Page 1

Options for ABB drives, converters and inverters

User’s manual

FDNA-01 DeviceNet adapter module

Page 2

List of related manuals

See section Related manuals on page 16.

Page 3

User’s manual

FDNA-01 DeviceNet adapter module

Table of contents

1. Safety

4. Mechanical installation

5. Electrical installation

6. Start-up

3AFE68573360 Rev E

EN

EFFECTIVE: 2012-04-04

© 2012 ABB Oy

All Rights Reserved.

Page 4

Page 5

Table of contents 5

Table of contents

1. Safety

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Use of warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety in installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. About the manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Purpose of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Terms and abbreviations used in this manual . . . . . . . . . . . . . . 19

General terms and abbreviations . . . . . . . . . . . . . . . . . . . . 19

DeviceNet terms and abbreviations . . . . . . . . . . . . . . . . . . . 20

3. Overview of the DeviceNet network and the FDNA-01

module

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DeviceNet network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Example topology of the DeviceNet link . . . . . . . . . . . . . . . 24

FDNA-01 DeviceNet adapter module . . . . . . . . . . . . . . . . . . . . 25

Layout of the adapter module . . . . . . . . . . . . . . . . . . . . . . . 26

4. Mechanical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Delivery check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mounting the adapter module . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5. Electrical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Page 6

6 Table of contents

General cabling instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the module to the DeviceNet network . . . . . . . . . . . 30

Terminal block description . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connection examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Switching on the bus termination . . . . . . . . . . . . . . . . . . . . . . . . 31

6. Start-up

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Drive configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DeviceNet connection configuration . . . . . . . . . . . . . . . . . . 34

FDNA-01 configuration parameters – group A (group 1) 35

FDNA-01 configuration parameters – group B (group 2) 47

FDNA-01 configuration parameters – group C (group 3) 48

Control locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Starting up ACS355 drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Parameter setting examples – ACS355 . . . . . . . . . . . . . . . . 50

ABB Drives profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ODVA AC/DC drive profile . . . . . . . . . . . . . . . . . . . . . . . 52

Starting up ACSM1 drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Parameter setting examples – ACSM1 . . . . . . . . . . . . . . . . 55

ABB Drives profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

ODVA AC/DC drive profile . . . . . . . . . . . . . . . . . . . . . . . 57

Starting up ACS850 and ACQ810 drives . . . . . . . . . . . . . . . . . . 59

Parameter setting examples – ACS850 and ACQ810 . . . . . 60

ABB Drives profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

ODVA AC/DC drive profile . . . . . . . . . . . . . . . . . . . . . . . 63

Starting up ACS880 drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Parameter setting examples – ACS880 . . . . . . . . . . . . . . . . 65

ABB Drives profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

ODVA AC/DC drive profile . . . . . . . . . . . . . . . . . . . . . . . 67

Configuring the master station . . . . . . . . . . . . . . . . . . . . . . . . . . 70

EDS files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

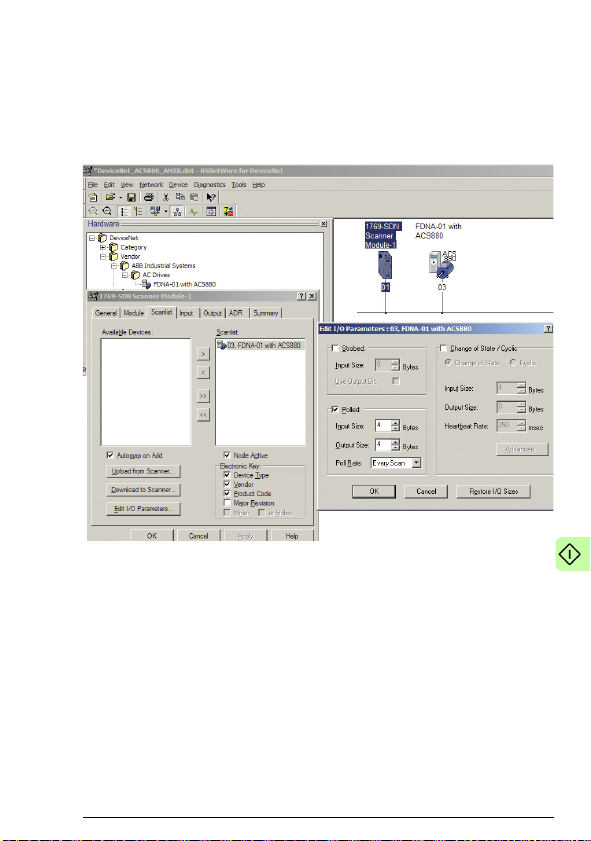

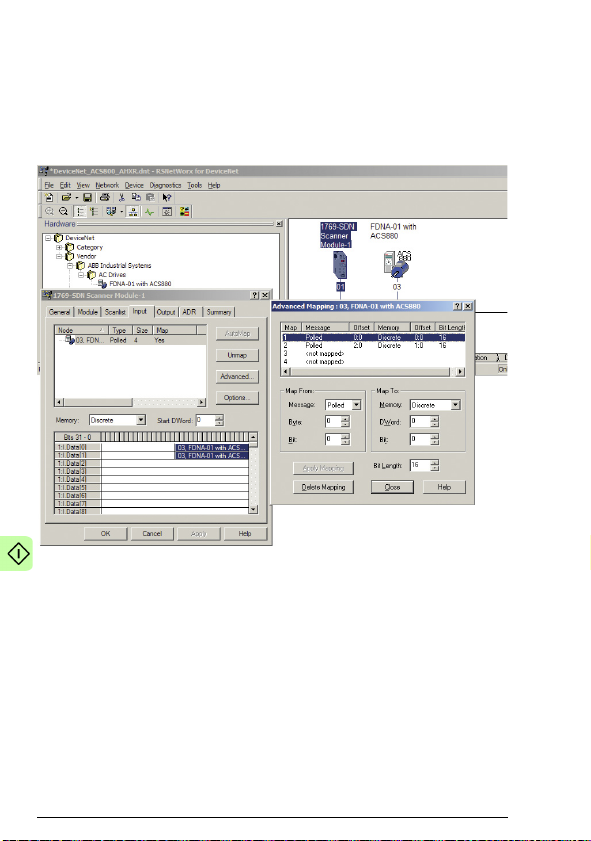

Configuring an Allen-Bradley® PLC . . . . . . . . . . . . . . . . . . 71

7. Communication profiles

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Page 7

Table of contents 7

Communication profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

ODVA AC/DC drive profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

ODVA output attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Run Forward & Run Reverse

(Control supervisor object) . . . . . . . . . . . . . . . . . . . . . . . 80

Fault Reset (Control supervisor object) . . . . . . . . . . . . . 80

Net Ctrl (Control supervisor object) . . . . . . . . . . . . . . . . 80

Net Ref (AC/DC drive object) . . . . . . . . . . . . . . . . . . . . . 80

Speed Reference (AC/DC drive object) . . . . . . . . . . . . . 80

Torque Reference (AC/DC drive object) . . . . . . . . . . . . 82

ODVA input attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Faulted (Control supervisor object) . . . . . . . . . . . . . . . . 83

Warning (Control supervisor object). . . . . . . . . . . . . . . . 83

Running Forward (Control supervisor object) . . . . . . . . 83

Running Reverse (Control supervisor object) . . . . . . . . 83

Ready (Control supervisor object) . . . . . . . . . . . . . . . . . 83

Ctrl From Net (Control supervisor object) . . . . . . . . . . . 83

Ref From Net (AC/DC drive object) . . . . . . . . . . . . . . . . 83

At Reference (AC/DC drive object) . . . . . . . . . . . . . . . . 84

State (Control supervisor object) . . . . . . . . . . . . . . . . . . 84

Speed Actual (AC/DC drive object) . . . . . . . . . . . . . . . . 86

Torque Actual (AC/DC drive object). . . . . . . . . . . . . . . . 87

ABB Drives communication profile . . . . . . . . . . . . . . . . . . . . . . . 88

Control word and Status word . . . . . . . . . . . . . . . . . . . . . . . 88

Control word contents . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Status word contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

State machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8. Communication protocol

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Object modeling and functional properties . . . . . . . . . . . . . . . . . 97

Page 8

8 Table of contents

Assembly objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Basic speed control assembly . . . . . . . . . . . . . . . . . . . . . . . 98

Basic speed control plus drive parameters assembly . . . . . 99

Extended speed control assembly . . . . . . . . . . . . . . . . . . . 101

Extended speed control plus drive parameters assembly . 102

Basic speed and torque control assembly . . . . . . . . . . . . . 104

Basic speed and torque control

plus drive parameters assembly . . . . . . . . . . . . . . . . . . . . 105

Extended speed and torque control assembly . . . . . . . . . . 108

Extended speed and torque control

plus drive parameters assembly . . . . . . . . . . . . . . . . . . . . 109

ABB Drives profile with set speed assembly . . . . . . . . . . . 111

ABB Drives profile with set speed

plus drive parameters assembly . . . . . . . . . . . . . . . . . . . . 112

ABB Drives profile with set speed and

set torque assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

ABB Drives profile with set speed and set torque

plus drive parameters assembly . . . . . . . . . . . . . . . . . . . . 116

Transparent 16 with one assembly . . . . . . . . . . . . . . . . . . 118

Transparent 16 with one assembly plus drive parameters 119

Transparent 16 with two assembly . . . . . . . . . . . . . . . . . . 121

Transparent 16 with two assembly plus drive parameters . 122

Transparent 32 with one assembly . . . . . . . . . . . . . . . . . . 125

Transparent 32 with one assembly plus drive parameters 126

Transparent 32 with two assembly . . . . . . . . . . . . . . . . . . 128

Transparent 32 with two assembly plus drive parameters . 130

Class objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Identity object, class 01h . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Class attributes (Instance #0). . . . . . . . . . . . . . . . . . . . 134

Instance attributes (Instance #1) . . . . . . . . . . . . . . . . . 135

Attribute explanations . . . . . . . . . . . . . . . . . . . . . . . . . . 135

DeviceNet object, class 03h . . . . . . . . . . . . . . . . . . . . . . . . 137

Class attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Instance attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Connection object, class 05h . . . . . . . . . . . . . . . . . . . . . . . 138

Class attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Page 9

Table of contents 9

Instance attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Acknowledge handler object, class 2Bh . . . . . . . . . . . . . . 141

Class attributes (Instance #0) . . . . . . . . . . . . . . . . . . . 141

Instance attributes (Instance #1) . . . . . . . . . . . . . . . . . 141

Motor data object, class 28h . . . . . . . . . . . . . . . . . . . . . . . 142

Class attributes (Instance #0) . . . . . . . . . . . . . . . . . . . 142

Instance attributes (Instance #1) . . . . . . . . . . . . . . . . . 143

Control supervisor object, class 29h . . . . . . . . . . . . . . . . . 143

Class attributes (Instance #0) . . . . . . . . . . . . . . . . . . . 144

Instance attributes (Instance #1) . . . . . . . . . . . . . . . . . 144

AC/DC-drive object, class 2Ah . . . . . . . . . . . . . . . . . . . . . 146

Class attributes (Instance #0) . . . . . . . . . . . . . . . . . . . 146

Instance attributes (Instance #1) . . . . . . . . . . . . . . . . . 146

Drive parameter object, Class 90h . . . . . . . . . . . . . . . . . . 147

Fieldbus configuration object 91h . . . . . . . . . . . . . . . . . . . 148

Class attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Instance #1: FDNA-01 configuration parameters

group A (group 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Instance #2: FDNA-01 configuration parameters

group B (group 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Instance #3: FDNA-01 configuration parameters

group C (group 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

9. Diagnostics

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

LED indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

10. Technical data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

FDNA-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

DeviceNet link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

11. Appendix A – Varying the number of drive parameters

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Modification of the EDS file . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Page 10

10 Table of contents

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . 167

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . 167

Page 11

Safety 11

1

Safety

What this chapter contains

The chapter presents the warning symbols used in this manual and

the safety instructions which you must follow when installing an

optional module into a drive, converter or inverter. If ignored,

physical injury or death may follow, or damage may occur to the

equipment. Read this chapter before you start the installation.

Page 12

12 Safety

Use of warnings

Warnings caution you about conditions which can result in serious

injury or death and/or damage to the equipment and advise on how

to avoid the danger. The following warning symbols are used in

this manual:

Electricity warning warns of hazards from electricity

which can cause physical injury and/or damage to the

equipment.

General warning warns about conditions, other than

those caused by electricity, which can result in physical

injury and/or damage to the equipment.

Page 13

Safety 13

Safety in installation

These warnings are intended for all who install an optional module

into a drive, converter or inverter.

WARNING! Ignoring the following instructions can cause

physical injury or death, or damage to the equipment.

• Only qualified electricians are allowed to install and maintain

the drive, converter or inverter!

• Disconnect the drive, converter or inverter into which the

module will be installed from all possible power sources. After

disconnecting, always wait for 5 minutes to let the intermediate

circuit capacitors discharge before you proceed.

• Do not work on the control cables when power is applied to the

external control circuits of the drive, converter or inverter.

Externally supplied control circuits may carry dangerous

voltage.

Page 14

14 Safety

Page 15

About the manual 15

2

About the manual

What this chapter contains

This chapter introduces this manual.

Applicability

This manual applies to the FDNA-01 DeviceNet adapter module

(+K451), SW version 0.223 or later.

Compatibility

The FDNA-01 DeviceNet adapter module is compatible with the

following drives:

• ACS355

• ACSM1

• ACS850

• ACQ810

• ACS880.

The FDNA-01 DeviceNet adapter module is compatible with all

master stations that support the DeviceNet™ protocol.

Page 16

16 About the manual

Target audience

The reader is expected to have a basic knowledge of fieldbus

interface, electrical fundamentals, electrical wiring practices and

how to operate the drive.

Purpose of the manual

The manual provides information on installing, commissioning and

using an FDNA-01 DeviceNet adapter module.

Related manuals

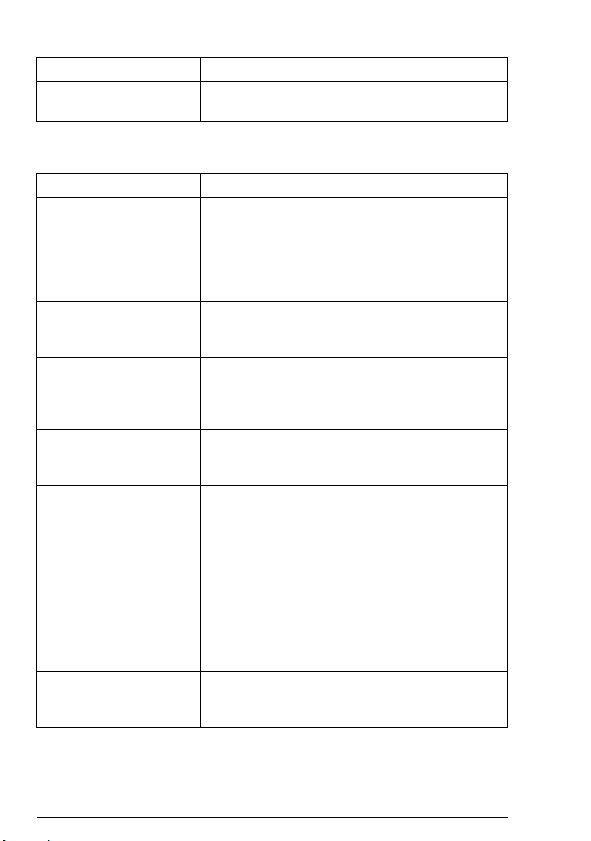

The related manuals are listed below.

Drive user’s manuals

ACS355 drives (0.37…22 kW,

0.5…30 hp) user’s manual

Drive hardware manuals and

guides

ACSM1-204 regen supply modules

(5.3 to 61 kW) hardware manual

ACSM1-04 drive modules (0.75 to

45 kW) hardware manual

ACSM1-04 drive modules (55 to 110

kW) hardware manual

ACSM1-04Lx liquid-cooled drive

modules (55 to 160 kW) hardware

manual

ACS850-04 (0.37…45 kW)

hardware manual

ACS850-04 (55…160 kW, 75…200

hp) hardware manual

ACS850-04 (200…500 kW,

250…600 hp) hardware manual

ACQ810-04 drive modules

(0.37…45 kW, 0.5…60 hp) hardware

manual

ACQ810-04 drive modules (55 to

160 kW, 75 to 200 hp) hardware

manual

Code (English)

3AUA0000066143

3AUA0000053713

3AFE68797543

3AFE68912130

3AUA0000022083

3AUA0000045496

3AUA0000045487

3AUA0000026234

3AUA0000055160

3AUA0000055161

Page 17

About the manual 17

ACQ810-04 drive modules

(200…400 kW, 250…600 hp)

hardware manual

ACS880-01 (0.55 to 250 kW, 0.75 to

350 hp) hardware manual

Drive firmware manuals and

guides

ACSM1 motion control program

firmware manual

ACSM1 speed and torque control

program firmware manual

ACSM1 regen supply control

program firmware manual

ACS850 standard control program

firmware manual

ACQ810 standard pump control

program firmware manual

ACS880 primary control program

firmware manual

Option manuals and guides

FDNA-01 DeviceNet adapter module

user’s manual

You can find manuals and other product documents in PDF format

on the Internet. See section Document library on the Internet on

the inside of the back cover. For manuals not available in the

Document library, contact your local ABB representative.

Code (English)

3AUA0000055155

3AUA0000078093

3AFE68848270

3AFE68848261

3AUA0000052174

3AUA0000045497

3AUA0000055144

3AUA0000085967

3AFE68573360

Before you start

It is assumed that the drive is installed and ready to operate before

you start the installation of the adapter module.

In addition to conventional installation tools, have the drive

manuals available during the installation as they contain important

information not included in this manual. The drive manuals are

referred to at various points of this manual.

Page 18

18 About the manual

Contents

The manual consists of the following chapters:

• Safety presents the safety instructions which you must follow

when installing a fieldbus adapter module.

• About the manual introduces this manual.

• Overview of the DeviceNet network and the FDNA-01 module

contains a short description of the DeviceNet network and the

adapter module.

• Mechanical installation contains a delivery checklist and

instructions on mounting the adapter module.

• Electrical installation contains cabling and bus termination

instructions and instructions on connecting the module to the

DeviceNet network.

• Start-up presents the steps to take during the start-up of the

drive with the adapter module and gives examples of

configuring the master system.

• Communication profiles describes the communication profiles

used in the communication between the DeviceNet network,

the adapter module and the drive.

• Communication protocol describes the DeviceNet

communication protocol for the adapter module and the

configuration of the scanner.

• Diagnostics explains how to trace faults with the status LEDs

on the adapter module.

• Technical data contains the technical data of the adapter

module and the DeviceNet link.

• Appendix A – Varying the number of drive parameters

describes how to reduce the number of drive parameter

members in FDNA-01 assemblies by modifying the EDS file.

Page 19

About the manual 19

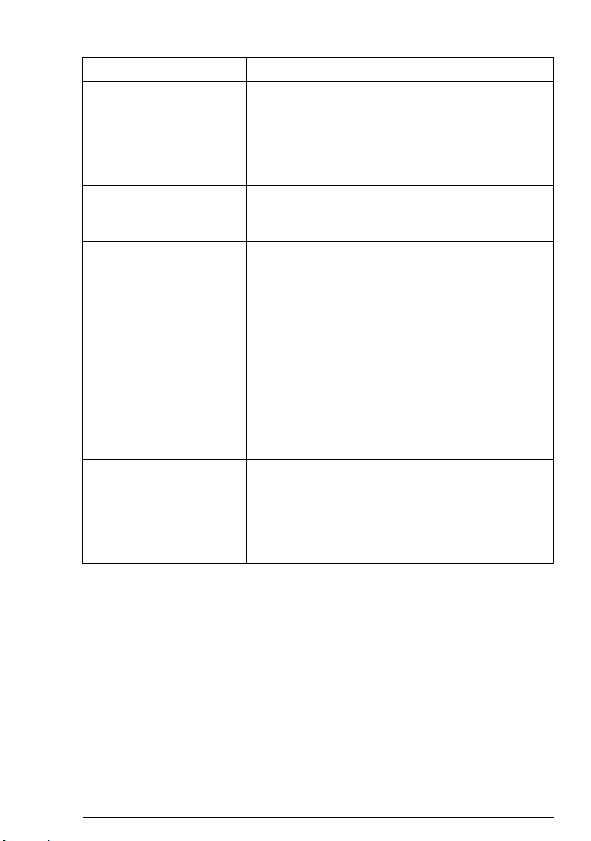

Terms and abbreviations used in this manual

General terms and abbreviations

Term Explanation

Command word See Control word.

Communication module Communication module is a name for a device

Control word 16-bit or 32-bit word from master to slave with

DCU profile Drive Control Unit profile, native profile used in

DTC Direct Torque Control is a motor control method

FBA profile Fieldbus Adapter profile, native profile used in

FDNA-01 DeviceNet

adapter module

LSW Least significant word

MSW Most significant word

Parameter An operating instruction for the drive.

Profile Adaptation of the protocol for certain application

RFG Ramp Function Generator

(eg, a fieldbus adapter) through which the drive

is connected to an external communication

network (eg, a fieldbus). The communication

with the module is activated with a drive

parameter.

bit-coded control signals (sometimes called the

Command word).

the ACS350 and ACS355 drives

for AC drives. DTC allows accurate control of

both motor speed and torque without pulse

encoder feedback from the motor shaft.

the ACQ810, ACS850 and ACSM1 drives

One of the optional fieldbus adapter modules

available for ABB drives. FDNA-01 is a device

through which an ABB drive is connected to a

DeviceNet serial communication bus.

Parameters can be read and programmed with

the drive control panel, drive PC tools or

through the adapter module.

field, for example, drives.

In this manual, drive-internal profiles (eg, DCU

or FBA) are called native profiles.

Page 20

20 About the manual

Term Explanation

Status word 16-bit or 32-bit word from slave to master with

bit-coded status messages

DeviceNet terms and abbreviations

Term Explanation

Change of State/Cyclic

Message

CIP™ Common Industrial Protocol (CIP) is an

EDS File Electronic Data Sheet (EDS) file identifies the

Input In the ODVA DeviceNet specification the word

I/O assembly selection Smart networked devices (like FDNA-01) can

MAC ID Every node on DeviceNet network has to have

Change of State/Cyclic Message is transmitted

by either the master or the slave. A Change of

State/Cyclic Message is directed towards a

single specific node (point-to-point). An

Acknowledge Message may be returned in

response to this message.

industrial protocol for industrial automation

applications. It is managed by ODVA.

properties of the device to the DeviceNet

Scanner. Each type of drive and application

program requires its own EDS file.

‘input’ is used to describe data flow from a

device (such as FDNA-01) to the network.

produce and/or consume more than one I/O

value. Typically, they produce and/or consume

one or more I/O value, as well as status and

diagnostic information. Each piece of data

communicated by a device is represented by an

attribute of one of the device’s internal objects.

Communicating multiple pieces of data

(attributes) across a single I/O connection

requires that the attributes be grouped or

assembled together into a single block.

a unique identifier. This node number is called

MAC ID (Media Access Control Identifier).

Page 21

About the manual 21

Term Explanation

ODVA™ ODVA stands for Open DeviceNet Vendor

Output In the ODVA DeviceNet specification the word

Poll Message Most DeviceNet Scanners as well as the FDNA-

Scanlist DeviceNet Scanner communicates with the

Association. ODVA is an independent

organization that promotes interoperativity

between different manufacturers’ DeviceNet

products. ABB is an Associate Member at

ODVA.

‘output’ is used to describe data flow from the

network into a device (such as FDNA-01).

01 module support two different data services.

These are Poll and Change of State/Cyclic

messages.

The Poll Command is an I/O Message that is

transmitted by the master. A Poll Command is

directed towards a single, specific slave (pointto-point, FDNA-01 always acts as a slave). A

master must transmit a separate Poll Command

Message for each of its slaves that is to be

polled. The Poll Response is an I/O Message

that a slave transmits back to the master when

the Poll Command is received.

DeviceNet slaves in a user-defined order. This

order of communication is the scanlist. The

scanlist contains a complete list of the slave

nodes and the order in which the slaves are

accessed.

Page 22

22 About the manual

Page 23

Overview of the DeviceNet network and the FDNA-01 module 23

3

Overview of the DeviceNet network and the FDNA-01 module

What this chapter contains

This chapter contains a short description of the DeviceNet network

and the FDNA-01 DeviceNet adapter module.

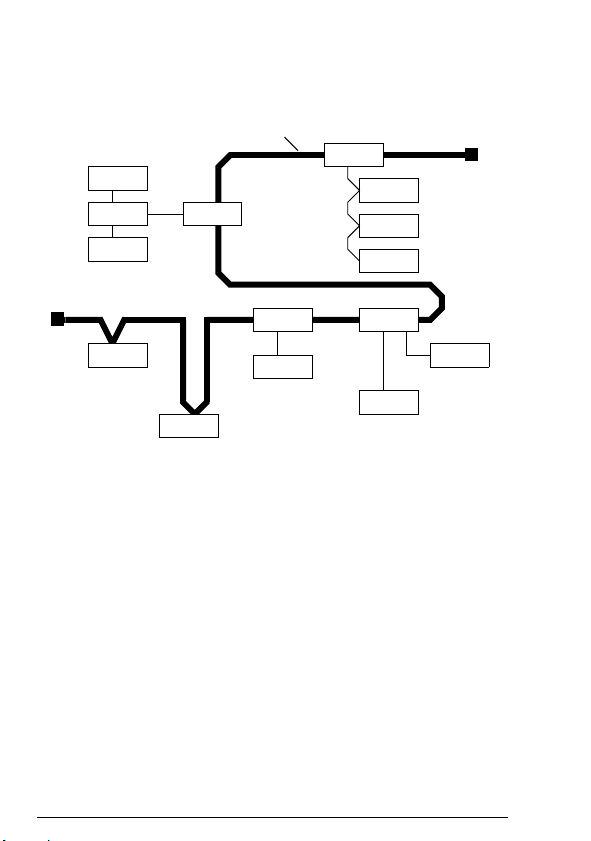

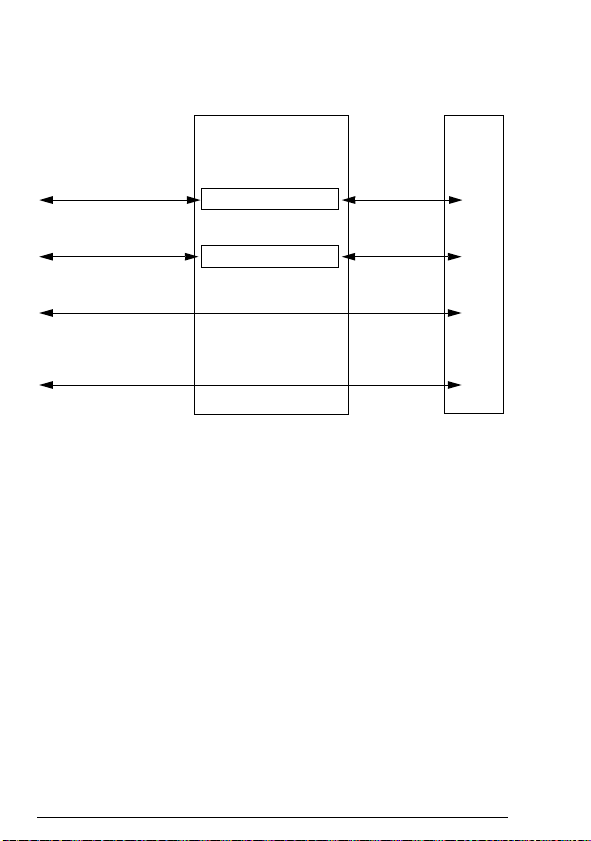

DeviceNet network

The DeviceNet network has a linear bus topology. Terminating

resistors are required on each end of the trunk line. Drop lines as

long as 6 metres (20 feet) each are permitted, allowing one or

more nodes to be attached. DeviceNet allows branching structures

only on drop lines.

The maximum length of the trunk cable depends on the data rate

and on the type of the cable used (see chapter Technical data).

Page 24

24 Overview of the DeviceNet network and the FDNA-01 module

Node

Node

Node

Node

Node

Tap

Tap

TapTap

Node

Node

Node

Node

Node

Node

Trunk li ne

Terminating

Resistor

Drop line

Example topology of the DeviceNet link

An example of an allowable topology is shown below.

Page 25

Overview of the DeviceNet network and the FDNA-01 module 25

FDNA-01 DeviceNet adapter module

The FDNA-01 DeviceNet Adapter module is an optional device for

ABB drives. It enables the connection of the drive to a DeviceNet

network. The drive is considered a slave in the DeviceNet network.

Through the adapter module you can:

• give control commands to the drive (for example, Start, Stop,

Run enable)

• feed a motor speed or torque reference to the drive

• give the actual value or reference of the process to the PID

controller of the drive

• read status information and actual values from the drive

• change drive parameter values

• reset a drive fault.

The adapter module acts as a class 2 slave only with predefined

master-slave connection set services. These include the explicit

messaging, the poll-response service and the change of state/

cyclic service. The DeviceNet commands and services supported

by the adapter module are described in chapter Communication

protocol.

The adapter module is mounted into an option slot on the motor

control board of the drive. See the drive manuals for the module

placement options.

Page 26

26 Overview of the DeviceNet network and the FDNA-01 module

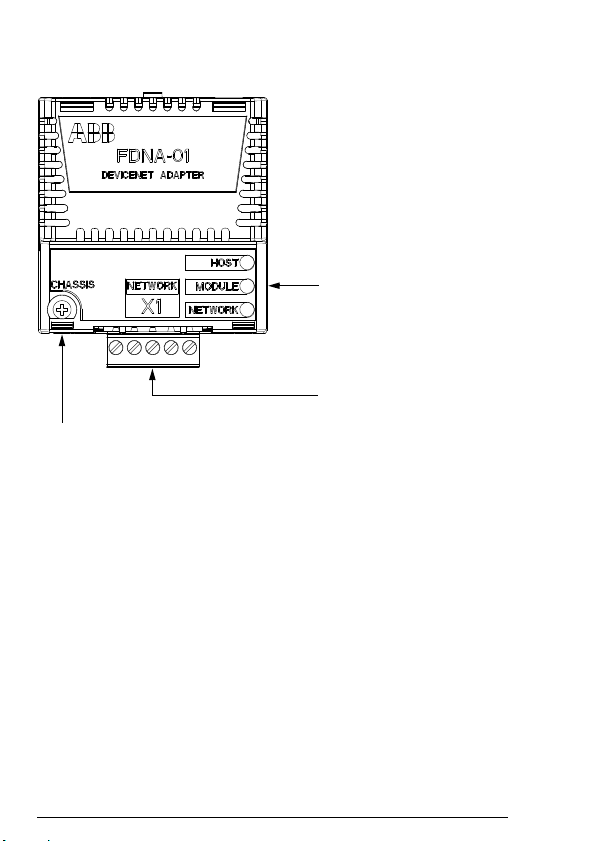

Diagnostic LEDs

(see chapter Diagnostics)

Bus connector X1

(see chapter Electrical

installation)

Mounting screw

Layout of the adapter module

Page 27

Mechanical installation 27

4

Mechanical installation

What this chapter contains

This chapter contains a delivery checklist and instructions on

mounting the adapter module.

WARNING! Follow the safety instructions given in this

manual and the drive documentation.

Delivery check

The option package for the adapter module contains:

• DeviceNet adapter module, type FDNA-01

• this manual.

Page 28

28 Mechanical installation

Mounting the adapter module

The adapter module is to be inserted into its specific position in the

drive. The module is held in place with plastic pins and one screw.

The screw also provides the electrical connection between the

module and drive frame for cable shield termination.

When the module is installed, the signal and power connection to

the drive is made through a 20-pin connector. (All drives do not use

all the available signals so the connector on the drive may have

fewer pins.)

Mounting procedure:

1. Insert the module carefully into its position on the drive.

2. Fasten the screw.

Note: It is essential to install the screw properly to fulfill the EMC

requirements and to ensure the proper operation of the module.

For more information on mounting, see the drive manuals.

Page 29

Electrical installation 29

5

Electrical installation

What this chapter contains

This chapter contains:

• general cabling instructions

• instructions on connecting the module to the DeviceNet

network

• instructions on switching on the bus termination.

WARNING! Before installation, switch off the drive power

supply. Wait five minutes to ensure that the capacitor bank

of the drive is discharged. Switch off all dangerous

voltages connected from external control circuits to the inputs and

outputs of the drive.

General cabling instructions

• Arrange the bus cables as far away from the motor cables as

possible.

• Avoid parallel runs.

• Use bushings at cable entries.

Page 30

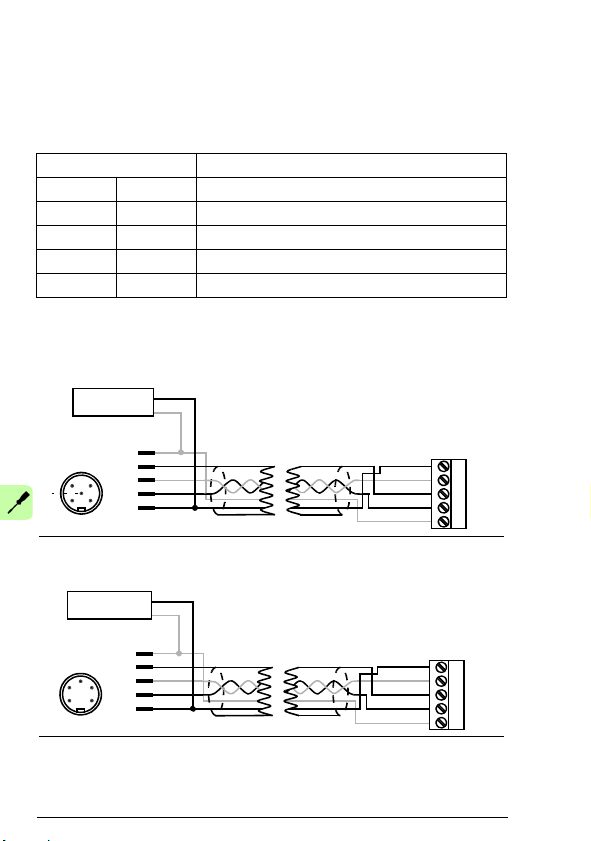

30 Electrical installation

5

3

Male micro-style

SHLD

CAN_L

CAN_H

V-

1234

connector

4

1

2

X1

0 V

+24 V

Network

power supply

4

5

3

1

2

FDNA

5

V+

V+

3

2

Male mini-style

4

5

3

1

2

connector

4

51

0 V

+24 V

Network

power supply

SHLD

CAN_L

CAN_H

V-

1234

X1

FDNA

5

Connecting the module to the DeviceNet network

Connect the bus cable to terminal block X1 on the adapter module.

Terminal block description

X1 Description

1 V- Network power supply ground (0V DC)

2 CAN_L CAN_L bus line

3 SHLD Network cable shield

4 CAN_H CAN_H bus line

5 V+ Network power supply source (24V DC)

Connection examples

5-pin micro-style connector:

5-pin mini-style connector:

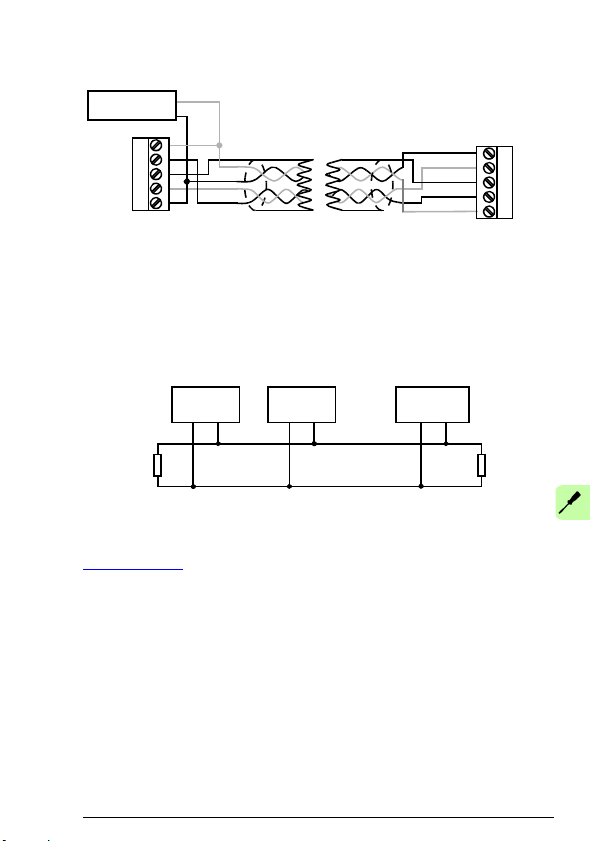

Page 31

Electrical installation 31

4321 5

SHLD

CAN_L

CAN_H

V-

1234

X1

FDNA

5

V+

0 V

+24 V

Network

power supply

Node 1 Node n

121

Ω

CAN_H

CAN_L

Scanner

121

Ω

1%

Metal Film

1/4 W

1%

Metal Film

1/4 W

…

Standard open-style screw connector:

Switching on the bus termination

The adapter module does not provide bus termination. The

DeviceNet network should be terminated at both ends of the trunk

cable with a 121 ohm, ¼ W, 1% metal film resistor. Connect the

resistor between the two signal wires (CAN_H, CAN_L) on the

DeviceNet cable, as shown in the figure below.

Further information on the DeviceNet protocol is available at

www.odva.org

.

Page 32

32 Electrical installation

Page 33

Start-up 33

6

Start-up

What this chapter contains

This chapter contains:

• information on configuring the drive for operation with the

adapter module

• drive-specific instructions on starting up the drive with the

adapter module

• examples of configuring the master station for communication

with the adapter module.

WARNING! Follow the safety instructions given in this

manual and the drive documentation.

Page 34

34 Start-up

Drive configuration

The following information applies to all drive types compatible with

the adapter module, unless otherwise stated.

DeviceNet connection configuration

After the adapter module has been mechanically and electrically

installed according to the instructions in chapters Mechanical

installation and Electrical installation, the drive must be prepared

for communication with the module.

The detailed procedure of activating the module for DeviceNet

communication with the drive depends on the drive type. Normally,

a parameter must be adjusted to activate the communication. See

the drive-specific start-up procedures starting on page 49.

Once communication between the drive and the adapter module

has been established, several configuration parameters are copied

to the drive. These parameters are shown in the tables below and

must be checked first and adjusted where necessary.

Note: Not all drives display descriptive names for the configuration

parameters. To help you identify the parameters in different drives,

the names displayed by each drive are given in grey boxes in the

tables.

Note: The new settings take effect only when the adapter module

is powered up the next time or when the fieldbus adapter refresh

parameter is activated.

Note: If communication between the adapter module and

DeviceNet master is established, changes to the configuration

parameters can be done also through Fieldbus configuration object

91h.

Page 35

Start-up 35

FDNA-01 configuration parameters – group A (group 1)

Note: The actual parameter group number depends on the drive

type. Group A (group 1) corresponds to:

• parameter group 51 in ACS355, ACSM1, ACS850 and

ACQ810

• parameter group 51 in ACS880 if the adapter is installed as

fieldbus adapter A or group 54 if the adapter is installed as

fieldbus adapter B.

No. Name/Value Description Default

01 FBA TYPE Read-only. Shows the fieldbus adapter type as

02 MAC ID Defines the MAC ID number for the drive the

ACS355:

FB PAR 2

ACSM1:

FBA PAR2

ACS850/ACQ810:

FBA par2

ACS880:

MAC ID

0…63 MAC ID

03 BAUD RATE Read-only. Indicates the detected

ACS355:

FB PAR 3

ACSM1:

FBA PAR3

ACS850/ACQ810:

FBA par3

ACS880:

Baud rate

0 = 125 kbit/s Communication speed is 125 kbit/s.

1 = 250 kbit/s Communication speed is 250 kbit/s.

2 = 500 kbit/s Communication speed is 500 kbit/s.

detected by the drive. Value cannot be adjusted

by the user.

If the value is 0 = None, the communication

between the drive and the module has not been

established.

adapter module is connected to. Each device

on the DeviceNet network must have a unique

MAC ID number.

communication speed in kbit/s.

1 = DeviceNet

63

0 = 125

kbit/s

Page 36

36 Start-up

No. Name/Value Description Default

04 DRIVE PROFILE Defines the communication used between the

ACS355:

FB PAR 4

ACSM1:

FBA PAR4

ACS850/ACQ810:

FBA par4

ACS880:

Drive profile

0 = Native prof Native profile of the drive selected

05 ODVA STOP

FUNC

ACS355:

FB PAR 5

ACSM1:

FBA PAR5

ACS850/ACQ810:

FBA par5

ACS880:

ODVA stop func

0 = Ramp stop Motor decelerates along the active deceleration

1 = Coast stop Motor comes to a stop by coasting.

module and the drive (not fie ldbus and module).

If a drive supports more than one drive profile,

this parameter is used to select the preferred

profile. Presently, to use the ODVA and ABB

Drives profiles, the drive must support a native

profile (eg, DCU or FBA). Transparent16 and

Transparent32 profiles may be used with any

drive profile.

Used with the ODVA AC/DC drive profile.

Determines how the motor is stopped when a

stop command is received via DeviceNet.

ramp.

0 =

Native

prof

0 = Ramp

stop

Page 37

Start-up 37

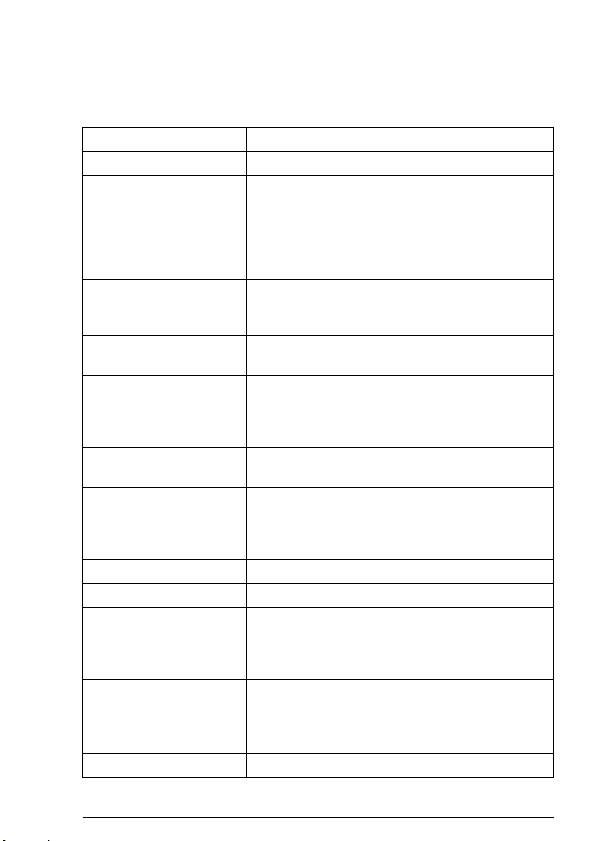

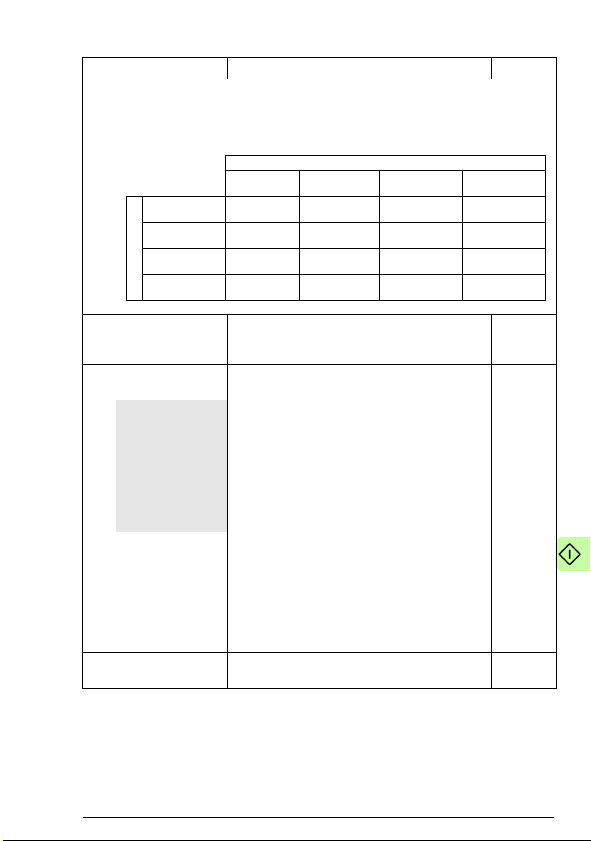

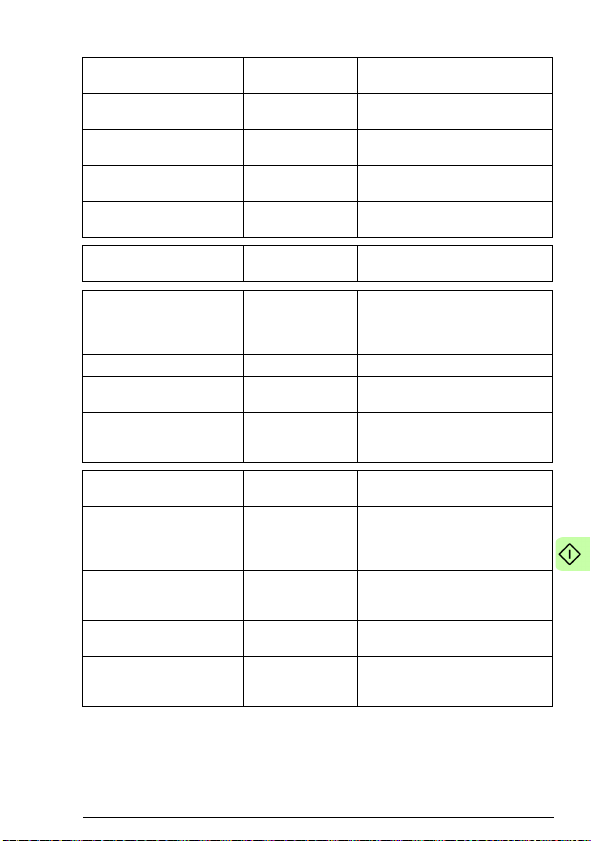

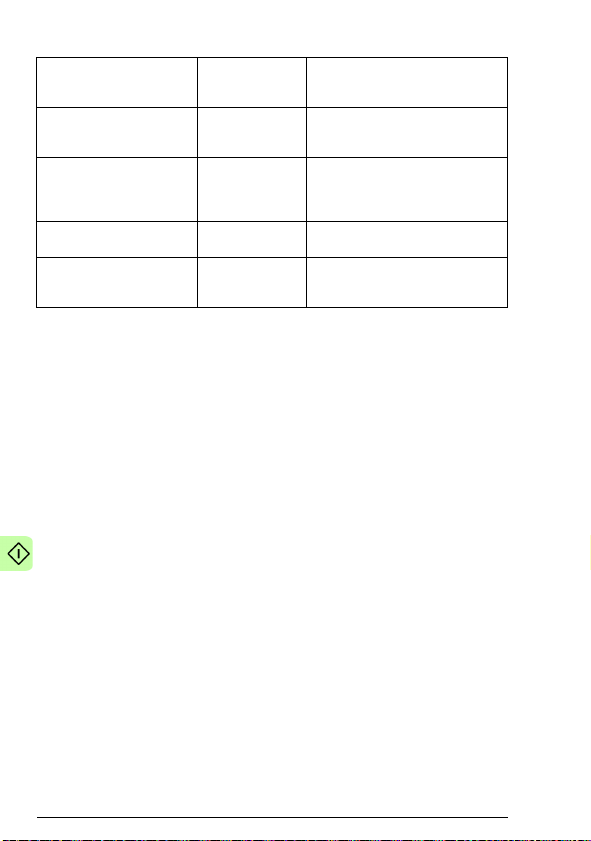

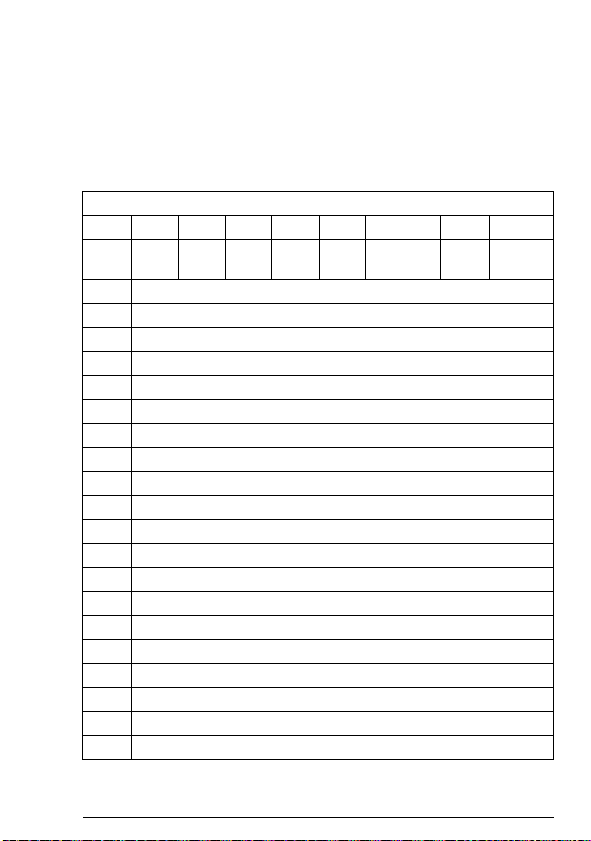

Name Output

instance

Input

instance

Default

input

size

(bytes)

Profile

Basic speed control 20 70 4 ODVA AC/DC drive

Extended speed

control

21 71 4 ODVA AC/DC drive

Basic speed and

torque control

22 72 6 ODVA AC/DC drive

Extended speed and

torque control

23 73 6 ODVA AC/DC drive

Basic speed control

plus drive parameters

120 170 24 ODVA AC/DC drive

Extended speed

control plus drive

parameters

121 171 24 ODVA AC/DC drive

Basic speed and

torque control plus

drive parameters

122 172 26 ODVA AC/DC drive

Extended speed and

torque control plus

drive parameters

123 173 26 ODVA AC/DC drive

ABB Drives profile

with set speed

801 851 4 ABB Drives

ABB Drives profile

with set speed and

set torque

802 852 6 ABB Drives

(continued)

No. Name/Value Description Default

06 OUTPUT

INSTANCE

ACS355:

FB PAR 6

ACSM1:

FBA PAR6

ACS850/ACQ810:

FBA par6

ACS880:

Output instance

Configures the output assembly instances used

by the adapter module. Tables below list the

supported assemblies and allowed

combinations. For the descriptions of the

assembly instances, see section Assembly

objects on page 98.

20

Page 38

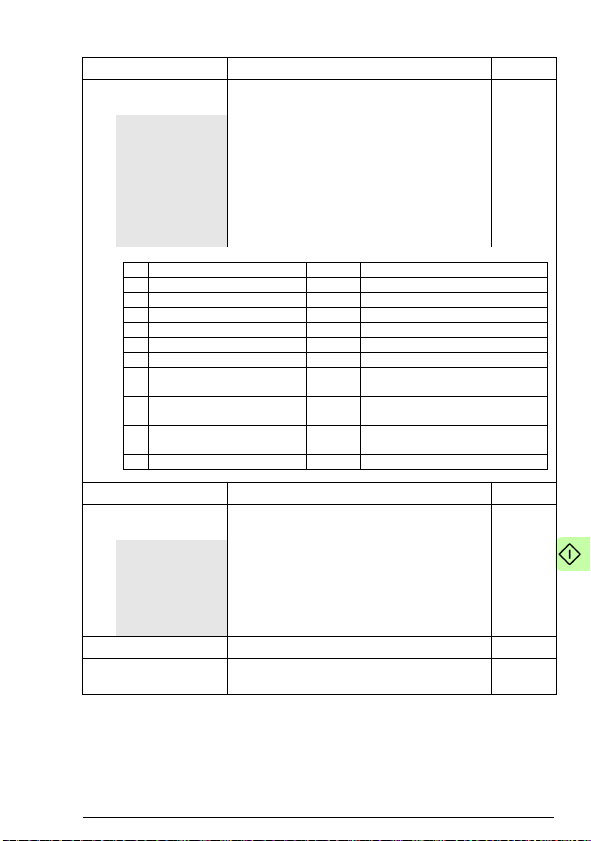

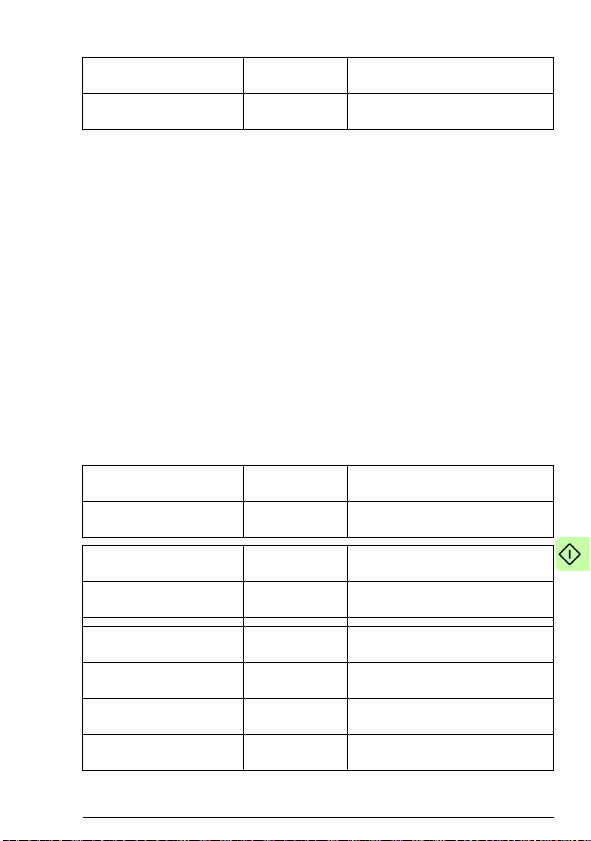

38 Start-up

Name Output

instance

Input

instance

Default

input

size

(bytes)

Profile

(continued)

ABB Drives profile

with set speed plus

drive parameters

901 951 24 ABB Drives

ABB Drives profile

with set speed and

set torque plus drive

parameters

902 952 26 ABB Drives

ABB Drives profile

with set speed plus

drive parameters

901 951 24 ABB Drives

Transparent16 with

one

811 861 4 Transparent16

Transparent16 with

two

812 862 6 Transparent16

Transparent16 with

one plus drive

parameters

911 961 24 Transparent16

Transparent16 with

two plus drive

parameters

912 962 26 Transparent16

Transparent32 with

one

821 871 8 Transparent32

Transparent32 with

two

822 872 12 Transparent32

Transparent32 with

one plus drive

parameters

921 971 28 Transparent32

Transparent32 with

two plus drive

parameters

922 972 32 Transparent32

No. Name/Value Description Default

Page 39

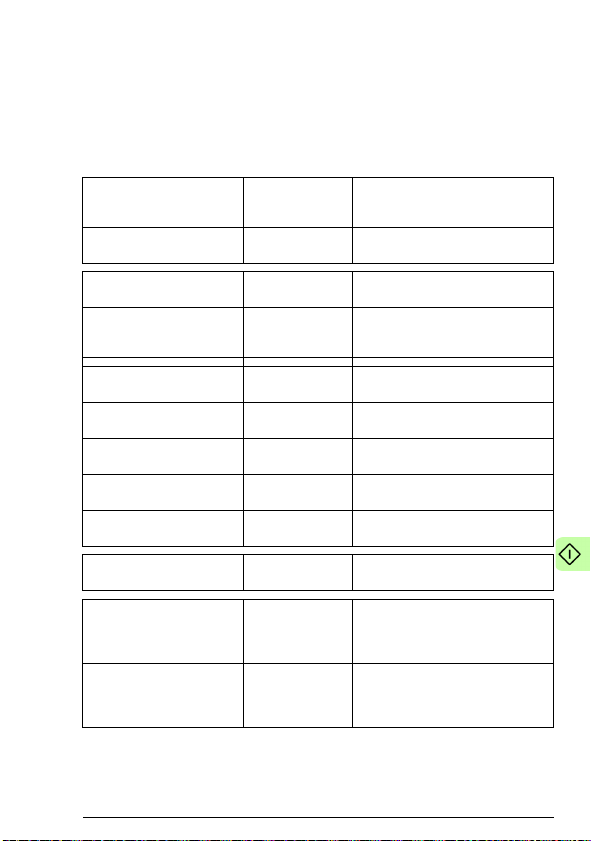

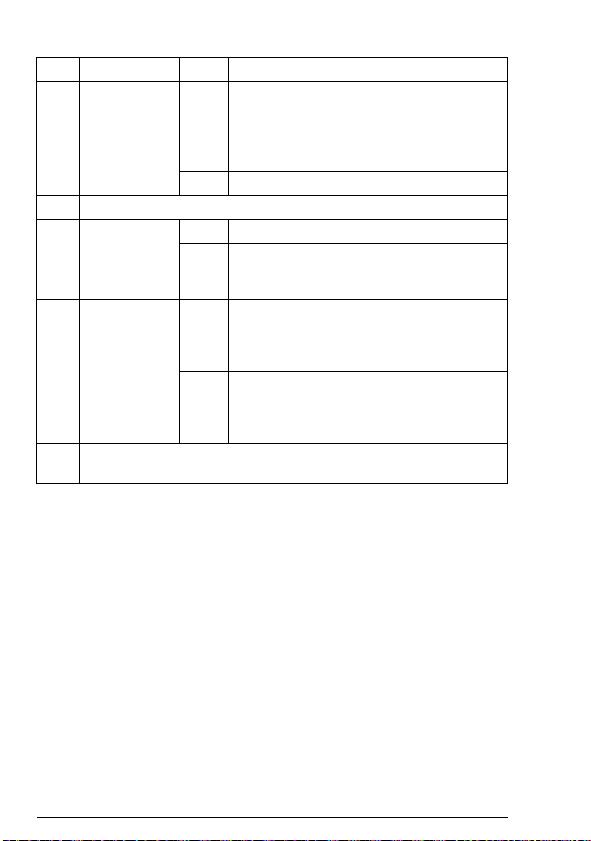

Input

ODVA

(70-73; 170-173)

ABB DRIVES

(851-852; 951-952

TRANSPARENT16

(861-862; 961-962)

TRANSPARENT32

(871-872; 971-972)

Output

ODVA

(20-23; 120-123)

x

ABB DRIVES

(801-802; 901-902)

x

TRANSPARENT16

(811-812; 911-912)

x

TRANSPARENT32

(821-822; 921-922)

x

Start-up 39

No. Name/Value Description Default

Note: With ACSM1, ACQ810, ACS850 and ACS880, when using the ODVA

AC/DC drive or ABB Drives profile, make sure that drive parameter 50.04 FBA

REF MODESEL is set to SPEED. With ACSM1, ACS850 and ACS880, make

sure that 50.05 FBA REF2 MODESEL is set to TORQUE.

For alternative values, see column Output

instance in the table describing parameter 06

OUTPUT INSTANCE.

07 OUTPUT NUM

PAR S

ACS355:

FB PAR 7

ACSM1:

FBA PAR7

ACS850/ACQ810:

FBA par7

ACS880:

Output num pars

1…10 Number or drive parameter values to be

Some assembly instances support transferring

drive parameter values between the I/O

scanner and drive. Parameters 07 OUTPUT

NUM PARS and 09 INPUT NUM PARS specify

how many drive parameter values should be

included in the respective assembly instance.

Changing the numbers of the drive parameters

to values other than the defaults also changes

the lengths of the associated assembly

instances. This requires manual changes to

either the EDS file or I/O scanner configuration.

Before changing these parameters, consult

Appendix A – Varying the number of drive

parameters.

Note: This parameter is only used when the

output assembly instance is 120, 121, 122, 123,

901, 902, 911, 912, 921, 922. It must always be

set to the default, 10, except as described in

Appendix A – Varying the number of drive

parameters

included in the assembly instance

10

Page 40

40 Start-up

No. Name/Value Description Default

08 INPUT INSTANCE Configures the input assembly instances used

ACS355:

FB PAR 9

ACSM1:

FBA PAR9

ACS850/ACQ810:

FBA par9

ACS880:

Input instance

09 INPUT NUM

PAR S

ACS355:

FB PAR 9

ACSM1:

FBA PAR9

ACS850/ACQ810:

FBA par9

ACS880:

Input num pars

1…10 Number or drive parameter values to be

by the adapter module. See parameter 06

OUTPUT INSTANCE.

For alternative values, see parameter 06

OUTPUT INSTANCE.

See parameter 07 OUTPUT NUM PARS.

Note: This parameter is only used when the

input assembly instance is 170, 171 , 172, 173,

951, 952, 961, 962, 971, 972. It must always be

set to the default, 10, except as described in

Appendix A – Varying the number of drive

parameters.

included in the assembly instance

70

10

Page 41

Start-up 41

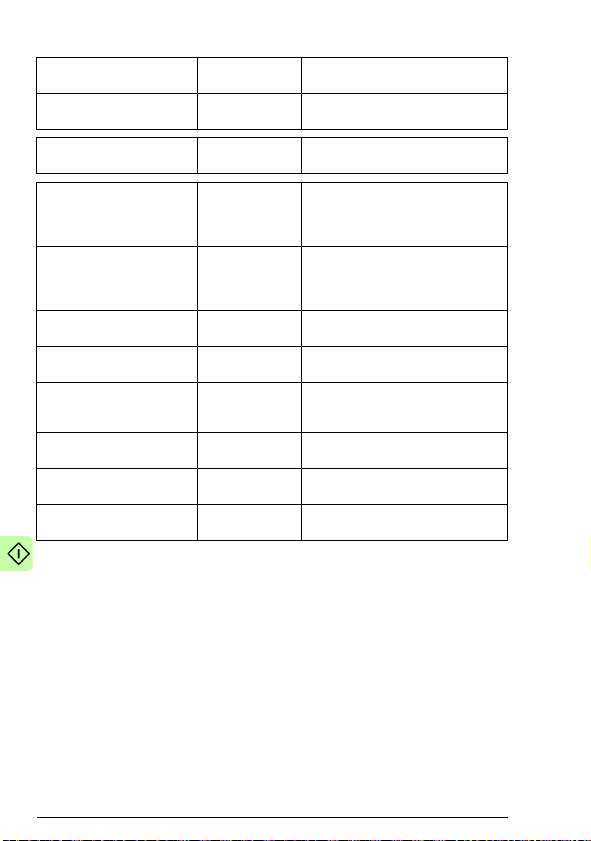

ODVA speed scale value1)Speed scale value of

drive parameter

2)

Unit

-5 123 32 RPM

-4 124 16 RPM

-3 125 8 RPM

-2 126 4 RPM

-1 127 2 RPM

0 (default) 128 1 RPM

1 129 0.5 RPM

2 130 0.25 RPM

3 131 0.125 RPM

4 132 0.06 25 RPM

5 133 0.03 125 RPM

1)

Use the ODVA speed scale value when reading/writing parameter ODVA

SPEED SCALE via AC/DC-drive object, class 2Ah. When written via the

AC/DC drive object, the new value takes effect immediately.

2)

Use the speed scale value of the drive parameter when reading/writing

parameter ODVA SPEED SCALE via the d rive control panel, Drive parameter

object, Class 90h and Fieldbus configuration object 91h. When written via

these methods, the new value takes effect after the drive is repowered or a

“Fieldbus Adapter Parameter refresh” is given.

No. Name/Value Description Default

10 ODVA SPEED

SCALE

ACS355:

FB PAR 10

ACSM1:

FBA PAR10

ACS850/ACQ810:

FBA par10

ACS880:

ODVA speed scale

Defines the speed scale in the ODVA AC/DC

drive profile. Units of reference and actual

speeds for the ODVA AC/DC drive profile are

given by the formula below. No effect on the

ABB Drives profiles.

Note: While a wide range of resolutions may be

configured, the actual performance is limited to

the performance capabilities of the drive.

Speed unit = RPM X 2

Table below shows how the values of drive

parameter ODVA SPEED SCALE correspond

to the ODVA Speed Scale units.

(-1 X ODVA speed scale value)

128

123…133 Speed scale value of the drive parameter

Page 42

42 Start-up

ODVA torque scale value1)Torque scale value of

drive parameter

2)

Unit

-5 123 32 N·m

-4 124 16 N·m

-3 125 8 N·m

-2 126 4 N·m

-1 127 2 N·m

0 (default) 128 1 N·m

1 129 0.5 N·m

2 130 0.25 N·m

3 131 0.125 N·m

4 132 0.0625 N·m

5 133 0.03125 N·m

1)

Use the ODVA torque scale value when reading/writing parameter ODVA

TORQUE SCALE via AC/DC-drive object, class 2Ah. When written via the

AC/DC drive object, the new value takes effect immediately.

2)

Use the torque scale value of the drive parameter when reading/writing

parameter ODVA TORQUE SCALE via the drive control panel, Drive

parameter object, Class 90h and Fieldbus configuration object 91h. When

written via these methods, the new value takes effect after the drive is

repowered or a “Fieldbus Adapter Parameter refresh” is given.

No. Name/Value Description Default

11 ODVA TORQUE

SCALE

ACS355:

FB PAR 11

ACSM1:

FBA PAR11

ACS850/ACQ810:

FBA par11

ACS880:

ODVA torque

scale

Defines the torque scale in the ODVA AC/DC

drive profile. Units of reference and actual

torques for the ODVA AC/DC drive profile are

given by the formula below. No effect on the

ABB Drives profiles.

Note: While a wide range of resolutions may be

configured, the actual performance is limited to

the performance capabilities of the drive.

(N·m = Newton x Meter)

Torque unit = N·m x 2

Table below shows how the values of drive

parameter ODVA TORQUE SCALE correspond

to the ODVA Torque Scale units.

(-1 X ODVA torque scale)

128

123…133 Torque scale value of the drive parameter

12

Reserved Not used by the adapter module. N/A

…

25

Page 43

No. Name/Value Description Default

Bit Name Value Description

1 DUP_MAC_ERROR 0x0001 Duplicate MAC ID error

2 RX_QUEUE_OVERRUN 0x0002 Message receive queue is full.

3 TX_QUEUE_OVERRUN 0x0004 Message transmit queue is full.

4 IO_SEND_ERROR 0x0008 Transmitting I/O data has failed.

5 CAN_BUS_OFF 0x0010 Bus-off is detected.

6 CAN_OVERRUN 0x0020 CAN message was lost.

7 DNS_RESET 0x0040 DeviceNet driver of the module is

reset.

8 DNS_BUS_SENSE_ERROR 0x0080 No voltage detected in the

network.

9 DNS_SWITCH_ERROR 0x0100 DeviceNet driver reset failed due

to an invalid MAC ID or baud rate.

13 SYS_FILE_ERR 0x1000 Initialization with the drive failed.

26 UNRECOVER-

ABLE ERROR

ACS355:

FB PAR 26

ACSM1:

FBA PAR26

ACS850/ACQ810:

FBA par26

ACS880:

Unrecover. error

0…65535 Active unrecoverable errors

27 FBA PAR

REFRESH

ACS355/ACSM1:

FBA PAR

REFRESH

ACS850/ACQ810/

ACS880:

FBA par refresh

0 = Done Refreshing done

1 =

Refresh/Configure

Read-only. Shows information about the cause

of an unrecoverable error in the ad apter

module. Bit field parameter, that is, several

status bits can be set at a time. Value 0

indicates that there are no errors.

Validates any changed adapter module

configuration parameter settings. After

refreshing, the value reverts automatically to

0 = Done.

Note: This parameter cannot be changed while

the drive is running.

Refreshing

Start-up 43

0

0 = Done

Page 44

44 Start-up

No. Name/Value Description Default

28 PAR TABLE VER Read-only. Displays the parameter table

ACS355:

FILE CPI FW REV

ACSM1:

PAR TABLE VER

ACS850/ACQ810/

ACS880:

Par table ver

0x0000…0xFFFF Parameter table revision

29 DRIVE TYPE

CODE

ACS355:

FILE CONFIG ID

ACSM1:

DRIVE TYPE

CODE

ACS850/ACQ810/

ACS880:

Drive type code

0…65535 Drive type code of the fieldbus adapter module

30 MAPPING FILE

VER

ACS355:

FILE CONFIG

REV

ACSM1:

MAPPING FILE

VER

ACS850/ACQ810/

ACS880:

Mapping file ver

0…65535 Mapping file revision

revision of the fieldbus adapter module

mapping file stored in the memory of the drive.

In format xyz, where

x = major revision number

y = minor revision number

z = correction number

OR

in format axyz, where

a = major revision number

xy = minor revision numbers

z = correction number or letter.

Read-only. Displays the drive type code of the

fieldbus adapter module mapping file stored in

the memory of the drive.

mapping file

Read-only. Displays the fieldbus adapter

module mapping file revision stored in the

memory of the drive in decimal format.

Example: 0x107 = revision 1.07.

N/A

N/A

N/A

Page 45

Start-up 45

No. Name/Value Description Default

31 D2FBA COMM

STA

ACS355:

FBA STATUS

ACSM1:

D2FBA COMM

STA

ACS850/ACQ810/

ACS880:

D2FBA comm sta

0 = Idle Adapter is not configured.

1 = Exec.init Adapter is initializing.

2 = Time out Time-out has occurred in the communication

3 = Conf.err Adapter configuration error: Major or minor

4 = Off-line Adapter is off-line.

5 = On-line Adapter is on-line.

6 = Reset Adapter is performing a hardware reset.

32 FBA COMM SW

VER

ACS355:

FBA CPI FW REV

ACSM1:

FBA COMM SW

VER

ACS850/ACQ810/

ACS880:

FBA comm SW

ver

0x0000…0xFFFF Common program version of the adapter

Read-only. Displays the status of the fieldbus

adapter module communication.

Note: The value names may vary by drive.

between the adapter and the dr ive.

revision code of the common program revision

in the fieldbus adapter module is not the

revision required by the module or mapping file

upload has failed more than three times.

Read-only. Displays the common program

revision of the adapter module in format axyz,

where:

a = major revision number

xy = minor revision numbers

z = correction number or letter.

Example: 190A = revision 1.90A

module

0 = Idle

N/A

Page 46

46 Start-up

No. Name/Value Description Default

33 FBA APPL SW

VER

ACS355:

FBA CPI APPL

REV

ACSM1:

FBA COMM APPL

VER

ACS850/ACQ810/

ACS880:

FBA appl SW ver

0x0000…0xFFFF Application program revision of the adapter

Read-only. Displays the application program

revision of the adapter module in format axyz,

where:

a = major revision number

xy = minor revision numbers

z = correction number or letter.

Example: 190A = revision 1.90A

module

N/A

Page 47

Start-up 47

0Not used

1…99 Virtual address area of drive control.

Not used with the FDNA-01 module.

101…

9999

Parameter area of the drive

FDNA-01 configuration parameters – group B (group 2)

Note: The actual parameter group number depends on the drive

type. Group B (group 2) corresponds to:

• parameter group 55 in ACS355

• parameter group 53 in ACSM1, ACS850 and ACQ810

• parameter group 53 in ACS880 if the adapter is installed as

fieldbus adapter A or group 56 if the adapter is installed as

fieldbus adapter B.

No.1)Name/Value Description Default

01 DATA OUT 1

(master to drive)

ACS355:

FBA DATA OUT 1

ACSM1:

FBA DATA OUT1

ACS850/ACQ810/

ACS880:

FBA data out1

0 Not used

101…9999 Parameter index with format xxyy, where xx is

02…10DATA OUT 2…

DATA OUT 10

1)

The number of parameters in this group may vary by drive type and drive firmware.

In the output assembly instances that include

drive parameters, this parameter specifies

which parameter’s value is placed in location

DATA OUT 1 value received by the drive from

the DeviceNet network. Content is defined by a

decimal number in the range of 0 to 9999 as

follows:

Note: The FDNA-01 configuration parameters

are 16-bit parameters. If the mapped parameter

is a 32-bit parameter, it automatically reserves

two consecutive parameters. For example,

mapping a 32-bit parameter to parameter no. 1

also reserves parameter no. 2.

the parameter group number (1…99) and yy is

the parameter number index within that group

(01…99).

See parameter DATA OUT 1.0

0

Page 48

48 Start-up

0 Not used

1…99 Virtual address area of drive control.

Not used with the FDNA-01 module.

101…

9999

Parameter area of the drive

FDNA-01 configuration parameters – group C (group 3)

Note: The actual parameter group number depends on the drive

type. Group C (group 3) corresponds to:

• parameter group 54 in ACS355

• parameter group 52 in ACSM1, ACS850 and ACQ810

• parameter group 52 in ACS880 if the adapter is installed as

fieldbus adapter A or group 55 if the adapter is installed as

fieldbus adapter B.

No.1)Name/Value Description Default

01 DATA IN 1

(drive to master)

ACS355:

FBA DATA IN 1

ACSM1:

FBA DATA IN1

ACS850/ACQ810/

ACS880:

FBA data in1

0 Not used

101…9999 Parameter index with format xxyy, where xx is

02…10DATA IN 2…

DATA IN 10

1)

The number of parameters in this group may vary by drive type and drive firmware.

In input assembly instances that include drive

parameters, this parameter specifies which

parameter’s value is placed in location DATA IN

1 value sent by the drive to the DeviceNet

network. Content is defined by a decimal

number in the range of 0 to 9999 as follows:

Note: The FDNA-01 configuration parameters

are 16-bit parameters. If the mapped parameter

is a 32-bit parameter, it automatically reserves

two consecutive parameters. For example,

mapping a 32-bit parameter to parameter no. 1

also reserves parameter no. 2.

the parameter group number (1…99) and yy is

the parameter number index within that group

(01…99).

See parameter DATA IN 1.0

0

Page 49

Start-up 49

Control locations

ABB drives can receive control information from multiple sources

including digital inputs, analog inputs, the drive control panel and a

communication module (for example, the adapter module). ABB

drives allow the user to separately determine the source for each

type of control information (Start, Stop, Direction, Reference, Fault

Reset, and so on).

To give the fieldbus master station the most complete control over

the drive, the communication module must be selected as the

source for this information. The parameter setting examples below

contain the drive control parameters needed in the examples. For

a complete parameter list, see the drive documentation.

Starting up ACS355 drives

1. Power up the drive.

2. Enable the communication between the adapter module and

the drive by setting parameter 9802 COMM PROT SEL to EXT

FBA.

3. Set the FDNA-01 configuration parameters in parameter group

51.

At the minimum, set the required number in parameter 5102

MAC ID and the required baud rate in 5103 BAUD RATE. In

addition, select the communication profile in 5104 DRIVE

PROFILE. With the ODVA AC/DC drive profile select the way

in which the motor is stopped in 5105 ODVA STOP FUNC.

4. Define the process data transferred to and from the drive in

FDNA-01 parameter groups 54 and 55.

Note: If communication between the FDNA-01 and DeviceNet

master is established, changes to the configuration parameters

can be done also through Fieldbus configuration object 91h.

5. Validate the settings made in parameter group 51 by setting

parameter 5127 FBA PAR REFRESH to REFRESH.

Page 50

50 Start-up

6. Set the relevant drive control parameters to control the drive

according to the application. Examples of appropriate values

are shown in the tables below.

Parameter setting examples – ACS355

ABB Drives profile

This example shows how to configure the ACS355 drive to use the

ABB Drives profile with set speed and set torque plus drive

parameters assembly.

The used I/O assembly instances are 902 and 952.

The table below gives the recommended drive parameter settings.

Drive parameter Setting for

9802 COMM PROT SEL 4 = EXT FBA Enables communication between

5101 FBA TYPE DEVICENET

5102 FB PAR 2

(MAC ID)

5103 FB PAR 3

(BAUD RATE)

5104 FB PAR 4

(DRIVE PROFILE)

5105 FB PAR 5

(ODVA STOP FUNC)

5106 FB PAR 6

(OUTPUT INSTANCE)

5107 FB PAR 7

(OUTPUT NUM PARS)

5108 FB PAR 8

(INPUT INSTANCE)

ACS355 drives

2 Defines the MAC ID number of the

0 (= 125 kbit/s) Sets the baud rate for the

0 (= DCU Profile) Selects the profile used in the

0 (= Ramp) Motor decelerates along the active

902 Selects the ABB Drives profile with

10 Must always be set to 10, except as

952 Selects the ABB Drives profile with

Description

drive and adapter module.

1)

Displays the type of the adapter

module.

adapter module.

DeviceNet interface.

communication between drive and

adapter module.

deceleration ramp.

speed and torque plus drive

parameters output instance.

provided in Appendix A – Varying

the number of drive parameters.

speed and torque plus drive

parameters input instance.

Page 51

Start-up 51

Drive parameter Setting for

5109 FB PAR 9

(INPUT NUM PARS)

5110 FB PAR 10

(ODVA SPEED SCALE)

5111 FB PAR 11

(ODVA TORQUE SCALE)

5401 FBA DATA IN 1 104 Current

5402 FBA DATA IN 2 107 DC bus voltage

5403 FB DATA IN 3

…5410 DATA IN 10

5501 FBA DATA OUT 1 2205 Acceleration time 2

5502 FBA DATA OUT 2 2206 Deceleration time 2

5503 FB DATA OUT 3

…5510 DATA OUT 10

51.27 FBA PAR REFRESH 1 = REFRESH Validates the FDNA-01

1001 EXT1 COMMANDS 10 = COMM Selects the fieldbus interface as the

1003 DIRECTION 3 = REQUEST Allows control of rotation direction.

1103 REF1 SELECT 8 = COMM Selects the fieldbus reference 1 as

1604 FAULT RESET SEL 8 = COMM Selects the fieldbus interface as the

9904 MOTOR CTRL MODE 2 = VECTOR:

1002 EXT2 COMMANDS 10 = COMM Selects the fieldbus interface as the

1102 EXT1/EXT2 SEL 8 = COMM Enables external control location

1106 REF2 SELECT 8 = COMM Selects the fieldbus reference 2 as

ACS355 drives

10 Must always be set to 10, except as

128 Sets the scaling as 1 rpm for the

128 Sets the scaling as 1 Nm for the

0

0

TORQ

Description

provided in Appendix A – Varying

the number of drive parameters.

ODVA speed reference.

ODVA torque reference.

configuration parameter settings.

source of the start and stop

commands for external control

location 1.

the source for speed reference.

source for the fault reset signal.

Selects the vector control mode as

the motor control mode.

source of the start and stop

commands for external control

location 2.

1/2 selection through the fieldbus.

the source for torque reference.

Page 52

52 Start-up

Drive parameter Setting for

1601 RUN ENABLE 7 = COMM Selects the fieldbus interface as the

1)

Read-only or automatically detected/set

The start sequence for the parameter example above is given

below.

ACS355 drives

Description

source for the inverted Run enable

signal (Run disable).

Control word:

• 47Eh (1150 decimal) –> READY TO SWITCH ON

• 47Fh (1151 decimal) –> OPERATING (Speed mode)

or

C7Fh (3199 decimal) –> OPERATING (Torque mode).

ODVA AC/DC drive profile

The following example shows how to configure the ACS355 drive

to use the Extended speed and torque control assembly of the

ODVA AC/DC drive profile.

The used I/O assembly instances are 23 and 73.

The table below gives the recommended drive parameter settings.

Drive parameter Setting for

9802 COMM PROT SEL 4 = EXT FBA Enables communication between

5101 FBA TYPE DEVICENET

5102 FB PAR 2

(MAC ID)

5103 FB PAR 3

(BAUD RATE)

5104 FB PAR 4

(DRIVE PROFILE)

5105 FB PAR 5

(ODVA STOP FUNC)

ACS355 drives

5 Defines the MAC ID number of the

0 (= 125 kbit/s) Sets the baud rate for the

0 (= DCU Profile) Selects the profile used in the

0 (= Ramp) Motor decelerates along the active

Description

drive and adapter module.

1)

Displays the type of the adapter

module.

adapter module.

DeviceNet interface.

communication between drive and

adapter module.

deceleration ramp.

Page 53

Start-up 53

Drive parameter Setting for

5106 FB PAR 6

(OUTPUT INSTANCE)

5108 FB PAR 8

(INPUT INSTANCE)

5110 FB PAR 10

(ODVA SPEED SCALE)

5111 FB PAR 11

(ODVA TORQUE SCALE)

ACS355 drives

23 Selects the ODVA extended speed

73 Selects the ODVA extended speed

128 Sets the scaling as 1 rpm for the

128 Sets the scaling as 1 Nm for the

51.27 FBA PAR REFRESH 1 = REFRESH Validates the FDNA-01

1001 EXT1 COMMANDS 10 = COMM Selects the fieldbus interface as

Description

and torque control output instance.

and torque control input instance.

ODVA speed reference.

ODVA torque reference.

configuration parameter settings.

the source of the start and stop

commands for external control

location 1.

1003 DIRECTION 3 = REQUEST Allows control of rotation direction.

1103 REF1 SELECT 8 = COMM Selects the fieldbus reference 1 as

1604 FAULT RESET SEL 8 = COMM Selects the fieldbus interface as

9904 MOTOR CTRL MODE 2 = VECTOR:

TORQ

1002 EXT2 COMMANDS 10 = COMM Selects the fieldbus interface as

1102 EXT1/EXT2 SEL 1 = DI1 Selects digital input DI1 as the

1106 REF2 SELECT 8 = COMM Selects the fieldbus reference 2 as

1601 RUN ENABLE 7 = COMM Selects the fieldbus interface as

1)

Read-only or automatically detected/set

the source for speed reference.

the source for the fault reset

signal.

Selects the vector control mode as

the motor control mode.

the source of the start and stop

commands for external control

location 2.

source for the external control

location EXT1/EXT2 selection.

the source for torque reference.

the source for the inverted Run

enable signal (Run disable).

Page 54

54 Start-up

Note: In this example, digital input DI1 has been configured to

control whether to use the speed or torque control mode.

The start sequence for the parameter example above is given

below.

Control word:

• 0h (0 decimal) –> READY

• 1h (1 decimal) –> ENABLED (Running forward)

• 2h (2 decimal) –> ENABLED (Running reverse)

Starting up ACSM1 drives

1. Power up the drive.

2. Enable the communication between the adapter module and

the drive by setting parameter 50.01 FBA ENABLE to Enable.

3. Ensure that 50.04 FBA REF1 MODESEL is set to Speed and

50.05 FBA REF2 MODESEL is set to Torque.

4. Set the FDNA-01 configuration parameters in parameter group

51.

5. Define the process data transferred to and from the drive in

FDNA-01 parameter groups 52 and 53.

Note: If communication between the FDNA-01 and DeviceNet

master is established, changes to the configuration parameters

can be done also through Fieldbus configuration object 91h.

6. Validate the settings made in parameter groups 51, 52 and 53

by setting parameter 51.27 FBA PAR REFRESH to REFRESH.

7. Set the relevant drive control parameters to control the drive

according to the application. Examples of appropriate values

are shown in the tables below.

Page 55

Start-up 55

Parameter setting examples – ACSM1

ABB Drives profile

The following example shows how to configure the ACSM1 drive to

use the ABB Drives profile.

The used I/O assembly instances are 902 and 952.

The table below gives the recommended drive parameter settings.

Drive parameter Setting for

50.01 FBA ENABLE 1 = Enable Enables communication between

50.04 FBA REF1

MODESEL

50.05 FBA REF2

MODESEL

51.01 FBA TYPE DEVICENET1)Displays the type of the adapter

51.02 FBA PAR2

(MAC ID)

51.03 FBA PAR3

(BAUD RATE)

51.06 FBA PAR6

(OUTPUT INSTANCE)

51.07 FBA PAR7

(OUTPUT NUM PARS)

51.08 FBA PAR8

(INPUT INSTANCE)

51.09 FBA PAR9

(INPUT NUM PARS)

52.01 FBA DATA IN1 117 Motor temp

52.02 FBA DATA IN2 104 Motor current - MSW

52.03 FBA DATA IN3 0 Motor current - LSW

52.04 FBA DATA IN4 107 DC voltage - MSW

ACSM1 drives

Speed Selects speed as the adapter

Torque Selects torque as the adapter

6 Defines the MAC ID number of the

0 (= 125 kbit/s) Sets the baud rate for the DeviceNet

902 Selects the ABB Drives profile with

10 Must always be set to 10, except as

952 Selects the ABB Drives profile with

10 Must always be set to 10, except as

Description

drive and adapter module.

module REF1 type.

module REF2 type.

module.

adapter module.

interface.

speed and torque plus drive

parameters output instance.

provided in Appendix A – Varying

the number of drive parameters.

speed and torque plus drive

parameters input instance.

provided in Appendix A – Varying

the number of drive parameters.

Page 56

56 Start-up

Drive parameter Setting for

52.05 FBA DATA IN5 0 DC voltage - LSW

52.06 FBA DATA IN6 108 Encoder 1 speed - MSW

52.07 FBA DATA IN7 0 Encoder 1 speed - LSW

52.08 FBA DATA IN8…

52.10 FBA DATA IN10

53.01 FBA DATA OUT1 2503 Acceleration time - MSW

53.02 FBA DATA OUT2 0 Acceleration time - LSW

53.03 FBA DATA OUT3 2504 Deceleration time - MSW

53.04 FBA DATA OUT4 0 Deceleration time - LSW

53.05 FBA DATA OUT5 2408 Constant speed

53.06 FBA DATA OUT6 2410 Speed ref jog1

53.07 FBA DATA OUT7 2411 Speed ref jog2

53.08 FBA DATA OUT8…

53.10 FBA DATA OUT10

51.27 FBA PAR REFRESH 1 = REFRESH Validates the FDNA-01 configuration

10.01 EXT1 START FUNC 3 = FBA Selects the fieldbus interface as the

10.04 EXT2 START FUNC 3 = FBA Selects the fieldbus interface as the

24.01 SPEED REF1 SEL 3 = FBA REF1 Selects the fieldbus reference 1 as

32.01 TORQ REF1 SEL 4 = FBA REF2 Selects the fieldbus reference 2 as

34.02 EXT1 MODE 1/2SEL P. 2 . 1 2 . 1 5 =

34.03 EXT1 CTRL MODE1 1 = Speed Selects speed as the control mode

34.05 EXT2 CTRL MODE1 2 =Torque Selects torque as the control mode

ACSM1 drives

0

0

P.FBA MAIN

CW.15

Description

parameter settings.

source of the start and stop

commands for external control

location 1.

source of the start and stop

commands for external control

location 2.

the source for speed reference 1.

the source for torque reference 1.

Selects FBA Control word bit 15 as

the source for the external control

location EXT1/EXT2 selection.

for external control location 1.

for external control location 2.

Page 57

Start-up 57

Drive parameter Setting for

99.05 MOTOR CTRL

MODE

1)

Read-only or automatically detected/set

The start sequence for the parameter example above is given

below.

ACSM1 drives

0 = DTC Selects DTC as the motor control

Description

mode.

Control word:

• 47Eh (1150 decimal) –> READY TO SWITCH ON

• 47Fh (1151 decimal) –> OPERATING (Speed mode)

or

C7Fh (3199 decimal) –> OPERATING (Torque mode).

ODVA AC/DC drive profile

The following example shows how to configure the ACSM1 drive to

use the ODVA AC/DC drive profile.

The used I/O assembly instances are 23 and 73.

The table below gives the recommended drive parameter settings.

Drive parameter Setting for

50.01 FBA ENABLE 1 = Enable Enables communication between

50.04 FBA REF1

MODESEL

50.05 FBA REF2

MODESEL

51.01 FBA TYPE DEVICENET1Displays the type of the adapter

51.02 FBA PAR2

(MAC ID)

51.03 FBA PAR3

(BAUD RATE)

51.06 FBA PAR6

(OUTPUT INSTANCE)

ACSM1 drives

Speed Selects speed as the adapter

Torque Selects torque as the adapter

5 Defines the MAC ID number of the

0 (= 125 kbit/s) Sets the baud rate for the DeviceNet

23 Selects the ODVA extended speed

Description

drive and adapter module.

module REF1 type.

module REF2 type.

module.

adapter module.

interface.

and torque control output instance.

Page 58

58 Start-up

Drive parameter Setting for

51.08 FBA PAR8

(INPUT INSTANCE)

51.27 FBA PAR REFRESH 1 = REFRESH Validates the FDNA-01 configuration

10.01 EXT1 START FUNC 3 = FBA Selects the fieldbus interface as the

10.04 EXT2 START FUNC 3 = FBA Selects the fieldbus interface as the

24.01 SPEED REF1 SEL 3 = FBA REF1 Selects the fieldbus reference 1 as

32.01 TORQ REF1 SEL 4 = FBA REF2 Selects the fieldbus reference 2 as

34.01 EXT1/EXT2 SEL P. 2 . 1 . 0 = PI.DI

34.03 EXT1 CTRL MODE1 1 = Speed Selects speed as the control mode

34.05 EXT2 CTRL MODE1 2 =Torque Selects torque as the control mode

99.05 MOTOR CTRL

MODE

1)

Read-only or automatically detected/set

ACSM1 drives

73 Selects the ODVA extended speed

STATUS.0

0 = DTC Selects DTC as the motor control

Description

and torque control input instance.

parameter settings.

source of the start and stop

commands for external control

location 1.

source of the start and stop

commands for external control

location 2

the source for speed reference 1.

the source for torque reference 1.

Selects digital input DI1 as the

source for the external control

location EXT1/EXT2 selection.

for external control location 1.

for external control location 2.

mode.

Note: In this example, digital input DI1 has been configured to

control whether to use the speed or torque control mode.

The start sequence for the parameter example above is given

below.

Control word:

• 0h (0 decimal) –> READY

• 1h (1 decimal) –> ENABLED (Running forward)

• 2h (2 decimal) –> ENABLED (Running reverse)

Page 59

Start-up 59

Starting up ACS850 and ACQ810 drives

1. Power up the drive.

2. Enable the communication between the adapter module and

the drive by setting parameter 50.01 Fba enable to Enable.

3. Ensure that 50.04 Fb ref1 modesel is set to Speed (both

ACS850 and ACQ810) and 50.05 Fb ref2 modesel is set to

Torque (only ACS850).

4. Set the FDNA-01 configuration parameters in drive parameter

group 51.

5. Define the process data transferred to and from the drive in

FDNA-01 parameter groups 52 and 53.

Note: If communication between the FDNA-01 and DeviceNet

master is established, changes to the configuration parameters

can be done also through Fieldbus configuration object 91h.

6. Validate the settings made in parameter groups 51, 52 and 53

by setting parameter 51.27 FBA par refresh to Refresh.

7. Set the relevant drive control parameters to control the drive

according to the application. Examples of appropriate values

are shown in the tables below.

Page 60

60 Start-up

Parameter setting examples – ACS850 and ACQ810

ABB Drives profile

The following example shows how to configure the ACS850 or

ACQ810 drive to use the ABB Drives profile.

The used I/O assembly instances are 902 and 952.

The table below gives the recommended drive parameter settings.

Drive parameter Setting for

50.01 Fba enable 1 = Enable Enables communication between

50.04 Fb ref1 modesel Speed Selects speed as the adapter

50.05 Fb ref2 modesel Torque Selects torque as the adapter

51.01 Fba type DEVICENET

51.02 FBA par2

(MAC ID)

51.03 FBA par3

(BAUD RATE)

51.06 FBA par6

(OUTPUT INSTANCE)

51.07 FBA par7

(OUTPUT NUM PARS)

51.08 FBA par8

(INPUT INSTANCE)

51.09 FBA par9

(INPUT NUM PARS)

52.01 FBA data in1 123 Motor power

52.02 FBA data in2 0 Motor power - LSW

ACS850/ACQ810

drives

5 Defines the MAC ID number of the

0 (= 125 kbit/s) Sets the baud rate for the

902 Selects the ABB Drives profile with

10 Must always be set to 10, except as

952 Selects the ABB Drives profile with

10 Must always be set to 10, except as

Description

drive and adapter module.

module ref1 type.

module ref2 type (only with

ACS850).

1)

Displays the type of the adapter

module.

adapter module.

DeviceNet interface.

speed and torque plus drive

parameters output instance.

provided in Appendix A – Varying

the number of drive parameters.

speed and torque plus drive

parameters input instance.

provided in Appendix A – Varying

the number of drive parameters.

Page 61

Start-up 61

Drive parameter Setting for

52.03 FBA data in3 105 Motor current percent

52.04 FBA data in4 107 DC voltage

52.05 FBA data in5 0 DC voltage - LSW

52.06 FBA data in6 108 Encoder1 speed

52.07 FBA data in7 0 Encoder 1 speed - LSW

52.08 FBA data in8…

52.10 FBA data in10

53.01 FBA data out1 2204 Acc t ime 2

53.02 FBA data out2 0 Acceleration time 2 - LSW

53.03 FBA data out3 2205 Dec time 2

53.04 FBA data out4 0 Deceleration time 2 - LSW

53.05 FBA data out5 2606 Con st speed1

53.06 FBA data out6 2607 Con st speed2

53.07 FBA data out7 2608 Con st speed3

53.08 FBA data out8…

53.10 FBA data out10

51.27 FBA par refresh 1 = Refresh Validates the FDNA-01

10.01 Ext1 start func FB Selects the fieldbus interface as the

10.04 Ext2 Start func 3 = FB Selects the fieldbus as the source

12.01 Ext1/Ext sel P.2.22.15 = P.FBA

12.03 Ext1 ctrl mode 1 = Speed Selects speed as the operating

ACS850/ACQ810

drives

0

0

main cw.15

Description

configuration parameter settings.

source of the start and stop

commands for external control

location 1.

for start and stop commands for

external control location EXT2 (only

with ACS850).

Selects FBA Control word bit 15 as

the source for external control

location EXT1/EXT2 selection (only

with ACS850).

mode for external control location

EXT1.

Page 62

62 Start-up

Drive parameter Setting for

12.05 Ext2 ctrl mode 2 = Torque Selects torque as the operating

16.15 Menu set sel

(ACS850)

16.21 Menu selection

(ACQ810)

21.01 Speed ref1 sel FB Selects the fieldbus reference 1 as

24.01 Torq ref1 sel FBA ref2 Selects fieldbus reference 2 as the

1)

Read-only or automatically detected/set

ACS850/ACQ810

drives

2 = Load long

(ACS850)

2 = Full (ACQ810)

Description

mode for external control location

EXT2 (only with ACS850).

Load long parameter list. All

parameters will be displayed.

the source for speed reference 1.

source of the torque reference 1

(only with ACS850).

The start sequence for the parameter example above is given

below.

Control word:

• 47Eh (1150 decimal) –> READY TO SWITCH ON