Page 1

Technical Datasheet Catalogue Page

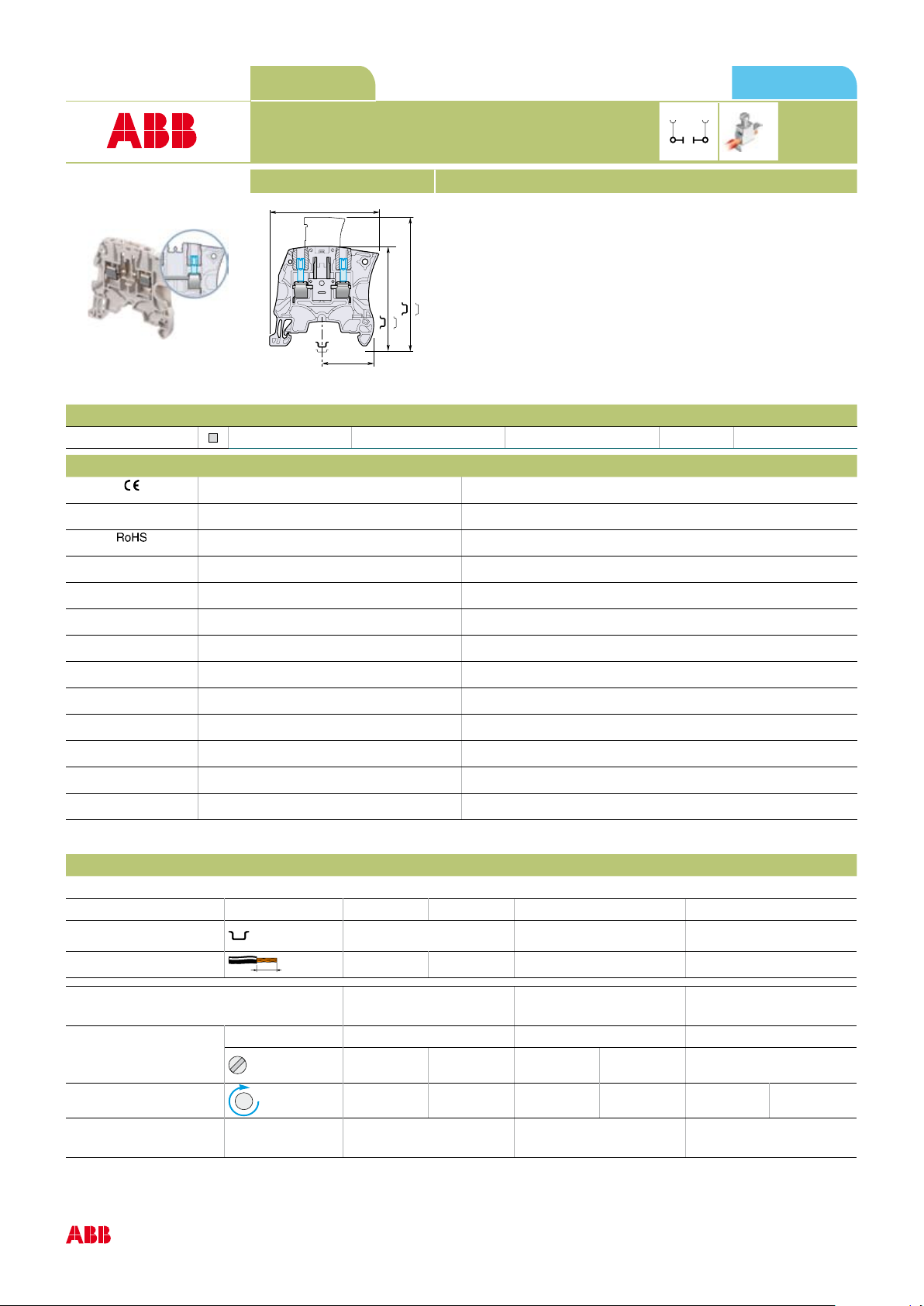

56.3 2.22"

48.8 1.92"

26.7 1.05"

53 2.09"

81 3.19"

73.5 2.89"

CE

RoHS

1SNK 161 041 D0201 1SNK 161 041 S0201

ZS4-SP-T2 Screw Clamp Terminal Block

Disconnect

5.2 mm 0.205 in Spacing

3D CAD outline drawings available on "Control Product 3D" portal

Ordering Details Type Order Code EAN Code

Grey

ZS4-SP-T2 1SNK 505 314 R0000 3472595053148 50 8.40

Declarations and Certificates Document Part Number

UE Directive 1SND 225 099 C1001

RoHS 1SND 230 491 F0203

Features and Benefits

- Ease your test operations with the 2 built-in test socket screws DIA 2 mm

0.079 in,

- Save time with our screwless component holder plug,

- Same prole as ZS4 feed-through terminal block for aligned marking and

identical end section use.

Pack

(ing)

Weight g (1 pce)

4 mm²

10 AWG

General Information

The following information must be strictly adhered to in order to guarantee the terminal block electrical, mechanical and environmental performance.

Protection IP 20 NEMA 1

Rail

Wire stripping length

Operating tool

Torque

Mechanical endurance

of disconnect system

DIN3-TH35

10.5 mm 0.413 in

Screw clamp Screw rail contact

(Maximum value)

Flat screwdriver

3.5 mm 0.138 in

0.6 Nm 5.31 lb.in

± 0.1 Nm ± 0.885 lb.in ± 0.1 Nm ± 0.885 lb.in

1

Page 2

Material Specifications

2

Insulating material Polyamide

IRC 600 V

Flammability UL94 V0

NF F 16 101 I2F2

Needle ame test IEC 60695-11-5 Compliant

Connecting capacity per clamp

1 Rigid conductor 0.2-4 mm² 24-10 AWG

1 Flexible conductor without ferrule 0.22-4 mm² 24-10 AWG

1 Flexible conductor with ferrule 0.22-4 mm² 24-12 AWG

Ferrule maximum outer diameter

4.7 mm 0.185 in

Multi Connecting capacity per clamp

2 Rigid conductors 0.2-1 mm² 24-18 AWG

2 Flexible conductors without ferrule 0.22-1 mm² 24-18 AWG

2 Flexible conductors with twin ferrule 0.22-1.5 mm² 24-16 AWG

Don't mix solid and flexible conductors in the same clamp

Don't mix solid or flexible conductors of different sizes in the same clamp

The "Connecting capacity with ferrule " data is guaranteed with ABB crimping tool PS-3

Cross section

Rated cross section 4 mm² 10 AWG

Maximum Cross section Manufacturer data 4 mm² Manufacturer data 10 AWG

Gauge A3-B3 / 3 mm / 0.118 in / IEC 60947-7-1

Electrical characteristics

Current

Rated current IEC 60947-7-1 20 A

Field and factory wiring Cat.2 UL 1059 20 A

Factory wiring Cat.1 UL 1059 20 A

CSA-C-22.2 n° 158

Rated short-time withstand current 1 s (Icw) 480 A

Short-time withstand current 0.5 s Manufacturer data

5 s Manufacturer data

10 s Manufacturer data

30 s Manufacturer data

1 mn Manufacturer data

Rated short circuit withstand CSA-C-22.2 n° 158

Max. current (45° temperature increase) / Max. cross section (mm²) Manufacturer data 20 A 4 mm²

Maximum short circuit current (1s) Manufacturer data 480 A

Short Circuit Current Rating (SCCR) SA UL 1059 supplement

With the following congurations:

Maximum voltage

Suitable conductor wire range

Fuse rating

Fuse designation

Fuse manufacturer name

Fuse type

Short circuit current

SCCR UL 1059

Page 3

Voltage

3

Rated voltage IEC 60947-1 400 V

Rated voltage UL 1059 150 V

Use Group UL 1059 C

Rated voltage CSA-C-22.2 n° 158 150 V

Rated voltage Ex e IEC/EN 60079-11

Rated impulse withstand voltage 6000 V

Dielectric test voltage 1890 V

Pollution degree IEC 60947-1 3

Overvoltage category IEC 60947-1 III

Dissipated power

Maximum dissipated power at rated current

IEC 0.6 W

Rated power dissipation at an ambient temperature of 23 °C - IEC 60947-7-3

Overload and short-circuit protection

Separate arrangement

Exclusive short-circuit protection

Separate arrangement

Overload and short-circuit protection

Compound arrangement

Exclusive short-circuit protection

Compound arrangement

1 fuse and 4 feed-through blocks

5 fuse blocks

Temperature range

Ambient temperature min/max Storage -55 +110 °C -67 +230 F

Installing -5 +40 °C -23 +104 F

Service IEC 60068-2-1 -55 +110 °C -67 +230 F

EN 60079-7

Current Derating curve for continuous service temperature

Page 4

Environmental Characteristics

4

Additional climatic tests

Dry heat IEC 60068-2-2 Compliant

Conditions Temperature +100 °C

Duration of test 96 h

Cyclic damp heat IEC 60068-2-30 Compliant

Conditions Temperature +55 °C

Number of cycles 2

Cold IEC 60068-2-1 Compliant

Conditions Temperature -40 °C

Duration of test 96 h

Z/ABDM climatic sequence IEC 60068-2-61 Compliant

Conditions Dry heat Duration of test / Temperature 16 h +85 °C

Cyclic damp heat Number of cycles / Temperature 1 +55 °C

Cold Duration of test / Temperature 2 h -25 °C

Corrosion

Salt mist IEC 60068-2-11 Compliant

Conditions Duration of test 96 h

Concentration 5 %

SO2 ISO 6988 Compliant

Conditions Duration of test 48 h

Concentration 0.2 dm³

Sulfur dioxide IEC 60068-2-42

Conditions Duration of test

Hydrogen sulfur IEC 60068-2-43

Conditions Duration of test

Flowing mixed gas corrosion test IEC 60068-2-60

Conditions Number of the test method

Duration of test

Vibrations

Vibrations IEC 60068-2-6 Compliant

Conditions Frequency range 10-55 Hz

Number of cycles 10

Amplitude

Acceleration 10 m/s²

Ramdom vibrations and climatic sequence IEC 60068-2-64

Conditions Duration of test

Frequency range

Acceleration

Climatic cycles

Step 1 -> Temperature / Duration of test

Step 2 -> Temperature / Duration of test

Temperature variation per minute

Page 5

ZS4-SP-T2 Terminal Block Accessories Compatibility

5

Description Type Order Code

1

End Stops

End Sections

2

Circuit Separators

3

Component Plugs

4

Disconnect Plugs

5

Test Plugs

6

Shield Connectors

7

Protecting Covers

8

Protecting Cover Kits

9

Tools

10

Terminal Block Markers

11

BAM3 1SNK 900 001 R0000 50 13.80 1SNK 160 026 D0201

ES4 1SNK 505 910 R0000 20 2.18 1SNK 160 022 D0201

CS-R1 1SNK 900 103 R0000 20 5.20 1SNK 160 018 D0201

PG5 1SNK 900 401 R0000 20 3.45 1SNK 160 038 D0201

PG5-R1 1SNK 900 402 R0000 20 3.45 1SNK 160 037 D0201

FC2.MC 1SNA 107 239 R0300 10 1.00 1SNK 160 036 D0201

SHBS 1SNK 900 600 R0000 20 3.50 1SNK 160 025 D0201

CO 1SNK 900 604 R0000 1 300.00 1SNK 160 020 D0201

PL5 1SNK 900 618 R0000 20 1.50 1SNK 160 021 D0201

KCO 1SNK 900 624 R0000 1 47,8 1SNK 160 028 D0201

PS-3 1SNK 900 650 R0000 1 380.00 1SNK 160 024 D0201

MC512 1SNK 140 000 R0000 22 0.06 1SNK 160 003 D0201

PROCAP5 1SNK 900 609 R0000 20 0.70 1SNK 160 013 D0201

UMH 1SNK 900 611 R0000 10 0.20 1SNK 160 001 D0201

SAT5 1SNK 900 614 R0000 5 6.00 1SNK 160 013 D0201

(ing)

Pack

Weight Technical Datasheet

pieces g (1 pce) PDF

Loading...

Loading...