ABB micro drives

Product guide

Smooth motor control and energy savings

What is an AC drive?

An AC drive is an electronic device that is used to adjust the

rotating speed or torque of a standard, electric AC motor. The

electric motor, in turn, drives a load such as a fan, pump or

conveyor.

AC drives are also referred to as frequency converters,

variable frequency drives (VFD), variable speed drives (VSD),

adjustable frequency drives (AFD), adjustable speed drives

(ASD) or inverters.

ABB - global market and technology leader in AC drives

ABB (www.abb.com) is a leader in power and automation

technologies that enable utility and industry customers to

improve their performance while lowering environmental

impact. ABB is the world’s largest drives manufacturer. The

ABB Group of companies operates in around 100 countries

and employs more than 140,000 people.

2 ABB low voltage AC drives | Product guide

ABB in North America

Our roots within North America begin with the Westinghouse

Electric Corporation, founded by George Westinghouse in 1886.

A tireless inventor and businessman, Westinghouse’s promotion

of an alternating current (AC) system revolutionized the power

industry.

Continuing to embrace the spirit of American industrialism, mining

pioneer Henry Harnischfeger joined the ABB family tree in 1981,

opening a new controls manufacturing facility in the heart of the

Midwest. Today, a cornerstone of ABB Automation Products’

business area resides within a state of the art production facility

in New Berlin, Wisconsin. The Drives and Controls operations are

responsible for the product development, applications design,

manufacture and servicing of AC and DC drives, engineered drives

and control systems, motors, generators, and power conditioning

and power quality systems.

Electric motors consume about 65% of all electricity

used throughout industry. Yet, less than 10% of those

motors are tted with a variable speed drive.

Benets of using

AC drives

Substantial energy savings

Rather than running an electric motor

continuously at full speed regardless

of the process, an electric drive allows

the user to slow down or speed up the

motor based on current demands.

Optimal process control

An electric drive enables the process

to achieve the right speed and torque

while maintaining its accuracy. This

contributes to more consistent quality

and throughput of the end product.

ABB drives common

features

Easy to select

Selecting a drive can be as simple as

choosing the power rating, voltage and

current through to more complex and

detailed dimensioning and the addition

of various options. See our guide on

page 5 to get started.

Easy to purchase

ABB drives are available from a large

network of approved ABB partners.

Please contact ABB for more details.

Reduced need for maintenance

Controlling the speed or torque of an

electric motor means there is less wear

and tear on the motor and the driven

machine.

Efficient system upgrade

An AC drive allows for the removal of

valves, gears and belts. It also ensures

network dimensioning based on a lower

starting current.

Easy to install

The drives are simple to install, featuring

a variety of mounting options from wallmounted to cabinet mounted.

Easy to operate

Once installed and commissioned, the

drives are incredibly easy to operate.

The user interface allows instant

adjustments to speed or other more

advanced parameters.

Product guide | ABB low voltage AC drives 3

Introducing the most extensive drives portfolio in the world

ABB micro drives

Precise speed control and simple integration.

ABB micro drives are suitable for many low power

applications such as pumps, fans, and conveyors. Designed

to be integrated into your machinery, they offer flexible

mounting alternatives and straightforward setup with easy

user interfaces and tools.

ABB micro machinery drives

Premium motor control with hardware flexibility.

ABB machinery drives can be configured to meet the precise

needs of industry with a wide power and voltage range and

both standard and optional features, including integrated

safety and ready-made control programs for different

applications.

ABB micro general purpose drives

Simplified selection, installation and use.

ABB general purpose drives of

one plug-and-play box. It’s designed to control a wide range

of variable torque applications, including pump and fan.

fer simplicity and intelligence in

Choosing the right drive for your application

Step Process Action

Identify the application

1

Identify the type of application and the likely demands of the drive.

Understand the load.

System inertia, required acceleration and deceleration rates, minimum and maximum speeds, overload requirements, etc.

2

This information can often be determined by the performance of the existing motor.

Gather the motor nameplate data.

3

Power, Voltage, Current, Frequency(Hz), RPM, Insulation Class, etc.

Choose a drive

Match the data gathered in Steps 1 to 3 against the table of drive features on page 6 and 7. Select a drive that meets the

4

motor requirements and has all the software features needed for the application.

Is the drive offered in the correct hp/amp rating?

The drive you choose must be able to supply the necessary current to the motor to produce the torque required. This

5

includes normal and overload conditions.

See selection table on page 6 and 7.

Is the drive offered in the correct enclosure and environmental ratings?

The drive you choose must be available in an enclosure style that will withstand the application’s environment. It also must

6

produce the required current at the application’s altitude and ambient temperature.

See selection table on page 6 and 7.

Continue to step 2.

Continue to step 3.

Continue to step 4.

Continue to step 5.

If yes, continue to

step 6.

If no, go to step 4.

If yes, continue to

step 7.

If no, go to step 4.

Does this drive have the features needed to meet the application’s demands?

The drive you choose must have a feature set that matches the application. It also must have sufficient hardware (inputs and

7

outputs, feedback, communications, etc.) to perform the application.

See selection table on page 6 and 7.

Does this drive have the motor control performance to meet the application’s demands?

The drive you choose must be able to produce the needed torque at the necessary speeds. It must also be able to control

8

speed and torque depending on the application requirements.

9

4 ABB low voltage AC drives | Product guide

The ABB AC drive you have chosen has the features and performance needed for a successful application.

If yes, continue to

step 8.

If no, go to step 4.

If yes, continue to

step 9.

If no, go to step 4.

Congratulations!

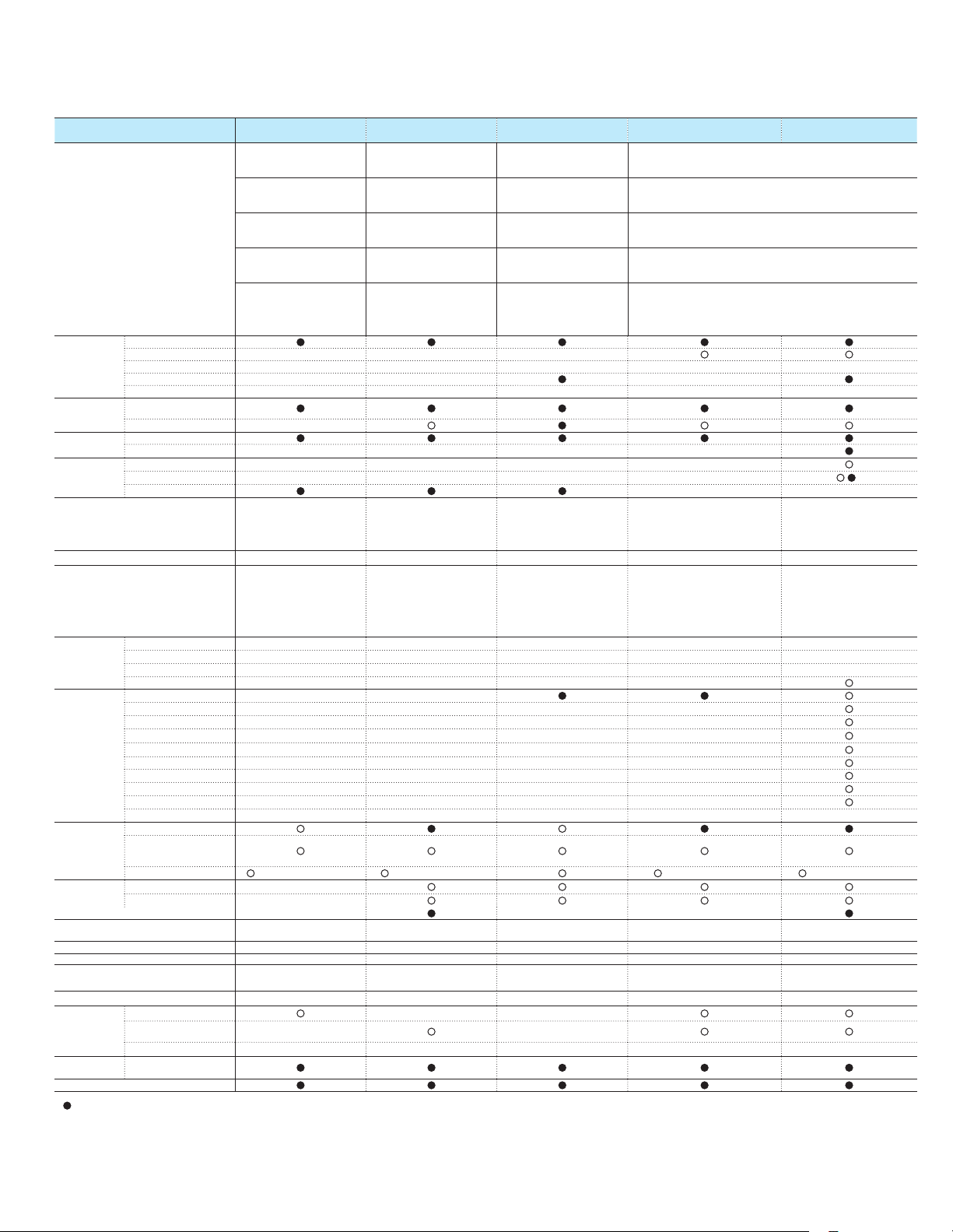

ABB drive selection table

Specification ACS55 ACS150 ACS250 ACS310 ACS355

Voltage and power ranges

Protection

classes

Mounting

arrangements

Programming

HumanMachine

interface

Motor Control

UL type 0/IP20

UL type 1/IP21 – – –

UL Type 12/IP54/IP55 – – – – –

UL Type 4X/IP66/IP67 – –

UL type 3R – – – – –

Optimal for cabinet

mounting

Optimal for wall mounting –

Parameter programming

Sequence programming – – – –

Basic control panel – – – O

Assistant control panel – – –

Integrated control panel

Supply Option

Ambient temperature -20 to 40 ˚C

Inputs and

outputs

Digital inputs/outputs 3/0 5/0 4/0 5/1 5/1

Relay outputs 1 1 1 (+1 as option) 1 1

1-phase, 100 to 120 V:

0.25 to 0.5 hp

(0.18 to 0.37 kW)

1-phase, 200 to 240 V:

0.25 to 3 hp

(0.18 to 2.2 kW)

Scalar (V/Hz) selectable

for linear (CT) or square

function (VT)

– – –

(-4 to 104 ˚F),

50 ˚C (122 ˚F)

with 15% derate,

55˚C (131˚C)

with 25% derate

No frost allowed.

1-phase, 200 to 240 V:

0.5 to 3 hp

(0.37 to 2.2 kW)

3-phase, 200 to 240 V:

0.5 to 3 hp

(0.37 to 2.2 kW)

3-phase, 380 to 480 V:

0.5 to 5 hp

(0.37 to 4 kW)

Scalar (V/Hz) selectable

for linear (CT) or square

function (VT)

o

14 to 104

(-10 to +40

122

No frost allowed.

o

F (+50 oC)

o

F

C),

1-phase, 110 to 120 V:

0.5 to 1.5 hp

(0.37 to 1.1 kW)

1-phase, 200 to 240 V:

0.5 to 3 hp

(0.37 to 2.2 kW)

3-phase, 200 to 240 V:

0.5 to 5 hp

(0.37 to 4 kW)

3-phase, 380 to 480 V:

1 to 10 hp

(0.37 to 7.5 kW)

3-phase, 500 to 600 V:

1 to 15 hp

(0.75 to 11 kW)

1 to 20 hp

(0.75 to 15 kW)

Scalar (V/Hz), enhanced V/

Hz or open loop vector

UL Type 0: 14 to 104 ºF

(-10 to 40 ºC),

122 ºF (50 ºC) with derate

UL type 4X: 14 to

104 ºF (-10 to 40 ºC),

No frost allowed.

1)

8)

1)

1)

1)

8)

1)

8)

1)

1-phase, 200 to 240 V:

0.5 to 5 hp

(0.37 to 2.2 kW)

3-phase, 200 to 240 V:

0.5 to 15 hp

(0.37 to 11 kW)

3-phase, 380 to 480 V:

0.5 to 30 hp

(0.37 to 22 kW)

–

O

–

Scalar (V/Hz) - Linear (CT),

squared (VT), or user defined

curve

– –

14 to 104 °F

(-10 to +40 °C),

up to 50°C with

10% derate

No frost allowed.

Analog inputs/outputs 1/0 2/1 2/1 2/1 2/1

Encoder feedback – – – –

Supported

fieldbus

protocols

Modbus RTU – –

Probus DP – – – –

TM

DeviceNet

ControlNet – – – –

®

CANopen

– – – –

– – – –

Ethernet (Modbus/TCP) – – – –

Ethernet (EtherNet/IPTM) – – – –

Ethernet (EtherCAT®)

– – – –

Ethernet (PROFINET IO) – – – –

Ethernet (PowerLink) – – – – –

EMC

compliance

(EN 61800-3)

C3, industrial use

C2, commercial use

(installation by EMC

experts)

C1, commercial use

(conductive emissions) (conductive emissions) (conductive emissions) (conductive emissions)

Input reactors –

Output reactors –

Brake chopper – Sizes 2 & 3 only –

Suggested maximum motor cable

length

Switching frequency up to 16 kHz up to 16 kHz up to 32 kHz up to 16 kHz up to 16 kHz

Output frequency 0-130Hz (0/250Hz)

Overload capacity

Number of preset speeds 1

PC tools

Drive commissioning tool

Drive ofine

programming tool

98.5 to 164 ft

(30 to 50 m)

150% for 60 s,

180% for 2s at start

10)

–

98.5 to 196.9 ft

(30 to 60 m)

10)

0 to 500 Hz 0 to 500 Hz 0 to 500 Hz 0 to 599 Hz

150% for 60 s,

180% for 2 s

328 ft (100 m)

150% for 60 s,

175% for 2 s

3 4 7 7

– –

–

98.5 to 196.9 ft

(30 to 60 m)

110% for 60 s,

180% for 2 s

Drive dimensioning tool – – – – –

Approvals UL, cUL, CE,

RoHS compliance

Standard

O Option

— Not Available

1)

IP66 product variants

2)

up to R2 as standard

C-Tick, EAC

3)

G1/G2 frames IP00

4)

Application Programming

5)

DO are DIO and can be used as DI

6)

Frame dependant

7)

CC, PC, and PD product variants

8)

IP20 variant

9)

IP54 variant

10)

Greater range when programmed with DriveCong software

11)

I/O can be expanded with optional modules

12)

Eight digital outputs can be configured to be DI or DO

1-phase, 200 to 240 V:

0.5 to 3 hp

(0.37 to 2.2 kW)

3-phase, 200 to 240 V:

0.5 to 15 hp

(0.37 to 11 kW)

3-phase, 380 to 480 V:

0.5 to 30 hp

(0.37 to 22 kW)

1)

1)

/

–

Open loop vector, Scalar (V/

Hz) and Closed loop control

14 to 104 ºF

(-10 to 40 ºC),

122 ºF (50 ºC)

No frost allowed.

98.5 to 196,9 ft

(30 to 60 m)

150% for 60 s,

180% for 2 s

Product guide | ABB low voltage AC drives 5

Horsepower Comparison Chart

ACS55 ACS150 ACS250 ACS310 ACS355

1-phase 1-phase 3-phase 1-phase 3-phase 1-phase 3-phase 1-phase 3-phase

115V 230V 230V 230V 460V 115V 230V 230V 460V 600V 230V 230V 460V 230V 230V 460V

50

40

30 30 30

25

20 20

15 15 15

10 10

7.5

5 5 5 5

3 3 3 3 3 3

0.5

1

0.25 0.25 0.5 0.5 0.5

1.5

0.5 0.5 0.5 1.0 1.0 0.5 0.5 0.5 0.5 0.5 0.5

Applications

Overview

Applications where to use ACS55 ACS150 ACS250 ACS310 ACS355

Pumps

Fans

Conveyors

Material handling machines

Exercise equipment

Home appliances

Gates, doors, barriers

Compressors

Cutting machines, shears, saws

Extruders

Machine tools, mixers, stirrers

Spinning machines

Centrifuges

Processing lines

Kilns

6 ABB low voltage AC drives | Product guide

ABB micro drives

ACS55, 0.25 to 3 hp (0.18 to 2.2 kW)

What is it?

The ACS55 drive has a compact and slim design that can be

integrated easily into existing panels, replacing contactors and

motor starters. Its compact size is ideal for new installations

or whenever speed control of AC induction motors is needed.

For users new to drives, it is programmed using simple DIP

switches and rotary dials.

The ACS55 drive meets the requirements of industrial end

users, installers, machine builders and panel builders.

ACS55 frame sizes: A, B, C, D

Feature Benefit Result

Single phase supply Suitable for single phase residential and commercial

applications

Slim design Fits easily into a variety of cabinet designs Cabinet size can be smaller or greater packing density

Flexible installation alternatives Screw or DIN rail mounting, sideways or side-by-side One drive type can be used in various designs, saving

High switching frequency Reduced motor noise Does not disturb occupants of buildings

Avoids cabling and installation costs associated with

three-phase supplies

can be achieved

installation costs and time

Integrated EMC filter as standard High electromagnetic compatibility Low EMC emissions in all environments

Easy configuration

DriveConfig kit PC tool DriveConfig kit PC tool is used to set drive parameters and

For additional technical information, see the ACS55 Technical Catalog (3AUA0000163305)

Quick setup with DIP switches and trimmers Substantial time savings. Minimal expertise needed.

Time savings with multiple drives. Drive configuration

to upload the parameter set to a drive in seconds, even

without a power connection to the drive. The DIP switches

and trimmers on the front panel of the drive are disabled

after using the DriveConfig kit. This prevents the end users

from altering the drive configuration.

protected from end user alterations.

Product guide | ABB low voltage AC drives 7

ABB micro drives

ACS150, 0.5 to 5 hp (0.37 to 4 kW)

What is it?

The ACS150 drive has a compact footprint that can be

incorporated into a wide variety of machines. It includes, as

standard, all necessary functions and interfaces for typical

applications with AC induction motors.

The ACS150 drive meets the requirements of new drive users,

installers, machine builders and panel builders.

ACS150 frame sizes: R0, R1, R2

Feature Benefit Result

User-friendly LCD control panel Clear alphanumeric display

Easy setup and use

Flexible mounting alternatives Screw or DIN rail mounting, sideways or side-by-side One drive type can be used in various designs,

Integrated EMC filter High electromagnetic compatibility Low EMC emissions in selected environments

Time savings

saving installation costs and time

Built-in brake chopper as

standard

Embedded potentiometer Easy to adjust output frequency Time savings

PID control Simple integration to process control Cost savings as a result of less cabling

FlashDrop tool FlashDrop is a hand held tool that is used to quickly and easily set

For additional technical information, see the ACS150 Technical Catalog (3AUA0000085631)

No need for an external brake chopper Space savings, reduced installation cost

Time savings, especially with multiple drives

drive parameters. FlashDrop tool uploads drive parameters directly

to unpowered drives. The tool can copy parameters from one drive

to another or between a PC and a drive.

8 ABB low voltage AC drives | Product guide

ABB micro drives

ACS250, 0.5 to 20 hp

What is it?

The ACS250 micro drive offers easy to use and compact

solutions for general purpose low power applications, such as:

mixers, pumps, fans, conveyors, food and beverage. All variants

include a built-in Modbus RTU serial communication to provide

straightforward integration with control and monitoring systems.

The drive’s design and ease of setup benefit a broad range of

industries.

Available in IP20 and IP66/NEMA4x enclosures.

ACS250, IP20 and IP66 enclosures

Feature Benefit Result

User-friendly LCD control panel Clear alphanumeric display

Optional front mounted operator

controls (IP66 variant)

Flexible mounting alternatives

(IP20 variant)

PI control Simple integration to process control Cost savings with PLC functionality built into the drive

Easy setup and use

Allows the drive to be mounted on the machine close to the

operator

Wall or DIN rail mounting without extra accessory kits One drive type can be used in various designs, saving

Time savings with programming and monitoring

Cost savings with operator controls already mounted on

the drive – no need for custom panels

installation costs and time

Slide-out help card

(IP20 variant)

Epoxy coated heatsink

(IP66 variant)

Integrated control panel Quick setup, easy configuration and commissioning, rapid

Enhanced V/Hz control for

variable or constant torque

applications

Flow through wiring

(IP20 variant)

Separate terminal cover (IP66

variant)

Built-in brake chopper as

standard (sizes 2 & 3)

Safe torque off function

(SIL2) as standard

(600V only)

Open loop vector speed control

(600V only)

High protection class variant

(IP20 variant, up to 20 hp)

(IP66 variant, up to 15 hp)

CopyStick tool CopyStick is used to quickly and easily set drive

For additional technical information, see the ACS250 product flyers (3AUA0000151036, 3AUA0000139676 or 3AUA0000139675)

Ready reference, right on the drive Time savings with setup and programming

Protects the heatsink from harsh washdown chemicals Cost savings with extended life in the harshest

environments

fault diagnosis

Optimized performance and energy savings for all

applications

Facilitates panel layout, or contactor replacement, with

power leads in at the top and motor cables out at the

bottom

No need to expose sensitive electronics to the environment

when connecting and commissioning the drive

No need for an external brake chopper Space savings, reduced installation cost

Built-in and certified function that is used for prevention of

an unexpected startup and other stopping related functions

Precise speed control and automatic motor setup Time and cost savings

No need to design special enclosure for applications that

require high ingress protection

parameters. The tool uploads drive parameters directly to

unpowered drives. The tool can copy parameters from one

drive to another or between a PC and a drive.

Substantial time savings locating faults and implementing

repairs, thereby reducing maintenance costs

Limited inventory of one drive that can efficiently power

both

VT or CT applications

Time and cost savings for panel builders

Time savings with easy access to connection terminals

Reduces the need for external safety components.

Helps machine builders to fulfill the requirements of

Machinery Directive 2006/42/EC

Time and cost savings

Time savings, especially with multiple drives

Product guide | ABB low voltage AC drives 9

ABB general purpose drives

ACS310, 0.5 to 30 hp (0.37 to 22 kW)

What is it?

The ACS310 drive is designed for variable torque

applications, such as booster pumps and centrifugal fans.

The drive contains a powerful set of features including built-in

PID controllers and pump and fan control (PFC) that varies the

drive’s performance in response to changes in pressure, flow

or other external data.

The ACS310 drive meets the requirements of new drive users,

installers, machine builders, system integrators and panel

builders.

Feature Benefit Result

Same height and depth

across power range

Commissioning assistants Easy set up of parameters for PID controllers, real-time clock,

Pump and fan control (PFC) One drive controls several pumps or fans.

Effective space usage Less engineering and installation time

serial communication, drive optimizer and drive startup

Auxiliary motors are driven according to the needed pump/fan

capacity.

One motor can be disengaged from the mains supply while others

continue operating in parallel.

ACS310 frame sizes: R0, R1, R2, R3, R4

Time savings.

Ensures all required parameters are set.

Saves cost of additional drives and external PLC.

Longer life for pump or fan system while reducing

maintenance time and costs.

Maintenance can be carried out safely without stopping

the process.

Pump protection functions Pre-programmed features such as pipe cleaning, pipefill, inlet/

PID controllers Varies the drive’s performance according to the need of the

Energy efficiency counters Illustrates saved energy, CO2 emissions and energy cost in local

Embedded Modbus

EIA-485 fieldbus interface

FlashDrop tool FlashDrop is a hand held tool that is used to quickly and easily

For additional technical information, see the ACS310 Technical Catalog (3AUA0000159910)

outlet pressure supervision and detection of under- or overload

application

currency using a baseline determined from the energy consumed

when the fan or pump is used directly online

No need for external fieldbus options.

Integrated and compact design.

set drive parameters. FlashDrop tool uploads drive parameters

directly to unpowered drives. The tool can copy parameters from

one drive to another or between a PC and a drive.

Reduces maintenance costs.

Longer life for pump and fan system.

Enhances production output, stability and accuracy

Shows direct impact on energy bill and helps control

operational expenditure (OPEX)

Saves cost of an external fieldbus device. Increases

reliability

Time savings, especially with multiple drives

10 ABB low voltage AC drives | Product guide

ABB machinery drives

ACS355, 0.5 to 30 hp (0.37 to 22 kW)

What is it?

The ACS355 drive is user-friendly, with a wide range of built-in

technology such as the safe torque off functionality and sequence

programming, which reduce the need for additional control

electronics. The product offers options and diverse functionality to

cater to the needs set for speed and torque control of AC induction

and permanent magnet motors.

The ACS355 drive meets the requirements of new drive users,

installers, machine builders, system integrators and panel builders.

ACS355 frame sizes: R0, R1, R2, R3, R4 and IP66 variants

Feature Benefit Result

Same height and depth across

power range

Assistant control panel with Help

functions

Scalar and vector control Optimum performance depending on application Ensures the end-product is produced cost efficienctly

Effective space usage Less engineering and installation time

Quick setup, easy configuration and commissioning,

rapid fault diagnosis

Substantial time savings locating faults and implementing

repairs, thereby reducing maintenance costs

Sequence programming Logic programming included as standard with PLC-like

Integrated EMC filter High electromagnetic compatibility Low EMC emissions in selected environments

Built-in brake chopper as standard No need for an external brake chopper Space savings, reduced installation cost

Safe torque off function

(SIL3) as standard

Product variant for demanding

environments with IP66/69K, UL

Type 4X protection classes

Product variant for solar pumps Drive converts PV energy from solar panels to AC

FlashDrop tool FlashDrop is used to quickly and easily set drive

For additional technical information, see the ACS355 Technical Catalog (3AUA0000081917)

functions

Built-in and certified function that is used for prevention

of an unexpected startup and other stopping related

functions.

No need to design special enclosure for applications

that require high ingress protection.

NSF certified.

current, it can be operated independent from the grid.

parameters. FlashDrop tool uploads drive parameters

directly to unpowered drives. The tool can copy

parameters from one drive to another or between

a PC and a drive.

Reduces components and wiring in control system

Reduces the need for external safety components.

Helps machine builders to fulfill the requirements of

Machinery Directive 2006/42/EC.

Time and cost savings

Long life time and reduced maintenance costs, energy use

and pollution. Improved reliability in electricity supply.

Time savings, especially with multiple drives

Product guide | ABB low voltage AC drives 11

Options

Overview

Fieldbus communications

Fieldbus adapter modules enable communication between

drives, systems, devices and software. Our drives are

compatible with a wide range of fieldbus protocols. The plugin fieldbus adapter module can easily be mounted inside the

drive.

− CANopen

− ControlNet

− DeviceNet

− EtherCAT

− Ethernet IP

− Ethernet Powerlink

Driveware options and PC tools

ABB offers a variety of options that allow you to enhance your

experience with our drives. These include various levels of

control panels, parameter selecting/copy tools, engineering/

optimization calculators, powerful integration/programming

software, and helpful start-up/maintenance software.

− Automation Builder

− DriveBrowser

− DrivePM

− DriveWindow Light

− Modbus RTU

− Modbus TCP

− Profibus DP

− Profinet I/O

− PROFIsafe

− EnergySave calculator

− FanSave / PumpSave

calculator

− Energy Calculator App

I/O options

Standar

analog and digital input/output extension modules. The modules

are easily installed in the extension slots located on the control

unit. The ACS355 product also offers TTL pulse encoder.

Safety features

Safe torque off (STO) is used to prevent unexpected startup

and in stopping-related functions, enabling safe machine

maintenance and operation. With safe torque off activated, the

drive will not provide a rotational field. This prevents the motor

from generating torque on the shaft. It is a cost-effective and

certified solution for safe machine maintenance by fulfilling IEC

61508, EN 62061 and EN ISO 13849-1 standards.

Application control programs

ABB’s industrial product family offers a range of ready-made

programs to optimize application productivity and usabiltiy.

d inputs and outputs can be extended by using optional

− Enhanced Sequence Programming

− High Speed Program

− Low Ambient Start w/ Motor Heating

− Solar Pump drive

Flexible product configurations

ABB understands every situation is unique. That is why we

offer a wide range of options for our drives such as EMC

filters, braking, enclosure, mounting, and cabling options.

Enclosure Options

− UL type 0 (IP00)

− UL type 1 (IP21)

− UL type 4X (IP66)

Operator interface

Control panels feature intuitive use and easy navigation.

Regardless of which control panel you choose, you are able

to control the drive, set parameter values, copy settings

from one drive to another, and more. The panel saves on

commissioning and learning time by means of different

assistants, making the drive simple to set up and use.

− Basic Control Panel

− Assistant control Panel

− Integrated or remote

mounting options

− Potentiometer

EMC Filters

st

Environment, Cat 1

− 1

− 1st Environment, Cat 2

− 2nd Environment, Cat 3

Remote monitoring

With a built-in web server and standalone datalogger, available

remote monitoring options enables worldwide and secure

access to drives.

12 ABB low voltage AC drives | Product guide

ABB automation products

Automation Builder

Automation builder integrates engineering and maintenance for PLC, Drives, Motion, HMI and Robotics. Automation Builder

complies with the IEC 61131-3 standard offering all five IEC programming languages for PLC and drive configuration. One tool for

your complete compact solution.

Stay in control of your project:

Automation Builder integrates

engineering tools for PLCs, safety,

robots, motion, drives and control

panels.

Build your distinct solution:

Automation Builder is open

for your specific products and

communication technology.

Automation Builder Basic Automation Builder Standard Automation Builder Premium

Reduce risk and save time:

Automation Builder integrates

products into solutions that create

value for your customers.

Connect to best in class tools:

Automation Builder enables you to

adapt the tool chain to your needs

and workflows.

Description Basic system engineering for FREE Integrated engineering of complex

Features − AC500-eCo, AC500 with local I/O,

TCP/IP, Modbus, CS-31, IEC60870-5

− All 5 IEC 61131-3 languages IL, LD,

FBD, SFC, ST, plus CFC

− Drive application programming

(IEC 61131-3)

− Mint WorkBench for motion

applications

− RobotStudio Basic

− PLC firmware update, download and

online change to single or several PLCs

− PLC simulation and debugging

− Language packs available for EN, DE,

ES, FR, CN

systems

Automation Builder Basic features plus

− Integrated engineering for Panel, Drive,

Motion, Robotics

− AC500 PROFIBUS, PROFINET,

EtherCAT, CAN, CMS

− AC500 Safety (1)

− Drive Manager

Productivity and Collaboration for System

Integrators and Machine Builders

Automation Builder Standard features plus

− C/ C++ application programming

interface

− ECAD Interface AC500/ AC500-eCo for

EPLAN P8

− Advanced CSV data exchange

− Project compare

®

and Zuken E3

®

Available software libraries to help with application solutions:

PS552-MC-E PS562-SOLAR PS563-WATER PS564-TEMPCTRL

Motion control library Solar tracker solution library Water solution library Temperature Control Library

Product guide | ABB low voltage AC drives 13

ABB automation products

AC500-eCo

This compact PLC offers flexible and economical configurations for your modern control system. The ideal choice for smaller

applications with micro drives.

High performance variant with large

memory available

– Up to 10 I/O modules connected

to the CPU

– Compatible with all standard I/O

modules (S500 and S500-eCo)

– Digital I/O module with

configurable I/O available

Comprehensive communication

options:

– Ethernet for communication

and web server for user defined

visualization

– Up to two serial ports

for decentralized I⁄O and

communication

– Three different types of terminal

blocks available

– Integrated onboard I⁄O

– AC versions with integrated power

supply

14 ABB low voltage AC drives | Product guide

ABB automation products

CP600-eCo

The economic control panel series offers touchscreen graphic displays from 4.3” up to 10.1”. The user-friendly configuration

software PB610-B Panel Builder 600 Basic provides the most commonly used HMI functions. Comprehensive sets of graphic

symbols are available to support the design of tailer-made HMI solutions. Great for a compact solution with the eCo PLC(s) and

micro drives.

– Improved flexibility and integration

– Housing

CP600-eCo: Plastic

CP600: Aluminium

– Front protection IP66

– Engineering software Panel

Builder 600 integrated in

Automation Builder

– Two versions available:

- CP600-eCo / CP600: Configuration with Panel

Builder 600 for clear tailor made visualization.

- CP600-WEB: visualization of AC500 web server

with Automation Builder visualization. The

Automation Builder debugging and diagnostics

screens can be converted effortless for use with

CP600-WEB control panels.

– Brilliant colored display

– Free reusable 3D graphic elements

(Widgets)

– Import tags from PLC, drives, motion

controller and robots configuration within

Automation Builder

– Slim design for easily installation even in

compact spaces

Type CP604 CP607 CP610

Application control panels for PB610-B Panel Builder 600 Basic applications

Display

Exact display size diameter 4.3" widescreen 7" widescreen 10.1" widescreen

Resolution 480 x 272 pixels 800 x 480 pixels 1024 x 600 pixels

Display type, colors TFT-LCD, 65536 colors

Touch screen material glass covered by plastic film

Touch screen type analog restitive, 4 wires

Backlight type, life LED, 20 000 h typ at 25 °C

Brightness 150 cd/m² 200 cd/m²

Housing

Protection class front, rear IP66, IP20

Product guide | ABB low voltage AC drives 15

Life cycle services

Your choice, your future

You made the choice to invest in the future of your business

by purchasing an ABB drive. Let us help you make another

easy choice: ABB Drive Care.

From install, to commissioning, to end-of-life support our

portfolio of options will help maintain or improve your drives’

performance and maximize their lifespan.

Your choice, our business

Our business is helping you stay focused on your business.

Whether your key concern is operational efficiency, life cycle

management, rapid response, or all of the above, we have a

service plan that will work for you throughout the entire lifetime

of your drives.

Need help making the right choice? Let’s talk about your

future.

Service offerings for your

business

Your needs in service usually depend on your operation, priorities, and life cycle phase of your

equipment. Here are the most typical service needs with some of our service product options that

satisfy them:

Is performance most critical to your

operation?

Get optimal performance out of your

machinery and systems.

Supporting services include:

− Training

− Inspections and Diagnostics

− Hardware and Control Upgrades

− Retrofits

− Workshop Repair

− Remote Care

Is uptime your priority?

Keep your drives running with precisely

planned and executed maintenance.

Supporting services include:

− Life Cycle Assessment

− Installation and Commissioning

− Spare Parts

− Preventive Maintenance

− Reconditioning

− Remote Care

Need to extend your assets’ lifetime?

Maximize your drive’s lifetime with our

services.

Supporting services include:

− Life Cycle Assessment

− Hardware and Control Upgrades

− Retrofits

− Replacement, Disposal and Recycling

16 ABB low voltage AC drives | Product guide

Is rapid response a key consideration?

If your drives require immediate action,

our global network is at your service.

Supporting services include:

− Technical Support

− Drive Exchange

− On-site repairs

− Remote Support

Loading...

Loading...