DpuScan 4.0

Special Scanner Options for

Scamax 2600 and 5000

Copyrights

© 1997-2003 J&K Imaging (Marietta, GA/USA) and Janich & Klass (Wuppertal, Germany). All rights

reserved

. Printed in Germany.

The information contained in this documentation is the property of J&K Imaging and Janich & Klass

Neither receipt nor possession hereof confers or transfers any right to reproduce or disclose any part

of the contents hereof, without the prior written consent of J&K Imaging and Janich & Klass.

.

Trademarks

DPU/DDU logos are registered trademarks of Janich & Klass. DpuScan is a trademark of J&K

Imaging

respective companies.

. All other product names and logos are copyrighted and/or registered trademarks of their

Disclaimer

The instructions and descriptions in this manual were accurate at the time of this manual's printing.

However, we reserve the right to alter the description and/or the product at anytime without prior

notice.

J&K Imaging and Janich & Klass assume no liability for damages incurred directly or indirectly from

errors, omissions, or discrepancies between the manual and the product.

Actuality

A more recent version of the scanner options for DpuScan may be available for download from the

Internet. Therefore, it is recommended that you compare the version by means of the date printed on

this page with the version on the Internet. You should use the most up-to-date version.

The actual version of this addition to the DpuScan Reference Manual is found on the web at:

www.jkimaging.com/pdf/scanner options/Options-Scamax2600.pdf

© 2003 Janich & Klass Computertechnik GmbH, Wuppertal, Germany

July 25, 2003

Scanner Options Scamax 2600 / 5000 DpuScan

Table of Contents

1 Description of the Scanner Options ................................................................................................5

1.1 Introduction.............................................................................................................................. 5

2 Device Properties ...........................................................................................................................6

3 Image Processing Options.............................................................................................................. 9

4 Image Index ..................................................................................................................................12

5 Expanded Endorser Control for Scamax 2600 ............................................................................. 15

5.1 What it is and How it Works................................................................................................... 15

5.2 Terms and Definitions............................................................................................................ 16

5.2.1 Header............................................................................................................................ 16

5.2.2 Image Address ............................................................................................................... 19

5.2.3 Counters......................................................................................................................... 19

5.2.4 Flags............................................................................................................................... 21

5.2.5 Level............................................................................................................................... 21

5.2.6 Mode ..............................................................................................................................22

5.3 Parameter Configuration .......................................................................................................22

5.3.1 Patchcodes..................................................................................................................... 24

5.3.2 How to Set and to Trigger Counters...............................................................................25

5.3.3 How to Print Counters .................................................................................................... 27

5.3.4 Level and Mode Output – "Print Flags" Tab ................................................................... 29

5.3.5 Preview of Endorser and Header ................................................................................... 30

5.3.6 Save and Load Modes ...................................................................................................32

5.4 Events and Actions................................................................................................................ 33

5.4.1 Events ............................................................................................................................34

5.4.2 Actions............................................................................................................................ 35

5.4.3 Course of Events and Actions ........................................................................................ 35

5.5 Defining the Rule ...................................................................................................................38

5.5.1 Counter Handling ...........................................................................................................38

5.5.2 Setting Flags And Level .................................................................................................39

5.5.3 Device Control................................................................................................................41

Page 3 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

Table of Illustrations

Illustration 1 – Inotec Properties Tab: Device........................................................................................ 6

Illustration 2 – Inotec Options: Front Page ............................................................................................ 9

Illustration 3 – Inotec Options: Index ................................................................................................... 12

Illustration 4 – Current Counters.......................................................................................................... 13

Illustration 5 – Scanner Properties with Links to the Patchcode Controlled Index............................... 16

Illustration 6 – Counter Confirmation ................................................................................................... 21

Illustration 7 – Patchcodes .................................................................................................................. 23

Illustration 8 – Counter Modes............................................................................................................. 25

Illustration 9 – Print Counter ................................................................................................................ 27

Illustration 10 – Print Flags .................................................................................................................. 29

Illustration 11 – Enabling the Endorser................................................................................................ 31

Illustration 12 – Load and Save JMD-Files.......................................................................................... 32

Illustration 13 – NDX Rules Patch II .................................................................................................... 33

Illustration 14 – Reset Values?............................................................................................................ 34

Illustration 15 – Setting Flags and Level.............................................................................................. 39

Illustration 16 – Device Control............................................................................................................ 41

Page 4 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

1 Description of the Scanner Options

1.1 Introduction

This documentation is valid for the following scanners of the company InoTec:

• Scamax 2600 / Scamax 2500

• Scamax 5000

You must use the following driver: jukscsi

The scanner is connected using a standard SCSI interface board, and an ASPI driver must be

installed.

This program module was developed to enable the user to set the special options of the Admis S31

scanner. The jukscsi driver from Janich & Klass forwards these settings to the scanner.

The special scanner settings are offered with the user interface, spread over several pages.

Page 5 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

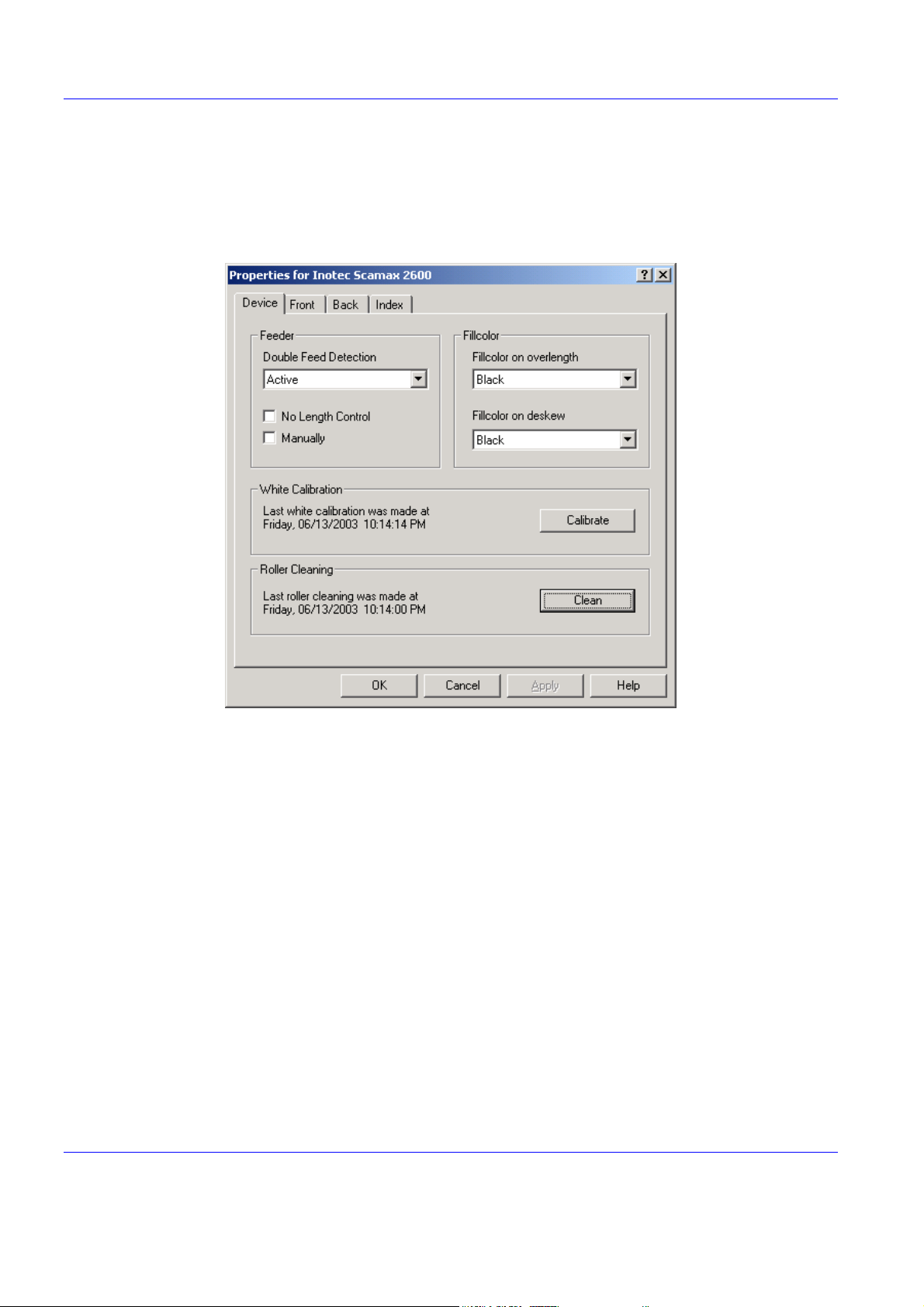

2 Device Properties

The first page gives setting possibilities for double feed detection, length control, manual feeding

mode, and fill color options.

Illustration 1 – Inotec Properties Tab: Device

Double Feed Detection

Standard Scamax Series document scanners are equipped with an ultrasonic double feed sensor.

The sensor is active during the entire scanning process (over the complete length of the document)

and gives an error report in the case of a double feed.

The following modes are available for double feed detection:

Active

Double feed detection is enabled.

Inactive

Double feed detection is disabled.

Only Start of Document (5cm)

The ultrasound sensor is active only for the first two inches of each original. Labels, Post-It

Notes, or other stickers that are not placed on top of the sheet, but at least two inches lower

the top, will not cause a double feed error message to appear.

Page 6 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

After Start of Document (5cm)

The ultrasound sensor becomes active only after the first two inches of each original. In

batches with different document types and very thin originals, a second sheet may feed too

deeply into the scanner, causing the sensor to report an error even though only one sheet was

fed and scanned.

In this mode, the above-mentioned event is unlikely to occur.

Reduced

The sensor will react only after a certain length of a detected double feed. These lengths

depend on the set paper size. Smaller stickers and labels do not automatically lead to a

double feed error message.

No Length Control

Normally, the scanner will use the length of the set paper size (paper format) in order to determine

when a sheet reaches its end. If the camera still captures paper after the defined paper length, it may

be caused by a document that is too long (larger than the set paper format), a staggered double feed,

or an extreme skew of the document. In such a case, the device will report an error.

On the other hand, if the paper is shorter than the expected format, the device will continue to scan

until enough image lines come together to result in an image of the desired format length. The

additional images lines are usually displayed in black. It is not filled up mathematically, so that the Fill

Color function has no influence here. Only when the image is complete will the next document feed

through the scanner. Thus, scanning a smaller original document will take the same amount of time

that it takes to scan an original with the defined paper format. The Deskew and Cropping functions

can be enabled.

If the length control is disabled (its box is checked), the device will scan in the defined paper format

length at a maximum, without regard as to whether the original is longer. Documents over this defined

length will be cut to match the defined format length (eventually creating an information loss) and the

double feed detection by paper length control will not be active. If, however, the paper is shorter than

the defined format length, the scanner will fill up the rest of the image mathematically to meet the

defined format length using the function Fillcolor on overlength. When the paper is shorter than

expected, there will be a gain in speed, because the next original is immediately fed and scanned

after the smaller original document.

Manually

Delayed feeder-empty-message for hand feeding

A sensor is located at the paper feeder of the scanner that reports "no paper" or "paper available" to

the scan application. If a paper batch is scanned and the last sheet is fed, the sensor reports "no

paper" to the software. The feeder rollers will then stand still and are reactivated only when new paper

is fed and a new scan command is given by the scan application.

If originals cannot be processed from the batch, it is possible to switch the scanner to manual feed by

means of the Manually function. Then, the scanner will no longer report "no paper" to the scan

application until there is a timeout of eight seconds. During this time, the feeder rollers continue

rolling, allowing fast and efficient scanning with the manual feeder.

Page 7 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

Please make sure the single sheet processor is switched on at the scanner.

Another possibility to effectively work with the manual feeder is the "Ignore paper status" function on

the Options property tab.

Fillcolor on Underlength

This parameter determines the fill color with which the missing length of an image that is shorter than

the defined paper length. This function can be executed only if "No Length Control" is enabled and if

the borders of the image are not cut. (Function: Border Cropping).

With a duplex scanner, this fill color is valid for the front side of a document and the back side.

Fillcolor on Deskew

This parameter determines the fill color for missing parts of an image due to a document skew and

automatic alignment.

With a duplex scanner, this fill color is valid for the front side of a document and the back side.

Roller Cleaning

The transport rolls of the machine should always be cleaned when the scanner no longer feeds the

paper from the batch.

To clean the rollers, take a fluff-free cloth or piece of paper and use the recommended cleaning liquid.

After starting the process, press the cloth to the underside of the feed rollers.

After pressing the Roller Cleaning button, a dialog appears that allows the user to start and stop the

process.

White Calibration

White calibration is required to compensate for differences in brightness that arise in the optical

transmission system. The calibration is made at the factory site, but it is also recommended in

situations when:

• a new lamp has been mounted in the scanner, or

• there are "stripes” and differences in brightness that are not caused by normal pollution of the

machine during the production process. Please make sure to clean the scanner before starting any

calibration.

The calibration is best made with the special white calibration sheets that were shipped together with

the machine. Put the calibration sheet into the feeder and press the calibration button.

Another dialog appears to start the process.

The process cannot be interrupted, and takes about ninety seconds to complete.

When the calibration is completed, a corresponding message dialog appears. Please restart the

scanner after every white calibration.

Page 8 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

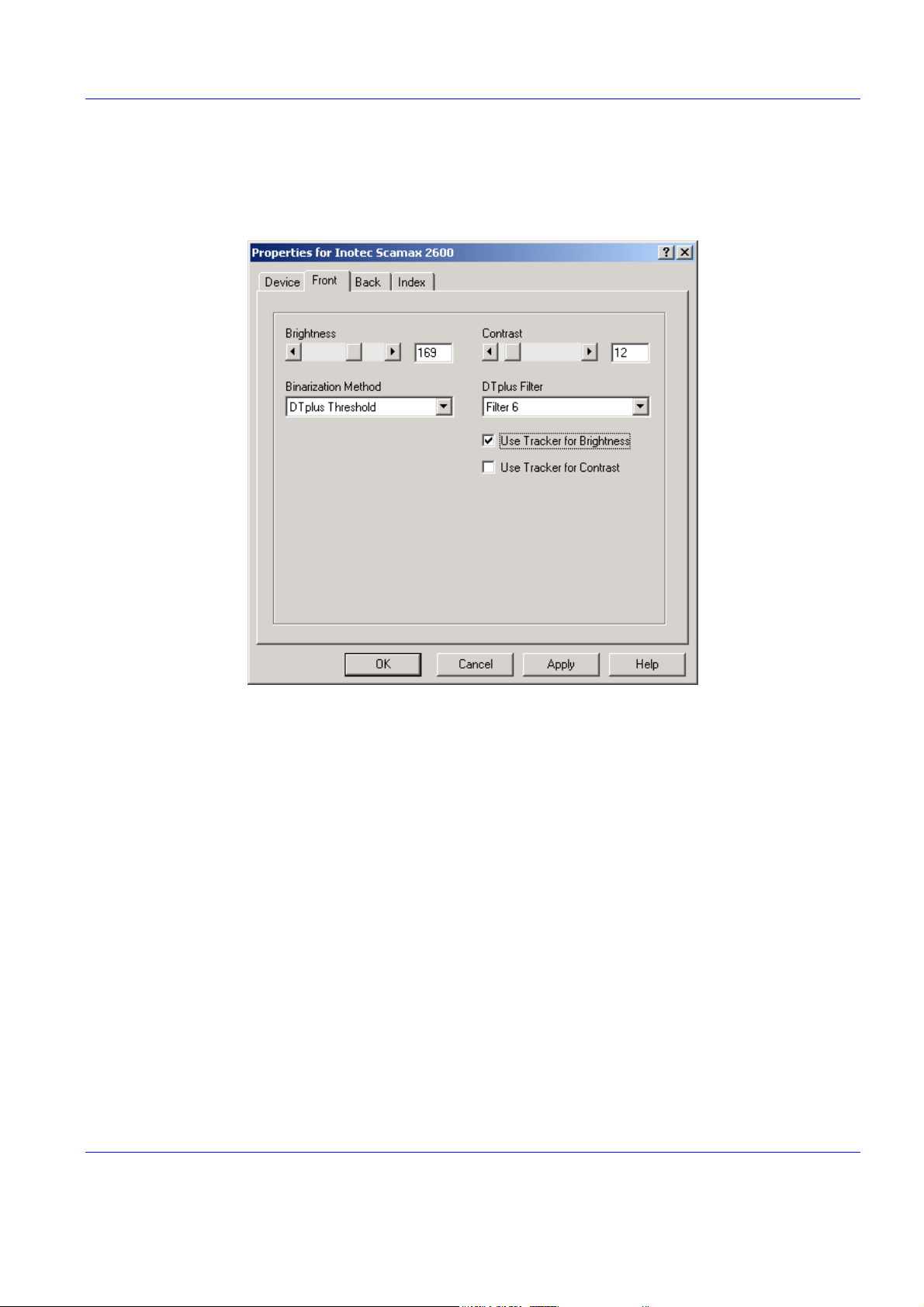

3 Image Processing Options

To optimize image quality you can set different image processing parameters. They are offered on the

next two pages, separately for Front and Back camera.

Illustration 2 – Inotec Options: Front Page

Binarization Method

The binarization method defines how the 256 possible grayscale values that come from the camera

will be transformed into bitonal information (black and/or white pixels).

Fixed Threshold

One of the 256 grayscale values is defined as the fixed threshold for the brightness. All levels

above will be represented as ”white”, and all others will be represented as ”black”. This simple

method is suited for "normal" documents without special colors, stains, or bad print.

Recommended Value: Brightness = 165

Automatic Threshold (one-dimensional)

The changes in gray levels in one line of the image are used to decide what is black and what is

white.

When deciding black or white, the scanner considers the previously read values of an image

line. Depending on the contrast settings, deviation levels in the grayscale values are considered

for the black/white decision dynamically.

Recommended Value: Brightness = 165; Contrast = 4

Page 9 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

DTplus Threshold (two-dimensional)

If the scanner has the DTplus board (optional), several image lines can be considered for the

black/white decision. As with the Automatic Threshold, not only the value itself, but also

deviations in its surroundings are considered.

The setting for brightness serves as the threshold for areas, and the setting for Contrast as the

sensitivity level for graylevel differences.

Recommended Values: Brightness = 165; Contrast = 12

Contrast

The contrast value defines the sensitivity for graylevel changes at neighboring pixels that will lead to

an interpretation of black or white. The lower the contrast, the higher the sensitivity level of the

scanner for graylevel changes.

For the automatic threshold, the Contrast can be set in 8 levels of sensitivity

Recommended Value = 4

If the device features a DTplus board, the two-dimensional DTplus threshold can also be used. Here,

127 theoretical sensitivity levels are available, but sensible settings are in the range between 5 and 25

Recommended Value = 12

Brightness

The brightness can be freely selected between values of 0 to 255. This represents the 256 graylevels

that the camera can capture. Sensible settings lie, as per the threshold method, between the values

of 120 and 180.

With the binarization method "Fixed Threshold", the brightness assumes a graylevel value between 0

and 255 as the limit from where the scan result for a pixel will be white or black.

Recommended Value = 165.

With the "Automatic Threshold", the brightness only serves as a threshold for the start value (white or

black) of every scan line.

Recommended Value = 165

With the binarization method "DTplus Threshold", the setting for brightness controls represents which

gray value will be represented as black or as white.

Recommended Value = 165

DTplus Filter

With the DTplus option, filters are available to reduce unwanted pixel "noise". The filter deletes black

and white pixels (despeck function) immediately after scanning, and even before the image is saved.

The table below lists the 60 possible values for the filter. With the value of 0, pixels will not be filtered

out at all. With the value of 1, black specks of 1x1 pixel are deleted. With the value of 16, black

specks of 4x2 pixels size are deleted, and all white specks of 1x1 pixel size (within black areas) are

filled with black.

Page 10 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

For improved barcode reading, and for results at scan resolutions of any level other than 200 dpi, we

recommend that the user selects their settings using notchfilter (values 30 to 59).

Delete

Color/Size

B / no 0 10 20 30 40 50

B / 1x1 1 11 21 31 41 51

B / 2x2 2 12 22 32 42 52

B / 3x3 3 13 23 33 43 53

B / 4x4 4 14 24 34 44 54

B / 4x1 5 15 25 35 45 55

B / 4x2 6 16 26 36 46 56

B / 1x4 7 17 27 37 47 57

B / 2x4 8 18 28 38 48 58

B / 3x2 9 19 29 39 49 59

B = Black; W = White

Tracker for Brightness

Without Notchfilter With Notchfilter

W /

W / 1x1 W / 2x2

W /

W / 1x1 W / 2x2

This tracker can be enabled only if the scanner is equipped with a DTplus board.

The DTplus board also works with a background tracker. It calculates the gray value of the

background, using several scan lines.

When enabling the "Use Tracker for Brightness" function, the brightness is adjusted to the gray value

of the background, as evaluated by the background tracker, and is reregulated continuously during

several scan lines. This dynamic adjustment of brightness should be added for mixed documents if

their backgrounds have distinctly different colors (white, green, rose, gray, blue, etc.).

Tracker for Contrast

This tracker can be enabled only if the scanner is equipped with a DTplus board.

The DTplus board also works with a background tracker. It calculates the gray value of the

background, using several scan lines.

When enabling the "Use Tracker for Contrast" function, the contrast value is dynamically reregulated

with more sensitivity. The darker the gray value of the background has been calculated by the

background tracker, the lower the value. Because black text on a dark background results in a lower

gray value difference, the scanner will react more sensitively in this case. As with the "Use Tracker for

Brightness” function, this function is advised for mixed document batches with distinctly different

background colors.

Page 11 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

4 Image Index

If the device is equipped with the corresponding option, a header is created for each image. This

header may be used for indexing.

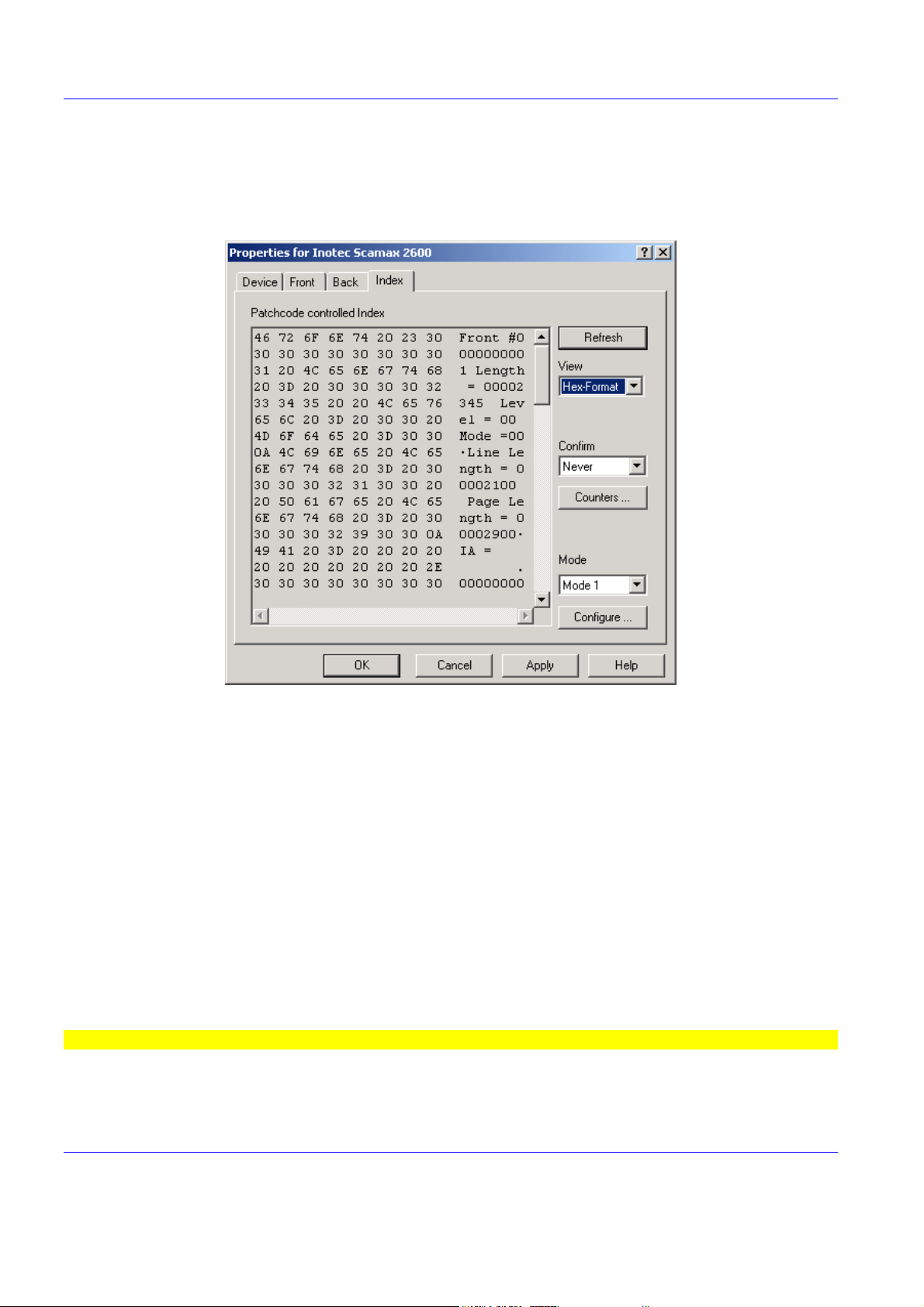

Illustration 3 – Inotec Options: Index

Refresh

Click the Refresh button to get and display the latest Image Header from the scanner.

View

There are several display possibilities for the data contained within the Image Header:

Line break

Word break

Hex Format

Variables

Changing the view format has no effect on the contents of the Image Header.

Displays the header "as is", including the integrated line breaks.

Breaks after every coherent sequence of numbers.

Displays the header, byte for byte, in hex format and as printable

characters.

Displays the individual parts of the header as variables.

Page 12 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

Mode

The mode is a combination of all settings made for Patchcode recognition, for counter behavior, for

endorser output, and for the rules to control the counters. This option allows the user to select from

one of the 16 operating modes.

To load, to change, and to save a mode, the user has to use the module Patchcode Controlled

Index, which you can reach by pressing the Configuration button.

Confirm

The driver permanently stores the counter positions. This way, they can be used continuously, as well

as after longer breaks. Use the following dialog to confirm the current counter position, which you can

reach by clicking the Counters button. The dropdown list allows you to determine when this dialog

shall display automatically:

• Never

• On every scan job start

• Only after an error occurs

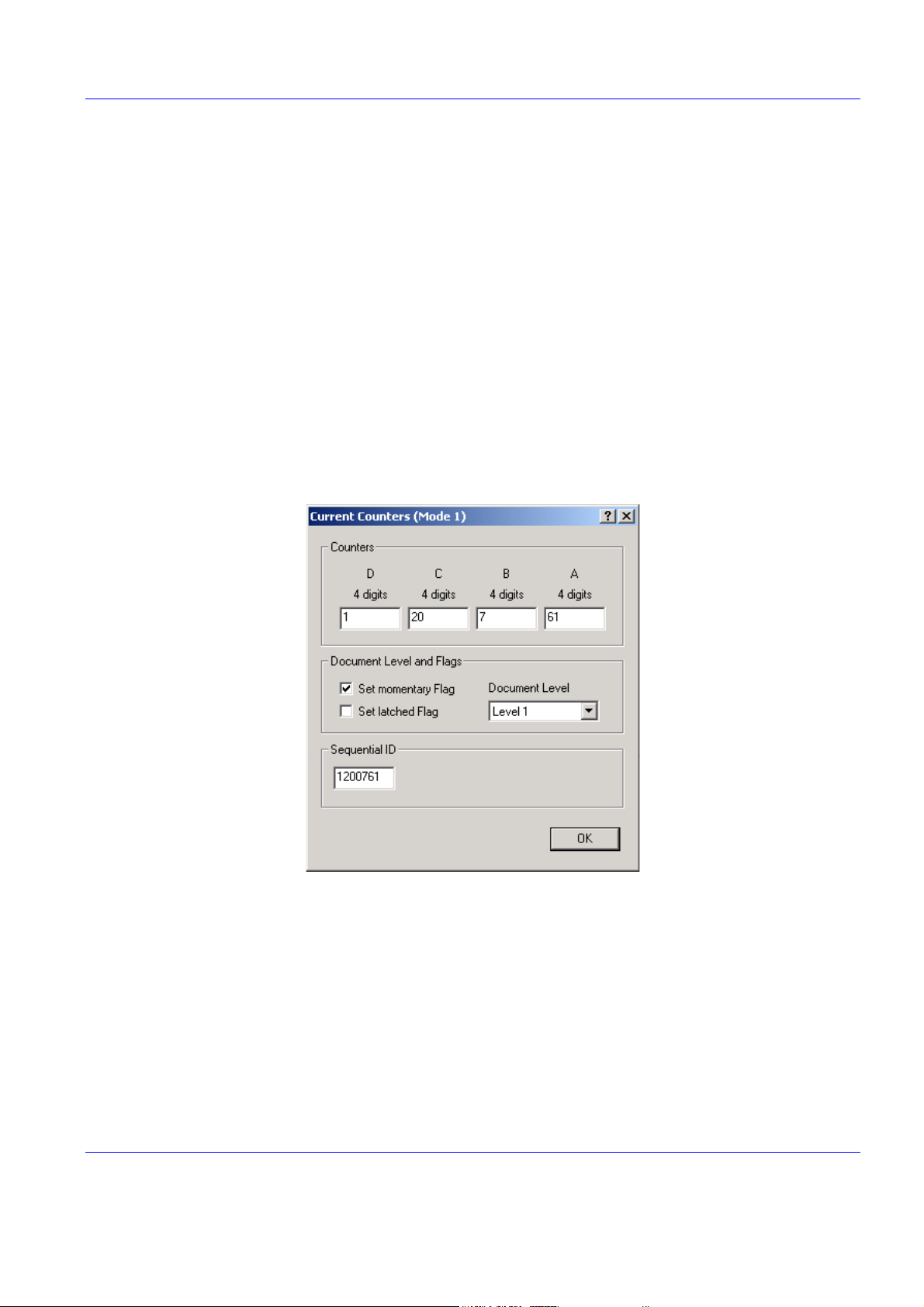

Illustration 4 – Current Counters

The Index Counters

Up to four counters can be used, depending on the kind of documents to be scanned:

Counter A ”Sheet counter”

Counter B ”Chapter counter”

Counter C ”Volume counter”

Counter D ”Film Roll number”

Page 13 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

If the counters are correspondingly set and enabled in the module Patchcode-Controlled Index, they

will be set and incremented as per the defined rules. So, for example, a document with the Patchcode

”Patch I” can indicate a new chapter. The chapter counter value increases incrementally by one and

the sheet counter is reset to zero.

The Index Flags

There are two flags that can be set for a sheet:

The latched flag remains set until it is reset, manually or via a defined Rule.

It can, for example, indicate that certain sheets are addenda to a certain form.

The momentary flag is valid only for the next sheet; it is then automatically reset.

You can use it, for example, to mark only the first document ("main document") of a new batch.

Document Level

The module uses the document level for Patchcode-Controlled Index, for example, to control

document separation.

Sequential ID

The scanner assigns a sequential number to the scanned sheets. This number usually cannot be

modified by a rule from the Patchcode-Controlled Index.

Exception: The sheet is "voided” or "not counted”.

Page 14 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

5 Expanded Endorser Control for Scamax 2600

5.1 What it is and How it Works

The Patchcode Controlled Index by Janich & Klass is intended as a method to control the scanning

process, to generate a data structure specific for each image, and simultaneously endorse the

paper.

The Patchcode Controlled Index requires an Agfa Admis S31 with SCSI firmware version 0.131

or higher. For printing on scanned documents the endorser must be built-in.

It is normally very difficult for a scan application to find out what a built-in endorser has printed on the

page, especially when the scanner works with a buffer. It is, for example, fairly impossible to change

the printout for page 11 depending on the information on page 10 that just comes right out of the

buffer, because by the time this has happened, the scanner is already at page 15 or 16.

A solution for this is to make the decision just before the new scan (and print) command is sent to the

machine. That works with a Janich & Klass SCSI scanner interface, which is mounted in several

scanner models.

The interface itself utilizes five counters that are incremented by user-defined values on every image.

Therefore, it is easy to change the endorsement every 100 images, for example.

Patchcodes are fast, reliable, and easy to identify, so it is ideal when they are printed on separator

sheets. The interface can recognize it fast enough to control the further process (e.g. to change the

printout for the endorser, to set/reset some counters, to drop/skip the page, or simply to stop the

scanner), on the condition that the code is printed at the top of the page.

The SCSI Interface sends the image to the host where it is handled by the application. When

Patchcode Controlled Index is utilized, an additional data structure, called a "Header", is sent along

with each image.

This header contains everything the interface board "knows" at this moment - the counters, date and

time, and the recognized Patchcode.

A scan application such as DpuScan can read this header and use its information to generate

directory and file structures. In summary, it is possible, for example, to name all files with exactly the

same text that is printed by the endorser.

To be able to print at all, the endorser must be enabled first:

Class Configuration | Data Source | Scanner | Options

At the bottom of the Options page, you will find the box labeled Text. You must enter the code %%I

Because the Patchcode Controlled Index depends on the hardware, the setup dialog for the Index is

found within the scanner’s setup dialog. For example, the Index setup for the Scamax 2600 is found

on the last tab.

Page 15 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

Illustration 5 – Scanner Properties with Links to the Patchcode Controlled Index

Note: If the required software modules are not installed, the button and the dropdown list for the

modes will not appear. When the scanner has the required hardware, the "Index" page is shown.

5.2 Terms and Definitions

Before we go to the configuration, we will take a look on some terms often used in this text:

5.2.1 Header

The header is the data structure, 512 bytes long, that is sent along with each image from the scanner

interface to the host. It is composed as per the following table:

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

F r o n t # - - - - - - - - - 0

18 19 20 21 22 23 24 25 26 27 88 29 30 31 32 33 34 35 36

L e n g t h = - - - - - - - 0

37 38 39 40 41 42 43 44 45 46 47

L e v e l = - 0

Page 16 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

48 49 50 51 52 53 54 55 56

M o d e = - 0 lf

57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

L i n e L e n g t h = - - - - - - - 0

81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103

P a g e L e n g t h = - - - - - - - 0 lf

104 105 106 107 108 109 ... 118 119 120 ... 129 130 131 ... 140 141 142 ... 151 152 153

I A = - - 0 . - - 0 . - - 0 . - - 0

154 155 156 157 158

- 0 - 0 lf

159 160 161 162 163 164 165 166 167

C m p = - 0

168 169 170 171 172 173 174 175 176 177 178 179 180 181

D a t e = m m d d y y

182 183 184 184 186 187 188 189 190 191 192 193 194 195

T i m e = h h m m s s

196 197 198 199 200 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215

R o l l # = - - - - - - - - - 0

216 217 218 219 220 221 222 223

R e s = - - 0

224 225 226 227 228 229

B o = - 0

230 231 232 233 234 235 236 237 238

S k = - - - 0 lf

239 ... 255

nu nu nu

------------------------------------------------------------------------------------------------------------------------

256 257 258 ... 287

: lf nu nu nu

Page 17 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

288 289 290 291 292 293 294 295

R e v = - 0

296 297 298 299 300 301 302 303 304 305 306 307 308 ... 322 323

I A _ F i x _ e x t = - - -

324 325 326 327 328 329 330 331 332 333 334 335 336 337

P a t c h c o d e = - 0

338 339 340 341 342 343 344 345 346 347 348 349 350

E n d o r s e d = - 0

351 ... 511

nu nu nu

Note:

This view uses the following measurements:

Length Image size in bytes

Level In range 0 to 3

Mode In range 0 to 15

LineLength In pixels

PageLength In lines

FlagM Momentary flag (Byte 155) 0 or 1

FlagL Permanent flag (Byte 157) 0 or 1

Compression (0=uncompressed, 1=G3(1-dim), 2=G3(2-dim), 4=G4)

Res Resolution in dpi

Bo Bit-Order (0="MSB to LSB", 1="LSB to MSB")

Sk Skew detected (value always remains unchanged)

Pol Polarity (0=black on white, 1=white on black)

Rev Revision Number (defines the additional information from Byte 296 on)

Page 18 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

Patchcode returns these values:

0 Patch T

1 Patch II

2 Patch III

3 Patch I

4 Patch IV

5 Patch VI

Endorsed (0 or 1)

Note:

All multi-digit numbers will be aligned to the right without any leading zeros. The format is completely

independent of the formats chosen for the printout.

5.2.2 Image Address

The image address is the part of the header that is sent to the application software with each image.

From left to right, it consists of the following parts:

Fixed Text Bytes 109 -118

Counter C (Volume Counter) Bytes 120 -129

Counter B (Chapter Counter) Bytes 131 -140

Counter A (Page Counter) Bytes 142 -151

All parts have 10 digits each and are separated by a point. Numbers will be aligned to the right.

5.2.3 Counters

Up to four counters can be managed. The name of the counters is based on the idea that there are

many "Pages" building several "Chapters". "Chapters" build "Volumes" which will be stored on "Film

Rolls".

Of course, these names should show the grouping and hierarchy only. Therefore, in another context

they may be called "Document Counter", "Enclosure Counter", "File Counter", etc.

This step in the document hierarchy is called Level.

The change from one level to another will be marked either by separator sheets with printed

Patchcodes, or will occur after a fixed number of pages.

Page Counter A

This counter will be incremented automatically by 1 for every scanned front side and back side of a

document.

Only after an event that resets the counter can it be incremented "manually" by the user-defined

value. After the first image, the counter will be incremented by 1 again automatically.

Page 19 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

The Page Counter A is the rightmost part of the Image Address in the Header.

Counter A fills Bytes 142 to 151 of the Image Header.

Chapter Counter B

Several documents form a chapter. The Chapter Counter B may be incremented when a chapter

separator sheet (e.g. Patchcode I) is found. On the other hand, it should be reset when a volume

separator (e.g. Patchcode II) comes in.

The Chapter Counter B is the second rightmost part of the Image Address in the Header; it fills Bytes

131 to 140.

Volume Counter C

A volume may consist of several chapters. Therefore, the Volume Counter C may be incremented

when the volume changes, and reset when a new "Film Roll" begins.

The Volume Counter C is the second leftmost part of the Image Address, and fills the Bytes 120 to

129 of the Image Header.

The leftmost part of the address is the Fixed Field.

Roll Number D

The roll number is the next highest level of file order. Several volumes are stored on a "Film Roll".

Several volumes are saved on a "Film Roll". The roll number is not part of the image address but it is

part of the header, at Bytes 205 to 214.

In addition to these counters, which will be incremented by a fixed or predefined value after scanning

a sheet, there is a running number called Sequential ID.

Sequential ID

The Sequential ID is another counter that is incremented automatically by 1 for each scanned

document.

It fills Bytes 8 to 17, just after the Front/Rear Information at the beginning of the Image Header.

The Sequential ID cannot be changed using the setup for the Patchcode Controlled Index. If however,

the corresponding scanner option is enabled, as seen in Illustration 5 – Scanner Properties with Links

to the Patchcode Controlled Index

on Page16, a dialog will appear at job start to confirm the counters.

Page 20 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

Illustration 6 – Counter Confirmation

5.2.4 Flags

There are two flags that can be managed by the Patchcode Controlled Index.

The latched flag can be set by means of a rule after a specific event. It remains set until it is reset by

another rule, or by the beginning of a new scan job. In the latter case, the latched flag must not be set

in the "Current Counters" dialog. With this flag, the user can, for example, mark the addendum of a

document.

The permanent flag can be set by means of a rule after a certain event has happened. It remains set

until it is reset by another rule, or when a new scan job is started. In the latter case, the permanent

flag cannot be set in the "Current Counters" dialog. This flag can be used to, for example, mark an

addendum to a document.

The momentary flag can also be set using a rule. It remains set only for the next document.

Afterwards it is automatically reset. This means that the user can mark the first page of a document

after a separator sheet.

If the scanner is equipped with the appropriate hardware, it is possible to handle the flags by pressing

a key.

5.2.5 Level

This defines the level in the document hierarchy. For example, many pages (Level 0) build a chapter

(Level 1), or an application form (Level 2) contains forms (Level 0) and attachments (Level 1).

With the Patchcode Controlled Index, the level can be a number between 0 and 3.

It is up to the user to define which actions should be executed for a specific level.

If the scanner is equipped with the appropriate hardware, it is possible to handle the level by pressing

a key or a foot switch.

Page 21 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

5.2.6 Mode

The Mode is the summary of all settings and rules that will be described in the succeeding

paragraphs. Depending on the scanner, up to 16 modes can be loaded permanently into the driver.

During a scan job, one mode is selected, as seen in Illustration 5 – Scanner Properties with Links to

the Patchcode Controlled Index

All succeeding settings work only for this selected mode, as shown in the title bar of the setup dialogs

in Illustration 7 – Patchcodes

After these definitions, we refer to the configuration dialog, which appears when the corresponding

button is pressed in the scanner’s setup dialog.

on page 15.

on page 23.

5.3 Parameter Configuration

The parameter dialog shows four tabs to set the Patchcode search options, the counter options, and

the endorser output. Below the pages there is a preview area to give the user an idea of the

endorser’s printout.

Placed on the right side of the dialog are buttons to save and reload the setting for this mode, and a

button labeled "Rules" that opens the "Control Configuration" dialog described later in this text (see

Chapter 5.5

on page 38).

Page 22 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

Illustration 7 – Patchcodes

As with the other dialogs, the buttons along the bottom work in the same well-known manner:

OK

Cancel

Apply

Help

The buttons on the right lead to further dialogs, which will be discussed later:

Rules…

Save…

Load…

The following several paragraphs describe the pages for the search and count options as related to

the endorser output configuration.

Closes the dialog box and saves your entries.

Closes the dialog without saving your entries.

Saves your entries without closing the dialog.

Opens the help screen.

Opens a dialog to define events and resulting actions.

Opens a dialog to save the current mode.

Opens a dialog to load stored modes.

Page 23 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

5.3.1 Patchcodes

With the "Patchcodes" tab several settings can be adjusted concerning the search for Patchcodes.

The search can be restricted to the front or rear side of a document, or to a specific search area on

the page. In addition, the quality level can be adjusted to look for thinner or thicker Patchcodes, or to

report an error if a code could not be identified exactly.

Search Patchcodes on

front / rear side

Interference Reduction

Detect thicker / thinner

Patchcodes

Stop on Error

Position and Size of

the Search Area

Enabling this option turns on the search separately for the front and rear

side.

If you disable the search, Patchcode dependent rules will not be

available.

This filter reduces white pixels from the black area of a Patchcode bar.

Noise like this can result from the scanner itself after retreatment of an

image by the IP hardware.

Patchcodes are defined with fixed sizes. To detect Patchcodes varying

the slightest bit from this size, one can choose this checkbox.

With this option enabled, the scanner stops when a Patchcode cannot be

identified exactly.

If the Patchcode bar is not printed over the whole page, but only in a

specific area, a search area can be defined.

With the means of these parameters, the location and the size of the

search area can be defined.

The values are given in 0.1 mm increments.

Please note that the upper border of the search area cannot be specified

because the upper border is always the top of the sheet.

As a general rule of thumb, the Patchcode should be recognized as

soon as possible; that means it should be printed at the upper edge

of a sheet (in direction of transport).

Page 24 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

5.3.2 How to Set and to Trigger Counters

Field Width

Increment Value (by a

certain value)

Illustration 8 – Counter Modes

This define how many digits the counter should have. If it is set to, for

example, 3 digits, the counter will count from 0 to 999. After that it resets

to 0 again.

Be aware that the reset and trigger value must be "in range”. In this

example, use a value before counter 1000, because 1000 will never

be reached.

We recommend the use of higher numbered digits for a lower level, and a

lower number of digits for a higher level. For example, if there are many

pages in just a few chapters, 6 digits should be chosen for the Page

Counter, and 2 digits for the Chapter Counter.

If a counter – including the automatic Page Counter A - has a field

width of zero, this counter will not be incremented and interpreted.

The Sequential ID will be incremented always as expected.

As a reaction to an event, the corresponding counter will be incremented

by the entered value. For example, the chapter counter can be

incremented while the page counter is at reset value.

Page 25 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

Page Counter A will always be incremented by 1. Only if Counter A

was reset as the result of an event (Patchcode found, for example)

will the counter be incremented for the next image by a user-defined

value. Afterwards, the counter will be incremented by 1 again.

Reset Value (reset the

counter to a certain

value)

Trigger Value (to cause

an event)

As a result of an event, the corresponding counter will be reset to the

entered value. For example, the page counter can be reset to 0 when a

new chapter begins. The reset value must be in a valid range, and it must

be within the defined field width, as seen in the notes above.

This defines which count causes an event. For example, the scan job can

be stopped after 200 pages.

The trigger value must also be in the valid range, as seen in the preceding

notes.

Page 26 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

5.3.3 How to Print Counters

Here, you configure the format to print counts of the counters on a document after being scanned.

Illustration 9 – Print Counter

It is required that the user selects a field width unequal to 0 on the Counter Modes tab. In the

Illustration above (Counter D), the Roll Number has a field width of 0, and thus it is not in use.

Print Format

Each counter with a field width unequal to 0 can be used to be printed on

the page that was just scanned. If the field width is 0, the counter will be

disabled.

Within the selected field width, the print can be aligned to the left or right,

padded with zero, or unformatted.

You can choose different formats, but the entire length of all counters and

delimiters to be printed are limited for technical reasons.

The result of the chosen format can be seen as a preview ("Numeric

Fields").

The order of the counter is predefined and fixed.

Page 27 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

If you want this order changed, you will have to configure the counters by

means of levels in events and actions. You can, for example, define that

Counter C will be incremented in level zero and Counter B will be

incremented in level one (new chapter). In this case, Counter C is the

page counter and Counter B is the chapter counter.

Set Counter Delimiter Delimiters are defined to separate the counters for printing. This means

that it is possible to separate page, chapter, and volume counters in a

different way. In front of the first, and after the last counter, you can enter

one character, and between two counters you can enter up to three

characters.

In the following example, the volume counter with two digits, the chapter

counter with three digits, and the page counter with four digits are

separated by different types of brackets and slashes:

[00]-(000)/<0000>

Page 28 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

5.3.4 Level and Mode Output – "Print Flags" Tab

The fourth tab allows the user to select how the Sequential ID, the level, the mode, and the flags

should be printed.

Sequential ID

Level /

Mode

Momentary Flag /

Latched Flag

Illustration 10 – Print Flags

The Sequential ID (running number) can be printed with 8 digits, aligned

to the left or to the right, with leading zeros, or of variable length.

Mode and Level can be printed with 2 digits aligned, aligned to the left or

to the right, with leading zeros, or of variable length.

The Momentary and the Latched Flag can be printed this way:

If they are set – as "1", or as "M" or "L"

If they are not set – as "0", as a blank, or just left out ("not in use”).

Page 29 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

Fixed Text

In addition to numeric values such as counters or flags, the endorser can

print text.

Only the printout text is limited to the number of characters selected here.

The text itself has to be entered in the field "Fixed Text Field", as seen

below. It can hold up to 15 characters.

It makes sense to enter a long, fixed text a lot of information and

send it along with the header to the scan application. On the other

hand, it may be applicable to print out only a small part of the text on

the original document to keep as close to its "original" state as

possible.

Delimiter

You can choose a delimiter to separate Sequential ID, level, mode, and

flags. This character will be printed after a parameter, on the condition

that in at least one of the boxes "Don't print" is not selected.

5.3.5 Preview of Endorser and Header

At the bottom of the Parameter Configuration dialog is a frame titled Endorsement Preview. It

contains an input field for the fixed endorser text, a grayed field for the summary of all counters and

flags output, and some lines that show how many characters are left for the several output fields.

Fixed Text Field

Numeric Fields

In addition to numeric values such as counters or flags, the endorser can

print text. The text is limited to 15 characters.

The first 10 characters from this string comprise the first (leftmost) part of

Image Address.

This field gives an idea of the printout; numbers with leading zeros are

shown as a sequence of zeros ("000"). Numbers with a fixed length are

shown as number/pound signs ("###").

The flags are displayed as their character, where ”L" means latched and

"M" stands for momentary.

If a number has variable length or a flag may be omitted (if unset), the

placeholder is a question mark ("?").

Page 30 of 42

For a SCAMAX the Counter A and the rightmost delimiter are

handled differently by the driver than the other counters, flags, and

delimiters. They do not account for the calculation of the maximum

field length.

The overall length for endorser text is limited by several machine

dependent parameters. For example, with a SCAMAX scanner, the fixed

text field and numeric fields are limited to 15 characters each (except

Counter A and its delimiter, as seen above).

Scanner Options Scamax 2600 / 5000 DpuScan

When using the %%I fieldcode and a longer lead or trail text in the

endorser setup, the printout may be cut at the end. Hence, it is

recommended that the user test the printout on any document

before starting a "real” scan job.

Below the preview areas for the fixed text field and numeric fields there is a display showing how

many characters are left for each field.

The symbol

It will change to

calculated is then represented by a question mark.

The symbol changes to

To enable a printout, the endorser must first be enabled:

Class Configuration | Data Source | Scanner | Options

At the bottom of the Options page the user will find the edit field String. Here the code %%I must be

entered. This causes the printout of the full endorser text – first the fixed field and then the numeric

fields.

indicates that enough space is available to print the complete text.

when the length of the print may vary. The part where length cannot be

as soon as the valid number of characters is surpassed.

Illustration 11 – Enabling the Endorser

Page 31 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

Note: Using the normal endorser counter %U when the Patchcode Controlled Index is also in use is

not recommended. This is because the endorser counter uses the same resources as Counter A.

The buttons to load and to save the settings and the button for the rules are located on the right side

of the Parameter Configuration dialog.

5.3.6 Save and Load Modes

All settings for search, count, and output, as well as all rules can be summarized as one mode and

can be stored as a JuK Mode Definition ("*.JMD" file). There is no limit in defining and storing different

modes, nor is there a restriction for definition and saving different modes. A certain number of such

configurations, 15 with an Admis S31 scanner, can be stored directly in the scanner itself, as seen in

Illustration 3 – Inotec Options: Index

The current mode can be stored as a *.JMD file and can later be reloaded as the current mode, using

the Save and Load buttons.

on Page 12.

Illustration 12 – Load and Save JMD-Files

It is useful to define modes for recurrent tasks or documents, to store them on a network drive, and to

load the required one to their respective workstations.

Pressing the button Rules, as seen in Illustration 10

control of the currently selected mode.

Page 32 of 42

on page 29, opens up the dialog for the Index

Scanner Options Scamax 2600 / 5000 DpuScan

5.4 Events and Actions

Use this dialog to set the actions that will happen with which event. The following example defines

that when a Patch II is found, the Chapter Counter is incremented and the Page Counter is reset. In

ther words, a new chapter has started within the batch. o

Illustration 13 – NDX Rules Patch II

The title line of the dialog displays to which mode the rules relate. On the left side, there is a list of

events that may happen. The box below gives a short description of the selected event; if an event

cannot happen, the reason is displayed here. If, for example, the Patchcode search is not enabled,

Patchcodes cannot be found.

The boxes at the start of each line can be checked only if at least one action is set. The user can

utilize them to make a rule void (e.g. for only the next job) without the need to completely set it again

at a later time.

Use the Reset button to reset all actions for the highlighted line, or for all events.

Page 33 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

Illustration 14 – Reset Values?

5.4.1 Events

There are several groups of events:

Patchcode Events

These events happen when a certain Patchcode is recognized. Because the search is stopped

after the first Patchcode found, only one such event can happen on any one page.

Level Events:

These events happen when a certain Level is set. Because only one Level can be valid, there

will be one event at max. Therefore, you can decide whether a page in a contract belongs

either to the contract itself, or to its addenda, for example.

Counter Events

Such an event happens when one of the counters reaches its trigger value. Because several

counters may reach their trigger value on the same page, several such events can happen at

one time as well.

Page 34 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

5.4.2 Actions

There are three groups of Actions:

Actions that set counters

These can reset and then increment the counters. This may influence the counter-based

events or the increment of the automatic counter.

Actions that set flags and level

These can change the flags, the mode, or the level. Changing the level disables checking for

level-based events for the actual sheet, where changing the mode or the flags does not affect

the further process.

Actions on the device control

These can drop the sheet, stop the scanner, or turn the endorser on and off.

5.4.3 Course of Events and Actions

Rules define what actions shall be taken when a special event appears. Checking for the events and

the execution of the resulting actions follows this procedure:

Step 0

Step 1

Patchcode-based

events

Assume that the scanner has scanned a sheet and has done the Patchcode

search. Both images (front and rear) and their headers are ready and waiting to

be sent to the application.

Note: The headers for the current images will not be changed. All

calculations and settings affect only the next sheet.

First of all the software checks if there was a Patchcode on the just incoming

sheet.

If Patchcode search is disabled this step will be skipped.

If there was a code found on the sheet the search for further Patchcodes stops.

So only one Patchcode is found on a sheet in a time.

If no Patchcode was found, the checking of the level (step 3) follows.

When a Patchcode-based rule becomes true the resulting actions take effect:

Page 35 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

Step 2

Patchcode-Based

Actions

If the field width is equal to a value of anything but 0, the Counters A, B, C,

and D will be reset and then incremented by the specified values. For details,

see Chapter 5.2.3 Counters

Then, the flags, the level, or the mode will be changed.

When the rule changes, the Counter A or the level will be denoted.

If the No Count action is wanted, this will be denoted as well.

In addition, all the hardware related actions such as Drop Page, Stop

Scanner, and Endorser On/Off will not take effect immediately. They will be

retained until Step 7.

on Page 19.

Step 3

Level-Based Events

Step 4

Level-Based Actions

Step 5

Increment the

Automatic Counters

Step 6

Counter-Based

Events und Actions

Now the current level will be checked.

This check will be done only if the level was not changed by a Patchcodebased rule before, as seen in Step 2 above. Otherwise, the procedure goes on

with Step 5, which is the incrementing of the automatic counters.

Only one level can be active at a time, so only one of the four levels can cause

resulting actions.

When a level-based rule becomes true the resulting action will be done:

This is the same as Step 2.

If the No Count option was enabled in Step 2 or Step 4, this step will be

skipped.

If not, the Sequential ID will now be incremented by 1.

If Counter A was not changed before, it will be incremented by 1 as well.

It doesn’t make sense to enable the No Count option after this step (i.e. in

the "Counter-based” rules).

The counters will now be checked to reach their trigger values. They will be

checked in the order A, B, C, and then D.

After each check the resulting actions (except the hardware actions, as seen in

Steps 2 and 4) will be performed immediately.

Page 36 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

Step 7

Hardware Control

The dialog on the next page is intended to define the rules.

After performing the counter and flag handling, the summary of the hardware

actions take effect.

Unless Drop Page is enabled, the page and the last header will be sent to the

host.

If necessary, the scanner stops now.

Otherwise, the endorser will be turned on or off for the following sheet.

Now the counters, flags, and other parts of the header will be updated.

The newly calculated counters are set for the next image, and not for the

current image.

Then, the next scan command including the print command for the endorser is

sent to the machine.

When the machine returns an image, the driver searches for Patchcodes and

merges the result and the further image-dependent values into the header.

Then the procedure restarts at Step 1.

Page 37 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

5.5 Defining the Rule

When defining a rule, the user must first determine the event and then which action shall result when

the event happens.

5.5.1 Counter Handling

Illustration 14 – Reset Values? on Page 34 shows the tab for counter handling. Depending on an

event, the four counters can be Reset to their initial start value.

After being Reset, the counters will be incremented by a specified value, as seen in Chapter 5.3.2

How to Set and to Trigger Counters

Example 1:

If you want to start page counting after a chapter break with 2 (in order to, for example, insert a large

formatted leading page at a later time) you can specify that Counter A is reset to zero and then

incremented starting from two.

Example 2:

If you want to use only even numbers for page counting only, you cannot use Counter A because it is

incremented automatically by 1 from the second page on. Therefore, you must disable Counter A (set

its field width to zero) and use another counter for these pages (such as Counter B). Each time a level

0 (normal page) document was scanned, Counter B will be incremented by 2.

on Page 25.

Page 38 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

5.5.2 Setting Flags And Level

Set momentary Flag

Set / Reset latched

Flag

Illustration 15 – Setting Flags and Level

Check this box to set the momentary flag in the header at Byte 155. The

Patchcode Controlled Index does not verify this flag, but the scan

application can use it to do something exactly for this one sheet, such as

call a function or start a new chapter.

The momentary flag will be reset automatically for the next sheet.

This sets the permanent flag in the header at Byte 157. Once the latched

flag is set, it remains set until it is reset by another rule or at the beginning

of a new scan job.

Just as with the momentary flag, the Patchcode Controlled Index does not

evaluate the permanent flag, but the scan application can use it to, for

example, mark the addendum pages of a tax form.

Because the flag setting is not evaluated, it can be done immediately after

verifying a rule. That means that the latched flag can be set by a rule and

can be reset later by another rule on the same sheet.

Page 39 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

Set Level for the next

document

Set Mode (Output

only)

Setting the level causes all rules dependent on the level to be ignored for

this sheet.

Therefore, the new level takes effect for next sheet.

Setting the mode number works only for the printout or the header.

It does not really select a new mode with new parameters and rules.

The mode can be changed only in the corresponding setup dialog of the

scanner, as seen in Illustration 5 – Scanner Properties with Links to the

Patchcode Controlled Index

on page 15.

Page 40 of 42

Scanner Options Scamax 2600 / 5000 DpuScan

5.5.3 Device Control

Stop Scanning

Discard the Sheet

(front and rear side)

Do not increment the

automatic counters

Endorser on /

Endorser off

Illustration 16 – Device Control

This stops the scanner before the next sheet. The current sheet will be

sent to the application unless it is not dropped.

If enabled, the document (front and rear side) will not be sent to the host.

This suppresses the automatic counting in Step 5 of the procedure as

seen in the previous chapter.

This enables or disables the endorser from the next sheet on, and the

current sheet is not affected.

If different rules enable and disable the endorser, the latter rule takes

precedent.

Page 41 of 42

DpuScan Scamax 2600 / 5000 Scanner Options

e

r

u

t

u

f

e

h

t

e

r

u

t

p

a

c

e

W

W

W

e

e

c

c

a

a

p

p

r

u

t

r

u

t

e

e

h

t

h

t

e

e

f

u

t

u

u

t

u

f

r

r

e

e

J&K Imaging, L.P. J&K Imaging South East Asia

1633 Sands Place 76 Wanaping Road

Marietta, GA 30067 Kenwick WA 6107

USA Australia

Phone: (770) 984-1212 Phone: +61 (0)8 9493 1591

Fax: (770) 953-8399 Fax: +61 (0)8 9493 2765

http://www.JKimaging.com

Janich & Klass Computertechnik GmbH Phone: +49 (0)202 2708-0

Zum Alten Zollhaus 20 Fax: +49 (0)202 700 625

D-42281 Wuppertal / Germany http://www.janichklass.com/

http://www.JKimaging.com

Page 42 of 42

408.89260.001 9

Loading...

Loading...