Installation and

directions for use

HERU 14 S AC, HERU 19 S AC

HERU 35 S AC, HERU 52 S AC

UL VERSION

CONTENTS

UNIT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . .3

INSTALLATION AND SECURITY . . . . . . . . . . . . . .4

”USE” ”SECURITY” ”MOUNTING””WARRANTY” . . . . . .4

”PLACING” ”FREE SPACE”

”SCHEMATIC DIAGRAM FOR PLACING” . . . . . . . . . . . . .5

STARTING UP THE UNIT . . . . . . . . . . . . . . . . . . . .6

CONTROL DIAGRAMS . . . . . . . . . . . . . . . . . . . . .7

REGULATION FUNCTIONS . . . . . . . . . . . . . . . . . .8

OPERATING THE CONTROL UNIT . . . . . . . . . . . .9

VIEW MODES 1-4 . . . . . . . . . . . . . . . . . . . . . . . .10

MAIN MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

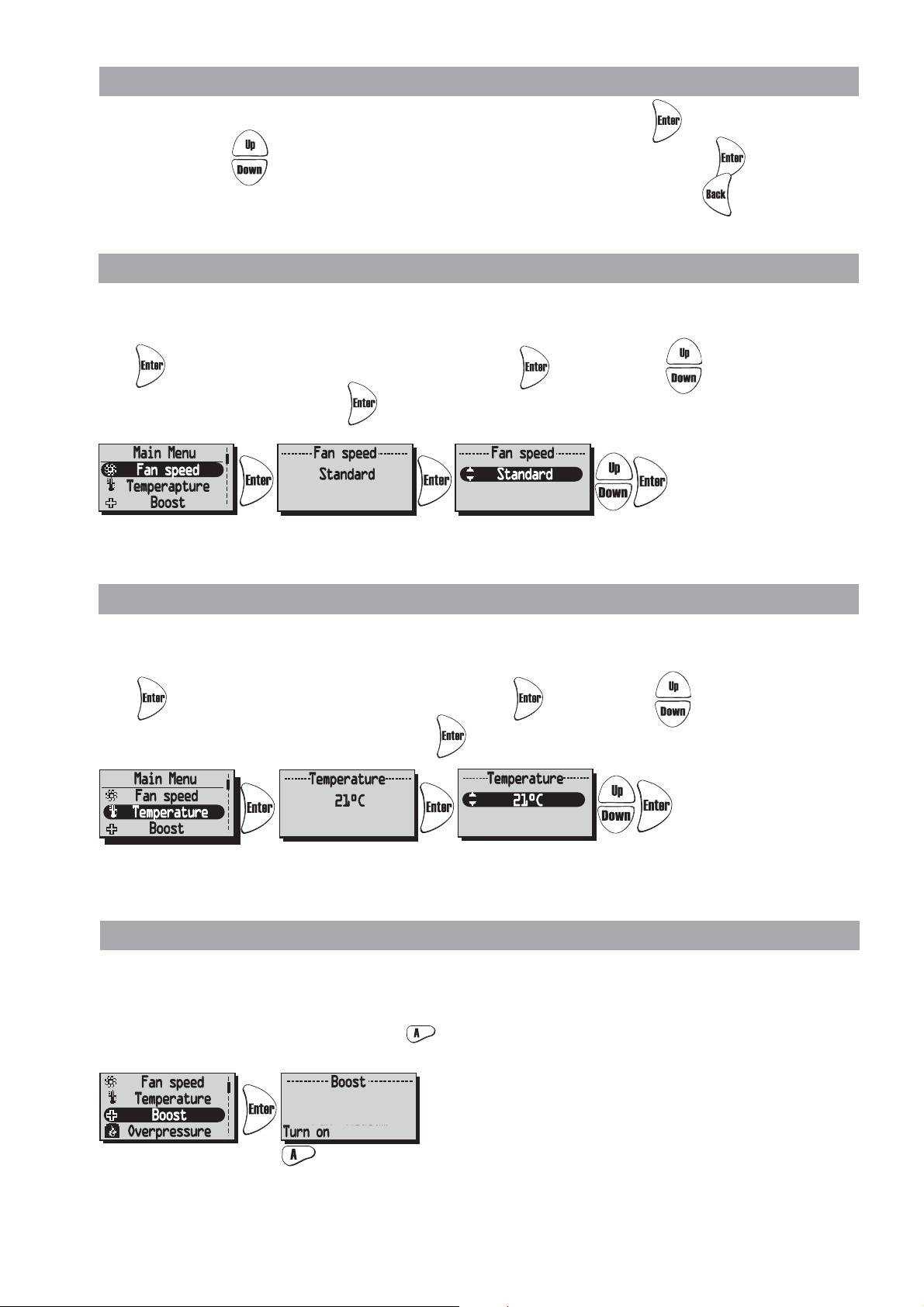

”FAN SPEED” MENU . . . . . . . . . . . . . . . . . . . . . .11

”TEMPERATURE” MENU . . . . . . . . . . . . . . . . . . .11

”BOOST” MENU . . . . . . . . . . . . . . . . . . . . . . . . .11

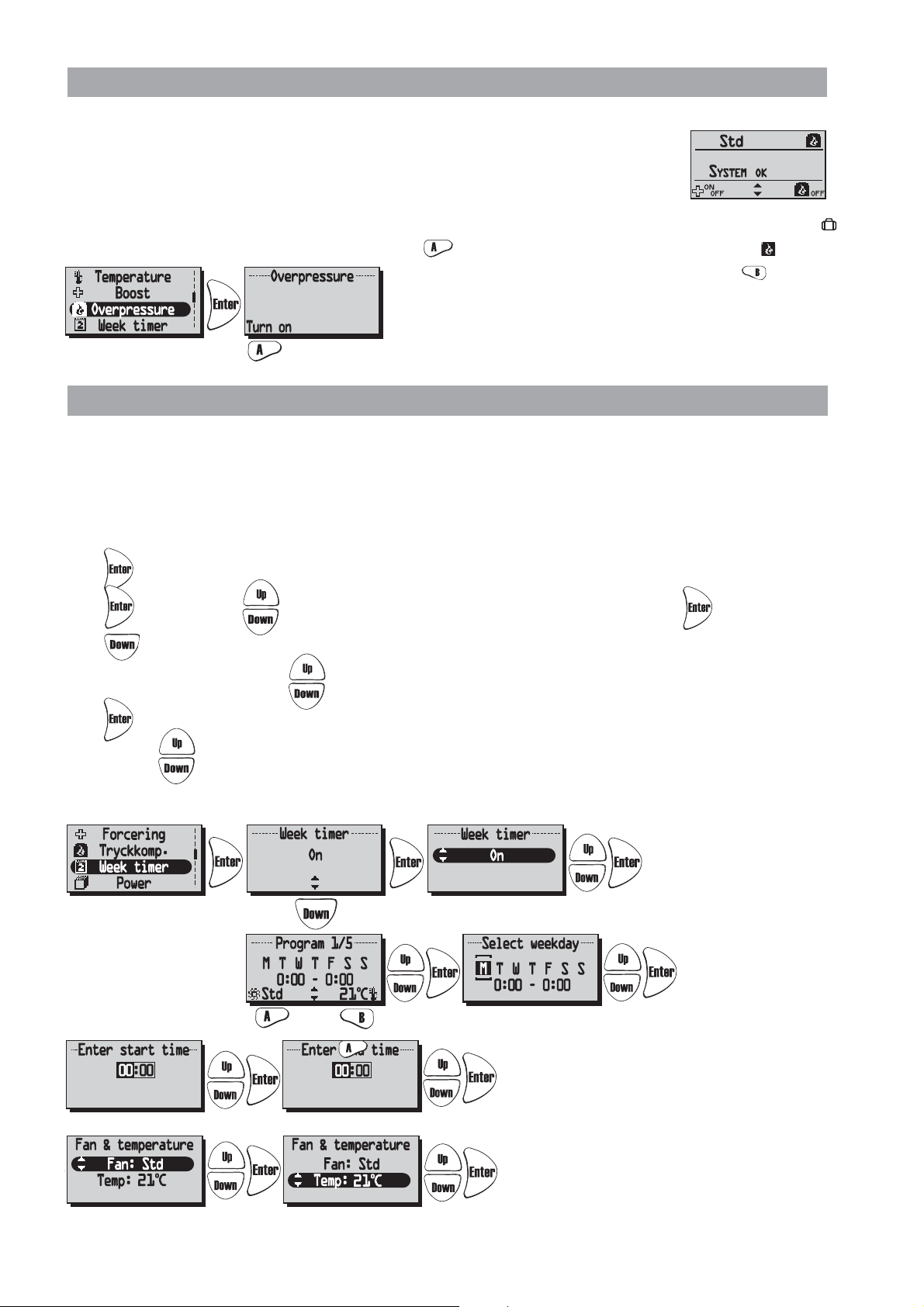

”OVERPRESSURE” MENU . . . . . . . . . . . . . . . . . .12

”WEEK TIMER” MENU . . . . . . . . . . . . . . . . . . . .12

”UNIT ON/OFF” MENU . . . . . . . . . . . . . . . . . . . .13

”ALARMS” MENU . . . . . . . . . . . . . . . . . . . . . . . .13

”SETTINGS” MENU . . . . . . . . . . . . . . . . . . . . . . .14

THE ”SERVICE MENU” . . . . . . . . . . . . . . . . . .14-21

”FILTER MEASUREMENT” ”AC FAN SETUP” . . . . . . . . . .15

”DISPLAY CONTRAST” ”BOOST” ”OVERPRESSURE” . . .16

”ALARM””CO2” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

”RH” ”HEATER” ”COOLER” . . . . . . . . . . . . . . . . . . . . .18

”SUPPLY LIMITS” ”REGULATION MODE”

”SUMMER COOLING” . . . . . . . . . . . . . . . . . . . . . . . . . .19

”FREEZE PROTECTION”FLOW DIRECTION”

”LOAD/SAVE SETTINGS” ”VERSION INFO” . . . . . . . . . . .20

”DEVICE PAIRS” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

OTHER FUNCTIONS . . . . . . . . . . . . . . . . . . . . . .21

SERVICE HERU S . . . . . . . . . . . . . . . . . . . . . . .22-23

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . .25

ERROR DETECTION DIAGRAM . . . . . . . . . . .26-27

ERROR DETECTION . . . . . . . . . . . . . . . . . . . . . . .28

INTERNAL SETTINGS . . . . . . . . . . . . . . . . . . . . .29

TECHNICAL INFORMATION

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . .30

TECHNICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

SOUND DATA . . . . . . . . . . . . . . . . . . . . . . . .32-33

PRESSURE-FLOW DIAGRAMS . . . . . . . . . . . .34-35

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . .36-37

This ”Installation and directions for use” contains following products:

HERU 14 S AC, HERU 19 S AC, HERU 35 S AC and HERU 52 S AC.

IMPORTANT! Please read this manual before installing the unit.

HERU 35 S AC

UNIT DESCRIPTION

HERU 52 S AC

HERU 14 S AC

HERU 19 S AC

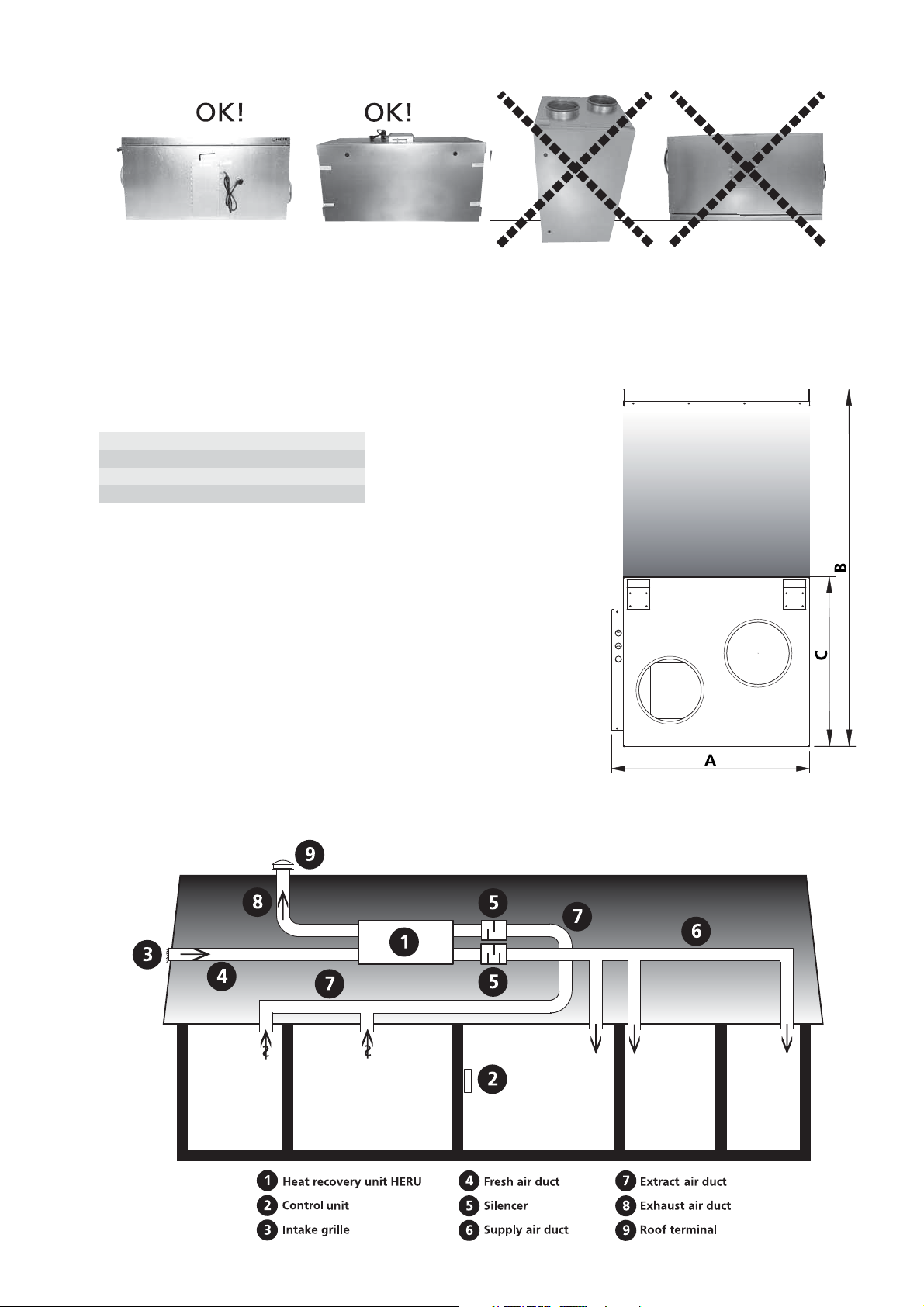

• HERU S is approved according to the standard

UL 1812 ”Ducted Heat Recovery Ventilators” and

CSA-C22.2 No. 113 ”Fans and Ventilators”.

• HERU S is a heat recovery unit (HRV) or an energy recovery unit (ERV). It is designed for supply

and exhaust air ventilation combined with heat

and cool recovery.

• HERU S can be used in homes, offices, apartments

etc. where there is a need for:

-clean. filtered and fresh air

-high temperature efficiency

-energy saving

-low sound levels

-safe operation

• HERU S;

- has a rotating heat exchanger, of hygroscopic or

non-hygroscopic type and is manufactured of aluminium, placed centrally in the unit. The ERV exchanger has a humidity efficiency of up to 85%.

The HRV exchanger has a temperature efficiency

of up to 85%.

- has backwardcurved centrifugal fans with maintenance free external rotor motors, which are connected with quick contacts, and are easily to

remove for cleaning.

- has built-in control for heating/cooling.

- can be fitted with a built-in electric heater.

- has as standard, disposable bagfilter,

class MERV 13.

- has a wireless remote controller for the operation

and monitoring of the unit.

- has a double skinned galvanised sheet steel casing

with intermediate insulation.

• The HERU S can be mounted in either warm or

cold space.

• The HERU S is delivered galvanized.

• All HERU S are operated via a wireless remote

controller which can operate and to preset the required parameters as well as monitor the unit’s

status. The operating range is approximately 50

meters/164 feet.

The antenna which is placed next to the unit can

have the range reduced if there are heavy reinforcing bars in the concrete structure and it should

then be moved either to a position where the signal is not shielded or nearer to the controller.

WARRANTY

The warranty is only valid under condition that the

HERU S unit is installed, adjusted and has been

record by a qualified person according to this

”Installation and directions for use”, and that regular

maintenance had been made.

NOTE!

Östberg Americas Inc. reserve the right to make

changes without further notice.

3

INSTALLATION AND SECURITY

USE

• When installing HERU consideration must be

given to any approval authority requirements and

recommendations concerning siting, accessibility,

electrical connections, etc.

• The HERU unit is accessible for the user, according to IEC 60335-2-40, to by themselves do the

service and maintenance, according to this

Directions for use. But before this work the unit

must be currentless.

With reservation according to IEC 60335-2-7.12

”This appliance is not intended for use by persons

(including children) with reduced physical, sensory or metal capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety.”

”Children should be supervised to ensure that they

do not play with the appliance.”

• The HERU unit should be storage in a sheltered

and dry place before installation.

• Dimensioned air flow should not exceed 60% of

the unit's maximum capacity.

• Check at regular intervals that supply air and exhaust air works.

• To avoid condensation in the unit during the cold

season, the unit should not be turned off for a

longer period. When installed in warm moisturre

environment as e.g. bathroom and utilityroom condense may appear on the outside of the unit at low

outside temperatures.

MOUNTING THE HERU S

• HERU S should be installed according to the

assembly instruction, see picture below.

• Place the unit on a high density insulation board,

min. 50 mm.

• Supply and extract air must be duct connected on

the same side of the unit.

• Acoustic silencer should be planned with the help

of sound data and required sound levels.

• Use duct clamp or flange with encompassing insulation when connecting to duct.

• If the supply and the extract air ducts are installed

in a cold space they should be insulated. To prevent condensation the supply air duct should also

be insulated if installed in warm space at low supply air temperatures.

• The fresh air and exhaust air duct should always be

condense insulated.

• The ducts should be insulated all the way towards

the unit.

• The duct sensor GT7 should be mounted in the

supply air duct, and the antenna on a suitably position beside the unit (not against metal).

• If a heating coil is connected a cut off damper must

be mounted in the fresh air duct.

• Cooker hoods must not be connected to the

HERU S.

SECURITY

Attention! Do not apply electric power until after

completion of the installation. Ensure the installation

and wiring is in accordance with CEC, NEC and

local electrical codes..

• Attention, look out for sharp edges and corners on

the HERU unit and fans.

• Consider the weight of the unit. See page 31.

• Before maintenance work the HERU unit must be

currentless. If there is a need of changing or complement any electrical components, it should be

done by a qualified person.

• The HERU unit includes rotating parts that could

cause serious danger on the occasion of contact.

This is why the unit must be duct connected and

the lid closed with the screws tightened, before

starting up the unit.

• After the current is cut for service and maintenance the electric heater may still be warm.

• Make sure that the access cable is not damage at

mounting and installation.

• The HERU S needs a permanent electrical supply.

The unit must be connected via a safety switch.

Any electrical connections must be made by a qualified electrician.

INSULATION BOARD

min. 50 mm

FLOOR

4

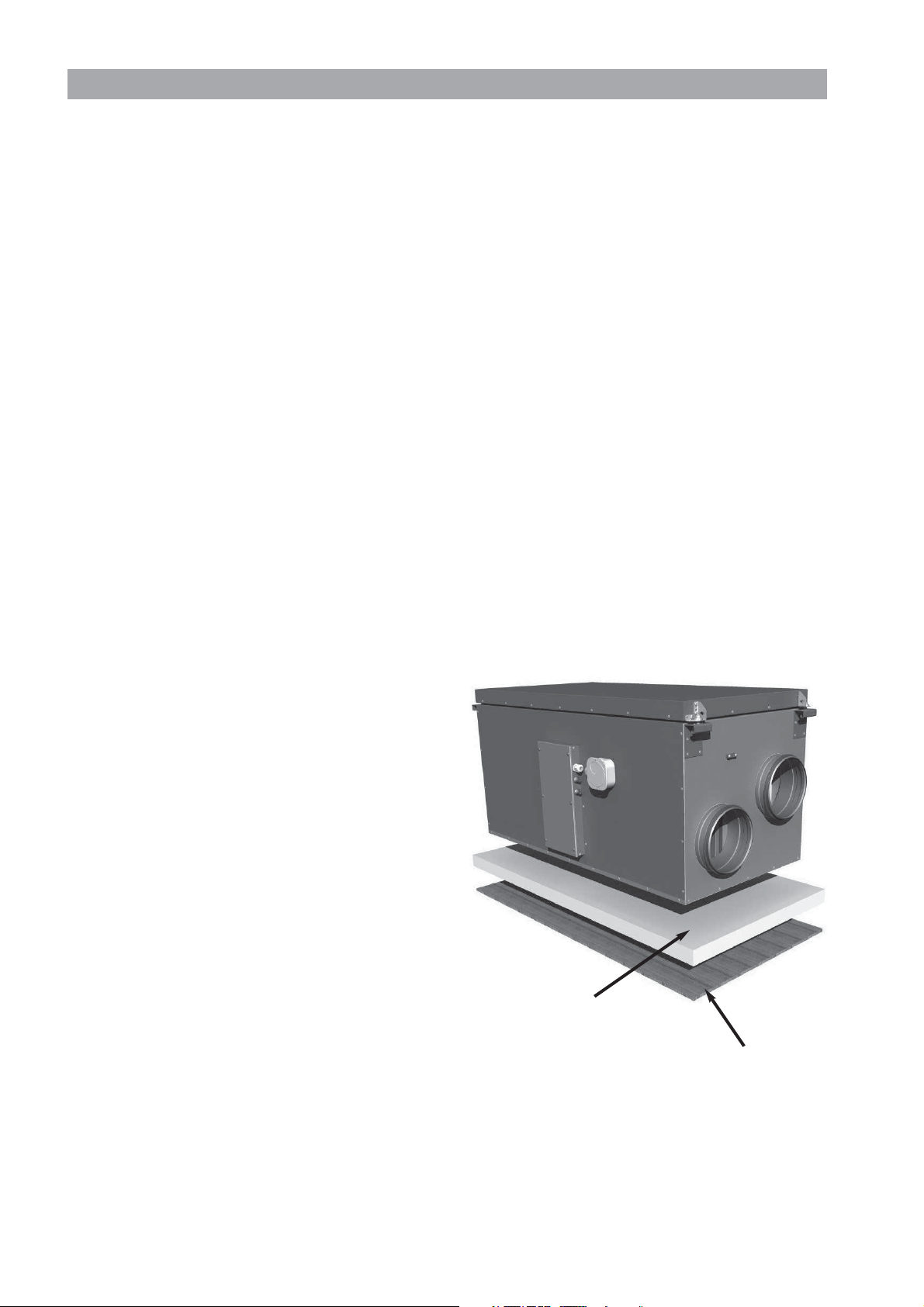

PLACING THE HERU S UNIT

A B C D

The HERU S should be installed with the lid upwards (A) or on the side (B). Because of the risk of injury

we do not recommend installing the unit vertically (C) or with the lid downwards (D). Allowances must be

made to access the unit for servicing or maintenance.

CLEARANCEE FOR SERVICING AND MAINTENANCE

mm A+D B C

®

H E R U

50 S 2, 75 S 2, 100 S EC 21

®

H E R U

130 S 2, 130 S EC 2 24 39

H E R U®180 S 2, 180 S EC 2 28 48 24

7/8311/2

16

3/8201/2

Clearance for servicing and maintenance

7/8

SCHEMATIC DIAGRAM FOR HERU S PLACED IN AN ATTIC

5

STARTING UP THE UNIT

Note! Important information before starting!

WARNING!

Improper installation, adjustment, alternation, service or maintenance can cause property damage, personel injury or loss of life.

Installation and service must be performed by a

qualified installer or service agency.

Carefully read through the manual before starting

up the unit.

• Note! Always mount the temperature sensor GT7

in the supply air duct. See page 7 and 36-37. GT7

is connected at the relay card. The temperature

sensor GT7 is placed in the control cabinet when

delivered.

• The antenna should be mounted outside the unit.

The antenna for HERU S is delivered connected,

is placed in the control cabinet.

Note! The antenna should not

any metal area or metal items as this will shield

the signal.

The antenna should be mounted as central as

possible. This to achieve the best signal all over

the house. If neede an extension cord is available

as an accessorie.

be mounted against

age, always check so the unit is starting up again.

• HERU S is supplied for right handing applica-

tion, see picture below. If the unit is installed left

handed, and no electrical heater is fitted, changes

can be made in the ”Service Menu” and in the submenu ”Flow Direction”. See page 20.

• Important when adjusting the flow: Go to Service

Menu (password 1199), choose “AC-motor setup”.

This disable functions such as Summer cooling or

Boost during flow adjustment. The preset fan

speed is standard. See page 11.

When adjusting the airflow of AC-fans there is a

possibility to change the voltage for the different

fan speeds via the separate transformers for supply

resp. exhaust fan. Normal operation should be

done in standard mode. HERU 14 S/19 S has 5step transformers and HERU 35 S/52 S has 7-step.

See wiring diagrams on pages 36-37.

Note! When ajusting fan speed manully, make

sure that the speed keeps the sequences.

• All HERU can be fitted with a built-in electric

heater. Choose heater ”On/Off” according to the

instruction on page 18.

• Install the 3 AA batteries in the wireless control

unit that are placed inside the HERU when delivered.

• HERU S starts automatically (with a few minutes

delay) when the power is switched on, or alternative with the wireless control unit. At power out-

EXHAUST

AIR

FRESH

AIR

• Set the temperature according to the instruction

on page 11.

• Save settings according to the instruction on page 20.

• Note! The unit must not be operating without

filter.

EXTRACT

AIR

SUPPLY

AIR

CONTROL CABINET

6

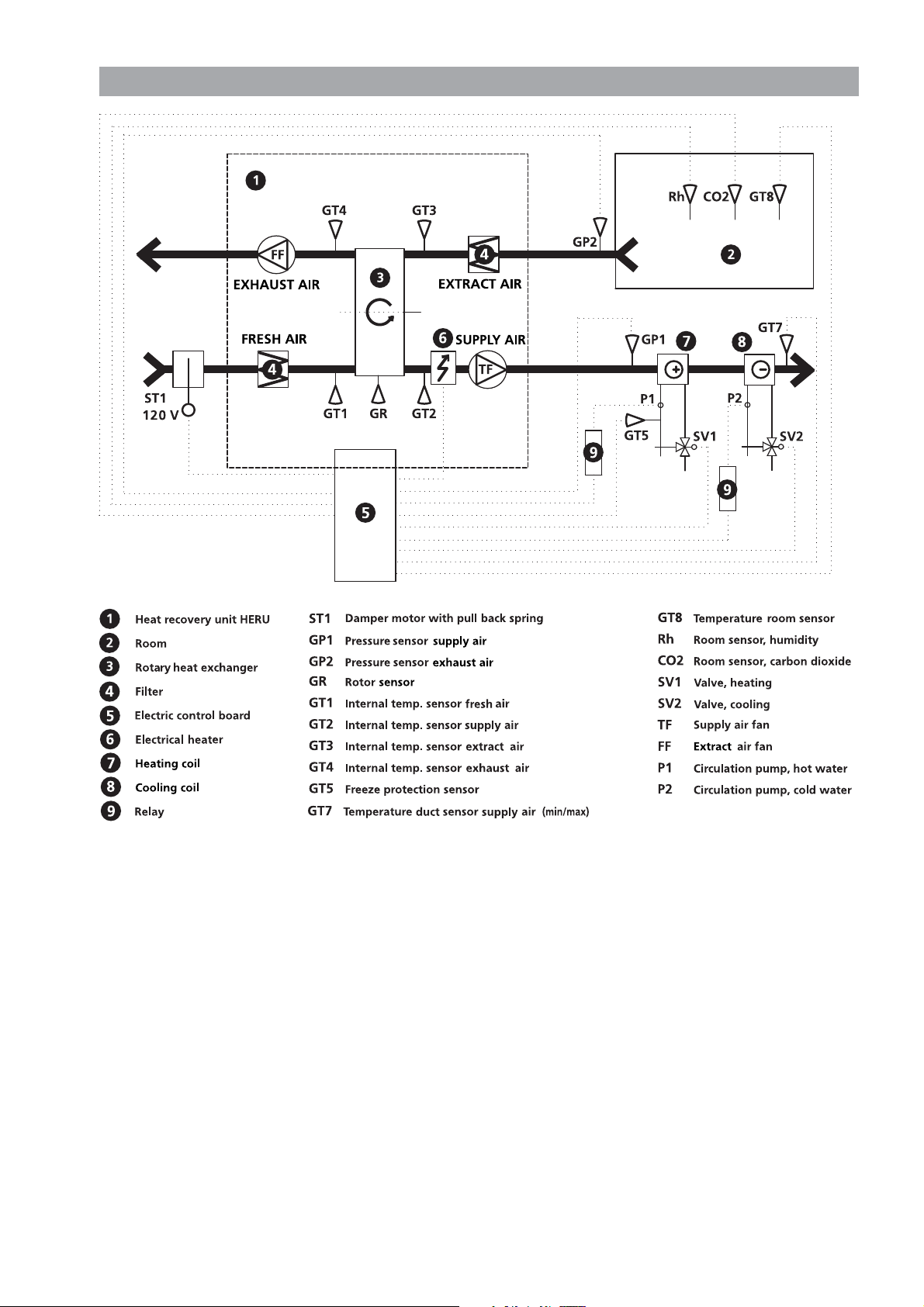

CONTROL DIAGRAM HERU

®

S

shows all sensors, flow direction right

*Accessories

*

*

*

*

*

*

*

*

*

*

*

*

*

7

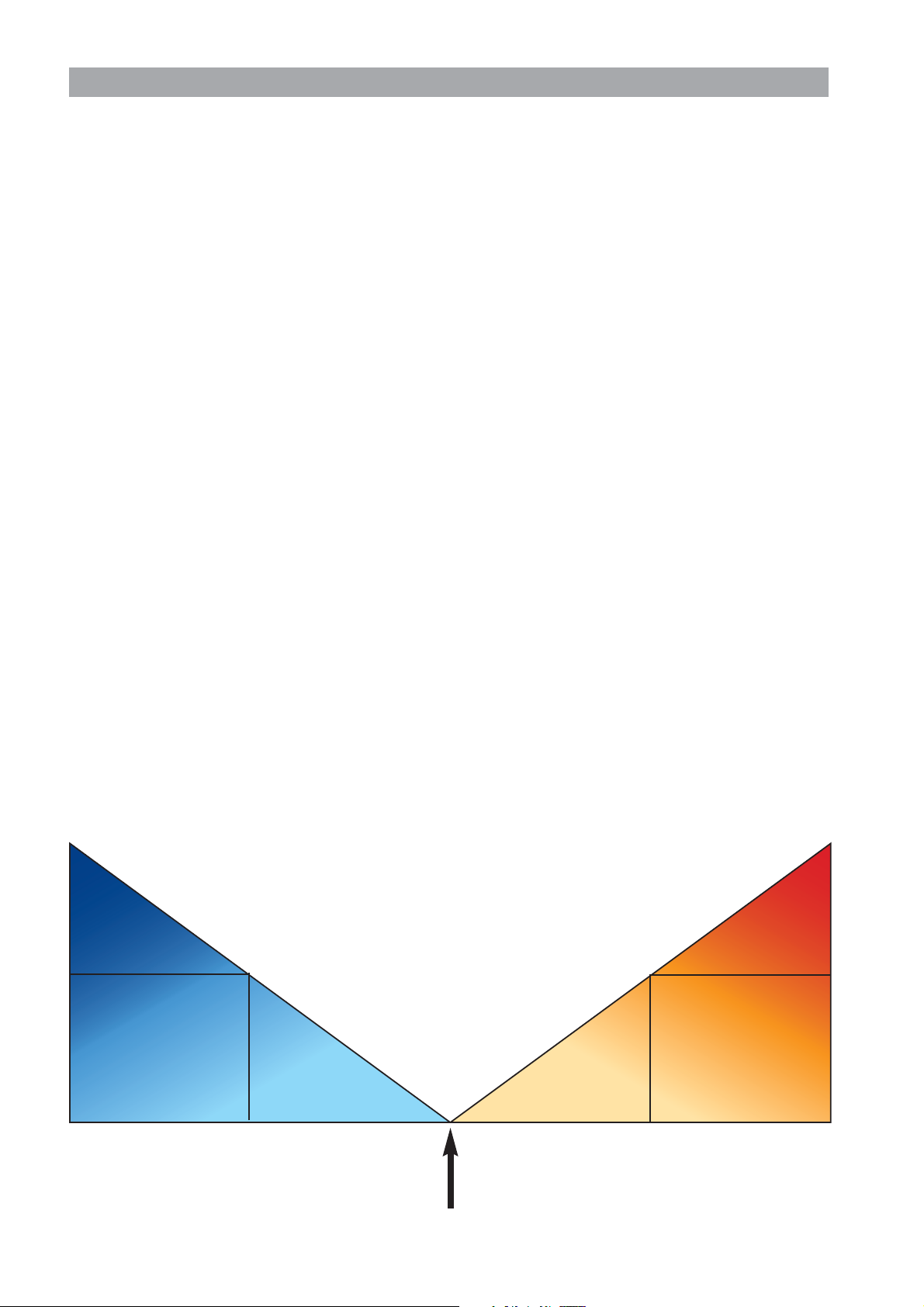

REGULATION FUNCTIONS

REGULATE THE TEMPERATURE

The air temperature can be regulated either for constant supply air temperature, constant room temperature or constant exhaust air temperature.

For constant room temperature a sensor should be

placed in the room for room regulation (this is also

suitable when a cooling coil is incorporated in the

system).

Exhaust air regulation functions in a similar way

but with the difference being that the sensor is

placed in the extract air duct.

The temperature can be regulated in 5 sequences:

1.Cooling recovery + After cooling: The regulation

unit can control a cooling coil (e.g. cooling water

from bedrock), when the cooling recovery from

the rotor is not enough.

2.Cooling recovery or regulated fresh air cooling:

The rotary heat exchanger starts if the extract air

temperature is lower than outside temperatur.

Fresh air cooling: The outside temperature is lower

than desired room temperature. The rotor regulate

the supply air temperature.

3.Outside temperature = desired temperature: When

the outside temperature is the same as desired sup-

ply air temperature the rotor stops.

4.Heat recovery: The rotary heat exchanger starts to

recover the warmer room temperature.

5.Heat recovery + heat: In climate conditions where

the rotary heat exchanger, in spite of its high effi-

ciency, is not sufficient to reach the desired supply

air temperature, the controller can regulate either

the built-in electric duct heater or a heating coil.

FAN CAPACITY

Airflow (fan speed) is regulated via the week timer

that can be programmed for specific time points

when the fan speed should change from one speed to

antoher (e.g. home or away setting). A special feature

is that you can pressure compensate when supplementary heating, using an open fire or stove (the

exhaust air fan then drops to a lower speed).

The wireless control unit can also manually adjust

the fan speed and even boost the airflow for an indicated length of time. The fan speed can also be controlled by a carbon dioxide (CO

(RH) sensor so that the unit gives a higher airflow

(boost) when the maximum limit value is reached.

”Summer Cooling” is a function where you can use

the cool outside temperature at night, to cool down

the inside air. The fan speed is boosted when the

ratio between the outside temperature and the

exhaust air temperature is within the programmed

criteria.

Via the wireless control unit the HERU can be put in

an ”Off mode”, which means that the motors for fans

and rotor are ”Off” but the unit is ”Stand by”. If there

is a requirement of totally cut off power, a switch

must be mounted on the mains.

Boosting the airflow for a specified time can be done

via the wireless control, there is also a opportunity to

do that via a timer connected to the ”0” and ”Boost”

connection on the PCB. With the connectors closed

the boost function will be ”On”.

) and humidity

2

Regulated

cooling coil

0-100%

Rotor 100%

1.

Cooling recovery

+

Cooling coil

Regulated rotor

0-100%

2.

Cooling recovery

Regulated rotor

0-100%

4.

Heat recovery

or Fresh air cooling

3.

Outside temperature = Desired temperature

8

Regulated

after heating

0-100%

Rotor 100%

5.

Heat recovery

+

After heat

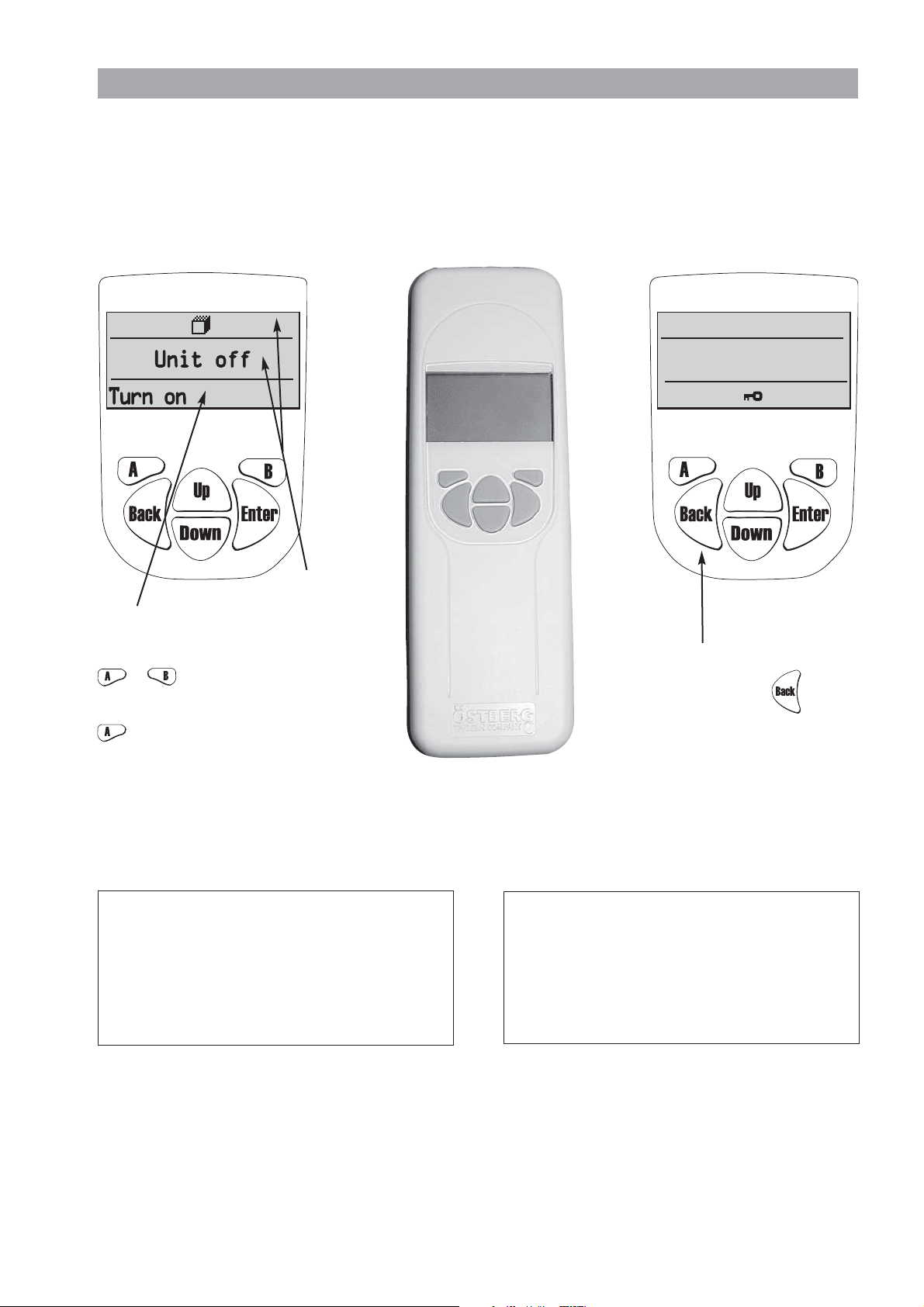

OPERATING THE CONTROL UNIT

StdStd

SYSTEMSYSTEM OK......

Information of the units current status such as temperature, fan speed, the rotor temperature efficiency when

operating, heat respectively cooling needs is shown in the VIEW MODE 1, 2, 3 and 4. These menus is normally

not lit up for battery-saving purposes but is lit up after the first press of the button and is switched off after

about 2 minutes of not being in use.

The control unit automatically returns to VIEW MODE 1 after one minute when one has viewed other submenus.

Note! At new setting a delay of 15 seconds should be taken into consideration.

Bottom row

shows the possible

choices with key

E.g turn on/off

the unit with the

USER INFORMATION FOR RF DEVICE:

Changes or modifications not expressly approved by the

party responsible for compliance could void the user’s authority to operate the equipment.

This exuipment has been tested and found to comply

with the limits for Class B digital device, pursuant to part

15 of the FCC Rules. These limits are digned to provide

reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and

can radiate radio frequency energy and, if not installed and

used in accordance with the instruction, may cause harmful interference to radio communications. However, there

Top row

and

middle field

displays

current

or .

values

and

activities.

key.

FCC ID: A8W-4020528

This device complies with part 15 of the FCC Rules

and RSS-210 of IC Rules. Operation is subject to

the following two conditions: (1) This device may

not cause harmful interference, and (2) this device

must accept any interference received, including

interference that may cause undesired operation of

the device.

To activate or disable

the keylock;

press down the key

for 3 seconds.

FCC ID: ASW-4020527

This device complies with part 15 of the FCC Rules

and RSS-210 of IC Rules. Operation is subject to

the following two conditions: (1) This device may

not cause harmful interference, and (2) this device

must accept any interference received, including

interference that may cause undesired operation of

the device.

is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be

determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or

more of the following measures: -Reorient or relocate the

receiving antenna. -Increase the separation between the

equipment and receiver. -Connect the equipment into an

outlet on a circuit different from that to which the receiver is connected. Consult the dealer or an experienced

radio/tv technician for help.

9

CO2

+

CO2

+

...

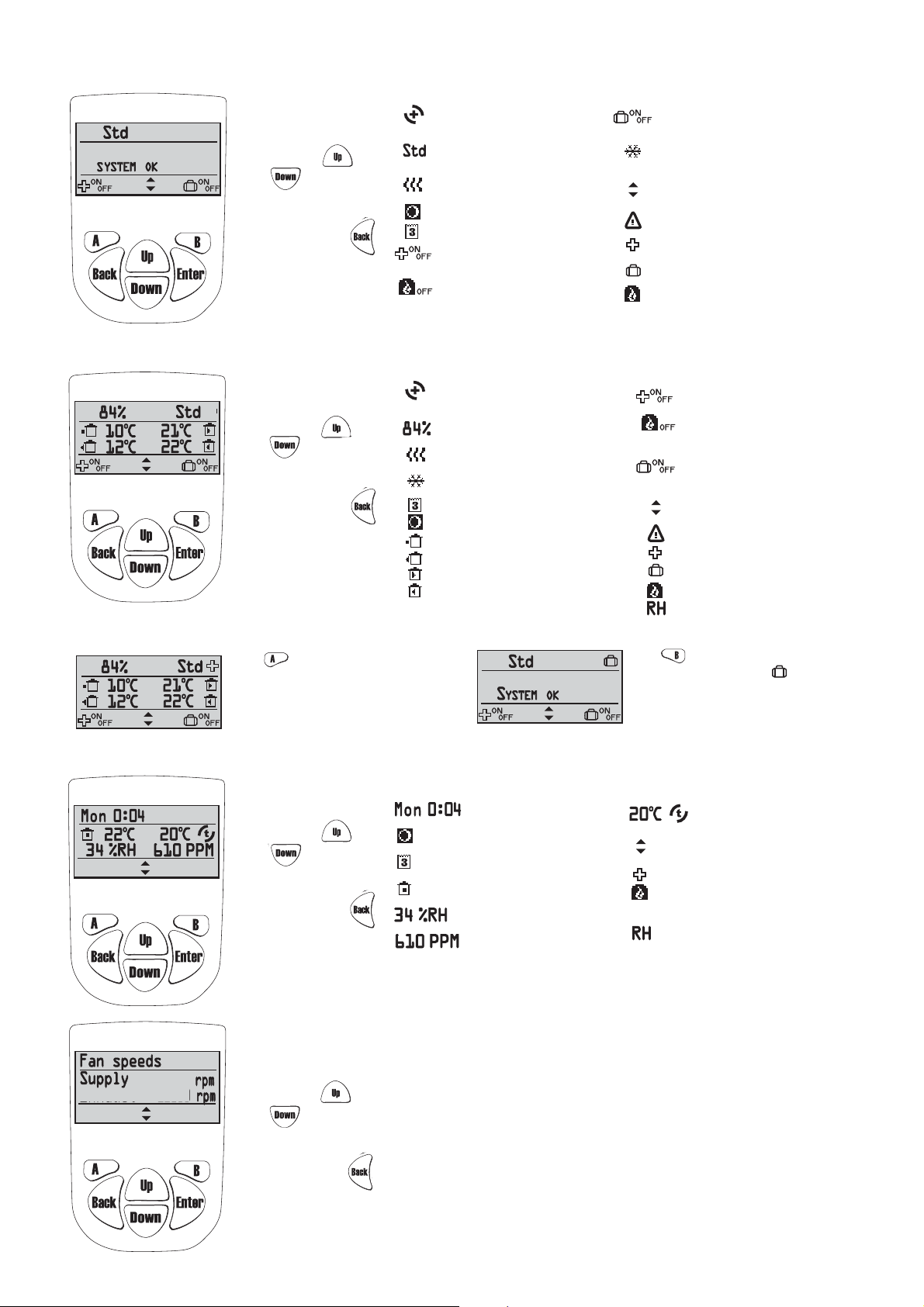

VIEW MODE 1

+

960

1060

Extract

SYMBOLS THAT CAN BE DISPLAYED IN VIEW MODE 1:

In order to go to

view mode 2, 3

or 4 press

or .

In order to

return to view

mode 1, press .

= Indicates that the rotor is operating.

+

= heat recovery

- = cooling recovery

= Fan speed. Choose from min,

standard, medium, max.

= Symbol indicates that

the heating coil is on.

= Summer cooling is active.

= Week timer is active.

= Function of A-key.

Press A-key to regulate ”boost”

of supply & extract air flow.

= Function of B-key.

Press B-key to turn off

pressure compensation.

VIEW MODE 2

SYMBOLS THAT CAN BE DISPLAYED IN VIEW MODE 2:

In order to go to

view mode 3

or 4 press

or .

In order to

return to view

mode 1, press .

IN VIEW MODE 1 AND 2 BOOST OFF/ON AND AWAY OFF/ON CAN BE CHOOSEN.

Press key to choose Boost off/on of the

supply & extract air flow for a specific time (time

and fan speed settings during the boost

is made in the Service menu ”Boost” page 11).

When the ”plus”

right corner, the boost is activated.

+

symbol is displayed in the

= Indicates that the rotor is operating.

= heat recovery

- = cooling recovery

= Temperature efficiency.

= Symbol indicates that

the heating coil is on.

= Symbol indicates that

the cooling coil is on.

= Week timer is active.

= Summer cooling is active.

= Outside temperature.

= Exhaust air temperature.

= Supply air temperature.

= Extract air temperature.

= CO

compensation is active.

2

= Function of B-key.

Press B-key to choose

”Away” on or off.

= Symbol indicates that

the cooling coil is on.

= Function of keys up and down

for view mode 2, 3 and 4.

= Alarm

= Indicates Boost is active.

= Indicates Away is active.

= Pressure compensation is active.

= Function of A-key.

Press A-key to regulate ”boost”

of supply & extract air flow

= Function of B-key.

Press B-key to turn off

pressure compensation.

= Function of B-key.

Press B-key to choose

”Away” on or off.

= Function of keys up and down

for view mode 1, 3 and 4.

= Alarm

= Indicates Boost is active.

= Indicates Away is active.

= Pressure compensation is active.

= RH compensation is active.

Press key to choose Away off/on.

When the symbol ”suitcase” is

displayed in the right corner, the away

mode is activated, i.e. the fan speed is

minimum.

9

In order to go to

view mode 2

or 4 press

or .

In order to

return to view

mode 1, press .

VIEW MODE 4 (only for HERU®EC)

In order to go to

view mode 2

or 3 press

or .

In order to

return to view

mode 1, press .

VIEW MODE 3

SYMBOLS THAT CAN BE DISPLAYED IN VIEW MODE 3:

= Display weekday and time.

= Indicates that Summer

cooling is active.

= Indicates that week timer

is active.

= Room temperature.

Sensor placed in room.

= Relative air humidity in per cent.

= Carbon dioxide level in PPM

(part per million).

SYMBOLS THAT CAN BE DISPLAYED IN VIEW MODE 4:

Displayes fan speed of supply and extract air in rpm.

At Constant pressure regulation the max speed, the fan speed and current pressure

sensor value is displayed in per cent.

= Supply air temperature

after the rotor.

= Function of keys up and down

for view mode 1, 2 and 4.

= Indicates Boost is active.

= Pressure compensation is active.

compensation is active.

= CO

2

= RH compensation is active..

10

”MAIN MENU”

In order to go forward in the menu from the View mode to the Main Menu press .

In the Main Menu is used to select the desired menu, after the choice is made with .

The procedure is the same in the submenu. In order to return to the previous page press .

”FAN SPEED” MENU (Only for Heru

In this menu desired fan speed is chosen. You can choose from 4 speeds: Min, Standard, Medium and Max.

Normal operation should be done in standard mode

Press in order to go forward from the Main Menu. Press again and then in order to choose

the desired fan speed. Confirm with .

Made settings is overridden if Week Timer is activated.

®

AC)

”TEMPERATURE” MENU

In this menu desired temperature is chosen (supply air, extract air or room temperature) depending on what

kind of regulation that is choosed, see page 19.

Press in order to go forward from the Main Menu. Press again and then in order to choose the

desired temperature (15°C-30°C); .Confirm with .

Made settings is overridden if Week Timer is activated.

”BOOST” MENU

In this menu Boost On/Off is chosen. The time has the factory setting of 30 min. and fan speed Medium.

To adjust the fan speed and time, see page 16.

Boost is activated/disable (On/Off) with the key.

The Boost function can also be activated with an external switch with double pressure or timer.

See wiring diagram page 36-37. The Boost is On as long as the breaker is closed.

11

“OVERPRESSURE” MENU

Off

Overpressure is a special feature were you can pressure compensate when supplementary

heating using an open fire or stove. The extract air fan then drops to a lower speed

during set time.

In this menu Overpressure On/Off is chosen. The time has the factory setting of 15 min.

To adjust the time, see page 16.

Overpressure is activated/disable (On/Off) with the key.

When pressure compensate is

activated the symbol ”Away”

will be change to the symbol

”Overpressure” in View

mode 1 and 2.

Than press directly in the

View mode to turn off Overpressure.

“WEEK TIMER” MENU

When in normal operation the unit runs with the fan speed that was choosen in the “Fan Speed” menu and

the temperature that was choosen in the “Temperature” menu. A departure from these programmed values that

you periodically want to recall is done in this menu. For example if you want to have a lower flow/temperature

during the daytime when nobody is at home then there is the possibility to adjust this here.

Week timer. If end time is the same or less than start time the program will end the following day.

Press in order to go forward from the Main Menu.

Press again and then in order to choose off/on of the week timer. Confirm with .

Press to choose/adjust the desired program. There are 5 programs for the adjustment of the fan speed

and temperature available. Press to choose a program.

Press in order to go forward to choose a weekday, start time, end time, fan speed and temperature.

Use the keys to choose the settings of weekday, start time, and end time, fan speed (Min, Standard,

Medium, Max) and temperature (15°C-30°C).

Cont. next line.

Cont.

Cont. next line.

Cont

N.B! The activated Week Timer is overridden manuel settings of fan speed and temperature.

12

“UNIT ON/OFF” MENU

! Filtertimer

Reset

In the ”Unit On/Off” Menu you have the possibility of turning off the unit via the wireless control unit.

This will just put the unit in a stand by mode.

NB! The unit must be currentless during service and maintenance.

Press in order to go forward from the Main Menu. Press in order to choose on/off of the unit.

To avoid condensation in the unit during the cold season the unit should not be turned off for a longer period.

“ALARMS” MENU

This meny displayes alarms.

View mode 1 shows alarm and

View mode 2 shows what kind of alarm.

Alarms is shown for:

• ”Rotor failure” • ”Supply temp. low” • ”Rotor temp. low” • ”Fire alarm” • ”Freeze alarm”

• ”Sensor open” • ”Sensor shorted” • ”Overheating” • ”Filter alarm” • ”Fan failure” • ”Filtertimer”

Press in order to go forward from the Main Menu and to view status. If no alarm ”System OK” is displayed.

When alerting a dialogue box for the alarm is shown in the Main Menu and the display will flash.

“View alarms” is shown and the possibility for equalization is given.

Press to see the cause of alarm in a submenu. Control the cause and remedy the alarm.

Press to ”Clear all” and than .

Current alarm is viewed. When "Sensor open" and "Sensor shorted" press "Show"

to view which sensor GT 1-8 is alerting.

See Control diagrams on page 7.

In order to return to the previous pages press .

When alarm for Filter timer the alarm can equalize with Reset.

A reminder to change filter comes with a seven-day interval.

To restart the timer see ”Service Menu Alarm” page 17.

13

!

“SETTINGS” MENU

Are you sure?

No Yes

In this menu settings for weekday, time and what language is made.

Press in order to go forward from the Main Menu. Press again and then in order to choose weekday.

Press again and then in order to enter the time.

Press and then in order to choose a language. 4 languages are available: Swedish, Finnish, Russian

and English.

THE “SERVICE MENU”

In this menu a password is required in order to make adjustments. The password is 1199 and it can not be changed.

Press in order to go forward from the Main Menu.

The password is entered with the keys and every digit is confirmed with .

After the password 1199 to the Service Menu the question “Are you sure?” will be displayed.

Press for “No” or for “Yes”.

A

To go further to the different functions in the ”Service menu” press or .

14

SERVICE MENU: “FILTER MEASUREMENT”

ServicemenyServicemeny

FiltermätningFiltermätning

EC-motor setupEC-motor setup

Display kontrastDisplay kontrast

Är du säker?

Bör endast ändras

av installatör!

Standard (%)

Tilluft: 60%

Frånluft: 70%

EC-motor setupEC-motor setup

StandardStandard

Min

MediumMedium

Avbryt Ok

Standard (%)

Tilluft: 60%

Frånluft: 70%

EC fan setup

AC fan setup

--Fan speed-Standard

Service menu

Filter switches or pressure sensors are not installed as standard, and this is displayed:

If filter switches are installed and activated, setting for day and time is choosed when the unit should

boost to measure increased pressure over supply air filter GP1 and exhaust air filter GP2.

SERVICEMENY: “AC FAN SETUP”:

When adjusting the unit, the speed is set to

standard and functions that may affect the

fan speed, such as “Away” and “Boost”,

should be inactivated.

15

SERVICE MENU: “DISPLAY CONTRAST”

EC fan setup

AC fan setup

AC fan setup

Display contrast

Display contrast

Boost

Alarm

Display contrast setting. The contrast can be set between 0-63.

SERVICE MENU: “BOOST”:

Time settings for Boost and Fan speed. Boost means that during a specific time increases

the air flow. This boost can then be activated at the View mode 1 and 2, and in the Main Menu “Boost”.

Press in order to go forward from the Main Menu. Press again and then in order to choose

the desired duration.(10-240 min. with the interval of 10 min.)

Press on order to confirm and go forward to fan speed.

Choose the desired fan speed with (medium or max) and confirm with .

Boost is activated/disable (on/off) with the key.

A

SERVICE MENU: “OVERPRESSURE”

Time settings for Overpressure. Overpressure compensate is a special feature when supplementary heating

using an open fire or stove (the extract air fan drops to a lower speed during a specific time).

Press in order to go forward from the Main Menu. Press again and then

in order to choose the desired duration (5-60 min.).

D

16

SERVICEMENY: “ALARM”

Reset

Interval: 5 min.

Interval: 5 min.

Interval: 5 min.

2

2

2

Autom.reset: Off

Autom.reset: Off

In this menu alarm limits is set for Filter timer, Low temperature and setting for Fire sensor.

”Filter timer” can be set from ”Off” to ”6-12 months” and generates alarm for filter change.

Filter timer can not be used in combination with another filter measurement, see page 15.

We recommend filter change at least once a year.

To restart the filter timer press “Reset” with the -key.

Alarm limits for ”Low temperature”.

Alarm limit A: (+2 till +10ºC but must be lower than ”Alarm limit B”)

Alarm for low rotor temperature is displayed when the temperature is lower than set value. Normally nothing

needs to be done. If “Rotor Alarm” appairs at the same time as “Rotor temp. Low” the unit is stopped.

Alarm limit B: Supply air flow is reduced with one step when the temperature in supply air duct (GT7) is

lower than set value, and the temperature efficiency increases (the temperature can be change from +5 to

+12ºC but have to be higher than ”Alarm limit A”).

If the unit operating at Min. speed the extract air increases one step.

In menu ”Fire sensor” type of installed fire sensor is set.

Choose ”Normally open” NO or ”Normally closed” NC depending on the type of smoke detector.

Choose ”Autom.reset” On/Off.

SERVICEMENY: “CO2” Carbon dioxide level in PPM (part per million).

In this menu settings are made for regulation with installed CO2 sensor.

Press again and then in order to choose the Limit value (500-1400 PPM).

Press again and then in order to choose Interval (1-10 min.).

At levels above the limit value the fan speed will increase one step according to the set Interval value.

Current CO2 value is displayed in View mode 3, see page 10.

17

SERVICEMENY: “RH”

Interval: 5 min.

Interval: 5 min.

Interval: 5 min.

Afterblow: On

Afterblow: On

Afterblow: On

Relative air humidity in percent

In this menu settings are made for regulation with installed RH sensor.

Press again and then in order to choose the Limit value of boost (50%-100%).

®

HERU

AC: Press again and then in order to choose Interval (1-10 min.).

At levels above the limit value the fan speed will increase one step according to the set Interval value.

Current RH value is displayed in View mode 3, see page 10.

SERVICEMENY: “HEATER”

In this menu type of Heater is chosen to be activated.

If a heating coil is used a freeze protection sensor (GT5) must be installed, and a damper ST1 must be

mounted in the fresh air duct. The GT7 must be mounted after the Heater.

Press again and then in order to choose On or Off.

”Afterblow” function means that the fan continues to run for 2 min. when the unit is put Off,

if the heater is On.

SERVICEMENY: “COOLER”

In this menu a cooling coil can be activated if installed.

Press again and then in order to choose On or Off.

18

SERVICEMENY: “SUPPLY LIMITS”

5 5

5

Extract

Extract

Extract

Extract

Extract

Extract

Extract

Extract

In this menu the upper and lower limit value for the supply air temperature at room or exhaust air regulation is set.

Press again and then in order to choose a minimum limit value (15°C-19°C).

Press again and then in order to choose a maximum limit value (20°C-40°C).

SERVICEMENY: “REGULATION MODE”

3 different types of regulation modes can be used.

• At a constant supply air regulation the temperature sensor (GT7) is placed in the supply air duct and

a constant incoming air temperature is obtained.

• At room regulation a sensor (GT8) is placed in the room and a sensor (GT7) in the supply air duct

(minimum/maximum limitation) and then a constant room temperature is obtained (suitable when

a cooling coil is installed).

• The extract air regulation works in a similar way as the room regulation with the difference being that

the temperature is measured in the extract air duct.

Press again and then in order to choose Supply reg., Extract reg. or Room reg.

SERVICEMENY: “SUMMER COOLING”

If ”Summer Cooling” ”On” is chosen, the Summer cooling is activated when the extract air temperature is

higher than ”Extract HI” (19°C-26°C) and outside air is colder than ”Exhaust - ‘In OutDiff’ (1°C-10°C

difference between the temperature outside and extract air)".

Summer cooling is deactivated when extract air temperature is lower than ”Extract LO” (18°C-24°C)

or when the outside temperature is warmer than "Extract air - 'InOutDiff + 1,0ºC' ".

If Summer Cooling is activated, water cooling is disabled.

Press again and then in order to choose On or Off. In order to go forward in “Summer Cooling” press .

Cont. next line.

Cont.

5

Press again and then in order to choose 'InOutDiff': (1°C-10°C), Extract HI: (19°C-26°C)

and Extract LO: (18°C-24°C).

19

SERVICEMENY: “FREEZE PROTECTION”

Setting of limit value when freeze protection sensor is installed. The sensor (GT5) is installed on the return pipe

from the heating coil. When 3°C higher than set point the valve opens completely. If the temperature continues

to fall to set point the unit will stop.

Press again and then in order to choose Limit: (5°C-10°C).

SERVICEMENY: “FLOW DIRECTION”

Make settings if the supply air and extract air are connected on the right or left hand.

Supply air and extract air have to be connected on the same side of the unit.

®

Note! If HERU

is fitted with built-in electrical heater, this can not be done.

Press again and then in order to choose Left or Right.

SERVICEMENY: “LOAD/SAVE SETTINGS”

"Load/Save" gives the installer the opportunity to save the set values in service menu after the installation, alt.

load previously saved values.

Press again and then in order to choose Load Settings or Save settings.

After you have ”load” or ”Saved” it may take a minute before the unit re-created connection to the wireless

control unit and the right data is displayed.

SERVICEMENY: “VERSION INFO”

Displays the software version of the unit (Heru) and the wireless control (RC).

Press again to see the version.

20

SERVICEMENY: “DEVICE PAIRS”

Flödesriktning

Ladda/Spara

Version info

Manöverenhet

Manöverenhet

Ingen, starta!

Manöverenhet

V.g. vänta...

Manöverenhet

RC: (C91E)

Unit: (92ED)

Start Synkronisera

Flow directionFlow direction

Load/SaveLoad/Save

Version infoVersion info

Device pairsDevice pairs

Device pairsDevice pairs

None, press start!None, press start!

Device pairsDevice pairs

Please wait...Please wait...

Device pairs

RC: (C91E)

Unit: (92ED)

StartStart

A

A

Syncronise

Manöverenhet

RC: (C91E)

Unit: (92ED)

Device pairsDevice pairs

RC: (C91E)RC: (C91E)

Unit: (92ED)Unit: (92ED)

A

SyncroniseSyncronise

Synchronize

In this menu, the wireless control unit seeking the frequency that the control unit is using.

This procedure has to be used e.g. when a new wireless control unit has obtained.

Connecting a new wireless control unit:

First of all push the Reset button at the back of the antenna.

Use something with a sharp point. See picture.

Than cut the power to the unit and allow it to stand the rejection of an hour. B

efore the unit is connected, press ”Start” with the key in the “Device pairs” menu,

and connect the unit within 20 seconds.

Within seconds you will return to ”Service menu” and the wireless control unit is connected.

If you end up in ”Device pairs” instead of ”Service menu” the connection has failured.

Try one more time.

If the wireless control unit has been used in an assembly earlier, it will say ”Synchronize” instead of ”Start”.

”Modbus” is a function for data communcation. A special wireless control unit is required.

Modbus is available on one RS485 port. The baud rate is set from the wireless control unit. Communication

uses 1 start bit, 8 data bits, one stop bit and no parity.

Enabling Modbus: Modbus is enabled when the relay unit is paired with a ”modbus enabled” wireless control

unit. Normal wireless control units are not ”modbus enabled”.

Disabling Modbus: Modbus is disabled when the relay unit is paired with a normal wireless control unit.

OTHER FUNCTIONS

• Function test of rotor motor.

The rotor runs for three minutes every day at

12.03, if the rotor has not been operate for 24

hours.

• Function test of heating coil valves and cirkulation

pumps.

Once a week (Mondays at 12.09) there is a

maintenance program running in order to secure

functions of valves and pumps.

21

SERVICE HERU S

CLEANING/FILTER CHANGE

• The filters should be change once a year or at

alarm for filter change. When alarm for Filter

Change, this should be done as soon as possible; as

there otherwise is a risk that the adjusted flow is

not obtained.

• Always turn off the electrical supply and ensure

that it cannot be turned on.

• Open the lid by removing the four screws in

every corner. Do not remove the protective plates

that covers the fans and rotor.

• The filters are taken out by pulling them straight

out from their fastening strips .

When changing a filter it is also appropriate to

check if the fans are dirty.

• Remove the the fans and rotor\s protective plates

when the fans have stopped and the heater has cooled.

16

• The fans are taken out, after the quick connectors

have been disconnected , removing the screw

and pulling it straight out from the unit .

Dismount the motor plate from the fan housing

(the outer screws) and lift out the motor with the

fan wheel. If necessary the fan wheel and fan housing are wiped clean with a damp cloth. The interior of the unit housing can be wiped when necessary.

• If necessary the rotor 1 can also be dismounted

(see Dismounting).

6

16

4

1

15

3

12

15

1

16

6

2

2

3

7

8

9

10

11

22

SERVICE HERU S

5

4

BELT/TIGHTENING MATERIAL CHANGE

EQUIPMENT

- Screwdriver TX20 or screwdriver 1x5 (0,8x4)

- Screwdriver PH 1

- 2 Allen keys 6 mm (preferably with round head)

- Service kit 6000171 for HERU 14 S/19 S.

- Service kit 6000169 for HERU 35 S.

- Service kit 6000170 for HERU 52 S.

DISMOUNTING

1.Loosen electrical socket 1 and screw 1 2 and carefully pull out fans 2 .

2.Pull out the filters 3 .

3.Dismount sealing joints on both sides of the rotor

4 , 2 long and 2 short pieces with a PH1 screwdri-

5

ver.

4.Remove the tape that keeps the rotor tightening

material 5 in place, 2 pieces, and move them in

towards the centre of the rotor .

5.Lift off belt from the rotor motor 8 , disconnect

the electrical socket and loosen the ground

cable 9 .

6.Pull out the rotor motor from the grippers and

than dismount them .

7.For HERU

with bracket 13 with screwdriver TX20 and hang

it over the egde towards the fan.

8.Dismount the Allen screws 11 , 2 pieces that hold

the rotor. Lift out the rotor.

6

9

®

130/180 S EC loosen electrical socket

12

1

3

4

5

14

8

11

13

14

2

7

10

12

13

Change the rotor tightenings and the rotor belt.

MOUNTING

1.Lift the rotor into the box using the new belt.

2.Mount with Allen screws, distancers and tightenings.

3.Push out the rotor tightening material over the

edge onto the middle wall. Mount a new tape.

4.Push in the rotor motor in the grippers and lift the

rotor belt onto the belt pulley.

5.Mount electrical socket with bracket.

6.Mount the brush seals.

7.Mount filters and fans (carefully so there’s no damage to the seal trim).

8.Mount the electrical sockets. Check the function

of the fans and rotor before closing the lid.

14

23

ACCESSORIES

Room sensor (GT8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4020310

CO2 Room sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4020302

RH Room sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4020301

Freeze protection sensor (GT5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4020309

Extension cord for antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6010011

Heating coil, 5 kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9510101

Cooling coil, 2.5 kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9510134

HEATING COIL (5,0 kW)

Air

Flow: 0.20 m3/s

Speed: 2.2 m/s

Temp. in: 10°C

Temp. out: 30.5°C

Capacity: 5.0 kW

7/8

7

10

12

Hot water

Flow: 0.10 l/s

Speed: 0.86 m/s

Temp. supply pipe: 60°C

Temp. return pipe: 40°C

Pressure drop: 15.0 kPa

7/16

10

4/16

10

15

BATTERY PRESSURE DROP

13/16

COOLING COIL (2,5 kW)

Air

Flow: 0.20 m3/s 0,15 m3/s

Speed: 2.2 m/s 1,7 m/s

Temp. in: 25°C, 50% Rh 25°C, 50% Rh

Temp. out: 14.4°C 13.5°C

Capacity: 2.5 kW 2.0 kW

11/16

19

10

13

Cold water

Flow: 0.16 l/s 0.13 l/s

Speed: 0.8 m/s 0.6 m/s

Temp. supply pipe: 7°C 7°C

Temp. return pipe: 12°C 12°C

Pressure drop: 12.4 kPa 8.8 kPa

4/16

10

22

15

13/16

Dimensioning of Cooling/Heating coil should be performed by a qualified person.

24

SPARE PARTS

Rotor motor, complete, HERU 14 S/19 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6000066

Rotor motor, complete, HERU 35 S/52 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6000062

Service kit (belt+tightening), HERU 14 S/19 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6010171

Service kit (belt+tightening), HERU 35 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6010169

Service kit (belt+tightening), HERU 52 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6010170

Bagfilter F7 the same for supply and exhaust air, HERU 14 S/19 S . . . . . . . . . . . . . . . . . . . . . . . . . . .1250152

Bagfilter F7 the same for supply and exhaust air, HERU 35 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1250151

Bagfilter F7 the same for supply and exhaust air, HERU 52 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1250153

Fan, HERU 14 S AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7710256

Fan, HERU 19 S AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7710255

Fan, HERU 35 S AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7710258

Fan, HERU 52 S AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7710253

Fan, HERU S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7710249

Fan, HERU S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7710250

Fan, HERU S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7710251

Electrical heater, built-in, with triac switch, 1200 W, HERU 14 S/19 S . . . . . . . . . . . . . . . . . . . . . . . .6010063

Electrical heater, built-in, with triac switch, 1700 W, HERU 35 S . . . . . . . . . . . . . . . . . . . . . . . . . . . .6010061

Electrical heater, built-in, with triac switch, 1700 W, HERU 52 S . . . . . . . . . . . . . . . . . . . . . . . . . . . .6010068

Capacitor HERU 14 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4030087

Capacitor HERU 19 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4030086

Capacitor HERU 35 S/52 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4030088

Duct sensor (GT7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4020497

Contact your installer/dealer for order.

25

26

(120V).

27

ERROR DETECTION

Type of fault Check... Remedy

Nothing shows on the display. ...The batteries. Change the 3 AA batteries.

Can’t enter the menus, ...If keylock is activated. Disable, push the left buttom down for 3 seconds.

the keys are locked

"Please wait" is displayed. Wait for 15 minutes. If the message still twinkles,

...That the unit has power. Check the fuse, residual current device and connection.

...The antenna, it should not be mounted against Move the antenna.

any metal ductwork as this can shield the signal.

...That the wireless control unit is synchronized See page 21.

with the unit.

The unit does not start. ...That the unit has power. Check the fuse, residual current device and connecting.

...That the unit is ”On”. See page 13.

...That the unit is connected correctly. See page 36-37.

When the electrical supply is turned on the unit See page 13.

starts automatically with a few minutes delay.

...Other alarms. See below.

The unit has stopped. ...That the unit has power. Check the fuse and safety switch.

...If alarm is triggered. Check why the alarm is on.

...That the right flow direction is choosed. See page 20.

When starting the unit the ...If the unit is installed left or right handed. Set the flow direction. See page 20.

wireless control unit displays

wrong temperature alt. alarm

of to low temperature.

Can’t activate ...That pressure sensor is installed. Activate sensor. See page 15.

the filter measurement.

Other alarms:

Filter. ...If filters are dirty. Change filter.

...If the set time for filter measurement is reached Change filter.

go to next step.

When caused error is resolved, restore alarm.

After alarm reset, check so the rotor motor is rotating

and the fans spinning.

Sensor open. ...Which sensor is triggered, see page 13. Connection to relay card. If error remains,

...The menus for heater and regulation mode. Make the right setting for heater and regulation mode.

Sensor shorted. ...Which sensor is triggered, see page 13. Connection to relay card. If error remains,

Rotor stop. ...The Function of rotor, rotor motor, roror sensor Replace the faulty part.

and that the rotor belt is intact?

Overheating. ...If the heat protection of the duct heater is Restore the manual overheating protection and

triggered. NB! The unit must be currentless. reset the alarm.

Low supply air temperature. ...If filters are dirty. Change filter.

...If the rotor belt slips. Change rotor belt.

...If the duct heater works. Ensure function before startup.

...That the right flow direction is choosed. See page 20.

Low rotor temperature. ...If filters are dirty. Change filter.

...If the rotor belt slips. Change rotor belt.

Fire alarm. ...Why the fire alarm is triggered. Ensure function before startup.

Freeze protection. ...There’s enough heat to the heating coil. Ensure function of the heating coil before startup.

...The valve actuator opens as it should. Ensure function of the valve actuator before startup.

Motor failure. ...Power to the fans and quick connectors. Ensure function and change broken fan before startup.

...That the impeller is not blocked Ensure function before startup.

Supply or exhaust air is missing. ...The air intake. Clean intake grille if dirty.

or effeciency too high. ...Supply and exhaust air filters. Change filter

Effeciency too low. ...If filters are dirty.. Change filter.

...If extract air temperature is low. Check the installation.

Problem when adjusting ...That the function for summer cooling is ”Off”. See page 19.

the air flow.

Electric heater is not warm. ...If the heater is correct connected. See page 36-37.

...That electric heater is ”On” in the Service menu. See page 18.

change broken sensor.

See page 18-19.

change broken sensor.

If none of the adjoining information helps to start/clear up the error then contact your electrician/retailer.

28

INTERNAL SETTINGS AC

Fan speed:

Temperature:

Time:

Fan:

Time:

Sensor:

Filter measurement:

Fan speed:

Limit:

Ramp:

Limit:

Ramp:

Electric:

Water:

Cooler:

Min:

Max:

Regulation mode:

InOutDiff:

Extract HI:

Extract LO:

Limit:

Flow direction:

Servicemeny

Filtermätning

EC-motor setup

Display kontrast

Är du säker?

Bör endast ändras

av installatör!

Standard (%)

Tilluft: 60%

Frånluft: 70%

Minimum

Min: 20%

EC-motor setup

Standard

Min

Medium

Avbryt Ok

Standard

(konst.tr.)

Till: 90Pa (45%)

Från: 110Pa (50%)

Till konst.tr.

EC-motor setup

Standard

Min

Medium

Minimum

Min: 20%

Standard (%)

Tilluft: 60%

Frånluft: 70%

Pressure inputsPressure inputs

Filter measurementFilter measurement

EC fan setupEC fan setup

Display contrastDisplay contrast

Are you sure?

Should not be

changed by user!

Standard (%)

Sup: 60%

Exh: 70%

EC fan setup

Standard

Min

Medium

Cancel Ok

Standard (%)

Sup: 60%

Exh: 70%

F

(min, standard, medium or max.)

Default: Std.

(15°C-40°C)

Default : 20°C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(10-240 min.) Default: 30 min.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(medium or max) Default: Med.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(5-60 min.)

Default : 15 min.

(None, SW, -50/+50, 0/100 Pa)

Default: None.

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

(500-1400 PPM) Default: 900 PPM

(2-200%/h) Default: 50%/h.

(50%-100%) Default: 70%.

(2-200%/h) Default: 5 min.

(On/Off) Default: Off.

( On/Off) Default: Off.

( On/Off) Default: Off.

(15°C-19°C) Default: 15°C.

(20°C-40°C) Default: 25°C.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILTER CHANGE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(Off/On) Default: Off.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(Standard, Min, Medium, Max)

Default : Standard 30%, Min 20%,

Medium 50%, Max 80%.

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

(Constant Supply reg./Exhaust reg./Room reg.

Default : Const. supply reg.

(1°C-10°C) Default: 5°C.

(19°C-26°C) Default: 24°C.

(18°C-24°C) Default: 18°C.

(5°C-10°C)

Default : 10°C.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

(Right/Left)

Default : Right.

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

)

SERVICE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

DIMENSIONS (inch)

HERU 14 S/ 19 S AC

21

20

7/8

5/8

Ø 6

1/16

10

9/16

5

5

5/8

14

HERU 35 S AC

7/8

23

7/16

22

Ø 8

5/16

11

13/16

6

15/16

5

1/4

16

3/8

42

1/4

38

5/8

18

11/16

48

4/8

44

5/8

22

HERU 52 S AC

7/32

28

13/16

26

Ø 10

13/32

13

23/32

7

5/16

6

13/32

19

FLOW DIRECTION RIGHT

Exhaust air

27

Extract air

53

49

13/32

7/32

Fresh air

Supply air

30

TECHNICAL DATA

Data stated at 100 Pa external pressure drop. See below for explanation of Sound pressure level.

Voltageg, V/Hz 120/60 120/60 120/60 120/60

Fan Current, A (2 fans) 1,39 2,34 3,67 4,14

Total Current, A 11,5 12,4 17,9 18,4

Fan input, W (2 fans) 162 277 436 494

Total input, W 1389 1504 2163 2221

Current electric heater, A 10,0 10,0 14,2 14,2

Input electric heater, W 1200 1200 1700 1700

Speed, rpm 2610 2680 2830 2470

Weight, lbs 146 146 190 258

Duct connection, inch Ø6 Ø6 Ø8 Ø10

HERU 14 S HERU 19 S HERU 35 S HERU 52 S

31

SOUND DATA

The sound data have been compiled by means of sound measurement methods as follows: Pressure and flow: SS-ISO 5801.Determination of acoustic sound power level in

duct: SS-ISO 5136.Determination of acoustic sound power level in reverberation room:

SS-EN ISO 3741.

DESIGNATIONS

The table above present the total A-weighted sound power level, LwA, as well as in octave bands in dB(A) (ref 10

In the ”Technical Data”, the total sound pressure, LpA, calculated from the total surrounding sound power level, LwA, at 230 V is presented in dB(A) (ref 20 x 10

The relationen between sound pressure and sound power is

L

= LwA+ 10 x log +

pA

where Q is the propagation factor, r is the distance from the unit and A

valent absorbtion area.

When calculationg the L

which gives L

-12

W).

Q 4

4pr

( )

it has been assumed that Q=2, r=3 m and A

pA

» LwA- 7.

pA

-6

Pa).

2

A

Ekv

Ekv

Ekv

is the equi-

=20 m

2

,

Ljuddata har framtagits med följande standarder för ljudmätning:

Tryck och flöde: SS-ISO 5801. Bestämning av ljudeffektnivå i kanal: SS-ISO 5136.

Bestämning av ljudeffektnivå i efterklangsrum: SS-EN ISO 3741.

FÖRKLARINGAR

Tabellen ovan visar total A-vägd ljudeffektnivå, LwA, samt denna uppdelad i oktavband

i dB(A) (ref 10

x 10

Relationen mellan ljudtryck och ljudeffekt är

L

pA

där Q är riktningsfaktor, r är avstånd från aggregatet och A

area. Vid beräkning av L

att L

-12

W). I ”Tekniska Data”, återfinns total ljudtrycksnivå, LpA, i dB(A) (ref 20

-6

Pa) beräknat på den totala ljudeffektnivån för aggregatljud vid 230 V.

= LwA+ 10 x log +

» LwA- 7.

pA

Q 4

2

4pr

A

( )

Ekv

har det antagits att Q=2, r=3 m och A

pA

är ekvivalent absorbtions-

Ekv

Ekv

=20 m

HERU 14 S AC

120 V / 108 CFM 0,96 H2OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

Surrounding 41 48 33 44 44 38 34 35 28 27

Supply 71 61 61 66 65 62 58 57 48

Extract 60 42 50 57 55 39 35 27 16

100 V / 102 CFM 0,50 H

Surrounding 38 45 32 41 42 34 32 32 26 27

Supply 67 53 57 63 61 57 53 52 41

Extract 57 35 48 55 50 35 30 22 10

80 V / 76 CFM 0,26 H

Surrounding 35 42 30 39 36 30 27 29 26 27

Supply 61 49 51 57 54 50 48 45 29

Extract 50 30 43 48 44 30 26 15 6

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

2

, vilket ger

65 V / 55 CFM 0,12 H

Surrounding 32 39 24 36 32 27 23 26 25 27

Supply 54 45 47 48 47 43 40 40 16

Extract 43 27 39 39 36 24 20 11 5

50 V / 38 CFM 0,04 H

Surrounding 29 36 24 32 26 24 22 24 25 27

Supply 47 41 41 41 39 36 33 34 10

Extract 37 23 34 32 29 18 17 8 6

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

HERU 19 S AC

120 V / 153 CFM 1,12 H2OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

Surrounding 44 51 38 44 46 46 43 40 36 33

Supply 79 68 68 71 75 71 68 64 54

Extract 64 53 54 57 62 53 42 32 18

100 V / 133 CFM 0,72 H

Surrounding 43 50 32 47 43 43 39 36 32 30

Supply 73 58 62 67 68 66 63 59 48

Extract 60 41 52 55 56 49 39 27 15

80 V / 97 CFM 0,43 H

Surrounding 39 46 31 44 40 37 34 31 28 28

Supply 67 54 59 61 61 59 55 50 37

Extract 54 35 49 49 50 42 32 20 9

65 V / 70 CFM 0,20 H

Surrounding 39 46 26 43 40 33 29 28 27 28

Supply 62 54 56 56 54 52 47 41 28

Extract 50 35 45 45 44 35 25 15 8

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

50 V / 51 CFM 0,08 H

Surrounding 44 51 25 51 34 30 23 23 25 28

Supply 55 45 51 50 47 44 36 33 22

Extract 43 26 40 36 37 27 16 13 11

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

32

SOUND DATA

HERU 35 S AC

120 V / 210 CFM 1,45 H2OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

Surrounding 53 60 44 53 55 56 46 41 36 32

Supply 85 61 68 77 83 75 72 69 62

Extract 71 49 60 68 66 53 44 34 22

105 V / 212 CFM 0,78 H

Surrounding 49 56 39 53 49 50 43 37 32 30

Supply 78 56 65 70 75 70 67 64 57

Extract 66 49 57 62 62 49 39 30 19

95 V / 186 CFM 0,56 H

Surrounding 46 53 42 50 46 48 40 34 30 28

Supply 75 55 64 67 72 67 64 61 53

Extract 63 47 55 58 60 46 37 28 18

85 V / 153 CFM 0,38 H

Surrounding 43 50 32 47 43 43 37 30 27 26

Supply 71 53 63 64 67 62 60 57 47

Extract 61 46 57 55 55 44 34 27 18

75 V / 136 CFM 0,24 H

Surrounding 42 49 32 48 40 38 35 28 27 26

Supply 62 52 54 56 57 52 50 47 34

Extract 56 48 52 49 47 41 31 26 18

65 V / 110 CFM 0,14 H

Surrounding 35 42 30 39 35 34 34 26 26 26

Supply 62 52 54 56 57 52 50 47 34

Extract 50 41 44 45 42 41 30 26 18

50 V / 72 CFM 0,06 H

Surrounding 32 39 27 34 30 29 33 25 27 26

Supply 56 49 46 50 50 46 43 40 30

Extract 50 41 44 45 42 41 30 26 18

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

HERU 52 S AC

120 V / 155 CFM 1,20 H2OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

Surrounding 44 51 34 42 48 44 39 36 32 26

Supply 77 58 64 67 75 67 67 63 57

Extract 61 47 55 58 54 46 38 28 14

105 V / 155 CFM 0,56 H

Surrounding 43 50 34 41 47 43 39 36 31 26

Supply 74 54 60 62 72 65 62 59 51

Extract 59 45 52 54 55 43 34 24 11

95 V / 141 CFM 0,42 H

Surrounding 43 50 33 41 48 42 37 34 30 26

Supply 69 53 59 62 65 60 59 56 47

Extract 57 43 50 53 52 40 31 21 13

85 V / 116 CFM 0,30 H

Surrounding 41 48 31 39 46 42 35 32 28 25

Supply 65 52 54 59 60 56 56 52 43

Extract 54 43 48 51 44 38 28 18 9

75 V / 96 CFM 0,20 H

Surrounding 38 45 28 37 42 38 33 30 27 25

Supply 63 49 51 58 57 53 52 48 37

Extract 52 38 43 51 41 36 25 14 8

65 V / 77 CFM 0,12 H

Surrounding 34 41 25 37 34 33 28 25 25 25

Supply 58 47 47 54 53 48 47 42 31

Extract 48 35 40 45 37 35 21 12 8

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

50 V / 57 CFM 0,04 H

Surrounding 32 39 22 38 27 27 26 23 25 25

Supply 52 44 45 45 46 41 39 36 23

Extract 42 32 37 36 33 34 17 11 8

OLpALwATotal dB 63 Hz 125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

2

33

PRESSURE-FLOW DIAGRAMS

The pressure/flow diagrams applies to both supply and exhaust air. Indicated power applies to both fans together.

HERU 14 S AC HERU 19 S AC

PRESSURE-FLOW

PRESSURE-FLOW

TOTAL FAN POWER-FLOW

TEMPERATURE EFFICIENCY

TRANSFORMER STEP

1234 5

50 V 65 V 80 V 100 V 120 V

TOTAL FAN POWER-FLOW

TEMPERATURE EFFICIENCY

TRANSFORMER STEP

1234 5

50 V 65 V 80 V 100 V 120 V

34

PRESSURE-FLOW DIAGRAMS

The pressure/flow diagrams applies to both supply and exhaust air. Indicated power applies to both fans together.

HERU 35 S AC HERU 52 S AC

PRESSURE-FLOW

PRESSURE-FLOW

TOTAL FAN POWER-FLOW

TEMPERATURE EFFICIENCY

TRANSFORMER STEP / TRANSFORMATORSTEG

1234 567

50 V 65 V 75 V 85 V 95 V 105V 120 V

TOTAL FAN POWER-FLOW

TEMPERATURE EFFICIENCY

TRANSFORMER STEP / TRANSFORMATORSTEG

1234 567

50 V 65 V 75 V 85 V 95 V 105V 120 V

35

WIRING DIAGRAM 4040155

HERU 14 S AC/19 S AC

Yellow

Violet

Green

Fan motor

Fan motor

Fan motor

Yellow/green

Black

Blue

Brown

White

Orange

Grey

36

WIRING DIAGRAM 4040149

HERU 35 S AC/52 S AC

Fan motor

Fan motor

Fan motor

Yellow/green

Black

Blue

Brown

White

Orange

Grey

Green

Violet

Yellow

37

OSTBERG AMERICAS INC.

55 Raglin PL # 3 • Cambridge, N1R 7J2 • Canada

Phone 519-623-6363

Telefax 519-623-8543

www.ostberg.com

1270316 UL 11.12 Utg 1

Loading...

Loading...