Corrigo manual

Ventilation application

© Copyright AB Regin, Sweden, 2013

DISCLAIMER

The information in this manual has been carefully checked and is believed to be correct. Regin however , makes no warranti es

as regards the contents of this manual and users are requested to report errors, discrepancies or ambiguities to Regin, so that

corrections may be made in future editio ns. The information in this document is subject to change without prior notification.

The software described in this document is supplied under licence by Regin and may be used or copied only in accordance

with the terms of the licence. No part of this document may be reproduced or transmitted in any form, in any fashion,

electronically or mechanically, without the express, written permission of Regin.

COPYRIGHT

AB Regin. All rights reserved .

TRADEMARKS

Corrigo, E tool

©

, EXOdesigner, EXOreal, EXOrealC, EXOline, EXO4, EXO4 Web Server, Optigo, Regio and Regio tool are

registered trademarks of AB Regin.

Windows, Windows 2000, Windows XP, Windows Vista, Windows 7, Windows 8 and Windows Server 2003 are registered

trademarks of Microsoft Corporation.

Some product names mentioned in this document are used for identification purposes only and may be the registered

trademarks of their respective companies.

Revision R, September 2013

Software revision: 3.3

Table of contents

CHAPTER 1 ABOUT THE MANUAL .................................................................................................. 6

More information ........................................................................................................................ 6

CHAPTER 2 ABOUT CORRIGO ......................................................................................................... 7

2.1 News in version 3.3 ................................................................................................................ 7

2.2 Application choice ................................................................................................................. 7

2.3 Technical data ...................................................................................................................... 12

CHAPTER 3 INSTALLATION AND WIRING ...................................................................................... 14

3.1 Installation ........................................................................................................................... 14

3.2 Wiring .................................................................................................................................. 14

CHAPTER 4 COMMISSIONING ...................................................................................................... 21

4.1 How to do it ......................................................................................................................... 21

CHAPTER 5 FUNCTIONAL DESCRIPTION ....................................................................................... 24

5.1 Temperature control ........................................................................................................... 24

5.2 Extra control circuit ............................................................................................................. 37

5.3 Humidity control .................................................................................................................. 38

5.4 Fan control ........................................................................................................................... 39

5.5 Pump control ....................................................................................................................... 45

5.6 Damper control .................................................................................................................... 45

5.7 Extended running and External switch ................................................................................ 46

5.8 Time-switch outputs ............................................................................................................ 47

5.9 Alarms .................................................................................................................................. 47

CHAPTER 6 STARTING AND STOPPING THE UNIT ......................................................................... 49

6.1 Start conditions .................................................................................................................... 49

6.2 Stop conditions .................................................................................................................... 49

6.3 Start sequence ..................................................................................................................... 50

6.4 Stop sequence ..................................................................................................................... 50

CHAPTER 7 DISPLAY, LEDS AND BUTTONS ................................................................................... 51

7.1 Display ................................................................................................................................. 51

7.2 LEDs ..................................................................................................................................... 51

7.3 Buttons ................................................................................................................................ 51

7.4 Navigating the menus .......................................................................................................... 51

CHAPTER 8 ACCESS RIGHTS .......................................................................................................... 53

8.1 Log on .................................................................................................................................. 53

8.2 Log off .................................................................................................................................. 53

8.3 Change password ................................................................................................................. 54

8.4 Change password to remove automatic logoff ................................................................... 54

CHAPTER 9 RUNNING MODE ....................................................................................................... 55

9.1 Running mode, unit ............................................................................................................. 55

9.2 Selected functions ............................................................................................................... 55

9.3 Alarm events ........................................................................................................................ 56

9.4 Inputs/Outputs .................................................................................................................... 56

CHAPTER 10 TEMPERATURE ........................................................................................................ 57

CHAPTER 11 AIR CONTROL........................................................................................................... 62

CHAPTER 12 HUMIDITY CONTROL................................................................................................ 65

CHAPTER 13 TIME SETTINGS ........................................................................................................ 66

13.1 Time / Date ........................................................................................................................ 66

13.2 Timer Normal speed .......................................................................................................... 66

13.3 Timer Reduced speed ........................................................................................................ 67

13.4 Extended running .............................................................................................................. 67

13.5 Timer outputs 1…5 ............................................................................................................. 67

13.6 Holidays ............................................................................................................................. 68

CHAPTER 14 MANUAL / AUTO ..................................................................................................... 69

CHAPTER 15 SETTINGS ................................................................................................................. 72

15.1 Control temp ...................................................................................................................... 72

15.2 Control pressure ................................................................................................................ 73

15.3 Control flow ....................................................................................................................... 73

15.4 Humidity control ................................................................................................................ 74

15.5 Control Extra unit ............................................................................................................... 74

15.6 Alarm settings .................................................................................................................... 74

15.7 Save and restore settings................................................................................................... 76

CHAPTER 16 EXPANSION MODEL ................................................................................................. 77

16.1 Ports ................................................................................................................................... 77

16.2 Wiring ................................................................................................................................ 77

CHAPTER 17 CONFIGURATION ..................................................................................................... 79

17.1 Inputs and outputs............................................................................................................. 79

17.2 Sensor settings ................................................................................................................... 81

17.3 Control function ................................................................................................................. 82

17.4 Fan control ......................................................................................................................... 82

17.5 Extra control circuit ........................................................................................................... 83

17.7 Extra sequence Y5 .............................................................................................................. 84

17.8 Heating coil ........................................................................................................................ 84

17.9 Exchanger .......................................................................................................................... 84

17.10 Chiller ............................................................................................................................... 85

17.11 Pump control ................................................................................................................... 86

17.12 Free cooling ..................................................................................................................... 86

17.13 Support control ................................................................................................................ 87

17.14 CO2 Demand control ........................................................................................................ 87

17.15 Fire function ..................................................................................................................... 87

17.16 Humidity control .............................................................................................................. 88

17.17 Exchanger de-icing ........................................................................................................... 88

17.18 Cooling recovery .............................................................................................................. 88

17.19 Minimum limit dampers .................................................................................................. 88

17.21 External setpoint .............................................................................................................. 89

17.22 Run indication / Motor protection .................................................................................. 89

17.23 Actuator type ................................................................................................................... 90

17.24 Running time, 3-position actuators ................................................................................. 90

17.25 Step controllers ................................................................................................................ 91

17.26 Recirculation .................................................................................................................... 92

17.27 Pretreatment ................................................................................................................... 93

17.28 Alarm setting ................................................................................................................... 93

17.29 Communication ............................................................................................................... 97

17.30 Other parameters ............................................................................................................ 99

17.31 System ........................................................................................................................... 102

CHAPTER 18 OTHER FUNCTIONS ................................................................................................ 105

18.1 Alarm handling ................................................................................................................. 105

18.2 Free text ........................................................................................................................... 105

18.3 Revision number .............................................................................................................. 105

18.4 Language .......................................................................................................................... 106

18.5 Indication LEDs ................................................................................................................ 106

18.6 Changing the battery ....................................................................................................... 106

18.7 Start-up wizard ................................................................................................................ 107

18.8 Energy calculation ............................................................................................................ 109

18.9 SFP (Specific Fan Power) .................................................................................................. 109

INDEX ........................................................................................................................................ 110

APPENDIX FREQUENCY CONVERTERS ........................................................................................ 114

6 Chapter 1 About the manual Manual Corrigo Ventilation, revision R

Chapter 1 About the manual

This manual co vers all t he models in the Corrigo ser ies used with the ventilation app lication. This

revision covers program revisions from 3.3.

More information

More information about Corrigo can be found in:

• Corrigo ventilation user guide – A simplified manual

• Manual E tool

©

– Manual on how to configure the controllers using t he PC software

E tool

©

, available i n Swedish, English, German and French.

• LON-interface variable list – Variable list for the Corrigo series, available in Swedish and

English.

• Corrigo ventilation variables for EXOline, Modbus and BACnet – Variable list for

EXOline, BACnet and Modbus communication, available in Engli sh.

• Corrigo ventilation Communication Guide – The most common Modbus and BACnet

variables.

• Editable PDF files for Co rrigo

• CE - Declaration of conformity, Corrigo

The information is available for download from Regin's website, www.regin.se

.

Manual Corrigo Ventilation, revision R Chapter 2 About Corrigo 7

Chapter 2 About Corrigo

The Corrigo series comprises three model sizes: 8, 15 or 28 in-/outputs.

In each third generation model Corrigo, all applications are loaded in a separate memory area. The

models have article number E...-3 (where 3 sta nds for third ge neration). A ne w feature in ver sion

3.3 are models with three communication ports. The 3 port Corrigo models have article number

E...3-3 (where the initial “3” stands for 3 ports). For more detailed information, see chapter 16.

The controllers are available with or without a front panel display and buttons. For all third

generation units, both with a nd without display, a separate, cable-connected terminal E3-DSP with

display and buttons is available.

All configuration and normal handling can be done using the display and buttons or using the

configuration tool E tool

©

, installed on a PC and connected via the communication cable E-cable.

2.1 News in version 3.3

• The operating system has been further improved and is now called EXOrealC.

• Support for three communication ports.

• BACnet/IP is now available as a communication protocol.

• New filter alarm: Separate filter alarms.

• Analogue filter alarm, filter pressure alarm.

• Temperature alarm for extra sensors 1-5.

• Support for 0…10V outdoor sensor and room sensor.

• Modulating recirculation air damper, Y4-Extra sequence.

• Communication with Danfoss model Frequency converters FC 101 now supported.

• Additional Modbus signals.

2.2 Application choice

On deliver y, t he ma i n me mor y i n the Corrigo is empty. All t he a p pl ic ati o n p r o grams that can b e ru n

in the Corrigo are located in a separate memory area.

On the first start-up, the controller will start a special program for downloading a suitable

application and suitable languages to the main memory.

For certain customised models, an application has already been selected when the product is

delivered. If so, the selected application will be started immediately.

E283W-3

PLA: 254 ELA: 30

Baud#1: 9600

Rev: 3.3-1-01

The initial screen details the model of the Corrigo unit, its communication address, communication

speed and which software revision is loaded into the unit.

Press down arrow to go to ”Application choices”.

Application

System

Communication

Time/Date

Input/Output

8 Chapter 2 About Corrigo Manual Corrigo Ventilation, revision R

Use the up and d own arrows to move the cursor in the left edge of the display to the function you

wish to select. Select “Application” and press the right arrow.

Corrigo Vent.131021

Expansion unit 1

Expansion unit 2

Corrigo Vent.140212

Move the cursor to the desired application. Press the right arrow.

Title:

Corrigo Ventilation

3.3

Activate? No

Press ”OK” and change ”No” into ”Yes”. Press ”OK”.

The most recently loaded ventilation ap plication will now be entered into memory. T his will take

approx. 30 seconds. The application start screen is displayed.

To change lang uages, press th e r ight ar r o w 3 ti me s a nd t he n cho o se a l ang uage i n the sa m e wa y you

selected an application.

2.2.1 Additional menu options

System:

Information on the Corrigo model and serial number.

EXOreal version.

MAC address and IP address.

Battery status and memory size.

Memory status and voltage frequency.

Communication:

Communication mode selection.

Serial:

Enables selecting EXOline address, communication speed, port mode and routing span.

TCP/IP:

Enables EXOline address selection and choice of DHCP (Yes/No).

Also enables manual IP address and subnet mask setting before the Corrigo is initiated. Default

Gateway and DNS name is also available under this menu.

Current sub net mask, gateway and DNS name.

Main computer status.

Main computer IP address.

Permit connection to main computer.

TCP port routing to serial port 1 or 2.

Time/Date:

Permits setting the time and date.

Manual Corrigo Ventilation, revision R Chapter 2 About Corrigo 9

Input/Output:

Enables In-/Output reading and writing.

2.2.2 Ventilation applicati on

The temperature controller is based on a supply air PI-controller for heating control with a preprogrammed set of control modes. A number of different control functions as well as analogue and

digital in- and output functions can be bound to this controller. Certain functions are necessary,

while others can be considered optional. The choice of which functions are to be used is free, the

only restriction is the physical number of inputs and outputs of the different models. The maximum

number of I/Os is 3*28 (a 2- or 3-port Corrigo with two expansion units).

The Corrigo is designed for DIN-rail mounting.

The program for an air handl ing unit conta ins, apart from other things, the following functions :

Different temperature control modes :

• Supply air temperature control, with or without outdoor temperature compensation

• Room temperature control (cascade control).

• Extract air control (cascade control).

• Seasonal switching between supply air temperature control and room/extract air

temperature control.

• Outdoor compensated room/extract air control.

• Extra, separate temperature control circuit for after-heaters, etc.

• Extra control sequences Y4 and Y5 (in addition to Y1, Y2 and Y3) for free integration

into the controller output.

With control of:

• Heat exchanger (liquid connected, plate or rotating) or mixing dampers.

• Heating coil: Water with or without frost protection or electric with high te mperature limit

switch.

• Cooling: Water or DX cooling in up to 3 steps.

• Circulatio n pumps heating, cooling, exchanger.

Fan control

• 1- or 2-speed supply air and extract air fans.

• Frequency controlled supply and extract air fans with pressure or flow control, manual

control or external control from a VAV sys tem.

• Pressure controlled supply air fan with slave connected extract air fan (output dependent or

flow dependent) or opposite function (pressure controlled extract air fan with slave

connected supply air fan, output dependent or flow dependent).

Humidity control

It is possible to use either humidification or dehumidification, or to use combined humidification

and dehumidification.

Timer control

For starting and stopping the unit, annual clock function. Up to 5 timer outputs for control of

external func tions such as lighting, doorlocks etc.

10 Chapter 2 About Corrigo Manual Corrigo Ventilation, revision R

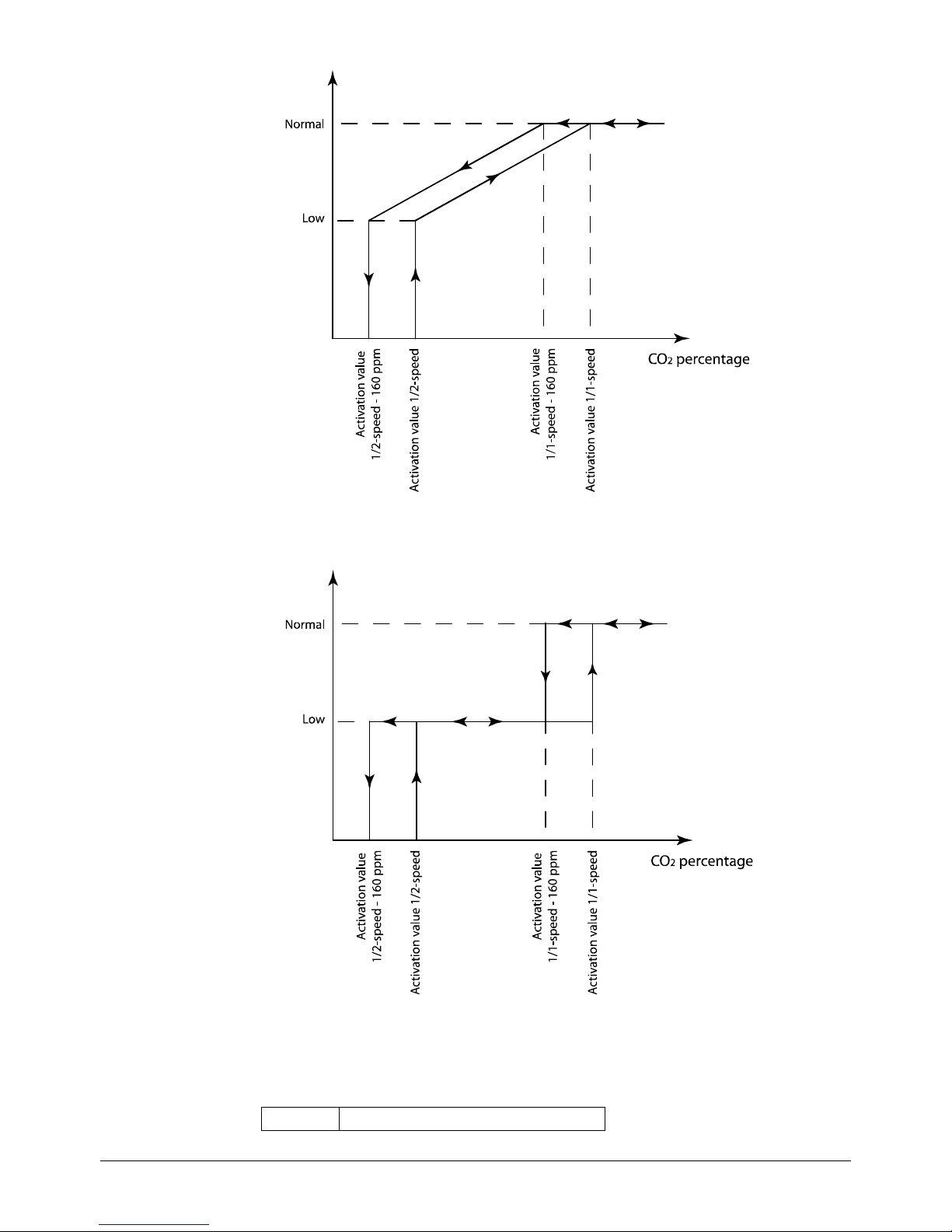

Demand controlled ventilation

In building s with strongl y varying occup ancy the fa n speeds or mixi ng dampers can be controlled

by the air quality measured by a CO

2

sensor.

Support control

When using the control funct ion room control or extract air temperature contro l, it is possible to

utilise support-heating and/or support-cooling.

Free cooling

When this function has been activated, it is used durin g the summer to cool the building durin g the

night using c ool outdoor air thereby reducing the need to run chillers during the day.

Free heating

If the outdoor temperature is higher than the indoor temperature and there is a heating demand, the

recovery damper will not open for recovery but instead open fully for outdoor air. This may occur

during low night-time outdoor temperatures, when the room has been cooled considerably and the

outside heat is rising faster than indoors. This function is activated at the same time as “Free

cooling”.

Enthalpy control

Measures and compares the energy content (enthalpy) of the outdoor air and the extract air

(temperature and air humidity). When this function is active, the mixing damper signal will be

overridden to recirculation if the enthalpy is higher outdoors than indoors.

Pretreatment

Damper and pump control for preheating or precooling of the outdoor air via an underground intake

channel.

Cooling recovery

If the extract air is colder than the outdoor air and cooling is required, the heat exchanger control is

reversed in order to return the cool extract air.

Recirculation control

Recirculation of air using a supply air fan and (optionally) extract air fan and a recirculation damper

with or witho ut temperature co ntrol. Used as a recove ry function or duri ng heating with supp ort

control during the night. Recirculation control is available as an analogue or a digital function.

Step controllers Heating/Cooling

As an alternative to the analogue control of ”Actuator heating Y1” or ”Actuator cooling Y3” step

controllers can be used for controlling hea ting or cooling in steps using digital contro l.

Change-over

In 2-pipe systems where a combination heater/cooler is operating together with a heat pump,

Change-over is a funct ion tha t ena bles usi ng the sa me pi pe for both heat ing and c ooli ng, dep ending

on which is currently requi red. It uses t he output Y1 Hea ting/Y3 Co oling.

Manual Corrigo Ventilation, revision R Chapter 2 About Corrigo 11

Corrigo hardware overvi ew

E81-3

E81D-3

E151-3

E151W-3

E151D-3

E151DW-3

E15D-S-LON

E152W-3

E152DW-3

E281-3

E281D-3

E281W-3

E281DW-3

E282W-3

E282DW-3

E28D-S-LON

E283W-3

E283DW-3

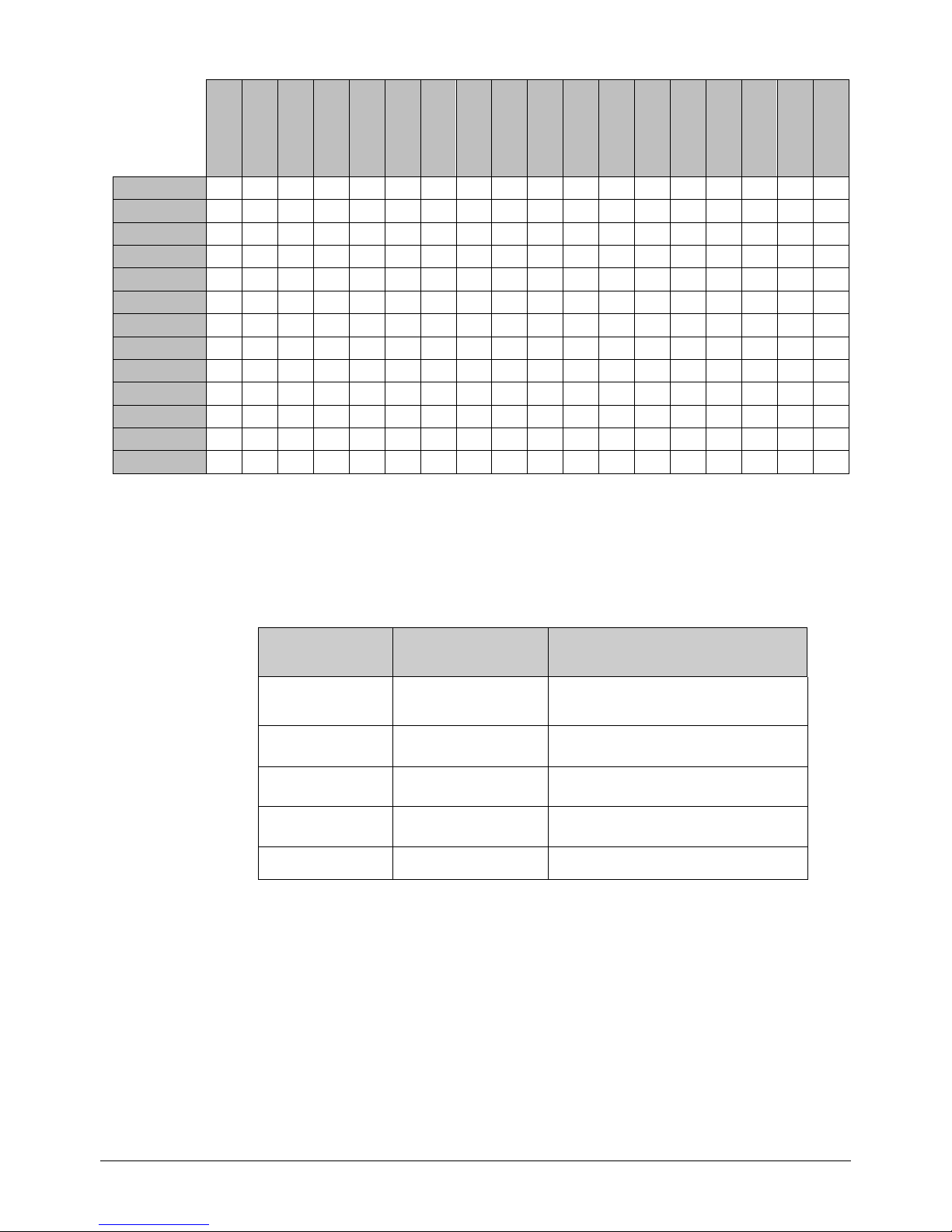

AI*

2 2 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

DI*

3 3 4 4 4 4 4 4 4 8 8 8 8 8 8 8 8

8

UI*

-

- - - - - -

- - 4 4 4 4 4 4 4 4 4

AO*

1 1 3 3 3 3 3 3 3 5 5 5 5 5 5 5 5 5

DO*

2 2 4 4 4 4 4 4 4 7 7 7 7 7 7 7 7

7

RS485

•

• •

•

• • • • •

• • • • •

BACnet/IP

• • • • • • • • •

•

LON

•

•

TCP/IP

•

•

• • • • • • • •

1 port

• • • • • • • • • • •

2 ports

• • • • •

3 ports

•

•

Display

•

•

• •

• •

•

• •

•

* AI=analog ue inputs, DI= digital inputs, A O=analogue out puts, DO=digita l outputs, UI= universal

inputs (can be configured to function a s either analogue input or digital input).

All third generation Corrigo contro lle r s support external displays.

Corrigo model overview

Models with dis play Models without display Description

E81D-3

E151D-3

E281D-3

E81-3

E151-3

E281-3

Standard controller with RS485 port

E15D-S-LON

E28D-S-LON

Controller with both LON an d RS485 port

E151DW-3

E281DW-3

E151W-3

E281W-3

Controller with TCP/IP port and built-in web server

E152DW-3

E282DW-3

E152W-3

E282W-3

Controller with one RS485 port, one TCP/IP port and

built-in web serv er

E283DW-3 E283W-3

Controller with two RS485 ports, one TCP/IP port

and built-in web server

12 Chapter 2 About Corrigo Manual Corrigo Ventilation, revision R

2.3 Technical data

Protection class .................................................................................................................. IP20

Display........................................................ 4 rows of 20 characters. Background illumination.

LEDs

Yellow ....................................................................................................... Settable parameter

Red ............................................................................................................... Alarm indication

Clock .................................................................. Year base 24 hour clock with battery backup.

Automatic summer-/winter-time changeover.

Operating sys te m .......................................................................................................... EXOreal

Supply voltage .................................................... 24 V AC ±15%, 50…60 Hz or 21…36 V DC

Power consumption ........................................ 5 VA, 3 W (DC), model …W: 9 VA, 5 W (DC)

Dimensions .................................................................... 148x123x60 (WxHxD incl. terminals)

Casing .......................................................................... Standard Euronorm (8.5 modules wide)

Mounting ................................................................................................................ On DIN-rail

Operation

Climatic conditions according to IEC 721-3-3 ........................................................ Class 3k5

Ambient temperature ..................................................................................................0...50°C

Ambient humidity .............................................................................................. Max 95% RH

Mechanical requirements according to IEC721-3-3 .............................................. Class 3M3

Vibration .......................................................... IEC60068-2-6, Test FC, vibration Sinusoidal

Shock ................................................................................................ IEC60068-2-27, Tes t Ea

Transport

Climatic conditions according to IEC 721-3-2 ........................................................ Class 2k3

Ambient temperature .............................................................................................. -20...70°C

Ambient humidity .............................................................................................. Max 95% RH

Mechanical requirements according to IEC721-3-2 .............................................. Class 2M2

Vibration .......................................................... IEC60068-2-6, Test FC, vibration Sinusoidal

Shock ................................................................................................ IEC60068-2-27, Tes t Ea

Free fall .............................................................................................IEC60068-2-27, Test Ed

Storage

Climatic conditions according to IEC 721-3-1 ........................................................ Class 1k3

Ambient temperature .............................................................................................. -20...70°C

Ambient humidity .............................................................................................. Max 95% RH

Battery

Type .................................................................................... Replaceable Lithium cell, CR2032

Battery life ................................................................................................... Better than 5 years

Warning .................................................................................................... Low battery warning

Battery backup ............................................................................... Memory and real time clock

Communication

EXOline Port 1, insulated via a b uilt-in RS485 contact.

EXOline Port 2, via a built-in RS485 contact.

EXOline TCP/IP.

Modbus communication via serial RS485 communication (not TCP/IP).

BACnet/IP.

LON serial communication.

Suitable model should be selected for appropriate needs.

EMC emission and immunity standard

This product conforms to the requirements of the EMC Directive 2004/108/EC through product

standards EN 61000-6-1 and EN 61000-6-3.

RoHS

This product conforms to the Directive 2011/65/EU of the European Par lia ment and of the Council.

Manual Corrigo Ventilation, revision R Chapter 2 About Corrigo 13

Inputs

Analogue inputs AI .............................................. Settable 0…10 V DC or PT1000, 12 bit A/D

Digital inputs DI ....................................................................................... Potential-free closure

Universal inputs UI ........................................... Can be set to act as either an a nalogue input or

a digital input with specifications as above

Outputs

Analogue outputs AO ............................................... Configurable 0…10 V DC; 2…10 V DC;

10…0 V DC or 10…2 V DC

8 bit D/A short-circuit protected

Digital outputs DO ........................................... Mo s fet outputs, 24 V AC/DC, 2 A c ontinuous.

Totally max 8 A.

Options

LON ................................................................... FT3150, gives a second communication route

…W (TCP/IP-port) ............................... Replaces RS485 for EXOline (Port 1) communication

2-port Corrigo models ........................ Two serial ports or one serial port and one TCP/IP port

3 ports Corrigo............................................................ .... Two serial ports and one TCP/IP port

External hand terminal, E3-DSP ......................... For use with Corrigo E units wit hout display

External room unit...................................................................... ED-RU / ED-RUD / ED-TCV

Position of the terminals on the Corrigo

14 Chapter 3 Installation and wiring Manual Corrigo Ventilation, revision R

Chapter 3 Installation and wiring

3.1 Installation

Corrigo can be mounted in a DIN-standard casing (minimum 9 modules), on a DIN-rail in a cabinet

or, using a suitable front-mounting kit, in a cabinet door or other control panel.

Ambient temperature: 0…50°C.

Humidity: Max. 90 % RH, non-condensing.

The picture below shows a wiring exa mple for Corrigo E283W-3.

3.2 Wiring

At the end of this chapter there are wiring diagrams showing the factory set configuration. There are

also empty wir ing diagrams. Sinc e the function of most of the inputs and out puts depends on t he

programming of the unit the f inal wiring diagram can not be filled in until the in staller has decided

how to use the inputs/ou tputs. It is impor tant to ensure that the wirin g is performed correctly and in

accordanc e with the instr uctions given in this manual.

Manual Corrigo Ventilation, revision R Chapter 3 Installation and wiring 15

3.2.1 Supply voltage

24 V AC ±15%, 50…60 Hz or 21…36 V DC

If Corrigo and its connected actuators share the same transformer, it is essential that the same

transformer pole is used as reference for all the equipment. The equipment may otherwise not

function as intended and may also suffer damages.

3.2.2 Inputs and outputs

The list of inp ut and outp ut functions in sectio n 3.2.3 is a handy instru ment to help you keep t rack

of which inputs and outputs you will need to configure.

Analogue inputs

Analogue inputs must refer to an Agnd terminal placed in the same terminal block as the input being

wired.

Analogue inputs can, depending on the configuration, be used for either PT1000 temperature

sensors or for 0…10 V DC analogue input signals, for example from a pressure transmitter.

Digital inputs

Digital inputs must refer to +C on terminal 4. Digital inputs may only be wired to voltage-free

contacts. Any external volta ge applied to a digital input ma y harm t he uni t. The input signa l can b e

set to either NO or NC.

Universal inputs

A universal i nput can be co nfigured to act as either an analogue input or as a digital input.

A universal i nput con figured a s an analog ue input c an, dep ending o n the confi guratio n, be used for

either PT 1000 temperat ure sensors o r for 0…10 V DC analogue i nput signal s, for exam ple from a

pressure transmitter.

Universal i nput s co nfig ured as an a nalo gue i npu t must refer to an Agnd terminal placed in the same

terminal block as the input being wired.

A universal input configured as a d igital input must, just like other digital inputs refer to C+ on

terminal 4. It may only be wired to voltage-free contacts.

Analogue outputs

Analogue outputs must refer to the Agnd te rminal placed in the AO terminal block.

All analogue outputs can be individually set to any one of the following signals:

0…10 V DC

2…10 V DC

10…0 V DC

10…2 V DC

If the Corrigo and the actuators connected to it share the same transformer it is essential that the

same transfor mer-pole is used as reference for all the equipment. Failure to do so will prevent the

equipment from functioning as intended and may also lead to damages.

Digital outputs

Digital outputs should normally refer to G

DO

on terminal 10. G

DO

is internally connected to G o n

terminal 1 and supplies 24 V AC or DC depending on the choice of supply voltage.

All the digital outputs are controlle d by MOSFET transistors. The outputs are inter nally connected

with G

0

and can deliver max 2 A per output. However, the total power for all the DOs must not be

over 8 A.

16 Chapter 3 Installation and wiring Manual Corrigo Ventilation, revision R

A number of different wiring alternatives are possible depending on the type of supply voltage to

the Corrigo and the relay type.

24 V AC supply and 24 V AC relays

24 V DC supply and 24 V DC relays

24 V AC supply and 24 V DC relays

G

G

0

10

11

12

L

N

24 V

AC

G

G

0

10

11

12

+

-

24 V DC

+ + + -

G

G0

10

11

12

L

N

24 VAC

24 V DC

+ -

+ -

+ -

+ -

24 V AC

24 V AC

Manual Corrigo Ventilation, revision R Chapter 3 Installation and wiring 17

24 V DC supply and 24 V AC relays

3.2.3 Input and output lists

The lists below are intended to be used during commissioning to help you keep track of the desired

input and output functions .

The left column contains a description of the in-/output signal, the middle c olumn displays the name

of the corresponding signal in E tool

©

and the right column shows the text displayed in the Corrigo

controller.

Analogue input signal

Description E tool© Display

Inactive inp ut

Not active

Not active

Outdoor temperature sensor, PT1000 or

0…10V

Outdoor Temp Outdoortemp

Supply air temperature sensor Supply Air Temp Supplytemp

Extract air temperature sensor Extract Air Temp Extracttemp

Exhaust air temperature sensor Exhaust Air Temp Exhausttemp

Room temperature sensor 1, PT1000 or

0…10V

Room Temp 1 Roomtemp1

Room temperature sensor 2 Room Temp 2 Roomtemp2

CO2 sensor, 0…10 V DC

CO2 Sensor

CO2

Pressure transmitter supply air, 0…10

V DC

SAF Pressure SAF pressure

Pressure transmitter extract air, 0…10

V DC

EAF Pressure EAF pressure

De-icing sensor, heat exchanger

Deicing Temp

Deicingtemp

Frost protection sensor Frost Protection Temp Frost prot. temp

Room humidity sensor

Humidity Room

Humidity room

Duct humidity sensor Humidity Duct Humidity duct

Outdoor humidity sensor Humidity Outdoor Humidity out

Temperature sensor, Extra controller

Extra unit temp

Extra unit temp

External control supply air fan External control SAF SAF ext. Ctrl

External control extract air fan

External control EAF

EAF ext. Ctrl

Pressure transmitter supply air 2 SAF Pressure 2 SAF pressure 2

G

G

0

10

11

12

+

-

24 V DC

24 VAC

L N

24 V AC

18 Chapter 3 Installation and wiring Manual Corrigo Ventilation, revision R

Description E tool© Display

Intake temperature Intake Te mp Intaketemp

Extra temperature sensor 1

Extra Sensor Temp 1

Extrasensor

Extra temperature sensor 2 Extra Sensor Temp 2 Extrasensor 2

Extra temperature sensor 3

Extra Sensor Temp 3

Extrasensor 3

Extra temperature sensor 4 Extra Sensor Temp 4 Extrasensor 4

Extra temperature sensor 5 Extra Sensor Temp 5 Extrasensor 5

Extra pressure transmitter supply air

Extra SAF Pressure

Extra SAF Pressure

Extra pressure transmitter extract air Extra EAF Pressure Extra EAF Pressure

External flow pressure transmitter

External flow setpoint

Ext sp flow

Analogue filter guard 1 Filter Guard 1 Filter alarm 1

Analogue filter guard 2 Filter Guard 2 Filter alarm 2

Digital input signal

Description E tool© Display

Inactive inp ut

Not active

Not active

Filter guard, supply air Filter Guard 1 Filter alarm 1

Filter guard, extract air

Filter Guard 2

Filter alarm 2

Run-indication/alarm circulation pump,

Heating

Heat Pump Indication P1-Heating

Run-indication/alarm circulation pump,

exchanger

Exchange P ump Indication P1-Exchanger

Run-indication/alarm circulation pump,

Cooling

Cooling Pump Indication P1-Cooling

Fire alarm

Fire Alarm

Fire alarm

Fire damper end-switch monitoring Fire Damper Indic a tion Fire damper-ind

Extended operation, Normal

Extended Operation, Normal

Ext run 1/1

Extended operation, Reduced Extended Operation, Reduced Ext run 1/2

External switch External Switch External switch

External alarm

External Alarm

External alarm

Flow switch Flow Switch Flow guard

Rotation guard exchanger

Exchange Rotation

Rot.sent.exch

Run-indication/alarm supply air fan SAF Indication SAF-Ind

Run-indication/alarm extract air fan EAF Indication EAF-Ind

Deicing thermostat exchanger

Deicing

De-icing

Frost protection ther mostat water heater Frost Protection Frostprotection

High temperature limit switch

Overheated Electric heater

Overheatprotection

Recirculation start Recirculation Recirculation

Change over Change over Change over

The universa l input s o n Corrigo E28 can be individually configured as either analogue inputs, using

any of the analogue input signals above, or as digital inputs using any of the digital inp uts above.

Manual Corrigo Ventilation, revision R Chapter 3 Installation and wiring 19

Analogue output signal

Description E tool© Display

Inactive output Not used Not used

Y1 Actuator Heating

Heating Y1

Y1-Heating

Y2 Actuat or Exchanger Exchanger Y 2 Y2-Exchanger

Y3 Actuator Cooling

Cooling Y3

Y3-Cooling

Frequency converter, supply air fan SAF SAF

Frequency converter, extract air fan EAF EAF

Actuator Humidity control Dehumidification/

Humidification

Humidity

Split of any one of temp outputs Y1, Y2,

Y3 or Y1 Heating/Y3 Cooling outputs

Split Sequence

Extra controller

Extra unit control

ExtraUnitCtrlVa

Y1 Heating / Y3 Cooling, Change-over

output

Y1 Heating/Y3 Cooling Y1-Heat/Y3-Cool

Y4 Extra Sequence

Also used for control of recirculation air

damper 0...10V

Extra Sequence Y4 Y4-extra sequence

Y5 Extra Sequence Extra Sequence Y5 Y5-extra sequence

Digital output signal

Description E tool© Display

Inactive output Not used N ot used

Start/stop Supply air fan Normal

SAF Start 1/1 Normal Speed

SAF 1/1-speed

Start/stop Extract air fan Normal EAF Start 1/1 Normal Speed EAF 1/1-speed

Start/stop Supply air fan Reduced

SAF Start 1/2 Reduced Speed

SAF 1/2-speed

Start/stop Extract air fan Reduced EAF Start 1/2 Reduced Speed EAF 1/2-speed

Start/stop circulation pump, heating Heating P ump Start P1-Heating

Fire damper

Fire Damper

Fire damper

Sum alarm A- and B-alarm Sum Ala rm Sum alarm

Sum alarm A-alarm

Sum Al a rm A

A-sum alarm

Sum alarm B-alarm Sum A larm B B-sum alarm

Start/stop circulation p ump, cooling Cooling Pump Start P1-Cooling

Start/stop circulation pump, liquid

exchanger

Exchanger Start P1-Exchanger

Activation-signal SAF frequency

converter

SAF Freq Start SAF-frequence

Activation-signal EAF frequency

converter

EAF Freq Start EAF-frequence

Activate heating

Heating Activate

Heat start

Activate cooling Cooling Activate Cool start

Activate exchanger Exchanger Activate Exch start

Exhaust air cl ose-off damper

Exhaust Air Damper

Exhaust air d

Fresh air close-off damper Outdoor Air Damper Fresh air dam

20 Chapter 3 Installation and wiring Manual Corrigo Ventilation, revision R

Description E tool© Display

Recirculation damper Recirculation Air Damper Recirc. da mper

Heating 3-position actuator, increase Heating Increase Heat-inc

Heating 3-position actuator, decrease Heating Decrease Heat-dec

Exchanger 3-position actuator, increase

Exchanger Increase

Exch-inc

Exchanger 3-position actuator, decrease Exchanger Decrease Exch-dec

Cooling 3-position actuator, increase Coo ling Increase Cool-inc

Cooling 3-position actuator, decrease Cooling Decrease Cool-dec

Step controller heating, step 1 Heat Step 1 Heat step1

Step controller heating, step 2

Heat Step 2

Heat step2

Step controller heating, step 3 Heat Step 3 Heat step3

Step controller heating, step 4 Heat Step 4 Heat step4

Step controller coo ling, step 1 Cool Step 1 Cool step1

Step controller coo ling, step 2 Cool Step 2 Cool step2

Step controller cooling, step 3

Cool Step 3

Cool step3

Extra time channel 1 Time Channel 1 Time r 1

Extra time channel 2 Time Channel 2 Time r 2

Extra time channe l 3 Time Channel 3 Timer 3

Extra time channel 4 Time Channel 4 Time r 4

Extra time channel 5

Time Channel 5

Time r 5

Humidity Humidity/DeHumidity Humidity

External controller active Extra unit ac tive ExtraUnitActi

Heating/cooling step 1 Heat/cool step 1 HeatCoolStep1

Heating/cooling step 2 Heat/cool step 2 HeatCoolStep2

Heating/cooling step 3

Heat/cool step 3

HeatCoolStep3

Free cooling operation Free cool run Free cool run

Pretreatment Pretreatment Pretreatment

Free cooling operation Free cool run Free cool run

Pretreatment Pretreatment Pretreatment

Split sequence active

Split Sequence

Split sequence

Run indication Run indication Run ind.

Pulse modulated heating output Heating PWM Heating PWM

Manual Corrigo Ventilation, revision R Chapter 4 Commissioning 21

Chapter 4 Commissioning

General

Before the Corrigo can be used, all inputs and outputs must first be configured, as well as all

relevant parameters.

All commissioning can be done using the Corrigo front panel display and buttons or using the

external display unit E3-DSP.

E tool

©

The best way however, is to configure the Corrigo by using E tool

©

.

E tool

©

is a P C-based configuration program specially developed to simplify the commissioning of

the Corrigo series.

When using E tool

©

the whole co nfiguratio n and al l settin gs can be done on t he computer a nd then

be downloaded to the Corrigo. An infinite number of different configurations can be saved in

computer memory for later use.

A communication cable is required in order to configure Corrigo. E-CABLE-USB, E-CABLE2USB or E-CABLE-RS232 are used for controllers featuring RS485 communication, and E-CABLETCP/IP for controllers with a TCP/IP port.

The Corrigo must be powered up and the application selected in order for it to be configured.

4.1 How to do it

For configuration using E tool©, see the E tool© manual.

For config uration using the fr ont panel or E3-DSP, there are two ways to go depending on how

much help you need .

Option 1:

• Jump straight to chapter 7 and 8, Display, LEDs and buttons and Access rights.

• After learni ng how to use the b uttons and menu system, connect power to your Corrigo,

log on as Admin and go to the menu "Configuration".

• For the time being, skip the configuration menu In-/Outputs and start by configuring

control functions.

• Run through the configurat ion menus in o rder and set wha tever functio ns and parame ters

you wish to include. Use chapter 6 of this manual for reference.

Keep track o f which i nputs a nd outp uts you will ne ed. T o help you, there i s a list o f input

and output functions provided in chapter 3, (3.2.3 Input / Output list.)

• Finally, configure In-/Outputs.

• Exit the "Configuration" menu and go to "Settings".

• Set the control values in "Settings" .

• Set the clock and scheduler functions in "Time Settings".

• Set the control setpoints in temperature and air control as well as in humidity control if

humidity control has been configured

Your Corrigo should now be ready to run.

22 Chapter 4 Commissioning Manual Corrigo Ventilation, revision R

Option 2:

Read this manual in the order given below: The manual has been designed to act as a guide through

the commissioning. The last chapters of the manual, not listed below, cover menus and functions

that are not used during commissionin g.

Functional description

Start by reading chapter 5. Functional description below. Some functions are essential to the

working of the unit and must be included. Others a re more of the natur e of optional ex tras which

can be excluded.

At the end of each function description there is a table of the necessary inputs and outputs to

implement the function. At t he end of the ma nual t here is a list o f all the a nalo gue a nd d igital inp uts

and outputs. As you read, mark in the list the inputs and outputs you will be using for the

application you are building. Note that the universal inputs in Corrigo E28 can, individually, be

configured as either analogue or digit al inputs.

Display, buttons and LEDs

Read chapter 7 on how to use the front panel buttons to navigate the Corrigo menu system.

Access rights

Chapter 8. Learn how to lo g on to the Corrigo.

Configuration

Chapter 16. Configuration.

Connect power to the Corrigo. Using the buttons and menu system, go through the configuration

menus covering the functions you wish to use.

On deliver y the unit s alrea dy have the inp uts and o utputs assi gned to va rious functio ns. T hese can,

of course, be changed.

Settings

Chapter 15

Set the control parameters, P-band, I-time for the temperature control.

Set the control parameters for the pressure control if you have pressure- or flow- controlled fans.

Set the control parameters for the humidity control if activated.

Set the alarm parameters; alarm levels and delay times.

Time settings

Chapter 13

Set the clock and calendar functions.

Setpoints

Chapters 10, 11 and 12:

Set all the setpoints for all active control loops.

Manual Corrigo Ventilation, revision R Chapter 4 Commissioning 23

Manual/Auto

Chapter 14

Learn to use manual control. Very useful for testing out your system.

Other functions

Chapter 18

Alarm handling etc.

24 Chapter 5 Functional description Manual Corrigo Ventilation, revision R

Chapter 5 Functional description

5.1 Temperature control

General

Corrigo has a choice of the following control modes:

1. Supply air control

2. Outdoor temperature compensated supply air control

3. Cascaded room temperature control

4. Cascade connected extract air temperature control

5. Outdoor temperature dependent switching between supply air control with outdoor

temperature compensation and room temperature control

6. Outdoor temperature dependent switching between supply air control with outdoor

temperature compensation and extract air control

7. Outdoor compensated room temperature control

8. Outdoor compensated extract air control

The supply air temperature controller is reverse acting, i. e. the output will increase for decreasing

temperature. The controller is a PI-controller with settable P-band and I-time.

In the first mode, the temperat ure a t the s upp ly air sensor wi ll be co nstantl y kep t at t he use r setp oint

value. In the second mode, the supply air temperature setpoint is adjusted depending on the outdoor

temperature.

In modes three and four the s uppl y air is controlled as part of a cascade controller together with the

room/extract temperature controller. The room/extract temperature offset will dictate the supply air

temperature setpoint.

Mode five and six vary according to the outdoor temperature: Outdoor temperature compensated

supply air control, as in mode two, in winter and cascaded room control or cascaded extract air

control in summer, as in modes three or four. The switch-over temperature is settable.

In applications with mixing dampers instead of heat exchanger the signal for the damper control will

be reversed compared to the signal for heat exchanger control i. e. decreasing signal on increasing

heat demand . This is done a utomatically on configuring the exchanger output = dampers.

The heater can be either a hot water heater battery or an electric heater.

Outputs

The supply air controller output is split between one or more of the output blocks "Heating Y1",

"Exchanger Y2" and "Cooling Y3". Each of these output blocks can be bound to either an analogue

0…10 V DC output or to two digital 3-position increase/decrease outputs.

Each output block has two parameters for setting the control range:

Heating Controller Output signal (H COut) at which the output should be 0 %

Heating Controller Output signal (H COut) at which the output should be 10 0 %

These settings are used to establish the output activatio n order and to split the P-band b etween the

outputs.

Manual Corrigo Ventilation, revision R Chapter 5 Functional description 25

Example:

0 % Cooling at HCOut = 30 %

100 % Cooling at HCOut = 0 %

0 % heat exch. at HCOut = 32 %

100 % heat exch. at HCOut = 50 %

0 % Heating at HCOut = 54 %

100 % Heating at HCOut = 100 %

In addition to these three, it is possible to c onnect t wo additio nal anolo gue outp ut signal s fo r control

of optional sequences, Y4 Extra sequence and Y5 Extra sequence. ”Y4 Extra sequence” and ”Y5

Extra sequence” are both set in the same way as above. It is also possible to select whether “Y4

Extra sequence” should be affected by the enthalpy control and/or the cooling recovery.

A change-over signal can also be configured, “Y1 Heating/Y3 Cooling”.

0 % at HCOut = 0% (HCOut= Heating Controller Output)

100 % at HCOut = 0% (HCOut=Heating Controller Output)

”Y4 Extra sequence” can also be used for control of a modulating recirculation air damper. In cases

where “Y4 Extra sequence" controls a water heater battery, frost protection control may be

activated.

A change-over signal can also be configured, “Y1 Heating/Y3 Cooling”.

It is also possible to split one o f the three a nalo gue o utputs Heatin g, Heat e xcha nger o r C oo ling into

two equal parts if an additional output function is desired.

Y4 Extra sequence, Y5 Extra sequence, Humidity control, Extra controller valve and Y1

Heating/Y3 Cooling can also b e sp lit.

There is also a pulse-width modulated digital output, ”Heating PWM”.

Its period time is settable with a de fault setting of 60 s.

Example:

With a controller output of 50 % and a period time of 60 s, the output will be on for 30 s and off for

30 s. With a controller output of 25 % the output will be on for 15 s and off for 45 s.

5

4%

50

%

32%

30

%

0

%

0

%

C

o

n

t

r

o

l

l

e

r

signal

C

o

o

l

i

n

g

H

e

a

t

i

n

g

Heat

e

x

c

h

.

Output signal

100%

1

0

0

%

Heat dem

an

d

26 Chapter 5 Functional description Manual Corrigo Ventilation, revision R

5.1.1 Control modes

1. Supply air control

The supply air temperature is kept at the setpoint value by controlling the output signals for

"Heating Y1 ", "Exchanger Y2", "C ooling Y3", "Extra sequence Y4" and “Extra sequence Y5”. A

single PI control loop is used.

The setpoint value is set using the front panel or alternatively using an external setpoint device.

Alarms which are activated when the supply air temperature is too high or too low are active.

Alarm for control offset of the supply air temperature is active.

2. Outdoor temperature compensated supp ly air control

The supply air temperature setpoint is outdoor temperature compensated using a control curve with

8 node points.

The suppl y air temperature i s kept at the setp oint value by co ntrolling the ou tput signals for " Y1

Heating", "Y2 Heat exchanger", " Y3 Cool ing", "Extra sequence Y4" and “Extra sequence Y5”. A

single PI control loop is used.

Alarms which are activated when the supply air temperature is too high or too low are active.

Alarm for control offset of the supply air temperature is active.

3. Cascaded room temperature control

Cascade control of room temperature and supply air temperature to achieve a constant, settable

room temperature. The room controller output signal generates the supply air controller’s setpoint

value.

One or two room sensors can be connected. If two sensors are connected the average of their values

will be used. The number of room sensors is detected automatically. The room temperature is kept

at the setpoi nt value b y contr olling the outp ut signa ls for " Y1 Hea ting", "Y2 Hea t exchange r", " Y3

Cooling", "Extra sequence Y4" and “Extra sequence Y5”. Two PI loops are used.

The room setpoint value is set using the front panel or alternatively using an external setpoint

device.

4. Cascaded extract air temperature control

Cascade control of extract air temperature and supply air temperature to achieve a constant, settable

room temperature. The extract air controller output signal generates the supply air controller’s

setpoint value.

The extract air temperature is kept at the setpoint value by controlling the output signals for "Y1

Heating", "Y2 Heat exchanger", "Y3 Cooling", "Extra sequence Y4" and “Extra sequence Y5”. Two

PI loops are used.

The extract air setpoint value is set using the front panel or, alternatively, by using an external

setpoint device.

5. Outdoor temperature dependent switching between supply air temperature

control and room temperature control

When the outdoor temperature is lower than a settable limit (winter), outdoor compensated supply

air temperature control will be ac tive, otherwise (summer) cascaded room temperature control.

6. Outdoor temperature dependent switching between supply air temperature

control and extract air temperature control

When the outdoor temperature is lower than a settable limit (winter), outdoor compensated supply

air temperature control will be active, otherwise (summer) cascaded room temperature control as in

control mode 4.

Manual Corrigo Ventilation, revision R Chapter 5 Functional description 27

7. Outdoor compensated room temperature contr o l

The room temperature can be compensated when the outdoor temperature increases. One can, for

instance, imagine accepting a slightly higher room temperature if it is warm outside or, conversely,

a slightly lower temperature if it is chilly. This function is included to conserve energy.

8. Outdoor compensated extract air control

The extract air temperature can be compensated when the outdoor temperature increases. One can,

for instance, imagine accepting a slig htly higher extract air temperature if it is warm outside or,

conversely, a slightly lower extract air temperature if it is chilly. This function is included to

conserve energy.

In- and outputs

1 2 3 4 5 6 7 8 Control mode

AI

AI

AI

AI

AI

AI

AI

AI

Supply air sensor

AI

AI

AI

AI

AI

Outdoor temperature sensor

AI AI

AI

Room sensor

AI AI AI

Extract air sensor

AO AO AO AO AO AO AO AO

Y1 Heating 0…10 V DC **

AO

AO

AO

AO

AO

AO

AO

AO

Y2 Exchanger 0…10 V DC **

AO

AO

AO

AO

AO

AO

AO

AO

Y3 Cooling 0…10 V DC **

AO

AO

AO

AO

AO

AO

AO

AO

Y4 Extra sequence 0...10 V DC

AO AO AO AO AO AO AO AO

Extra split Y1, Y2 or Y3 0…10 V DC (optional)

AO AO AO AO AO AO AO AO

Y1 Heating/Y3 Cooling

Change-over (option)

DO

DO

DO

DO

DO

DO

DO

DO

Heating 3-pos. increase **

DO DO DO DO DO DO DO DO

Heating 3-pos. decrease **

DO DO DO DO DO DO DO DO

Exch. 3-pos. increase **

DO DO DO DO DO DO DO DO

Exch. 3-pos. decrease **

DO DO DO DO DO DO DO DO

Cooling 3-pos. increase **

DO

DO

DO

DO

DO

DO

DO

DO

Cooling 3-pos. decrease **

** Choose output type depending on the actuator type: Either AO 0…10 V or DO 3-position

increase/decrease.

5.1.2 Heater types

5.1.2.1 Water heating

Control

When the unit is in running mode the heating valve is controlled by the analogue output ”Y1

Heating” or by two digital outputs “Heating 3-pos. actuator, increase” and “Heating, 3-pos. actuator,

decrease”.

Frost protection

The heater return water temperature is measured using the analogue input ”Frost prot.temp”. Lo w

temperatures will generate an inter nal, proportional signal that is used to force the heat ing valve

open thereby preventing freeze-up of the heater .

28 Chapter 5 Functional description Manual Corrigo Ventilation, revision R

The internal signal (“Internal signal”) will begin to rise as the frost protection temperature falls

below “Alarm level” + “Prop. Band” in order to reach 100 % output whe n the signal has fallen t o

“Alarm level”.

When ”Internal signal” reaches 100 % or the digital input ”Deicing Hea t exchanger” is activated,

the unit is shut down, the heating outpu t is set to completely ope n mode and an alarm is activated.

The unit is restarted when the alarm has been acknowledged and the temperature for the frost

protection sensor has risen above “Alarm limit frost” + “P-Band”.

Frost protection control is available on Y1 Heating, Y4 Extra sequence or on both Y1 and Y4.

The frost protection alarm level is set i n the menu Settings/Alarm settings/Alarm limit.

Shutdown mode

If frost protection is activated the controller will go into ”Shutdown mode” when the running mode

switches to ”Off”. The shutdo wn controller will control the heating output to maintain a co nstant

settable temperature at the frost protection sensor.

5.1.2.2 Electric heating

Control

The heating is controlled using the a nalogue outp ut ”Y1 He ating”. On acti vation of t he digital input

“High temp limit switch” the unit will be shut down, either according to the stop sequence described

in section Start/stop of unit or as an e mergency shutdown. The unit will restart after the alarm has

been acknowledged and “High te mp limit s witch” has reset. Note that activation of the in put signal

“Flow switch” will also stop the unit.

Relay el.

heating

Control voltage

Contr.

voltage

High limit

thermostat

Auxiliary

relay

Corrigo

Wiring suggestion high temp limit when using electri c heating.

Contactors drawn inactivated.

Note: It is important that the high temperature thermostat is hardwired to disconnect the power to

the heater to ensure that the heating is shut down when the thermostat is activated even if the

Corrigo should be faulty.

“Frost protection sensor”

“Internal signal”

0 %

100 %

Prop.band

Alarm level

Manual Corrigo Ventilation, revision R Chapter 5 Functional description 29

5.1.2.3 Water heating and electric heating

The water heating is controlled by "Y1 Heating", and the electric heating is controlled by the

sequence "Split". Split (see the section Split of optional temp sequence) must always be set to

"Heating". On increasing heat demand, the water heating is first activated and then, if needed, the

electric heating.

Frost protection and overheating protection are both active. If "step controller heati ng" is used , the

function is tied to the output signal "Split".

5.1.2.4 Fast stop on overheating

If the function "fast stop on overheating" is active, the fans will be immediately stopped when there

is an overheating alarm, regardless of the set cool-down time.

In- and outputs

Water

heating

Electric

heating

AI

Frost protection sensor (optional)

DI**

Frost protection thermostat wate r heater

(optional)

DI

High temperature limit switch

DI

Flow switch (optional)

**Frost protection can also be created using the digital input “Frost protection thermostat water

heater” and a n external t hermostat . Activatio n of the inpu t will force t he running mode to Off and

an alarm will be activated. The heating output is set to completely open, the remaining control

outputs are set to zero.

Frost protection thermostat cannot be combined with shutdown mode.

5.1.3 Heat exchangers

The heat exchanger unit can be set to one of the following alternatives:

• Plate exchanger

• Rotating exchanger

• Liquid connected exchanger

• Mixing dampers

Plate exchanger

Control

The airflo w through the exchanger is contro lled by a s hut-off damper and a by-pass damper. Both

dampers are controlled by the same analogue output ”Y2 Heat exchanger” or by two digital outputs

“Exchanger 3-pos. actuator, increase” and “Exchanger, 3-pos. actuator, decrease”, and are wired so

that one opens as the other closes.

De-icing

De-icing is activated either when the d igita l inp ut sig nal ”De-icing exchanger” is activated or when

the value of the analogue inp u t ”Deicingtemp” falls below the de-icing limit (-3°C). It is deactivated

when the digital input is reset or the analogue input rises above the limit value plus a settable

differential.

On de-icing:

30 Chapter 5 Functional description Manual Corrigo Ventilation, revision R

A PI-controller compares the de-icing setpoint with the signal ”De-icing Exchanger”. The lesser of

the output signal from this contro ller and the output from the ordinary controlle r is used as output to

the dampers.

Rotating exchanger

Control

Rotational speed is controlled by the analogue signal ”Y2 Heat exchanger” or by two digital outputs

“Exchanger 3-pos. actuator, increase” and “Exchanger, 3-pos. actuator, decrease”. A rotation

sentinel can be connected to the digital input ”Rotation sentinel Exchanger”. An alarm is generated

if this input is activated at the same time as the analogue output signal is higher t han 1.0V.

Liquid connected exchanger

Control

A mixing val ve in the exc hanger cir culation s ystem is con trolled b y the analog ue signal ” Y2 Heat

exchanger” or by two d igital outputs “Excha nger 3-pos. actuator, increase” and “Exchanger, 3-pos.

actuator, decrease”.

The circulation pump (digital output " Start/stop circulation pump, liquid exchanger" ) is started as

soon as the actuator control signal exceed s 0 .1 V and is s to ppe d whe n the val ve has been closed for

more than 5 minut e s.

De-icing

De-icing is activated either when the digital input signal ”De-icing exchan ger” is acti vate d or whe n

the value of the analogue input ”Deicingtemp” falls below the de-icing limit (-3°C). It is deactivated

when the digital input is reset or the analogue input rises above the limit value plus a settable

differential.

On de-icing:

A PI-controller compares the de-icing setpoint with the signal ”De-icing Exchanger”. The lesser of

the output signal from this contro ller and the output from the ordinary contro ller is used as outp ut to

the actuator.

Outdoor temp control of exchanger

Instead of usi ng Y2 for anal ogue control of t he heat excha nger it can be set to run on-off aga inst

outdoor temperature. The function co ntrols a digital outp ut “Exch contro l”, which is acti vated when

the outdoor temperature falls below a set value.

Mixing dampers

Control

The analogue output signal ”Exchanger Y2”, or the two digital output signals "Exchanger 3position, increase" and "Exchanger 3 -position, decrease", control two dampers for gradual mixing of

outdoor air and recirculated air. In this mode the output signal decreases with increasing heat

demand.

CO

2

If demand contro lled ventilation (see 5.4.2) is activated in combination with mixing dampers, and

the CO

2

-value rises abo ve t he setpoint value, the da mpers will let in more o utdoor air . The func tion

is controlled by a PI-controll er. Factory settings: P-band 100ppm and I-time 100 seconds. These

values can only be changed in E tool

©

.

CO

2

/VOC control can be used on ”Y2 Exchanger” or ”Y4 Extra sequence”. The control is

selectable for use on Y2, Y4 or on both outputs.

Manual Corrigo Ventilation, revision R Chapter 5 Functional description 31

Minimum limit

An outdoor air minimum limit for can be set using the front panel. The limit value is settable

between 0 and 100 %.

In- and outputs

Plate Rotating

Exch.

Liquid Dampers

AI AI AI AI

Outdoor temp. sensor (optional, outd. temp start)

DO

DO

DO

DO

Activate exchanger (optional, o utd . temp start)

AI AI

De-icing sensor (optional)

DI DI

De-icing signal (optional)

DI

Rotation sentinel (optional)

Start delay exchanger

This function delays the exchanger start at start-up of the unit.

100 % exchanger output at start-up

After the delay described above, the exchanger output will be 100 % during the set time.

5.1.4 Types of chillers

Step controller Heating / DX cooling

As alternative or complement to the above mentioned analogue control, heating and cooling can be

activated in steps. The internal signal is then used to activate digital outputs for control of the

heaters/chillers. Up to four heater outputs and three cooler outputs can be configured. There are two

possible modes:

Sequential

Each output s tep has individuall y settable on and off val ues in percent of the co ntrol signal. The

number of steps is equal to the number of heater/chiller groups. Minimum on and off times can be

set, i.e. the minimum time the step has to be inactive or active for a change to occur.

Binary

The heater power outputs should be binary weighted (1:2:4:8 for heating, 1:2:4 for cooling). The

number of loads to be controlled is set. Thereafter the program will automatically calculate the

individual activation levels. Switching differential and minimum on/off times can be set. The

number of heating steps will be: 2

no. of groups

-1. In binary mode, the analogue output signal may be

used to fill out between the steps. The signal will go 0…100 % between the activation of each step.

The load c onnected to the analo gue signal should have the same size as the smallest o f the binary

groups. In the example below there are 4 heater groups (1:1:2:4) and the total number of heating

steps is eight.

32 Chapter 5 Functional description Manual Corrigo Ventilation, revision R

Step controllers and Change-over

The digital output signals "Heating/coo ling step 1", "Heating/cooling step 2 " and "Heating/cooling

step 3" are used for step controllers during Change-over control (see s ectio n 5.1 .12 ). They ha ve the

same functions as other step controller outputs, but are set to either heating or cooling depending on

whether heating or cooling is required.

DX cooling with room or extract air control

If DX cooling is used in conjunction with room temperature control or extract air temperature

control, there are two configuratio n alte r natives, DX cooling or DX cooling with exchanger control.

DX cooling without exchanger control

When running cascade control, the supply air controller setpoint is normally controlled by the

room/extract air controller output signal.

When DX cooling is activated, the supply air controller setpoint is lowered to five degrees

(adjustable) below the setpoint given by the room/extract air controller. This prevents the DX

cooling from being activated/deactivated too often.

DX cooling with exchanger control

When running cascade control, the supply air controller setpoint is normally controlled by the

room/extract air controller output signal.

When DX cooling is activated, the supply air controller setpoint is lowered to five degrees

(adjustable) below the setpoint given by the room/extract air controller. This prevents the DX

cooling from being activated/deactivated too often. If the supply air temperature falls below the

setpoint given by the room/extr a c t a ir controller, the heat exchanger output will be activated in order

to try to mai ntain the supply air setpo int given by the r oom/extract ai r c o ntr o lle r. T he o ut p ut u se s P control with a P-band of half the setpoint lowering (adjustable, 2.5°C as default). The setpoint given

by the room/extract air controller cannot drop below the set min limit. When there is no longer a

cooling de mand, the sup pl y ai r controller setp oint wil l ret urn t o t he va lue give n b y the ro om/e xtrac t

air controller.

Note: The function cannot be used if the exchanger sig nal controls a mixing damper.

Example:

The room controller gives a supply air setpoint of 16°C. If there is a cooling demand, the supply air

controller setpoint is lowered to 11°C (16 – 5) and DX cooling is activated. Should the supply air

temperature fall below 16°C, the exchanger output will be activated and reach 100 % output when

the supply air temperature has fallen to 13.5°C (16 - 2.5).

Blocking of DX cooling at low outdoor temperature

DX cooling can be blocked when the outdoor temperature is low. It is possible to block the three

cooling steps individually or to block all DX coo ling. The temperature limits are adjustable (+13°C

default) and have a fixed one degree hysteresis.

1

1

1

1

2

4

2

Y1 = 1

Manual Corrigo Ventilation, revision R Chapter 5 Functional description 33

When two DX cooling steps are used with binary function, the cooling effect is divided into three