Page 1

—

ABB MEASUREMENT & ANALYTICS |

CEMcaptain GAA610

Advanced emission gas monitoring system for marine

applications

—

GAA610

Introduction

GAA610

continuously monitoring SO2/CO2 emissions of

vessels.

Reducing maintenance hassles during ship

operation has been the guiding

development. An increased uptime is provided

with the GAA610

design as well as its innovative digital features

allowing for tailoring services to your needs.

It is proven for use on board by all major

classificatio

Annex IV requirements and NOx Technical Code

2008.

ABB has the right gas analyzer to allow vessels to

stay compliant with current and upcoming

regulations.

Additional Information

OPERATING INSTRUCTION | OI/GAA610-M -EN REV. B

-M

Measurement made easy

-M

-M is a multi-component analyzer system

Additional documentation on CEMcaptain GAA610-M

is available for download free of charge at

www.abb.com/analytical.

Alternatively simply scan this code:

principle for

-M by its robust and simple

n societies and complies with Marpol

Page 2

2 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

Table of contents

1 Safety ........................................................................ 5

General information and instructions ................................. 5

Warnings .................................................................................. 5

Warranty provisions ............................................................... 5

Intended use ............................................................................ 6

Improper use ........................................................................... 6

Safety instructions ................................................................. 6

Requirements for safe operation .................................... 6

Personnel qualifications ................................................... 6

Special information and precautions ............................. 6

National regulations .......................................................... 6

Safety of the equipment and safe operation................. 6

Working with hazardous gases ........................................ 7

Protective lead connection ............................................... 7

Risks involved in opening the covers .............................. 7

When safe operation can no longer be assured ............ 7

Risks involved in opening the gas paths ........................ 7

Notes on data safety .............................................................. 7

Services and ports on the Ethernet interface ................ 7

Access authorizations ....................................................... 7

Manufacturer’s address ......................................................... 8

Service address ....................................................................... 8

2 Design and function ................................................. 9

Measuring principle ................................................................ 9

Device description .................................................................. 9

Type approvals ................................................................... 9

Measurement ranges ........................................................... 10

Inputs and outputs ............................................................... 10

Analog output .................................................................. 10

Digital output ................................................................... 10

System structure .................................................................. 11

System cabinet................................................................. 11

System schematic ............................................................ 12

Sample Gas Cooler SCC-C............................................... 13

Sample Gas Feed Unit SCC-F ......................................... 14

3 Product identification ............................................ 15

Name plate ............................................................................ 15

Plates and symbols .............................................................. 15

Scope of delivery .................................................................. 15

4 Transport and storage ............................................ 16

Safety instructions ............................................................... 16

Inspection .............................................................................. 16

Transporting the device ...................................................... 16

Transporting the analyzer cabinet ................................ 16

Unpacking the analyzer cabinet..................................... 16

Storing the device ................................................................ 17

Ambient conditions ......................................................... 17

Packaging .............................................................................. 17

Returning devices ................................................................. 17

5 Preparation for Installation ................................... 18

Safety instructions ...............................................................18

Installation – Overview .........................................................18

Requirements for the installation site ...............................18

Choosing the extraction point .......................................18

Wall tube installation .......................................................18

Short gas paths ................................................................19

Protection from adverse ambient conditions ..............19

Installation indoors ..........................................................19

Dimensions and space requirement ..............................19

Installation site stability..................................................19

Climatic Conditions .........................................................19

Backpurging Unit ................................................................. 20

Design of the back-purging unit ................................... 20

Distance to sampling probe .......................................... 20

Protection from adverse ambient conditions ............. 20

Instrument air supply ..................................................... 20

Power supply ........................................................................ 20

Sample gas inlet conditions ............................................... 20

Dimensions ............................................................................ 21

Analyzer cabinet ............................................................... 21

Type 40 probe tube and filter unit ................................ 22

Backpurging Unit ............................................................ 23

Material required for installation ....................................... 24

Gas sampling ........................................................................ 24

Gas lines............................................................................ 24

Mounting material........................................................... 24

Cable specification ......................................................... 24

6 Installation ............................................................... 25

Probe tube and filter unit installation ............................... 25

Before the installation .................................................... 25

Filter unit overview ......................................................... 25

Installation ....................................................................... 26

Sample gas line installation .................................................27

Installing the sample gas line .........................................27

Fundamentals for laying the sample gas line ..............27

Procedures for laying the sample gas line ................... 28

Permissible values for laying the sample gas line ...... 29

Back-purging unit installation............................................ 29

Before the installation .................................................... 29

Installation site ................................................................ 29

Connecting the compressed-air tubes ........................ 29

Analyzer cabinet installation .............................................. 30

Transporting the analyzer cabinet................................ 30

Unpacking the analyzer cabinet .................................... 30

Mounting the analyzer cabinet ...................................... 30

Connecting the condensate water drain of the cabinet air

conditioner............................................................................ 30

Page 3

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 3

7 Gas connections ...................................................... 31

Position and design of the gas connections .................... 31

Connecting the gas lines ..................................................... 32

Connecting the heated sample gas line ....................... 32

Calibration gas ................................................................. 32

Connecting the condensate bottle ............................... 32

Connecting the sample gas outlet ................................ 32

8 Electrical connections ............................................. 33

Safety instructions ............................................................... 33

Protective lead connection ............................................. 33

Notes ...................................................................................... 33

Cable specification ............................................................... 33

Cable glands ..........................................................................34

Terminal assignment – Analyzer cabinet........................... 35

Electrical Data .................................................................. 37

Connecting the electrical leads ..................................... 38

Connecting the signal leads ........................................... 38

Connecting the power supply ........................................ 38

Terminal assignment – Sample gas probe ........................ 39

Electrical data ................................................................... 39

Electrical connection ....................................................... 39

Digital communication ........................................................ 39

Modbus® communication ............................................... 39

Ethernet communication ................................................ 39

9 Gas sampling with automatic back-purging ....... 40

General .................................................................................. 40

Filter plugging ...................................................................... 40

Pump suction increase ................................................... 40

Filter cleaning .................................................................. 40

Components for back-purging .......................................... 40

Control of the back-purging procedure ...................... 40

Start of the back-purging procedure ............................... 40

Start controlled by time ................................................. 40

Start controlled by event ............................................... 40

Manually controlled start ............................................... 40

Filter unit backpurging sequence .................................. 41

Switch over ....................................................................... 41

Cycle time .............................................................................. 42

Cycle time duration ......................................................... 42

Cycle time factory setting .............................................. 42

Optimum cycle time setting........................................... 42

Cycle time minimum value .............................................. 42

Event-controlled start of the back-purging procedure

by filter plugging ............................................................. 42

Adjustment of the cycle time ......................................... 42

Post-purge time .................................................................... 42

Post-purge time duration ............................................... 42

Guide for the post-purge time ....................................... 42

Adjustment of the post-purge time .............................. 42

10 Commissioning and operation .............................. 43

Safety instructions .............................................................. 43

When safe operation can no longer be assured ......... 43

Transportation restraints removal .................................... 43

Sample Gas Feed Unit SCC-F ......................................... 43

Sample Gas Cooler SCC-C .............................................. 43

Analyzer cabinet air conditioner ........................................ 44

Overload protection........................................................ 44

Principles of operation ................................................... 44

Start-up ................................................................................. 44

Prior to start-up............................................................... 44

Power supply activation ................................................. 44

Function check................................................................. 44

Date and time check ....................................................... 44

Warm-up phase .................................................................... 45

End of the warm-up phase ............................................. 45

Readiness, sample gas supply ....................................... 45

Calibration ........................................................................ 45

11 Operation ................................................................ 46

General................................................................................... 46

HMI priority ...................................................................... 46

Access lock ....................................................................... 46

LCD indicator ........................................................................ 47

Menu levels of the LCD indicator .................................. 47

LCD display ...................................................................... 47

Display of status messages ........................................... 48

Status LEDs ...................................................................... 48

Numeric keypad ............................................................... 49

Cancel keys ....................................................................... 49

Softkeys ............................................................................ 49

Entering text .................................................................... 50

Selecting and changing parameters .................................. 51

Value Input ........................................................................ 51

Key Entry........................................................................... 52

Password protection ........................................................... 53

Password Level ................................................................ 53

User Group ....................................................................... 53

Password .......................................................................... 53

Viewing Menu Items ........................................................ 54

Changing Menu Items ..................................................... 54

Change Privilege .............................................................. 54

Change password ........................................................... 54

Menu structure ..................................................................... 55

Basic Setup ........................................................................... 57

Setting the time zone, date and time........................... 57

Selecting user interface language ................................ 57

Page 4

4 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

12 Diagnosis / Troubleshooting ................................ 58

Safety instructions ...............................................................58

The Dynamic QR Code..........................................................58

Application ........................................................................58

Handling ............................................................................58

Dynamic QR-Code Accessing .........................................58

Status messages ..................................................................59

Information available as digital output ........................59

Information displayed on the analyzer system ...........59

Possible status messages ...................................................59

“Status messages” table ................................................59

SCC-C – Sample gas cooler problems ............................... 66

SCC-F – Sample gas feed unit problems ........................... 67

AO2020 Gas analyzer problems .......................................... 67

AO2020-Uras26 problems .................................................. 68

Analyzer cabinet problems ................................................. 68

Analyzer cabinet air conditioner problems ...................... 69

Notify Service ........................................................................ 70

Who should you contact for further help? ................... 70

Before you notify Service … ........................................... 70

If the Service Dept. has been informed … .................... 70

Returning devices ................................................................. 70

13 Maintenance ............................................................ 71

Safety instructions ............................................................... 71

Maintenance plan ................................................................. 72

Spare parts ............................................................................ 72

Spare parts information ................................................. 72

Analyzer cabinet – Visual inspection .................................. 73

Visual inspection .............................................................. 73

Cleaning hints................................................................... 73

Status LEDs ...................................................................... 73

Calibrating the analyzer system ......................................... 74

Conversion of concentration values ............................. 74

Basics................................................................................. 74

Calibration – Principles ................................................... 74

Automatic calibration ..................................................... 75

Manual calibration ........................................................... 76

Basic calibration............................................................... 77

Measurement of calibration cells with test gas .......... 78

Checking the seal integrity ................................................. 78

When is the seal integrity check needed? .................... 78

Procedure .......................................................................... 78

Replacing the filter element in the filter unit .................... 79

Soot filter ............................................................................... 81

Changing of the filter filling and the filter element .... 81

Aqua stop filter ..................................................................... 82

Changing the aqua stop filter ........................................ 82

Ambient air filter (zero gas) ................................................ 82

Changing the ambient air filter ..................................... 82

Analyzer air conditioner ....................................................... 83

Compressor ...................................................................... 83

Inlet air filter ..................................................................... 83

Emptying the condensate collection bottle ..................... 83

SCC-C – Replace peristaltic pump hose ........................... 84

SCC-C – Clean condenser fins .............................................85

When should the condenser fins be cleaned? ............. 85

SCC-F – Replacing the diaphragm and valve plates ........ 86

Replacing the SCC-C ............................................................ 88

Remove the old SCC-C .................................................... 88

Prepare the new SCC-C .................................................. 89

Install the new SCC-C...................................................... 89

Replacing the SCC-F ............................................................ 90

Remove the old SCC-F .................................................... 90

Prepare the new SCC-F ....................................................91

Install the new SCC-F ...................................................... 92

Replacing the AO2020 ......................................................... 92

Remove the old AO2020 ................................................. 92

Prepare the new AO2020 ................................................ 93

Install the new AO2020 ................................................... 93

14 Decommissioning .................................................. 94

Safety instructions .............................................................. 94

Shutting Down the Analyzer System ................................. 94

Emptying the Condensate Collecting Bottle ................... 94

Transportation restraints activation ................................ 94

Sample Gas Feed Unit SCC-F ......................................... 94

Sample Gas Cooler SCC-C .............................................. 94

Ambient conditions ............................................................. 94

15 Recycling and disposal ...........................................95

16 Specification ...........................................................95

17 Additional documents ............................................95

18 Appendix ................................................................. 96

Fuses type 5×20mm ............................................................ 96

Location diagram ................................................................. 97

Piping diagram ..................................................................... 98

Return form ........................................................................... 99

Page 5

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 5

DANGER

severe injury.

WARNING

severe injury.

CAUTION

moderate injury.

NOTICE

The signal word

‘NOTICE’

indicates possible material damage.

1 Safety

General information and instructions

These instructions are an important part of the product and

must be retained for future reference.

Installation, commissioning, and maintenance of the product

may only be performed by trained specialist personnel who have

been authorized by the ship operator accordingly. The specialist

personnel must have read and understood the manual and must

comply with its instructions.

For additional information or if specific problems occur that are

not discussed in these instructions, contact the manufacturer.

The content of these instructions is neither part of nor an

amendment to any previous or existing agreement, promise or

legal relationship.

Modifications and repairs to the product may only be performed

if expressly permitted by these instructions.

Information and symbols on the product must be observed.

These may not be removed and must be fully legible at all times.

The operating company must strictly observe the applicable

national regulations relating to the installation, function testing,

repair and maintenance of electrical products.

Warnings

The warnings in these instructions are structured as follows:

The signal word ‘DANGER’ indicates an imminent danger.

Failure to observe this information will result in death or

The signal word ‘WARNING’ indicates an imminent danger.

Failure to observe this information may result in death or

The signal word ‘CAUTION’ indicates an imminent danger.

Failure to observe this information may result in minor or

Note

‘Note’ indicates useful or important information about the

product.

Warranty provisions

Using the device in a manner that does not fall within the scope

of its intended use, disregarding this manual, using

underqualified personnel, or making unauthorized alterations

releases the manufacturer from liability for any resulting

damage. This renders the manufacturer's warranty null and void.

Page 6

6 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

… 1 Safety

Intended use

The CEMcaptain GAA610-M analyzer system is designed for

continuous measurement of exhaust gases of marine diesel

engines. Measurement components are CO

and SO2 which are

2

sampled downstream of the scrubber.

Any other use is not as specified. The specified use also includes

taking note of this operating instruction.

Improper use

The following are considered to be instances of especially

improper use of the device:

• For use as a climbing aid, for example for mounting

purposes.

• For use as a bracket for external loads, for example as a

support for piping, etc.

• Material application, for example by painting over the

housing, name plate or welding/soldering on parts.

• Material removal, for example by spot drilling the

housing.

The analyzer system must not be used to measure flammable

gases or combustible gas/air or gas/oxygen mixtures.

The analyzer system must not be installed in hazardous

locations.

Safety instructions

Requirements for safe operation

In order to operate in a safe and efficient manner the device

should be properly handled and stored, correctly installed and

set-up, properly operated and correctly maintained.

Personnel qualifications

Only persons familiar with the installation, set-up, operation and

maintenance of comparable devices and certified as being

capable of such work should work on the device.

Special information and precautions

These include:

• The content of this operating instruction,

• The safety information affixed to the device,

• The applicable safety precautions for installing and

operating electrical devices,

• Safety precautions for working with gases, acids,

condensates, etc.

National regulations

The regulations, standards and guidelines cited in this operator's

manual are applicable in the Federal Republic of Germany. The

applicable national regulations should be followed when the

device is used in other countries.

Safety of the equipment and safe operation

The device was built and tested in accordance with

EN 61010 Part 1 ‘Safety regulations for electrical measuring,

control and laboratory equipment’ and it left the factory in

perfect condition.

To maintain this condition and to assure safe operation, read

and follow the safety instructions in this operating instruction as

well as applicable type approval standards of classification

societies.

Failure to do so can put persons at risk and can lead to device

damage as well as damage to other systems and devices.

Page 7

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 7

Port

Description

22/tcp

No direct access to the device.

502/tcp

8100/tcp

terminated

Working with hazardous gases

Some gas components whose concentration is measured with

the analyzer system are hazardous to health.

For this reason, the sample gas must under no circumstances be

allowed to escape uncontrolled from the sample gas path in

either the measurement mode or when performing maintenance.

• The analyzer system must be checked for leaks regularly.

• The measured stack gas must be returned to the process or

discharged in a suitable exhaust duct.

• Ensure adequate ventilation of the room in which the

analyzer system is installed.

• The legal requirements for the maximum work place limit

values of the measurement and test gases must be observed.

Protective lead connection

The protective lead (ground) should be attached to the

protective lead connector before any other connection is made.

Risks of a disconnected protective lead

The device can be hazardous if the protective lead is interrupted

inside or outside the device or if the protective lead is

disconnected.

Risks involved in opening the covers

Current-bearing components can be exposed when the covers or

parts are removed, even if this can be done without tools.

Current can be present at some connection points.

When safe operation can no longer be assured

If it is apparent that safe operation is no longer possible, the

device should be taken out of operation and secured against

unauthorized use.

The possibility of safe operation is excluded:

• If the device is visibly damaged,

• If the device no longer operates,

• After prolonged storage under adverse conditions,

• After severe transport stresses.

Risks involved in opening the gas paths

Do not open any gas paths in the analyzer system or in the

integrated analyzers.

Doing so will damage gas path seal integrity.

If system-internal gas paths are opened, a seal integrity check

must be performed with a leak detector (thermal conductivity)

when the device is reassembled.

Notes on data safety

This product is designed to be connected to and to

communicate information and data via a network interface.

It is operator’s sole responsibility to provide and continuously

ensure a secure connection between the product and your

network or any other network (as the case may be).

Operator shall establish and maintain any appropriate measures

(such as but not limited to the installation of firewalls,

application of authentication measures, encryption of data,

installation of anti-virus programs, etc.) to protect the product,

the network, its system and the interface against any kind of

security breaches, unauthorized access, interference, intrusion,

leakage and / or theft of data or information.

ABB Ltd and its affiliates are not liable for damages and / or

losses related to such security breaches, any unauthorized

access, interference, intrusion, leakage and / or theft of data or

information.

Services and ports on the Ethernet interface

Used only for software updates.

Used for Modbus/TCP.

The device allows connection to any Modbus client. The port

must be activated via ECT, the port is delivered in a deactivated

state.

Used for test and calibration software Optima TCT Light.

Binary proprietary protocol.

The port is deactivated. It can be activated for TCT access via a

secure connection, and deactivated when the TCT access is

Access authorizations

Access to the calibration and to the menus used to change the

configuration of the instrument is restricted by password

protection.

It is recommended that the factory-set passwords be changed

by the operator, see Password protection on page 53.

Page 8

8 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

… 1 Safety

Manufacturer’s address

ABB Automation GmbH

Measurement & Analytics

Stierstädter Str. 5

60488 Frankfurt am Main

Germany

Tel: +49 69 7930-4666

Email: cga@de.abb.com

ABB Engineering (Shanghai) Ltd.

Measurement & Analytics

No. 4528, Kangxin Highway, Pudong New District

Shanghai, 201319,

P.R. China

Tel: +86(0) 21 6105 6666

Fax: +86(0) 21 6105 6677

Email: china.instrumentation@cn.abb.com

Service address

If the information in this Operating Instruction does not cover a

particular situation, ABB Service will be pleased to supply

additional information as required.

Please contact your local service representative.

For emergencies, please contact:

Contact Center

www.abb.com/contacts

Page 9

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 9

2 Design and function

Measuring principle

The GAA610-M is based on ABB’s proven NDIR (Non-Dispersive

Infrared) measurement technology.

The analyzer module Uras26 allows for reliable measuring and

monitoring of the limit values for SO

and CO2 and reports the

2

ratio as specified by the IMO (International Maritime

Organization), and it can be employed for continuous monitoring

of CO if required.

Therefore, additional devices, such as the sampling probe, the

sample gas line, the sample gas cooler, pumps and filters ensure

that the sample gas entry conditions of the connected gas

analyzer are met, and a proper measurement result is obtained

regardless of the process and the local conditions.

The sample handling system is specific for the applied

measuring principle.

The GAA610-M analyzer system is a complete turn-key solution

Device description

The GAA610-M is a multi-component analyzer system

continuously providing real-time data of relevant pollutants like

SO

/CO2 ratio.

2

It proves compliance of vessels to low emission limits of

emission control areas (ECA zones) and global limits.

The measurement can be used to control the exhaust gas

cleaning system on board, so called scrubber as well.

The GAA610-M is proven for use on board by all major

classification societies and complies with Marpol Annex IV

requirements and NO

Technical Code2008.

x

Reducing maintenance hassles during ship operation has been

the guiding principle for development. An increased uptime is

provided with the GAA610-M by its robust and simple design as

well as its innovative digital features allowing for tailored

services according your needs.

The GAA610-M analyzer system extracts the sample gas from the

exhaust gas stream.

The gas analyzer cannot process the sample without further

treatment as e.g. an excessive dust content, temperature and

dew point, excessive or insufficient pressure and interference

components in the sample gas can affect the operating ability of

the gas analyzer and distort the measurement result.

with the following components:

• Probe and filter unit for proper gas sampling

• Heated sample gas line for feeding the sample to the gas

analyzer

• Sample conditioning components like sample gas cooler,

filters and pump to ensure the gas conditions for reliable

measurement results

• AO2020-Uras26 gas analyzer (Advance Optima – AO2000

series) for measuring SO

and CO2

2

The sample conditioning components and the gas analyzer are

integrated into the analyzer cabinet of the analyzer system.

Available options are:

• Air conditioning unit for operation at ambient

temperature 5 to 55 °C (41 to 131 °F). Higher ambient

temperature during operation on request.

• Dual sampling for simultaneous measurement at two

different sampling locations (on request)

Type approvals

• DNV GL

• Lloyd's Register

• Bureau Veritas

• ABS Group

• Korean Register of Shipping (KR)

• ClassNK

Page 10

10 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

Sample component

Standard measuring ranges

CO

2

SO

SO

2

O

2

CO (option)

… 2 Design and function

Measurement ranges

Sample components and measuring ranges

0 to 20 Vol.-%

0 to 250 ppm

2

0 to 500 ppm

/CO2 ratio Calculated

(option) 0 to 25 Vol.-%

0 to 500 ppm

Inputs and outputs

Analog output

The measured concentrations of CO2 and SO2 as well as the ratio

SO

/CO2 are available as 4 to 20 mA signals for further use in the

2

process control system.

Digital output

The following digital signals are provided for the process control

system of the ship:

• System failure / common alarm

• Maintenance

• Maintenance Request

• SO

meas. range feeback

Further digital signals can be added

2

Page 11

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 11

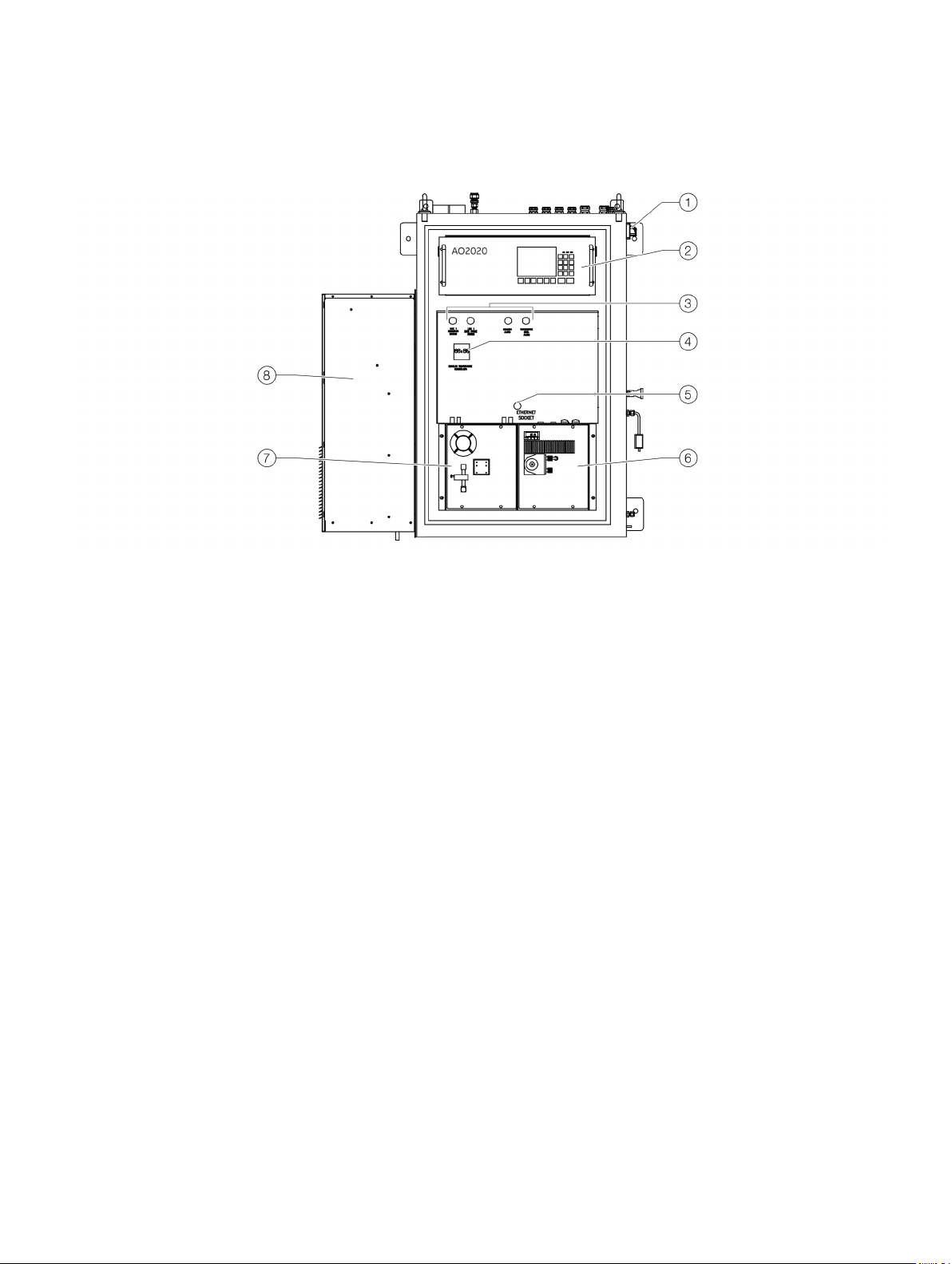

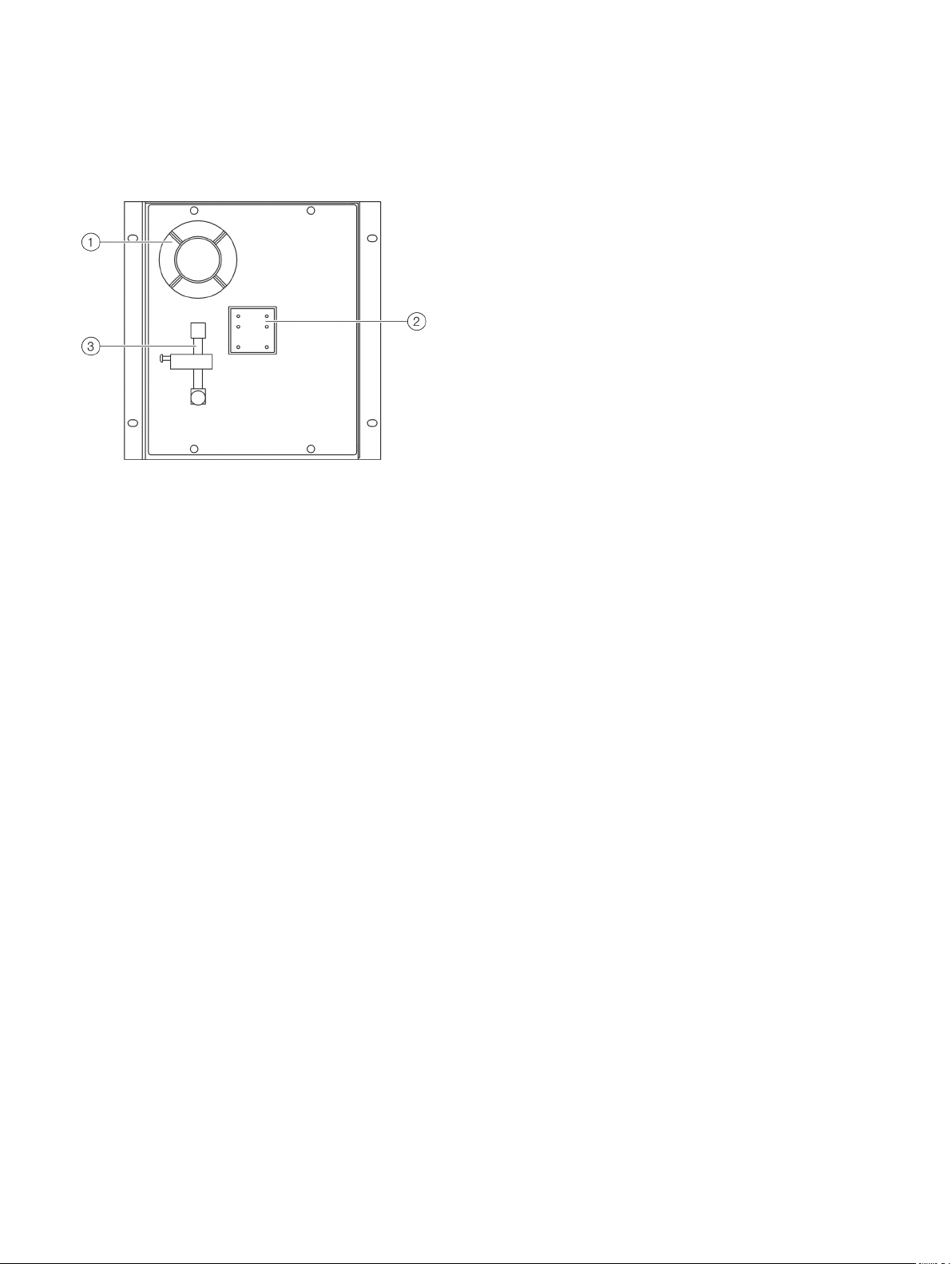

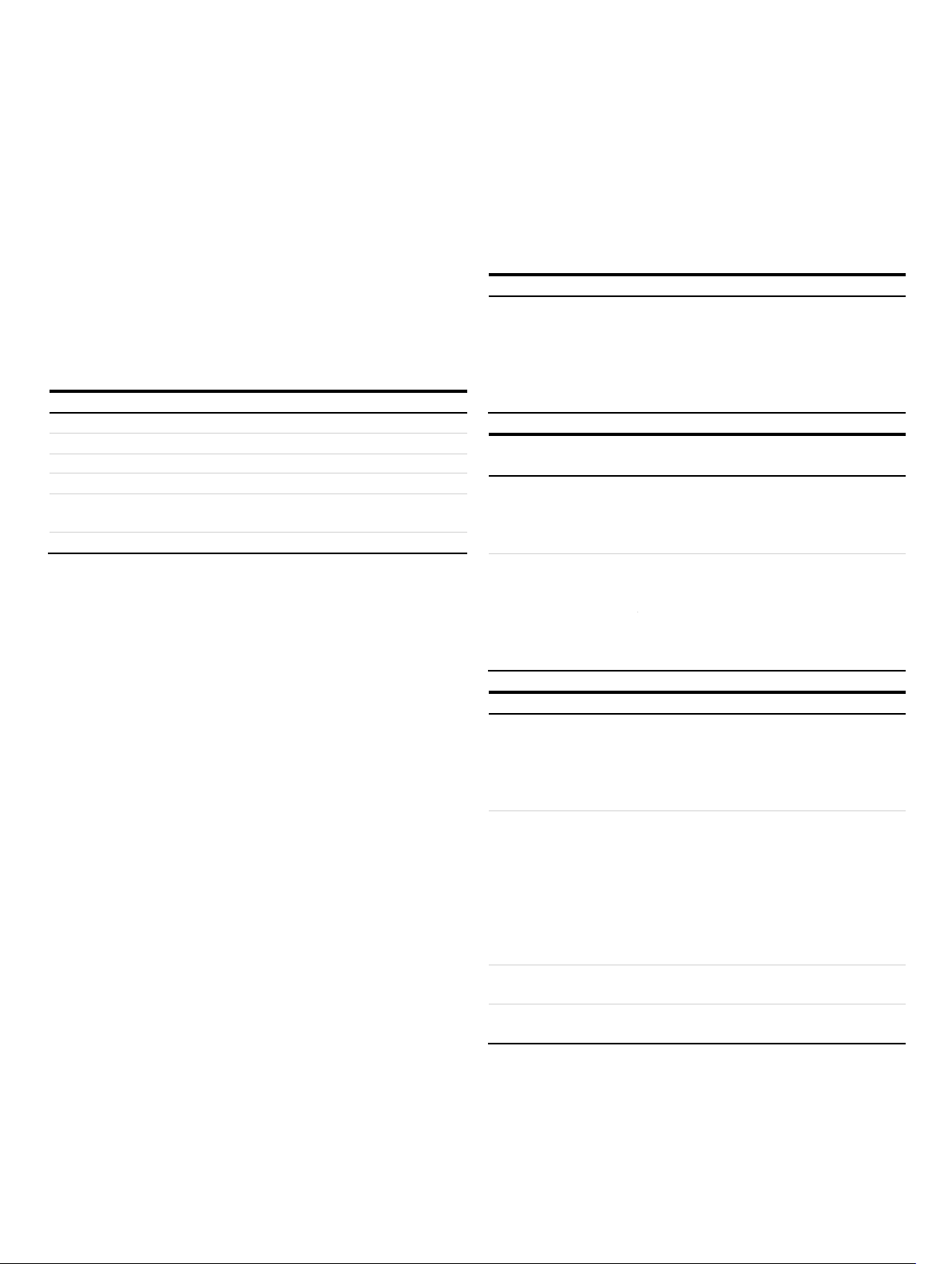

1

2

3

4

5

6

7

8

System structure

System cabinet

Main switch

Gas analyzer AO2020

Status indicators for measuring, back purge, general alarm, condensate

level

Heated sample gas line temperature controller

Figure 1: GAA610-M system cabinet

Front Door

The front door can be opened without any risks.

Behind the front door is the front panel, the Sample Gas Feed

Unit SCC-F and the Sample Gas Cooler SCC-C.

Front panel

On top is the NDIR gas analyzer AO2020-Uras26.

Below, on the left side of the status signal board, are signal

lamps as indication of activity of measuring point and backpurging.

Directly below them is the temperature controller for the heated

sample gas line.

In the middle of the status signal board are red LEDs for the

Common Alarm and for the condensate level alarm.

Below the alarm signals is an ethernet socket for maintenance

purpose.

Ethernet port

Sample Gas Cooler SCC-C

Sample Gas Feed Unit SCC-F

Cabinet air conditioner

Cabinet interior

The cabinet contains the sample conditioning components,

pump, valves, filters and gas analyzer.

It also contains the main switch, the power supply and the fuses

for all components, as well as the connection terminals for

analog and digital signals.

Page 12

12 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

A

B

C

D

E

F

1

2

3

4

5

6

7

8

9

0

k

l

m

… 2 Design and function

… System structure

System schematic

Exhaust gas stream

Compressed instrument air inlet

Calibration gas inlet

Exhaust pipe

Heated sample probe with probe tube and filter unit

Backpurging solenoid valves

Backpurging air panel

Heated sample gas line

Sample gas solenoid valve

Sample gas cooler SCC-C

Figure 2: System schematic

Sample gas flow

The sample gas is extracted from the exhaust duct after the

scrubber by a heated sample probe.

The heated sample gas line is the connection and supplying line

between sample probe and analyzer cabinet. The probe and the

sample gas line are heated to avoid condensation.

To clean the filters in the sample probe a back-purging system

via the filter chamber can be integrated. The filters are cleaned

with pressurized air every 12 hours cyclically or automatically

when the flow is below the minimum value.

At the entrance of the analyzer cabinet there is a 3/2-way

solenoid valve. The gas flow goes to the gas cooler and via filter,

flow meter, pump and aqua stop filter to the gas analyzer.

See also Piping diagram on page 98.

Ambient air / zero gas inlet

Sample gas outlet

Condensate outlet

Oil/Soot removal filter

Sample gas feed unit SCC-F

Aqua stop filter

AO2020 gas analyzer with Uras26

Cooling unit for analyzer cabinet

10 l condensate bottle with condensate alarm switch

Sample probe

The sample probe is connected gas tight to the process with a

flange. The probe tube extracts the gas in the middle of the

exhaust duct.

An external heated filter separates the dust from the sample

gas. The Filter is heated by a self-limiting PTC heater to 180 °C

(356 °F). The filter is equipped with a ceramic filter element.

To clean the filters in the sample probe a back purging system

via the filter can be integrated.

Page 13

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 13

1

2

Heated sample gas line

The heated sample gas line is directly connected to the filter at

the probe. The core is a PTFE hose. The line is heated to 180 °C

(356 °F).

The temperature is controlled with a Pt100 resistance

thermometer and the power/temperature is adjusted with a

temperature controller installed in the cabinet. In case of a

deviation from the set value a message is generated and

displayed on the AO2020-Display.

Temperature controller

A Temperature controller is used to control the temperature of

the heated sample gas line.

An alarm signal is output as soon as the temperature drops

below the minimum temperature limit.

Solenoid valve

A solenoid valve is installed to switch between measuring gas

and ambient air during calibration and standby mode.

Aqua stop filter

The aqua stop filter is the final protection for the analyzer. The

aqua stop filter holds back any humidity.

AO2020-Uras26 gas analyzer

The AO2020-Uras26 gas analyzer is integrated into the analyzer

system for measuring CO

The main components are an infrared source (lamp), a sample

cell, a wavelength filter, and the infrared detector.

The sample gas is pumped into the sample cell, and the gas

concentration is measured electro-optically by its absorption of

a specific wavelength in the infrared wavelength range.

and SO2.

2

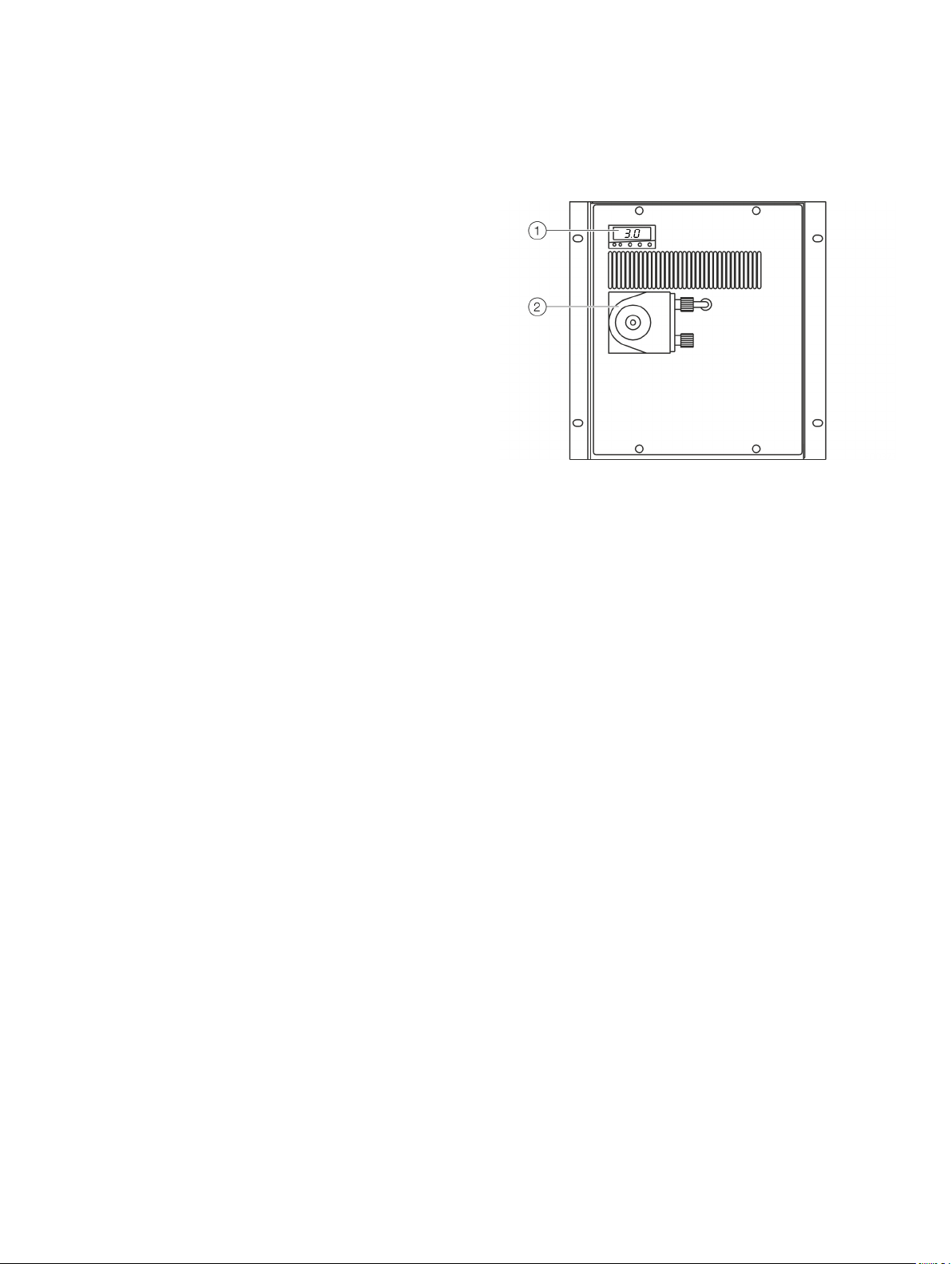

Sample Gas Cooler SCC-C

Temperature controller

Figure 3: Sample Gas Cooler SCC -C

The sample gas cooler defines the water content of the sample

at a certain dew point (typically 3 °C). Therefore, the temperature

of the sample falls from approx. 180 °C to the set point of the

sample gas cooler and condensation will occur. The condensate

is removed with a hose pump and collected in a separate bottle.

The sample gas cooler is controlled by the system and the

following signals can be output:

• Condensate level:

The level of the condensate collecting bottle is monitored

and a signal will output (displayed via a red lamp on the

front panel) when maintenance / emptying the bottle is

required.

• Fault cooler:

A status signal "fault cooler" is set if the cooler

temperature is too high. The signal is also provided as

"Failure" status signal.

• Failure alarm:

If a failure of the cooler is detected, the feed pump is

switched off and the system is set to system failure

mode. The system failure mode is displayed on the panel

and provided as a status signal.

Condensate pump

Page 14

14 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

1

2

3

… 2 Design and function

… System structure

Sample Gas Feed Unit SCC-F

Condensate monitor

LED display and reset switch for

condensate and flow alarm

Figure 4: Sample Gas Feed Unit SCC-F

Flow monitor with needle valve

The sample gas feed unit sucks the sample from the exhaust gas

and continuously feeds the gas analyzer with the sample gas.

The pump is a diaphragm pump. If the pump fails a flow alarm

occurs.

Flow control

The flow meters monitor the sample gas flow through the

analyzer.

The following parameters are considered:

• Typical flow: 60 l/h

• Minimum flow level: 40 l/h

• Maximum flow level: 80 l/h

• Flow error: 10 l/h

If the flow violates a limit value an alarm is displayed on the front

panel. In addition, the sample probe is automatically

backpurged.

Page 15

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 15

Products that are marked with the adjacent symbol

may

(domestic waste).

They should be disposed of through separate

collection of electric and electronic devices.

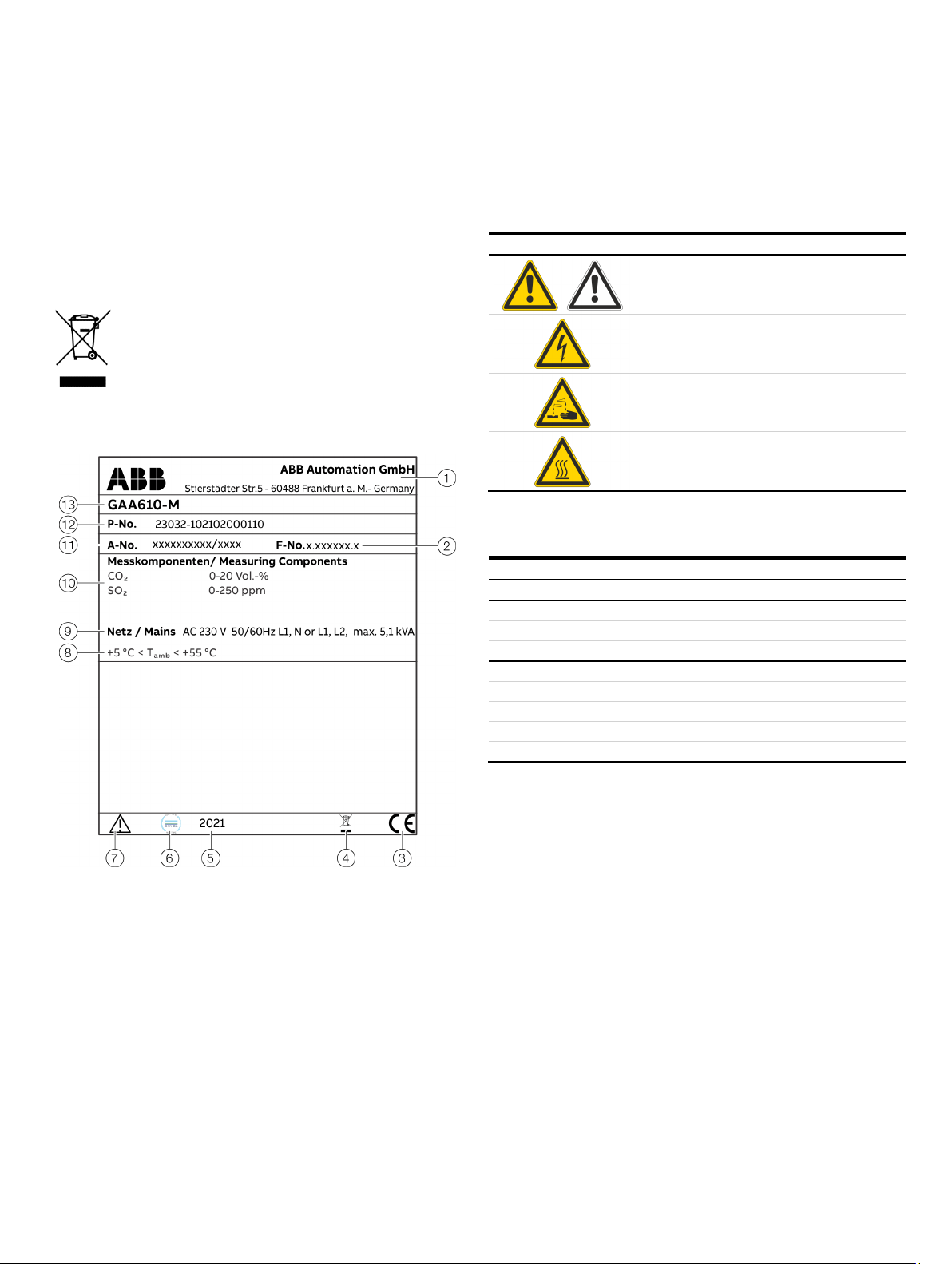

1

2

3

4

5

6

7

8 Permissible ambient temperature

9

0

k

l

m

Label / Symbol

Quantity

Description

Standard equipment

1

Analyzer cabinet

1

System documentation

Additional items delivered per order

1

Gas sampling probe tube type

1

Filter unit and 2

1

Sample gas line, heated

1

Condensate collection bottle

1

Wear

3 Product identification

Name plate

Note

The name plates displayed are examples. The device

identification plates affixed to the device can differ from this

representation.

Note

not be disposed of as unsorted municipal waste

The type plate is located at the top right of the right-hand side

panel of the analyzer cabinet near the cable glands.

Plates and symbols

The following labels and symbols are attached to the analyzer

system or to the individual components.

Meaning

Consult documentation, i.e. consult this

operating instruction.

Risk of electric shock!

Corrosive material!

Hot surface!

(Temperature > 60 °C)

Scope of delivery

Manufacturer, address

Serial number

CE marking

Disposal marking

Manufacture date

Type approval marking

‘Observe operating instruction’

symbol

Figure 5: Name plate (example)

range

Power supply

Measuring Components

Order number

Product configuration number

Model name

×

× set

×

×

×

×

×

40 (unheated)

-stage back-purging unit

parts set (optional)

Page 16

16 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

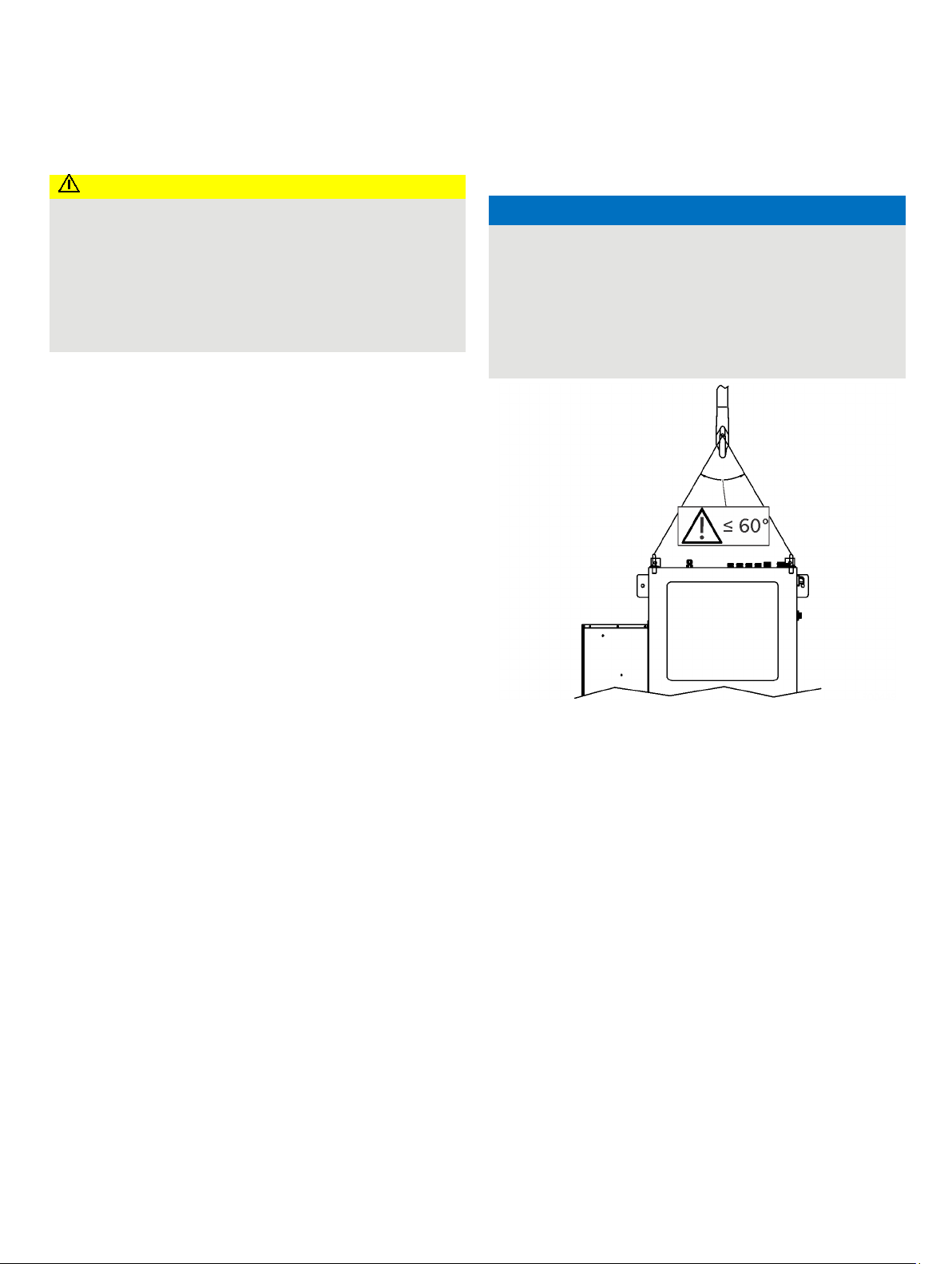

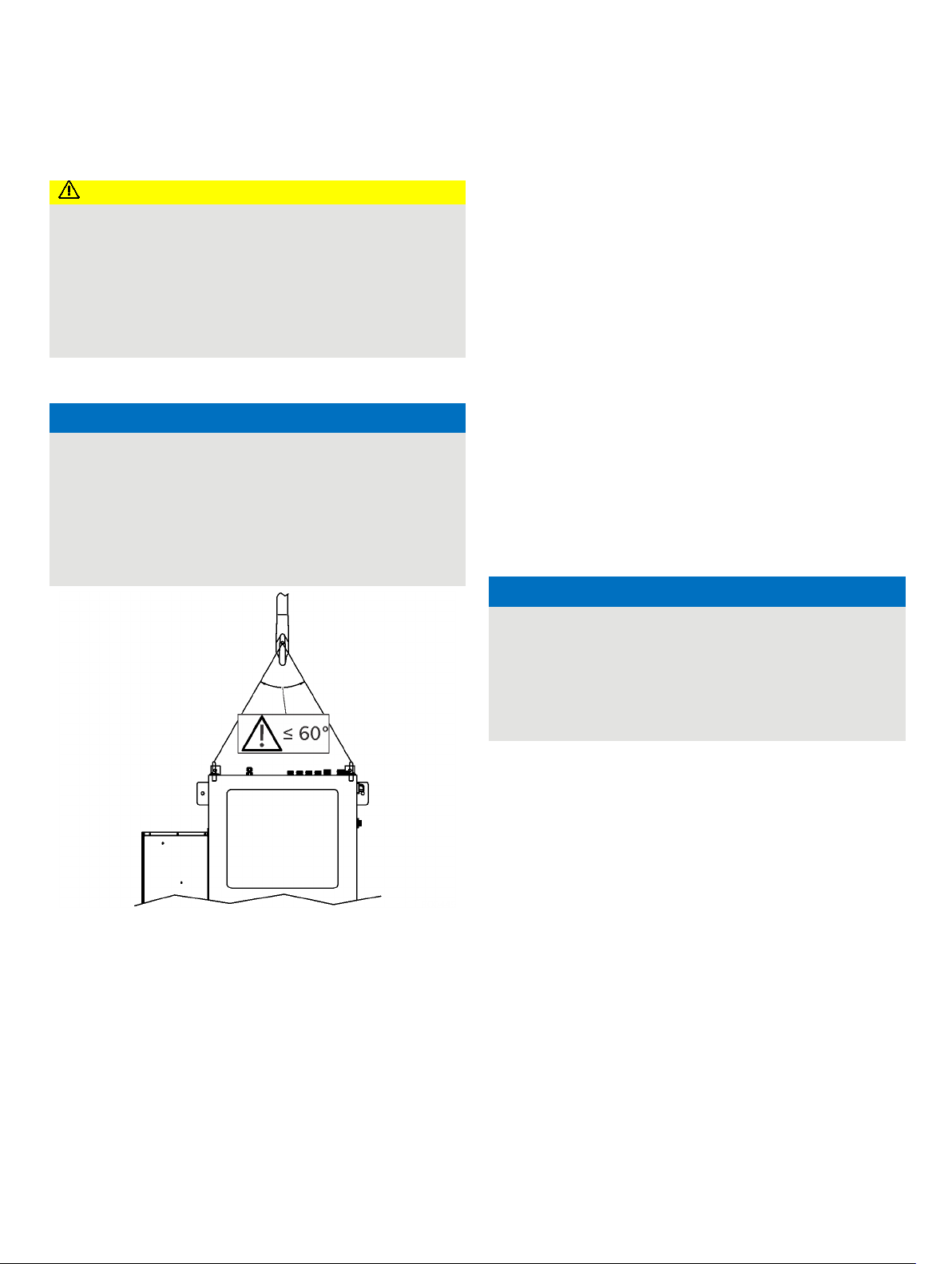

CAUTION

cables to the analyzer cabinet.

NOTICE

the analyzer cabinet can be warped.

4 Transport and storage

Safety instructions

Injury hazard due to heavy weight

Depending on the version, the gas analyzer cabinet weighs

approx. 240 kg (529 lb)!

• A suitable lifting device (crane, block and tackle, lifting

truck, etc.) is required for transport, setting upright and

installation!

• Only use the handling lugs provided to connect any lift

Inspection

Check the devices immediately after unpacking for possible

damage that may have occurred from improper transport.

Details of any damage that has occurred in transit must be

recorded on the transport documents.

All claims for damages must be submitted to the shipper

without delay and before installation.

Transporting the device

Transporting the analyzer cabinet

Potential damage to the device!

Damage to the device due to improper transport.

• Use the handling lugs provided to connect any lift cables

to the analyzer cabinet.

• The lift cable must be long enough to have an angle of at

least 60° relative to the top of the cabinet when under

tension. If this is not done the handling lugs can be bent or

Figure 6: Lift-Up the analyzer cabinet

Note

It is strongly recommended that the analyzer cabinet is

transported by a specialist firm, transported in a horizontal

position!

Unpacking the analyzer cabinet

1. Lift out the analyzer cabinet from the shipping box.

2. Do not remove the plastic sheet in which the analyzer cabinet

is wrapped. Unpacking a cold analyzer cabinet can lead to

condensation.

3. Remove the plastic sheet only once the analyzer cabinet is at

room temperature. This takes at least 24 hours.

Page 17

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 17

Storing the device

Bear the following points in mind when storing devices:

• Store the device in its original packaging in a dry and

dust-free location.

• Observe the permitted ambient conditions for transport

and storage.

• Avoid storing the device in direct sunlight.

• In principle, the devices may be stored for an unlimited

period. However, the warranty conditions stipulated in

the order confirmation of the supplier apply.

Ambient conditions

Ambient temperature during transport / storage

• 2 to 60 °C (35.6 to 140 °F);

• −20 to 70 °C (−4 to 158 °F) after draining and drying parts

in contact with condensate.

Max. permissible humidity

Year-round average max. 75%, short-term max. 95%,

occasional slight condensation is permitted.

Packaging

1. If the original packing material is no longer available, wrap

the device in bubble foil or corrugated cardboard.

When shipping overseas, also heat-seal the device air-tight in

0.2 mm thick polyethylene, including a desiccant (e.g. silica

gel). The amount of desiccant used should be adequate for

the package volume and the probable shipping time (at least

3 months).

2. Pack the device in an adequately large box lined with shock

absorbent material (e.g. foam material). The thickness of the

cushioning material should be adequate for the weight of the

device and the mode of shipping. The box should also be

lined with a double layer of bitumen paper for overseas

shipping.

3. Mark the box ‘Fragile! Handle with care!’.

Returning devices

Use the original packaging or a secure transport container of an

appropriate type if you need to return the device for repair or

recalibration purposes.

Fill out the return form (see Return form on page 99) and include

this with the device.

In accordance with the EU Directive governing hazardous

materials, the owner of hazardous waste is responsible for its

disposal or must observe the following regulations for shipping

purposes:

All devices delivered to ABB must be free from any hazardous

materials (acids, alkalis, solvents, etc.).

Address for the return:

Contact Center

www.abb.com/contacts

Page 18

18 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

CAUTION

cables to the analyzer cabinet.

DANGER

locations.

1

2

3

4

5

5 Preparation for Installation

Safety instructions

Injury hazard due to heavy weight

Depending on the version, the gas analyzer cabinet weighs

approx. 240 kg (529 lb)!

• A suitable lifting device (crane, block and tackle, lifting

truck, etc.) is required for transport, setting upright and

installation!

• Only use the handling lugs provided to connect any lift

Note

• The system must be installed by ABB or by personnel trained

by ABB.

• When installing the analyzer system, in addition to this

operating instruction, comply with the information

contained in the drawings set.

• If there is shipping damage which points to improper

handling file a damage claim with the shipper (railway, mail

or freight carrier) within seven days.

• Make sure the enclosed accessories are not lost.

• Keep the packaging material for future shipping needs.

Requirements for the installation site

Risk of explosion

The analyzer system must not be installed in hazardous

Choosing the extraction point

The extraction point must be suitable for extracting a

representative specimen flow.

In case of emission monitoring of exhaust gases, the extraction

point is specified in accordance with responsible technical

inspection authority, e.g. classification society.

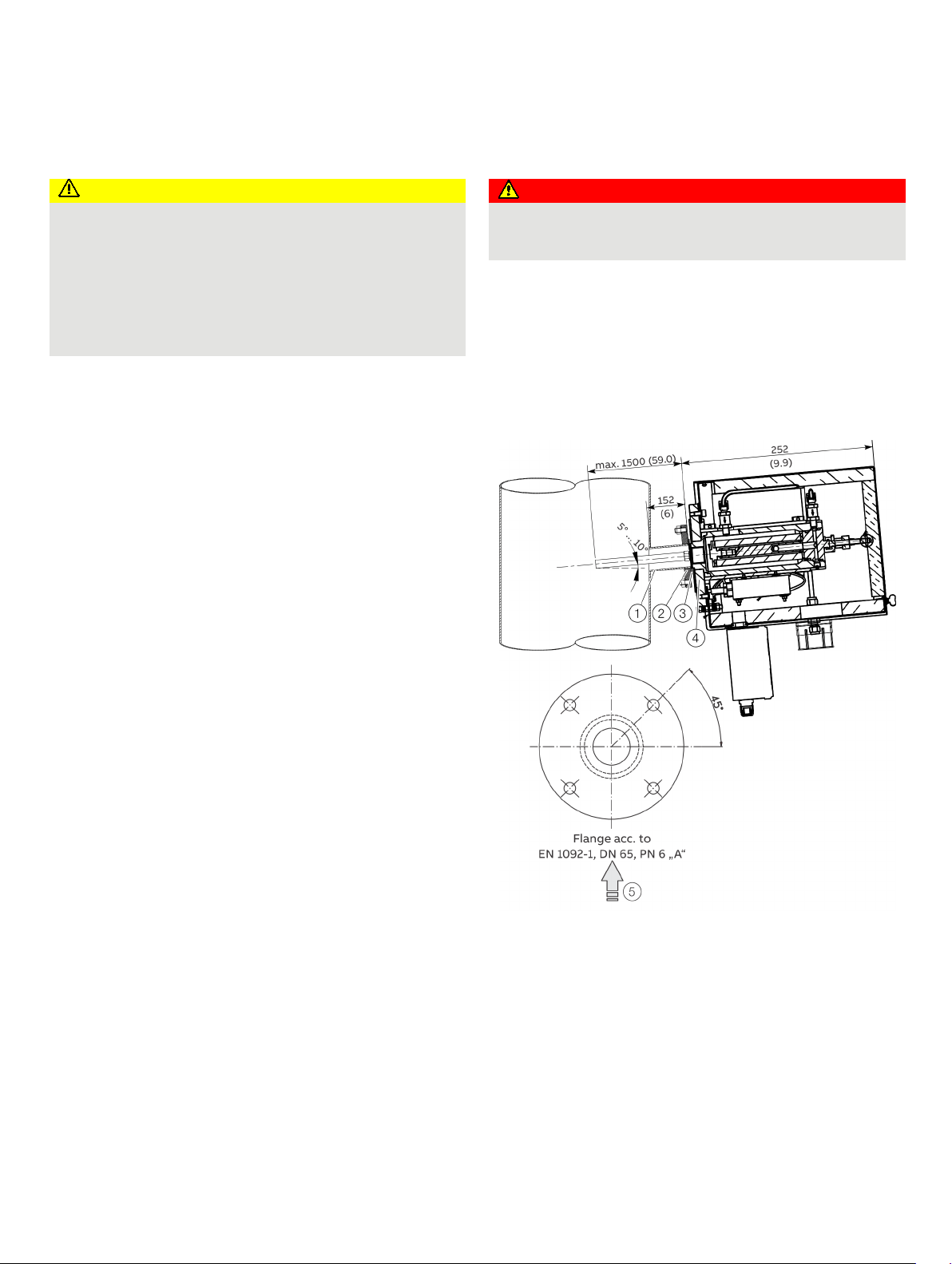

Wall tube installation

Installation – Overview

1. Prepare the gas sampling probe installation site, see

Choosing the extraction point on page 18.

2. Prepare the analyzer cabinet installation site, see

Requirements for the installation site on page 18.

3. Install the gas sampling probe and filter unit, see Probe tube

and filter unit installation on page 25.

4. Install the sample gas line, see Sample gas line installation

on page 27.

5. Install the back-purging unit (if applicable), see Back-purging

unit installation on page 29.

6. Install the analyzer cabinet, see Analyzer cabinet installation

on page 30.

7. Install the instrument air and test gas supply

(if applicable), see Gas connections on page 31.

8. Connect the gas lines to the analyzer cabinet, see

Connecting the gas lines on page 32.

9. Connect the electrical leads to the analyzer cabinet, see

Electrical connections on page 33.

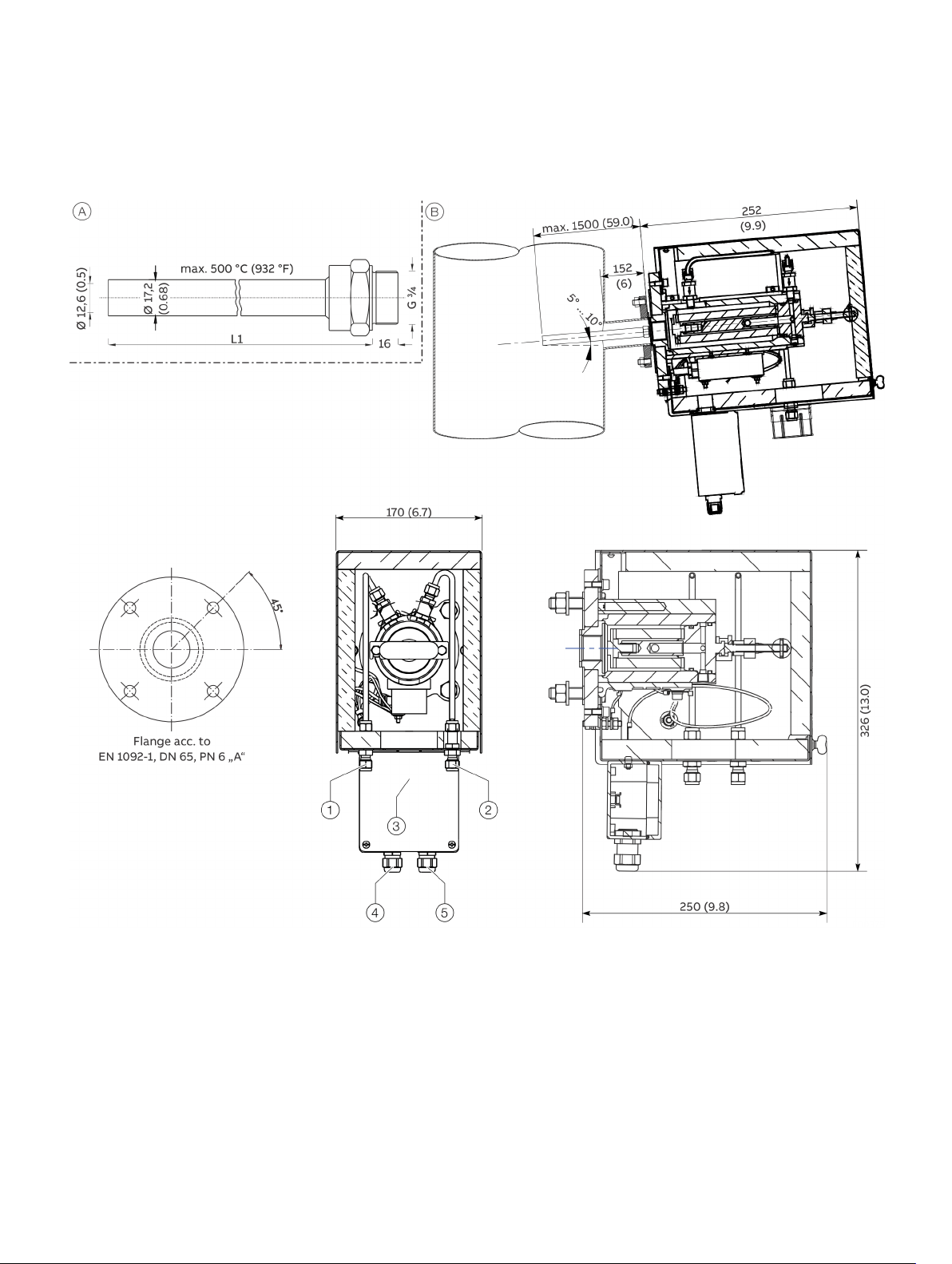

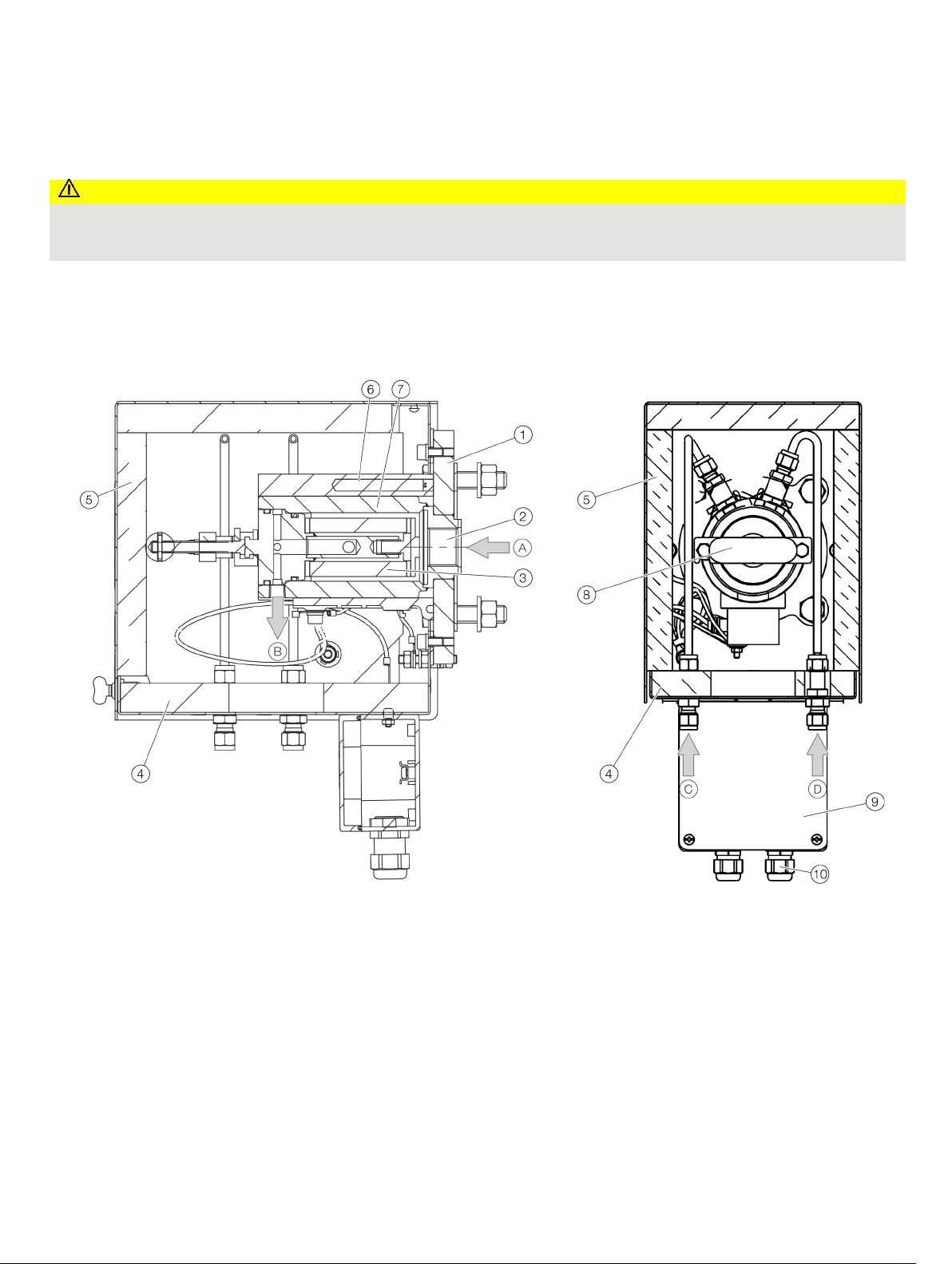

Wall tube

Wall tube mounting flange

Gasket

Figure 7: Wall tube installation, Dimensions in mm (inch)

Sample probe tube flange

Flow direction

Install the wall tube with mounting flange (DN 65, PN 6, facing

type A to EN 1092-1; not supplied) at the extraction point in such

a way that the sampling probe tube can be easily installed and

removed.

The sampling probe tube must be easily accessible to allow

maintenance work to be performed. Align the boreholes of the

mounting flange in relation to the flow direction

5 of the

process gas.

Page 19

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 19

Short gas paths

The analyzer cabinet should be installed as close as possible to

the sampling site. A short sample gas line results in short T

times.

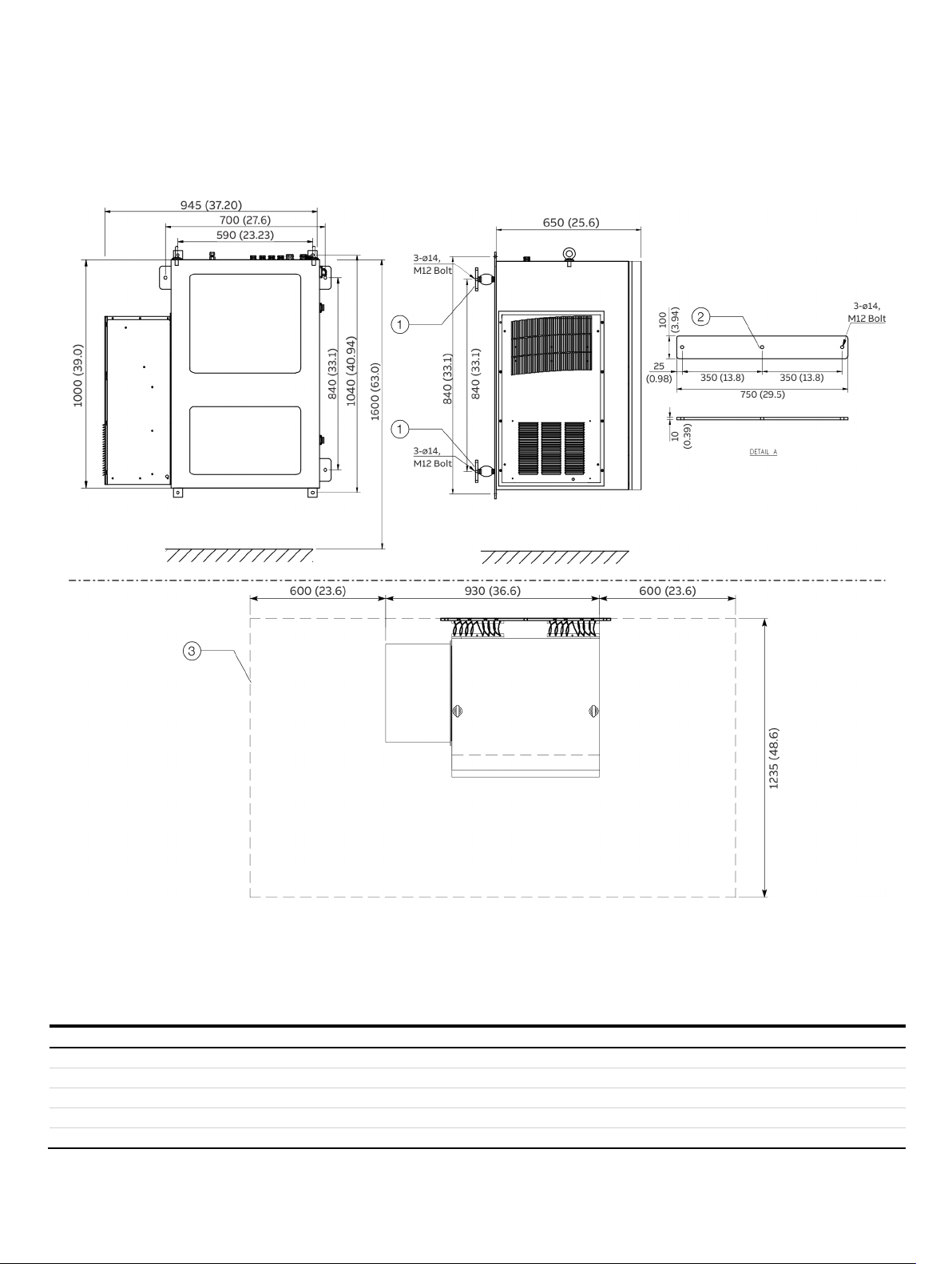

The sample gas line length is limited to 30 meters with 230 VAC

power on account of pressure drop build-up in the line and the

required electrical fusing.

The test gas cylinders should be installed as close as possible to

the analyzer system. Test gas cylinders are only required for

regular adjustment during operation if CEMS is not equipped

with internal gas filled cells.

Protection from adverse ambient conditions

Protect the gas analyzer cabinet from the following influences:

• Water spray

• Contact with chemicals

• Strong sunlight and heat radiation

• Strong air currents

• Heavy dust load

• Corrosive atmospheres

Installation indoors

The analyzer system is intended for installation aboard a ship.

Thereby, the installation location height is naturally limited to

sea level.

The analyzer cabinet is only suitable for installation indoors. An

air-conditioned room is recommended.

Dimensions and space requirement

Refer to Dimensions on page 21 in the drawings set.

Installation site stability

The installation site floor must be plane and the wall capable of

supporting the cabinets weight.

90

Climatic Conditions

Ambient temperature

In operation: 5 to 55 °C* (41 to 131 °F)*

* Higher ambient temperature during operation on request.

Ambient temperature during transport / storage

• 2 to 60 °C (35.6 to 140 °F);

• −20 to 70 °C (−4 to 158 °F) after draining and drying parts

in contact with condensate.

Max. permissible humidity

Year-round average max. 75%, short-term max. 95%,

occasional slight condensation is permitted.

IP rating

IP 54

Vibration resistance in accordance with IEC 60068-2-6

Vibrations according the below tested conditions showed

negligible influence on measurement value.

Test Fc:

±1.0 mm, 2

0.7 g at 13.2 Hz up to 100 Hz

Overvoltage category

II

Pollution degree

2

+3

Hz up to 13.2 Hz;

−0

Page 20

20 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

GAA610-M – Instrument air inlet conditions

Quality

Oil free, dry with dew point < −20 °C (−4 °F)

Pressure

Min. 400 kPa (60 psig)

Max. 600 kPa (90 psig)

Air consumption

< 0.2 Nm3/day

NOTICE

• Only use dry and clean compressed air.

Power supply

Terminals

: L, N, PE or L1, L2, PE

Operating voltage

%

Frequency

50 / 60 Hz, ±3 Hz

External fuse

A

Power consumption

System cabinet

w

Air conditioner

W

Sampling probe

300 W

Heated sample gas line

W/m

DANGER

ignitable gas / air or gas / oxygen mixtures

GAA610-M – Sample gas inlet conditions

Temperature

Max. 500 °C (932 °F)

Pressure

850

… 5 Preparation for Installation

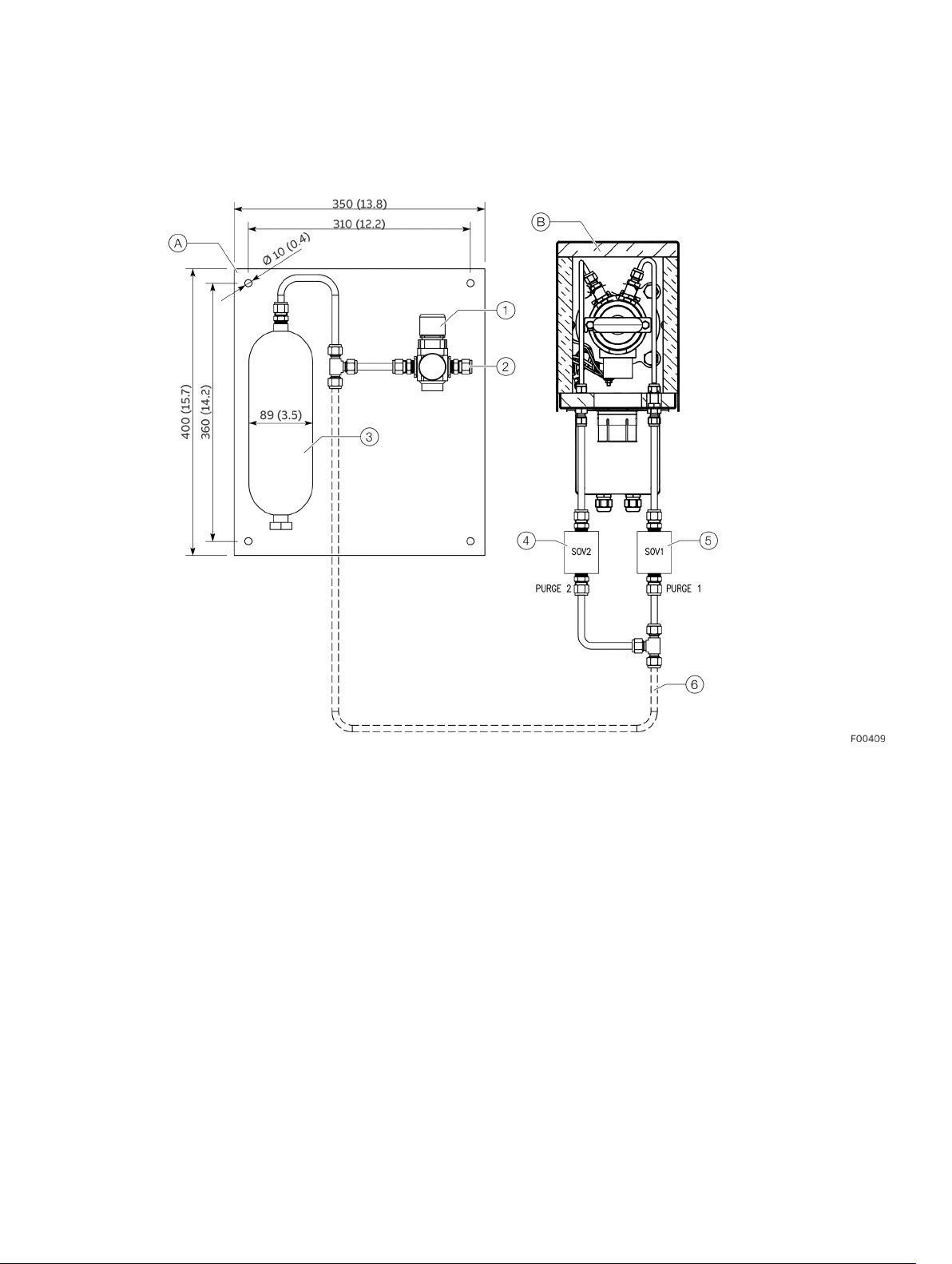

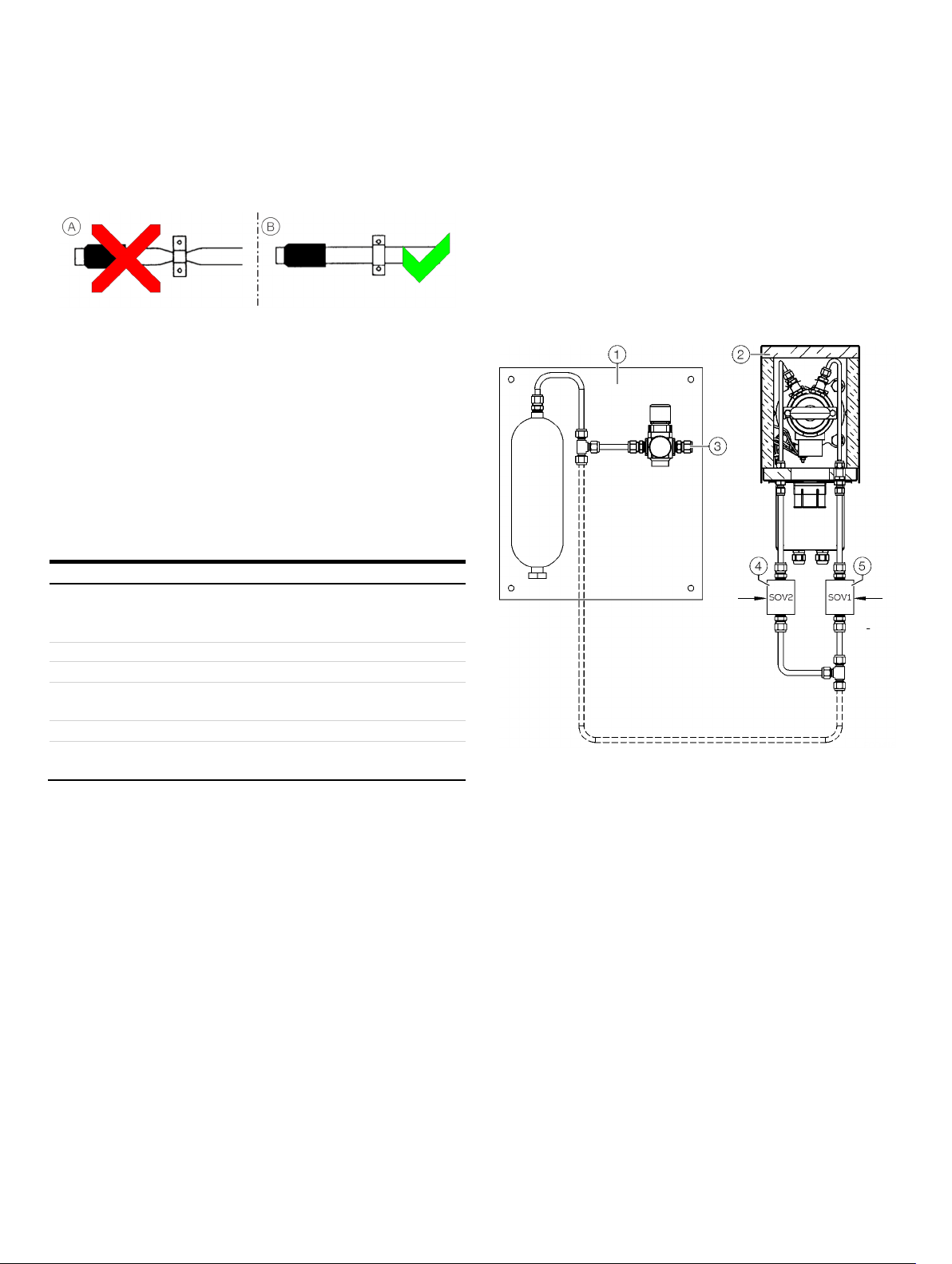

Backpurging Unit

Design of the back-purging unit

The back-purging unit consists of a protective cabinet with shutoff valve, 6 bar pressure reduction valve, solenoid valves for

back-purging, pressure regulator and 2 l compressed air receiver

(pressure buffer tank) for effective pressure pulses also with

lower airflow rate.

Distance to sampling probe

The distance between the back-purging unit and the sampling

probe should be as short as possible and must not exceed 2 m

(6.6 ft).

Protection from adverse ambient conditions

Protect the back-purging unit against:

• Water spray

• Contact with chemicals

• Strong sunlight and heat radiation

• Strong air currents

• Heavy dust load

• Corrosive atmospheres

• Vibration

Instrument air supply

Compressed air for back-purging

Power supply

-X60

230 V AC, ±10

25

500

1600

Approx. 90

Sample gas inlet conditions

Explosion hazard

Explosion hazard when measuring ignitable gas / air or

gas / oxygen mixtures

• The gas analyzer may not be used for the measurement of

to 1100 hPa (0.85 to 1.1 bar), (12.3 to 16 psi)

Damage to the sample conditioning components

If the compressed air is not dry and clean, this will result in

damage to the sample conditioning components (valves,

filters, sample gas cooler, sample gas feed unit) as well as to

the gas analyzer.

Page 21

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 21

1

2

3

Component

Weight

Analyzer cabinet

240 kg (441 lb), depending on configuration

Probe tube type 40

Filter unit, heated, with protective case

20 kg (44 lb)

Back Purging Unit

Heated sample gas line type TBL01-S

1 kg/m (2.2 lb/m)

Dimensions

Analyzer cabinet

Vibration damper

Mounting plate for vibration dampers

Figure 8: Dimensions an alyzer cabinet, mm (in)

Weight of the individual system components

8 kg (18 lb)

Approx. 5 kg (11 lb)

Maintenance area

Page 22

22 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

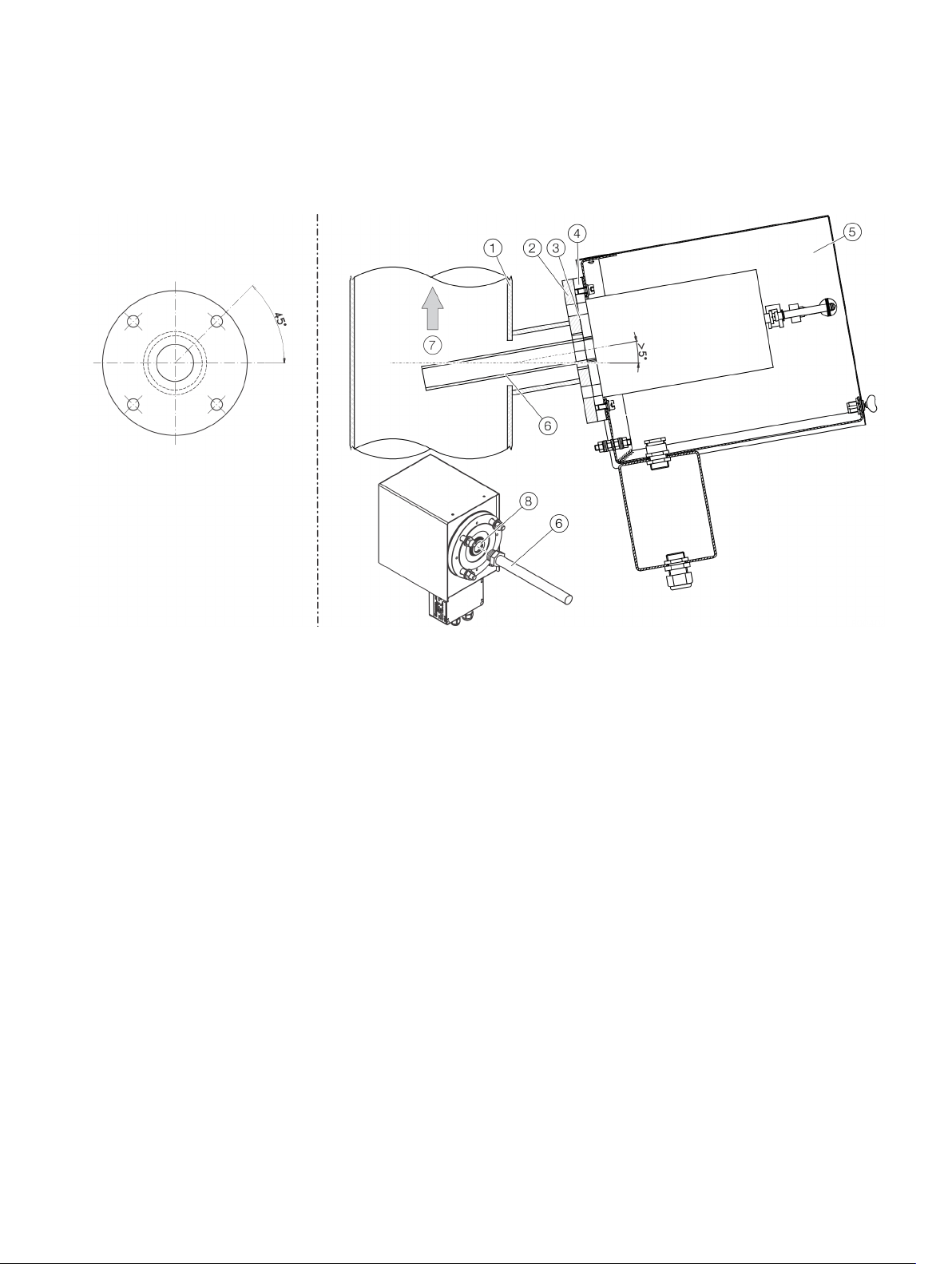

A

B

1

2

3

4

5

L1

… 5 Preparation for Installation

… Dimensions

Type 40 probe tube and filter unit

Type 40 probe tube

Backpurging air inlet from solenoid valve S0V2

Backpurging air inlet from solenoid valve S0V1

Sample gas outlet (heated sample gas line)

Figure 9: Type 40 probe tube and filter unit

Heated filter unit

Cable gland for heated filter unit power supply

Cable gland for heated filter unit alarm signal

500 mm (19.7 in) / 1000 mm (39.4 in)

Page 23

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 23

A

B

1

2

3

4

5

6

Backpurging Unit

Backpurging panel

Pressure regulator

Instrument air inlet, 10 mm O.D. Tube fitting for stainless steel pipe

Pressure buffer tank

Figure 10: Backpurging panel

Filter unit

Backpurging solenoid valve SOV2

Backpurging solenoid valve SOV1

Stainless steel pipe 10 mm O.D., to be intalled by customer

Page 24

24 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

Gas line

Material

Sample gas

PTFE pipe 4/6×1 mm

Sample gas outlet

PTFE pipe 4/6×1 mm

Ambient air / Zero (N

2

PTFE pipe 4/6×1 mm

Calibration gases 1, 2, 3

PTFE pipe 4/6×1 mm

Instrument air

,

via tube fitting

Condensate collecting bottle

PVC tube 4/6×1 mm

Power supply lines

Analyzer cabinet supply

Connecting cables between analyzer cabinet and sample handling

components

Sample probe power supply

Probe Heater Alarm Signal

• Cable Type: 2×0.75 mm2

Back

Valves (SOV1/SOV2)

Signal lines (Connection between CEMS cabinet and scrubber system)

Analogue Signals to DCS

(only, if hardwired

connection is required)

• Cable Type: 6×1 mm2

Digital Signals to DCS

(only, if hardwired

connection is required)

(Measuring Range Feedback SO2)

Modbus Signal to DCS

Cable Entry: M20 Cable gland for customer supply

cable

Ethernet to DCS

supply

… 5 Preparation for Installation

Material required for installation

Note

The materials listed below are not included in the scope of

delivery of the device, and must be provided by the customer.

Gas sampling

Wall tube with mounting flange

DN 65, PN 6, facing type A to EN 1092-1.

Gas lines

(unheated line)

)

Stainless steel pipe, 10 mm

Mounting material

Screws and nuts to mount the analyzer cabinet on the wall.

A suitable lifting device (crane, block and tackle, lifting truck,

etc.) and lifting gear are required for transport and installation

of the analyzer cabinet.

For details regarding the size of the screws and nuts see the

‘Layout Plan’ in the drawings set.

Cable specification

Note

All cables entering the system must comply with the

flammability class VW1, FT1 or EN60332-1-2/-2-2.

• 230 V AC, 50 / 60 Hz, Single Phase NON-UPS

power supply; fuse (external) 25A

• Cable Entry: M25 Cable gland for customer

supply cable;

• Cable Type: 3×10 mm2

• Grounding cabl e: > 6 mm2

• 230 V AC 50/60 Hz;

• Cable Entry: M20 Cable gland for customer

supply cable;

• Cable Type: 3×2.5 mm2

• Cable Entry: M20 Cable gland for customer

supply cable

-purge Unit Solenoid

• Cable Entry: M20 Cable gland for customer

supply cable

• Cable Type: 2×1.5 mm2

• Shielded cables for the analog outputs

(current outputs)

• Cable Entry: M25 Cable gland for customer

supply cable

• Cable Entry: M20 Cable gland for customer

supply cable

• Cable Type: 2×1 mm2 (System failure)

• Cable Type: 2×1 mm2 (Maintenance)

• Cable Type: 2×1 mm

(Maintenance Request)

• Cable Type: 2×1 mm

Cable Entry: M20 Cable gland for customer

cable

2

2

Note

Further signal lines might be needed, please check your specific

wiring diagram.

Page 25

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 25

CAUTION

• Two persons are required for transportation and mounting!

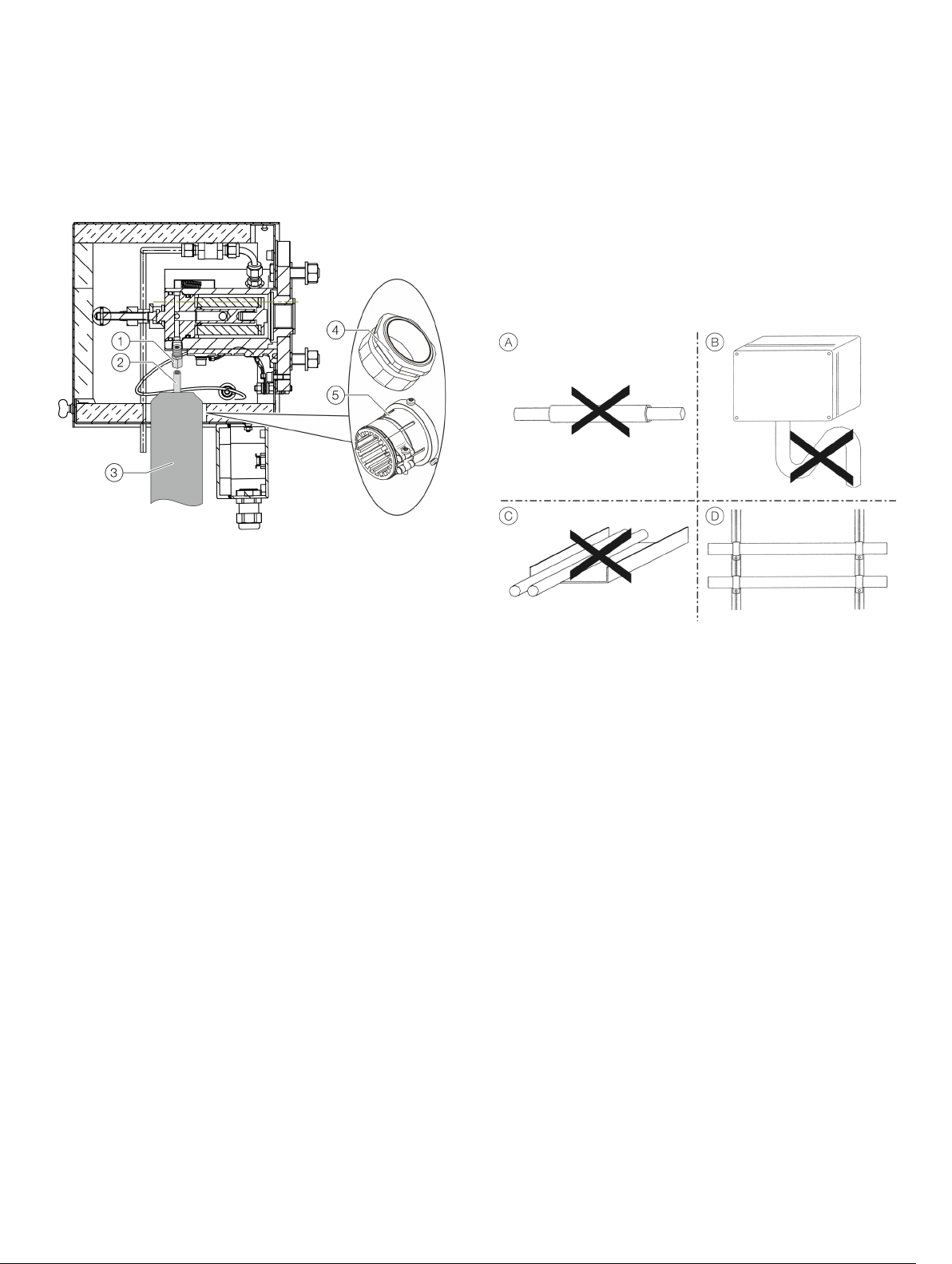

A

B

C

D

1

2

3

4

5

6

7

8

9

0

6 Installation

Probe tube and filter unit installation

Injury hazard due to heavy weight

The weight of the probe tube with filter unit amounts to approx. 18 to 20 kg!

Before the installation

• Observe the ‘Piping plan’ in the drawings set.

• Make sure that the wall tube is installed at the extraction point, see .

Filter unit overview

Sample gas inlet

Sample gas outlet

Backpurging air inlet from solenoid valve S0V2

Backpurging air inlet from solenoid valve S0V1

Flange

Internal thread connection for probe tube

Filter element

Figure 11: Filter unit

Housing with thermal Insulation

Cover with thermal insulation

Heater element

Filter housing

T-handle

Terminal box for heater power supply and status contact

Cable glands

Page 26

26 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

Flange orientation

Filter unit

1

2

3

4

5

6

7

8

… 6 Installation

… Probe tube and filter unit installation

Installation

Duct wall

Flange

Flange gasket

Probe flange

Figure 12: Filter unit installation

Filter Unit

Probe tube

Flow direction

Sample gas inlet

1. Screw the probe tube 6 into the sample gas inlet 8 of the filter unit.

2. Insert the pre-assembled probe tube with filter unit in the wall tube and screw the flange of the filter unit to the flange of the wall

tube. Use the green seal from the accessories pack to seal the space between the flanges of wall tube and filter unit.

3. Mount the heating sleeve on the filter unit.

4. If applicable, install the compressed-air hoses between the filter unit and the back-purging unit.

Page 27

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 27

Connection of the heated sample gas line

Figure 13: Connection of the heated sample gas line

Note

The heated sample line must be strain relieved and must not be

hung on the fitting.

1. Mount ⅛“ NPT fitting

unit.

2. Attach heated sample line

moveable PG 42 cable conduit

3. Connect the line

1 at the sample gas outlet of the filter

3 on probe enclosure with

4 or mounting clamp 5.

2 with the fitting 1 gas-tight.

Sample gas line installation

Installing the sample gas line

• Observe the "Piping plan" in the drawings set.

• Connect the sample gas line to the filter unit/gas sampling

probe.

• Route the sample gas line through the opening provided in

the top of the cabinet.

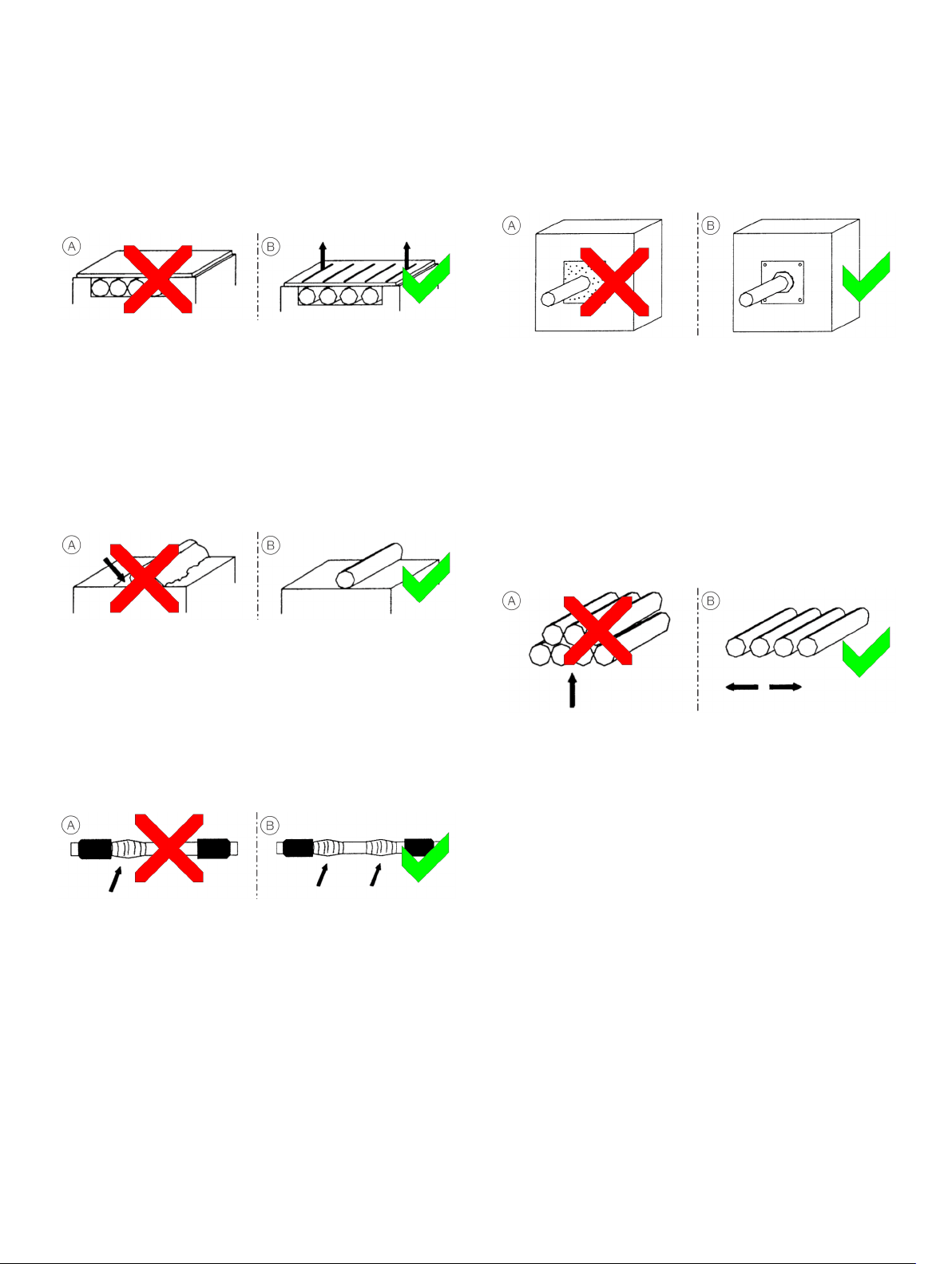

Fundamentals for laying the sample gas line

Figure 14: Laying the sample gas line

A Do not lay the heated sample gas line in a thermowell.

B When laying the sample gas line, avoid the formation of

water locks, particularly at the sampling points.

C Do not lay the heated sample gas line in a cable tray together

with other electrical or pneumatic lines, especially not in an

enclosed cable tray.

D When laying the heated sample gas lines on exposed C-

profiles with BBS cable clips: Do not overtighten the cable

clips, in order to prevent damage to the sample gas line

through crushing.

Page 28

28 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

Incorrect

Correct

Incorrect

Correct

Incorrect

Correct

Incorrect

Correct

Incorrect

Correct

… 6 Installation

… Sample gas line installation

Procedures for laying the sample gas line

Wall break-through

Laying in ducts or shafts

Figure 15: Laying in ducts or shafts

A Do not lay the heated sample gas lines directly side-by-side

in an enclosed duct or shaft. This results in heat

accumulation.

B Ensure that the hoses do not touch. Maintain a distance of

25 mm. Provide adequate ventilation. Heat can be conducted

away as a result.

Soiling the heated sample gas line

Figure 18: Wall break-through

A Do not lay the heated sample gas line in a wall break-through

which is subsequently sealed with a sealing compound under

any circumstances. The sample gas line will be destroyed by

overheating in this case!

B When laying the heated sample gas line through a wall break-

through, use bulkhead plates with conduit thread cable

glands, in order to provide adequate cooling of the sample

gas line.

Laying several heated sample gas lines

Figure 16: Soiling

A Prevent powdery substances, adhesives or other thermally

insulating materials from soiling the heated sample gas line.

Otherwise, over\-heating will occur at these points.

B If soiling occurs, clean the materials and remedy the cause.

Heat can be conducted away again as a result.

Wrapping the heated sample gas line

Figure 17: Wrapping

A Avoid heat accumulation through wrapping the heated

sample gas line with other materials, otherwise the sample

gas line will overheat at these points. Do not cover the area

near the temperature sensor, otherwise the rest of the

sample gas line will cool down.

B Do not wrap the sample gas line. Ensure that the area near

the temperature sensor is exposed.

This results in error-free temperature measurement.

Figure 19: Bundling several gas lines

A Avoid bundling or laying several heated sample gas lines, so

that they touch each other. This results in overheating at the

contact points.

B Lay several heated sample gas lines separately with a

distance of at least 2.5 cm and provide adequate ventilation.

Heat can be conducted away as a result.

Page 29

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 29

Incorrect

Correct

Characteristic

Permissible value

Type

W/m if other is used

Maximum line length

Minimum bending radius

300 mm

Maximum clip distance

Lowest laying temperature

−10 °C

Temperature of the

sheathing

1

2

3

4

5

Mounting brackets

Back-purging unit installation

Before the installation

Observe the ‘Piping plan’ in the drawings set.

Installation site

The distance between the back-purging unit and the sampling

probe should be as short as possible and must not exceed 2 m

(6.6 ft).

Figure 20: Mounting brackets

A Do not squeeze the heat insulation in mounting brackets

Connecting the compressed-air tubes

tightly together, so that the outer braiding is pressed on to

the heat conductor. If you disregard this, damage to the

protective braiding and the heated sample gas line may

occur.

B Tighten the BBS cable clips sufficiently but not excessively, in

order to prevent damage to the protective braiding and the

heated sample gas line.

Permissible values for laying the sample gas line

Heated, Type TBL01-S, regulated heating, 180 °C,

heating power 90 W/m (TBL01-S); approx. 100

230 V AC: max. 30 m

1.2 m with horizontal laying

3.5 m with vertical laying

max. 60 °C

Back-purging panel

Filter unit

Instrument air inlet

Figure 21: Connecting the back purging unit

Solenoid valve SOV2

Solenoid valve SOV2

1. Mount the solenoid valves on the filter unit as illustrated.

2. Connect the compressed-air pipes for purge air and control

air to the respective ports at the filter unit.

3. Connect the electrical cables of the solenoid valves to the

corresponding terminal strip in the analyzer cabinet. For

details see the wiring diagram or Terminal assignment –

Analyzer cabinet on page 35.

Page 30

30 GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B

CAUTION

cables to the analyzer cabinet.

NOTICE

the analyzer cabinet can be warped.

NOTICE

following points:

… 6 Installation

Analyzer cabinet installation

Injury hazard due to heavy weight

Depending on the version, the gas analyzer cabinet weighs

approx. 240 kg (529 lb)!

• A suitable lifting device (crane, block and tackle, lifting

truck, etc.) is required for transport, setting upright and

installation!

• Only use the handling lugs provided to connect any lift

Transporting the analyzer cabinet

Potential damage to the device!

Damage to the device due to improper transport.

• Use the handling lugs provided to connect any lift cables

to the analyzer cabinet.

• The lift cable must be long enough to have an angle of at

least 60° relative to the top of the cabinet when under

tension. If this is not done the handling lugs can be bent or

Mounting the analyzer cabinet

• Observe the installation site requirements.

• The loading capacity of the wall must be high enough to bear

the weight of the analyzer cabinet.

• Follow the ‘Layout plan’ in the drawings set.

• The vibration dampers are ready pre-installed. For easy

installation, the upper and lower vibration dampers are each

connected to a mounting plate. See also Dimensions on

page 21.

1. Mount the cabinet with the vibration dampers on the wall

and fix it to the screw holes provided on the mounting plate

using M12 Bolts.

2. Tighten all screws of the analyzer cabinet.

3. Ground the analyzer cabinet by means of the grounding bolt

(grounding cable ≥ 6 mm

Connecting the condensate water drain of the cabinet air conditioner

2

/≥ AWG 10).

Figure 22: Lift-Up the analyzer cabinet

Note

It is strongly recommended that the analyzer cabinet is

transported by a specialist firm, transported in a horizontal

position!

Unpacking the analyzer cabinet

1. Lift out the analyzer cabinet from the shipping box.

2. Do not remove the plastic sheet in which the analyzer cabinet

is wrapped. Unpacking a cold analyzer cabinet can lead to

condensation.

3. Remove the plastic sheet only once the analyzer cabinet is at

room temperature. This takes at least 24 hours.

Damage to the cabinet air conditioner

Damage to the cabinet air conditioner due to incorrect

connection of the condensate drain and overflow of the

condensate pan.

• When connecting the condensate water drain port (TP10)

of the analyzer cabinet air conditioner, observe the

• When routing the drain tube, caution should be taken to keep

it from kinking or being elevated above the exit point of the

air conditioner.

• The drain tube must be on a continuous downward slope. A

slight elevation of the tube could result in secondary trap.

Page 31

GAA610-M ADVANCED EMISSION GAS MONITORING SYSTEM | OI/GAA610-M-EN REV. B 31

Pos. Connection

Design

TSG2 Sample gas

T

TP7

Calibration gas inlet

—

Tube fitting for PTFE pipe 4/6 × 1 mm

TP8 Sample gas outlet / Analyzer cabinet

ATM vent

Tube fitting for

TP9

Condensate water drain port

—

Tube fitting DN 6 / 4 mm, PVDF

TP10 Condensate water drain port

10

— Instrument air inlet

10

or

compressed