to for the

Series B Pico controller. Earlier versions of PicoSoft

can only be used with Series A Pico controllers.

Find the Series Letter

The Series letter is printed on the side of the housing as shown.

Download the Software

You can download a free copy of PicoSoft version 6.1 from our web

site. Go to http://www.ab.com/picosoft6

For PicoSoft Pro, please contact your Allen-Bradley Distributor or

Rockwell Automation representative.

.

Publication 1760-GR001C-EN-P - April 2005

Page 56

3-4 Pico Interface Socket

Publication 1760-GR001C-EN-P - April 2005

Page 57

Physical Specifications

Specifications

Appendix

A

Clock

1760-OW2

Display and

Keypad

Specification 1760-L12xxx 1760-L18xxx,

1760-L20xx

1760-IA12XOW6I,

1760-IA12XOW4I

1760-IB12XOB8

1760-IB12XOB8

Weight 200g (7 oz) 300g (10.6 oz) 70g (0.154 lb)

Ambient temperature, (operation) -25°C to + 55°C (-18°F to 131°F)

Storage Temperature -40°C to +70°C (-40°F to +158°F)

Operating Humidity 5 to 95%, non-condensing

Emitted interference, interference

immunity

Standards and regulations

Approvals

Product Selection Table

Catalog Number Inputs Outputs Line Power Real Time

EN 55011, EN 55022, Class B

EN 50178

UL, CSA, CE, C-Tick

Controllers

Analog

1760-L12AWA 8 (120/240V ac) 4 (relay) 100 - 240V ac Yes Yes No

1760-L12AWA-NC

1760-L12AWA-ND

1760-L18AWA 12 (120/240V ac) 6 (relay) Yes Yes

1760-L18AWA-EX

1760-L18AWA-EXND

1 Publication 1760-GR001C-EN-P - April 2005

(1)

(2)

(3)

(2)(3)

No Yes

Yes No

Yes Yes

Yes No

Page 58

A-2 Specifications

Catalog Number Inputs Outputs Line Power Real Time

Clock

Display and

Keypad

Analog

1760-L12BWB 8 (24V dc) 4 (relay) 24V dc Yes Yes 2 (0 to 10V dc)

1760-L12BWB-NC

1760-L12BWB-ND

(1)

(2)

No Yes

Yes No

1760-L12BBB 4 (MOSFET) Yes Yes 2 (0 to 10V dc)

1760-L12BBB-ND Yes No

1760-L12NWA 8 (24V ac) 4 (relay) 24V ac Yes Yes

1760-L12NWA-ND Yes No

1760-L12DWD 8 (12V dc) 12V dc Yes Yes

1760-L12DWD-ND Yes No

1760-L18BWB-EX

(3)

1760-L18BWB-EXND

1760-L20BBB-EX

(3)

1760-L20BBB-EXND

1760-L18DWD-EX

(3)

1760-L18DWD-EXND

1760-L18NWA-EX

(3)

1760-L18NWA-EXND

12 (24V dc) 6 (relay) 24V dc Yes Yes

(2)(3)

6 (relay) Yes No 2 (0 to 10V dc)

8 (MOSFET) Yes Yes 4 (0 to 10V dc)

(2)(3)

8 (MOSFET) Yes No

12 (12V dc) 6 (relay) 12V dc Yes Yes

(2)(3)

6 (relay) 12V dc Yes No

12 (24V ac) 6 (relay) 24V ac Yes Yes 4 (0 to 10V dc)

(2)(3)

12 (24V ac) 6 (relay) Yes No

(1) NC = no real time clock

(2) ND = no display

(3) EX = suitable for use with expansion modules

Publication 1760-GR001C-EN-P - April 2005

Page 59

Expansion Modules

Catalog Number Inputs Outputs Line Power

1760-IA12XOW6I 12 (100 - 240V ac) 6 (relay) 100 - 240V ac

1760-IA12XOW4IF 12 (100 - 240V ac) 4 (relay) 100 - 240V ac

1760-IB12XOW6I 12 (24V dc) 6 (relay) 24V dc

1760-IB12XOB8 12 (24V dc) 8 (transistor) 24V dc

1760-OW2 - 2 (relay) 24V dc

Accessories

Catalog Number Description

Specifications A-3

1760-MM1 Memory Module for 12 I/O Pico Controller

1760-MM2 Memory Module for 18 I/O Pico Controller

1760-MM2B Memory Module for Pico Series B Controllers

1760-CBL-PM02 Programming Cable for Pico Controller

1760-RPLCONN Expansion Module Connector - included with expansion module. Catalog number listed is replacement part.

1760-SIM Input Simulator for 12 I/O 24V dc Pico Controller

1760-PICOSOFT Configuration Software for Pico Controllers.

D1760GR001BENP Pico Controllers Getting Results Manual, publication number 1760-GR001B-EN-P

D1760UM001BENP Pico Controllers User Manual, publication number 1760-UM001B-EN-P

Publication 1760-GR001C-EN-P - April 2005

Page 60

A-4 Specifications

Dimensions

Pico 1760-L12xxx

10.75 50 1.97"

0.423"

M4

35.75 1.41"

71.5 2.81"

90 3.54"

102 4.02"

45 1.77"

110 4.33"

4.5 0.177"

47.5 1.87"

56.5 2.22"

58 2.28"

Pico 1760-L18xxx, 1760-L20xxx and Expansion Modules

75 2.96" 16.2516.25

107.5 4.23"

0.640"0.640"

M4

90 3.54"

110 4.33"

102 4.02"

4.5 0.177"

47.5 1.87"

56.5 2.22"

58 2.28"

45 1.77"

Publication 1760-GR001C-EN-P - April 2005

Page 61

Pico 1760-OW2 Expansion Module

0.295"

7.5

90 3.54"

110 4.33"

102 4.01"

M4

0.295"

7.5

35.5 1.4"

Specifications A-5

Dimensions of the 1760-RM… Remote Processor modules

176-RM… 1760-DU… and 176-RM…

58 2.28"

22.5

0.89"

75 2.95"

30 1.18"

22.5

0.89"

36.2 1.43"

20.5

0.81"

43.2 1.7"

27.5

1.08"

Publication 1760-GR001C-EN-P - April 2005

Page 62

A-6 Specifications

Publication 1760-GR001C-EN-P - April 2005

Page 63

Index

A

accessories A-3

Allen-Bradley

contacting for assistance

support Preface-iii

Analog comparator 2-18

Preface-iii

B

Basic circuit

Exclusive OR circuit (XOR)

Flip-flop output 2-23

Impulse relay 2-23

Motor start/stop circuit 2-25

Negation (NOR) 2-23

Permanent contact 2-23

Series connection (AND) 2-24

Break contact 2-5

Buttons 1-10

Use in circuit diagrams 2-1

2-24

C

Cable 3-3

Change operating mode 2-4

Circuit diagram

Access relay parameters

Choosing relay type 2-10

Displaying 2-9

Example 2-9, 2-20

Inserting contacts 2-9

Loading 3-2

Select marker relay 2-20

Storing 3-2

Symbols 1-14

Testing 2-11

Using a function relay 2-20

Using buttons in 2-1

Circuit diagram elements 2-5

Coil function 2-8

common techniques used in this manual

2-21

Preface-ii

contacting Allen-Bradley for assistance

Preface-iii

Contactor function 2-8

Contacts

Overview

Counter relay 2-16

Parameter display 2-16

Cursor display 1-13

2-5

D

dimensions

1760-L12

1760-L18 A-4

1760-L20 A-4

1760-OW2 A-5

1760-RM A-5

expansion modules A-4

A-4

E

Example

Basic circuits

Circuit diagram 2-9

Contacts and relays 2-9

Example of function relay 2-20

2-23

F

Function relays

Analog comparator

Counter relay 2-16

Overview 2-13

Text display 2-19

Time switch 2-17

Timing relay 2-13

2-18

K

Keypad 1-10

L

Logic tables 2-23

M

Make contact 2-5

manuals, related Preface-ii

Memory Module (optional) 3-1

Menu guidance 1-11

Menu structure 1-15

Mounting 1-3

O

Operating buttons 1-10

P

Parameter display

Analog comparator

Counter relay 2-16

For timing relays 2-15

Time switch 2-17

2-18

Publication 1760-GR001C-EN-P - April 2005

Page 64

2 Index

physical specifications A-1

Overview of Pico 1-2

PicoSoft 3-3

Programming cable 3-3

publications, related Preface-ii

Purpose of this Manual Preface-ii

R

related publications Preface-ii

Relay types

Overview

2-6

S

selection table

controllers

selections table

expansion modules

Setting the time 2-3

Setting week day 2-3

Software 3-3

specifications

physical

Startup behavior 2-4

Status display 1-12

Summer time 2-4

A-1

A-3

A-1

Symbols in circuit diagram 1-14

System menu 1-18

T

Terminals, inputs/outputs 1-4

Text display 2-19

Time switch 2-17

Parameter display 2-17

Timing relays 2-13

Parameter display 2-15

troubleshooting

contacting Allen-Bradley for assistance

Preface-iii

W

Winter time 2-4

Wiring diagrams

1760-L12AWA-NC, 1760-L12AWA, and

1760-L12AWA-ND

1760-L12AWA-xx and 1760-L12BWB-xx

1-5

1760-L12BWB and 1760-L12BWB-NC

1-4

1760-L18AWA 1-9

1760-OW2 1-9

1-4

Publication 1760-GR001C-EN-P - April 2005

Page 65

Page 66

Rockwell Automation

Support

Rockwell Automation provides technical information on the web to assist you

in using our products. At http://support.rockwellautomation.com, you can

find technical manuals, a knowledge base of FAQs, technical and application

notes, sample code and links to software service packs, and a MySupport

feature that you can customize to make the best use of these tools.

For an additional level of technical phone support for installation,

configuration and troubleshooting, we offer TechConnect Support programs.

For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24

hours of installation, please review the information that's contained in this

manual. You can also contact a special Customer Support number for initial

help in getting your module up and running:

United States 1.440.646.3223

Monday – Friday, 8am – 5pm EST

Outside United

States

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of our products to ensure that they are fully operational

when shipped from the manufacturing facility. However, if your product is

not functioning and needs to be returned:

United States Contact your distributor. You must provide a Customer Support case

number (see phone number above to obtain one) to your distributor in

order to complete the return process.

Outside United

States

Please contact your local Rockwell Automation representative for

return procedure.

Publication 1760-GR001C-EN-P - April 2005 2 PN 40072-085-01(3)

Supersedes Publication 1760-GR 001B-EN-P - July 2001 Copyright © 2005 Rockwell Automation, Inc . All rights reserved. Printed in the U.S.A.

Loading...

Loading...