Abon Tech RF88157101 User Manual

RFID Transponder Reader

User Manual

(Model: 88-157-101)

FCC ID: S44RF88157101

DOCUMENT INFORMATION

DOCUMENT ID:

ISSUED DATE:

UT-RFID-LFRD157-MN01

SEP , 1 , 2004

VERSION NO:

REVISIED DATE:

1.9

APR , 14 , 2005

RFID Transponder Reader User Manual

Version:1.9

IMPORTANT NOTES:

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

Any changes or modifications not expressly approved by the party responsible for

compliance could void the authority to operate equipment.

! CAUTION:

01. Read and understand all safety and operating instructions before installing and

operating the device.

02. This instruction is designed for specially trained personnel. This device is NOT

intended for use by the “general population” in an uncontrolled environment.

Installation, operation and error handling the device shall be carried out by specially

trained personnel only.

03.The device cannot be sold retail ,to the general public or by mail order. It must be sold to

dealers.

04. Install in accordance with the manufacturer's instructions only.

05.This product is designed to be mounted and operated in an industrial environment as a

built-in-device only. It is not designed to be used as a stand-alone or a portable device or

in a non-industrial environment, such as a household, vehicle or open-air environment.

06. This manual is designed for specially trained personnel only. This device must be

installed and maintained by the manufacturer or its specially trained representatives.

Intervention or error handling not expressively approved in this manual must be carried

out by the manufacturer’s personnel only. If you are unsure about the qualifications that

are actually required, contact the manufacturer.

z Unqualified interventions may result in personal injury or damage to the device!

07. Do not connect the device to any kind of power supply such as a standard household

power supply. The device should be connected to a power supply of the type described

in these instructions only.

08. When you disconnect a cable, pull on its conductor and not on the cable itself. Keep the

connector evenly aligned to avoid bending any connector pins. When you connect a

cable, ensure that the connector pins are positioned correctly.

This document is prepared by UNISON Technology Inc. All rights reserved.

Page 2 of 31

RFID Transponder Reader User Manual

Version:1.9

09. Never over bend the antenna cable or expose it to mechanical loads.

10. When replacement parts are required, use the replacement parts specified by the

manufacturer only. Unauthorized substitutions may result in fire, electric shock, or

other hazards.

11. This equipment generates , uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications.

12. Never locate the antenna so that it is very close to or touching parts of the body while

transmitting.

This document is prepared by UNISON Technology Inc. All rights reserved.

Page 3 of 31

RFID Transponder Reader User Manual

Version:1.9

TABLE OF CONTENT

IMPORTANT NOTES AND CAUTION ……………………………………………………….

1. INTRODUCTION …………..…………………………………………………………………

2. PRODUCT DESCRIPTION ………………………………………………………………….

2.1. OVERVIEW ……………………………………………………………………………… 7

2.2. LAYOUT …………………………………………………………………………………. 8

2.3. FUNCTION ………………………………………………………………………………. 11

2.4. SPECIFICATION ………………………………………………………………………… 13

2.5. LOAD PORT INTEGRATION …………………………………………………………... 14

3. SECS OPERATION …………………………………………………………………………..

3.1. INTRODUCTION ………………………………………………………………………... 15

3.2. SECS II MESSAGE ………………………………………………………………………. 15

3.2.1. Message Set ………………………………………………………………………... 15

3.2.2. Message Set Format ……………………………………………………………….. 16

3.3. INTRODUCTION TO SEMI E99 ………………………………………………………... 20

3.3.1. State Model and Transition ………………………………………………………… 21

3.3.2. Services …………………………………………………………………………….. 22

3.3.3. Service Operability ………………………………………………………………… 23

4. ASCII OPERATION ………………………………………………………………………….

4.1. HOST COMMAND FORMAT …………………………………………………………… 23

4.2. READER COMMAND FORMAT ……………………………………………………….. 24

5. SETUP ………………………………………………………………………………………….

5.1. INSTALLATION PROCEDURE ………………………………………………………… 26

5.2. INITIAL TEST PROCEDURE …………………………………………………………… 26

6. TROUBLE SHOOTING ………………………………………………………………………

6.1. ERROR INDICATOR …………………………………………………………………….. 27

6.1.1. Watch Dog Timer …………………………………………………………………... 27

6.1.2. Read/Write indicator ……………………………………………………………….. 27

6.2. ERROR RECOVERY …………………………………………………………………….. 27

7. ACCESSORIES ………………………………………………………………………………..

7.1. RS232 ……………………………………………………………………………………… 28

7.2. ANTENNA ………………………………………………………………………………... 29

7.3. POWER ADAPTER ………………………………………………………………………. 30

8. SERVICE INFORMATION ………………………………………………………………….

2

6

6

15

23

25

27

28

31

This document is prepared by UNISON Technology Inc. All rights reserved.

Page 4 of 31

RFID Transponder Reader User Manual

FIGURES

FIGURE 2-1. SYSTEM INTEGRATION ARCHITECTURE…………………………………

Version:1.9

7

FIGURE 2-2. READER OPERATION PANEL ……………………………………………….

FIGURE 2-3. READER FLANK CONNECTORS ……………………………………………

FIGURE 2-4. STICK TYPE ANTENNA ………………………………………………………

FIGURE 2-5. READER APPEARANCE SIZE ……………………………………………….

FIGURE 2-6. STICK TYPE ANTENNA ……………………………………………………...

FIGURE 2-7. RFID READER CONTROLLER LAYOUT …………………………………...

FIGURE 2-8. DIP SWITCH SETTING ………………………………………………………..

FIGURE 2-9. I/O CONNECTOR PIN ASSIGNMENT ……………………………………….

FIGURE 3-1. CIDRW STATE MODEL DIAGRAM …………………………………………

FIGURE 7-1. STICK TYPE ANTENNA READOUT DIAGRAM …………………………...

TABLES

TABLE 2-1. RFID READER SYSTEM SPECIFICATION …………………………………..

8

8

9

10

10

11

11

12

21

30

13

TABLE 2-2. RFID READER STANDARD COMPLIANT …………………………………...

TABLE 2-3. KITS P/NS FOR DIFFERENT LOAD PORTS ………………………………….

TABLE 3-1. SECS STREAM FUNCTION LIST ……………………………………………...

TABLE 3-2. SECS-II RETURN CODE ………………………………………………………..

TABLE 3-3. CIDRW STATE TRANSITIONS ………………………………………………..

TABLE 3-4. COMPLIANT SERVICES LIST …………………………………………………

TABLE 3-5. VALID SERVICES PER STATE ………………………………………………..

TABLE 4-1. ASCII HOST COMMAND FORMAT …………………………………………..

TABLE 4-2. ASCII HOST COMMAND LIST ………………………………………………...

TABLE 4-3. ASCII READER COMMAND FORMAT ……………………………………….

TABLE 4-4. ASCII READER COMMAND LIST …………………………………………….

TABLE 7-1-1. RS232 CABLE SPEC ………………………………………………………….

TABLE 7-1-2. RS232 PIN DEFINITION ……………………………………………………..

TABLE 7-2. ANTENNA CABLE SPEC ………………………………………………………

TABLE 7-3. SWITCHING POWER ADAPTOR ……………………………………………...

14

14

15

20

21

22

23

23

24

24

24

28

28

29

30

This document is prepared by UNISON Technology Inc. All rights reserved.

Page 5 of 31

RFID Transponder Reader User Manual

Version:1.9

1. INTRODUCTION

The history of RFID technology could be retraced to early 20th century which is

involving the study of radio wave generation and transmission. The RFID became

reality from 1970’s, many developers、inventors、companies、academic institutions and

Lab are all actively working on RFID. In the past thirty years, the electronic technique

and integrated circuit development were promoted in tenfold speed. It has gradually

driven the RFID technology to commercial and practical applications.

The characteristic of RFID depends on the operating frequency. Unison RFID Reader

works in LF (Low Frequency) range of 134.2 kHz and 125kHz. It uses inductive

coupling and FSK (Frequency Shift Keying) technologies to transmit data between

reader and tag. Non-contact communication reduces the abrasion of tag, and the

read/write do not restrict within line of sight. In addition, the passive tag is energy by

reader, no battery needed during operation. The cost of tag is reduced substantially.

The response time of reader is within hundreds of millisecond, which is dependent on

the data transmission. The reader controller provides standard serial port and Ethernet

port (not support yet

) for host connection, most field applications can easily integrate

the reader with those standard ports.

This manual describes the system specification and operation, as well as the procedure

of installation and maintenance. It recommends user to operate reader after reading this

document.

This document is prepared by UNISON Technology Inc. All rights reserved.

Page 6 of 31

RFID Transponder Reader User Manual

2. PRODUCT DESCRIPTION

2.1. OVERVIEW

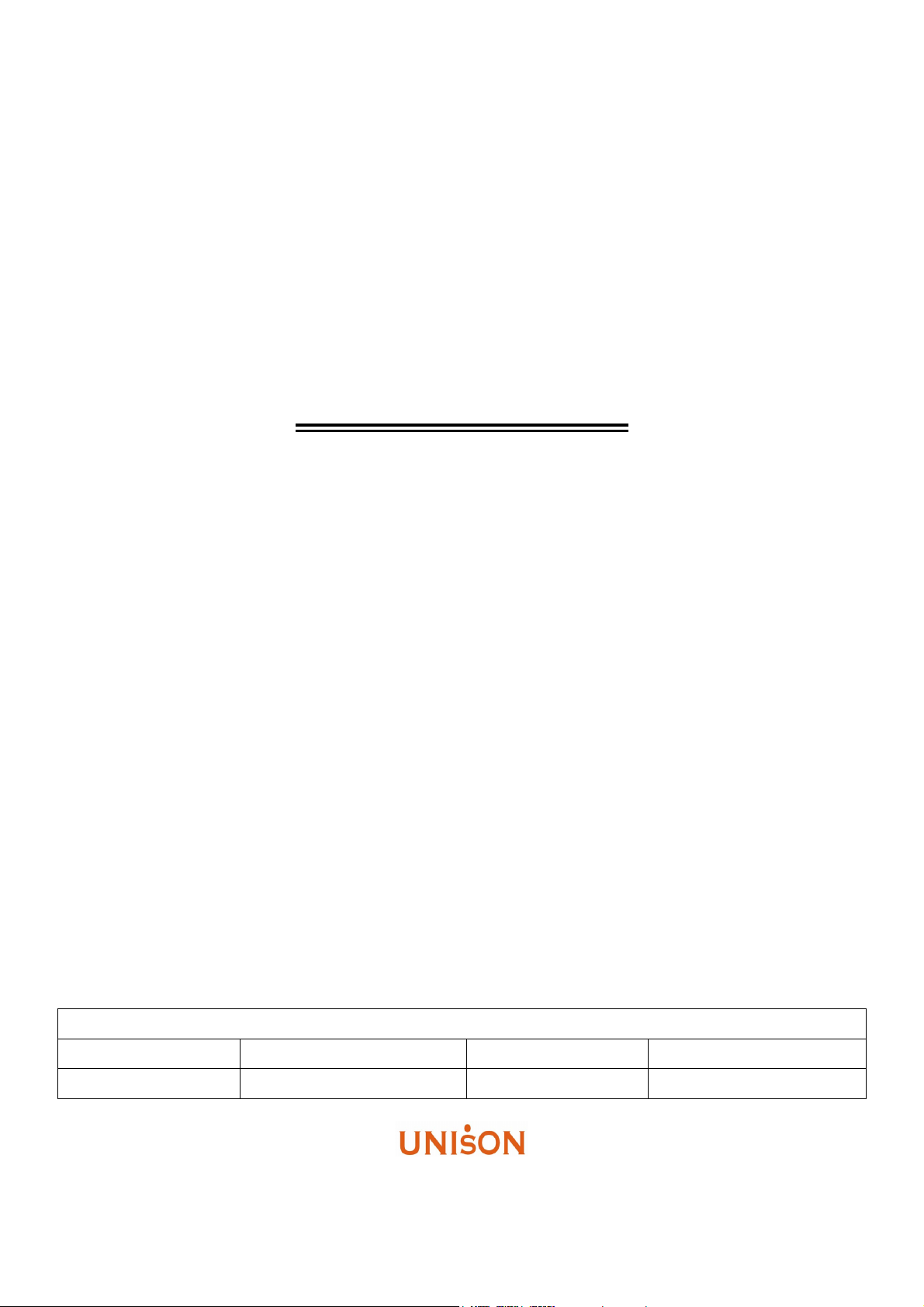

With safe、reliable、low cost requirements, UNISON RFID Reader is specifically designed for

semiconductor and TFT-LCD industry material tracking system by using low frequency RFID

technology. Take semiconductor FAB as an example, the integration of RFID reader and machine

load port can let EAP or MCS to track the cassette/carrier location in the FAB. CIM system can also

take advantage of rich tag information to achieve more efficient automation management.

UNISOSN RFID Reader is composed of reader controller and reader antenna. The RS232 (SECS

I/II) and Ethernet (HSMS) communication ports provide system integration for semiconductor

industry. The tag (transponder) specification is TI® ‘s 134.2kHz low frequency solution, it is the

most popular used RFID tag in 300mm FAB. UNISON RFID Reader is compliant with TI® ‘s LF

transponder. Following figure illustrate a typical single-wired application with process tool. The

RFID reader controller and antenna are installed in tool load port, and communicate with tool host

Version:1.9

by RS232 connection (ASCII or SECS). The lot tracking become more easy and efficient for

automation system.

PROCESS TOOL

LOAD

PORT

LOAD

PORT

RS232

ASCII / SECS

SECS

HSMS

H

O

S

T

STATION

CONTROLLER

RFC READER

Figure 2-1. System Integration Architecture

This document is prepared by UNISON Technology Inc. All rights reserved.

Page 7 of 31

2.2. LAYOUT

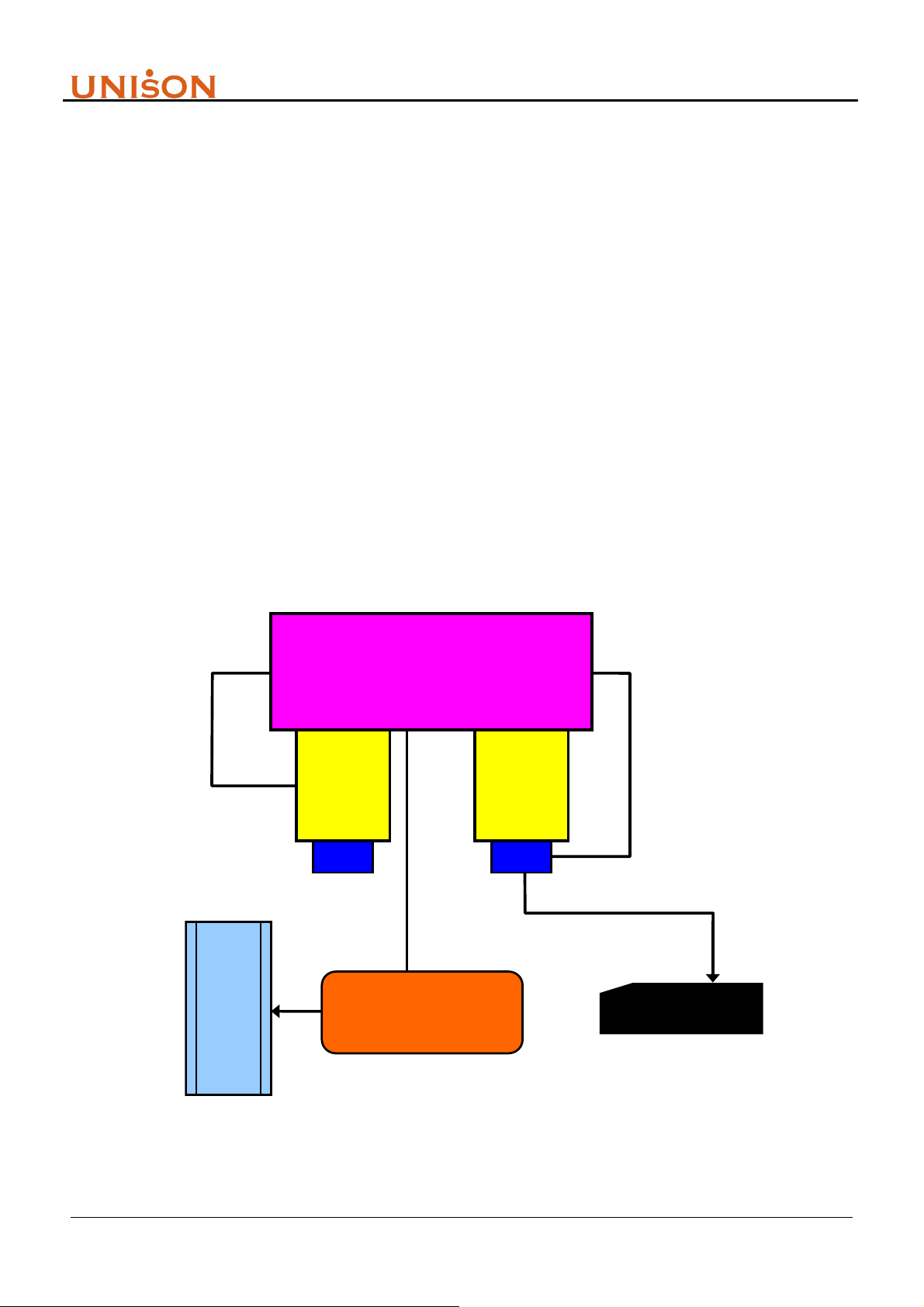

The housing material of UNISON RFID Reader is made by A.B.S. which is used in electrical device

and will not impact the FAB cleanness. All connectors and switch are designed at controller flank,

and operation panel locate at top side. It make user easily to use it. The appearance and layout are

described as follow.

<1>. Operation Panel :

RFID Transponder Reader User Manual

Version:1.9

<2>. Flank connectors :

Figure 2-2. Reader operation panel

(not support yet)

Figure 2-3. Reader flank connectors

This document is prepared by UNISON Technology Inc. All rights reserved.

Page 8 of 31

RFID Transponder Reader User Manual

Version:1.9

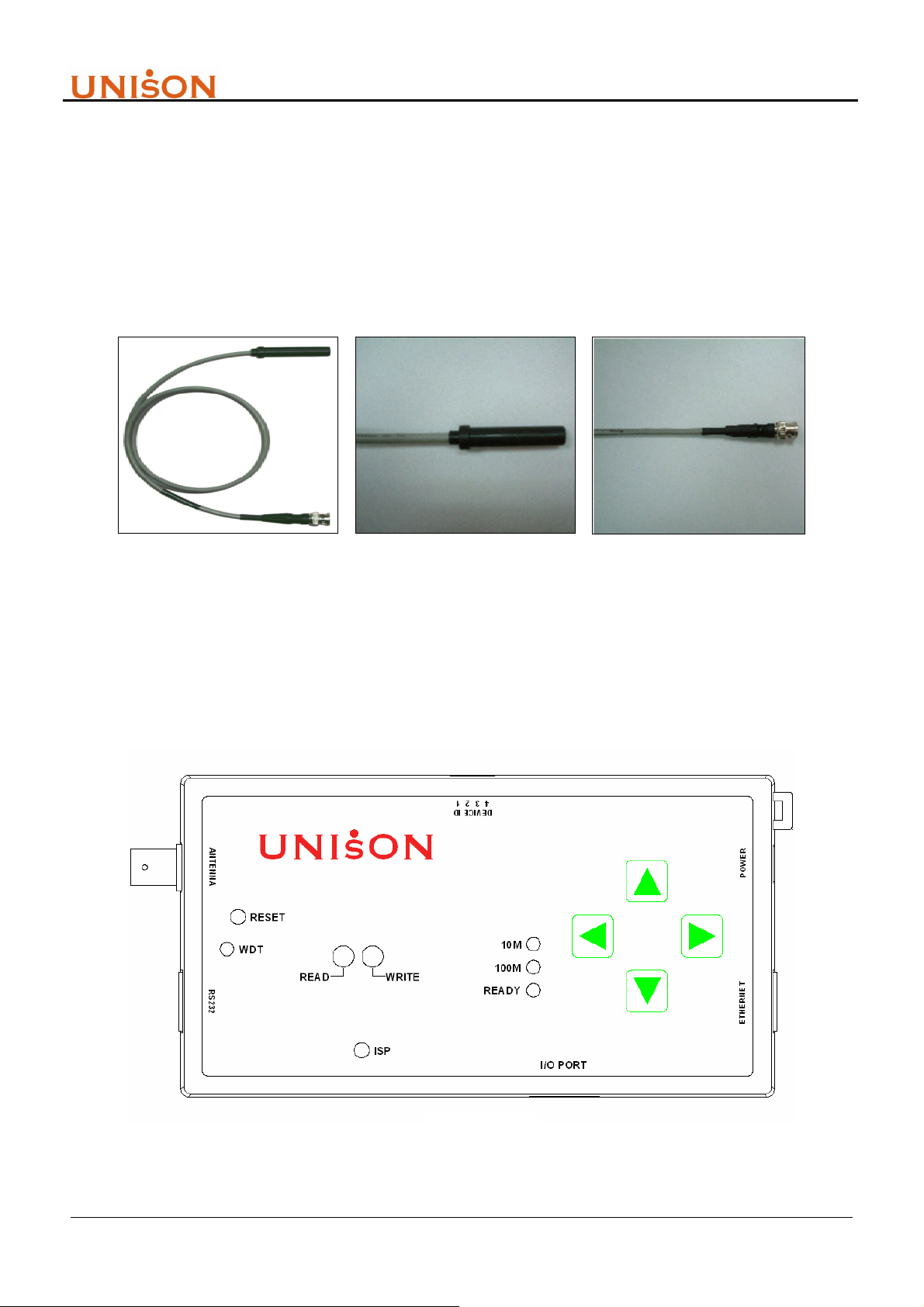

<3>. Antenna :

! Never over bend the antenna cable or expose it to mechanical loads.

The antenna design and RFID reader controller design are physically separated, and can connect

them by common interface. Based on TI® ‘s glass type transponder, UNISON RFID Reader use the

induction coil which is wired and packaged as stick type. Follow pictures show their appearance.

Overall Antenna BNC Connector

Figure 2-4. Stick type antenna

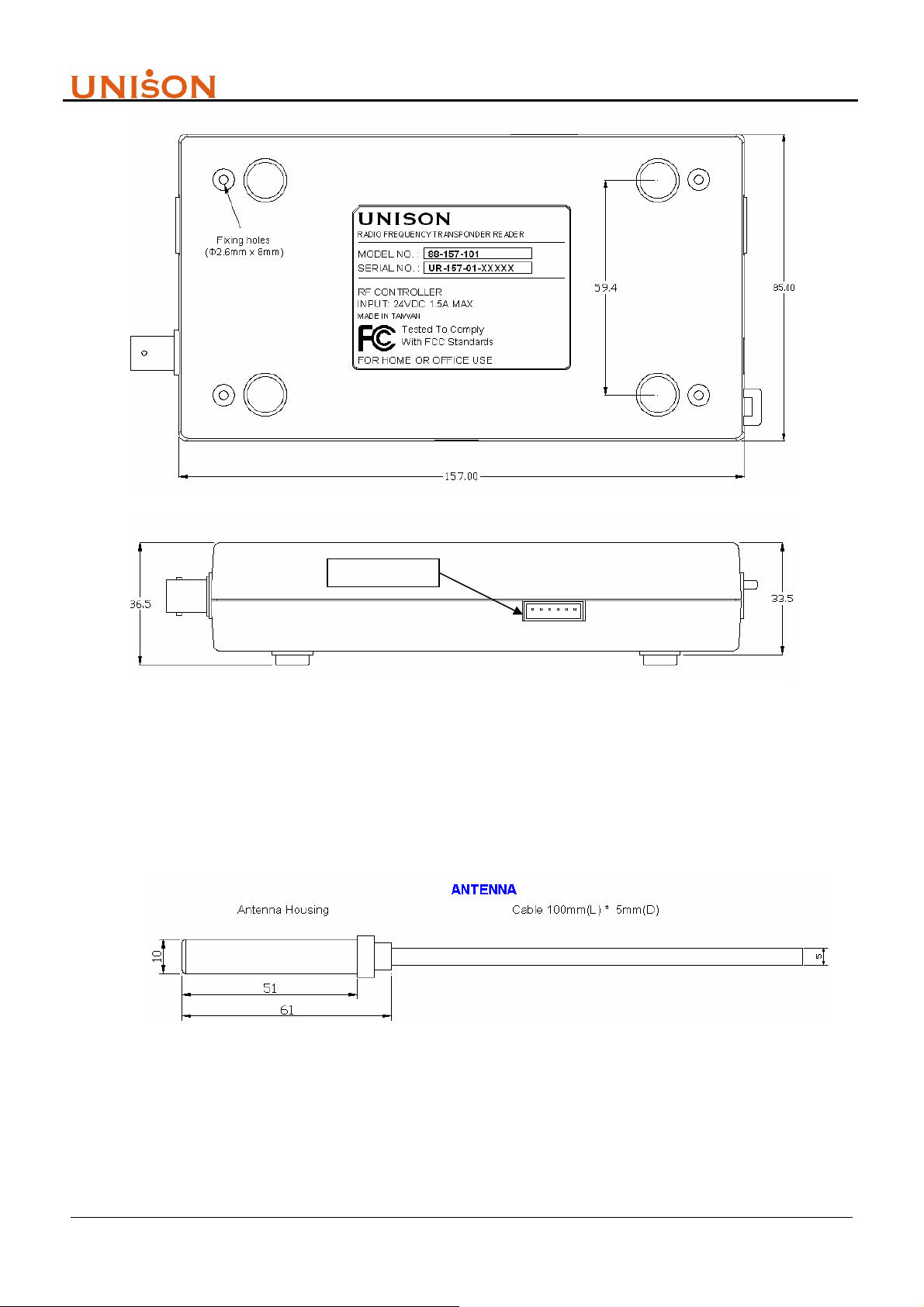

<4>. Size

Standard version of Reader size (product number 88-157-XXX) is listed below,

TOP VIEW

This document is prepared by UNISON Technology Inc. All rights reserved.

Page 9 of 31

RFID Transponder Reader User Manual

Version:1.9

BACKVIEW

not support yet

SIDE VIEW

Figure 2-5. Reader appearance size

Antenna size

Figure 2-6. Stick type antenna dimension

The description of UNISION RFID Reader functions are referred to section 2.3.

This document is prepared by UNISON Technology Inc. All rights reserved.

Page 10 of 31

Loading...

Loading...