Page 1

The Shredder Company

POSTFACH 1420

D-88672 MARKDORF/BODENSEE - GERMANY

Schleicher International

802CC

852CC

Tel.: +49(0)7544/60-0

Fax: +49(0)7544/60-248

E-mail: vertrieb@schleicher.de

http//www.schleicher.de

Vor der Inbetriebnahme die Bedienungsanleitung durchlesen!

Before operating, please read the Operating Instructions!

Veuillez lire le mode d’emploi avant la mise en service!

Voor de inbedrijfstelling de gebruiksaanwijzing doorlezen!

Leer las instrucciones de uso antes de la puesta en servicio!

Antes de pôr a máquina em funcionamento leia as instruções de operação!

Prima della messa in funzione leggere attentamente le istruzioni!

Typ/Type/Type/Tipo: 648 / 649

Serie/Series/Série/Serie: 648 / 649

Bedienungsanleitung

Operating instructions

Instructions d’opération

Gebruiksaanwijzing

Instrucciones de uso

Instruções de Operação

Istruzioni per l’uso

Schaltplan / Wiring Diagram / Plan de montage / Schakelschema

Diagrama eléctrico / Esquema electrico / Schema Elettrico

1-800-658-8788 - www.abcoffice.com

(page 8-10)

(pagina 11-13)

(página 14-16)

(página 17-19)

(pagina 20-22)

(Seite / page / pagina

página / pagina

(Seite 2-4)

(page 5-7)

D

GB

F

NL

E

P

I

23-24)

Page 2

GB

IMPORTANT SAFETY NOTES

Schleicher International

802CC

852CC

<< The machine may not be operated by more

than one person at any given time!

The machine was designed for safe operation

by “one person only”.

<< During the shredding process no other

work may be performed on the machine

(for example cleaning, etc.).

<< Keep children

away from the machine.

This machine’s design and safety concept

are based on adult dimensions (inlet guide,

safety cut-off switches, etc.) to ensure that it

can be operated safely by adults only.

<< Repairs may only be performed by trained

personnel.

APPLICATION:

The INTIMUS 802CC/852CC shredder is used in

all areas where large quantities of printed material

need to be shredded.

The machine (model 852CC) can shred cardboard

and crumpled paper as easily as it shreds smooth

paper.

CAUTION: The shredder should only

be fed with paper or cardboard!

Shredding other data carriers can cause

injury(e.g. by splintering of hard materials)

or may damage the shredder (e.g.

destruction of the cutting system).

<< Never insert fingers into opening.

Serious injury may result!

STOP

<< In case of danger switch the machine

off with the mains switch, or with the

emergency switch, or unplug the

machine.

<< Always unplug the machine from the

mains power supply before opening

the machine.

INITIAL START UP

INSTALLATION REQUIREMENTS:

Note: Be certain that three phase current is

available at the point of installation (see

TECHNICAL DATA for information concerning

required pre-fusing of the electrical outlet).

- Unpack and set machine upright.

- Put the collecting bag into the sliding frame (see

description „EMPTYING THE COLLECTING

BAG“)

- Plug in the machine.

The air vents in the housing are

necessary for cooling and may not be

covered or closed!

The mains connection at the machine

must be freely accessible!

Only operate the machine in enclosed

rooms at temperatures between 10°C

and 40°C!

<< Keep all loose articles of clothing,

ties, jewelery, long hair or other

loose objects away from opening,

injury may result!

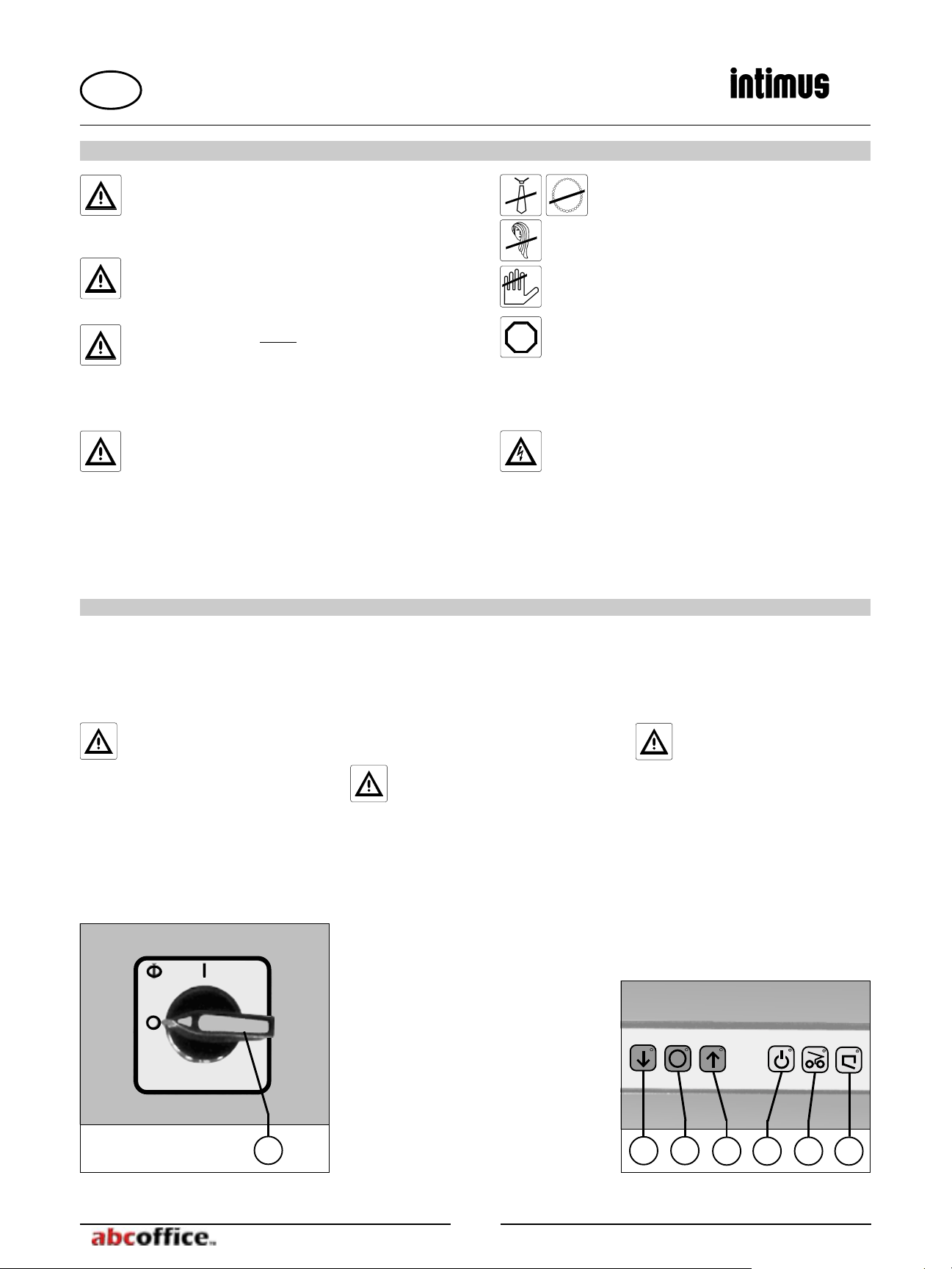

CHECKING THE RUNNING DIRECTION:

1. Move the main switch (1) (fig. 1) to position „1“.

2. Press the „forward“ button (2) (fig. 2). The

cutting system starts running.

3. Check that the cutting system is running in the

correct direction and correct the phase relation

of the power plug if necessary.

Correcting the phase relation of the

power plug may only be carried out

by a qualified electrician!

Now that everything has been correctly assembled

and connected, you can proceed to operating the

machine.

I

MAINS SWITCH

fig. 1

POWER SUPPLY CONNECTION:

a) The maximum value for loop impedance at the

mains connection point is 0.5 Ohms.

b) The conductor cross-section of the power supply

line should be of a magnitude so as to cause a

15% voltage drop in the case of a machine

blockage (inhibit current = 6 x nominal current).

S

1

3

4

2 5 6 7

fig. 2

5

1-800-658-8788 - www.abcoffice.com

Page 3

GB

OPERATING FUNCTIONS (Figs. 1, 2 and 4):

1 = Mains switch (Emergency-stop) (fig. 1)

This switch turns the machine either on

(position „1“) or off (position „0“).

2 = „Cutting system forward“

pushbutton (fig. 2)

Pressing this button starts the cutting system.

Material can now be fed to the shredder.

3 = „Cutting system stop“

pushbutton (fig. 2)

Pressing this button switches the shredder

off, thereby halting the cutting system.

4 = „Cutting system reverse“

pushbutton (fig. 2)

Pressing this button starts the cutting system

in reverse.

5 = Pilot lamp (fig. 2)

a) „ready“

Continously lights when the mains switch

(1) is operated.

b) „motor protection“

Flashes when the motor is overloaded.

While the motor is cooling down, the

machine cannot be switched on to „forward“

run.

6 = Pilot lamp „paper jam“ (fig. 2)

Lights when too much paper is fed to the

cutters (see description „AUTOMATIC

RESPONSE IN CASE OF OVERLOADING“).

7 = Pilot lamp (fig. 2)

a) „door open“/„hopper open“

Lights when the door is not closed or when

the hopper is open. The machine then

switches off automatically and it cannot be

started as long as the door is open or the

hopper is open.

b) „collecting bag full“ (fig. 2)

Lights as soon as the collecting bag is full

and needs to be emptied. At the same time

the machine switches off automatically.

8 = Light barrier (forward operation) (fig. 4)

The shredding operation is started as soon

as a sheet of paper passes through the feed

slot.

OPERATION

OPERATING THE MACHINE:

To start, switch on the unit by operating the mains

switch (1) (fig. 1). The pilot lamp marked „ready for

operation“ (5), as well as the red stop-button „S“

(3) (fig. 2) will light to indicate that the machine is

ready for operation.

The paper tray may not be used as a

step ladder or as a seat. Danger of

tipping over!

FEEDING CRUMPLED PAPER

(MODEL 852CC):

In order to avoid a reduction of user

safety by increasing the height of the

hopper side panels, and in order to

allow for filling the hopper while

standing on the floor, the height of the

hopper side panels is not in compliance

with EN 294:1992.

The deviation from EN 294:1992 is

identified with a yellow-black mark.

1. Fill the hopper with crumpled paper.

Note: The crumpled paper can be dropped

directly from the wastepaper basket into the

hopper of the machine. The apportioning wings

preceding the cutting mechanism ensure more

or less uniform distribution of the paper.

Attention:The wastepaper basket is no refuse

tin and should not be emptied into the machine

thoughtlessly - in no way can the machine

destroy bottles, pens, pencil sharpeners etc.

2. Press the pushbutton switch „forward“ (2) (fig.

2). The cutting system runs and begins to shred

the paper.

Note: Do not feed any smooth paper until the

crumpled paper is completely shredded.

3. To switch the machine off press the red stopbutton (3) (fig. 2).

FEEDING SMOOTH PAPER:

- Feed smooth paper through the opening at the

lower part of the hopper (model 852CC) or

through the opening of the hopper (model 802CC)

to the cutting system.

- Machine switches automatically to forward and

draws paper in.

- The machine switches off automatically after

shredding.

Schleicher International

Never feed the shredder with a quantity

of paper exceeding the maximum

indicated in the technical details.

Should the machine be overfed, follow

the instructions under „AUTOMATIC

RESPONSE IN CASE OF

OVERLOADING“.

AUTOMATIC RESPONSE

IN CASE OF „OVERLOADING“:

In case you accidentally overload the shredder, it

will automatically alleviate the problem as follows:

1. The cutting system becomes jammed. The pilot

lamp (6) (fig. 2) lights up.

2. The cutting system runs briefly in reverse,

thereby freeing the material to be shredded.

3. The cutting system automatically switches back

to forward mode.

The machine repeats this process until all the

material has been shredded satisfactorily.

EMPTYING THE COLLECTING BAG (Fig. 3):

When the collecting bag is full, the machine turns

off automatically. The pilot lamp (7) (fig. 2) lights

up. Empty the collecting bag as follows:

- Open the door and take out the sliding frame

with the collecting bag.

- Remove the rubber band, take out the full bag

and dispose of contents.

- Put the empty bag from below through the

sliding frame and put the edges of the bag

approx. 10 cm over the frame outwardly.

- Fix the collecting bag with the rubber band at the

sliding frame.

- Move back the sliding frame with the collecting

bag and close door.

Note: The machine will only run with

802CC

closed door!

852CC

I

MAINS SWITCH

fig. 1

S

1

3

4

2 5 6 7

fig. 3fig. 2

6

1-800-658-8788 - www.abcoffice.com

Page 4

GB

CLEANING THE PHOTOCELLS (8) (Fig. 4):

If paper particles should come to rest in the inlet

guide (for example after a paper jam) it is possible

that the machine will not turn off, due to the broken

light barrier.

To remove these paper strips and also to clean the

photocell, pass another sheet of paper through

the feed slot, or switch the machine to reverse and

wipe both „eyes“ of the photocell with a brush.

MAINTENANCE

8

fig. 4

Schleicher International

CUTTING SYSTEM MAINTANANCE:

After about 2 hours of continuous operation run

the cutting system in reverse for about 30 seconds

and, at the same time, spray some of the enclosed

special oil onto the cutting system.

ENERGY SAVING TIP:

Be certain that the machine is turned off overnight

(mains switch (1) (fig. 1) switched to „0“).

802CC

852CC

MALFUNCTION

TAKING OUT EXCESS PAPER

IN CASE OF OVERLOAD:

If the shredder has stopped due to an overload

(motor protection) take the excess paper out of

the inlet as follows:

1. Depress the reverse pushbutton (4) (fig. 2). The

material is released.

2. Lift up the hopper. The pilot lamp „door open“ or

„hopper open“ (7) (fig. 2) will light.

3. Remove the excess material by hand from the

inlet guide.

Note: In this case, there is no danger of injury

as all circuits are interrupted when the hopper

is lifted and the machine cannot be started.

MOTOR FAULT:

The machine is equipped with a thermally protected

motor. Should this motor be overloaded, it will

switch off automatically. In such case the pilot

lamp „ready“ (5) (fig. 2) flashes.

After a cooling down period of approx. 10 minutes

(depending on the room temperature) you can

restart the machine and continue shredding.

Note: When the motor is overloaded, only the

forward run is cut off. To take the excess paper out

of the inlet opening, the cutting system may at any

time be switched on „reverse“.

FAULT CHECKLIST:

If the machine is not functioning properly, you

should check the following:

- is the plug conneted to the mains?

- is the mains switch (1) turned on?

- is the door closed?

- is the collecting bag full?

The bag has to be emptied.

- is the motor overloaded?

Please refer to the section headed „Motor Fault“.

- is there a phase failure?

Check the three-phase fuse at the power supply

socket, and replace if necessary.

If you still cannot isolate the fault after carrying

out all these checks, please notify our customer

service department.

TECHNICAL DATA

Cutting width:

802CC: 1.9x15 (cross-cut)

852CC: 3.8x40 (cross-cut)

Cutting capacity:

802CC: 35-40 sheets (70 g/m2)

852CC: 70-80 sheets (70 g/m2)

Working width: 444 mm

Power: 3.9 kW

Supply voltage: 400V/50Hz

230V/50Hz

415V/50Hz

220V/60Hz

200V/50Hz

200V/60Hz

Pre-fusing:

(gl fuse, type 1 assignment)

400V-415V/50Hz: 16 A

220V-230V/50-60Hz: 25 A

200V/50-60Hz: 25 A

Width: 750 mm

Depht: 550 mm

Height:

802CC: 1275 mm

852CC: 1600 mm

Noise level: approx. 75 dB(A)

Weight:

802CC: approx. 185 kg

852CC: approx. 201 kg

ACCESSORIES

Description Order-No.

Plastic bag, 600 x 380 x 1100 x 0,6 mm 80946

Lubrication bottle, 125 ml 99943

Note: For orders of special accessories and spare parts, please contact your dealer.

7

1-800-658-8788 - www.abcoffice.com

Page 5

Konformitätserklärung

Certificate of Conformity

Attestation de Conformité

Bezeichnung der Maschine: Datenshredder

Type of machine: Document Shredder

Déscription de la machine: Destructeur de Document

Schleicher International

802CC

852CC

Modelle / Models / Modèles:

intimus 802CC

intimus 852CC

Typen / Types / Types:

Hiermit wird bestätigt, daß o. g. Geräte den Anforderungen der Maschinen-Richtlinie 89/392/EWG, sowie

der EMV-Richtlinie 89/336/EWG (Klasse B) einschließlich allen bis heute veröffentlichten Änderungen

bzw. Nachträgen entsprechen. Die o. g. Geräte entsprechen folgenden Normen bzw. Richtlinien:

We do hereby certify that the above mentioned products meet the requirements set forth in EEC-Guidelines

89/392 and EMC 89/336 (Class B) including all changes and addendums to date thereto. The above

mentioned products meet the following standards and guidelines:

Nous Vous Confirmons que les appareils cités ci-dessus correspondent aux exigences des directives 89/

392/CEE ainsi qu’ à la directive CEM 89/336/CEE (Classe B), ci-inclus toutes les modifications ainsi que

tous les suppléments publiés jusqu’à ce jour. Les appareils mentionnés correspondent aux normes citées

ci-après:

EN 292-1, Ausgabe / dated / en date du 1991

EN 294-1, Ausgabe / dated / en date du 1992

EN 60204-1, Ausgabe / dated / en date du 1993

EN 55011, Ausgabe / dated / en date du 1993

EN 61000-4-2 /-4 (IEC 1000-4-2 /-4), Ausgabe / dated / en date du 1995

ENV 50140 (IEC 1000-4-3), Ausgabe / dated / en date du 1993

648 / 649

November / November / Novembre 2000

The Shredder Company

POSTFACH 1420

D-88672 MARKDORF/BODENSEE - GERMANY

Dieses Papier ist aus 100 % Altpapier ohne optische Aufheller hergestellt

This paper made from 100 % unbleached recycled paper

Papier recyclable à 100 %

ppa. D. Schuster i. A. J. Erlecke

Leiter Technik Leiter Elektrik

Head of Technical Dpt. Head of Electrical Dpt.

Responsable Dép. Technique Responsable Dép. Electricité

00000 1 07/01

1-800-658-8788 - www.abcoffice.com

Loading...

Loading...