®

Impella

Circulatory Support System

Controller

With Impella® 2.5

INSTRUCTIONS

FOR USE

IMPORTANT NOTICE: Read this entire manual before using the Impella® Controller and Impella® 2.5 Circulatory Support System

(Impella® 2.5 System). The Impella® 2.5 System is to be used only in accordance with this manual. This manual is only applicable to

Impella® systems using the Impella® Controller.

Information contained in this document is subject to change without notice.

©2009 ABIOMED, Inc. All rights reserved.

The ABIOMED logo and ABIOMED are trademarks of ABIOMED, Inc. and are registered in the U.S.A. and certain foreign countries.

Recovering hearts. Saving lives.

Impella® and RECOVER are trademarks of ABIOMED Europe GmbH, a wholly owned subsidiary of ABIOMED, Inc.,

and are registered in the U.S.A. and certain foreign countries.

is a trademark of ABIOMED, Inc.

IMPELLA® CONTROLLER

®

WITH IMPELLA

2.5

CIRCULATORY SUPPORT SYSTEM

INSTRUCTIONS FOR USE

Rx Only

Abiomed, Inc.

22 Cherry Hill Drive

Danvers, MA 01923

978-777-5410 (voice)

978-777-8411 (fax)

clinical@abiomed.com (email)

Abiomed Europe GmbH

Neuenhofer Weg 3

52074 Aachen, Germany

+49 (241) 8860-0 (voice)

+49 (241) 8860-111 (fax)

europe@abiomed.com (email)

www.abiomed.com

24-Hour Emergency Hotlines:

N. America 1-800-422-8666

Europe +49 (0) 1805 2246633

September 2009

Document No. 0042-9000 Rev. A Draft 3

TABLE OF CONTENTS

INTRODUCTION

Introduction ............................................................................................. I

1 WARNINGS AND CAUTIONS

Warnings ................................................................................................. 1.1

Cautions .................................................................................................. 1.3

2 INDICATIONS, CONTRAINDICATIONS,

AND POTENTIAL ADVERSE EVENTS

Indications ............................................................................................... 2.1

Contraindications ..................................................................................... 2.2

Potential Adverse Events .......................................................................... 2.3

3 THE IMPELL A® 2.5

AND IMPELLA® CONTROLLER

Overview ................................................................................................. 3.1

Impella® 2.5 Catheter .............................................................................. 3.3

Impella® Controller .................................................................................. 3.5

Purge Cassette ......................................................................................... 3.6

Accessories ..............................................................................................3.8

4 USING THE IMPELLA® CONTROLLER

Overview ................................................................................................. 4.1

Impella® Controller Features .................................................................... 4.2

Impella® Controller Home Screen Display .................................................4.4

Impella® Controller Waveform Screen Display .......................................... 4.7

5 USING THE IMPELLA® CONTROLLER

WITH THE IMPELLA® 2.5

Startup ..................................................................................................... 5.1

Case Start ................................................................................................ 5.3

Inserting the Impella® 2.5 Catheter .......................................................... 5.8

Positioning and Starting the Impella® 2.5 Catheter .................................. 5.11

Use of the Repositioning Introducer

and the 13 Fr Peel-Away Introducer .........................................................5.14

Purger Procedures .................................................................................... 5.15

Troubleshooting the Purge System ........................................................... 5.18

Patient Weaning ......................................................................................5.19

How to Change to Backup Controller .......................................................6.15

Emergency Shutdown Procedure .............................................................. 6.15

7 CLEANING, STOR AGE, DISPOSAL,

AND RETURNS

Cleaning .................................................................................................. 7.1

Storing the Impella® Controller ................................................................ 7.1

Disposing of the Pump and Accessories (EU) ............................................ 7.1

Returning an Impella® Pump to Abiomed (US).......................................... 7.1

8 TERMINOLOGY, ABBREVIATIONS,

AND SYMBOLS

Terminology, Abbreviations, and Symbols ................................................ 8.1

9 SYSTEM SPECIFICATIONS

Impella® Controller Mechanical ................................................................ 9.1

Impella® Controller Electrical ................................................................... 9.1

Equipment Design .................................................................................... 9.2

Equipment Classifications ........................................................................ 9.2

Federal Communications Commission (FCC) Notice .................................. 9.3

Electromagnetic Compatibility ................................................................. 9.3

Patient Environment ................................................................................. 9.6

White Connector Cable ............................................................................ 9.8

Pump Parameters ..................................................................................... 9.8

Impella® 2.5 Dimensions ..........................................................................9.9

10 IMPELLA® CONTROLLER ALARMS

Impella® Controller Alarms ....................................................................... 10.1

APPENDICES

Appendix A: Impella® System Limited Service Warranty ..........................A.1

Appendix B: Technical Safety Inspections, Maintenance, and Repair ....... B.1

Appendix C: Abiomed-Approved Guidewires .......................................... C.1

Appendix D: Impella® Controller Menu Structure .................................... D.1

6 PATIENT MANAGEMENT TOPICS

Patient Management Overview ................................................................ 6.1

General Patient Care Considerations ....................................................... 6.1

Transport Within the Hospital .................................................................. 6.1

Right Heart Failure ................................................................................... 6.2

Cardiopulmonary Resuscitation (CPR) ...................................................... 6.2

Defibrillation ............................................................................................ 6.3

ECG Interference ...................................................................................... 6.3

Latex ........................................................................................................ 6.3

Positioning and Placement Devices ..........................................................6.3

Suction .................................................................................................... 6.4

Hemolysis ................................................................................................ 6.4

Understanding and Managing Impella® Position Alarms .......................... 6.6

Repositioning Guide ................................................................................. 6.10

Data Snap Shot Recording ........................................................................ 6.13

Infusion History ........................................................................................ 6.13

Operating the Impella® 2.5 Without Heparin in

the Purge Solution ................................................................................... 6.14

Guidelines for Explant .............................................................................. 6.14

TABLE OF CONTENTS

FIGURES

Figure 3.1 Impella® 2.5 ............................................................................... 3.1

Figure 3.2 Impella® Controller, Impella 2.5, and Accessories ....................... 3.2

Figure 3.3 Impella® 2.5 Catheter ................................................................ 3.3

Figure 3.4 Impella® Controller – Front View ................................................ 3.5

Figure 3.5 Purge Cassette ........................................................................... 3.6

Figure 3.6 White Connector Cable ..............................................................3.8

Figure 3.7 Introducer Kit .............................................................................3.8

Figure 3.8 0.018 in/260 cm Placement Guidewire ....................................... 3.8

Figure 3.9 20% Dextrose in Water .............................................................. 3.9

Figure 3.10 Impella® Controller Cart ........................................................... 3.9

Figure 4.1 Impella® Controller Features – Front and Side Views .................. 4.2

Figure 4.2 Impella® Controller Home Screen Display ...................................4.4

Figure 4.3 Waveform Screen Display (Waveform TBD) ................................. 4.7

Figure 5.1 Impella® Controller Power Switch ...............................................5.1

Figure 5.2 Impella® Controller Startup Screen ............................................. 5.2

Figure 5.3 Inserting Purge Cassette into Impella® Controller ....................... 5.4

Figure 5.4 Default Values for Purge Fluid ....................................................5.5

Figure 5.5 Snapping Plastic Hook to Connector Cable ................................. 5.6

Figure 5.6 Squeezing the White Flush Valve to Prime

the Impella® Catheter Pressure Lumen ..................................... 5.7

Figure 5.7 Inserting the 13 Fr Peel-Away Introducer .................................... 5.8

Figure 5.8 Inserting the 6 Fr Diagnostic Catheter ........................................ 5.9

Figure 5.9 Loading the Catheter on the Guidewire ...................................... 5.10

Figure 5.10 Exiting of the Placement Guidewire from the Catheter .............. 5.10

Figure 5.11 Inserting the Impella® 2.5 Catheter .......................................... 5.10

Figure 5.12 Ventricular Waveform on Placement Signal Screen .................... 5.11

Figure 5.13 Aortic Waveform on Placement Signal Screen ........................... 5.12

Figure 5.14 Selecting Target Flow ............................................................... 5.12

Figure 5.15 Confirming Placement on the Placement Signal Screen ............. 5.13

Figure 5.16 Removing the 13 Fr Peel-Away Introducer ................................ 5.14

Figure 6.1 Correct Catheter Position ........................................................... 6.6

Figure 6.2 Catheter Fully in Ventricle .......................................................... 6.7

Figure 6.3 Impella® Completely in the Aorta or Inlet and Outlet Area

in Ventricle and Pressure Port in Aorta ..................................... 6.8

Figure 6.4 Pump Position Unknown Due to Low Pulsatility

[Waveform TBD; Motor Current y-axis scale to be revised] ....... 6.9

Figure 6.5 Impella® Outlet Area on or near Aortic Valve ............................. 6.10

Figure 6.6 First Repositioning Guide Screen ................................................6.11

Figure 6.7 Second Repositioning Guide Screen ........................................... 6.11

Figure 6.8 Third Repositioning Guide Screen ............................................... 6.12

Figure 6.9 Exit Repositioning Guide Screen ................................................. 6.12

Figure 6.10 Infusion History Screen ............................................................. 6.13

Figure 9.1 Impella® Controller Patient Environment..................................... 9.7

Figure 9.2 Impella® 2.5 Dimensions ............................................................ 9.9

Figure B.1 Inspection Sticker Showing Inspection Required in May 2010 ..... B.1

TABLES

Table 3.1 Impella

Table 3.2 Purge Cassette Components ....................................................3.7

Table 3.3 Impella® 2.5 and Impella® Controller Accessories .................... 3.8

Table 4.1 Impella® Controller Features ....................................................4.3

Table 4.2 Impella® Controller Display Elements .......................................4.4

Table 6.1 Guide for Managing Hemolysis in Various Circumstances ......... 6.5

Table 8.1 Terminology and Abbreviations ................................................ 8.1

Table 8.2 Symbols ................................................................................... 8.1

Table 10.1 Audible Alarm and Notification Indicators................................ 10.1

Table 10.2 Critical (Red) Alarms ................................................................ 10.3

Table 10.3 Warning (Yellow) Alarms.......................................................... 10.5

Table 10.4 Advisor y (White) Notifications ................................................. 10.6

®

2.5 Catheter Components .......................................... 3.3

INTRODUCTION

PURPOSE OF MANUAL

This Instructions for Use manual is designed for healthcare professionals. It contains clinical and

®

technical considerations to guide healthcare professionals in their use of the Impella

®

with the Impella

2.5 Catheter. The Impella® 2.5 and Impella® Controller perform life-sustaining

functions. Use of these components requires a thorough understanding of and adherence to

®

these instructions for use. The Impella

Controller with the Impella® 2.5 may only be used for its

intended purpose.

MANUAL OVERVIEW

®

This manual provides instructions for use of the Impella

Controller with the Impella® 2.5. The

following summarizes the contents of each section:

• Section 1: Warnings and Cautions discusses the warnings and cautions pertaining

®

to the use of the Impella

Controller with the Impella® 2.5.

• Section 2: Indications, Contraindications, and Potential Adverse Events

®

discusses indications for use of the Impella

Controller with the Impella® 2.5 and potential

adverse events.

®

• Section 3: The Impella

2.5 and Impella® Controller provides an overview of the

blood pump and controller and describes the major components and features of each.

®

• Section 4: Using the Impella

®

types on the Impella

Controller.

• Section 5: Using the Impella

Controller describes the controls and various screen

®

Controller with the Impella® 2.5 provides the

procedures for using the controller and blood pump.

Controller

INTRODUCTION

• Section 6: Patient Management Topics provides key information on various topics

®

related to management of patients with the Impella

Controller and Impella® 2.5.

• Section 7: Cleaning, Storage, Disposal, and Returns provides instructions on

cleaning and storing the components, as well as disposing of components and returning

components to Abiomed.

• Section 8: Terminology, Abbreviations, and Symbols provides definitions for key

terms that appear in the manual as well as descriptions of the abbreviations and symbols

®

that appear on Impella

Controller and Impella® 2.5 components and packaging.

• Section 9: System Specifications lists technical information pertaining to the

®

Impella

• Section 10: Impella

Controller and Impella® 2.5.

®

Controller Alarms provides a listing of Impella® Controller

alarms and notifications as well as information on what to do to resolve them.

• Appendices at the end of the manual provide supplemental information about topics

®

including the Impella

and repair; Abiomed-approved guidewires; and the Impella

Impella® Controller with Impella® 2.5

Limited Service Warranty; technical safety inspection, maintenance

®

Controller menu structure.

I

1 WARNINGS AND CAUTIONS

WARNINGS ...................................................................................................1.1

CAUTIONS ....................................................................................................1.2

WARNINGS

1 WARNINGS AND CAUTIONS

The Impella® 2.5 System is intended for use only by personnel trained in accordance

with the Abiomed® Training Program.

Fluoroscopy is required to guide placement of the Impella® 2.5. The small

placement guidewire must be reliably observed at all times.

The sterile components of the Impella® 2.5 System can be used only if the

sterilization indicators show that the contents have been sterilized, the packaging is

not damaged, and the expiration date has not elapsed.

Do NOT resterilize or reuse the Impella® 2.5 Catheter. It is a disposable device and

is intended for single use only.

Retrograde flow will occur across the aortic valve if the Impella® 2.5 is set at a flow

rate of 0 L/min.

To prevent failure of the 13 Fr peel-away introducer, remove the 13 Fr peel-away

introducer prior to transport when activated clotting time (ACT) is less than

150 seconds.

Do NOT use saline in the purge system.

Do NOT use an Impella® 2.5 System if any part of the system is damaged.

To prevent the risk of explosion, do NOT operate the Impella® 2.5 System near

flammable anesthetics.

Warnings

Warnings alert you to

situations that can cause

death or serious injury. The

red symbol

warning messages.

appears before

To prevent malfunction of the locking mechanism of the 13 Fr peel-away introducer,

do NOT hold the hemostatic valve while inserting into the artery.

If at any time during the course of support with the Impella®, the Impella®

Controller alarms “Impella Failure: Sudden Purge Pressure Drop,” follow the

instructions presented in Section 5 of this manual.

Do NOT subject a patient who has been implanted with an Impella® 2.5 to

magnetic resonance imaging (MRI). The strong magnetic energy produced by an

MRI machine may cause the Impella® System components to stop working, and

result in injuries to the patient. An MRI may also damage the electronics of the

Impella® System.

During defibrillation, do NOT touch the pump, cables, or Impella® Controller.

Power the Impella® Controller using its internal battery if the integrity of the

protective earth conductor is questionable.

Impella® Controller with Impella® 2.5

1.1

Medical electrical equipment needs special precautions regarding EMC and needs

to be installed and put into service according to the electromagnetic compatibility

(EMC) information provided in the accompanying documents.

Portable and mobile RF communications equipment can affect medical electrical

equipment.

The equipment or system should not be used adjacent to or stacked with other

equipment. If adjacent or stacked use is necessary, the equipment or system should

be observed to verify normal operation in the configuration in which it will be used.

Use of cables, other than those sold by Abiomed, may result in increased emissions

or decreased immunity of the Impella

®

Controller.

The Impella® Controller uses RFID (radio frequency identification) to identify and

communicate with the purge cassette. Other equipment may interfere with the

Impella® Controller even if that other equipment complies with CISPR emission

requirements.

1.2

1.2

Instructions for Use

CAUTIONS

1 WARNINGS AND CAUTIONS

Handle with care. The Impella® 2.5 Catheter can be damaged during removal from

packaging, preparation, insertion, and removal. Do NOT bend, pull, or place excess

pressure on the catheter or mechanical components at any time.

Do NOT touch the inlet or outlet areas of the catheter and avoid manual

compression of the inlet cannula assembly while placing the device.

Patients with aortic stenosis or other abnormal aortic valve performance may be

compromised by the use of the Impella® 2.5. Patients with aortic valve disease

should be observed for aortic insufficiency.

Use only original accessories and replacement parts supplied by Abiomed.

Do NOT use damaged or contaminated connector cables.

To prevent device failure, do NOT start the Impella® 2.5 Catheter until the

guidewire has been removed.

Do NOT remove the Impella® 2.5 Catheter over the length of the guidewire.

When replacing the purge cassette, the replacement process must be completed

within 4 minutes. The Impella® 2.5 Catheter may be damaged if replacement takes

longer than 4 minutes.

Cautions

Cautions indicate a situation

in which equipment may

malfunction, be damaged, or

cease to operate. The yellow

symbol

caution messages.

appears before

To prevent malfunction of the Impella® Controller, avoid long-term exposure to

direct sunlight and excessive heat (40°C).

To prevent overheating and improper operation, do NOT block the cooling vents of

the Impella® Controller while it is operating.

Do not kink or clamp the Impella® 2.5 Catheter or the 13 Fr peel-away introducer.

The Li-Ion batteries must be charged for 10 hours prior to system operation. After

being unplugged, the Impella® Controller will operate for at least 60 minutes after

the batteries have been fully charged.

Minimize exposure of Impella® 2.5 System components to sources of

electromagnetic interference (EMI). Exposure to sources of EMI, such as cell phones

and two-way radios, may cause operational interference. To clear interference,

either increase the distance between system components and the EMI source or

turn off the EMI source.

Operation of Impella® 2.5 System components may interfere with the operation of

other devices. If interference occurs, increase the distance between the device and

system components.

Impella® Controller with Impella® 2.5

1.3

The use of high-frequency surgical devices may cause temporary interference to the

sensor signals. If continuous interference persists, the following warning message

appears on the display screen: “Sensor Value not Reliable.” Please acknowledge

this message. There is no reason to discontinue use of the pump.

Have a backup Impella® Controller available in the unlikely event of controller

failure.

Do NOT use the bed mount as a handle.

1.4

Instructions for Use

2 INDICATIONS, CONTRAINDICATIONS,

AND POTENTIAL ADVERSE EVENTS

INDICATIONS ................................................................................................2.1

Indications for Use in the United States ............................................................ 2.1

Intended Use in the European Union and Canada ............................................ 2.1

CONTRAINDICATIONS ................................................................................. 2.2

Contraindications in the United States .............................................................2.2

Contraindications in the European Union .........................................................2.2

Contraindications in Canada ............................................................................2.2

POTENTIAL ADVERSE EVENTS ..................................................................... 2.3

Potential Adverse Events (US) ..........................................................................2.3

Possible Complications (EU and Canada) .........................................................2.3

INDICATIONS

INDICATIONS FOR USE IN THE UNITED STATES

®

The Impella

extracorporeal bypass control unit, for periods up to 6 hours. It is also intended to be used to

provide partial circulatory support (for periods up to 6 hours) during procedures not requiring

cardiopulmonary bypass.

The Impella

useful in determining intravascular pressure.

2.5 Circulatory Support System is intended for partial circulatory support using an

®

2.5 Circulatory Support System also provides pressure measurements which are

2

INDICATIONS, CONTRAINDICATIONS, AND POTENTIAL ADVERSE EVENTS

Investigational Device

Exemption (IDE) Clinical

Trials

INTENDED USE IN THE EUROPEAN UNION AND CANADA

®

The Impella

2.5 (intracardiac pump for supporting the left ventricle) is intended for clinical

use in cardiology and in cardiac surgery for up to 5 days for the following indications, as well

as others:

®

• The Impella

2.5 is a circulatory support system for patients with reduced left ventricular

function, eg, post-cardiotomy, low output syndrome, cardiogenic shock after acute

myocardial infarction, or for myocardial protection after acute myocardial infarction

®

• The Impella

2.5 may also be used as a cardiovascular support system during coronary

bypass surgery on the beating heart, particularly in patients with limited preoperative

ejection fraction with a high risk of postoperative low output syndrome

• Support during high risk percutaneous coronary intervention (PCI)

• Post PCI

In addition to the indications

for use outlined in this IFU,

the Impella

Support system is being

evaluated in various FDA

approved clinical trials for

additional indications and

patient populations. Refer

to the study protocols

for additional indications,

contraindications, and

inclusion and exclusion criteria

if the device is being used

under a clinical trial protocol.

®

2.5 Circulatory

Impella® Controller with Impella® 2.5

2.1

CONTRAINDICATIONS

Patients with aortic stenosis or other abnormal aortic valve performance may be

compromised by the use of the Impella® 2.5. Patients with aortic valve disease

should be observed for aortic insufficiency.

CONTRAINDICATIONS IN THE UNITED STATES

• Mechanical aortic valve or heart constrictive device.

• Aortic valve stenosis/calcication (graded as ≥ +2 equivalent to an orice area of 1.5 cm

or less).

• Moderate to severe aortic insufciency (echocardiographic assessment of aortic

insufciency graded as ≥ +2).

®

• Severe peripheral arterial obstructive disease that would preclude Impella

placement.

CONTRAINDICATIONS IN THE EUROPEAN UNION

2.5 device

2

• Mechanical aortic valves, severe aortic valvular stenosis or valvular regurgitation

• Hematological disorder causing fragility of the blood cells or hemolysis

• Hypertrophic obstructive cardiomyopathy (HOCM)

• Aneurysm or necrotomy or severe anomaly of the ascending aorta and/or the aortic arch

• Mural thrombus in the left ventricle

• Ventricular septal defect (VSD) after myocardial infarction

• Anatomic conditions precluding insertion of the pump

• Other illnesses or therapy requirements precluding use of the pump

• Severe peripheral arterial occlusion disease (PAOD) is a relative contraindication

CONTRAINDICATIONS IN CANADA

• Prosthetic aortic valves, severe aortic valvular stenosis or valvular regurgitation

• Hematological disorder causing fragility of the blood cells or hemolysis

• Hypertrophic obstructive cardiomyopathy (HOCM)

• Aneurysm or necrotomy or severe anomaly of the ascending aorta and/or the aortic arch

2.2

• Mural thrombus in the left ventricle

• Ventricular septal defect (VSD) after myocardial infarction

• Anatomic conditions precluding insertion of the pump

• Other illnesses or therapy requirements precluding use of the pump

• Peripheral arterial occlusion disease (PAOD)

Instructions for Use

POTENTIAL ADVERSE EVENTS

POTENTIAL ADVERSE EVENTS (US)

2

INDICATIONS, CONTRAINDICATIONS, AND POTENTIAL ADVERSE EVENTS

• Death

• Aortic insufciency

• Arrhythmia

• Bleeding

• Cardiogenic shock

• Hemolysis

• Insertion site infection

• Perforation

• Respiratory dysfunction

• Thrombocytopenia

• Transient ischemic attack (TIA)

• Ventricular brillation

POSSIBLE COMPLICATIONS (EU AND CANADA)

There are risks of complications with every procedure using a blood pump. These include

among others:

• Cerebral vascular accident (CVA) / Stroke

• Aortic valve injury

• Atrial brillation

• Cardiac tamponade

• Device malfunction

• Hepatic failure

• Myocardial infarction

• Renal failure

• Sepsis

• Thrombotic vascular (non-CNS) complication

• Vascular injury

• Ventricular tachycardia

• Hemolysis

• Bleeding

• Immune reaction

• Embolism, thrombosis

• Vascular injury through to

angionecrotomy

• Positioning problems

• Infection and septicemia

• Dislocation of the pump

• Cardiovalvular injuries due to extreme

movement of the suction cannula in

relation to the cardiac valve or as a result of

attachment by suction of the pump to the

valve system following incorrect positioning

• Endocardiac injuries as a result of

attachment of the pump due to suction

• Pump failure, loss of pump components

following a defect

• Patient dependency on the pump after use

for support

Impella® Controller with Impella® 2.5

2.3

3 THE IMPELLA® 2.5

AND IMPELLA® CONTROLLER

OVERVIEW .................................................................................................... 3.1

IMPELLA

IMPELLA

PURGE CASSETTE .........................................................................................3.6

ACCESSORIES ...............................................................................................3.8

®

2.5 CATHETER ............................................................................ 3.3

®

CONTROLLER ...............................................................................3.5

OVERVIEW

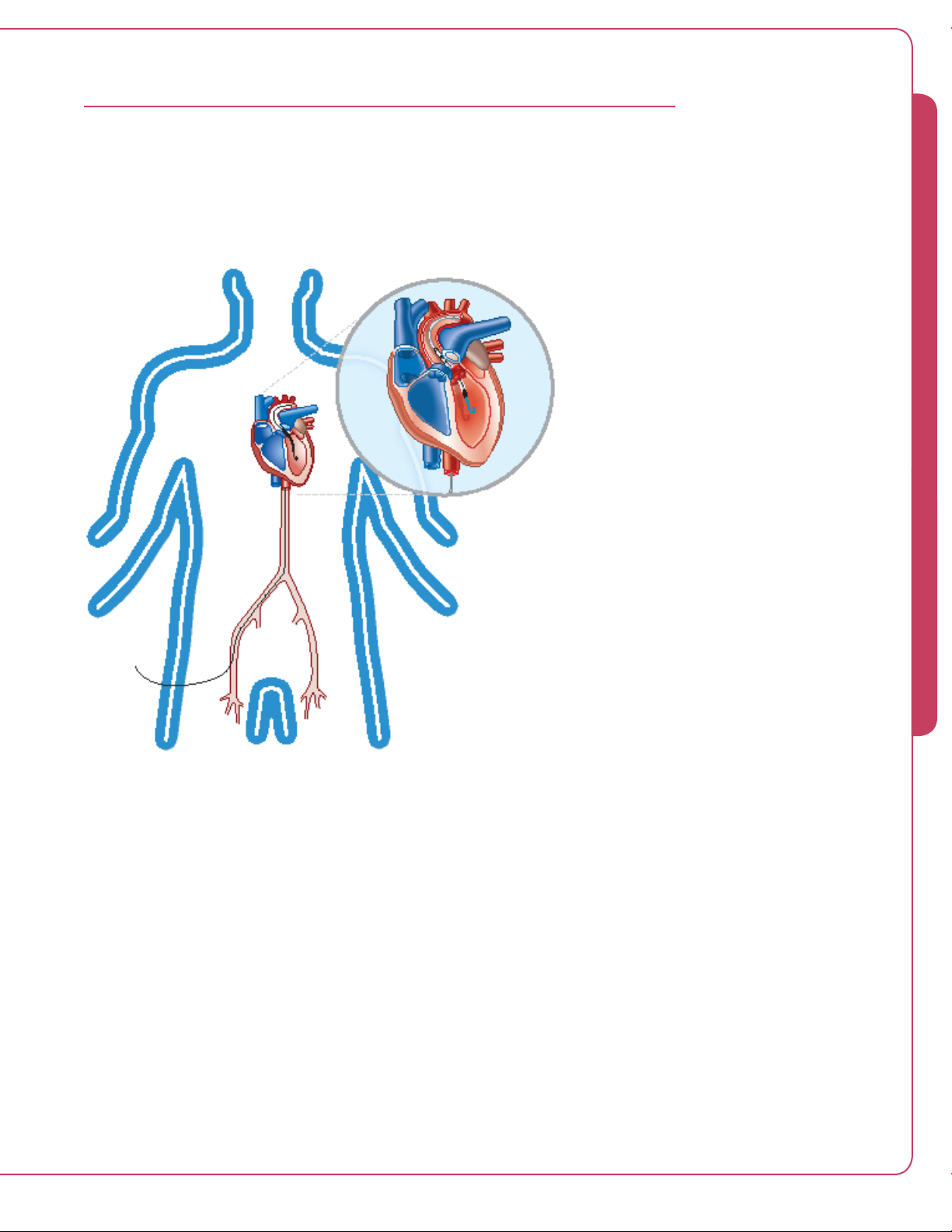

The Impella® 2.5 is an intravascular microaxial blood pump that supports a patient’s circulatory

system. The pump is inserted percutaneously through the femoral artery and into the left

ventricle. (See Figure 3.1.)

3 THE IMPELLA

®

2.5 AND IMPELLA

®

CONTROLLER

Figure 3.1 Impella® 2.5

When properly positioned, the pump delivers blood from the inlet area, which sits inside the

left ventricle, through the cannula, to the outlet opening in the ascending aorta. Physicians and

device operators monitor the correct positioning and functioning of the pump on the display

®

screen of the Impella

This section describes the components of the Impella

Controller.

®

2.5, the Impella® Controller, and the

accessory components.

Impella® Controller with Impella® 2.5

3.1

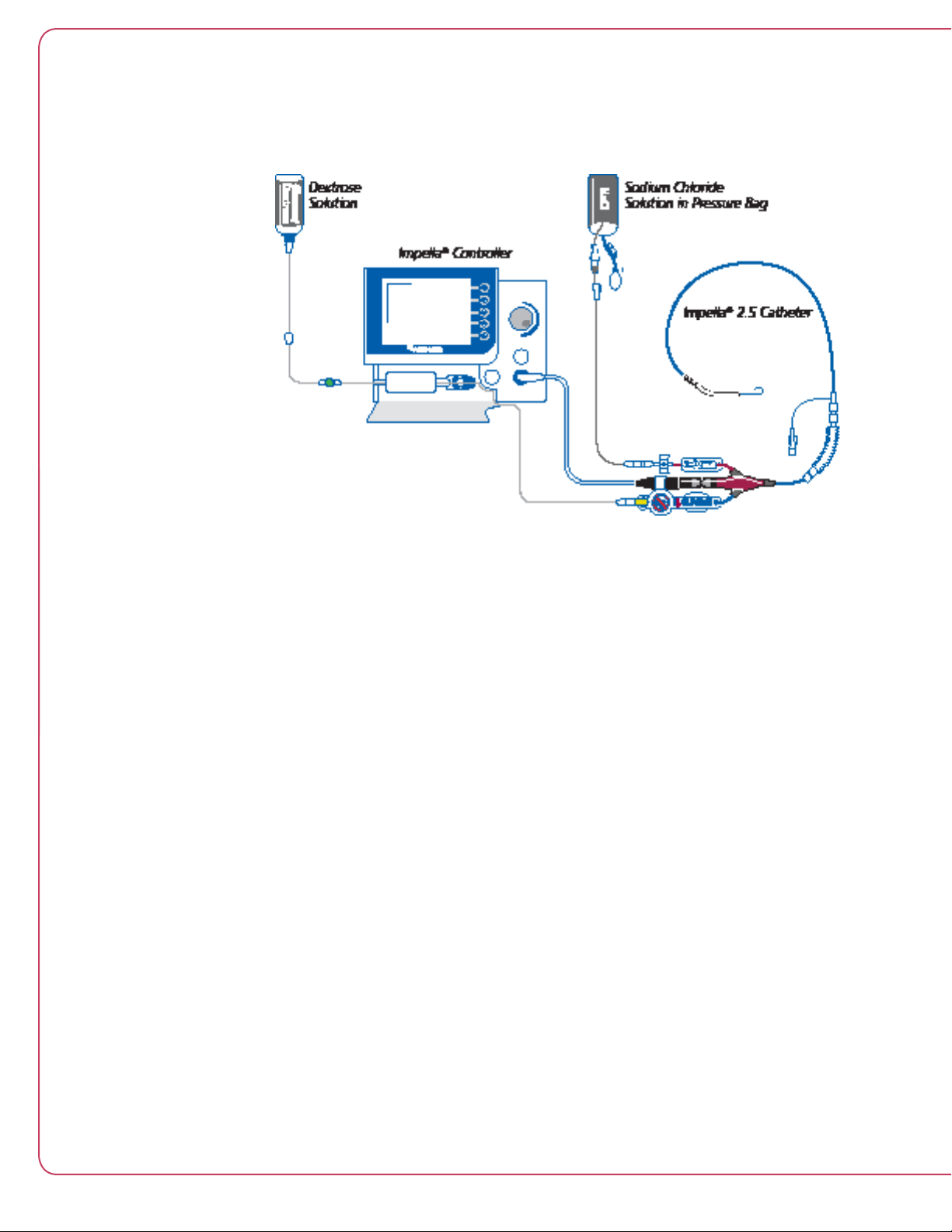

Figure 3.2 illustrates how the Impella® Controller connects to the Impella® 2.5 and accessory

components.

Figure 3.2 Impella® Controller, Impella 2.5, and Accessories

3.2

Instructions for Use

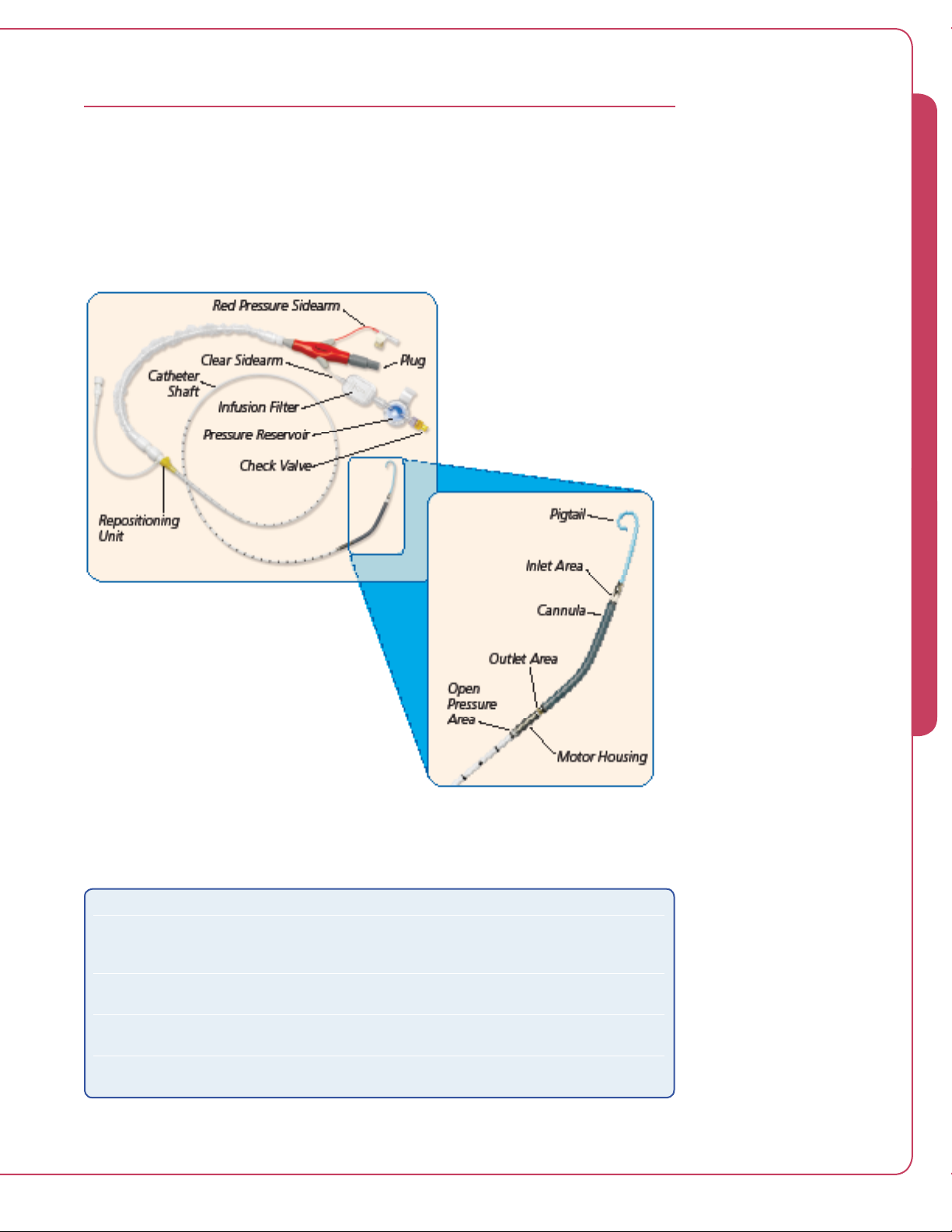

IMPELLA® 2.5 CATHETER

The Impella® 2.5 Catheter is an intravascular microaxial blood pump that delivers up to 2.5

liters of blood per minute from the left ventricle into the aorta. Figure 3.3 illustrates the

®

Impella

check valve on the other end.

2.5 Catheter. Table 3.1 describes each component from the pigtail at one end to the

3 THE IMPELLA

®

2.5 AND IMPELLA

®

CONTROLLER

Figure 3.3 Impella® 2.5 Catheter

®

Table 3.1 Impella

2.5 Catheter Components

Component Description

Pigtail The 6 Fr pigtail is attached to the cannula at the distal end of the inlet

area. It assists with stabilizing the catheter in the correct position in

the left ventricle.

Cannula The 12 Fr cannula has a spiral-shaped reinforced body that is shaped in

a 45-degree angle.

Inlet area The inlet area, where the blood enters the cannula, is located at the

distal tip of the cannula.

Outlet area The proximal end of the cannula is attached to the outlet area where

the blood exits the cannula.

Impella® Controller with Impella® 2.5

3.3

Table 3.1 Impella

®

2.5 Catheter Components (cont’d)

Component Description

Motor housing The motor housing is 12 Fr in diameter and consists of a completely

encapsulated motor.

Open pressure area The open pressure area is an opening located between the motor

housing and the distal end of the catheter shaft.

Catheter shaft A 9 Fr catheter shaft is located between the motor housing and

the plug. The lumen of the catheter shaft contains a purge lumen,

a pressure measurement lumen, and a pump monitoring cable.

The catheter shaft has longitudinal and transversal marks:

• The longitudinal marks along the inner radius of the cannula show

the position of the curved, flexible cannula.

• The transversal marks at 1 cm intervals aid in proper positioning.

Repositioning unit The repositioning unit consists of an introducer and an

anticontamination sleeve with an anchoring ring.

• The introducer (with hemostatic valve) is graduated from 11 Fr to

15 Fr. It is located on the catheter shaft and allows repositioning of

the catheter.

• The anchoring ring of the anticontamination sleeve secures the

catheter sheath to the introducer.

Plug The plug at the proximal end of the catheter connects the catheter to

the Impella® Controller through a connector cable. It has two sidearms:

a red pressure sidearm and a clear sidearm.

Red pressure sidearm The red pressure sidearm is attached to a standard pressure bag and is

used to prime the line of the pressure measurement system.

Clear sidearm The clear sidearm is attached to the purge cassette purge line. It leads

to the infusion filter, the pressure reservoir, and the check valve.

Infusion filter The infusion filter prevents bacterial contamination and prevents air

from entering the catheter.

Pressure reservoir The pressure reservoir includes a flexible rubber diaphragm that

provides additional filling volume by means of an expansion chamber

during purge solution change.

Check valve The yellow check valve ensures that purge fluid does not flow in the

reverse direction when the purge solution is exchanged.

3.4

Instructions for Use

IMPELLA® CONTROLLER

3 THE IMPELLA

The Impella® Controller (see Figure 3.4) provides three vital functions to the operation of the

®

Impella

2.5:

• The controller provides an interface for monitoring and controlling the function of the

Impella 2.5

• The controller provides a uid purge to the Impella 2.5 motor

• The controller provides backup power when the controller is operated away from AC

power

The controller weighs 26 lbs (11.8 kg) and can operate on its internal battery for at least 60

minutes when fully charged.

®

Impella

Controller operation is described in detail in Section 4 of this manual.

Impella® Controller

Battery Power

The controller can operate

on its internal lithium-ion

(Li-Ion) battery for at least 60

minutes when fully charged.

®

2.5 AND IMPELLA

®

CONTROLLER

Figure 3.4 Impella® Controller – Front View

Impella® Controller with Impella® 2.5

3.5

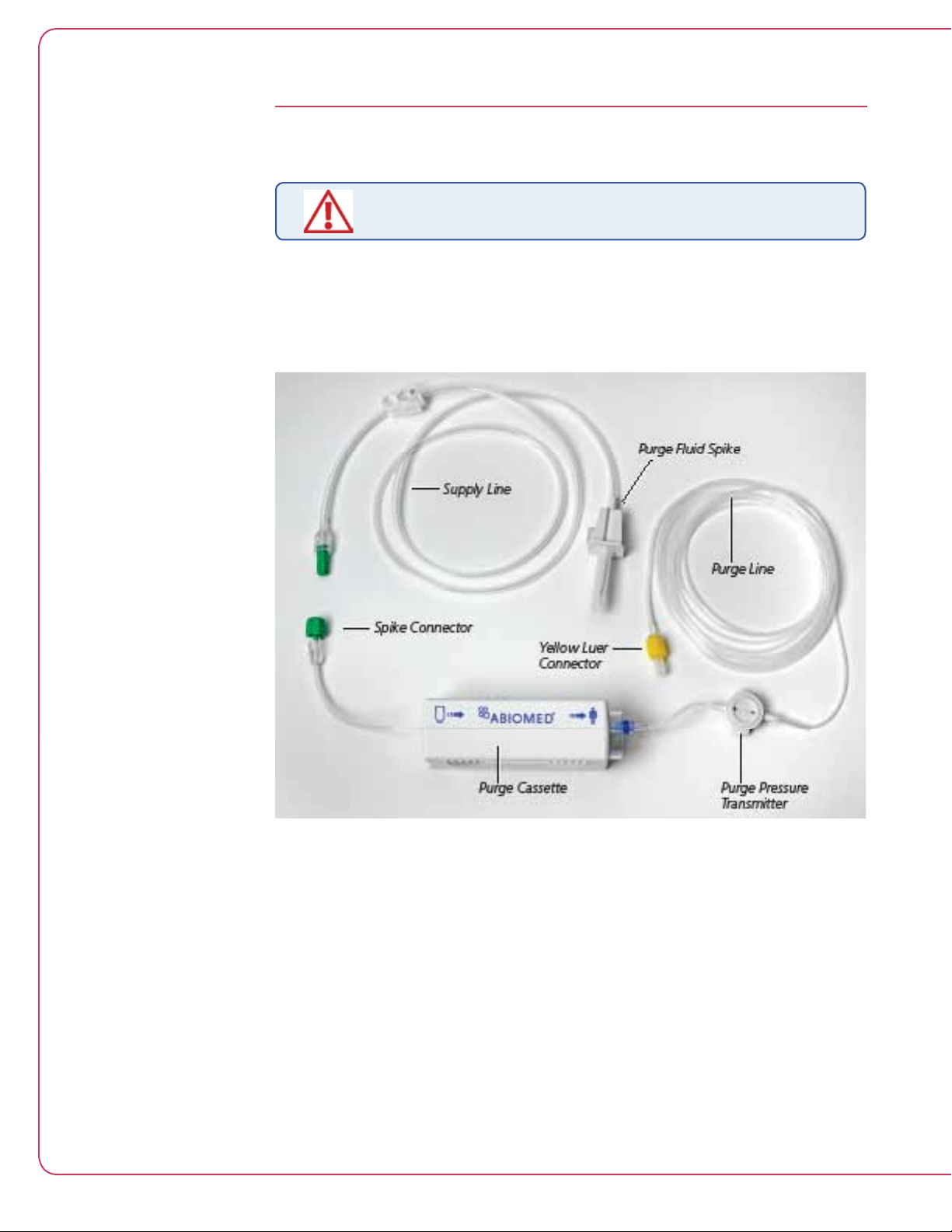

PURGE CASSETTE

Do not use saline in the purge system.

The purge cassette delivers rinsing fluid to the Impella® pump. The purge fluid (typically 20%

dextrose solution plus heparin 50 IU/mL) flows from the purge cassette through the catheter to

the microaxial blood pump to prevent blood from entering the pump motor. Figure 3.5 illustrates

the purge cassette and related components. Table 3.2 describes each component.

3.6

Figure 3.5 Purge Cassette

Instructions for Use

Table 3.2 Purge Cassette Components

Component Description

Purge cassette Contains the components for circulating the purge fluid; maintains the

pressure barrier between the blood and the motor at the proper level

Purge pressure

transmitter

Purge line Carries purge fluid from the purge cassette to the Impella® pump

Yellow luer connector Connects the purge line to the pressure reservoir (yellow luer lock) on

Purge fluid spike One end spikes the purge fluid bag and the other end connects the

Spike connector Connects the purge cassette supply line to the purge fluid spike

Supply line Carries fluid from the purge fluid bag to the purge cassette

Contains a membrane that transmits pressure to the controller based

on the purge pressure in the purge line; a transducer in the controller

measures the pressure so that it can be displayed on the screen

the Impella® pump

bag to the purge cassette supply line

3 THE IMPELLA

®

2.5 AND IMPELLA

®

CONTROLLER

Impella® Controller with Impella® 2.5

3.7

ACCESSORIES

Table 3.3 illustrates and describes the accessories used with the Impella® 2.5 and Impella®

Controller.

Table 3.3 Impella® 2.5 and Impella® Controller Accessories

Component Description

The white connector cable connects the Impella®

2.5 Catheter to the Impella® Controller. The

connector cable is attached to the Impella® pump

in the original packaging.

• The socket at the black end of the cable

connects to the Impella® catheter plug.

• The white plug at the opposite end of the cable

is inserted into the blue pump plug on the front

of the Impella® Controller.

Figure 3.6 White Connector Cable

The introducer kit is used to position the pump.

It contains:

• 13 Fr peel-away introducer with hemostatic valve

• 13 Fr dilator

• 18 G Seldinger needle

• 10 cc syringe

• 0.035 in stiff guidewire

Guidewire Use

It is important to use only

the guidewire supplied with

the system or an Abiomedapproved alternative. Refer

to Appendix C for more

information about Abiomedapproved guidewires.

Figure 3.7 Introducer Kit

The 0.018 in/260 cm placement guidewire is used

for the placement of the catheter. The guidewire

has a radiopaque, shapable tip.

Figure 3.8 0.018 in/260 cm Placement

Guidewire

3.8

Instructions for Use

Component Description

20% dextrose solution with 50 IU/mL of heparin is

used as the purge fluid. The purge cassette infuses

the purge fluid through the catheter.

Figure 3.9 20% Dextrose in Water

The Impella® Controller Cart holds the Impella®

Controller. The cart has wheels for easy transport

of the controller and a storage basket.

3 THE IMPELLA

®

2.5 AND IMPELLA

®

CONTROLLER

Figure 3.10 Impella® Controller Cart

Impella® Controller with Impella® 2.5

3.9

4 USING THE IMPELLA® CONTROLLER

OVERVIEW ....................................................................................................4.1

IMPELLA

IMPELLA

IMPELLA

®

CONTROLLER FEATURES............................................................. 4.2

®

CONTROLLER HOME SCREEN DISPLAY ...................................... 4.4

®

CONTROLLER WAVEFORM SCREEN DISPLAY ..............................4.7

Placement Signal Waveform.............................................................................4.7

Motor Current Waveform ................................................................................. 4.8

OVERVIEW

The Impella® Controller is the primary user control interface for the Impella® 2.5. It controls

®

the pump performance, monitors the Impella

position information regarding the location of the pump across the aortic valve. The controller

can be powered by AC power or can operate on internal battery power for at least 60 minutes

when fully charged.

This section of the manual discusses Impella

2.5 for alarms, and provides real time catheter

®

Controller features and displays.

4 USING THE IMPELLA

®

CONTROLLER

Impella® Controller with Impella® 2.5

4.1

IMPELLA® CONTROLLER FEATURES

Figure 4.1 illustrates the features of the Impella® Controller. These features are described

in Table 4.1.

4.2

Figure 4.1 Impella® Controller Features – Front and Side Views

Instructions for Use

Table 4.1 Impella

®

Controller Features

Feature Description

Display screen Displays user information, including the labels for the soft buttons.

(Display screen elements described in detail later in this section.)

Soft buttons Display, open, navigate, and close menus. The function for each soft button is

defined by labels adjacent to the button on the display screen; function changes

depending on the screen. (Soft button functions are described in Table 4.2)

When the pump is running the default soft button labels are as follows:

• MUTE ALARM

• TARGET FLOW

• DISPLAY

• PURGE SYSTEM

• MENU

Selector knob Rotating push button; turn clockwise and counterclockwise to scroll through

menu items; push to make a selection.

NOTE: In many situations, selector knob function is circular—that is, once

you scroll to the end of the list of selections, the system circles through the

list again as you continue to turn the knob. On some screens, however, the

selector knob function is NOT circular and you must turn the knob in the

reverse direction to get to previous items.

®

Pump plug Connection point on the controller for the Impella

Purge cassette

Spring-loaded door that opens to provide access to the purge cassette

door

Purge cassette Contains the components for circulating purge fluid; maintains the pressure

barrier between the blood and the motor at the proper level. (The purge

cassette and its components are described in Section 3 of this manual.)

Purge pressure

transmitter

Applies pressure to the transducer in the controller so that purge presure can

be measured

Bed mount Metal bracket on the back of the controller; attaches controller to the bed

Purge cassette

door release

RS-232 service

Located on the left side of the controller; press to open the purge cassette

door

Interface for data transfer to an external device

jack

USB connector Connection for downloading data

Ethernet jack Connection for downloading data or software upgrades

®

Equipotential

Used to ground the Impella

Controller according to hospital procedures

ground stud

AC fuses Electrical safety device in the event of current overload

Power cord

For mounting power cord retainer

retainer

mounting holes

Power switch Turns the controller ON or OFF

• ON: Press and hold the power switch key for 3 seconds

®

• OFF: (1) Disconnect the Impella

Catheter from the Impella® Controller.

(2) Press and hold the power switch for 3 seconds.

(3) Press OK to confirm that the controller should be turned off.

NOTE: Holding down the power switch for longer than 30 seconds during

operation will cause the controller to initiate hardware switch-off

AC plug Connection point on the controller for the AC power cord

pump

4 USING THE IMPELLA

®

CONTROLLER

Impella® Controller with Impella® 2.5

4.3

IMPELLA® CONTROLLER HOME SCREEN DISPLAY

The home screen displays operating parameters and information for the entire system.

®

Figure 4.2 illustrates the Impella

described in Table 4.2.

Controller home screen display. Each element of the display is

Figure 4.2 Impella® Controller Home Screen Display

®

Table 4.2 Impella

Controller Display Elements

Display Element Description

Patient identification (ID) Displayed in the upper left corner of the display screen if the

information has been entered. The Patient ID can be up to 31

characters in length.

Pump serial number Displayed in the upper center of the display screen if a blood pump is

connected to the controller.

System date and time The current date and time (24-hour format) are displayed in the upper

right corner of the screen display.

Alarm window The alarm window displays up to 3 alarms simultaneously, in order of

priority from top to bottom.

For each alarm, the alarm window displays:

• Alarm header – displayed in the left column; window is color-

coded red for critical alarms, yellow for warning alarms, white for

advisory notifications, gray for resolved alarms

• Alarm subhead (if applicable) – further describes the alarm

condition

• Detailed text – up to 3 lines of instructions for resolving the alarm

condition are displayed in the right column of the alarm window

next to the alarm header and subhead information

(See Section 10 of this manual for further discussion of Alarms.)

4.4

Instructions for Use

Table 4.2 Impella

®

Controller Display Elements (cont’d)

Display Element Description

Supply line Carries fluid from the purge fluid bag to the purge cassette

Mute Alarm indicator Displayed below the system date and time in the upper right

of the display screen. (See Section 10 of this manual for more

information about the Mute Alarm function.)

• Yellow bell with red X displayed when an alarm is muted.

• Not displayed when an alarm is active but not muted or when

there are no active alarms.

Soft button labels The soft buttons on the Impella® Controller have corresponding

labels adjacent to them on the display screen. These labels change

depending on the type of screen displayed.

MUTE ALARM

• Mutes (silences) active alarms

TARGET FLOW (or NEXT)

• TARGET FLOW – Brings up the target flow icon, which

enables users to set the current flow rate for the Impella 2.5

• NEXT – Advances to the next screen

DISPLAY (or BACK)

• DISPLAY – Brings up the Display menu for viewing

waveforms and navigating to other screen displays

• BACK – Returns to the previous screen

PURGE SYSTEM (or EXIT)

• PURGE SYSTEM – Brings up the Purge System menu for

making changes in purge fluid, purge cassette, or the purge

system, or de-airing the purge system

• EXIT – Exits the current procedure

MENU (or Exit Repositioning Guide)

• MENU – Brings up a menu of options related to controller

settings, alarm history, repositioning, and starting a

procedure

• Exit Repositioning Guide – Exits the repositioning guide

System power area System power information is displayed to the right of the purge

system information on the bottom of the display screen

Battery status

• Bar within battery symbol indicates the overall remaining

capacity of the batteries

• Full green bar for fully charged battery

• Partial green bar for battery that is at least 50% charged

• Partial yellow bar for battery that is between 25% and 50%

charged

• Partial red bar for battery that is less than 25% charged

• Moving gray bar indicates battery is in charging mode

• Numeric percentage of battery power remaining displayed

below the battery icon

AC plug indicator

• Green plug symbol indicates that the controller is running on AC

power

• Gray plug icon with a red X indicates no AC power detected

and the controller is running on battery power

4 USING THE IMPELLA

®

CONTROLLER

Impella® Controller with Impella® 2.5

4.5

Table 4.2 Impella

®

Controller Display Elements (cont’d)

Display Element Description

Purge system area Information about the purge system is displayed to the right of

the flow area at the bottom of the display screen

Purge system marquee

• Strobes from left to right when the purge system is operating

• Slow strobing represents normal purge ow rate

• Fast strobing represents bolus ow rate

Purge rate

• Current purge rate displayed in mL/hr below the purge system

marquee if the purge rate is known

• Not displayed if there is no purge cassette or the procedure has

not yet started

Time remaining in reservoir

• Displays the remaining runtime based on the volume of the

purge fluid bag at the start of the case and the cumulative time

and flow rate of delivery of purge fluid

• Not displayed if there is no purge cassette or the procedure has

not yet started

Flow area Information about Impella® flow is displayed in the lower left

corner of the display screen

Current flow rate

• Mean pump ow displayed in liters per minute (L/min)—

the numbers appear in white if the pump position is correct;

yellow if the pump position is incorrect or unknown

• If the system is unable to calculate ow, a yellow triangular

caution icon is displayed with the message “Flow Calculation

Disabled”

Pump icon

• The circular pump icon rotates when the blood pump is running

Central display area On the home screen, the central display area displays a heart

pictogram and Impella® position indicator message.

Heart pictogram appears in the center of the home screen display

• Provides a visual representation of the current Impella® pump

position

• Overlaid with a translucent yellow “?” when the controller

detects an incorrect pump position or cannot detect pump

position

Impella® position indicator message displayed to the left of the

heart image

• Displays “Impella® Position OK” in green when pump position

is correct

• Displays “Impella® Position Unknown” in yellow when pump

position is unknown

• Displays specic message in yellow when pump position is

incorrect

4.6

Instructions for Use

IMPELLA® CONTROLLER WAVEFORM SCREEN DISPLAY

The waveform screen (see Figure 4.3) displays operating data for the system. The screen displays

up to two waveforms and current pump data in the central display area of the screen.

4 USING THE IMPELLA

®

CONTROLLER

Figure 4.3 Waveform Screen Display (Waveform TBD)

Figure 4.3 shows two time-based waveform signals from different sources.

• Placement signal waveform

• Motor current waveform

PLACEMENT SIGNAL WAVEFORM

The placement signal waveform displays a pressure measurement that corresponds to the

location of the open pressure area of the catheter. The placement signal is used to verify the

position of the microaxial blood pump by evaluating the current pressure waveform as an aortic

or ventricular waveform. The scale for the placement signal waveform is displayed to the left of

the waveform. The default scaling is 0–160 mmHg in 20 mmHg increments, with a minimum

upper limit of 100 mmHg and a maximum upper limit of 240 mmHg for the Impella 2.5.

To the left of the waveform is a display that labels the waveform, provides the units of

measurement, shows the upper and lower range values, and the average value from the samples

received from the last value update. At the bottom of that window is the time scale, which can

be set to 10 seconds, 5 minutes, or 5 hours using the DISPLAY soft button. The default time

scale is 10 seconds.

Impella® Controller with Impella® 2.5

4.7

Motor Current

Motor current is the

measurement of electricity

through the Impella

required to rotate the

®

Impella

microaxial pump.

®

motor

MOTOR CURRENT WAVEFORM

The motor current waveform is a measurement of the electricity through the pump motor. The

scale for the motor current waveform is displayed to the left of the waveform. The default scaling

is 0–1000 mA in 100 mA increments for the Impella 2.5, with a minimum difference between

upper and lower limits of 200 mA and a maximum difference of 1000 mA.

To the left of the waveform is a display that labels the waveform, provides the units of

measurement, shows the upper and lower range values, and the average value from the samples

received from the last value update. The time scale at the bottom of that window can be set

to 10 seconds, 5 minutes, or 5 hours using the DISPLAY soft button. The default time scale

is 10 seconds.

4.8

Instructions for Use

5 USING THE IMPELLA® CONTROLLER

WITH THE IMPELLA® 2.5

STARTUP ....................................................................................................... 5.1

Turning ON the Impella

®

Controller .................................................................. 5.1

The Startup Screen ..........................................................................................5.2

Starting a Case Procedure................................................................................ 5.2

CASE START ..................................................................................................5.3

Overview .........................................................................................................5.3

Initial Setup .....................................................................................................5.3

Prime Purge Tubing .........................................................................................5.4

Enter Purge Fluid Data .....................................................................................5.5

Plug Impella

Prime Impella

®

into Controller ...........................................................................5.6

®

Purge Lumen ...........................................................................5.6

Prime Blood Pressure Lumen ............................................................................5.7

Pre-Insertion Impella

®

Impella

Test Successful ..................................................................................5.7

INSERTING THE IMPELLA

POSITIONING AND STARTING THE IMPELLA

®

Test ..............................................................................5.7

®

2.5 CATHETER ...................................................5.8

®

2.5 CATHETER .................... 5.11

USE OF THE REPOSITIONING INTRODUCER

AND THE 13 Fr PEEL-AWAY INTRODUCER ..................................................5.14

PURGER PROCEDURES ...............................................................................5.15

Purge System Change .................................................................................... 5.15

Purge Fluid Change ....................................................................................... 5.16

Purge Cassette Change ................................................................................. 5.16

De-Air Purge System ...................................................................................... 5.17

TROUBLESHOOTING THE PURGE SYSTEM .................................................. 5.18

Low Purge Pressure .......................................................................................5.18

High Purge Pressure ...................................................................................... 5.18

Purge System Blocked .................................................................................... 5.18

PATIENT WEANING ..................................................................................... 5.19

Rapid Weaning .............................................................................................. 5.19

Slow Weaning ............................................................................................... 5.19

1

STARTUP

Do

NOT

use an Impella® 2.5 System if any part of the system is damaged.

The sterile components of the Impella® 2.5 System can be used only if the

sterilization indicators show that the contents have been sterilized, the packaging is

not damaged, and the expiration date has not elapsed.

Do

NOT

resterilize or reuse the Impella® 2.5 Catheter. It is a disposable device and

is intended for single use only.

To prevent malfunction of the Impella® Controller, avoid long-term exposure to

direct sunlight and excessive heat (40°C).

5 USING THE IMPELLA

®

CONTROLLER WITH THE IMPELLA

To prevent overheating and improper operation, do NOT block the cooling vents of

the Impella

®

Controller while it is operating.

The Li-Ion batteries must be charged for 10 hours prior to system operation. After

being unplugged, the Impella® Controller will operate for at least 60 minutes after

the batteries have been fully charged.

Have a backup Impella® Controller available in the unlikely event of controller

failure.

TURNING ON THE IMPELLA® CONTROLLER

To turn the controller ON:

1. Press and hold the power switch on the right side of the Impella

seconds (see Figure 5.1).

®

Controller for 3

®

2.5

Figure 5.1 Impella® Controller Power Switch

The Impella® Controller automatically performs a system test when turned ON.

A display bar shows the progress of the system test. If the system test passes, the system

displays the startup screen (see Figure 5.2).

Impella® Controller with Impella® 2.5

5.1

If the system test fails, the controller displays a system self check failure message:

SYSTEM SELF CHECK FAILED.

CHANGE CONSOLE IMMEDIATELY.

The controller displays the reason for the system test failure at the bottom of the screen.

THE STARTUP SCREEN

The startup screen (Figure 5.2) appears when you successfully turn ON the Impella® Controller.

Figure 5.2 Impella® Controller Startup Screen

The startup screen displays:

®

• The current status of the Impella

pump (currently no pump connected to the Impella®

Controller in Figure 5.2).

• The current status of the purge cassette (no purge cassette detected in Figure 5.2).

®

• The current version of the software that the Impella

Controller is running.

The startup screen also displays system power information along the bottom of the screen and

two active soft buttons—MUTE ALARM and MENU—along the right side of the screen.

STARTING A CASE PROCEDURE

To start a case procedure:

1. Press the MENU soft button from the startup screen.

2. Scroll the selector knob to “Case Start” on the pop-up menu that appears on the screen.

3. Press the selector knob to select “Case Start”.

After you press the selector knob to select “Case Start” from the menu, the controller displays

®

an 8-screen series that leads you from initial setup through the pre-insertion Impella

test.

5.2

Instructions for Use

CASE START

5 USING THE IMPELLA

Fluoroscopy is required to guide placement of the Impella® 2.5. The small

placement guidewire must be reliably observed at all times.

The sterile components of the Impella® 2.5 System can be used only if the

sterilization indicators show that the contents have been sterilized, the packaging is

not damaged, and the expiration date has not elapsed.

Do

NOT

remove the Impella® 2.5 Catheter over the length of the guidewire.

Handle with care. The Impella® 2.5 Catheter can be damaged during removal from

packaging, preparation, insertion, and removal. Do

NOT

bend, pull, or place excess

pressure on the catheter or mechanical components at any time.

Do

NOT

touch the inlet or outlet areas of the catheter and avoid manual

compression of the inlet cannula assembly while placing the device.

Do not kink or clamp the Impella® 2.5 Catheter or the 13 Fr peel-away introducer.

OVERVIEW

You will need the following materials to complete the setup before starting the case:

• 500 cc bag of D20 with 50 IU of heparin per cc. (Recommended)

Sensitive Medical Device

®

The Impella

is a sensitive medical device

with a microaxial pump with

extremely fine tolerances.

In particular, the inflow and

outflow areas of the distal

and proximal areas of the

pump assembly may be

damaged if subjected to

strong external forces.

2.5 Catheter

®

CONTROLLER WITH THE IMPELLA

®

2.5

• IV ush solution (NaCl) with pressure bag and 96 inches of sterile infusion line.

NOTE: The distal end of the infusion line must remain sterile.

®

The Impella

Controller displays eight screens of instructions to lead you through a case start:

• Initial setup

• Prime purge tubing

• Enter purge uid data

®

• Plug Impella

• Prime Impella

into controller

®

purge lumen

• Prime blood pressure lumen

®

• Pre-insertion Impella

®

• Impella

test successful

test

INITIAL SETUP

1. Open the purge cassette package.

2. Using sterile technique, connect the purge fluid spike to the spike connector on the

end of the purge fluid supply line. Secure the yellow luer connector and pass the purge

®

cassette and supply line to the Impella

Controller operator.

Shaded Steps

All shaded steps require sterile

technique.

Impella® Controller with Impella® 2.5

5.3

Selector Knob Function

3. Open the purge cassette door by pressing the release on the left side of the controller.

®

Insert the purge cassette into the Impella

Controller (as shown in Figure 5.3).

The selector knob function

here is NOT circular (you

CANNOT keep turning

the knob in one direction

to scroll between START

and STOP). Turn the knob

clockwise to scroll to STOP

and counterclockwise to scroll

to START.

• The purge cassette snaps into a molded compartment on the front of the controller.

Follow the diagram on the inside of the purge cassette door for proper placement.

• Slide the purge pressure transmitter into the slot to the right of the purge cassette

until it snaps into place.

• Extend the purge line and close the purge cassette door. There is sufcient room

around the edges of the purge cassette door so that it will not pinch the purge line as

it exits.

Figure 5.3 Inserting Purge Cassette into Impella® Controller

4. Spike the purge fluid bag with the purge fluid spike attached to the end of the supply

line and hang the purge fluid bag.

5. Press the NEXT soft button to advance to the next screen.

PRIME PURGE TUBING

1. Use the selector knob to scroll to START on the screen and press the knob to begin

priming the purge line. The controller will start the priming process at a bolus rate of

250 mL/hr or greater.

®

2. When purge fluid is discharged from the tip of the yellow Impella

connector at the end

of the purge line, scroll to STOP and press the selector knob to stop the flow of purge

fluid.

3. Press NEXT after selecting STOP to proceed to entering purge fluid data.

If you press the BACK button on this screen, the controller will return to step 1 of priming the

purge tubing.

If you do not press STOP within 60 seconds of pressing START, you will get a message that the

purger has stopped. Press BACK if additional purging is required. If the purge fluid has been

discharged from the purge tubing and priming is complete, press NEXT.

5.4

Instructions for Use

ENTER PURGE FLUID DATA

®

The Impella

Controller displays a table of recommended default values for the purge fluid

(see Figure 5.4).

5 USING THE IMPELLA

System Timeout

1. To select the default values displayed on the screen, scroll to OK below the table and

press the selector knob. This will select those values and automatically advance you to

the next screen.

The purger will stop after 60

seconds if the user does not

press STOP. If this happens,

press BACK for additional

priming or NEXT if purge fluid

has been discharged.

®

CONTROLLER WITH THE IMPELLA

®

2.5

Figure 5.4 Default Values for Purge Fluid

2. To change the purge fluid information, scroll to the appropriate item push the selector

knob to select it. Then scroll through the values and push the selector knob to make a

new selection. The controller will use the default values if no other selections are made.

• Purge uid can be set to 100 mL, 250 mL, 500 mL (the default), or 1000 mL.

• Dextrose concentration can be set to 5%, 10%, 20% (the default), 30%, or 40%.

• Heparin concentration can be set to 0, 5, 10, 12.5, 15, 20, 25, or 50 units/mL. (50

units/mL is the default.)

Impella® Controller with Impella® 2.5

5.5

PLUG IMPELLA® INTO CONTROLLER

Important Step

Snapping the plastic hook on

the pressure reservoir to the

connector cable is important

to prevent the tube from

kinking.

Time Delay

Expect a 5 to 10 second

time delay after plugging

in the Impella

before the Impella

automatically advances to the

next screen.

Infusion Bag Pressure

®

pump and

®

Controller

1. Open the Impella® Catheter package using sterile technique and snap the plastic hook

(located on the pressure reservoir of the clear sidearm) to the connector cable as shown

in Figure 5.5.

Figure 5.5 Snapping Plastic Hook to Connector Cable

2. Pass the sterile white connector cable from the Impella® pump off the sterile field. Line

®

up the notch on the Impella

the front of the Impella

3. When the Impella

®

the Impella

flow icon appears on the screen. The controller automatically advances to

®

Controller detects that an operational Impella® pump is plugged in,

connector cable with the notch in the blue pump plug on

®

Controller and plug the cable into the controller.

the next screen.

If the infusion bag is

underinflated, the progress

bar will not be activated.

If the infusion bag is

overinflated, an alarm

will occur.

If a “Sensor Value not

Reliable” alarm appears while

priming the catheter, check

that the pressurized saline

bag is inflated to a pressure

between 300 and 350 mmHg

and not overinflated.

5.6

®

PRIME IMPELLA

PURGE LUMEN

1. Connect the yellow connector on the end of the purge line to the yellow luer connector

®

on the clear sidearm of the Impella

2. Select START to begin priming the Impella

pump.

®

purge lumen. The Impella® Controller will

start at a bolus rate of 250 mL/hour or greater.

®

3. When purge fluid is discharged from the Impella

pump, scroll to and select STOP.

When you press STOP, the bolus stops but purge fluid continues to flow at a low rate.

4. Press NEXT to advance to the next screen.

Instructions for Use

PRIME BLOOD PRESSURE LUMEN

1. Using sterile technique, connect the flush solution tubing to the red luer connector on

®

the red sidearm of the Impella

2. Blood pressure lumen priming starts automatically. Prime the Impella

pressure lumen by squeezing the white flush valve until the Impella

pump.

®

Catheter

®

Controller beeps.

(see Figure 5.6).

When the system detects the target flush solution pressure within the required amount

of time (60 seconds), the system will go to the next step automatically.

5 USING THE IMPELLA

®

CONTROLLER WITH THE IMPELLA

Figure 5.6 Squeezing the White Flush Valve to Prime

the Impella

®

Catheter Pressure Lumen

PRE-INSERTION IMPELLA® TEST

1. Select TEST to start the pre-insertion Impella® test.

The test runs for 2 seconds. When the system detects that the pump is spinning, it

automatically advances to the next step.

If the pre-insertion test fails, the system will instruct you to unplug the Impella

from the controller and disconnect the purge and flush lines from the Impella

®

connectors. You can then press NEXT to set up a new Impella

IMPELLA

®

TEST SUCCESSFUL

pump.

®

®

luer

®

2.5

1. This screen tells you that the Impella® test was successful. Press NEXT to finish Startup.

Impella® Controller with Impella® 2.5

5.7

Use Fluoroscopy for

Placement

INSERTING THE IMPELLA® 2.5 CATHETER

NOTE – Proper surgical procedures and techniques are the responsibility of

the medical professional. The described procedure is furnished for information

purposes only. Each physician must evaluate the appropriateness of the procedure

based on his or her medical training and experience, the type of procedure, and

the type of systems used.

®

Impella

will be compromised if

correct placement cannot

be confirmed. While

other imaging techniques,

such as transesophageal

echocardiography (TEE), can

help confirm the position

of the Impella

placement, TEE does not

allow visualization of the

entire catheter assembly and

is inadequate for reliably

placing the Impella

across the aortic valve.

Maintaining ACT

After insertion of the catheter

(and until explant), ACT

should be maintained at 160

to 180 seconds.

2.5 performance

®

2.5 after

®

2.5

Fluoroscopy is required to guide placement of the Impella® 2.5. The small placement

guidewire must be reliably observed at all times.

To prevent malfunction of the locking mechanism of the 13 Fr peel-away introducer,

do

NOT

hold the hemostatic valve while inserting into the artery.

Do not kink or clamp the Impella® 2.5 Catheter or the 13 Fr peel-away introducer.

Handle with care. The Impella® 2.5 Catheter can be damaged during removal from

packaging, preparation, insertion, and removal. Do

NOT

bend, pull, or place excess

pressure on the catheter or mechanical components at any time.

Do

NOT

touch the inlet or outlet areas of the catheter and avoid manual

compression of the inlet cannula assembly while placing the device.

1. Obtain access to the femoral artery.

2. Insert a 6–8 Fr introducer over the 0.035 guidewire (provided) to pre-dilate the vessel.

3. Remove the 6–8 Fr introducer over the 0.035 guidewire and insert the 13 Fr peel-away

introducer with dilator (see Figure 5.7). While inserting the 13 Fr introducer, hold the

shaft of the introducer to slide it into the artery.

5.8

Figure 5.7 Inserting the 13 Fr Peel-Away Introducer

4. Administer heparin. When the ACT is above 250, remove the 13 Fr dilator.

Instructions for Use

5. Insert a 6 Fr diagnostic catheter with diagnostic guidewire with no side holes (Judkins

Right, Multipurpose, or pigtail recommended, see Figure 5.8) into the 13 Fr introducer

and advance it over a diagnostic guidewire into the left ventricle.

Impella® 2.5 Use in Open

Heart Surgery

5 USING THE IMPELLA

®

CONTROLLER WITH THE IMPELLA

Figure 5.8 Inserting the 6 Fr Diagnostic Catheter

6. Remove the diagnostic guidewire and insert the supplied 0.018 in/260 cm placement

guidewire.

7. Advance the placement guidewire into the left ventricle until the floppy end and 3 to

4 cm of the stiffer part of the guidewire are visible in the left ventricle.

8. Remove the 6 Fr diagnostic catheter.

9. Wet the cannula with sterile water and backload the pigtail section of the catheter onto

the placement guidewire. One or two people can load the catheter on the guidewire.

One-person technique

a. Advance the guidewire into the Impella® Catheter and stabilize the cannula

between the fingers as shown in Figure 5.9. This prevents pinching of the inlet

port. The guidewire must exit the outlet port on the inner radius of the cannula,

as shown by the arrow in Figure 5.9 and in Figure 5.10. The catheter can be

hyperextended as necessary to ensure the guidewire exits on the inner radius of

the cannula.

If the Impella

the OR as part of open heart

surgery, manipulation may be

performed only through the

9 Fr steering catheter. Direct

manipulation of the pump

assembly through the aorta or

ventricle may result in serious

damage to the Impella

device and serious injury to

the patient.

Avoid Damaging Inflow

Area

During placement of the

Impella

care to avoid damage to the

inflow area while holding

the catheter and loading the

placement guidewire.

®

2.5 is used in

®

2.5 device, take

®

2.5

®

2.5

Two-person technique

b. The scrub assistant can help stabilize the catheter by holding the catheter proximal

to the motor. This will allow the implanting physician to visualize the inner radius.

The guidewire must exit the outlet port on the inner radius of the catheter, as

shown by the arrow in Figure 5.9 and in Figure 5.10. The physician can focus on

advancing the guidewire and, if the cannula needs to be hyperextended, the scrub

assistant is available to assist.

Impella® Controller with Impella® 2.5

5.9

Figure 5.9 Loading the Catheter on the Guidewire

Figure 5.10 Exiting of the Placement Guidewire from the Catheter

Do NOT Touch Inlet or

Outlet Areas

While feeding the Impella

through the 13 Fr introducer,

hold the device at the cannula

or motor housing. Do NOT

touch the inlet area or the

outlet area.

®

10. Advance the catheter through the hemostatic valve into the femoral artery

(see Figure 5.11) and along the placement guidewire into the left ventricle using a fixed-

wire technique. Follow the catheter under fluoroscopy as it is advanced into the left

ventricle, being careful not to coil the guidewire in the left ventricle.

Figure 5.11 Inserting the Impella® 2.5 Catheter

5.10

Instructions for Use

To prevent device failure, do not start the Impella® 2.5 Catheter until the guidewire

has been removed.

Do

NOT

remove the Impella® 2.5 Catheter over the length of the guidewire.

11. Remove the placement guidewire.

®

12. Confirm that a ventricular waveform is displayed on the Impella

Controller.

POSITIONING AND STARTING THE IMPELLA® 2.5

CATHETER

Retrograde flow will occur across the aortic valve if the Impella® 2.5 is set at a flow

rate of 0 L/min.

1. Place the catheter plug at the same level as the patient’s heart.

®

2. Confirm that a ventricular waveform is displayed on the Impella

(see Figure 5.12). If a ventricular waveform is not present, gently advance the