Latch key safety limit switches

1 2 3 5 10

Current (A)

0.1

0.2

0.3

0.5

1

2

3

5

Millions of operating cycles

12 - 24

48

130

230

Technical data

General Data

Standards IEC 60947-1, IEC 60947-5-1, EN 60947-1, EN 60947-5-1, UL 508,

and CSA C22-2 No. 14

Certications - Approvals UL and CSA

Air temperature near the device

– during operation °C -25 ... +70

– for storage °C -30 ... +80

Climatic withstand According to IEC 68-2-3 and salty mist according to IEC 68-2-11

Mounting positions All positions are authorised

Shock withstand (according to IEC 68-2-27 and EN 60068-2-27) g Limit switch with small latch (key): 10 g

(1/2 sinusoidal shock for 11 ms) no change in Limit switch with rotative axis or lever: 40 g

contact position

Resistance to vibrations g 5 g (10 ... 500 Hz) no change in position of contacts > 100 μs

Protection against electrical shocks (acc. to IEC 536) Class II

Degree of protection (according to IEC 529 and EN 60529) UL Type 4 & IP65

Minimum actuation speed m/s Slow action contacts 0.060 / Snap action contacts 0.001

limit switches

Safety

Electrical Data

Rated insulation voltage U

– according to IEC 60947-1 and EN 60947-1 V 690 (degree of pollution 3)

– according to UL 508, CSA C22-2 No. 14 A600, Q600

Rated impulse withstand voltage U

(according to IEC 60947-1 and EN 60947-1)

Conventional free air thermal current I

(according to IEC 60947-5-1 and EN 60947-5-1) (0 < 40 °C)

Short-circuit protection - gG type fuses A 10

Rated operational current

/ AC-15 – acc. to IEC 60947-5-1 24 V - 50/60 Hz A 10

I

e

130 V - 50/60 Hz A 5.5

230 V - 50/60 Hz A 3.1

240 V - 50/60 Hz A 3

400 V - 50/60 Hz A 1.8

– according to UL 508, CSA C22 No.14 A600

Ie / DC-13 – acc. to IEC 60947-5-1 24 V - d.c. A 2.8

110 V - d.c. A 0.6

250 V - d.c. A 0.27

– according to UL 508, CSA C22 No.14 Q600

Positivity Contacts with positive opening operation as per IEC 60947-5-1 chapter 3

and EN 60947-5-1

Resistance between contacts mΩ 25

Mechanical durability Millions of operations > 1 million of operating cycles

Max. switching frequency Cycles/h 600

Electrical durability (according to IEC 60947-5-1 appendice C) Utilization categories AC-15 and DC-13 (see curves and values below)

– Max. switching frequency Cycles/h 3600

– Load factor 0.5

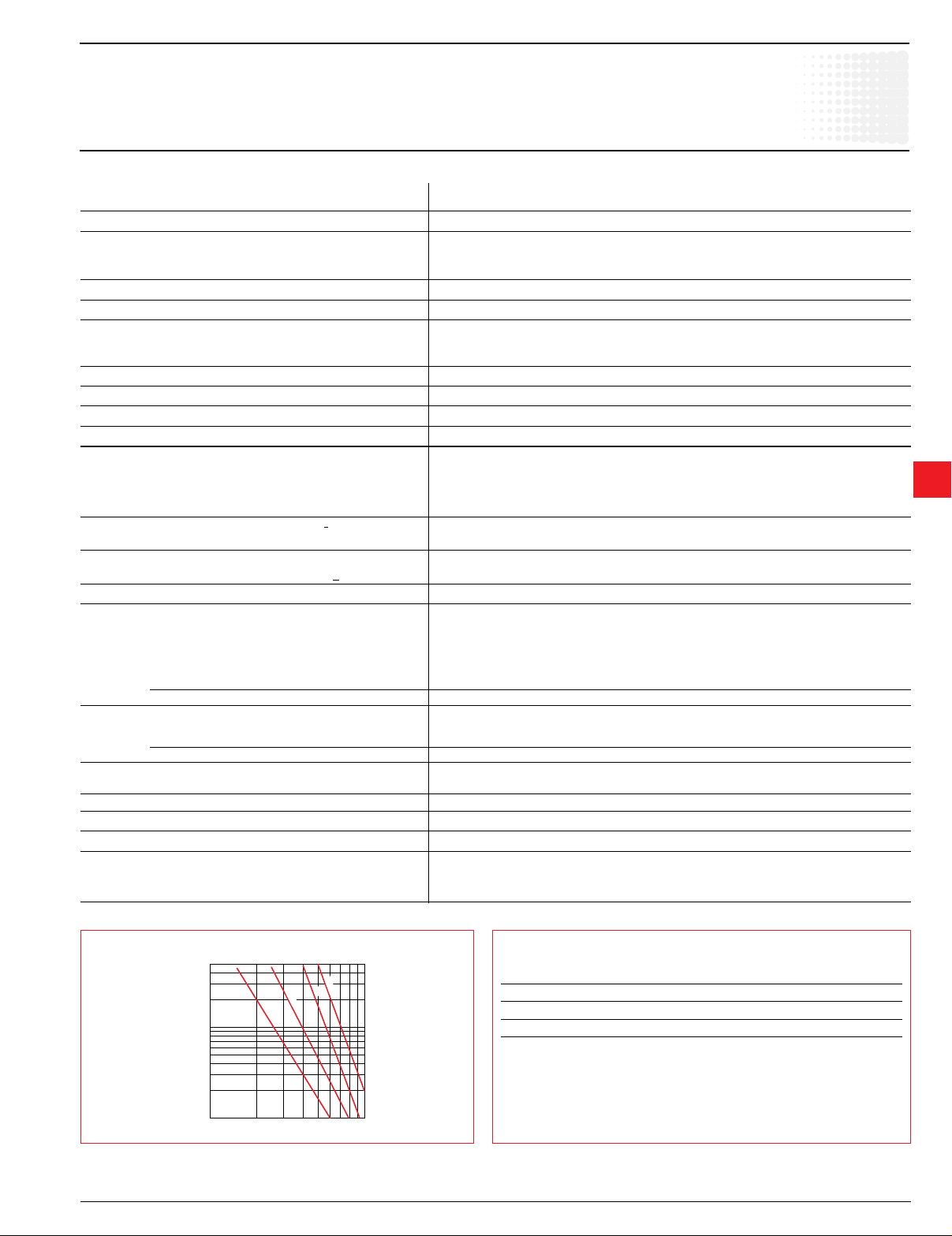

ElectricaldurabilityforAC-15utilizationcategory ElectricaldurabilityforDC-13utilizationcategory

Slow action Slow action

Power breaking for a durability of

5 million operating cycles

Voltage 24 V 12 W

Voltage 48 V 9 W

Voltage 110 V 6 W

i

kV 6

imp

A 10

th

9

Low Voltage Products & Systems 9.91

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage 1SXU000023C0202

Latch key safety limit switches

90˚

180˚

270˚

0˚

0˚...360˚

= =

Front translation

movement

Vertical translation

movement

Clearance = 2 to 3 mm

Gasket 1.6 mm thick

included

Vertical translation

movement

Clearance = 2 to 4 mm

Gasket 1.6 mm thick included

Front transition movement

Safety

limit switches

Implementation

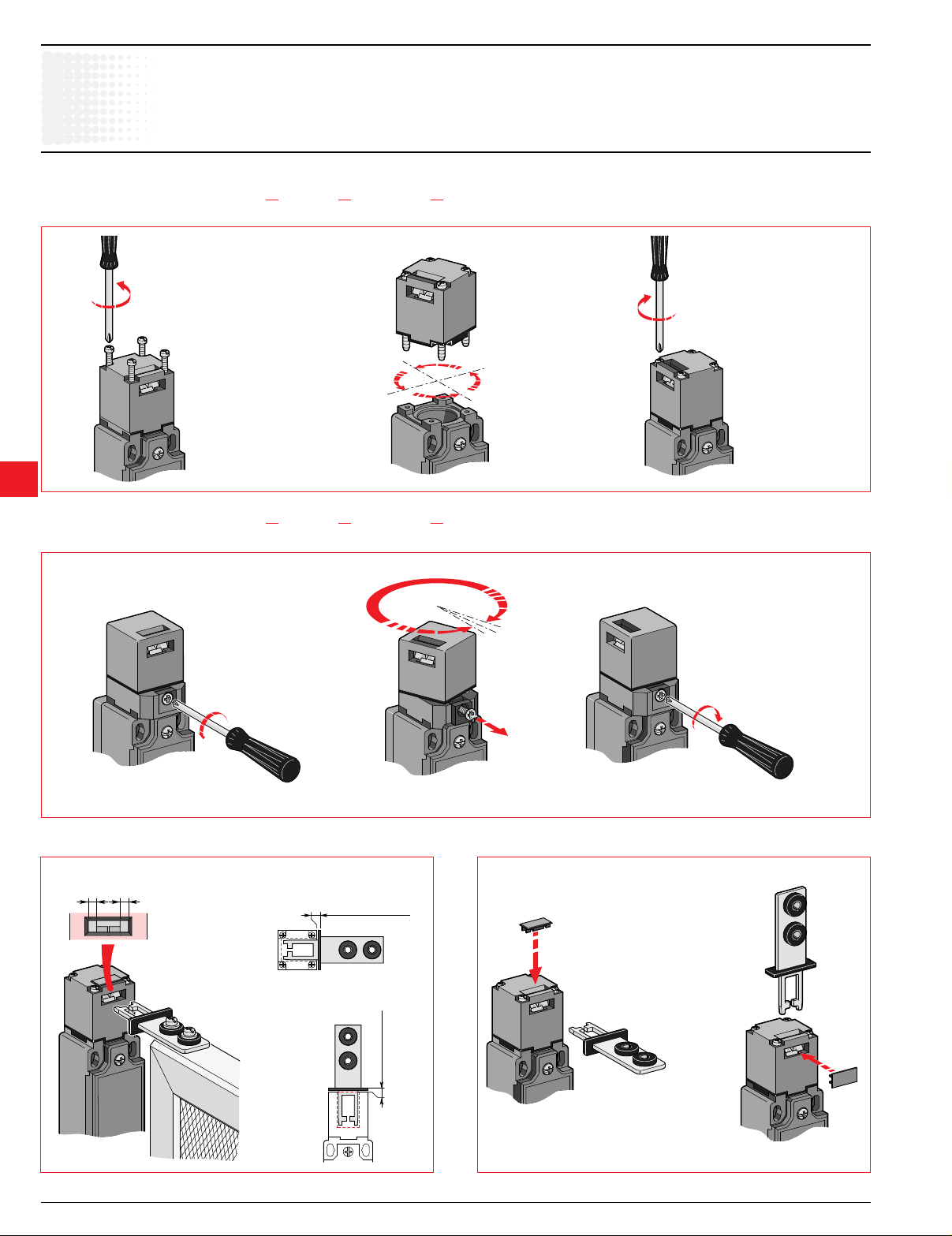

Limit switches with small latch (key) LS30P80...-S,LS31P80...-SandLS35P80...-S

• Head adjustment every 90°.

9

Limit switches with small latch (key) LS30P81...-S,LS31P81...-SandLS35P81...-S

• Pivoting head continuous between 0° to 360°.

Technical data

Adjusting the small latches (keys) Blanking off the window not used (NEMA 4x protection)

Clearances to be respected on installation

9.92 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Safety

90˚

180˚

270˚

0˚

90˚

180˚

270˚

0˚

90˚

180˚

270˚

0˚

Heads P75 and P76

Head P81 Head P77

Head P80

A

F

B

C

C

D

E

C

limit switches

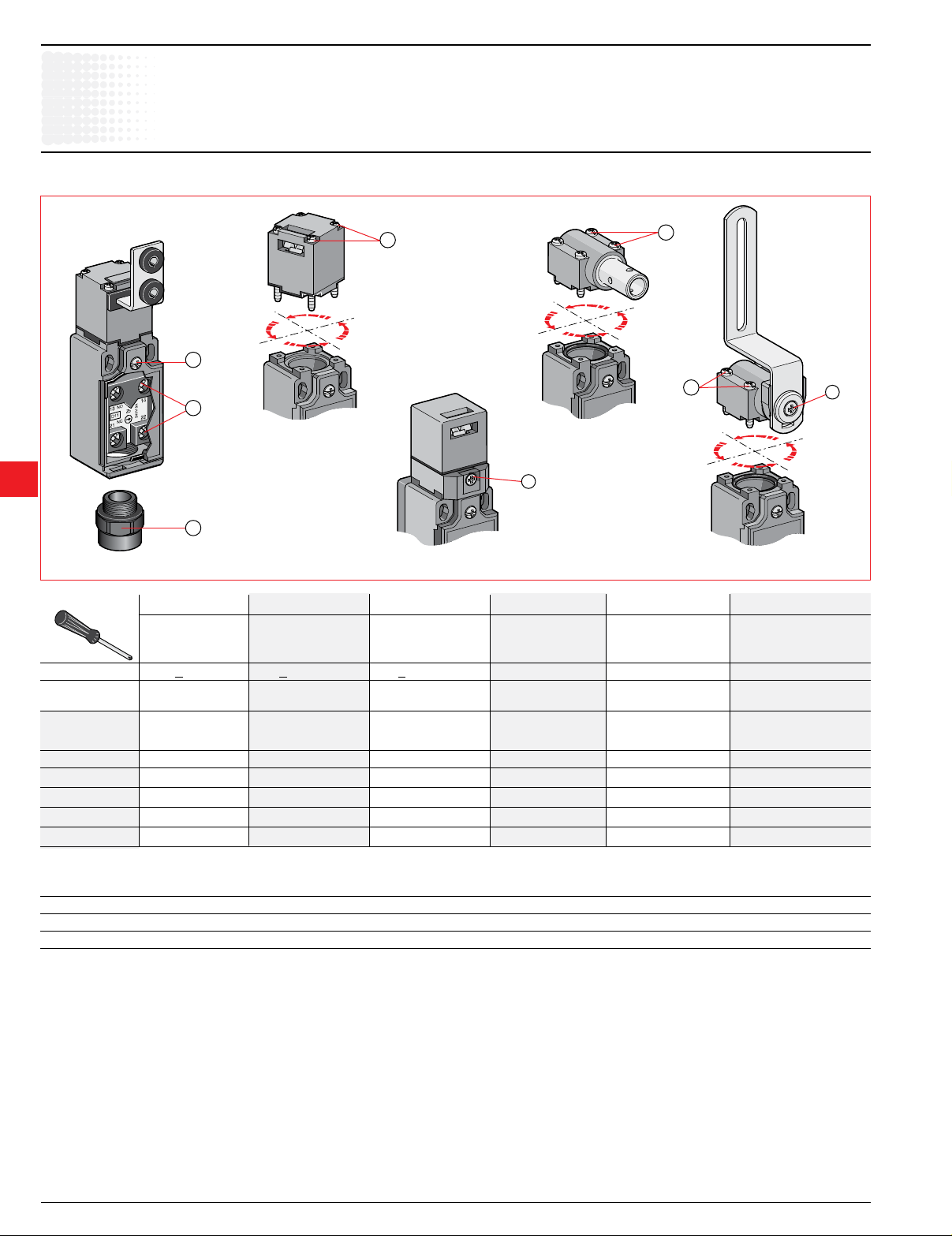

Tightening torques

9

Rotative axis safety limit switches

Technical data

A B C D E F

Contact block Closing Assembling Assembling Adjusting Cable

connecting the cover the operating the ush mounting the pivoting inlet by

terminals head right angle lever head 1/2" NPT adaptor

Screws

Tightening Recommended Max. Recommended Max. Recommended Max. Recommended Max. Recommended Max. Recommended Max.

torque N.m / lb.in N.m N.m / lb.in N.m N.m / lb.in N.m N.m / lb.in N.m N.m / lb.in N.m N.m / lb.in N.m

Limit

switches

M3.5 + pozidriv 2 ø3 + pozidriv 1 ø3 + pozidriv 1 M3.5 pozidriv 2 M3 Philips No. 1 –

LS35P80...-S 0.8 / 7 0.9 0.5 / 4.3 0.8 0.5 / 4.3 0.8 – – – – 17 / 150 18

LS35P81...-S 0.8 / 7 0.9 0.5 / 4.3 0.8 – – – – 0.3 / 2.63 0.5 17 / 150 18

LS35P75...-S 0.8 / 7 0.9 0.5 / 4.3 0.8 0.5 / 4.3 0.8 – – – – 17 / 150 18

LS35P76...-S 0.8 / 7 0.9 0.5 / 4.3 0.8 0.5 / 4.3 0.8 – – – – 17 / 150 18

LS35P77...-S 0.8 / 7 0.9 0.5 / 4.3 0.8 0.5 / 4.3 0.8 0.5 / 4.3 0.8 – – 17 / 150 18

Connecting data of contact blocks

Connecting terminals M3.5 (+,–) pozidriv 2 screw with cable clamp

Connecting capacity 1 or 2 x mm

2

/ AWG 0.5 mm2 / AWG 20 to 2.5 mm2 / AWG 14

Terminal marking According to EN 50013

9.94 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Safety Limit Switches

L0538D

0

C C

C1

C2

F1

CP

P

O

P

A

P

P

L

C

L

L0539D

C C

0

C C

5.00

11-12

21-22

21.5 mm

3.5

31° 31°6° 6°

0°

21-22

13-14

90° 90°

15° 15°

21-22

13-14

C

C

C C

0

C

L0537D

L0544D

C

1-1

C

1-2

C

P

C

L

P

P

Key extraction

21-22

13-14

Key insertion

C

1-1

C

1-2

C

P

C

L

P

P

21-22

13-14

21-22

13-14

0

Actuation

and

Release

21-22

21-22

Contact closed

Contact open

Contacts identication (example)

Travel and Operating diagrams

Key

extraction

C: travel in millimetres C: travel in degrees C: travel in degrees

PO Free position:

position of the switch actuator when no

external force is exerted on it.

PA Operating position:

position of the switch actuator, under the

effect of force F1, when the contacts leave

their initial free position.

PP Positive opening position:

position of the switch actuator from which

positive opening is ensured.

L Max. travel position:

maximum acceptable travel position of the

switch actuator under the effect of a force

F1.

Note: C

C

= pre-travel of contact 21-22,

1-1

= pre-travel of contact 13-14.

1-2

C1 Pre-travel (average travel):

distance between the free position PO and

the operating position PA.

CP Positive opening travel:

minimum travel of the switch actuator, from

the free position, to ensure positive opening

operation of the normally closed contact

(N.C.).

C2 Over-travel (average travel):

distance between the operating position PA

and the max. travel position L.

CL Max. travel (maximum travel):

distance between the free position PO and

the max. travel position L.

Examples:

LS35P80L02-S LS35P76D11-S

Simultaneous slow action contacts non-overlapping slow action contacts

Diagram for non-overlapping slow

action contacts:

C: travel

Diagram for non-overlapping slow

action contacts:

Diagram Diagram

in millimetres / key travel in degrees / lever rotation

48

AC1300

C: travel

Contacts position

Safety

Stop

Gap

Stop

Gap

To foresee a mechanical stop unit

and a function gap

Gap: Setting of small latches (key),

page 9.75

R...

The small latch (key) shall be presented in the axis of the control head.

Correct

Wrong

Curve of connecting cable Cable gland orientation

Wrong

limit switches

9

Rotative axis safety limit switches

Technical data

Utilization cautions

9.96 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Safety

limit switches

Safety limit switches

Technical data

Specications, directives, standards & EC conformity

Definitions

The ABB limit switches listed in this catalogue are developed and manufactured according to the rules set out in IEC international publications and EN European standards. In

most countries, the devices are not subject to further obligation for approval. In some

countries, however, the law stipulates obligation for approval.

Specifications

• InternationalSpecications

The International Electrotechnical Commission, IEC, which is part of the International

Standards Organization, ISO, publishes IEC publications which act as a basis for the

world market.

• EuropeanSpecications

The European Committee for Electrotechnical Standardization (CENELEC), grouping

18 European countries, publishes EN standards for low voltage industrial apparatus.

These European standards vary very little from IEC international standards and use

a similar numbering system. The same is true of national standards. Contradicting

national standards are withdrawn.

• HarmonizedEuropeanSpecications

The European Committees for Standardization (CEN and CENELEC), grouping 18

European countries, publish EN standards relating to safety of machinery.

• SpecicationsinCanadaandtheUSA

These are equivalent, but differ markedly from IEC, UTE, VDE and BS specications.

UL Underwriters Laboratories (USA)

CSA Canadian Standards Association (Canada)

Remark concerning the label issued by the UL (USA). Two levels of acceptance be-

9

tween devices must be distinguished:

"Recognized" Authorized to be included in equipment, if the equipment in

They bear the mark:

"Listed" Authorized to be included in equipment and for separate sale

They bear the mark:

European directives

The guarantee of free movement of goods within the European Community assumes

elimination of any regulatory differences between the member states. European

Directives set up common rules that are included in the legislation of each state while

contradictory regulations are cancelled.

There are three main directives:

• LowVoltageDirective73/23/EEC, amended by Directive 93/68/EEC concerning

electrical equipment from 50 to 1000 V a.c. and from 75 to

1500 VDC. This species that compliance with the requirements that it sets out is

acquired once the equipment conforms to the standards harmonized at European

level: EN 60947-1 and EN 60947-5-1 for limit switches.

• MachinesDirectives-89/392/EEC,91/368/EEC,93/44/EEC,93/68/EEC - dening main safety and health requirements concerning design and manufacture of the

machines and other equipment including safety components in European Union

countries.

• ElectromagneticCompatibilityDirective89/336/EEC, amended by Directive

92/31/EEC and Directive 93/68/EEC concerning all electrical devices likely to create

electromagnetic disturbances.

Signification of CE marking:

CE marking must not be confused with a quality label.

CE marking placed on a product is proof of conformity with the European Directives

concerning the product.

CE marking is part of an administrative procedure and guarantees free movement of

the product within the European Community.

Standards

• Internationalstandards

IEC 60947-1 Low-voltage switchgear and controlgear – Part 1: General

IEC 60947-5-1 Low-voltage switchgear and controlgear – Part 5: Control

IEC 60204-1 Electrical equipment of industrial machines – Part 1: General

IEC 60204-2 Electrical equipment of industrial machines – Part 2: Item

question has been entirely mounted and wired by qualied

personnel. They are not valid for use as "General purpose

products" as their possibilities are limited.

as "General purpose products" components in the USA.

Rules (NFC 63-001).

circuit devices and switching elements – Section 1: Electromechanical control circuit devices (NFC 63-146) – Chapter 3:

Special requirements for control switches with positive opening

operation.

requirements (≈ NFC 79-130).

designation and examples of drawings, diagrams, tables and

instructions (Appendices D and E of Publications

IEC 60204-1).

.

.

• EuropeanStandards

EN 50005 Low-voltage switchgear and controlgear for industrial use – Termi-

EN 50013 Low-voltage switchgear and controlgear for industrial use –

EN 50041 Low-voltage switchgear and controlgear for industrial use –

EN 50047 Low-voltage switchgear and controlgear for industrial use –

EN 60947-1 Low-voltage switchgear and controlgear for industrial use –

EN 60947-5-1 Low-voltage switchgear and controlgear for industrial use – Part

• HarmonizedEuropeanStandards

These standards are common to all European Union and EFTA (European Free Trade

Association) countries. They were prepared (prEN project) and written (EN nal text)

by the European standardization committees CEN or CENELEC.

Harmonized European standards were drawn up to allow denition of the rules and

technical means to be used to satisfy the main safety requirements on machines and

thus guarantee conformity with the Machines Directive.

Compliance with a harmonized European standard is presumption of conformity with

the relevant Directive.

European standards relating to machine safety are divided into groups (A, B and C

types).

Type A standards: basic standards: setting out design principles and the general

EN 292-1 Safety of machinery – Basic concepts, general principles for

EN 292-2 and Safety of machinery – Basic concepts, general principles for

EN 292-2/A1

EN 1050 Safety of machinery – Principles for risk assessment.

Type B standards: group standards:

B1: dealing with specic safety aspects.

EN 60204-1 Safety of machinery – Electrical equipment of machines – Part

EN 954-1 Safety of machinery – Safety-related parts of control systems –

B2: dealing with components and devices determining safety.

EN 1088 Safety of machinery – Interlocking devices associated with

Type C standards: specic standards or standards per machine family giving

EN 81-1 Safety rules for the construction and installations of lifts – Part

nal marking and distinctive number: General rules (NFC 63-030).

Terminal marking and distinctive number for particular control

switches (NFC 63-033).

Control switches – Position switches 42.5 x 80 – Dimensions

and characteristics.

Control switches – Position switches 30 x 55 – Dimensions and

characteristics.

Part 1: General rules (NFC 63-001).

5: Control circuit devices and switching elements – Section 1:

Electromechanical control circuit devices (NFC 63-146) – Chapter 3: Special requirements for control switches with positive

opening operation.

aspects valid for all machine types.

design – Part 1: Basic terminology, methodology.

design – Part 2: Technical principles and specications.

1: General requirements.

Part 1: General principles for design.

guards – Principles for design and selection.

detailed safety specications applicable to a machine or to a

group of machines.

1: Electric lifts.

Content of the "EC" Declaration of Conformity for Safety

Components

The "EC" Declaration of Conformity is intended to certify that the safety component

complies with the main safety and health requirements of

Machines Directive 89/392/EEC.

It must contain the following information:

– the name and address of the manufacturer or his representative established in the

European Community,

– the description of the safety component (brand, type, serial number, etc.),

– the safety function performed by the safety component if this is not obvious from the

description,

– when needed, the name and address of the notied organization and the number of

the type "CE" certicate,

– when needed, the name and address of the notied organization to which the le

has been sent as per article 8, paragraph 2, point c), rst hyphen,

– when needed, the name and address of the notied organization who performed the

check referred to in article 8, paragraph 2, point c), second hyphen,

– when needed, the reference to the harmonized standards,

– when needed, the national technical standards and specications used,

– identication of the signatory authorized to hire the manufacturer or his representa-

tive established in the European Community.

9.88 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

limit switches

Safety limit switches

Safety

Technical data

Control system categories as per EN 954-1

The main aim of all machine designers is to guarantee that the faults on safety-related control system parts or external disturbances cannot result

in a dangerous situation or a dangerous event on the machine.

The summarizing table below determines the category of the safety-related control system parts.

Categories

The parts of the safety-related control system

and / or its devices must be designed, manu-

B

1

2

3

4

Important: The safety categories apply to the entire control system and not to the individually considered safety components.

factured, selected, mounted and combined

according to proper procedures so as to

withstand expected inuences.

The requirements formulated in category B are

combined with use of tried and tested safety

components and principles.

The requirements formulated in category B

and use of tried and tested safety principles

apply.

The safety function(s) must be tested regularly

by the machine control system. Test frequency

must be adapted to the machine and to its

application.

The requirements formulated in category B

and use of tried and tested safety principles

apply.

The control system must be designed so

that:

a) a single fault in the control does not lead to

loss of the safety function and…

b)

b) if this is reasonably feasible, the single fault

must be detected by appropriate technical

means.

The requirements formulated in category B

and use of tried and tested safety principles

must be applied.

The control system must be designed so

that:

a) a single fault in the control does not lead to

loss of the safety function and…

b).

b) if possible the single fault must be detected

as soon as or before the next tripping of

the safety function or... (

c) if this was not possible, an accumulation

of faults must not lead to loss of the safety

function.

Summary of control

system requirements

– Occurrence of a fault may lead to pos-

– Occurrence of a fault may lead to possible

– Loss of the safety function is detected

– When a single fault occurs, the safety

– Some faults will be detected, but not

– Accumulation of undetected faults may

(see paragraph

.

– When faults occur, the safety function is

– The faults will be detected in time to

(see paragraph

see paragraph c).

Control system behavior

If a fault occurs, it may lead to possible

loss of the safety function.

sible loss of the safety function, but this

is less probable than in category B.

loss of the safety function between the

periodic test intervals.

at each test.

function is always guaranteed.

all.

lead to loss of the safety function.

always guaranteed.

prevent loss of the safety function.

Main principle for ensur-

ing safety

By selection of components conforming to

relevant standards.

By choice and use of

safety components and

principles.

By improvement of

safety circuit structure.

9

By improvement of

safety circuit structure.

By improvement of

safety circuit structure.

Low Voltage Products & Systems 9.89

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage 1SXU000023C0202

Safety limit switches

Safety

limit switches

Classication of a machine into categories to EN 954-1

Pursuant to the Machinery Directive 89/392/EEC, every machine must comply with

the relevant Directives and standards. Measures must be taken to keep the risk to

persons below a tolerable extent.

In the rst step, the project planner performs a risk evaluation to EN 1050 "Risk

Assessment". This must take into consideration the machine's ambient conditions

for instance. Any overall risk must then be assessed. This risk assessment must be

conducted in such a form as to allow documentation of the procedure and the result

9

Technical data

Risk assessment & determination of control system categories

achieved. The risk, dangers and possible technical measures to reduce risks and

dangers must be stipulated in this risk assessment. After stipulating the extent on

the risk, the category on the basis of which the safety circuits are to be designed is

determined with the aid of EN 954-1 "Safety-Related Components of Controls".

This determined category denes the technical requirements applicable to the

design of the safety equipment. There are ve categories (B, 1, 2, 3 and 4) whereby

B (standing for basic category) denes the lowest risk and, thus, also the minimum

requirements applicable to the controller.

9.90 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Loading...

Loading...