—

FOR SMOOTH MOTOR CONTROL AND ENERGY SAVINGS

Low voltage micro & machinery drives

Product guide

—

AC drives.

For smooth

motor control

and energy

savings.

—

Table of contents

04– 05 Smooth motor control

and energy savings

06 Choosing the right drive

for your application

07 Horsepower comparison for

ABB drives

3

08 – 09 ABB drive selection table

10 – 12 ABB micro drives

13– 15 ABB machinery drives

16–17 Introducing the most extensive

drives portfolio in the world

18– 19 Services to match your needs

20 A lifetime of peak performance

4 PRODUCT GUIDE

—

Smooth motor control

and energy savings

What is an AC drive?

An AC drive is an electronic device that is used to

adjust the rotating speed and torque of a

standard, electric AC motor. The electric motor, in

turn, drives a load such as a fan, pump or

conveyor.

AC drives are also referred to as frequency

converters, variable frequency drives (VFD), variable

speed drives (VSD), adjustable frequency drives

(AFD), adjustable speed drives (ASD) or inverters.

ABB - global market and

technology leader in AC drives

ABB (www.abb.com) is a leader in power and

automation technologies that enable utility and

industry customers to improve their performance

while lowering environmental impact. ABB is the

world’s largest drives manufacturer. The ABB

Group of companies operates in around 100

countries and employs more than 140,000 people.

—

Electric motors consume about 65% of all electricity used

throughout industry. Yet, less than 10% of those motors are

fitted with a variable speed drive.

PRODUCT GUIDE

5

—

Improve your processes

with AC drives

Increased life time

Reduced starting current decreases the

electrical stress on the motor and network.

Smooth ramp up to full speed also reduces

mechanical wear on the equipment, prolonging

its life time.

Increased productivity

Using a drive increases the productivity of the

applications by reducing the number of

unintended stops caused by excessive heating

of the motor or sudden breakdowns of

mechanical equipment due to high mechanical

stress.

Reduced need for maintenance

Being able to apply a softer starting moment

and vary the speed and torque of an electric

motor means there is less wear and tear on the

motor and the driven machine.

—

Further optimize

your processes with AC drives

Substantial energy savings

Rather than having an electric motor running

continuously at full speed, an AC drive allows

the user to slow down or speed up the motor

depending on the demand.

Optimal process control

An electric drive enables the process to achieve

the right speed and torque while maintaining

its accuracy. This contributes to more

consistent quality and throughput of the end

product.

Efficient system upgrade

An AC drive allows the removal of valves, gears

and belts. It also ensures network dimensioning

based on a lower starting current.

—

ABB drives common features

• Easy to select

You can be sure to find a right product for your

application from a wide selection of ABB drives.

• Easy to purchase

ABB drives are available from ABB and selected

ABB partners. Please contact ABB for more

details.

• Easy to install

The drives are simple to install, featuring a

variety of mounting options from wall-mounted

to cabinet mounted.

• Easy to operate

Once installed and commissioned, the drives are

incredibly easy to operate. The user interface

allows instant adjustments to speed or other

more advanced parameters.

6 PRODUCT GUIDE

—

Choosing the right drive

for your application

Step Process Action

1 Identify the application

Identify the type of application and the likely demands of the drive. Continue to step 2.

2 Gathe r the load data: system inertia, required acceleration and deceleration rates, minimum

and maximum speeds, overload requi rements, etc.

This information c an often be determined by the performance of the existing motor. Continue to step 3.

3 Gather the motor data: rated torque, kW/hp, volts, insulation class, speed, etc.

Whether an existing motor or a new motor is being used, the motor information is critical to

choosing a drive. Continue to step 4.

4 Choose a drive

Match the data gathered in Steps 1 to 3 against the table of dr ive features on page 8 -9. Select

a drive that meets the motor requirements and has all the software features needed for the

application. Continue to step 5.

5 Is the drive offered in the correct hp rating?

The drive you choose must be able to supply the necessary current to the motor to produce

the torque required. This includes normal and overload conditions. Select current from the

tables on pages 7, depending on drive type selected.

6 Is the drive offered in the correct enclosure and environmental ratings?

The drive you choose must be available in an enclosure style that will withstand the

application’s environment. It also must produce the required current at the application’s

altitude and ambient temperature.

7 Does this drive have the features needed to meet the application’s demands?

The drive you choose must have a feature set that matches the applic ation. It also must have

sufficient hardware (inputs and outputs, feedback, communications, etc.) to per form the

application.

8 Does this drive have the motor control performance to meet the application’s demands?

The drive you choose must be able to produce the needed torque at the necessary speeds. It

must also be able to control speed and torque depending on the application requirements.

9 Congratulations!

The ABB AC drive you have chosen has the features and performance needed

for a successful application.

continue to step 6.

If yes,

If no, go to step 4.

If yes,

continue to step 7.

If no, go to step 4.

If yes,

continue to step 8.

If no, go to step 4.

If yes,

continue to step 9.

If no, go to step 4.

Micro drives Machinery drive

Applications

Food & beverage l l

Irrigation l l

Conveyor l l l l

Fan l l l l

Pump l l

Integrated / machinery l l l l l

Overhead / gantr y crane l l

ACS55 ACS150 ACS255 ACS355 ACS380

PRODUCT GUIDE

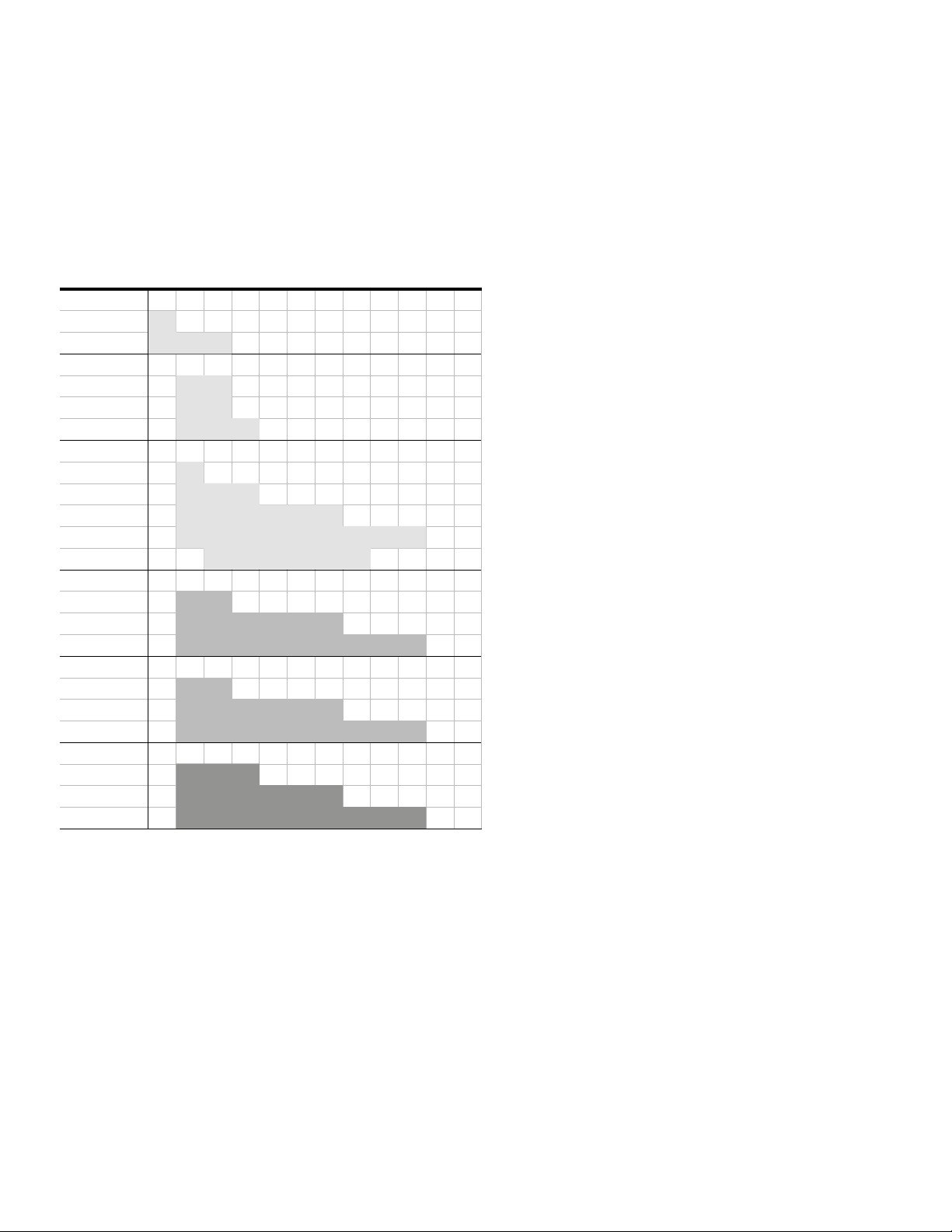

—

Horsepower comparison

ACS55

1-phase, 120V

1-phase, 240V

ACS150

1-phase, 240V

3-phase, 240V

3-phase, 480V

ACS255

1-phase, 120V

1-phase, 240V

3-phase, 240V

3-phase, 480V

3-phase, 60 0V

ACS355

1-phase, 240V

3-phase, 240V

3-phase, 480V

ACS380

1-phase, 240V

3-phase, 240V

3-phase, 480V

ACS310

1-phase, 240V

3-phase, 240V

3-phase, 480V

0.25-0. 5

0.25

3

0.5 3

0.5 3

0.5 5

0.5-1.5

0.5 5

0.5 15

0.5 30

1 20

0.5 3

0.5 15

0.5 30

0.5 3

0.5 15

0.5

0.5

0.5

5

15

30

30

7

0.25 0.5 1 3 5 7.5 10 15 20 25 30 40 50

8 PRODUCT GUIDE

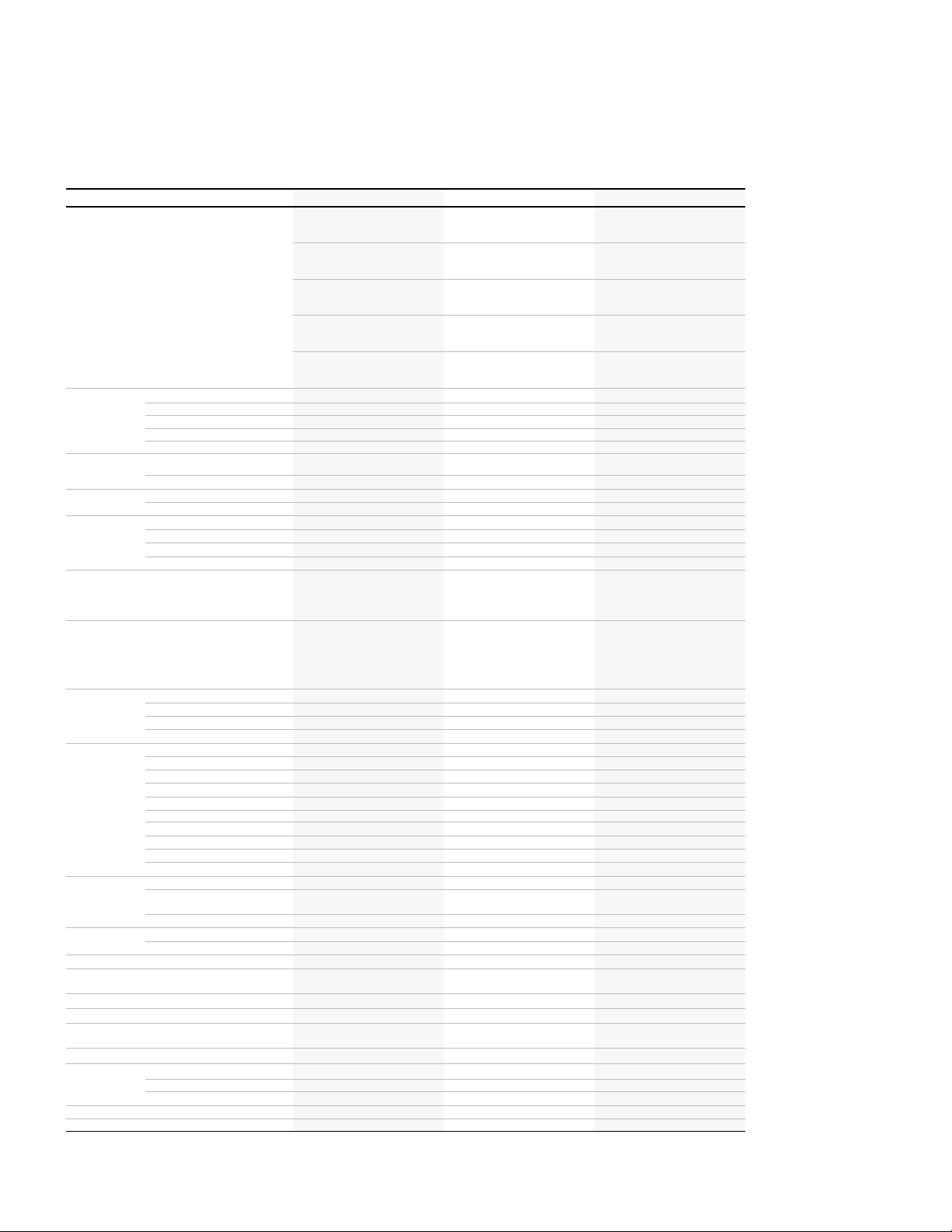

—

Drive selection table

Specification ACS55 ACS150 ACS255 Specification ACS355 ACS380 ACS310

Voltag e and powe r ranges

Protection

classes

UL typ e 0/IP20

UL typ e 1/IP21

UL Type 12/IP 54/IP55

UL Type 4X/IP66/IP 67

UL typ e 3R

Mounting

arrangements

Programming

HumanMachine

interface

Motor Control

Optimal for cabinet mounting

Optimal for wall mounting

Parameter programming

Sequence programming

Basic c ontrol pane l

Assistant control panel

Bluetooth-enabled panel

Integrated control panel

Ambient temperature

Inpu ts and

outputs

Digital inputs/outputs

Relay outputs

Analog inputs/outputs

Encoder feedback

Supp orted

fieldbus

protocols

Modbus RTU

Profibus DP

DeviceNetTM

ControlNet

CANopen®

Ethernet (Modbus/TCP)

Ethernet (EtherNet/IPTM)

Ethernet (EtherCAT®)

Ethernet (PROFINET IO)

Ethernet (PowerLink)

EMC

compliance

(EN 61800-3)

C3, ind ustrial us e O

C2, com mercial use

(installation by EMC experts)

C1, comm ercial use O

Input reactors

Output reactors

Brake chopper

Suggested maximum motor cable length

Switching frequency

Output frequency

Overload capacity

Numb er of preset spee ds

PC tools

Drive commissioning tool O – –

Drive o ffline pro g tool – O – Drive o ffline pro g tool O

Drive dimensioning tool – – – Drive dimensioning tool –

Approvals

UL, cUL, CE , RMS, C-Tick , EAC

RoHS compliance

1)

l

Standard

O Optio n

— Not Avai lable

IP66 p roduct var iants

2)

up to R2 a s standa rd

3)

G1/G2 fr ames IP 00

4)

Application Programming

1-phase, 100 to 120 V:

0.25 to 0.5 hp

(0.18 to 0.37 kW)

1-phase, 200 to 240 V:

0.25 to 3 hp

(0.18 to 2.2 kW)

Scalar (V/Hz) selectable

for linear (CT) or square function

-4 to 104˚F (-20 to 40˚C),

with 15% de rate,

with 25% de rate

No fros t allowed.

(VT)

50 ˚C (122˚F)

55˚C (13 1˚C )

3/0 5/0 4/0

1/0 2/1 2/1

(conductive emissions)

98.5 to 164 ft

(30 to 50 m)

up to 16 kHz up to 16 kHz up to 32 kHz

0-130Hz (0/250Hz)

150% for 60 s,

180% for 2s at sta rt

1

5)

DO are DI O and can be used a s DI

6)

Frame de pendant

7)

CC, PC , and PD produc t variants

8)

IP20 variant

1-phase, 200 to 240 V:

(0.37 to 2.2 kW )

3-phase, 200 to 240 V:

(0.37 to 2.2 kW )

3-phase, 380 to 480 V:

(0.37 to 4 kW)

0.5 to 3 hp

0.5 to 3 hp

0.5 to 5 hp

1 to 15 hp (0.75 to 11 kW)

1-phase, 110 to 120 V:

0.5 to 1.5 hp

(0.37 to 1.1 kW)

1-phase, 200 to 240 V:

3-phase, 200 to 240 V:

3-phase, 380 to 480 V:

0.5 to 5 hp

(0.37 to 4 kW)

0.5 to 15 hp

(0.37 to 11 kW)

0.5 to 30 hp

(0.37 to 22 kW)

3-phase, 50 0 to 600 V:

1 to 20 hp (0.75 to 15 kW)

l l l

– – –

– – –

– –

– – –

l l l

–

O

l

l l l

– – –

– – –

– – –

– – –

l l l

Scalar (V/Hz) selectable

for linear (CT) or square function

14 to 104˚F (-10 to +40˚C ),

No fros t allowed.

(VT)

122˚F (+50˚C)

with derating

1 1 1 (+1 as optio n)

– – –

– –

– – –

– – –

– – –

– – –

– – –

– – –

– – –

– – –

– – –

Open loop vector,

Scalar (V/Hz), enhanced

V/Hz or open l oop vector

14 to 104˚F (-10 to 40˚C ),

122˚F (50˚C) with derate

14 to 104˚F (-10 to 40˚C ),

UL Type 0:

UL type 4X:

No fros t allowed.

l

O O O

O (conductive emissions)

–

–

–

98.5 to 196.9 f t

10)

150% for 60 s,

10)

O O Input reactors O

O O Output reactors O

Sizes 2 & 3 only

328 ft

(100 m)

(30 to 60 m)

l

0 to 500 Hz 0 to 500 Hz

180% for 2 s

150% for 60 s,

175% for 2 s

3 4

l l l

l l l

9)

IP54 variant

10)

Greate r range when pr ogramm ed with Dri veConf ig software

11)

I/O can be ex panded wit h option al modul es

12)

Eight di gital ou tputs ca n be configured to be DI or D O

1)

l

8)

1)

l

O

O C1, comm ercial use

Loading...

Loading...