ABB ZX0 Manual For Installation And Operation

Manual for installation and operation HB 600/05 en

ZX0 - block design

Gas-insulated medium voltage switchgear

Your safety first - always!

That‘s why our instruction manual begins with these recommendations:

− Operate the switchgear as prescribed for its intended purpose.

− Ensure that the technical data on the name plate and in the specification are not exceeded during operation of the switchgear.

− Only install the switchgear in enclosed rooms suitable for electrical equipment.

− With the aim of a smooth installation sequence and ensuring a high quality standard, have installation at site performed by

specially trained personnel or managed and supervised by the ABB Service Department.

− Ensure that installation, operation and maintenance are only performed by specialist electricians familiar with this manual.

− Comply in full with the legally recognized standards (IEC / DIN VDE), the connection conditions of the local electrical utility

and the applicable safety at work regulations.

− Follow the instructions in the documentation when performing any work on switching devices and switchgear.

− Keep all documentation accessible to all persons concerned with installation, operation and maintenance.

− The user’s personnel bear unlimited responsibility in all matters affecting safety at work and the correct handling of the

switchgear in accordance with EN 50110 and national regulations.

− Always observe the five safety rules set out in EN 50110 on establishing and securing the off-circuit condition at the place

of work for the duration of work on the switchgear. Gas-insulated switchgear are notable for maximum safety, as the circuitbreaker performs the earthing switch function in conjunction with the three position disconnector. The sequence of safety

rules therefore deviates from that proposed in the standard as follows:

Isolate,

Check the off-circuit condition,

Earth and short-circuit,

Secure to prevent reconnection,

Cover or guard off adjacent live

parts.

If you have any further questions on this manual, the members of our field organization will be pleased to provide the required information.

Contents

Page

Standards, regulations, notes, further documents 6

1 Despatch and storage 10

1.1 Condition on delivery 10

1.2 Delivery 10

1.3 Packaging 10

1.4 Handling 10

1.4.1 Handing by fork lift truck or trolley jack 10

1.4.2 Handling by crane 11

1.4.3 Handling by hydraulic lift trolley 12

1.5 Intermediate storage 13

2 Installation of the switchgear at site 13

2.1 Fundamental notes on installation work 13

2.1.1 General site requirements 13

2.1.2 Tightening torques 13

2.1.3 General information on treatment of plug-in connectors with silicone insulating parts 14

2.1.4 Handling sulphur hexafluoride (SF6) 16

2.2 Foundation bars 16

2.2.1 Installation of the standard foundation frame 17

2.3 Assembly of the switchgear 19

2.3.1 Preparatory work 19

2.3.1.1 Checking the SF6 pressure in the gas compartments 19

2. 3.1. 2 Greasing the foundation bars 20

2.3.1.3 Preparing the panel blocks 20

2.3.2 Erection of the panel blocks 21

2.3.3 Closure of extendable busbar sockets 25

2.3.4 Assembling the end covers 26

2.3.5 Handling of voltage transformers 27

2.3.5.1 Installation of plug-in voltage transformers 27

2.3.5.2 Wiring of voltage transformers 28

2.3.5.3 Dismantling of plug-in voltage transformers 33

2.4 Connection of cables and wiring 33

2. 4.1 Control cables and wiring 33

2.4.2 High voltage cables 34

2.5 Fitting blanking plugs 34

2.6 Connecting the main earthing bar 34

2.7 Concluding installation work 34

3 Commissioning 35

3.1 Conditions for commissioning of the switchgear 35

3.2 Energizing the system 36

4 Operation 37

4.1 Panels with circuit-breakers and three position disconnectors 37

4.1.1 Notes on earthing of a feeder panel or system section 37

4.1.2 Mechanism variants 40

4.1.2.1 Manual mechanism 1 40

4.1.2.1.1 Operation of the circuit-breaker 40

4.1.2.1.2 Operation of the three position disconnector 40

4.1.2.1.3 Emergency manual operation 42

4 | Manual ZX0 HB 600 en - Revision 05

Page

4.1.2.2 Manual mechanism 2 43

4.1.2.2.1 Operation of the circuit-breaker 43

4.1.2.2.2 Operation of the three position disconnector 44

4.1.2.2.3 Emergency manual operation 45

4.1.2.3 Motor operated mechanism 1 46

4.1.2.3.1 Emergency manual operation 46

4.1.2.4 Motor operated mechanism 2 49

4.1.2.4.1 Operation of the circuit-breaker 49

4.1.2,4.2 Manual operation of the three position disconnector 49

4.1.2.4.3 Motorized operation of the three position disconnector 49

4.1.2.4.4 Emergency manual operation 51

4.2 Panels with three position switch-disconnectors 52

4.2.1 Notes on earthing of a feeder panel or system section 52

4.2.2 Manual mechanism 53

4.2.3 Motor operated mechanism 53

4.2.4 Emergency manual operation of the motor operated mechanism 53

4.3 Panels with three position switch-disconnectors with HRC fuses 54

4.3.1 Notes on earthing of a feeder panel or system section 54

4.3.2 Manual mechanism 55

4.3.3 Motor operated mechanism 55

4.3.4 Emergency manual operation of the motor operated mechanism 55

4.3.5 Replacement of HRC fuses 56

4.4 Observation of the display and monitoring facilities 61

4.4.1 Gas monitoring with density sensors 61

4.4.2 Gas monitoring with pressure gauge 61

4.5 Operation of the isolating device for voltage transformers 62

5 Test procedures 64

5.1 Testing for the off-circuit condition 64

5.1.1 LRM system 64

5.1.2 KVDS and CAVIN systems 64

5.2 Testing for the in-phase condition 65

5.3 High voltage tests 65

5.3.1 Cable tests with DC voltage 65

5.3.2 Voltage test of the main circuit 66

5.4 Secondary protection testing 67

5.5 Protection testing by primary current injection 67

6 Maintenance 68

6.1 Inspection of the switchgear 68

6.2 Maintenance of the switching devices and their operating mechanisms 68

7 Actions at the end of the service life 68

8 List of tools 69

9 Working materials, auxiliary materials and accessories 70

9.1 Working materials 70

9.2 Auxiliary materials 70

9.3 Accessories 71

10 Technical data 72

Manual ZX0 HB 600 en - Revision 05 | 5

The relevant standards for switchgear over 1 kV and their switching devices

IEC

Switchgear 62271-1 Common specifications for high-voltage switchgear and controlgear standards

Switchgear 62271-200

Circuit-breaker 62271-100

Disconnector and earthing switch 62271-102

High-voltage switchgear and controlgear, Part 200: A.C. metal-enclosed switchgear and

controlgear for rated voltages above 1 kV and up to and including 52 kV

High-voltage switchgear and controlgear

Part 100: High voltage alternating current circuit-breakers

High-voltage switchgear and controlgear

Part 102: Alternating current disconnectors and earthing switches

Switch disconnector 60265-1 High-voltage switches - Part 1: Switches for rated voltages above 1 kV and less than 52 kV

Switch disconnector – fuse

combination

62271-105

High-voltage switchgear and controlgear

Part 105: Alternating current switch-fuse combinations

HRC - fuses 60282 High-voltage fuses - Part 1: Current-limiting fuses

Take particular account of the relevant standards listed below. Observe the national technical specifications and the accident prevention

regulations of the country in which the switchgear is operated.

IEC 60364 Low-voltage electrical installations

IEC 61936 Power installations exceeding 1 kV a.c.

DIN EN 50110 Operation of electrical installations

National technical accident prevention regulations e.g. for electrical systems and equipment and SF6 installations

6 | Manual ZX0 HB 600 en - Revision 05

Fundamental notes on this manual:

Read the relevant sections of this manual through in full before performing work, so as to ensure correct handling.

Paragraphs in this manual are marked in accordance with their significance. The markings mean the following:

Hazard warning, meaning in this manual that death or serious injury and considerable damage may occur if the

actions described are not performed.

Important note, meaning in this manual that injury and damage may occur if the actions described are not performed.

?

Attention is drawn to further documents.

&

Note on safety

The internal arc classification to IEC 62271-200 confirms a tested degree of operator protection. The information on accessibility of the

switchgear as required by IEC 62271-200 can be found on the type plates of the panels. The coding is as follows (exemplary):

IAC AFLR 31,5 kA 1 sec

Duration of fault current

Level of fault current

Successfully tested accessibility of the area behind the switchgear (R – rear, only with pressure

relief duct and enclosed cable termination compartment))

Successfully tested accessibility of the area to the side of the switchgear (L - lateral)

Successfully tested accessibility of the area in front of the switchgear (F- front)

Switchgear installed in closed rooms with access restricted to authorised personnel

Internal arc classification

The operator of the switchgear must prevent access by personnel to non-arc classified areas, for instance by issuing

instructions.

Within the ratings stated on the type plate, the switchgear is safe for operating personnel in accordance with IEC

62271-200 when all system components are completely and properly installed.

Commissioning, servicing and extension work require special attention with regard to safety (see also IEC

62271-20 0 ).

Operator safety in accordance with IEC 62271-200 assumes that the conditions stipulated by us are complied with (see also Technical

Catalogue TK 500).

The IAC qualification relies on a system consisting of at least three panels.

1)

At a room height of at least 2400 mm and a short-circuit current ≤ 21 kA (only possible with wall installation), the length of the switchgear system

must be at least 1600 mm.

1)

Manual ZX0 HB 600 en - Revision 05 | 7

You have chosen a gas-insulated switchgear of series ZX0 in block

design. This switchgear from the ZX range is notable for the following features:

Please observe further documents in addition to this manual. The

documents relevant to your switchgear are part of the final documentation.

− SF6 gas-insulated with hermetically sealed pressure

systems

− Rated voltages up to 24 kV

− Up to 1250 A and 25 kA

− Single busbar design

− Up to six panels grouped together in a block (one common

gas compartment)

− Stainless steel enclosures, fabricated from laser cut sheet

steel

− Modular structure

− Switchgear with a leakage rate of less than 0.1 % per year

− Integrated routine leakage testing of the panel blocks exworks

− Indoor installation and free-standing installation

− Wall installation

− Panel widths 400 mm and 600 mm

& Installation checklist MC 600 E

& Order documents

− Single line diagram

− Front view

− Construction data if compiled specifically

for this order

− Circuit diagrams

− Earthing diagram – switchgear earth

to station earth (not part of ABB supply)

& Instruction manuals

− Use of SF6 insulating gas HB 605 E

− Circuit-breaker VD4 X0 BA 440 E

− Snap-action mechanism for

switch-disconnector BA 445 E

− Stored-energy spring mechanism for

switch-disconnector with fuse BA 446 E

− Material supplement BA 509 E

& Operating instructions and directions for components,

e.g.

− Surge arresters

− Current and voltage transformers

− Current and voltage sensors

− Protection and control devices

− Capacitive indicators.

Do not use cleaning agent containing chlorine for cleaning the switchgear.

If you have technical questions, please contact our service staff

Power technology customer service Call number +49 180 6222-007

8 | Manual ZX0 HB 600 en - Revision 05

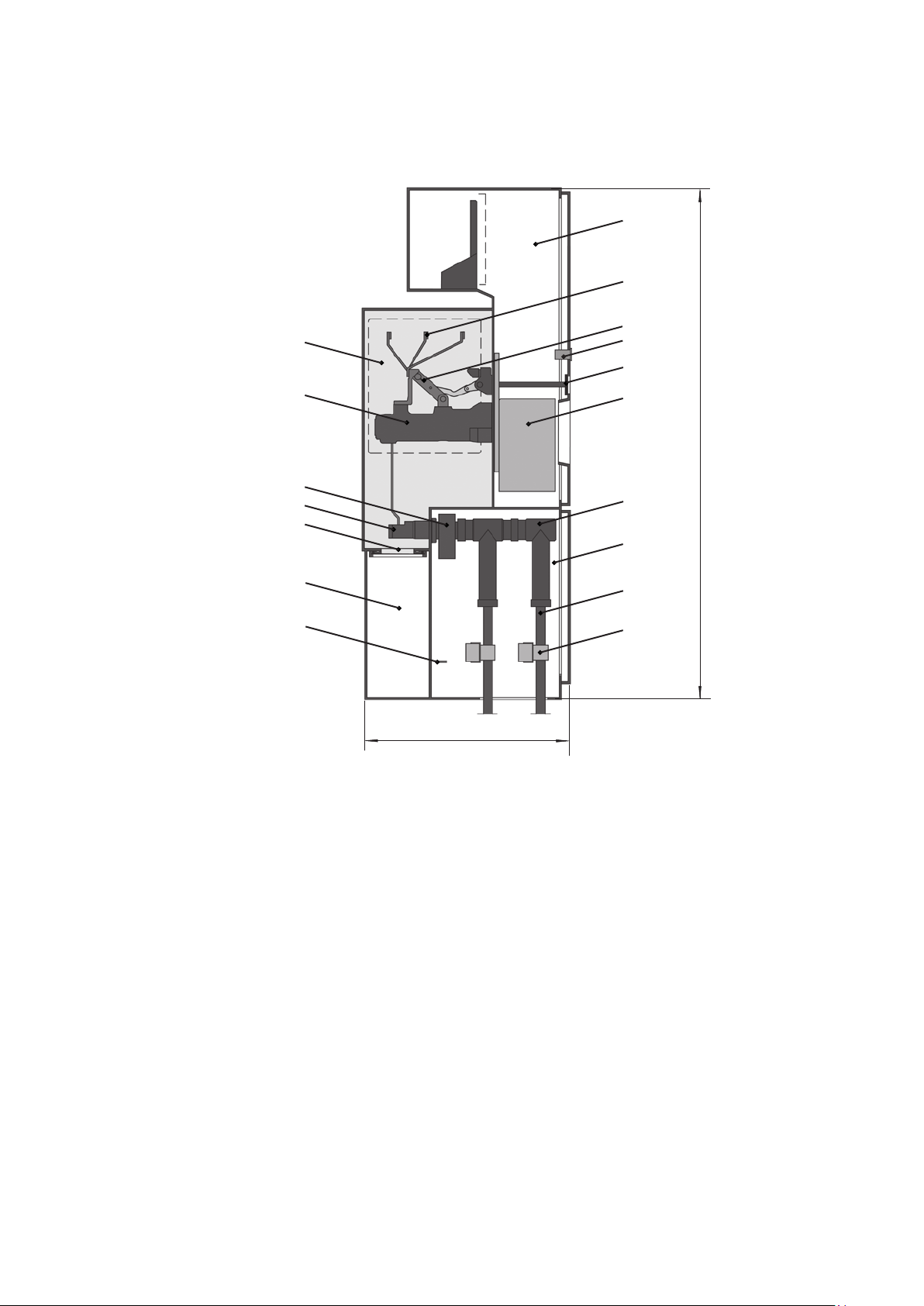

Fig. 1: Circuit-breaker panel, 800 A, panel width 400 mm, example configuration

1.0

6.0

2.1

2.3

1.5

2.4

1.1

1.9

1.3

1.13

4.0

3.5

1.2

2100 mm (2250 mm)

3.1

3.0

3.2

3.3

850 mm

1.0 Panel module

1.1 Circuit-breaker pole

1.2 Circuit-breaker operating

mechanism

1.3 Outer cone

1.5 Sockets for capacitive voltage

indicator system

1.9 Current transformer

1.13 Pressure relief disk

2.1 Busbar

2.3 Three position disconnector

2.4 Operating mechanism for three

position disconnector

3.0 Cable termination compartment

3.1 Cable connector

3.2 High voltage cable

3.3 Cable clamp

3.5 Main earthing bar

4.0 Pressure relief compartment

6.0 Low voltage compartment

Manual ZX0 HB 600 en - Revision 05 | 9

1. Despatch and storage

The possible packaging methods are as follows:

− No packaging

1.1 Condition on delivery

− The panels have been assembled into system blocks ready

for operation.

− The panel blocks have been routine tested to IEC 62271-

200.

− The busbar sockets are sealed with plastic film to protect

them during transport.

The busbar sockets are not shockproof in this

transport condition. Do not operate the switchgear

with sealed busbar sockets (e.g. on extendable end

panels). Close off unused busbar sockets with shockproof

blanking plugs (see section 2.3.3).

− In normal cases, the gas compartments have been filled

with sulphur hexafluoride (SF6) insulating gas to the rated

filling pressure. When airfreighted, however, the panel

blocks are delivered with reduced pressure.

− If delivered by airfreight, increase the pressure to the

rated filling pressure before installing the panels (see

instruction manual HB 605 E for the procedure to be

adopted).

− Packaged in plastic sheeting

− Packaged in plastic sheeting and surrounded by protective

cardboard

− Heat sealed in plastic sheeting with drying agent enclosed

− Packaged in aluminium foil in transport crate with drying

agent enclosed

1.4 Handling

− The transport units are the panel blocks.

− Always handle the panel blocks in the upright position.

− Take account of the weight of the transport units when

selecting the handling equipment.

Due to the high centre of gravity of the panel blocks,

there is a risk that the transport units may tip over! Take

all precautions to protect personnel and the materials

transported.

Only ever handle the panel blocks by

− The installation material and accessories and the documentation are packaged separately from the panel blocks.

1.2 Delivery

Check the consignment for completeness and freedom from damage. Document any transport damage found on the waybill and

inform us of it immediately. Take photographs of the damage.

1.3 Packaging

The panel blocks have been prepared for transport by the agreed

method and for the desired duration of any interim storage required. Details of the length of preservation and the storage location (indoors or outdoors) can be found in the order documents. If

the panel blocks are packaged, they are mounted on a pallet and

secured to prevent them from slipping.

− fork lift truck,

− trolley jack,

− crane, or

− hydraulic lift trolley.

1.4.1 Handling by fork lift truck

or trolley jack

The panel block must be standing on a pallet. The pallet

must rest fully on the forks of the truck or jack. The high

centre of gravity means there is a high risk of tipping.

Avoid jerky motions.

10 | Manual ZX0 HB 600 en - Revision 05

1.4.2 Handling by crane

− The methods of handling by crane differ, depending on

the width of the panel blocks. Up to a block width of 1 m,

there are lugs on the top of the panel modules for fastening

of the suspension ropes (figure 1.4.2.1), and from a width

of 1.2 m upwards there are transport crossbeams with lugs

for fastening of the suspension ropes located at the bottom

(figure 1.4.2.2).

− Attach suspension ropes of a sufficient load bearing capacity (see section 10, Technical data, for the panel weights) to

the lugs with shackles (figure 1.4.2.1). The ABB scope of

supply does not include suspension ropes and shackles.

Fig. 1.4.2.1: Crane handling of a block with width up to 1 m Fig. 1.4.2.2: Crane handling of a block with width of 1.2 m and more

Manual ZX0 HB 600 en - Revision 05 | 11

1.4.3 Handling by hydraulic lift trolley

− Attach one hydraulic lift trolley (figure 1.4.3.1) of suitable

load bearing capacity to each of the left and right sides

of the panel block in accordance with the manufacturer’s

instructions.

The high centre of gravity means there is a high risk

of tipping. Avoid jerky motions!

Fig. 1.4.3.1: Handling by hydraulic lift trolley

12 | Manual ZX0 HB 600 en - Revision 05

1.5 Intermediate storage

− Store the panel blocks in the upright position.

2. Installation of the

switchgear at site

− Do not stack the panel blocks.

− Protect the transport units from damage.

The conditions for optimum intermediate storage without

packaging or with basic packaging are as follows:

− The storeroom must comply with the normal operating

conditions for a switchgear installation (see IEC 62271-1).

− Cover the unpackaged panel blocks with protective sheeting, remembering to preserve sufficient air circulation.

− cccc

The conditions for optimum intermediate storage with

packaging and preservation are as follows:

− Check the packaging for damage.

− Store the transport units in a dry place protected from the

weather.

− Contact us if

2.1 Fundamental notes on

installation work

2.1.1 General site requirements

At the start of installation, the switchgear room at site must be

complete and fitted with lighting and power for the installation

work. It must also be lockable, dry, and with good ventilation facilities. All necessary provisions such as openings, ducts, etc. for

laying of the power cables must already be in place. Compliance

with the conditions for indoor switchgear to IEC 62271-1 must be

ensured.

2.1.2 Tightening torques

Use DIN screws of tensile class 8.8. Use the tightening torques

stated in table 2.1.2.1. The tightening torques apply to unlubricated screw connections.

− the storage life of the preservation is exceeded,

− the packaging with preservation is damaged.

Please consult the manufacturer’s installation instruc-

&

and surge arresters.

Table 2.1.2.1: Tightening torques

Nut on studbolt 12,5

Steel screw in pulling nut 18 - 24

Screw in inner cone socket 20

Other screws of tensile class 8.8 26 50

tions for the tightening torques of cable connectors

M 8 M 10

Manual ZX0 HB 600 en - Revision 05 | 13

2.1.3 General information

on treatment of plug in connectors with

silicone insulating parts

This section generally explains the procedure for treatment of sili-

cone insulating parts in the busbar sockets, blanking plugs for the

busbars, the silicone insulating parts on plug-in voltage transformers and blanking plugs for voltage transformer sockets. Only treat

the silicone parts immediately before use. Section 2.3 indicates

when the treated silicone parts are needed.

Please consult the documents from the cable connector manufacturer for details of the treatment procedure for silicone insulating

parts on the cable connectors.

− Remove surplus or dirty grease from the silicone part with

a soft, clean, non-fraying cloth.

− Clean the silicone insulating part when required with intensive cleaner M.X.T. 60 forte and a soft, non-fraying cloth.

Only use intensive cleaner M.X.T. 60 forte as the

?

− Only moisten the cloth slightly with intensive cleaner. Apply

only moderate pressure when cleaning the insulating parts

of busbar connections. Do not wipe from the black areas

towards the light insulating surfaces. By adopting this procedure you avoid transferring black, conductive material

onto the light, insulating area.

− After cleaning with intensive cleaner M.X.T. 60 forte, wipe

the silicone insulating part with a dry cloth.

cleaning agent.

− Perform the following work to prepare silicone insulating

parts for assembly:

− Inspect the silicone insulating parts

− Clean soiled silicone insulating parts

− Grease the insulating parts

− Clean the sockets, the contact tubes and the outer cone

Inspecting the silicone insulating parts

Only remove the relevant component from its protec-

?

?

?

with our service department.

tive packaging immediately before assembly.

Check the silicone insulating part for damage prior to

installation.

If you note any damage on the silicone insulating part,

only use the component after this has been agreed

As the cleaner causes the silicone to swell slightly, it

?

Greasing the insulating parts

Grease the components immediately before use as follows:

Use the quantities of assembly paste listed in table 2.1.3.1.

− Silicone insulating parts on the busbar connection:

Evenly grease the light, outer areas of the silicone part as

shown in figure 2.1.3.1.

− Blanking plugs for the busbar connection:

Evenly grease the light, outer areas of the silicone part as

shown in figure 2.1.3.2.

− Silicone insulating parts of plug-in voltage transformers or

test plugs:

Evenly grease the silicone part as shown in figure 2.1.3.3.

− Silicone insulating parts of the blanking plugs for voltage

transformers sockets:

Evenly grease the silicone part as shown in figure 2.1.3.4.

then has to dry for approx. 15 minutes in the air.

The silicone surface must be free of

− gas bubbles,

− scoring,

− damage,

− abrasions,

− foreign bodies.

Cleaning of soiled silicone insulating parts

− Perform cleaning work immediately before assembly of the

relevant component as follows:

14 | Manual ZX0 HB 600 en - Revision 05

Table 2.1.3.1: Quantities of assembly paste for silicone insulating parts

Component

Silicone insulating part on the

busbar connection, both

Blanking plugs for the busbar

bushing, silicone insulating parts

of voltage transformers or blanking

plugs for voltage transformer

sockets

Quantity of assembly paste to be

used

Approx. 20 g each

insulating part

Approx. 10 g

each part

Cleaning the sockets, the contact tubes and the outer

cone

− Degrease and clean the mating piece for the silicone

insulating part (the busbar socket or socket for the voltage

transformer) with intensive cleaner M.X.T. 60 forte.

− Clean the outer cone on the cable connector with intensive

cleaner M.X.T. 60 forte.

Assemble the components immediately to avoid

?

soiling.

Fig. 2.1.3.1: Greasing the light, outer areas of the silicone insulating part on

the busbar connection

Fig. 2.1.3.2: Greasing the light, outer area of the blanking plug for the busbar bushing in the area between the arrows

Fig. 2.1.3.3: Greasing the silicone insulating part of the voltage transformer

in the area between the arrows

Fig. 2.1.3.4: Greasing the silicone insulating part of the blanking plug for

voltage transformer sockets in the area between the arrows

Manual ZX0 HB 600 en - Revision 05 | 15

2.1.4 Handling sulphur hexafluoride

(SF6)

As a rule, no gas work is required during installation.

We recommend that gas work should only be performed by personnel trained in the handling of SF6.

Gas may only be extracted by certified personnel.

See manual HB 605 “Use of SF6 insulating gas” for details on

handling SF6.

2.2 Foundation bars

− When a raised false floor is used, load-bearing sections of

the floor frame serve as supports for the panel blocks. No

additional foundation frame is necessary.

The slabs of the raised false floor must be fas-

?

− If there is a concrete floor and the switchgear consists of

several panel blocks (with busbar connections), a foundation frame is required. Standard foundation frames supplied by ABB must be embedded in the floor topping.

?

raised false floor:

− Evenness tolerance: ± 1 mm / m

− Straightness tolerance: Max. 1 mm / m, but max. 2 mm for

the entire length

&

If no standard ABB foundation frames are used, observe the relevant construction and laying drawings for the special frames.

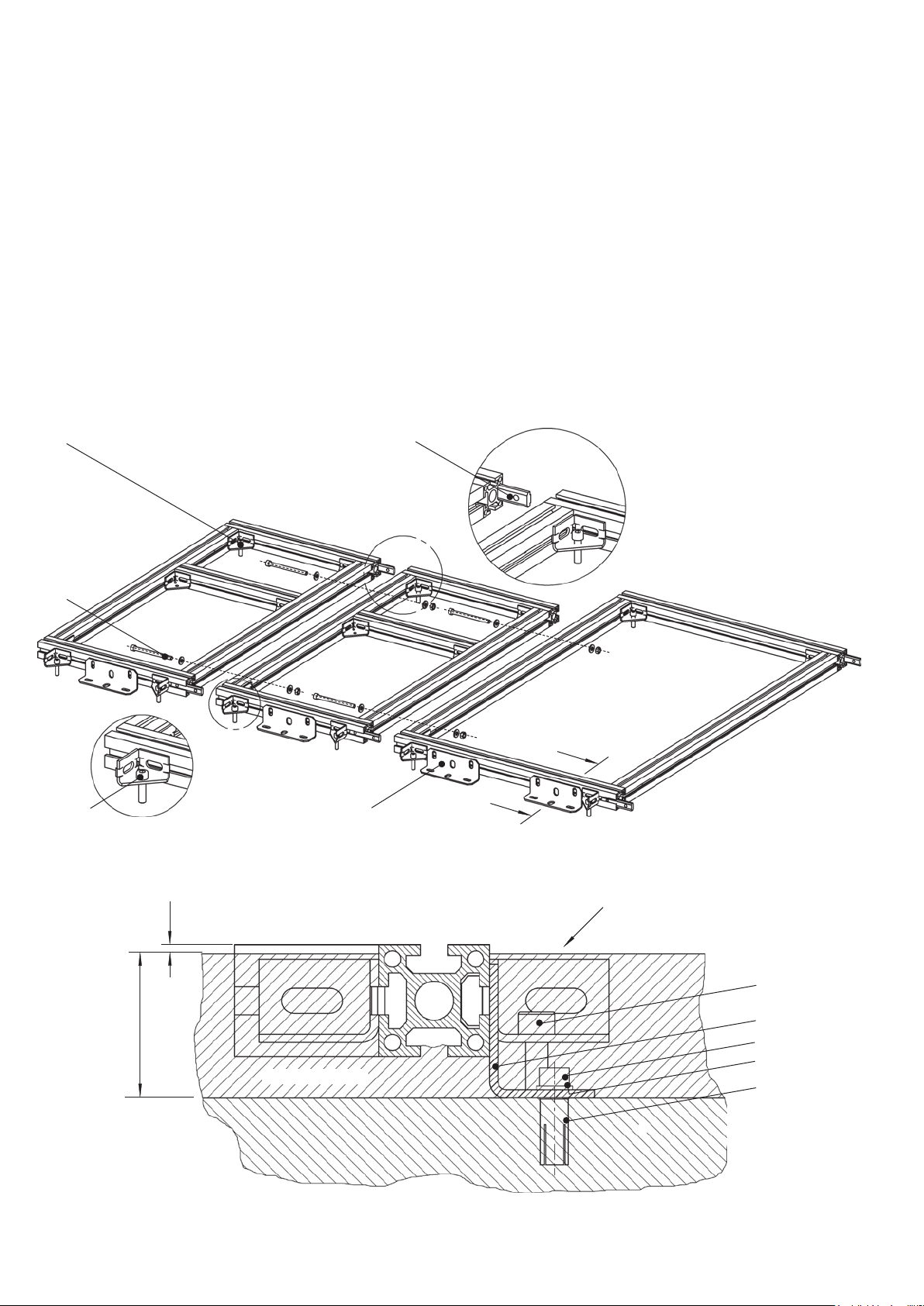

The standard foundation frames are shown in figure 2.2.1.

tened to the supporting frame.

Maintain the following evenness and straightness tolerances when installing the foundation frame or a

Consult the order documents for the position of the

foundation bars in the switchgear room.

Fig. 2.2.1: Foundation frames, top view

a)

(400 mm)

rear side

b)

(814 mm)

(814 mm)

(400 mm)

front side

a) For feeder panels, width 400 mm

b) For metering, sectionalizer and riser panels, width 400 mm

16 | Manual ZX0 HB 600 en - Revision 05

c)

rear side

d)

rear side

(965 mm)

(600 mm)

front side

c) For panels of 600 mm width

d) For air-insulated metering panels, width 1000 mm

2.2.1 Installation of the standard

foundation frame

(890 mm)

(1000 mm)

front side

Standard foundation frames are delivered to site completely preassembled.

Installation principle:

The foundation frames are bolted together at the front and rear.

Vertical alignment is effected by jacking screws. Brackets are

used to fasten the frames to the floor. The foundation frames are

finally embedded in the floor topping to provide their load bearing

capacity.

Detailed description of installation

(Fig. 2.2.2.1)

- Position the foundation frame sections in the correct loca-

tions on the concrete floor.

- Align the foundation frame vertically with the four screws

(1), taking account of any deviation in floor level in the

direction of the foundation frames which are still to be laid.

- Fasten the brackets (2) of the foundation frame to the

floor, using one knock-in anchor (5) and one screw (3) with

dished washer (4) for each bracket.

- Slide a slot rod (6) into the front slot of the front section

and, if the rear sections of the two frames to be connected

are aligned (i.e. have the same depth) a slot rod into the

rear slot of the rear section. Tighten the grub screws in the

slot rods.

- Place the following foundation frame in the correct position

on the floor, allowing the inserted slot rods to slide into the

sections of the frame to be installed. Bolt the foundation

frames together with two M 8 x 100 cheese head screws

(7) and nuts and washers. Tighten the grub screws in the

slot rods.

- Align the foundation frame vertically as described above

and fasten it to the floor.

- Install the following foundation frames in the same way.

Manual ZX0 HB 600 en - Revision 05 | 17

- Earth the completely assembled frame. Further details on

this can be found in the order documents.

When applying the floor topping, carefully fill under

?

Fig. 2.2.1.1: Installation of the floor frame

the foundation frame with topping material.

1

7

1

1

A

A

2

Section A-A

Top of finished floor

< 3

55 ± 5

18 | Manual ZX0 HB 600 en - Revision 05

Floor topping

1

2

3

4

5

2.3 Assembly of the

switchgear

2.3.1 Preparatory work

− Remove the protective cap (2) from the filling connector (1)

by turning it counter-clockwise.

Do not press the valve pin (3) in, as otherwise gas will

?

− While pulling the locking ring (4) outwards, press the coupling of the pressure gauge (5) into the filling connector.

flow out of the valve.

2.3.1.1 Checking the SF6

pressure in the gas

compartments

Each panel block (= delivery unit) forms a gas compartment and is

fitted with one filling connector. The filling connectors are located

in the low voltage compartments and are accessible from the front

when the low voltage compartment door is open.

− Check the gas pressure in each gas compartment with

a temperature-compensated pressure gauge (see list of

tools) before aligning and connecting the panel blocks, as

follows:

Fig. 2.3.1.1.1: Filling connector (1) with protective cap (2) in the low voltage

compartment

1

− Check the reading on the scale of the pressure gauge.

The reading must be in the green area of the instru-

?

than 1000 m, please contact us.

− Remove the pressure gauge by pulling out the locking

ring on the filling connector.

− Screw the protective cap onto the filling connector.

Fig. 2.3.1.1.2: Filling connector (1) with valve pin (3)

ment’s scale. If it is not, or if the site altitude is greater

1

2

Fig. 2.3.1.1.3: Filling connector with pressure gauge (5) and locking ring (4)

4

5

3

Manual ZX0 HB 600 en - Revision 05 | 19

2.3.1.2 Greasing the foundation bars

For standard foundation frames supplied by ABB, remove the

protective film. Grease the top surfaces of the foundation frame or

raised false floor beams. This facilitates erection and alignment of

the panel blocks.

2.3.1.3 Preparing the panel blocks

− Remove the covers from the cable termination compartments on all panel blocks.

− Screw guide pins to the side of the panel block to be extended, using a threaded plate (see figure 2.3.1.3.1).

In the cases of sectionalizer, riser or metering panels, there is

a second fastening bracket below the busbar bushings. Fit the

guide pins to this fastening bracket using a threaded plate (figure

2.3.1.3.3).

Guide pins are only to be fitted to one of the panel

?

guide pins remain in the relevant position after erection of the

panel blocks and must not be removed.

− Lightly grease the guide pins for better sliding.

block at the joint between two panel blocks. The

Fig. 2.3.1.3.1: Fitting the guide pins using a threaded plate

Fig. 2.3.1.3.2: Fitted guide pins

Fig. 2.3.1.3.3: Position of the guide pins in sectionalizer, riser and metering

panels

20 | Manual ZX0 HB 600 en - Revision 05

2.3.2 Erection of the panel blocks

- Set up the furthest panel block precisely at the specified

position.

When the standard foundation frame is used:

- Insert M 8 T-nuts through the holes in the floor plates into

the slots in the foundation frame sections. Join the floor

plates using washers (1 x washer 8.5 x 30 x 3 and 1 x

dished washer 8) and M 8 x 16 cheese head screws to the

previously positioned T-nuts (Fig. 2.3.2.1and Fig. 2.3.2.2).

Fig. 2.3.2.1: View of the fastening points for the panels

400 mm

- Each panel is fastened to the foundation frame with four

screws (Fig. 2.3.2.1).

When a special foundation frame or raised false floor is used:

Fasten the panels in accordance with the instruction

&

documents supplied.

Section A-A

Panel floor

(simplified)

Coupler panel

Riser panel

Metering panel

T-nut M8

Feeder panel

400 mm

600 mm

Washer 8,5 x 30 x 3

Dished washer

Cheese head screw

M8 x 16

Floor frame

A

A

Manual ZX0 HB 600 en - Revision 05 | 21

Fig.. 2.3.2.1: Fastening the panel to the foundation frame

Slot in the foundation frame section

T-nut, M8

Fastening of the panel to the foundation frame

22 | Manual ZX0 HB 600 en - Revision 05

− Check the position of the panel block and align the panel

block to the precise dimensions if necessary.

− Tighten the fastening screws in the panel block.

Increased force is required to overcome the spring

?

before the contact tube can be pressed into the socket up to

the stop.

force of the spiral contact inside the busbar socket

− Remove the protective film from the busbar sockets on the

panel block which has been erected and the next panel

block to be erected (figure 2.3.2.2).

− Prepare the silicone insulating parts, contact tubes and

busbar sockets for the busbar connection between the two

panel blocks as described in section 2.1.3.

− Insert the contact tubes into the busbar sockets of the

panel which has been erected until they reach a tangible

stop (figure 2.3.2.3).

Fig. 2.3.2.2: Protective film for busbar sockets

− Carefully insert the silicone insulating parts into the busbar

sockets of the panel block which has already been erected.

(figure 2.3.2.4).

Align the contact tubes horizontally.

?

Fig. 2.3.2.4: Fitted contact tubes and silicone insulating parts

Fig. 2.3.2.3: Inserting a contact tube

Fig. 2.3.2.5: Positioning of the panel block to be erected

Manual ZX0 HB 600 en - Revision 05 | 23

− Slide the extension panel carefully against the existing system without tipping it, in such a way that the contact tubes

slide into the busbar sockets and the guide pins into the

corresponding bores in the fastening bracket.

Apply drawing or pressing tools to a large area on

?

instance by using a wooden beam between the tool and the

panel block) so as to avoid damage to the panel block.

− As soon as the distance between the two panel blocks is

small enough, insert two M10 x 40 cheese head screws

into the bores provided in the fastening bracket. Dismantling the lid in the rear wall of the low voltage compartment

the panel blocks directly above the floor (for

facilitates access to the front screw connection from inside

the low voltage compartment (figure 2.3.2.6).

− The rear screw connection is located behind the low voltage compartment. Turn both the screws into the pulling

nuts on the previously assembled threaded plate and

tighten the screws alternately (figure 2.3.2.7 ).

− Connect the low voltage compartments and cable termination compartments of the two panel blocks at the specified

locations (figure 2.3.2.8) with the aid of screws.

Fig. 2.3.2.6: Screw connections between the panel blocks: Accessibility of

the front screw connection from the inside of the low voltage compartment

Tool inside

the low voltage compartment

Fig. 2.3.2.7: Complete screw connections on the fastening brackets

Fig. 2.3.2.8: Further fastening points on the panel blocks

24 | Manual ZX0 HB 600 en - Revision 05

Fig. 2.3.2.9: Screwing the low voltage compartments together

Loading...

Loading...