Page 1

Page 2

41-923.4M

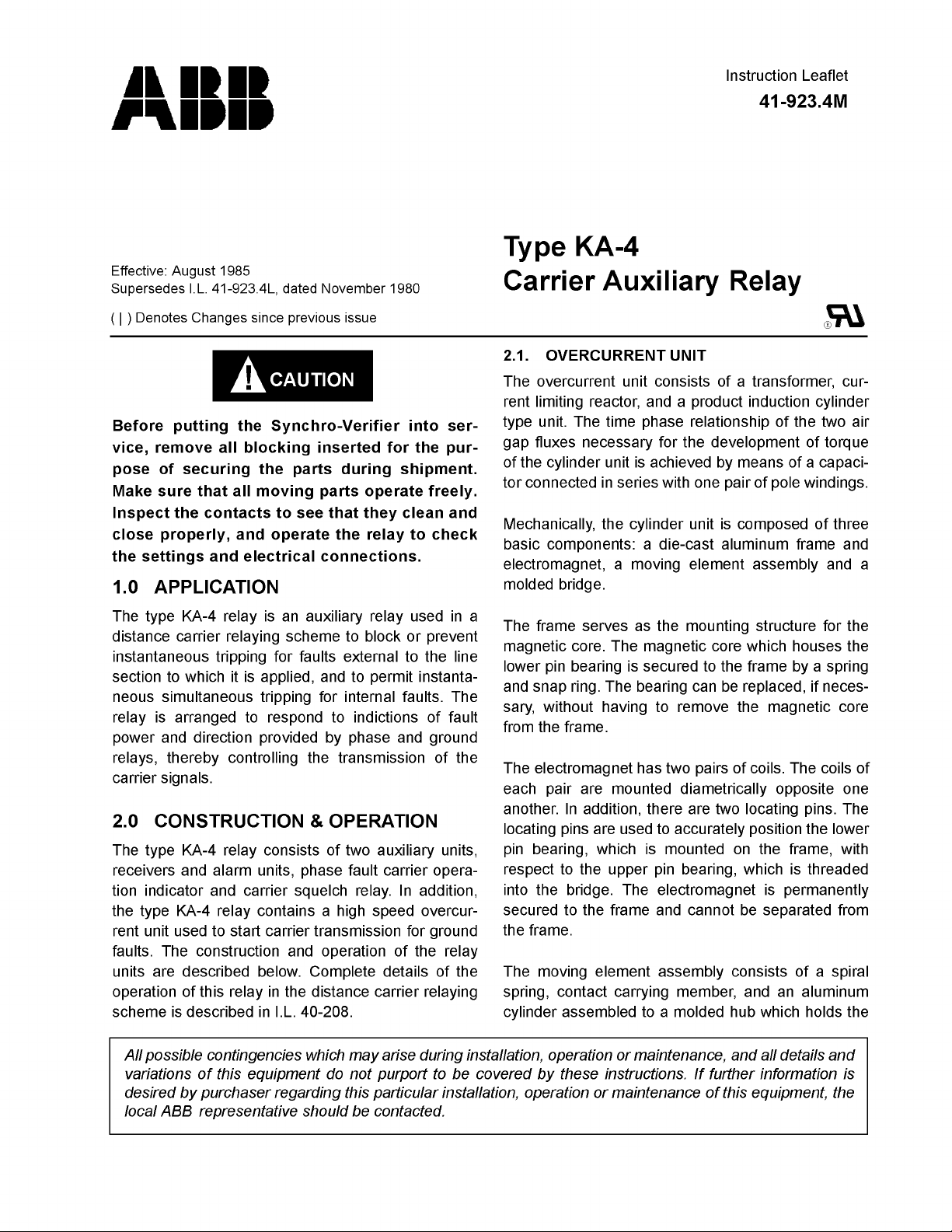

Figure 1. Type KA-4 Relay without case. (Front View)

2

Page 3

41-923.4M

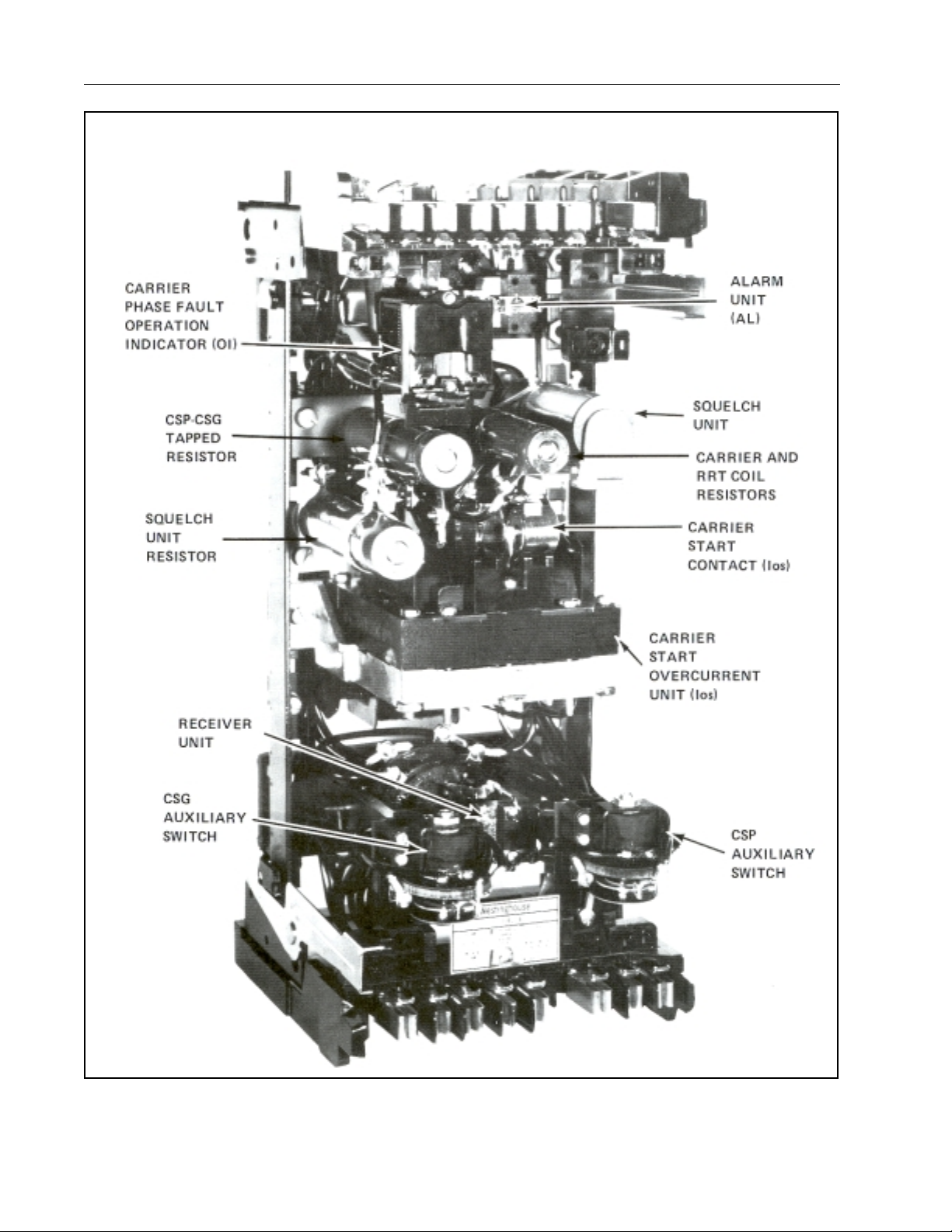

Sub 3

629A389

Figure 2.Internal Schematic of the Type KA-4 Relay for KR

Carrier Set.

Sub 9

629A476

Figure 3. Inter nal Schema tic of the Type KA-4 Re lay for TC

Carrier Set.

Sub 1

3491A17

Figure 4.Internal Schematic of the Type KA-4 Relay with

Modified Carrier Stop to Terminal 11 for TC Carrier

Set.

Sub 1

349A16

Figure 5.Internal Schematic of the Type KA-4 Relay for the

TA-3 tones.

3

Page 4

41-923.4M

shaft. The shaft has remo va ble top and botto m jewel

bearings. The shaft rides between the bottom pin

bearing and the upper pin bearing with the cylinder

rotating in an air gap formed by the electromagnet

and the magnetic core.

The bridge is secured to the electromagnet and

frame by two mounti ng sc rews . In a ddi tio n t o h old in g

the upper pin bear ing, the bridge is used for mounting the adjustable stationary contact housing. The

stationary contact housing is held in position by a

spring type clamp. The spring adjuste r is located on

the underside of the bridge and is attached to the

moving contact arm by a spiral spring. The spring

adjuster is also held in place by a spring type clamp.

With the contacts closed, the el ectrical connec tion is

made through the stationary contact housing clamp,

to the moving contact, through the spiral spring out to

the spring adjuster clamp.

When the current in the overcurrent uni t exceeds the

pick-up value the contacts open, allowing positive

potential to be applied to the carrier transmitter.

A transformer and cu rrent limiting reactor is used i n

conjunction with the cylinder unit. The transformer

supplies one set of coils on the cylinder unit with voltage shifted by approximately 90° from the residual

current supplied directly to another set of coils. The

transformer and reactor are of the saturating type

which limits energy to the cylinder unit and reduces

the burden on the transmission line CT.

2.2. AUXILIARY UNITS

These are two solenoid- type cont actor switches designated as CSP and CSG. The plunger of the contactor switch has a circular conduc ting disc mou nted on

its lower end and as the pl unger travels upwar d, the

disc bridges three silver stationary contacts. The

CSP switch is ener gized by the operati on of t he sec ond zone or KD-10 distance relay, and the CSG

switch, by the operation of the directi onal and overcurrent units of the KRD-4 ground relay. The contacts

of the two switches are connected in parallel as

shown in the internal schematic. The operation of

either of these switches conn ects the carrier control

circuit to negative to stop carrier, and energizes the

RRT operating coil of the receiver relay unit.

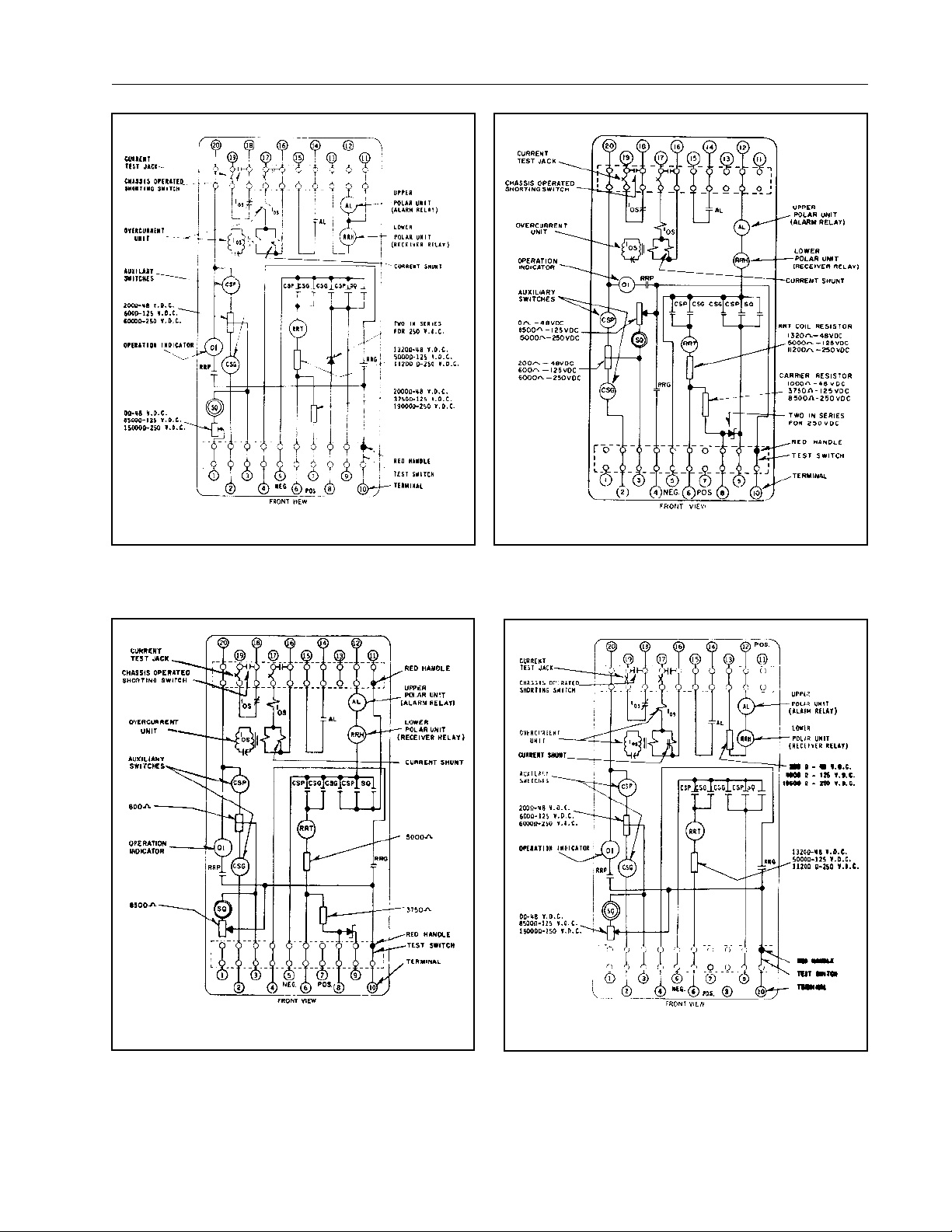

Figure 6.Typical Time Characteristics of c arrier start over-

current unit of the type KA-4 Relay.

2.3. RECEIVER UNIT

The receiver unit consists of an armature and contacts mounted on a leaf spring supporte d symmetrically within a magnet frame. The armature rides in

the front air-gap of the fr ame with the contacts projecting outside. The poles of a permanent magnet

clamp directly to each side of the frame. Two adjustable shunts are located across the rear air-gaps.

These change the reluctance of the magnetic path as

shown in Figure 7 so as to force some of the flux thru

the moving armature which is fastened to the fram e

midway between the two rear air gaps. Flux in the

armature polarizes it and creates a magnetic bias,

causing it to move towards either the left or right,

depending upon the adjustment.

Tw o st ati ona ry c onta ct sc re ws ar e m ount ed t o t he l eft

(front view) of the moving contact assembly and

adjusted for normally open contac ts. These co ntacts

are designated, RRP and RRG, and are connected in

the phase and ground trip circuit respecti vely. These

contacts are operate d by two concentric coils, RRT

and RRH, which are placed around the armature and

within the magnetic fra me. RRT is the operating coil

and receives its en ergy from the local battery when

either CSP or CSG is clo se d. R R H is th e h o ld ing c oil

and receives its en ergy from the carrier transmitted

either from the local tra nsmi tter or th e o ne a t th e en d

of the line section. These two coils are connect ed in

oppose each other with the operating coil, RRT oper-

4

Page 5

Shunt

41-923.4M

N

S

N

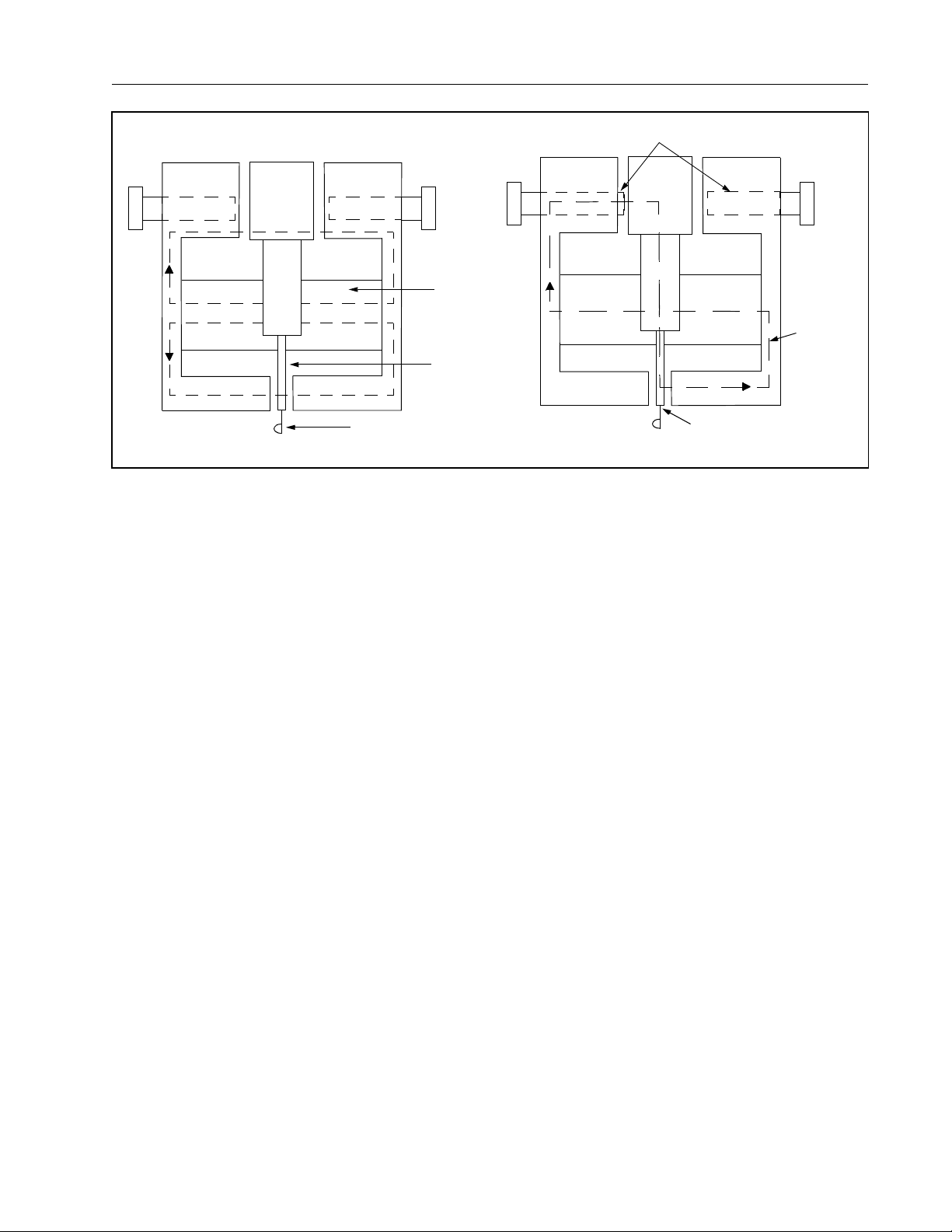

BALANCED AIR GAPS UNBALANCED AIR GAPS

S

Moving Contact

Figure 7. Permanent Magnet Flux Paths of Receiver and Alarm Units

Permanent

Magnet

Armature

ating to close the RRP and RRG contacts and trip;

and the holding co il, R RH to h old t he RRP and RRG

contacts open and block tripping. The restraining

torque of the RRH coil is sufficient to overcome th e

operating torque of the RRT coil. Consequently, RRP

and RRG contacts cannot c lose as long as RRH is

energized.

2.4. ALARM UNIT

The alarm unit is similar in construction to the

receiver unit except that it is energized by a single

coil and opera tes a singl e set of c ontac ts. T he c oil is

energized by the received carrier to close its contacts

and give an alarm. This unit has a higher pick-up

than that of the receiver unit in order to obtain a

direct check on the sensi tivity of the car rier transmitter-receiver. The failure of the alarm unit to pick-up

when carrier is started indicates insufficient output

from the transmitter receivers.

2.5. SQUELCH UNIT

The function of the squelch unit is to hold of the carrier for a period o f 15 0 m il lise co nds af ter th e B r eaker

“a” contact opens. This is to insure that all other ter minals of the line are tripp ed before allowing carrier

to be transmitted for any functions.

The squelch unit is a telephone type unit of slow

release type.

N

S

N

S

N

Additional

Flux Path

183A062

In these relays, an electromagnet attracts a right

angle iron bracket which in turn operates one normally open contact. The sl ow release is obtained by

a copper slug locat ed at the end opposite from the

armature. When the coil beco mes deenergized, the

change in flux through the slug results in an e lectromotive force and associated current in it. This current

produces a flux whic h aids the main flux and d elays

the release of the arm ature. When the coil is energized, the operation of the relay is not appreciably

delayed because the armature is operated by flux not

linking the slug.

2.6. OPERATION INDICATOR

The operation indicator gives a visual indication of a

carrier tripping op eration for phase faul ts by the distance relay through the RRP contac ts. For a groun d

fault carrier relaying ope ration, the indi cating conta ctor switch (ICS) located in the ground relay will drop a

target.

3.0 CHARACTERISTICS

The characteristics of the various elements of the

relays are as follows:

The pick-up and o perating values of thes e units are

given under “Adjustments and Maintenance”.

The time characteristic of the overcurrent unit is

5

Page 6

41-923.4M

For Use With KR-Set

CSP or CSG Coil

CSP & CSG Tapped Resistor

Carrier Resistor

RRT Operating Coil

RRT Coil Resistor

RRH Holding Coil

AL-Alarm Coil

Operation Indicator (1 amp.)

Squelch Unit Coil

Squelch Unit Adj. Resistor

For Use With TC-Set

CSP or CSG Coil

CSP & CSG Tapped Resistor

Carrier Resistor

RRT Operating Coil

RRT Coil Resistor

RRH Holding Coil

AL-Alarm Coil

Operation Indicator (1 amp.)

Squelch Unit Coil

Squelch Unit Adj. Resistor

For Use With TA-3 Tones

CSP or CSG Coil

CSP & CSG Tapped Resistor

Carrier Resistor

RRT Operating Coil

RRT Coil Resistor

RRH Holding Coil

AL-Alarm Coil

Operation Indicator (1 amp.)

Squelch Unit Coil

Squelch Unit Adj. Resistor

48V

Avg.

Ohms

27

200

2000

1100

1320

1700

500

0.1

3300

27

200

1000

1100

1320

20

0.1

3300

27

200

200

1100

1320

1700

500

0.1

3300

125

Avg.

Ohms

600

3750

1100

5000

1700

500

3300

-

8500

27

0.1

250

Avg.

Ohms

435

6000

19000

1100

11200

1700

500

0.1

3300

1500

the rear mounting stud or studs for projec tion mounting. Either a mounting stud or the mounting screws

may be utilized for grounding the relay. The electrical

connections may be made directly to the terminals by

means of screws for steel panel mounting or to the

terminal studs furnished with the rela y for thick panel

mounting. The terminal studs may be easily removed

or inserted by lock ing two nuts on the st ud and then

turning the proper nut with a wrench.

The carrier relaying schematic (supplied with the carrier order) should be consulted for details of the

external connections of these relays.

27

600

3750

1100

5000

4

20

4

0.1

3300

-

8500

45

6000

1100

11200

20

0.1

3300

15000

6.0 ADJUSTMENTS & MAINTENANCE

-

The proper adjustments to insure correct operation of

this relay have been made at the factory. Upon

4

receipt of the relay, no customer adjustments, other

than those covered under “SETTINGS”, should be

required.

6.1. ACCEPTANCE CHECK

27

600

4000

1100

5000

1700

500

0.1

3300

-

8500

435

6000

10600

1100

11200

1700

500

0.1

3300

15000

The following check is recommended to insure that

the relay is in proper working order.

6.1.1. Overcurrent Unit

Pass 0.5 amperes of altered current through relay

terminals 16 and 17, the contact should pickup within

.475 and .525 amp.

shown in figure 6.

The pick-up value of the overcurrent unit can be

changed from the factory adjusted value of 0.5

amperes to any value up to 1 amp. by increasing

spring restraint.

4.0 SETTINGS

There are not settings to be made

5.0 INSTALLATION

The relays should be mounted on switchbo ard panels or their equivalent in a location free from dirt,

moisture, excessive vibration, and heat. Mount the

relay vertically by means of the four mounting holes

on the flange for semi-flus h mou nting or by mea ns of

6

6.1.2. Auxiliary Units (CSP and CGS)

Each contactor switch has a section of a tapped

resistor in series with it, and will pick up positively

when rated control voltage is applied across the coil

and its section of the resistor.

These units should o per at e a t 24 v olts f or the 48 -vol t

relay, 60 volts for the 125-volt relay, and 120 volts for

250-volt relay. These units have an interm ittent rating, and should not be energized for more than a few

seconds.

6.1.3. Operation Indicator (OI)

With the polar unit contacts closed, apply direct cur rent to the operation indicator relay terminals. The

operation indicator should pick-up a nd drop the indicator target between 1 ampere and 1.2 amperes dc.

Page 7

41-923.4M

6.1.4. Squelch Unit (SQ)

Apply rated dc voltage to relay terminals that will

energize the squelch unit and note contact operation.

6.1.5. Blocking Zener Diode

Apply rated dc voltage in series with 10,000 ohm

resistors across te rminal s 8 a nd 9 wi th pos itiv e on 9 ,

the current leakage fl ow should not exceed .25 mA.

Reserve polarity of the applied voltage; the current

flow should be equ al to the applied voltage divide d

by the series resistance.

6.2. FOR RELAYS TO BE USED WITH

TC-TYPE CARRIER

6.2.1. Receiver Unit

Connect a jumper between the middle and left-hand

contact connection of the CS G or CSP switch. The

CSG switch is locate d on the left-hand pe destal and

CSP is located on the right-hand pedestal on the

relay (front view). Apply rated voltage across the

RRT coil and the RRT coil resistor, observing polarity

as shown in the internal schematic. The armature

should move to the left.

To the holding coil (RRH) relay terminals, apply direct

current observing pol arity. Increase the current until

the armature moves to the right.

The armature should move to the right at approximately 60 mA. Now reduce the current and the armature should move to the left at approximately 40 mA.

6.2.2. Alarm Unit (AL)

Connect direct curren t to the alarm unit relay terminals. Increase the cu rrent until the contacts p ick-up.

The contacts should pick up at approximately 80 mA.

Now reduce the current and the contacts should

open at 40 to 60 mA.

6.3. FOR RELAYS TO BE USED WITH

TYPE KR CARRIER OR TA-3 TONES

6.3.1. Receiver Unit

Connect a jumper between the middle and left-hand

contact connection of the CSG or CSP switch.

CSG switch is locate d on the left-hand pe destal and

CSP is located on the right-hand pedestal on the

relay (front view). Apply rated voltage across the

RRT coil and the RRT coil resistor, observing polarity

as shown in the internal schematic. The armature

should move to the left.

To the holding coil (RRH) relay terminals, apply direct

current observing correct polarity. Increase the current until the armature mov es to the right. The armature should move t o the r ight at a pprox imately 6 mA .

Now reduce the current and the armature should

move to the left at approximately 4 mA.

6.3.2. Alarm Unit (AL)

Connect direct curren t to the alarm unit relay terminals. Increase the curren t until the contacts pickup.

The contacts should pick up at approximately 8 mA.

Now reduce the current and the contacts should

open at 4 to 6 mA.

7.0 ROUTINE MAINTENANCE

All relays should be inspected periodically and the

operation should be checked at least once every

year or at such other tim e intervals as may be dictated by experience to be suitable to the particular

application.

All contacts should be periodically cleaned. A contact

burnisher Style # 182A836H01 i s recommended for

this purpose.

ing contacts is not recommended

danger of embedding small particles in the face of

the soft silver and thus impairing the contact.

7.1. CALIBRATION

Use the following procedure for calibrating the relay if

the relay has been taken apart for repairs or the

adjustments have been disturbed. This procedure

should not be used unless it is apparent that the relay

is not in proper working order. (See “Acceptance

Check”).

7.1.1. Overcurrent Unit

The upper bearing screw should be screwed down

until there is appr oximately 1/6 4” clearanc e between

it and the top of the shaft bearing. Securel y lock in

position with the lock nut. T he lower bearing po sition

is fixed and cannot be adjusted.

The use of abrasive mater ial for clean-

, because of the

7

Page 8

41-923.4M

With the moving contact in the normally closed position, i.e., against the right side of the bridg e, screw i n

the stationary conta ct until both contacts just close .

Then screw in the stationary contact a pproximately

one-quarter turn farther to provide the correct

amount of follow for KR & TC type carrier, one-half

turn for TA-3 tones.

The clamp holding the stationary contact housing

need not be loosened for the adjustment since the

clamp utilizes a spring- type action i n holding the s tationary contact in position.

The sensitivity adjustment is made by varying the

tension of the spiral spring attached to the moving

element assembly. The spring is adjusted by pl acing

a screwdriver or simila r tool into one of the notches

located on the periphery of the spring adjuster and

rotating it. The spring adjuster is located on the

underside of the bridge and is held in place by a

spring type clamp that d oes no t have to be lo osene d

prior to making the necessary adjustments.

Pass 0.5 amp of ac t hrough relay terminals 16 and

17. Adjust the spring until the contact just opens. In a

similar manner the pick- up value can be adjusted for

any value between .5 and 1.0 amp.

250-volt relay. These units have an interm ittent rating, and should not be energized for more than a few

seconds.

7.1.3. Squelch Unit

Check operation with timer. Adjust series resistor to

measure approximately 5000 ohms for 125 Vdc

relays and for 13000 ohms for 250 Vdc relay. With

armature closed, adjust the residual air gap to be

.002” – .003”. Contact gap should measure from

.020” to .035”. Check for dropout time betwe en .140

and .160 seconds. If ne cessary dropout ti me can be

adjusted by changing the residu al air gap. After final

adjustment the gap should be at lease .002”. The

pickup time should be below 16 milliseconds at -20%

rated dc voltage. If nec essary readjust series resistor.

7.1.4. Operation Indicator

The operation indicator s hould pickup and drop the

indicator target when the current is between 1 and

1.2 amperes dc.

Make sure that the target drops freel y when the uni t

operates.

7.1.2. Auxiliary Units (CSP and CSG)

The two contactor switches, CSP and CSG, have

adjustable plunger trave l. Adjust the stationary core

and the moving core of 1/64” when the switch is

picked up. This can be done by turning the relay

upside-down and screwing up the core screw of the

switch until the conta cts just separate. Then back off

the core screw approximately one turn and lock in

place. This prevents the moving core from striking

and sticking to th e stationary core beca use of residual magnetism. Adjust the contact clearance for

approximately 1/32” by me ans of the two small nuts

on either side of the Micarta disc.

Each contactor switch has a section of a tapped

resistor in series with it, and will pick up positively

when rated trip circuit voltages is applied across the

coil and its section of the resi stor.

The units should operate at 24 volts for the 48-volt

relay, 60 volts for the 125-volt rel ay and 120 v olts for

7.2. ZENER DIODE TEST

7.2.1. F orw ard Chara ct eri st ics

Pass 200 mA of dc current through terminals 8 and 9

with positive on terminal 8. Measure voltage drop

across terminal s 8 an d 9 with pos i tiv e o n 9 . T he vo ltage drop should not exceed 3.5 volts.

7.2.2. Reverse Characteristics –

Breakdown Voltage

The breakdown Voltage is determined by increas ing

voltage across terminal s 8 and 9 with positive on 9.

Place 10,000 ohm resistor in series with ammeter.

Increase voltage until current reads .25 mA. Measure

dc voltage across terminals 8 and 9. The voltage

should be between 16 0 a nd 2 40 v olts for 48 an d 12 5

Vdc rated relay s; and 320 to 480 volts for 250 Vdc

rated relays.

circuit.

DO NOT

exceed 3.0 mA current in the

8

Page 9

41-923.4M

7.3. FOR RELAY TO BE USED WITH

TC-TYPE CARRIER

7.3.1. Receiver Unit

Back off contact screws so that they do not make

contact. Screw magnetic shunts into the all- out position (5 or 6 screw threads showing.) The armature

should remain against whichever side it is pushed

with this adjustment.

Adjust the stationary contacts for a contact gap of

approximately .020” . This can be done by inse rting a

.010” steel thickness gage between the large rivet

head on the moving armature and the right-hand pole

face (a .010” travel of the rivet hea d is eq ual to .02 0”

travel of the moving contacts). Using an indicating

light in each contact circuit, adjust the upper and

lower stationary contacts to touch the moving contact

at the same time. W it h th e fe el er ga uge r emo ved th e

contact gap is 0.20” and the moving contacts close

simultaneously.

Connect a jumper between the middle and left-hand

contact connection of the CS G or CSP switch. The

CSG switch is located on the right-hand pedestal and

CSP is located on the right-hand pedestal of the

relay (front view). Apply rated voltage across the

RRT coil and the RRT coil resistor observing p olarity

as shown in the internal schematic diagram. The

armature should move to the left.

To the holding coil, RRH, a pply 100 to 200 milliamperes dc current observing correct polarity. The

armature should no w move to the right. Deenergiz e

both coils and see that the armature stays up against

the right-hand side.

Run both shunt screws all the way in, and the n back

out the left-hand shunt scr ew approximately 6 turns.

Back out the right-hand shun t screw appr oximate ly 9

turns.

Re-energize the operating coil with rated voltage and

the holding coil wi th 40 milliamperes dc. Adjust the

right-hand shunt scre w until the armature moves to

the left. If the armature moves to the left, at a value of

holding coil current gre ater tha n 40 millia mpere s, the

right-hand shunt sc rew sho uld be turned out to lower

this value to the correct 40 milliampere point.

Increase the holding coil curren t to 60 milliamperes

and adjust the left -hand shunt screw unti l the armature resets, or moves to the right. If the armature

resets at a value of current less than 60 milliamperes, the left-hand shunt screw should be turned

out. This will increase the reset value of the armature

and provide for the correct 60 milliampere reset

value.

Minor adjustments of both shunt screws must be

made several times until the desire d oper ating poi nts

are obtained, since the adjustments of one shunt

screw affect the adjustment on the other shunt screw.

7.3.2. Alarm Unit

The contacts should close with 80 milliamperes dc

±

5% applied to the alarm coil. Adjust the contact

screws to obtain an .050” contact gap such tha t the

armature motion between the left and right-hand contacts is in the central part of the air gap betw een the

pole faces. Tighten the contact locking nuts. Approximate adjustments of the two magne tic shunt screws

are as follows:

Turn both shunt screws all the way i n. Th en back out

both shunt screws app roximately seven tu rns. Apply

80 milliamperes dc to the coil, observing correct

polarity, and screw in the left-hand shunt screw until

the armature moves to the right. If the armature

moves to the right at a value of current less than 80

milliamperes, screw the left -hand shunt out until the

armature moves to the right at 80 milliamperes.

Check the dropout poi nt by reducing the dc cu rrent.

The armature should move to the left between the

limits of 40 and 60 milliamperes. If it fai ls to do so,

adjust the right-hand shunt screw until it does. It will

then be necessary to recheck the pickup and dropout

points again and make any minor adjustmen ts to the

shunt screws that may be necessary until correct calibration is obtained.

In general, screwing in the left-hand shunt screw

reduces the pickup current of the relay. Screwing in

the right-hand shunt screw increases the dropout

current. This will in turn cause a change in the pickup

current, making necessary several slight readjustments of both shunt screws to obtain the desired calibration. The armature as finally calibrated should

pickup and dropout with a snappy action.

9

Page 10

41-923.4M

7.4. FOR RELAYS TO BE USED WITH

KR-TYPE CARRIER OR TA-3 TONES

7.4.1. Receiver Unit

Calibrate as outlined under TC Type Carrier. Apply

15 mA dc cu r re nt fo r po la ri t y check. Th e pi ck up v al ue

should be 4 milliamperes dc ( armature moves to left)

instead of 40 mA. T he calibration of re set (armature

moves to the right) should be done at 6 milliam peres

instead of 60 mA.

7.4.2. Alarm Unit

Calibrate as outlined under TC-type Carrier. Check

pick-up at 8 mA ±5% instead of 80 mA. Dropout

should be between 4 and 6 mA ins tead o f 40 an d 60

mA.

8.0 RENEWAL PARTS

Repair work can be done most satisfactorily at the

factory. However, interchangeable parts can be furnished to the custom ers who are equipped for doing

repair work. When ordering parts, always give the

complete nameplate data.

9.0 ENERGY REQUIREMENTS

9.1. CURRENT BURDEN AT 60 CYCLES

Power

Current

Amperes

0.5

5

20

40

60

†

Current lagging voltage

††

Current leading voltage.

9.2. RATING OF OVERCURRENT UNIT

Continuous rating 5 amperes. One second rating 100

amps.

Volt

Amperes

2.2

43

394

1240

2760

.

Factor

Angle

†

33°

†

70°

††

49°

39.2°

32.5°

††

††

10

Page 11

THIS P AGE LEFT BLANK

41-923.4M

11

Page 12

41-923.4M

12

Sub 4

5307D96

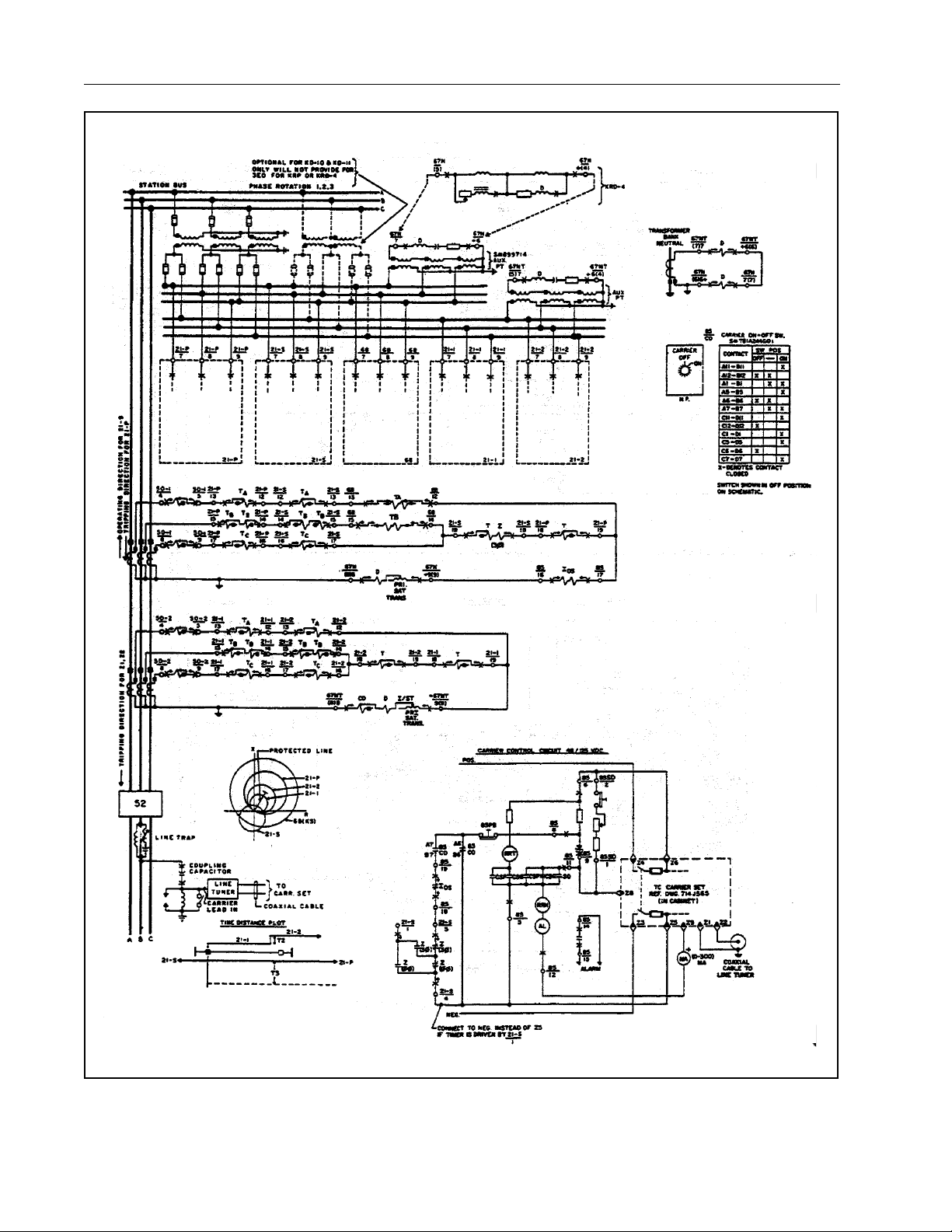

Figure 8. Typical External Schematic of a KA-4 Relay in a KD-4/TC Blocking System

Page 13

41-923.4M

Figure 8. Typical External Schematic of a KA-4 Relay in a KD-4/TC Blocking System

Sub 4

5307D96

13

Page 14

41-923.4M

14

Figure 9A. Typical External Schematic of a KA-4 Relay in a KD-10/TC Blocking System

Page 15

41-923.4M

Figure 9B. Typical External Schematic of a KA-4 Relay in a KD-10/TC Blocking System

15

Page 16

Loading...

Loading...