Page 1

ABB Power T&D Company Inc.

Power Automation and Protection Division

Coral Springs, FL 33065

Type KLF

Instruction Leaflet

41-748.21C

Effective: January 1997

Supersedes I.L. 41-748.21B, Dated December 1993

( | ) Denotes Changed Since Previous Issue

CAUTION

!

Before putting protective relays into service, make sure that all moving parts operate freely, inspect the contacts to see that

they are clean and close properly, and operate the relay to check the settings and electrical connections.

1. APPLICATION

These relays have been specially designed and

tested to establish their suitability for Class 1E

applications in accordance with the ABB Power

T&D Company program for Class 1E Qulification

Testing ad detailed in bulletin STR-1. Materials

have been selected and tested to insure that the

relays will perform their intended functions for their

design life when operated in a normal environment

as defined by ANSI standards when exposed to

radiation levels up to 104 rads, and when subjected

to seismic events producing a Shock Response

Spectrum within the limits of the relay rating.

“Class 1E” is the safety classification of the electronic equipment and systems in nuclear power

generating stations that are essential to emergency

shutdown of the reactor, containment isolation,

cooling the reactor, and heat removal from the containment and reactor, or otherwise are essential in

preventing significant release of radioactive material to the environment.

The KLF relay is a single-phase relay connected to

the ac side of a synchronous machine and contains

three units connected so that the operation of two

units sounds an alarm warning the operator of a

low excitation condition, and the additional opera-

Loss-of-Field Relay

(For Class 1E Application)

tion of the third unit sets up the trip circuit. The

relay can be applied without modification to all

types of synchronous machines, such as turbo generators, water wheel generators or motors.

The KLF relay is designed for use with 3-phase 3wire voltage supply and may use wye or delta-connected voltage transformers. The type KLF-1 relay

may be used to increase security during inadvertent loss-of-potential (such as due to a blown potential fuse).

2. CONSTRUCTION

The relay consists of two (2) air-gap transformers

(compensators), two tapped auto-transformers,

one reactor, one cylinder-type distance IT, directional unit with adjustable reactor, an under-voltage

unit with adjustable resistor, telephone relay with

solid state time delay circuit, and an ICS indicating

contactor switch.

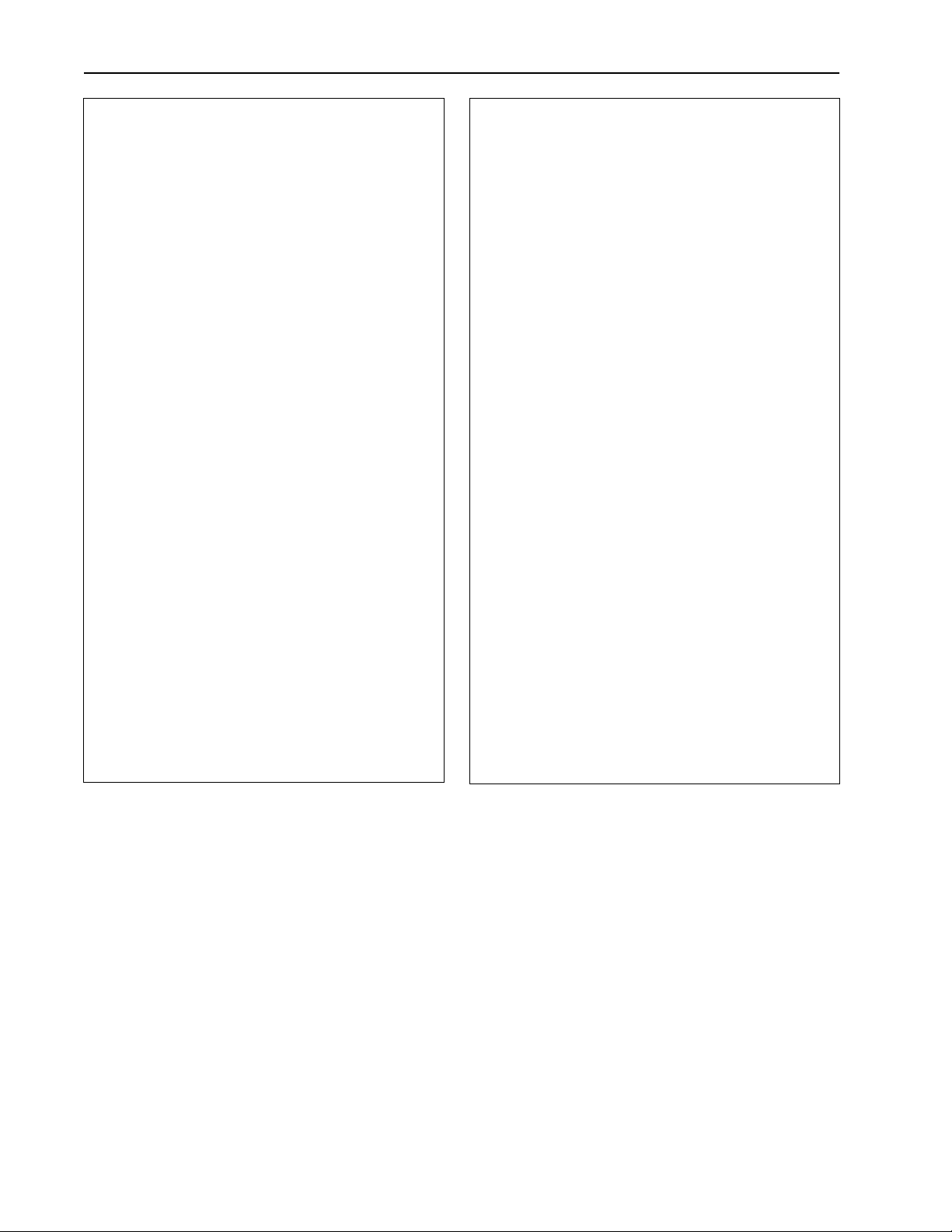

2.1 Compensator

The compensators, which are designated TA and

TC, are two (2) winding air-gap transformers (Fig-

ure 2). The primary or current winding of the

long-reach compensator TA has seven taps which

terminate at the tap block. They are marked 2.4,

3.16, 4.35, 5.93, 8.3, 11.5, 15.8. The primary winding of the short-reach compensator TC also has

seven taps which terminate at this tap block. They

are marked 0.0, 0.91, 1.27, 1.82, 2.55, 3.64, 5.1.

Voltage is induced in the secondary which is proportional to the primary tap and current magnitude.

This proportionality is established by the cross sectional area of the laminated steel core, the length of

an air gap which is located in the center of the coil,

and the tightness of the laminations. All of these

factors which influence the secondary voltage proportionality have been precisely set at the factory.

All possible contingencies which may arise during installation, operation or maintenance, and all details and

variations of this equipment do not purport to be covered by these instructions. If further information is desired

by purchaser regarding this particular installation, operation or maintenance of this equipment, the local ABB

Power T&D Company Inc. representative should be contacted.

Printed in U.S.A.

Page 2

41-748.21C

Front View Rear View

Figure 1. Type KLF Relay

The clamps which hold the laminations should not

be disturbed by either tightening or loosening the

clamp screws.

The secondary winding is connected in series with

the relay terminal voltage. Thus voltage, which is

proportional to the line current, is added vectorially

to the relay terminal voltage.

2.2Auto-Transformer

The auto-transformer has three taps on its main

winding, S, which are numbered 1, 2, and 3 on the

tap block. A tertiary winding M has four taps which

may be connected additively or subtractively to

inversely modify the setting by any value from -15

to +15 percent in steps of 3 percent.

2

The sign of M is negative when the R lead is above

the L lead. M is positive when L is in a tap location

which is above the tap location of the R lead. The

M setting is determined by the sum of per unit values between the R and L lead. The actual per unit

values which appear on the tap plate between taps

are 0,.03,.06, and.06.

The auto-transformer makes it possible to expand

the basic ranges of the long and the short reach

compensators by a multiplier of . Any relay

S

-------------1 M±

ohm setting can be made within±1.5 percent from

2.08 ohms to 56 ohms for the long-reach and

from.79 ohms to 18 ohms for the short-reach.

Page 3

Sub 1

185A181

Figure 2. Compensator Construction

2.3 Impedance Tripping Unit

The distance unit is a four pole induction cylinder

type unit. The operating torque of the unit is proportional to the product of the voltage quantities

applied to the unit and the sine of the phase angle

between the applied voltages. The direction of the

torque depends on the impedance phasor seen by

the relay with respect to its characteristic circle.

Mechanically, the cylinder unit is composed of four

basic components: A die-cast aluminum frame,

and electromagnet, a moving element assembly,

and a molded bridge. The frame serves as a

mounting structure for the magnetic core. The

magnetic core which houses the lower pin bearing

is secured by the frame by a locking nut. The bearing can be replaced, if necessary, without having

to remove the magnetic core from the frame.

The electromagnet has two sets of two series connected coils mounted diametrically opposite one

another to excite each set of poles. Locating pins

on the electromagnet are used to accurately position the lower pin bearing, which is mounted on the

frame, with respect to the upper pin bearing, which

is threaded into the bridge. The electromagnet is

secured to the frame by four mounting screws.

The moving element assembly consists of a spiral

spring, contact carrying number, and an aluminum

cylinder assembled to a molded hub which holds

the shaft. The hub to which the moving-contact

41-748.21C

arm is clamped has a wedge and cam construction, to provide low-bounce contact action. A

casual inspection of the assembly might lead one

to think that the contact arm bracket does not

clamp on the hub as tightly as it should. However,

this adjustment is accurately made at the factory

and is locked in place with a lock nut and should

not be changed. Optimum contact action is

obtained when a force of 4 to 10 grams pressure

applied to the face of the moving contact will make

the arm slip from the condition of reset to the point

where the clamp projection begins to ride up on

the wedge. The free travel can vary between 15° to

20°.

The shaft has removable top and bottom jewel

bearings. The shaft rides between the bottom pin

bearing and the upper pin bearing with the cylinder

rotating in an air-gap formed by the electromagnet

and the magnetic core. The stops are an integral

part of the bridge.

The bridge is secured to the electromagnet and

frame by two mounting screws. In addition to holding the upper pin bearing, the bridge is used for

mounting the adjustable stationary contact housing. This stationary contact has .002 to .006 inch

follow which is set at the factory by means of the

adjusting screw. After the adjustment is made the

screw is sealed in position with a material which

flows around the threads and then solidifies. The

stationary contact housing is held in position by a

spring type clamp The spring adjuster is located on

the underside of the bridge and is attached to the

moving contact arm by a spiral spring. The spring

adjuster is also held in place by a spring type

clamp.

When contacts close, the electrical connection is

made through the stationary contact housing

clamp, to the moving contact, through the spiral

spring and out to the spring adjuster clamp.

2.4 Directional Unit

The directional unit is an induction cylinder unit

operating on the interaction between the polarizing

circuit flux and the operating circuit flux.

Mechanically, the directional unit is composed of

the same basic components as the distance unit: a

die-cast aluminum frame, an electromagnet, a

moving element assembly, and a molded bridge.

The electromagnet has two series-connected

polarizing coils mounted diametrically opposite

one another; two series-connected operating coils

3

Page 4

41-748.21C

* Sub 4

3531A58

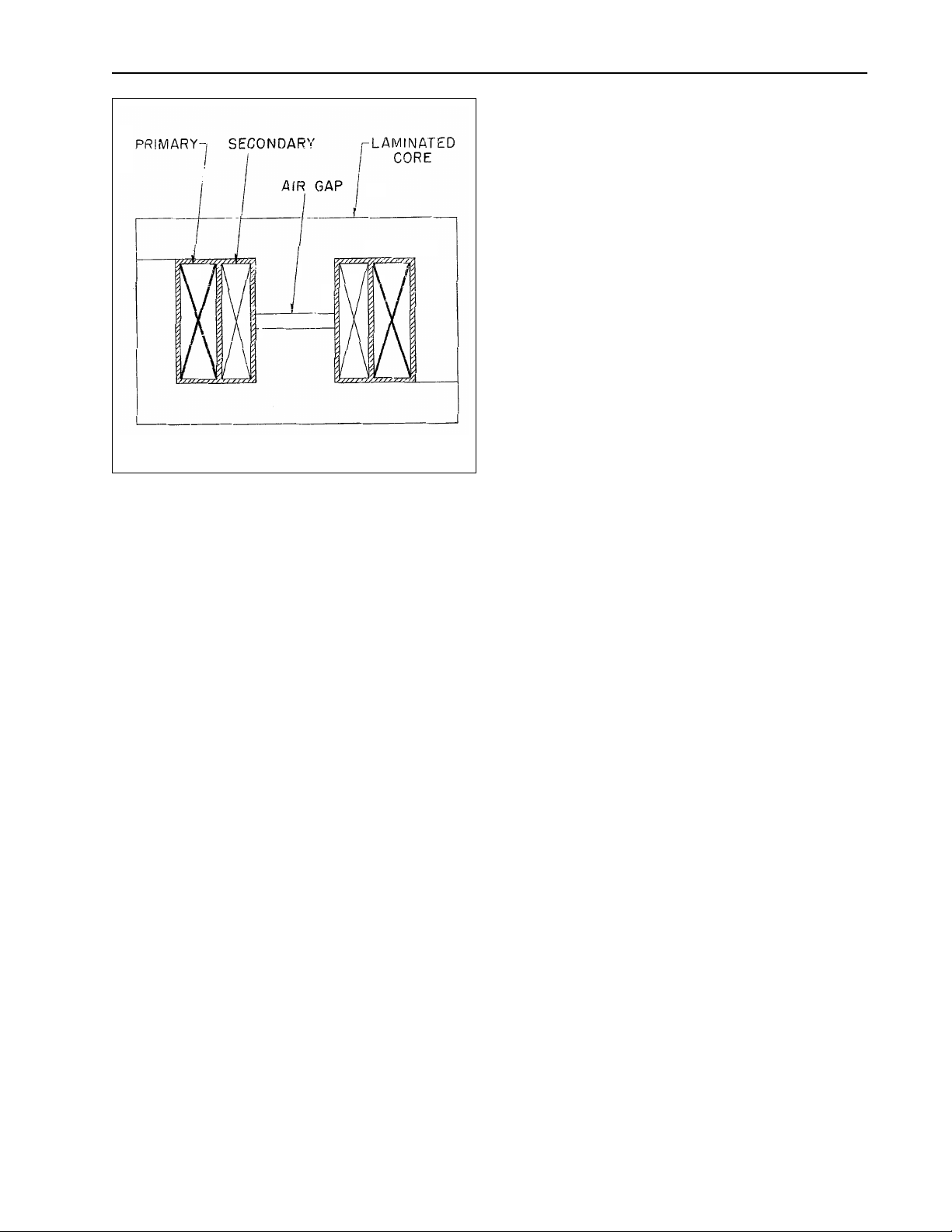

Figure 3. Internal Schematic of Type KLF Relay in FT-41 Case

*Denotes Change

mounted diametrically opposite one

another; two magnetic adjusting plugs;

upper and lower adjusting plug clips, and

two locating pins. The locating pins are

used to accurately position the lower pin

bearing, which is threaded into the

bridge. The electromagnet is secured to

the frame by four mounting screws.

The moving element assembly consists

of a spiral spring, contact carrying member, and an aluminum cylinder assembled to a molded hub which holds the

shaft. The shaft has removable top and

bottom jewel bearings. The shaft rides

between the bottom pin bearing and the

upper pin bearing with the cylinder rotating in an air gap formed by the electromagnet and the magnetic core.

The bridge is secured to the electromagnet and frame by two mounting screws.

In addition to holding the upper pin bearing, the bridge is used for mounting the

adjustable stationary contact housing.

The stationary contact housing is held in

position by a spring-type clamp. The

spring adjuster is located on the underside of the bridge and is attached to the

moving contact arm by a spiral spring.

The spring adjuster is also held in place

by a spring type clamp.

2.5 Undervoltage Unit

The voltage unit is an induction-cylinder

unit.

Mechanically, the voltage unit is composed, like the directional unit, of four

components: A die-cast aluminum frame,

and electromagnet, a moving element

assembly, and a molded bridge.

The electromagnet has two pairs of voltage coils. Each pair of diametrically

opposed coils is connected in series. In

addition one pair is in series with an

adjustable resistor. These sets are in

Sub 4

3533A29

parallel as shown in Figure 3. The

adjustable resistor serves not only to

shift the phase angle of the one flux with

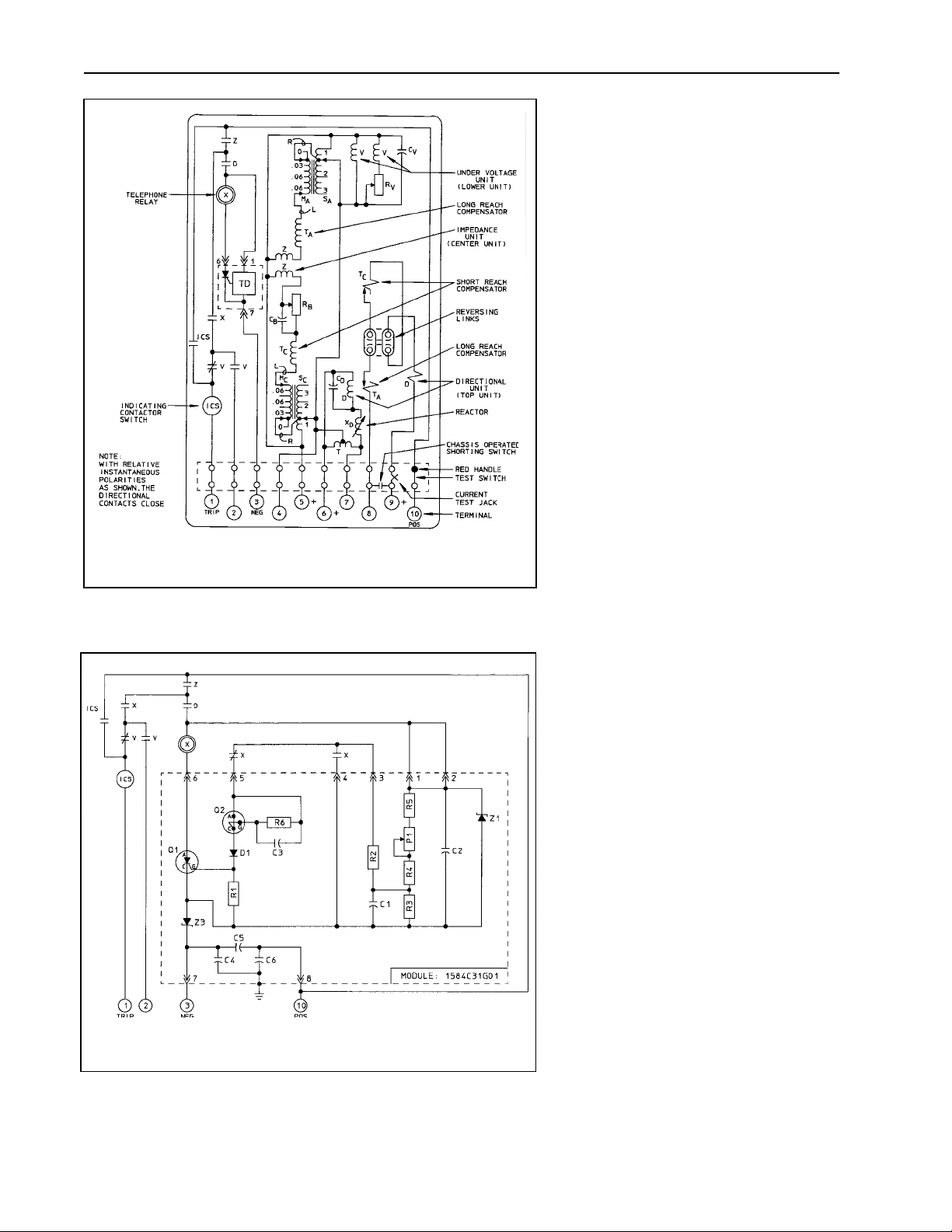

Figure 4. KLF Time Delay Schematic

respect to the other to produce torque,

but it also provides a pickup adjustment.

4

Page 5

41-748.21C

Sub 3

1487B21

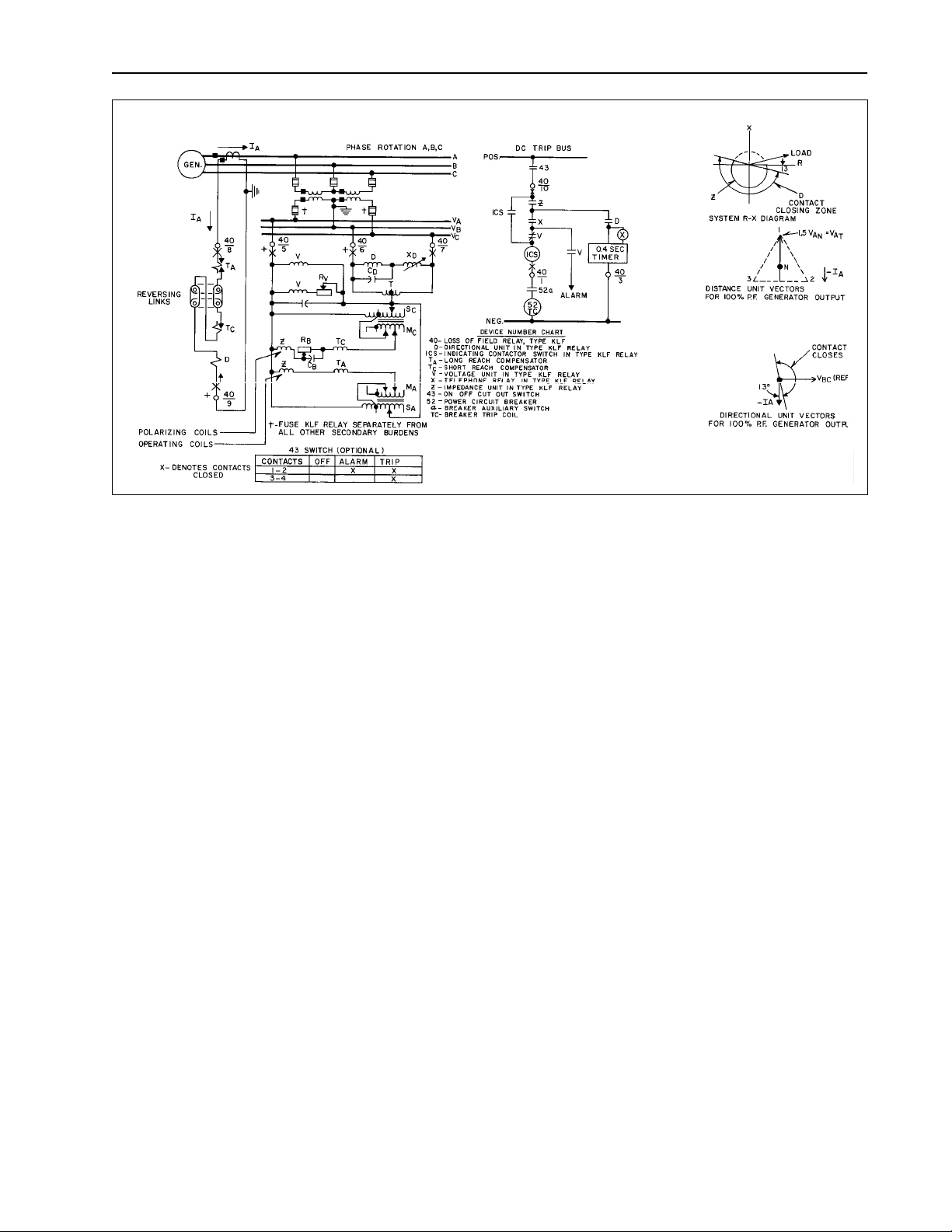

Figure 5. External Schematic of Type KLF Relay

Otherwise the undervoltage unit is similar in its

construction to the directional unit.

2.6 Solid State Time Delay Circuit

The telephone relay (x) is energized through a

solid state time delay circuit (TD) as shown in Fig-

ure 3. The solid state time delay circuit shown in

Figure 4 consists basically of an adjustable inte-

grating RC circuit with quick reset. The RC circuit

is adjusted to provide the voltage level to trigger

the SCR through a multi-layer silicon switch. The

SCR in turn energizes the relay.

2.7 Indicating Contactor Switch Unit (ICS)

The dc indicating contactor switch is a small clapper-type device. A magnetic armature, to which

leaf-spring mounted contacts are attached, is

attracted to the magnetic core upon energization of

the switch. When the switch closes, the moving

contacts bridge two stationary contacts, completing the trip circuit. Also during this operation two

fingers on the armature deflect a spring located on

the front of the switch, which allows the operation

indicator target to drop. The target is reset from the

outside of the case by a push rod located at the

bottom of the cover. The front spring, in addition to

holding the target, provides restraint for the armature and thus controls the pickup of the switch.

3. OPERATION

The relay is connected and applied to the system

as shown if Figure 5. The directional unit closes its

contacts for lagging VAR flow into the machine. Its

zero torque line has been set at -13° from the

R-axis. Its primary function is to prevent operation

of the relay during external faults. The impedance

unit closes its contacts when, as a result of reduction in excitation, the impedance of the machine as

viewed from its terminals is less than a predetermined value. The operation of both impedance and

directional units energize the time delay circuit

which operates the X unit after .4 ±.05 seconds.

The operation of impedance, directional and X unit

sounds an alarm, and the additional operation of

the under voltage unit trips the machine. This time

delay is to insure positive contact coordination

under all possible operating conditions. During a

seismic event which exposes the relay to a ZPA

level of 5.7g, the operate time of the X unit may

vary from .25 second to 1.25 seconds due to

bounce induced in the Z and the D contacts. During normal conditions, all contacts are open.

3.1 Principle of Distance Unit Operation

The distance unit is an induction cylinder unit having directional characteristics. Operation depends

on the phase relationship between magnetic fluxes

in the poles of the electromagnet.

5

Page 6

41-748.21C

Sub 2

185A331

Figure 7. Effect of Compensator Voltages

(ZC is positive)

One set of opposite poles, designated as the operating poles are energized by voltage V1Tmodified

by a voltage derived from the long reach compensator TA. The other set of poles (polarizing) are

energized by the same voltage V1T except modified by a voltage derived from the short reach com-

pensator TC. The flux in the polarizing pole is so

adjusted that the unit closes its contacts whenever

flux in the operating set of poles leads the flux in

the polarizing set.

The voltage V1T is equal to:

V120.5 V

+ 1.5 V

==

1T

23

1N

(1)V

As shown in Figure 5, one-half of V23, voltage is

physically derived in the relay at midtap of a reac-

tor connected across voltage V23.

Reach of the distance unit is determined by com-

pensators TA and TC as modified by auto-transformer settings. Compensators TA and TC are

designed so the their mutual impedances ZA and

ZC have known and adjustable values as

described below under “CHARACTERISTICS” and

“SETTING CALCULATIONS”. The mutual imped-

ance of a compensator is defined here as the ratio

of secondary induced voltage to primary current

and is equal to T. Each secondary compensator

voltage is in series with the voltage V1T. Compen-

sator voltages are equal to 1.5 I1 ZAfor long reach

compensator and 1.5 I1 ZC for short reach compensator, where I, is the relay current.

Figure 6 shows how the compensation voltages

1.5 I1 ZA and 1.5 I1 ZC influence the R-X circle.

Notice that ZA independently determines the “long

reach”, while ZC independently determines the

“short reach”. With the reversing links in the nor-

mal position (+ZC) the circle includes the origin;

with the opposite link position (-ZC) the circle

misses the origin. The following paragraphs

explain this compensator action.

Referring to Figure 5 notice that resistor RB and

capacitor CB cause the polarizing voltage to be

shifted 90° in the leading direction. Thus, when the

current is zero, polarizing voltage V

leads the

POL

operating voltage VOP by 90° and of sufficient

magnitude to operate the relay. This means the

apparent impedance is along the X axis. Notice in

Figure 7(b) that the ZA compensation reverses the

operating voltage phase position. The relay balances when this voltage is zero. Note also this balance is unaffected by the ZC compensation, since

this compensation merely increases the size of

V

.

POL

Sub 2

185A182

Figure 6. R-X Diagram Characteristics with various

ZC - Compensator Settings.

6

For lagging current conditions notice Figure 7(c)

illustrates how V

is reversed by the ZC com-

POL

pensation. In this case the ZA compensation has

no effect of the balance point. This explains why

the reach point is fixed independently by ZC.

Figure 7 assumes that ZC is positive (circle

includes origin). If the current coil link is reversed,

Page 7

41-748.21C

the compensation becomes +1.5 IZC. In Figure

7(b) this change would result in V

POL

being

reduced rather than increased by the compensation. As the current increases V

will finally be

POL

reversed establishing restraining torque. Thus, the

current need not reverse in order to obtain a “short

reach” balance point. Instead the apparent impedance need only move towards the origin in the - X

circle region to find the balance point. Therefore

the circle does not include the origin with a

reversed link position.

4. CHARACTERISTICS

The type KLF relay is available in one range.

4.1 Distance Unit

The distance unit can be set to have characteristic

circles that pass through origin, include it, or

exclude it, as shown in Figure 6.

The ZAand ZC values are determined by compensator settings and modified by auto-transformer

settings, S, L, and R. The impedance settings in

ohms reach can be made for any value from 2.08

to 56 ohms for ZA, and from 0.79 ohm to 18 ohms

for ZC in steps of 3 percent.

The taps are marked as follows:

T

-------------------------------------------------------------------------------------

2.4 3.16 4.35 5.93 8.3 11.5 15.8,,,,,,

-------------------------------------------------------------------------------------

0.0 0.91 1.27 1.82 2.55 3.64 5.1,,,,,,

,()

S

ASC

----------------------

123,,

---------------------------------------------------------------------------------

values between taps .03, .06, .06±

A

T

C

MAMC,()

age. This voltage is equal to 1.5 V1N voltage. The

contacts can be adjusted to close over the range of

65 to 85 percent of normal system voltage. The

dropout ratio of the unit is 98 percent or higher.

4.4 Trip Circuit

The main contacts will safely close 30 amperes at

250 volts dc and the seal-in contacts of the indicating contactor switch will safely carry this current

long enough to trip a circuit breaker.

4.5 Trip Circuit Constant

Indicating Contactor Switch (ICS)

0.2 ampere rating

1.0 ampere rating

2.0 ampere rating

8.5 ohm dc resistance

.37 ohms dc resistance

.1 ohm dc resistance

4.6 Burden

Current

5 amps, 60 Hz

T

& T

A

C

Settings VA

MAX.

MIN.

Phase AB

S

= SC VA

A

1

2

3

18.0

14.4

13.9

Rating Watts + Rated

125

250

18.6

3.8

POTENTIAL

120 VOLTS, 60 Hz

Angle

of LAG

°

2

31°

39°

dc Circuit

Angle

of LAG

°

77

51°

Phase BC

Angle VA of LAG

2.6

5.9

6.6

12°

38°

42°

3.9

7.8

4.2 Directional Unit

The KLF relay is designed for potential polarization

with an internal phase shifter, so that maximum

torque occurs when the operating current leads the

polarizing voltage by approximately 13 degrees.

The minimum pickup has been set by the spring

tension to be approximately 1 volt and 5 amperes

at maximum torque angle.

4.3 Undervoltage Unit

The undervoltage unit is designed to close its contacts when the voltage is lower than the set value.

The undervoltage unit is energized with V1T-volt-

4.7 Thermal Ratings

Potential: 132 volts (L-L) continuous

Current: 8 amperes continuous

200 amperes for 1 second

5. SETTING CALCULATIONS

5.1 General Setting Recommendations

The KLF relay may be applied as a single-zone

device, or two relays may be used to provide

two-zone protection. The single-zone setting may

be fully offset (Zone 1) or may include the origin

(Zone 2). The two-zone application would require a

7

Page 8

41-748.21C

Zone 1 KLF and a Zone 2 KLF, approximately

equivalent to two-zone step-distance line protection. A generalized external schematic, which is

applicable to either Zone 1 or Zone 2 relays is

shown in Figure 10. The recommended settings

and relative advantages of these varioi4us configurations are summarized on Table 1.

The single-zone and two-zone setting recommendations are modified when two or more machines

are bussed at the machine terminals. The voltage

and time delay considerations are treated in detail

in other sections of this leaflet. The recommended

settings are outlined in Table 2.

5.2 Zone 2 Setting Calculations (Distance Unit)

Set the distance unit to operate before the

steady-state stability limit is exceeded. Also, to

allow maximum output without an alarm, set the

distance unit to allow the machine to operate at

maximum hydrogen pressure and 0.95 per unit

voltage (lowest voltage for which the capability

curve machine cannot be realized without exceeding the steady-state stability limit, set the distance

unit to operate before the steady-state limit is

exceeded. Capability curves similar to Figure 8 are

obtained from the generator manufacturer.

To determine the desired setting convert the capability curve Figure 8 of the impedance curve Figure

Since the angle remains the same, the impedance

plot conversion is:

Z1.4 33.6°, as shown in Figure 9.–∠=

After plotting the steady-state stability limit and the

machine capability curves on the R-X diagram, plot

the relay circle between the stability limit and the

capability curve. (Note in Figure 9 that the relay

circle cannot be plotted within the 60# -VT = 0.95

curve, since the machine is beyond the

steady-state stability limit for these conditions.)

This plot defines the desired reach ZA and radius

R of the relay circle. Then use the following procedure to select tap settings.

Z

base

---------------------------------kva()R

1000 kv()2R

C

V

ohms=

(2)

where

Z

= one per unit primary ohms/

base

as seen from the relay.

kv = rated phase-to-phase voltage

of the machine.

kVA = rated kVA of the machine.

R

R

= the current transformer ratio.

C

= the potential transformer ratio.

V

9 by calculating , where VT is the per unit

|VT2|

--------------------KVA()

C

terminal voltage and (KVA)c is the per unit output.

The angle of each point on the impedance curve

(from the horizontal) is the same angle as the corresponding point on the capability curve.

For example, from Figure 8, an output of 0.6 per

unit KW on 30# hydrogen pressure curve is -0.4

per unit reactive KVA. Therefore,

KVA()

C

0.6()20.4–()

+=

2

= 0.715 per unit

0.4–

and,

θTan 1

– 33.6°–==

----------

0.6

Converting to the impedance curve:

2

V

Z

T

==

--------------------KVA()

C

1.0

-------------

0.715

2

= 1.4 per unit

The actual settings, ZA and ZC, are:

ZA=(ZA per unit) x (Z

ZC=(ZC per unit) x (Z

= (ZR - ZA) x (Z

base

) (3)

base

)

base

) (4)

Where R = radius of circle in per unit.

The tap-plate settings are made according

to equations:

ZAor Z

()

C

=

TS

-------------1 M±

(5)

where:

T = compensator tap value.

S = auto-transformer primary tap value.

M = auto-transformer secondary tap

value.

(M is a per unit value determined by taking the sum

of the values between the L and the R leads. The

sign is positive when L is above R and acts to

8

Page 9

41-748.21C

2

lower the Z setting. The sign is negative when R is

above L and acts to raise the Z setting).

The following procedure should be followed to

obtain an optimum setting of the relay:

1. Select the lowest tap S which give a prod-

uct of 18.6SA greater than desired ZA and a product of 6SC greater than desired Z

C

2. Select a value of M that will most nearly

make it equal to:

TS

M

------- Z

1.–=

If the sign is negative, then the M taps are connected with the R lead above the L lead to raise

the setting.

5.3 Sample Calculations

Assume that a KLF relay is to be applied to the following machine:

3-phase, 60 hertz, 3600 rpm, 18 kV, rated at 0.9

pf, 183,500 KVA at 45#H2.

RC= 1400/1 RV= 150/1

Step 3:

TAS

-------------Z

A

M

A

1–

15.8 2×

-------------------

27.6

1– 1.145 1– +.145=====

Set M = +.15. Place R lead in 0, L lead in

upper .06. The relay setting is now:

ActualZ

TAS

--------------

A

1 M±

A

15.8 2×

-------------------

1 0.15+

31.6

----------

1.15

27.5== ==

This is 99.7% of the desired setting.

To set ZC= 3.29 ohms:

Step 1: The lowest tap SC for 6SC greater than

3.29 is SC = 1.

Set SC = 1

Step 2: TC nearest to

329,

----------- -

1

3.29 is 3.64=

Set TC in 3.64 tap.

Step 3:

M

TCS

C

---------------

C

Z

C

1–

3.64 1×

-------------------

3.29

1– 1.107 1– +.107== ==

If the recommended setting from Figure 9 is used:

ZA per unit = 1.68

ZC per unit = 2R - ZA = 2 x 0.94 - 1.68 = 0.20

(The relay circle in Figure 9 was obtained by trial

and error using a compass to get the desired

radius and offset.)

(1)

2

× 1400×

16.48Ω== =

se

1000 kv()

----------------------------- -

()R

kva

V

R

1000 18()

c

------------------------------------------------- -

183 500 150×,

(2)

Z

Z

A

per unit()Z

A

base

(1.68 ) 16.48()27.6Ω===

(3)

Z

Z

C

per unit()Z

C

()0.20()16.45()3.29Ω===

base

To set ZA= 27.6

Step 1: The lowest tap SA for 18.6 SA greater

than ZA = 27.6 is 2. Set SA in tap 2.

Step 2: TA nearest to = 13.8 is TA= 15.8

27.6

----------

2

Set TA in 15.8 tap

Hence, the nearest MC value is + .12. Now set R

lead in 0.03 tap and L lead in the upper .06 tap.

(Since MC has plus sign lead L must be over R.)

T

S

Then, , or

Z

C

C

----------------------

1M

+()

3.64 1×

C

-------------------

1 0.12+

C

3.25Ω===

98.8% of the desired value.

5.4 Undervoltage Unit

A. The undervoltage unit is usually set to a value

corresponding to the minimum safe system voltage for stability. This voltage depends on many

factors, but is usually between 70 and 80 percent

of normal system voltage. The undervoltage unit

is set at the factory for 77% of normal system

voltage, or 92 V

(equivalent to 80 volts on the

L-L

undervoltage unit). In cases where each generator is equipped with its own transformer (unit

connected system) the standard factory setting is

usually satisfactory for the undervoltage unit.

B. In applications where multiple units are con-

nected to the same bus, loss of field of one unit

may not depress the bus voltage to the point

where the undervoltage unit will operate if it has

the standard setting. The following recommenda-

9

Page 10

41-748.21C

TABLE 1

RECOMMENDED SETTINGS FOR KLF RELAY

ZONE 1 (ALONE) ZONE 2 (ALONE) BOTH ZONE 1 AND 2

IMPEDANCE SETTING

VOLTAGE SETTING

TD-1

TD-2

ADVANTAGES

See Figure 11 See Figure 12 See Figures 11 & 12

(a) Contact shorted or

(b) Set at 80% for

security

1/4 to 1 sec

(1 sec preferred)

Not required for

(a) above. For

(b) above use 1 Min.

Less sensitive to

stable system swings

1) More sensitive to

2) Can operate on

3) Provide alarm

80%

1/4 to 1 sec

(1 sec preferred)

1 Min.

LOF condition

partial LOF

features for

manual operation

Zone 1 voltage contact

shorted with Zone 2 set

at 80%

Zone 1 timer = 1/4 sec

Zone 2 timer = 1 sec

1 Min

(1) Same as (1), (2)

and (3) at left.

(2) Provides back-up

protection

SPECIAL SETTINGS FOR MULTI MACHINES BUSSED AT MACHINE TERMINALS

IMPEDANCE SETTING

VOLTAGE SETTING

TD-1

TD-2

TABLE 2

ZONE 1 (ALONE) ZONE 2 (ALONE) BOTH ZONE 1 AND 2

See Figure 11 See Figure 12 See Figures 11 & 12

(a) Contact shorted or

(b) Set at 87% for

security

1/4 to 1 sec

(1 sec preferred)

Not required for

(a) above. For

(b) above use 10 sec

for cond. cooled,

25 sec for conv.

cooled

10 sec for cond. cooled.

25 sec for conv. cooled.

87%

1/4 to 1 sec

(1 sec preferred)

Zone 1 voltage contact

shorted with Zone 2 set

at 87%

Zone 1 timer = 1/4 sec

Zone 2 timer = 1 sec

10 sec for cond. cooled.

25 sec for conv. cooled.

10

Page 11

41-748.21C

tions should be considered:

1. For cross-compound turbine generator applications, the dropout voltage (i.e., the voltage

at which the back contact of the undervoltage unit closes) of the undervoltage unit

should be set for 87% of normal voltage

(equivalent to 90 volts on the undervoltage

unit).

2. For waterwheel generator applications, with

multiple machine tied to a common bus, the

dropout voltage of the undervoltage unit

should be set at 87%.

3. For all applications where the alarm function

is not to be used the undervoltage unit contact should be jumped (shorted).

4. For industrial applications, with two or more

generators on the same bus, the undervoltage unit contact should be jumped (shorted)

and the alarm circuit not used.

5. For small Synchronous condenser and large

motor applications, the undervoltage unit

contact should, in general, be jumped

(shorted), and the alarm circuit not used. In

special cases the machine may be treated

as in 2, above, where knowledge exists of

expected undervoltage level.

6. For gas turbine units, with high generator

impedance, the undervoltage unit may not

operate. For these applications the undervoltage contacts should be short circuited.

C. The desired undervoltage unit setting is com-

puted by:

Setting = VIT = 1.5 V

IN

where VINis phase-to-neutral voltage.

NOTE: An electrical check of this particular

setting is outlined in this instruction

leaflet, under the heading “Acceptance

Check”.

5.5 Time Delay Considerations

It may be conservatively stated that the rotor structure and stator heating, as a result of a shorted

field can be tolerated for 10 seconds on a conductor-cooled machine and 25 seconds for a conventional machine. This time may be as low as 5

seconds for an open field (as opposed to a field

closed through a field discharge resistor or an

exciter armature) and as high as one minute where

the concern is protection of an adjacent tandem

compound unit against partial loss-of-excitation in

the faulted machine.

In view of the above considerations, it is often

desirable to use an external timer in conjunction

with the KLF Relay. The following examples are

applications where an external timer would be

desirable:

1. Cross-compound units, with undervoltage

unit setting of 90 volts, should use an external timer to assure tripping before thermal

damage can result. The timer is energized at

the alarm output and should be set for 10

seconds for a cross-compound conductor

cooled machine. For a conventionally cooled

cross-compound machine, the external timer

should be set for 25 seconds.

As an alternative to this, the KLF with

shorted undervoltage contacts may be

applied and the alarm feature not used. With

this arrangement, tripping takes place after

the 0.4 second time delay provided by the X

unit in KLF relay.

2. Machines connected to a common high voltage bus may be protected against loss of

voltage due to loss-of-excitation in an adjacent machine by using a one minute timer

driven by the alarm output of the loss-of-field

relay.

3. In some critical applications 2 zone

loss-offield protection may be desirable. In

this case, the Zone 1 KLF impedance circle

should be small and fully offset in the negative reactance region. The long-reach should

be set equal to synchronous reactance, Xd.

The short-reach should be set equal to

one-half transient reactance, XD1/2. The trip

circuit should trip directly, with no time delay.

The alarm circuit should operate a timer

which may be set from 0.4 - 1.0 seconds,

depending on user preference. If the condition persists, this timer permits tripping.

The second-zone KLF may be set with a

larger impedance characteristic and will

detect partial loss-of-field conditions. A typical setting would be to just allow the machine

to operate at maximum hydrogen pressure

11

Page 12

41-748.21C

and 9.5 per unit voltage. If a low voltage condition occurs, it is recommended that tripping

be accomplished through a timer set for 0.6

second. Added to the X unit operate time of

0.4 second, this gives an overall time of 1.0

second. If the voltage is maintained, then the

alarm circuit should start a “last-ditch” timer.

This timer may be set anywhere from 10 seconds to one minute depending on machine

type and user preference.

5.6 Performance During Reduced Frequency

During major system break-ups, it is possible that

the generators may be called upon to operate at

reduced frequency for long periods of time. During

this condition the loss-of-field relay should be

secure and not over-trip for load conditions. The

KLF relay has a favorable characteristic during this

condition, since its tripping characteristic becomes

more secure during reduced frequencies, as

shown in Figure 13.

6. SETTING THE RELAY

The type KLF relay requires a setting for each of

the two compensators TA and TC, for each of the

two auto-transformers, primaries SA and SC, and

for the undervoltage unit.

6.1 Compensator (TA and TC)

Each set of compensator taps terminates in inserts

which are grouped on a socket and form approximately three quarters of a circle around a center

insert which is the common connection for all the

taps. Electrical connections between common

insert and tap inserts are made with a link that is

held in place with two connectors screws, one in

the common and one in the tap.

A compensator tap setting is made by loosening

the connector screw in the center. Remove the

connector screw in the tap end of the link, swing

the link around until it is in position over the insert

for the desired tap setting, replace the connector

screw to bind the link to this insert, and retighten

the connector screw in the center. Since the link

and connector screws carry operating current, be

sure that the screws are turned to bind snugly.

Compensator TC requires an additional setting for

including or excluding the origin of R-X diagram

from the distance unit characteristic. If the desired

characteristic is similar to that shown on Figure 6b,

the links should be set vertically in the + TC arrow

direction. If a characteristic similar to that shown in

Figure 6c is desired, set links horizontally in the TC arrow direction.

6.2 Auto-Transformer Primary (SA and SC)

Primary tap connections are made through a single

lead for each transformer. The lead comes out of

the tap plate through a small hole located just

below the taps and is held in place on the proper

tap by a connector screw.

An S setting is made by removing the connector

screw, placing the connector in position over the

insert of the desired setting, replacing and tightening the connector screw. The connector should

never make electrical contact with more than one

tap at a time.

6.3 Auto-Transformer Secondary (MA and MC)

Secondary tap connections are made through two

leads identified as L and R for each transformer.

These leads comes out of the tap plate each

through a small hole, one on each side of the vertical row of M tap inserts. The lead connectors are

held in place on the proper tap by connector

screws.

Values for which an M setting can be made are

from -.15 to +.15 in steps of .03. The value of a

setting is the sum of the numbers that are crossed

when going from the R lead position to the L lead

position. The sign of the M value is determined by

which lead is in the higher position on the tap

plate. The sign is positive (+) if the L lead is higher

and negative (-) if the R lead is higher.

Z M L Lead R Lead

0.87 TS

0.89 TS

0.92 TS

0.94 TS

0.97 TS

TS

1.03 TS

1.06 TS

1.1 TS

1.14 TS

1.18 TS

+.15

+.12

+.09

+.06

+.03

0

-.03

-.06

-.09

-.12

-.15

Upper .06

Upper .06

Lower .06

Upper .06

.03

0

0

Lower .06

0

.03

0

0

.03

0

Lower .06

0

0

.03

Upper .06

Lower .06

Upper .06

Upper .06

An M setting may be made in the following manner: Remove the connector screws so that the L

and R leads are free. Determine from the following

table the desired M value and tap positions. Neither lead connector should make electrical contact

with more than one tap at a time.

12

Page 13

41-748.21C

6.4 Undervoltage Unit

The voltage unit is calibrated to close its contact

when the applied voltage is reduced to 80 volts.

The voltage unit can be set to close its contacts

from 70 volts to 90 volts by adjusting the resistor

located next to the directional unit (to the left of the

upper operating unit). The spiral spring is not disturbed when making any setting other than the calibrated setting of 80 volts.

The undervoltage unit range of 70 to 90 volts is

equivalent to 80 to 104 V

(or 67% to 87% nor-

L-L

mal system voltage). This is because the voltage

on the unit is equal to 1.5 times V

L-N

.

6.5 Directional Setting

There is no setting to be made on the directional

unit.

6.6 Indicating Contactor Switch (ICS)

No setting is required on the ICS.

7. INSTALLATION

The relays should be mounted on switchboard

panels or their equivalent in a location free from

dirt, moisture, excessive vibration, and heat.

Mount the relay vertically by means of the four

mounting holes on the flange for semi-flush mounting or by means of the rear mounting stud or studs

for projection mounting. Either a mounting stud or

the mounting screws may be utilized for grounding

the relay. The electrical connections may be made

directly to the terminals by means of screws for

steel panel mounting of the terminal studs furnished with the relay for thick panel mounting. The

terminal studs may be easily removed or inserted

by locking two nuts on the stud and then turning

the proper nut with a wrench.

For detailed FT Case information refer to I.L.

41-076.

8. ADJUSTMENTS AND MAINTENANCE

The proper adjustments to insure correct operation

of this relay have been made at the factory. Upon

receipt of the relay, no customer adjustments,

other than those covered under “SETTINGS,”

should be required.

8.1 Performance Check

The following check is recommended to insure that

the relay is in proper working order: Relay should

be energized for at least one hour.

A. Distance Unit (Z)

1. Connect the relay as shown in Figure 14 with

the switch in position 2 and the trip circuit

deenergized.

2. Make the following tap settings:

TA= 11.5 TC= 2.55

SA=2 SC=1

MA= -.03 MC= -.09

TC link in middle block should be set for +T

direction.

This setting corresponds to ZA = 23.7, ZC = 2.80

Adjust the phase shifter for 90° current lagging

the voltage.

3. With the terminal voltage at 80 volts,

increase current until contacts just close.

This current should be within ±3% of 2.25

amps (2.32 - 2.18 amps). This value corresponds to 1.5 ZA setting since the voltage as

applied to terminals 4 and 5 is equivalent to

1.5 VIN voltage, or

V

Z

--------- -

A

I

1N

1

80

1

× 23.7Ω== =

------ -

--------- -

1.5

2.25

4. Adjust phase shifter for 90° current leading

the voltage.

5. With the terminal voltage at 80 volts increase

current until contacts just close. This current

should be within ±3% of 19.0 amps. (19.6 -

18.4 amps.) This value corresponds 1.5Z

setting for the same reason as explained

above.

5. Contact Gap

The gap between the stationary contact and

moving contact with the relay in deenergized

position should be approximately.040”.

B. Directional Unit Circuit (D)

1. Connect the relay as shown in Figure 14 with

the switch in position 1 and the trip circuit

deenergized.

2. With a terminal voltage of 1 volt and 5

amperes applied, turn the phase shifter to

13° (current leads voltage). The contacts

should be closed. This is the maximum

torque position.

3. Raise the voltage to 120 volts and vary the

phase shifter to obtain the two angles where

C

C

13

Page 14

41-748.21C

the moving contact just makes with the left

hand contact. These two angles (where

torque reverses) should be where the current

leads the voltage by 283° and 103°, ± 4°.

4. Contact Gap

The gap between the stationary contact and

moving contact with the relay in deenergized

position should be approximately.020”.

C. Undervoltage Circuit

1. Connect the relay as shown in Figure 14 with

switch in position 2 and the trip circuit deenergized.

2. Decrease the voltage until the contacts close

to the left. This value should be 80 ± 3%

volts.

D. Reactor Check

Apply 120 volts ac across terminals 6 and 7. Mea-

sure voltage from terminal 6 to 4 and 7 to 4. These

voltages should be equal to each other within

± 1volt.

E. Solid State Time Delay Circuit

Then release the contacts and observe that they

open positively.

All contacts should be checked and cleaned if necessary. A contact burnisher Number 182A836H01

is recommended for this purpose. The use of abrasive material for cleaning contacts is not recommended, because of the danger of embedding

small particles in the face of the soft silver and

thus impairing the contact.

8.3 Repair Calibration

Relay should be energized for at least one hour.

A. Auto-transformer check

Auto-transformers may be checked for turns ratio

and polarity by applying ac voltage to terminals 4

and 5 and following the procedure below.

1. Set SA and SC on tap number 3. Set the “R”

leads of MA and MC all on 0.0 and disconnect the “L” leads. Adjust the voltage for 90

volts. Measure voltage from terminal 5 to the

tap #1 of SA. It should be 30 voltages (± 1).

From terminal 5 to tap #2 of SA should be 60

volts. The same procedure should be followed for taps #1 and #2 of SC.

Block the contacts of the Z unit closed. Apply 125

volts dc with positive at terminal 10 and negative at

terminal 3. Manually close the contacts of the D

unit. Using oscilloscope measure the time delay by

observing the voltage block waveform between the

relay terminal 3 (-) and terminal 1 (+). Operate time

should be 0.4 ± .05 second.

F. Indicating Contactor Switch (ICS)

Close the main relay contacts and pass sufficient

dc current through the trip circuit to close the contacts of the ICS. This value of current should not

be greater than the particular ICS nameplate rating. The indicator target should drop freely.

Repeat above except pass 85% of ICS nameplate

rating current. Contacts should not pickup and target should not drop.

8.2 Routine Maintenance

All relays should be inspected periodically. They

should receive a “Performance Check” at least

once every year or at such other time intervals as

may be dictated by experience to be suitable to the

particular application. A minimum suggest check

on the relay system is to close the contacts manually so that the breaker trips and the target drops.

2. Set SA and SC on 1 and adjust the voltage at

the relay terminals for 100 volts. Measure

voltage drop from terminals 5 to each of the

MA and MC taps. This voltage should be

equal to 100 (± 1) plus the sum of values

between R and tap being measured. Example 100 (1 + .03 +.06) = 109 volts

Transformers that have an output different

from nominal by more than 1.0 volt probably

have been damaged and should be

replaced.

B. Distance Unit (Middle Unit) Calibration

Make the following tap plate settings.

TA = 15.8; TC = 5.1

SA = SC = 1

Make MA= MC = -.15 settings:

“L” lead should be connected to the “O” insert.

“R” lead should be connected to the upper “.06”

insert. (-.03-.06 - .06 = -.15 between L & R)

For the most accurate calibration preheat relay

for at least an hour by energizing terminals 5, 6,

14

Page 15

41-748.21C

& 7 with 120 volts, 3 phase.

The links in the middle tap block should be set

for the +TC direction.

1. Contact Gap Adjustment

The spring type pressure clamp holding the

stationary contact in position should not be

loosened to make the necessary gap adjustments.

With moving contact in the opened position,

i.e., against right stop on bridge, screw in

stationary contact until both contacts just

make (use neon light for indication). Then

screw the stationary contact away from the

moving contact 1

of .040”.

1

turn for a contact gap

/

3

2. Sensitivity Adjustment

Using the connections of Figure 14 apply 10

volts ac 90° lagging, to terminals 4 and 5

pass .420 amperes through current circuit

(terminals 9 and 8). The spiral spring is to be

adjusted such that the contacts will just

close. Deenergize the relay. The moving

contact should return to open position

against the right hand stop.

C. Impedance characteristic Check

1. Maximum Torque Angle

Adjust resistor RB (mounted on the back of

the relay) to measure 8800 ohms. Applying

100 volts ac to terminals 5 and 4 and passing 5.2 amperes, through the current circuit

turn the phase shifter until the moving contact opens. Turn the phase shifter back (few

degrees) until contacts close. Note degrees.

Continue to turn the phase shifter until contact closes again. Note degrees. The maximum torque angle should be (± 3°)

computed as follows:

Degrees to Close Contacts at Left +

Degrees to Close Contacts at Right

-------------------------------------------------------------------------------------

2

Adjust resistor RB until the correct maximum-torque angle is obtained.

2. Impedance Check

a. Adjust voltage to be 90 volts.

For current lagging 90° the impedance

unit should close its contacts at 3.12 –

3.35 amp.

Reverse current leads, the impedance

unit should close its contacts at 9.7 – 10.3

amperes.

b. Reverse the links in the middle tap block

to -TC position. Apply current of 10 amps.

The contacts should stay open. Reverse

current leads to original position. The contacts should open when current is

increased above 9.7 – 10.3 amperes.

Set links back to +TC position. Change S

A

and SC to setting “2”. Keeping voltage at

90 volts, 90° lagging, check pick-up current. It should be 1.56 – 1.68 amperes.

Now set the phase shifter so that voltage

leads the current by 90°. Impedance unit

should trip now at 4.85 – 5.15 amperes.

c. Set TA = 11.5, TC = 2.55, SA = 2, SC = 1,

MA = -.03 MC = -.09. Set voltage at 90

volts leading the current by 90°. Impedance unit should trip at 2.61 – 2.45 amp.

Reverse current leads. Pickup should be

20.8 –22.1 amp.

Change SA, SC = 3. Check pickup. It

should be 6.95 – 7.35 amps. Reverse current leads. Pick-up should now be 1.74 –

1.63 amps.

D. Directional Unit (Top Unit)

1. Contact Gap Adjustment

The spring type pressure clamp holding the

stationary contact in position should not be

loosened to make the necessary gap adjustments.

With moving contact in the open position,

i.e., against right stop bridge, screw in stationary contact until both contacts just make.

Then screw the stationary contact away from

90°=

the moving contact 3/4 of one turn for a contact gap of .022”.

2. Sensitivity Adjustment

With reactor X having its core screwed out

by about 1/8 inch apply 1.00 volt to terminals

6 and 7. Observing polarities as per schematic, and 5 amperes current leading the

voltage by 13°, the spiral spring is to be

15

Page 16

41-748.21C

adjusted such that the contacts will just

close. The adjustment of the spring is

accomplished by rotating the spring adjuster

which is located on the underside of the

bridge. The spring adjuster has a notched

periphery so that a tool may be used to

rotate it. The spring type clamp holding the

spring adjuster should not be loosened prior

to rotating the spring adjuster.

3. Plug adjustment for Reversing of Spurious

Torques

a. Set TC = 0.0. Connect a heavy current

lead from TA center link to terminal 8.

b. Short circuit terminals 6 and 7.

c. Screw in both plugs as far as possible

prior to starting the adjustment.

d. Apply 80 amps only momentarily, and the

directional unit need not be cooled during

initial rough adjustment. But, the direc-

tional unit should be cool when final

adjustment is made.

e. When relay contact closes to the left,

screw out the right hand plug until spuri-

ous torque is reversed.

f. When plug adjustment is completed check

to see that there is no closing torque when

relay is energized with 40 amps and volt-

age terminals 6 and 7 short-circuited.

4. Maximum Torque Angle Check

With 120 volts and 5 amperes applied, vary

the phase shifter to obtain the two angles

where the moving contacts just close. These

two angles (where torque reverses) should

be where the current leads the voltage by

283° ±4 and 103° ± 1. Readjust the reactor

Xd if necessary.

E. Undervoltage Unit (Lower Unit)

NOTE: The moving contact is in closed posi-

tion to the left when deenergized.

1. Contact Gap Adjustments

the moving contact (use neon light for indication) and then continue for one more complete turn.

b. R.H. (Normally Open) Contact Adjustment

With moving contact arm against the left

hand stationary contact, screw the right hand

stationary contact until it just touches the

moving contact. Then back the right hand

contact out two-thirds of one turn to give

0.020 inch contact gap.

2. Sensitivity Adjustment

a. Apply voltage to terminals 4 and 5. With the

adjustable resistor, which is located at the

upper left hand corner, set for maximum

resistance (2500 ohms) adjust the spring so

that contacts make (to the left) at 70 volts.

The contacts should open when unit is energized with 71 or more volts.

b. Relay is shipped with 80 volts setting. This is

accomplished by lowering resistance value

until contacts make at 80 volts and open

when unit is energized with 81 or more volts.

The spring should not be used for this setting.

F. Solid State Time Delay Circuit

Refer to Figure 4 for the following test.

a. Connect a jumper between the “D” contacts

(top unit) and connect a switch between the

D-contact and relay terminal 10.

b. Connect a scope probe, common and exter-

nal trigger to relay terminals 1, 3 and contact

“D” respectively.

c. Connect a rated dc power supply between

relay terminals 10 (+) and 3 (-).

d. Turn on the dc power supply and then turn

on the switch. The voltage at terminal 1

should jump from 0 to the rated voltage after

a time delay of 0.4± 10% seconds. A trimpot

on the PC board can be adjusted to obtain

the desired time delay from 0.3 to 0.5 seconds.

a. L.H. (Normally Closed) Contact Adjustment

With the moving contact arm in the closed

position, against left hand side of bridge,

screw the left-hand contact in to just touch

16

G. Indicating Contactor Switch (ICS)

Initially adjust unit on pedestal so that armature

fingers do not touch the yoke in the reset position.

This can be done by loosening the mounting screw

Page 17

41-748.21C

in the molded pedestal and moving the ICS in the

downward direction.

1. Contact Wipe. Adjust the stationary contacts

so that both stationary contacts make with

the moving contacts simultaneously and

wipe 1/64” to 3/64” when the armature is

against the core.

2. Target. Manually raise the moving contacts

and check to see that the target drops at the

same time as the contacts make or up to

1/16” ahead. The cover may be removed

and the tab holding the target reformed

slightly if necessary. However, care should

be exercised so that the target will not drop

with a slight jar.

3. Pickup. Unit should pickup at 98% of rating

and not pickup at 85% of rating. If necessary

the cover leaf springs may be adjusted. To

lower the pickup current use a tweezer or

similar tool and squeeze each leaf spring

approximately equal by applying the tweezer

between the leaf spring and the front surface

of the cover at the bottom of the lower window.

If the pickup is low, the front cover must be

removed and the leaf springs bent outward

equally.

2. Disconnect the L-leads of sections MA and

M

C

3. Pass 10 amperes ac current in terminal 9

and out of terminal 8.

4. Measure the compensator voltage with an

accurate high resistance voltmeter (5000

ohms/volt).

5. Compensator A-voltage should be checked

between lead L

and terminal 5.

A

For TA = 15.8 the voltage measured should

be 23.7 volts (±3%).

6. Compensator C voltage should be checked

between lead LC and the fixed terminal on

the resistor which is mounted in the rear.

For TC = 5.1, the voltage should be 76.5

volts (±3%).

7. For all other taps the compensator voltage is

1.5IT (±3%).

Where I = relay current

T = tap setting

H. Compensator Check

Accuracy of the mutual impedance T of the com-

pensators is set within very close tolerances at factory and should not change under normal

conditions. The mutual impedance of the compensators can be checked with accurate instruments

by the procedure outlined below:

1. Set TA on the 15.8 tap

TC on the 5.1 tap

9. RENEWAL PARTS

Repair work can be done and the relay recertified

most satisfactorily at the factory. However, interchangeable parts can be furnished to the customers who are equipped for doing repair work. When

ordering parts, always give the complete nameplate data. Note that replacement parts are not

“certified” and repair work done outside the factory

can not be certified by ABB.

17

Page 18

41-748.21C

18

Sub 2

185A183

Figure 8. Typical Machine Capability Curves

Page 19

41-748.21C

Sub 2

185A184

Figure 9. Typical Machine Capability Curves and Sample KLF Relay Setting

19

Page 20

41-748.21C

3

Figure 10. Generalized External Schematic

Su

35

20

Sub 1

3491A03

Figure 11. Zone 1 Impedance Characteristic

Page 21

+X

-X

R

DIRECTIONAL ELEMENT

STEADY STATE STABILITY LIMIT

ZONE 2 RELAY

MACHINE CAPABILITY CURVE

MEL

(MAX. H2 PRESSURE)

Figure 12. Zone 2 Impedance Characteristic

41-748.21C

Sub 1

3491A03

NOTE - FOR 50 HZ RELAY ALL FREQUENCY

VALUES SHOULD BE MULTIPLIED BY

A FACTOR OF 0.8333

X

50 HERTZ

55 HERTZ

R

Figure 13. KLF Frequency Response for Impedance Unit

60 HERTZ

68 HERTZ

Sub 2

3491A08

21

Page 22

41-748.21C

22

Sub 2

1487B22

Figure 14. Diagram of Test Connections for KLF Relay

Page 23

41-748.21C

Figure 15. Outline and Drilling Plan for the Type KLF Relay in the FT-41 Case

Sub 4

3519A70

23

Loading...

Loading...