Page 1

Options for ABB drives, inverters and converters

User’s manual

FCAN-01 CANopen adapter module

Page 2

List of related manuals

See section Related manuals on page 16.

Page 3

User’s manual

FCAN-01 CANopen adapter module

Table of contents

1. Safety

4. Mechanical installation

5. Electrical installation

6. Start-up

3AFE68615500 Rev D

EN

EFFECTIVE: 2012-01-25

© 2012 ABB Oy

All Rights Reserved.

Page 4

Page 5

Table of contents 5

Table of contents

1. Safety

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Use of warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety in installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. About the manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Purpose of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Terms and abbreviations used in this manual . . . . . . . . . . . . . . 19

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CANopen abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Overview of the CANopen protocol and the FCAN-01

adapter module

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

CANopen protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Topology of the CANopen link . . . . . . . . . . . . . . . . . . . . . . . . . . 24

FCAN-01 CANopen adapter module . . . . . . . . . . . . . . . . . . . . . 25

Layout of the adapter module . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4. Mechanical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Delivery check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mounting the adapter module . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5. Electrical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Page 6

6 Table of contents

General cabling instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the module to the CANopen network . . . . . . . . . . . 30

Bus termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

AC and DC parameters for the CANopen network . . . . . . . . . . . 32

Bus cable and termination resistors . . . . . . . . . . . . . . . . . . . 32

6. Start-up

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Drive configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

CANopen connection configuration . . . . . . . . . . . . . . . . . . . 36

Data transfer rates supported. . . . . . . . . . . . . . . . . . . . . 36

FCAN-01 configuration parameters – group A (group 1) 37

FCAN-01 configuration parameters – group B (group 2) 51

FCAN-01 configuration parameters – group C (group 3) 54

Additional information on the virtual address area

allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Control locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Starting up ACS355 drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Parameter setting examples – ACS355 . . . . . . . . . . . . . . . . 59

CiA 402 vl velocity mode with default PDO mapping . . . 59

Speed and torque control using ABB Drives

communication profile with parameter-configured PDO

mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Starting up ACSM1 drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Parameter setting examples – ACSM1 . . . . . . . . . . . . . . . . 66

Using position control with the CiA 402 Profile Position

mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Starting up ACS850 drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Parameter setting examples – ACS850 . . . . . . . . . . . . . . . . 70

CiA 402 Velocity mode with default PDO mapping . . . . 70

ABB Drives communication profile with parameter-

configured PDO mapping . . . . . . . . . . . . . . . . . . . . . . . . 72

Starting up ACS880 drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Parameter setting examples – ACS880 . . . . . . . . . . . . . . . . 76

CiA 402 Velocity mode with default PDO mapping . . . . 76

Configuring the master station . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Page 7

Table of contents 7

EDS files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Configuring an ABB AC500 PLC . . . . . . . . . . . . . . . . . . . . . 79

7. Communication profiles

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Communication profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

CANopen device profile CiA 402 . . . . . . . . . . . . . . . . . . . . . . . . 89

Device Control state machine . . . . . . . . . . . . . . . . . . . . . . . 89

Modes of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Homing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Profile position mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Position demand value. . . . . . . . . . . . . . . . . . . . . . . . . . 91

Position actual value . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Interpolated position mode . . . . . . . . . . . . . . . . . . . . . . . . . 91

Profile velocity mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Target velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Velocity actual value . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Profile torque mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Target torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Torque actual value . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Velocity mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Target velocity of CiA 402 Velocity mode . . . . . . . . . . . 93

Control effort of CiA 402 Velocity mode . . . . . . . . . . . . . 93

Control word and Status word of the CiA 402 profile . . . . . . 93

State machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

ABB Drives communication profile . . . . . . . . . . . . . . . . . . . . . . 100

Control word and Status word . . . . . . . . . . . . . . . . . . . . . . 100

Control word contents . . . . . . . . . . . . . . . . . . . . . . . . . 100

Status word contents . . . . . . . . . . . . . . . . . . . . . . . . . . 103

State machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Page 8

8 Table of contents

8. Communication protocol

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

CAN data frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

FCAN-01 boot-up sequence and

Network Management (NMT) . . . . . . . . . . . . . . . . . . . . . . . 111

Process Data Objects (PDO) . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Rx PDO1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Tx PDO1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Rx PDO6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Tx PDO6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Rx PDO21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Tx PDO21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Mapping format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

PDO configuration via the CAN bus . . . . . . . . . . . . . . . . . . . . . 121

Service Data Objects (SDO) . . . . . . . . . . . . . . . . . . . . . . . . . . 124

SDO Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

SDO Upload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Read Service (SDO Upload) . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Initiate SDO Upload Protocol . . . . . . . . . . . . . . . . . . . . . . . 126

Write Service (SDO Download) . . . . . . . . . . . . . . . . . . . . . . . . 127

Initiate SDO Download Protocol . . . . . . . . . . . . . . . . . . . . 127

Abort SDO Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Abort SDO Transfer Protocol . . . . . . . . . . . . . . . . . . . . . . . 128

Abort code description . . . . . . . . . . . . . . . . . . . . . . . . . 129

CANopen Object Dictionary . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Object Dictionary Structure . . . . . . . . . . . . . . . . . . . . . . . . 131

Communication profile area (1000...1FFF) . . . . . . . . . . . . 132

Manufacturer-specific profile area (2000...5FFF) . . . . . . . . 142

Manufacturer-specific profile objects . . . . . . . . . . . . . . 142

Drive actual signals and parameters . . . . . . . . . . . . . . 143

Standardized device profile area (6000...9FFF) . . . . . . . . 145

9. Diagnostics

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

LED indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Page 9

Table of contents 9

10. Technical data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

FCAN-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

CANopen link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

11. Appendix A – Dictionary structure and entries

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Description of transmission type . . . . . . . . . . . . . . . . . . . . . . . 158

Description of PDO COB-ID entry . . . . . . . . . . . . . . . . . . . . . . 158

PDO mapping entry structure – example . . . . . . . . . . . . . . . . . 159

12. Appendix B – CANopen error codes

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . 171

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . 171

Page 10

10 Table of contents

Page 11

Safety 11

1

Safety

What this chapter contains

The chapter presents the warning symbols used in this manual and

the safety instructions which you must follow when installing an

optional module into a drive, converter or inverter. If ignored,

physical injury or death may follow, or damage may occur to the

equipment. Read this chapter before you start the installation.

Page 12

12 Safety

Use of warnings

Warnings caution you about conditions which can result in serious

injury or death and/or damage to the equipment and advise on how

to avoid the danger. The following warning symbols are used in

this manual:

Electricity warning warns of hazards from electricity

which can cause physical injury and/or damage to the

equipment.

General warning warns about conditions, other than

those caused by electricity, which can result in physical

injury and/or damage to the equipment.

Page 13

Safety 13

Safety in installation

These warnings are intended for all who install an optional module

into a drive, converter or inverter.

WARNING! Ignoring the following instructions can cause

physical injury or death, or damage to the equipment.

• Only qualified electricians are allowed to install and maintain

the drive, converter or inverter!

• Disconnect the drive, converter or inverter into which the

optional module will be installed from all possible power

sources. After disconnecting, always wait for 5 minutes to let

the intermediate circuit capacitors discharge before you

proceed.

• Always ensure by measuring with a multimeter (impedance at

least 1 Mohm) that:

• there is no voltage between the input power terminals of

the drive, converter or inverter and the ground

• there is no voltage between the output power terminals of

the drive, converter or inverter and the ground.

• Do not work on the control cables when power is applied to the

external control circuits of the drive, converter or inverter.

Externally supplied control circuits may carry dangerous

voltage.

Page 14

14 Safety

Page 15

About the manual 15

2

About the manual

What this chapter contains

This chapter introduces this manual.

Applicability

This manual applies to the FCAN-01 CANopen adapter module

(+K457), SW version 1.046 or later.

Compatibility

The FCAN-01 CANopen adapter module is compatible with the

following drives:

• ACS355

• ACSM1

• ACS850

• ACS880.

Target audience

The reader is expected to have basic knowledge of fieldbus

interface, electrical fundamentals, electrical wiring practices and

how to operate the drive.

Page 16

16 About the manual

Purpose of the manual

The manual provides information on installing, commissioning and

using an FCAN-01 CANopen adapter module.

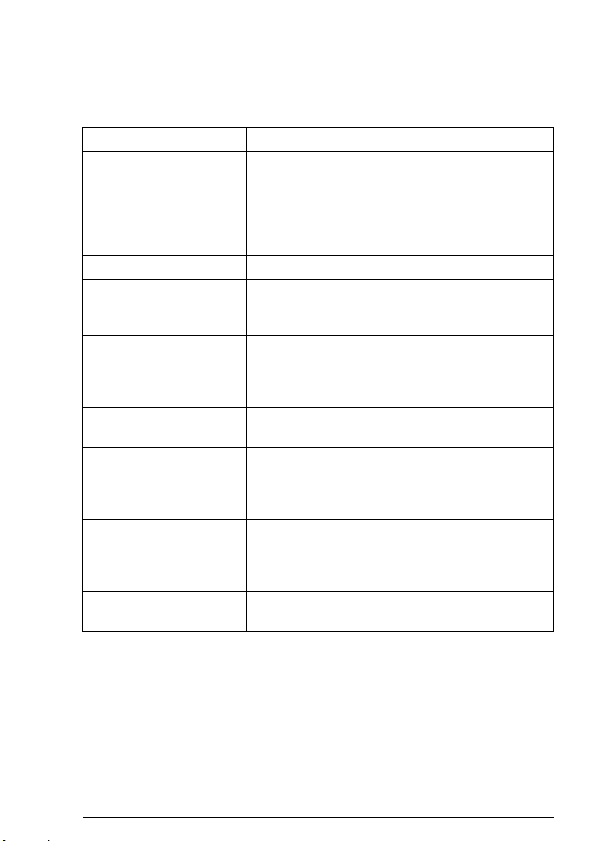

Related manuals

The related manuals are listed below.

Code (English)

Drive user’s manuals

ACS355 drives (0.37…22 kW,

0.5…30 hp) user’s manual

Drive hardware manuals and

guides

ACSM1-204 regen supply modules

(5.3 to 61 kW) hardware manual

ACSM1-04 drive modules (0.75 to

45 kW) hardware manual

ACSM1-04 drive modules (55 to

110 kW) hardware manual

ACSM1-04Lx liquid-cooled drive

modules (55 to 160 kW) hardware

manual

ACS850-04 (0.37…45 kW)

hardware manual

ACS850-04 (55…160 kW, 75…200

hp) hardware manual

ACS850-04 (200…500 kW,

250…600 hp) hardware manual

ACS880-01 (0.55 to 250 kW, 0.75

to 350 hp) hardware manual

3AUA0000066143

3AUA0000053713

3AFE68797543

3AFE68912130

3AUA0000022083

3AUA0000045496

3AUA0000045487

3AUA0000026234

3AUA0000078093

Page 17

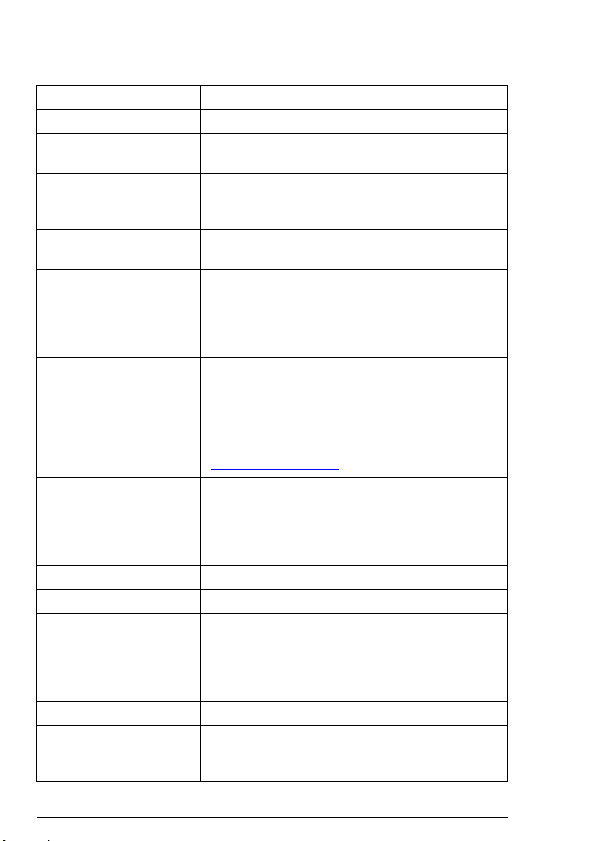

About the manual 17

Code (English)

Drive firmware manuals and

guides

ACSM1 motion control program

firmware manual

ACSM1 speed and torque control

program firmware manual

ACSM1 regen supply control

program firmware manual

ACS850 standard control program

firmware manual

ACS880 primary control program

firmware manual

Option manuals and guides

FCAN-01 CANopen adapter

module user’s manual

3AFE68848270

3AFE68848261

3AUA0000052174

3AUA0000045497

3AUA0000085967

3AFE68615500

You can find manuals and other product documents in PDF format

on the Internet. See section Document library on the Internet on

the inside of the back cover. For manuals not available in the

Document library, contact your local ABB representative.

Before you start

It is assumed that the drive is installed and ready to operate before

you start the installation of the adapter module.

In addition to conventional installation tools, have the drive

manuals available during the installation as they contain important

information not included in this manual. The drive manuals are

referred to at various points of this manual.

Page 18

18 About the manual

Contents

The manual consists of the following chapters:

• Safety presents the safety instructions which you must follow

when installing a fieldbus adapter module.

• About the manual introduces this manual.

• Overview of the CANopen protocol and the FCAN-01 adapter

module contains a short description of the CANopen protocol

and the adapter module.

• Mechanical installation contains a delivery checklist and

instructions on mounting the adapter module.

• Electrical installation contains wiring and bus termination

instructions.

• Start-up presents the steps to take during the start-up of the

drive with the adapter module and gives examples of

configuring the master system.

• Communication profiles describes the communication profiles

used in communication between the CANopen network, the

adapter module and the drive.

• Communication protocol describes the communication on a

CANopen network.

• Diagnostics explains how to trace faults with the status LEDs

on the adapter module.

• Technical data contains the technical data of the adapter

module and the CANopen link.

• Appendix A – Dictionary structure and entries contains

information about PDO transmission and mapping.

• Appendix B – CANopen error codes contains reference tables

for decoding CANopen error messages.

Page 19

About the manual 19

Terms and abbreviations used in this manual

Terms

Term Explanation

Communication module Communication module is a name for a device

Command word See Control word.

Control word 16-bit or 32-bit word from master to slave with

FCAN-01 CANopen

adapter module

Object dictionary Local storage of all Communication Objects

Parameter Operating instruction for the drive. Parameters

Profile Adaptation of the protocol for certain application

Status word 16-bit or 32-bit word from slave to master with

(eg, a fieldbus adapter) through which the drive

is connected to an external communication

network (eg, a fieldbus). The communication

with the module is activated with a drive

parameter.

bit-coded control signals (sometimes called the

Command word)

One of the optional fieldbus adapter modules

available for ABB drives. FCAN-01 is a device

through which an ABB drive is connected to a

CANopen network.

(COB) recognized by a device

can be read and programmed with the drive

control panel, drive PC tools or through the

adapter module.

field, for example, drives. In this manual, driveinternal profiles (eg, DCU or FBA) are called

native profiles.

bit-coded status messages

Page 20

20 About the manual

CANopen abbreviations

Abbreviation Explanation

CAN Controller Area Network

CiA CAN in Automation, International User’s and

CMS CAN Message Specification; one of the service

COB Grouping of pre-defined data objects accessible

DBT Distributor; one of the service elements of the

EDS Electronic Data Sheet; a node-specific ASCII-

LMT Layer Management; one of the service

LSB Least significant bit/byte

MSB Most significant bit/byte

NMT Network Management; one of the service

OSI Open Systems Interconnection

PDO Process Data Object; a type of COB. Used for

Manufacturer’s Group

elements of the CAN Application Layer in the

CAN Reference Model

via the network.

CAN Application Layer in the CAN Reference

Model. It is the responsibility of the Distributor to

distribute COB IDs to the COBs that are used

by a CMS.

format file required when configuring the CAN

network. The EDS file contains general

information on the node and its dictionary

objects (parameters). EDS files for ABB Drives

are available at the Document library

(www.abb.com/drives

elements of the CAN Application Layer in the

CAN Reference Model. It serves to configure

parameters for each layer in the CAN

Reference Model.

elements of the CAN Application Layer in the

CAN Reference Model. It performs initialization,

configuration and error handling on a CAN

network.

transmitting time critical data, such as control

commands, references and actual values.

).

Page 21

About the manual 21

Abbreviation Explanation

RO Denotes read-only access.

RW Denotes read/write access.

SDO Service Data Object; a type of COB. Used for

transmitting non-time-critical data, such as

parameters.

Page 22

22 About the manual

Page 23

Overview of the CANopen protocol and the FCAN-01 adapter module 23

3

Overview of the CANopen protocol and the FCAN-01 adapter module

What this chapter contains

This chapter contains a short description of the CANopen protocol

and the FCAN-01 CANopen adapter module.

CANopen protocol

CANopen is a higher layer protocol based on the CAN (Control

Area Network) serial bus system and the CAL (CAN Application

Layer). CANopen assumes that the hardware of the connected

device has a CAN transceiver and a CAN controller as specified in

ISO 11898.

The CANopen Communication Profile, CiA 301, includes both

cyclic and event driven communication, which makes it possible to

reduce the bus load to minimum while still maintaining extremely

short reaction times. High communication performance can be

achieved at relatively low baud rates, thus reducing EMC problems

and cable costs.

CANopen device profiles define both direct access to drive

parameter and time critical process data communication. The

adapter module fulfills CiA (CAN in Automation) specification CiA

402 (CANopen device profile for drives and motion control).

Page 24

24 Overview of the CANopen protocol and the FCAN-01 adapter module

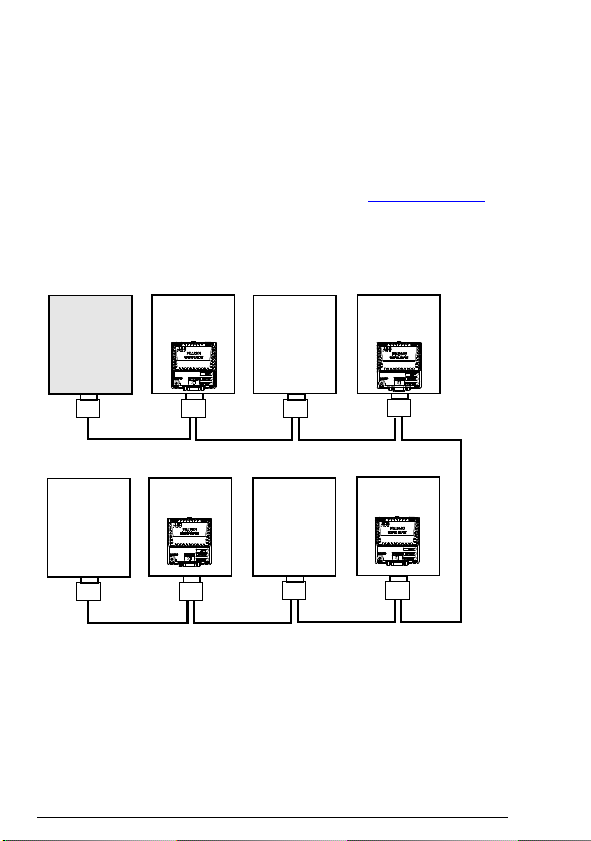

CANopen

master

ABB drive

Other slave

device

T = Termination

T

ABB drive

ABB drive

Other slave

device

Other slave

device

T

ABB drive

The physical medium of CANopen is a differentially driven two wire

bus line with common return according to ISO 11898. The

maximum length of the bus is limited by the communication speed.

The maximum theoretical number of nodes is 127. However, in

practice, the maximum number depends on the capabilities of the

used CAN transceivers.

Further information is available from the CAN in Automation

International Users and Manufacturers Group (www.can-cia.org

).

Topology of the CANopen link

The following figure describes the topology of the CANopen link.

Page 25

Overview of the CANopen protocol and the FCAN-01 adapter module 25

FCAN-01 CANopen adapter module

The FCAN-01 CANopen adapter module is an optional device for

ABB drives. It enables the connection of the drive to a CANopen

network. The drive is considered as a slave (server) on the

CANopen network.

Through the adapter module you can:

• give control commands to the drive

(for example, Start, Stop, Run enable)

• feed a motor speed, torque or position reference to the drive

• give a process actual value or a process reference to the PID

controller of the drive

• read status information and actual values from the drive

• change drive parameter values

• reset a drive fault.

The CANopen commands and services supported by the adapter

module are discussed in chapter Communication protocol. Refer to

the drive manuals as to which commands are supported by the

drive.

The adapter module is mounted into an option slot on the motor

control board of the drive. See the drive manuals for module

placement options.

Page 26

26 Overview of the CANopen protocol and the FCAN-01 adapter module

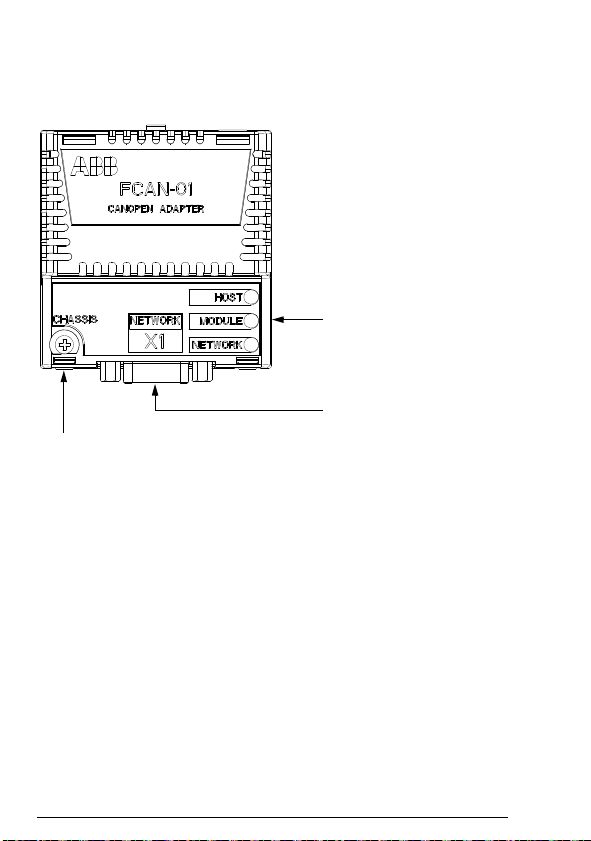

Diagnostic LEDs

(see chapter Diagnostics)

Bus connector X1

(see chapter Electrical

installation)

Mounting screw

Layout of the adapter module

The following figure describes the layout of the adapter module.

Page 27

Mechanical installation 27

4

Mechanical installation

What this chapter contains

This chapter contains a delivery checklist and instructions on

mounting the adapter module.

WARNING! Follow the safety instructions given in this

manual and the drive documentation.

Delivery check

The option package for the adapter module contains:

• CANopen adapter module, type FCAN-01

• this manual.

Page 28

28 Mechanical installation

Mounting the adapter module

The adapter module is inserted into its specific position in the drive.

The module is held in place with plastic pins and one screw. The

screw also provides the electrical connection between the module

and drive frame for cable shield termination.

When the module is installed, the signal and power connection to

the drive is made through a 20-pin connector. (All drives do not use

all the available signals so the connector on the drive may have

fewer pins.)

Mounting procedure:

1. Insert the module carefully into its position on the drive.

2. Fasten the screw.

Note: It is essential to install the screw properly to fulfill the EMC

requirements and to ensure the proper operation of the module.

For more information on mounting the adapter module, see the

drive manuals.

Page 29

Electrical installation 29

5

Electrical installation

What this chapter contains

This chapter contains:

• general cabling instructions

• bus termination instructions

• instructions on connecting the adapter module to the CANopen

network.

WARNING! Before installation, switch off the drive power

supply. Wait five minutes to ensure that the capacitor bank

of the drive is discharged. Switch off all dangerous

voltages connected from external control circuits to the inputs and

outputs of the drive.

General cabling instructions

• Arrange the bus cables as far away from the motor cables as

possible.

• Avoid parallel runs.

• Use bushings at cable entries.

Page 30

30 Electrical installation

5

96

1

X1

SUB-D9

(male)

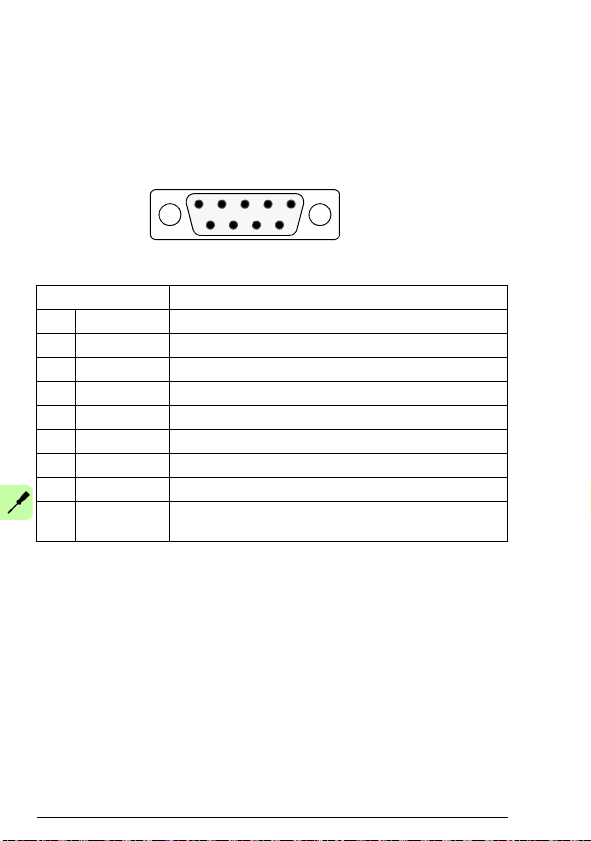

Connecting the module to the CANopen network

Connect the bus cable to connector X1 on the adapter module.

The connector pin allocation described below follows the CANopen

specification CiA 301.

X1 Description

1- Not in use

2 CAN_L CAN_L bus line (dominant low)

3 CAN_GND CAN ground

4- Not in use

5 CAN_SHLD Optional CAN shield

6 GND Optional ground

7 CAN_H CAN_H bus line (dominant high)

8- Not in use

9 CAN_V+ Optional CAN external power supply. Not supported

by FCAN-01.

Page 31

Electrical installation 31

CANopen

node

ON

CANopen

node

OFF

CANopen

node

ON

CANopen

node

OFF

Ter m . Ter m . Ter m. Te r m.

121 ohm

CAN_H

CAN_L

121 ohm

1%

Metal Film

1/4 W

1%

Metal Film

1/4 W

CANopen

node

CANopen

node

CANopen

node

…

Bus termination

Bus termination is required to prevent signal reflections from the

bus cable ends. The adapter module is not equipped with internal

bus termination. Therefore the first and last nodes of the bus must

be included with bus termination. Termination is done by

connecting one resistor between the CAN_H and CAN_L signals.

The nominal value for the terminating resistor is 120 ohms. The

resistors can be connected between the CAN_H and CAN_L wires

or a D-SUB connector with a built-on termination can be used.

In the following diagram, the built-on terminations of the D-SUB

connectors at the first and last nodes are switched on.

In the following diagram, the bus line is terminated with 121 ohm,

1 % (E96) resistors connected between the CAN_L and CAN_H

wires at each end.

Note: Further information on CANopen wiring is available from

www.can-cia.org

.

Page 32

32 Electrical installation

AC and DC parameters for the CANopen network

Bus cable and termination resistors

The cables, connectors, and termination resistors used in

CANopen networks must meet the requirements specified in ISO

11898.

The table below lists the standard values for DC parameters for

CANopen networks with less than 64 nodes:

Bus length

[m]

0…40 70 0.25…0.34 124 1000 at 40 m

40…300 < 60 0.34…0.6 150…300 > 500 at 100 m

300…600 < 40 0.5…0.6 150…300 > 100 at 500 m

600…1000 < 26 0.75…0.8 150…300 > 50 at 1 km

1)

Recommended cable for AC parameters: 120 ohm impedance and 5

ns/m line delay

Bus cable

Length-

related

resistance

[mohm/m]

1)

Cross-

section

2

[mm

]

Termination

resistance

[ohm]

Baud rate

[kbit/s]

With drop cables the recommended cable cross-section is

0.25…0.34 mm

In addition to the cable resistance, the real resistance of the

connectors should be taken into account in voltage drop

calculation. The transmission resistance of one connector should

2

.

be 2.5...10 mohm.

The following table lists the maximum bus cable length for different

node numbers (n), when

• minimum dominant value V

diff.out.min

• minimum differential input resistance R

• requested differential input voltage V

• minimum termination resistance R

= 1.5 V

diff.min

th.max

= 118 ohm.

T. mi n

= 20 kohm

= 1.0 V

Page 33

Electrical installation 33

Wire

cross-

section

2

[mm

Maximum length [m]

n = 32 n = 64 n = 100 n = 32 n = 64 n = 100

]

1)

Maximum length [m]

0.25 200 170 150 230 200 170

0.5 360 310 270 420 360 320

0.75 550 470 410 640 550 480

1)

Safety margin of 0.2

2)

Safety margin of 0.1

2)

Page 34

34 Electrical installation

Page 35

Start-up 35

6

Start-up

What this chapter contains

This chapter contains:

• information on configuring the drive for operation with the

adapter module

• drive-specific instructions on starting up the drive with the

adapter module

• examples of configuring the master station for communication

with the adapter module.

WARNING! Follow the safety instructions given in this

manual and the drive documentation.

Drive configuration

The following information applies to all drive types compatible with

the adapter module, unless otherwise stated.

Page 36

36 Start-up

CANopen connection configuration

After the adapter module has been mechanically and electrically

installed according to the instructions in chapters Mechanical

installation and Electrical installation, the drive must be prepared

for communication with the module.

The detailed procedure of activating the module for CANopen

communication with the drive depends on the drive type. Normally,

a parameter must be adjusted to activate the communication. See

the drive-specific start-up sections on pages 58, 64, 69 and 75.

Once communication between the drive and the adapter module

has been established, several configuration parameters are copied

to the drive. These parameters are shown in the tables below and

must be checked first and adjusted where necessary.

Note: Not all drives display descriptive names for the configuration

parameters. To help you identify the parameters in different drives,

the names displayed by each drive are given in grey boxes in the

tables.

An example on how to configure PDOs via the CAN bus is given in

section PDO configuration via the CAN bus.

Note: The new settings take effect only when the adapter module

is powered up the next time or when the fieldbus adapter refresh

parameter is activated.

Data transfer rates supported

The FCAN-01 CANopen adapter module supports the following

CANopen communication speeds: 50 kbit/s, 100 kbit/s, 125 kbit/s,

250 kbit/s, 500 kbit/s, 1 Mbit/s.

Note: 100 kbit/s is not recommended for a new installation.

Page 37

Start-up 37

FCAN-01 configuration parameters – group A (group 1)

Note: The actual parameter group number depends on the drive

type. Group A (group 1) corresponds to:

• parameter group 51 in ACS355, ACSM1 and ACS850

• parameter group 51 in ACS880 if the adapter is installed as

fieldbus adapter A or group 54 if the adapter is installed as

fieldbus adapter B.

No. Name/Value Description Default

01 FBA TYPE Read-only. Shows the fieldbus adapter type as

02 NODE ID Selects the node address of the module.

ACS355:

FB PAR 2

ACSM1:

FBA PAR2

ACS850:

FBA par2

ACS880:

Node ID

1…127 Node address

detected by the drive. Value cannot be adjusted

by the user.

If the value is 0 = None, the communication

between the drive and the module has not been

established.

Each device on the CANopen network must

have a unique node identifier. Used to define a

node identifier for the drive it is connected to.

setting

1 =

CANopen

3

Page 38

38 Start-up

No. Name/Value Description Default

03 BIT RATE Sets the bit rate for the CANopen interface.

ACS355:

FB PAR 3

ACSM1:

FBA PAR3

ACS850:

FBA par3

ACS880:

Bit rate

0 = 1 Mbit/s 1 Mbit/s

1 = 500 kbit/s 500 kbit/s

2 = 250 kbit/s 250 kbit/s

3 = 125 kbit/s 125 kbit/s

4 = 100 kbit/s 100 kbit/s

5 =50kbit/s 50kbit/s

04 CONF LOC Selects the source of the PDO configuration.

ACS355:

FB PAR 4

ACSM1:

FBA PAR4

ACS850:

FBA par4

ACS880:

Conf location

0 = Network PDO configuration via CAN bus: CANopen

1 = Parameters PDO configuration with drive parameters:

This is user selectable, but must be the same

on every node on the CANopen network.

Note: 100 kbit/s is not recommended for a new

installation.

Note: The first mapping entries of the Tx/Rx

PDO1 and Tx/Rx PDO6 are fixed in the

ACS355 drive.

Note: Make sure that the PLC does not

overwrite the selected configuration during the

initialization phase when the configuration is

taken from the FCAN-01 configuration

parameter groups.

objects 1400h, 1600h, 1405h, 1605h, 1414h,

1614h, 1800h, 1A00h, 1805h, 1A05h, 1814h

and 1A14h only.

adapter module configuration parameter group

A (group 1), group B (group 2) and group C

(group 3) (initial values).

setting

3 =125

kbit/s

0

Page 39

Start-up 39

No. Name/Value Description Default

05 PROFILE Selects the used communication profile used by

ACS355:

FB PAR 5

ACSM1:

FBA PAR5

ACS850:

FBA par5

ACS880:

Profile

0 = CiA 402 CANopen device profile CiA 402 selected

1 = ABB Drives ABB Drives profile selected

2 = Transp. 16 Transparent 16 profile selected

3 = Transp. 32 Transparent 32 profile selected

06 T16 SCALE Defines the reference multiplier/actual value

ACS355:

FB PAR 6

ACSM1:

FBA PAR6

ACS850:

FBA par6

ACS880:

T16 scale

0…65535 Reference multiplier/actual value divisor

the adapter module:

For more information on the communication

profiles, see chapter Communication profiles.

divisor for the adapter module. The parameter

is effective only when the Transparent 16 profile

is selected AND the drive is using the native

communication profile (for example, DCU or

FBA) and a 16-bit transparent Reference

1/Actual value 1.

With an ACS355 drive, the speed reference

from the PLC is multiplied by the value of this

parameter plus one. For example, if the

parameter has a value of 99 and a reference of

1000 given by the master, the reference will be

multiplied by 99 + 1 = 100 an d forwarded to the

drive as 100000. According to the DCU profile,

this value is interpreted as a reference of 100

rpm in the drive.

With ACSM1, ACS850 and ACS880, setting

this parameter to 65535 provides the

approximation of 1 ≈ 1 rpm.

setting

1 = ABB

Drives

99

Page 40

40 Start-up

No. Name/Value Description Default

07 RPDO1-COB-ID Defines the COB-ID for Rx PDO1.

ACS355:

FB PAR 7

ACSM1:

FBA PAR7

ACS850:

FBA par7

ACS880:

RPDO1-COB-ID

0 = Disable Rx PDO1 is not valid (disabled). COB-ID is

1 = Default Rx PDO1 is valid and configured to use the

385…1407 (dec) =

181h … 57Fh

08 RPDO1-TR TYPE Defines the Rx PDO1 transmission type. See

ACS355:

FB PAR 8

ACSM1:

FBA PAR8

ACS850:

FBA par8

ACS880:

RPDO1-TR type

0…255 (dec) Rx PDO1 transmission type. See section

Note: It is recommended to use the default

COB-ID.

80000200h + Node-ID.

default COB-ID (200h + Node-ID).

Rx PDO1 is valid and configured to use a

custom COB-ID defined with this parameter.

COB-ID must be within the allowed PDO COBID range (181h - 57Fh).

chapter Appendix A – Dictionary structure and

entries.

Description of transmission type on page 158.

setting

1

255

Page 41

Start-up 41

No. Name/Value Description Default

09 RPDO1-EV TIME Defines the event time (time-out time) for the

ACS355:

FB PAR 9

ACSM1:

FBA PAR9

ACS850:

FBA par9

ACS880:

RPDO1-EV time

0 = Disable Time-out supervision is disabled.

1…65535 (ms) Event time in ms

10 TPDO1-COB-ID Defines the COB-ID for Rx PDO6.

ACS355:

FB PAR 10

ACSM1:

FBA PAR10

ACS850:

FBA par10

ACS880:

TPDO1-COB-ID

0 = Disable Tx PDO1 is not valid (disabled). COB-ID is

1 = Default Tx PDO1 is valid and configur ed to use the

385…1407 (dec) =

181h … 57Fh

Rx PDO1 in the asynchronous transmission

mode. If the Rx PDO1 communication between

the adapter module and the bus master fails,

the adapter module sets the communication

between the module and the drive to the off-line

mode.

Event timer (time-out timer) elapses as a

multiple of 1 ms of the entry of this parameter.

Note: The time-out supervision is activated

upon a successful reception of an Rx PDO1.

Note: It is recommended to use the default

COB-ID.

80000180h + Node-ID.

default COB-ID (180h + Node-ID).

Tx PDO1 is valid and configured to use a

custom COB-ID defined with this parameter.

COB-ID must be within the allowed PDO COBID range (181h - 57Fh).

setting

0 =

Disable

1 =

Default

Page 42

42 Start-up

No. Name/Value Description Default

11 TPDO1-TR TYPE Defines the PDO1 transmission type. See

ACS355:

FB PAR 11

ACSM1:

FBA PAR11

ACS850:

FBA par11

ACS880:

TPDO1-TR type

0…255 (dec) PDO1 transmission type. See section

12 TPDO1-EV TIME Defines the event time for the Tx PDO1

ACS355:

FB PAR 12

ACSM1:

FBA PAR12

ACS850:

FBA par12

ACS880:

TPDO1-EV time

0 = Disable Event timer is disabled.

1…65535 (ms) Event time in ms.

13 RPDO6-COB-ID Defines the COB-ID for Rx PDO6.

ACS355:

FB PAR 13

ACSM1:

FBA PAR13

ACS850:

FBA par13

ACS880:

RPDO6-COB-ID

0 = Disable Rx PDO6 is not valid (disabled). COB-ID is

1 = Default Rx PDO6 is valid and configured to use the

385…1407 (dec) =

181h … 57Fh

chapter Appendix A – Dictionary structure and

entries.

Description of transmission type on page 158.

asynchronous transmission mode.

Event timer elapses as a multiple of 1 ms of the

entry of this parameter.

Note: It is recommended to use the default

COB-ID.

80000300h + Node-ID.

default COB-ID (300h + Node-ID).

Rx PDO1 is valid and configured to use a

custom COB-ID defined with this parameter.

COB-ID must be within the allowed PDO COBID range (181h - 57Fh).

setting

255

0 =

Disable

0 =

Disable

Page 43

Start-up 43

No. Name/Value Description Default

14 RPDO6-TR TYPE Defines the Rx PDO6 transmission type. See

ACS355:

FB PAR 14

ACSM1:

FBA PAR14

ACS850:

FBA par14

ACS880:

RPDO6-TR type

0…255 (dec) Rx PDO6 transmission type. See section

15 RPDO6-EV TIME Defines the event time (time-out time) for the

ACS355:

FB PAR 15

ACSM1:

FBA PAR15

ACS850:

FBA par15

ACS880:

RPDO6-EV time

0 = Disable Time-out supervision is disabled.

1…65535 (ms) Event time in ms.

16 TPDO6-COB-ID Defines the COB-ID for Tx PDO6.

ACS355:

FB PAR 16

ACSM1:

FBA PAR16

ACS850:

FBA par16

ACS880:

TPDO6-COB-ID

0 = Disable Tx PDO6 is not valid (disabled). COB-ID is

1 = Default Tx PDO6 is valid and configur ed to use the

385…1407 (dec) =

181h … 57Fh

chapter Appendix A – Dictionary structure and

entries.

Description of transmission type on page 158.

Rx PDO6 in the asynchronous transmission

mode. If the Rx PDO6 communication between

the adapter module and the bus master fails,

the adapter module sets the communication

between the module and the drive to the off-line

mode.

Event timer (time-out timer) elapses as a

multiple of 1 ms of the entry of this parameter.

Note: The time-out supervision is activated

upon a successful reception of an Rx PDO6.

Note: It is recommended to use the default

COB-ID.

80000280h + Node-ID.

default COB-ID (280h + Node-ID).

Tx PDO6 is valid and configured to use a

custom COB-ID defined with this parameter.

COB-ID must be within the allowed PDO COBID range (181h - 57Fh).

setting

255

0 =

Disable

0 =

Disable

Page 44

44 Start-up

No. Name/Value Description Default

17 TPDO6-TR TYPE Defines the Tx PDO6 transmission type. See

ACS355:

FB PAR 17

ACSM1:

FBA PAR17

ACS850:

FBA par17

ACS880:

TPDO6-TR type

0…255 (dec) Tx PDO6 transmission type. See section

18 TPDO6-EV TIME Defines the event time for the Tx PDO6

ACS355:

FB PAR 18

ACSM1:

FBA PAR18

ACS850:

FBA par18

ACS880:

TPDO6-EV time

0 = Disable Event timer is disabled.

1…65535 (ms) Event time in ms.

19 RPDO21-COB-ID Defines the COB-ID for Rx PDO21.

ACS355:

FB PAR 19

ACSM1:

FBA PAR19

ACS850:

FBA par19

ACS880:

RPDO21-COB-ID

0 = Disable Rx PDO21 is not valid (disabled). COB-ID is

1 = Default Rx PDO21 is valid and configured to use the

385…1407 (dec) =

181h … 57Fh

chapter Appendix A – Dictionary structure and

entries.

Description of transmission type on page 158.

asynchronous transmission mode.

Event timer elapses as a multiple of 1 ms of the

entry of this parameter.

Note: It is recommended to use the default

COB-ID.

80000400h + Node-ID.

default COB-ID (400h + Node-ID).

Rx PDO21 is valid and configured to use a

custom COB-ID defined with this parameter.

COB-ID must be within the allowed PDO COBID range (181h - 57Fh).

setting

255

0 =

Disable

0 =

Disable

Page 45

Start-up 45

No. Name/Value Description Default

20 RPDO21-TR

TYPE

ACS355:

FB PAR 20

ACSM1:

FBA PAR20

ACS850:

FBA par20

ACS880:

RPDO21-TR type

0…255 (dec) Rx PDO21 transmission type. See section

21 RPDO21-EV TIME Defines the event time (time-out time) for the

ACS355:

FB PAR 21

ACSM1:

FBA PAR21

ACS850:

FBA par21

ACS880:

RPDO21-EV time

0 = Disable Time-out supervision is disabled.

1…65535 (ms) Event time in ms.

Defines the Rx PDO21 transmission type. See

chapter Appendix A – Dictionary structure and

entries.

Description of transmission type on page 158.

Rx PDO21 in the asynchronous transmission

mode. If the Rx PDO21 communication

between the adapter module and the bus

master fails, the adapter module sets the

communication between the modu le and the

drive to the off-line mode.

Event timer (time-out timer) elapses as a

multiple of 1 ms of the entry of this parameter.

Note: The time-out supervision is activated

upon a successful reception of an Rx PDO21.

setting

255

0 =

Disable

Page 46

46 Start-up

No. Name/Value Description Default

22 TPDO21-COB-ID Defines the COB-ID for Tx PDO21.

ACS355:

FB PAR 22

ACSM1:

FBA PAR22

ACS850:

FBA par22

ACS880:

TPDO21-COB-ID

0 = Disable Tx PDO21 is not valid (disabled). COB-ID is

1 = Default Tx PDO21 is valid and configured to use the

385…1407 (dec) =

181h … 57Fh

23 TPDO21-TR

TYPE

ACS355:

FB PAR 23

ACSM1:

FBA PAR23

ACS850:

FBA par23

ACS880:

TPDO21-TR type

0…255 (dec) Tx PDO21 transmission type. See section

Note: It is recommended to use the default

COB-ID.

80000380h + Node-ID.

default COB-ID (380h + Node-ID).

Tx PDO21 is valid and configured to use a

custom COB-ID defined with this parameter.

COB-ID must be within the allowed PDO COBID range (181h - 57Fh).

Defines the Tx PDO21 transmission type. See

chapter Appendix A – Dictionary structure and

entries.

Description of transmission type on page 158.

setting

0 =

Disable

255

Page 47

Start-up 47

No. Name/Value Description Default

24 TPDO21-EV TIME Defines the event time for the Tx PDO21

ACS355:

FB PAR 23

ACSM1:

FBA PAR23

ACS850:

FBA par23

ACS880:

TPDO21-EV time

0 = Disable Event timer is disabled.

1...65535 (ms) Event time in ms.

25

Reserved Not used by the adapter module. N/A

…

26

27 FBA PAR

REFRESH

ACS355/

ACSM1:

FBA PAR

REFRESH

ACS850/ACS880:

FBA par refresh

0 = Done Refreshing done

1 =

Refresh/Configure

28 PAR TABLE VER Read-only. Displays the parameter table

ACS355:

FILE CPI FW REV

ACSM1:

PAR TABLE VER

ACS850/ACS880:

Par table ver

asynchronous transmission mode.

Event timer elapses as a multiple of 1 ms of the

entry of this parameter.

Validates any changed adapter module

configuration parameter settings. After

refreshing, the value reverts automatically to 0

= Done.

Note: This parameter cannot be changed while

the drive is running.

Refreshing

revision of the fieldbus adapter module

mapping file stored in the memory of the dri ve.

In format xyz, where:

x = major revision number

y = minor revision number

x = correction number

OR

in format axyz, where

a = major revision number

xy = minor revision numbers

z = correction number or letter.

Parameter table revision

setting

0 =

Disable

0 = Done

N/A

Page 48

48 Start-up

No. Name/Value Description Default

29 DRIVE TYPE

CODE

ACS355:

FILE CONFIG ID

ACSM1:

DRIVE TYPE

COD

ACS850/ACS880:

Drive type code

30 MAPPING FILE

VER

ACS355:

FILE CONFIG

REV

ACSM1:

MAPPING FILE

VER

ACS850/ACS880:

Mapping file ver

Read-only. Displays the drive type code of the

fieldbus adapter module mapping file stored in

the memory of the drive.

Drive type code of the fieldbus adapter module

mapping file

Read-only. Displays the fieldbus adapter

module mapping file revision stored in the

memory of the drive in decimal format.

Mapping file revision

setting

N/A

N/A

Page 49

Start-up 49

No. Name/Value Description Default

31 D2FBA COMM

STA

ACS355:

FBA STATUS

ACSM1:

D2FBA COMM

STA

ACS850/ACS880:

D2FBA comm sta

0 = Idle Adapter is not configured.

1 = Exec.init Adapter is initializing.

2 = Time out Time-out has occurred in the communication

3 = Conf.err Adapter configuration error: Major or minor

4 = Off-line Adapter is off-line.

5 = On-line Adapter is on-line.

6 = Reset Adapter is performing a hardware reset.

32 FBA COMM SW

REV

ACS355:

FBA CPI FW REV

ACSM1:

FBA COMM SW

VER

ACS850/ACS880:

FBA comm SW

rev

Read-only. Displays the status of the fieldbus

adapter module communication.

Note: The value names may vary by drive.

between the adapter and the dr ive.

revision code of the common program revision

in the fieldbus adapter module is not the

revision required by the module or mapping file

upload has failed more than three times.

Read-only. Displays the common program

revision of the adapter module in format axyz,

where:

a = major revision number

xy = minor revision numbers

z = correction number or letter.

Example: 190A = revision 1.90A

Common program version of the adapter

module

setting

0 = Idle

OR

4 = Offline

N/A

Page 50

50 Start-up

No. Name/Value Description Default

33 FBA COMM APPL

REV

ACS355:

FBA CPI APPL

REV

ACSM1:

FBA COMM APPL

VER

ACS850/ACS880:

FBA appl SW ver

Read-only. Displays the application program

revision of the adapter module in format axyz,

where:

a = major revision number

xy = minor revision numbers

z = correction number or letter.

Example: 190A = revision 1.90A

Application program revision of the adapter

module

setting

N/A

Page 51

FCAN-01 configuration parameters – group B (group 2)

CANopen

master

ABB drive

Control word (CW)

References

FBA DATA OUT

(Rx PDO)

0 Not used

1…99 Virtual address area of drive control

101…

9999

Parameter area of the drive

Note: The actual parameter group number depends on the drive

type. Group B (group 2) corresponds to:

• parameter group 55 in ACS355

• group 53 in ACSM1 and ACS850

• parameter group 53 in ACS880 if the adapter is installed as

fieldbus adapter A or group 56 if the adapter is installed as

fieldbus adapter B.

No.1)Name2)/Value Description Default

01 For ACS355:

Rx PDO1 word 2

For other drives:

Rx PDO1 word 1

ACS355:

FBA DATA OUT 1

ACSM1:

FBA DATA OUT1

ACS850/ACS880:

FBA data out1

Start-up 51

Selects data word 1 received by the drive over

the CANopen network. From the drive's

perspective this corresponds to Rx PDO

communication in CANopen.

Content is defined by a decimal number in the

range of 0 to 9999 as follows:

See also Additional information on the virtual

address area allocation on page 57.

Note: The FCAN-01 configuration parameters

are 16-bit parameters. If the mapped parameter

is a 32-bit parameter, it automatically reserves

two consecutive parameters. For example,

mapping of a 32-bit parameter to parameter no.

1 also reserves parameter no. 2.

Note: In ACS355 drives, Rx PDO1 word 1 and

Rx PDO6 word 1 are fixed and always mapped

to object 6040h Control word. The first

configuration parameters have effect on the 2nd

words of these PDOs in ACS355 drives.

0 = Not

used

Page 52

52 Start-up

No.1)Name2)/Value Description Default

0 = None Not used

1 = CW 16bit Control word (16 bits)

2 = Ref1 16bit Reference REF1 (16 bits)

3 = Ref2 16bit Reference REF2 (16 bits)

11 = CW 32bit Control word (32 bits)

12 = Ref1 32bit Reference REF1 (32 bits)

13 = Ref2 32bit Reference REF2 (32 bits)

101…9999 Parameter number with format xxyy, where:

02 For ACS355:

Rx PDO1 word 3

For other drives:

Rx PDO1 word 2

03 For ACS355:

Rx PDO1 word 4

For other drives:

Rx PDO1 word 3

04 For ACS355:

Rx PDO6 word 2

For other drives:

Rx PDO1 word 4

05 For ACS355:

Rx PDO6 word 3

For other drives:

Rx PDO6 word 1

06 For ACS355:

Rx PDO6 word 4

For other drives:

Rx PDO6 word 2

07 For ACS355:

Rx PDO21 word 1

For other drives:

Rx PDO6 word 3

08 For ACS355:

Rx PDO21 word 2

For other drives:

Rx PDO6 word 4

• xx is the parameter group number (1 to 99)

• yy is the parameter number index within that

group (01 to 99).

Note: In ACS880, choose Other to display a list

of mappable drive parameters.

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

Page 53

Start-up 53

No.1)Name2)/Value Description Default

09 For ACS355:

Rx PDO21 word 3

For other drives:

Rx PDO21 word 1

10 For ACS355:

Rx PDO21 word 4

For other drives:

Rx PDO21 word 2

11 For ACS355:

N/A

For other drives:

Rx PDO21 word 3

12 For ACS355:

N/A

For other drives:

Rx PDO21 word 4

1)

The number of parameters in this group may vary by drive type and drive firmware.

2)

For more information, see chapter Communication protocol.

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above.

Note: ACS355 has only ten FBA DATA OUT

parameters, indexes 1 to 10.

See parameter 01 above.

Note: ACS355 has only ten FBA DATA OUT

parameters, indexes 1 to 10.

0

0

Page 54

54 Start-up

CANopen

master

ABB drive

Status word (SW)

Actual values

FBA DATA IN

(Tx PDO)

0Not used

1…99 Virtual address area of drive control

101…

9999

Parameter area of the drive

FCAN-01 configuration parameters – group C (group 3)

Note: The actual parameter group number depends on the drive

type. Group C (group 3) corresponds to:

• parameter group 54 in ACS355

• group 52 in ACSM1 and ACS850

• parameter group 52 in ACS880 if the adapter is installed as

fieldbus adapter A or group 55 if the adapter is installed as

fieldbus adapter B.

No.1)Name2)/Value Description Default

01 For ACS355:

Tx PDO1 word 2

For other drives:

Tx PDO1 word 1

ACS355:

FBA DATA IN 1

ACSM1:

FBA DATA IN1

ACS850/ACS880:

FBA data in1

Data word 1 sent by the drive over the

CANopen network. From the drive's perspective

this corresponds to Tx PDO communication in

CANopen.

Content is defined by a decimal number in the

range of 0 to 9999 as follows:

See also Additional information on the virtual

address area allocation on page 57.

Note: The FCAN-01 configuration parameters

are 16-bit parameters. If the mapped parameter

is a 32-bit parameter, it automatically reserves

two consecutive parameters. For example,

mapping of a 32-bit parameter to parameter no.

1 also reserves parameter no. 2.

Note: In ACS355 drives, Tx PDO1 word 1 and

Tx PDO6 word 1 are fixed and always mapped

to object 6041h Status word. The first

configuration parameters have effect on the 2nd

words of these PDOs in ACS355 drives .

0 = Not

used

Page 55

Start-up 55

No.1)Name2)/Value Description Default

0 = None Not used

4 = SW 16bit Status word (16 bits)

5 = Act1 16bit Actual value ACT1 (16 bits)

6 = Act2 16bit Actual value ACT2 (16 bits)

14 = SW 32bit Status word (32 bits)

15 = Act1 32bit Actual value ACT1 (32 bits)

16 = Act2 32bit Actual value ACT2 (32 bits)

101…9999 Parameter number with format xxyy, where:

02 For ACS355:

Tx PDO1 word 3

For other drives:

Tx PDO1 word 2

03 For ACS355:

Tx PDO1 word 4

For other drives:

Tx PDO1 word 3

04 For ACS355:

Tx PDO6 word 2

For other drives:

Tx PDO1 word 4

05 For ACS355:

Tx PDO6 word 3

For other drives:

Tx PDO6 word 1

06 For ACS355:

Tx PDO6 word 4

For other drives:

Tx PDO6 word 2

07 For ACS355:

Tx PDO21 word 1

For other drives:

Tx PDO6 word 3

08 For ACS355:

Tx PDO21 word 2

For other drives:

Tx PDO6 word 4

• xx is the parameter group number (1 to 99)

• yy is the parameter number index within that

group (01 to 99).

Note: In ACS880, choose Other to display a list

of mappable drive parameters.

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above. 0

Page 56

56 Start-up

No.1)Name2)/Value Description Default

09 For ACS355:

Tx PDO21 word 3

For other drives:

Tx PDO21 word 1

10 For ACS355:

Tx PDO21 word 4

For other drives:

Tx PDO21 word 2

11 For ACS355:

N/A

For other drives:

Tx PDO21 word 3

12 For ACS355:

N/A

For other drives:

Tx PDO21 word 4

1)

The number of parameters in this group may vary by drive type and drive firmware.

2)

For more information, see chapter Communication protocol.

See parameter 01 above. 0

See parameter 01 above. 0

See parameter 01 above.

Note: ACS355 has only ten FBA DATA IN

parameters, indexes 1 to 10.

See parameter 01 above.

Note: ACS355 has only ten FBA DATA IN

parameters, indexes 1 to 10.

0

0

Page 57

Additional information on the virtual address area allocation

The drive virtual address area is allocated as follows:

Profile

1)

hm pp ip pv pt vl

Virtual address

Description

word

ence 1

ence 2

word

value 1

value 2

word

ence 1

ence 2

word

value 1

value 2

Data length

16-bit 6040h 6040h

16-bit - -

16-bit - -

16-bit 6041h 6041h

16-bit - -

16-bit - -

32-bit - -

32-bit - 607Ah

32-bit - -

32-bit - -

32-bit - 6064h

32-bit - -

1 Control

2Refer-

3Refer-

4Status

5Actual

6Actual

7…10 Reserved N/A - -

11 C ont ro l

12 Refer-

13 Refer-

14 Status

15 Actual

16 Actual

hm = homing mode

pp = profile position mode

ip = interpolated position mode

CiA 402

6040h 60 40h 6040h 6040h 6040h -

- 6071h 6042h 6042h 604 2h -

- - 2000h03 2000h03 -

6041h 60 41h 6041h 6041h 6041h -

- 6077h 6044h 6044h 604 4h -

- - - 2000h06 2000h06 -

------

- - - - - 2001h

60FFh - - - - 2002h

- - - - - 2003h

- - - - - 2004h

606Ch - - - - 2005h

- - - - - 2006h

pv = profile velocity mode

pt = profile torque mode

vl = velocity mode

ABB Drives

1)

ACS355 supports only vl.

1)

ACS850 and ACS880 support vl and

pt.

1)

ACSM1 supports hm, pp, pv, pt and vl.

Start-up 57

Transparent 16

Transparent 32

Page 58

58 Start-up

Control locations

ABB drives can receive control information from multiple sources

including digital inputs, analog inputs, the drive control panel and a

communication module (for example, FCAN-01). ABB drives allow

the user to separately determine the source for each type of control

information (Start, Stop, Direction, Reference, Fault reset, etc.).

To give the fieldbus master station the most complete control over

the drive, the communication module must be selected as the

source of this information. The drive-specific parameter setting

examples below contain the drive control parameters needed in

the examples. For a complete parameter list, see the drive

documentation.

Starting up ACS355 drives

1. Power up the drive.

2. Enable the communication between the adapter module and

the drive with parameter 9802 COMM PROT SEL.

3. Set the FCAN configuration parameters in drive parameter

group 51.

At the minimum, set the required node address in parameter

5102 NODE ID, the required bit rate in 5103 BIT RATE, select

the source of the PDO configuration in 5104 CONF LOC and

the communication profile in 5105 PROFILE.

4. With parameter 3018 COMM FAULT FUNC, select how the

drive reacts to a fieldbus communication break.

5. With parameter 3019 COMM FAULT TIME, define the time

between communication break detection and the selected

action.

6. If group 51 is selected as the source for the PDO configuration,

select the application specific configuration for the PDOs with

parameters 5107…5124.

Page 59

Start-up 59

7. If group 51 is selected as the source for the PDO configuration,

define the process data transferred to and from the drive in

FCAN-01 parameter groups 54 and 55.

Note: If the PDO configuration is written from the PLC,

parameters 5107…5124 are not used and the parameter

groups 54 and 55 display the process data selected in the

PLC.

8. To validate the settings made in parameter groups 51, 54 and

55, set parameter 5127 FBA PAR REFRESH to REFRESH.

9. Set the relevant drive control parameters to control the drive

according to the application.

Examples of appropriate values are shown in the tables below.

Parameter setting examples – ACS355

CiA 402 vl velocity mode with default PDO mapping

The following example shows how to configure a basic speed

control application that uses the CiA 402 profile. The start/stop

commands are according to the CiA 402 profile velocity control

mode.

Rx PDO1 and Tx PDO1 are enabled by default. In ACS355 drives,

the first mapping entries of Rx PDO1 and Tx PDO1 are fixed and

always mapped to objects 6040h and 6041h.

PDO Word 1 Length

Rx PDO1 6040h Control word 16 bits

Tx PDO1 6041h Status word 16 bits

Note: The Tx PDO1 default transmission type is 255 (acyclic) and

event time is 0. The event time should be changed with CANopen

object 1800h05 if the default transmission type is used.

Page 60

60 Start-up

The ACS355 parameters and recommended parameter settings

for the CANopen fieldbus communication are listed in the following

table.

Drive parameter Setting for ACS355

drives

9802 COMM PROT SEL 4 = EXT FBA Activates the communication

5101 FBA TYPE 32 (= CANopen)

5102 FBA PAR 2

(NODE ID)

5103 FBA PAR 3

(BIT RATE)

5104 FBA PAR 4

(CONF LOC)

5105 FBA PAR 5

(PROFILE)

3018 COMM FAULT

FUNC

3019 COMM FAULT

TIME

5127 FBA PAR

REFRESH

1001 EXT1

COMMANDS

1103 REF1 SELECT 1 = AI1

2)

3

3 (= 125 kbit/s)

2)

0 (= Network) CANopen objects (14xxh,

0 (= CiA 402) CiA 402 mode communication

1 = FAULT Sets the fieldbus communication

3.0 s Fieldbus communication loss

1 = REFRESH Fieldbus configuration

10 = COMM Communication module as the

2)

1601 RUN ENABLE 7 = COMM Communication module as the

1604 FAULT RESET

SEL

1)

Automatically detected

2)

Example

8 = COMM Communication module as the

Description

(fieldbus) module.

1)

Communication module type

Adapter module node ID

Bit rate used on the CANopen

network

16xxh, 18xxh and 1Axxh) as the

source for the PDO settings

profile

loss functionality.

supervision time-out

parameter settings activation

source for the start, stop and

direction commands

Analogue input as the source for

reference 1

source for the Run enable signal

source for the fault reset signal

Page 61

Start-up 61

The start sequence for the parameter example above is given

below.

Control word:

• Reset the fieldbus communication fault (if active).

• 7Eh (126 decimal) –> SWITCH ON DISABLED

• 7Fh (127 decimal) –> OPERATION ENABLED

Speed and torque control using ABB Drives communication profile with parameter-configured PDO mapping

This example shows how to configure a speed and torque control

application that uses the ABB Drives profile. In addition, some

application specific data is added to the communication.

The start/stop commands and references are according to the ABB

Drives profile. (For more information, see section ABB Drives

communication profile on page 100.)

When reference 1 (REF1) is used, reference value ±20000

(decimal) corresponds to the reference set with parameter 1105

REF1 MAX in the forward and reverse directions.

When reference 2 (REF2) is used, a reference value of ±10000

(decimal) corresponds to the reference set with parameter 1108

REF2 MAX in the forward and reverse directions.

The minimum and maximum 16-bit integer values that can be

given through the fieldbus are -32768 and 32767 respectively.

PDO Word 1 Word 2 Word 3 Word 4 Length

Rx PDO1 6040h

Tx PDO1 6041h

1)

According to the ABB Drives profile mode

2)

Example

Note: In ACS355 drives, the first mapping entries of PDOs 1 and 6 are fixed. See

Process Data Objects (PDO) on page 113.

Control

word

Stat us

word

6042h

Ta rg et

1)

velocity

6044h

vl control

1)

effort

2000h03

Reference

1)

1)

2

2000h06

Actual value

1)

1)

2

4001h23

Par. 0135

COMM

VAL UE 1

4001h06

Par. 0106

POWER

64 bits

2)

64 bits

2)

Page 62

62 Start-up

Note: The settings of the PDOs can be changed with CANopen

objects 14xxh, 16xxh, 18xxh and 1Axxh. The communication

parameter settings of CANopen objects 14xxh and 18xxh are valid

only to the next boot-up unless they are stored to the non-volatile

memory.

The ACS355 parameters and recommended parameter settings

for the CANopen fieldbus communication are listed in the following

table.

Drive parameter Setting for ACS355

9802 COMM PROT SEL 4 = EXT FBA Activates the communication

5101 FBA TYPE 32 (= CANopen)

5102 FBA PAR 2

(NODE ID)

5103 FBA PAR 3

(BIT RATE)

5104 FBA PAR 4

(CONF LOC)

5105 FBA PAR 5

(PROFILE)

3018 COMM FAULT

FUNC

3019 COMM FAULT

TIME

5107 FBA PAR 7

(RPDO1-COB-ID)

5108 FBA PAR 8

(RPDO1-TR TYPE)

5110 FBA PAR 10

(TPDO1-COB-ID)

drives

2)

3

2 (= 250 kbit/s)2) Bit rate used on the CANopen

1 (= Parameters) PDO configuration is done with

1 (= ABB Drives) ABB Drives profile mode (that is,

1 = FAULT Sets the fieldbus communication

3.0 s Fieldbus communication loss

1 (= Default) Rx PDO1 is enabled and

2552) Asynchronous transmission

1 (= Default) Tx PDO1 is enabled and

Description

(fieldbus) module.

1)

Communication module type

Adapter module node ID

network

FCAN-01 configuration

parameters, that is, ACS355

parameter groups 51, 55 and

54.

communication profile used by

the module)

loss functionality.

supervision time-out

configured to use the default

COB-ID.

mode is used by Rx PDO1.

configured to use the default

COB-ID.

Page 63

Start-up 63

Drive parameter Setting for ACS355

5111 FBA PAR 11

(TPDO1-TR TYPE)

5112 FBA PAR 12

(TPDO1-EV TIME)

drives

255 Asynchronous transmission

2)

100

5401 FBA DATA IN 1 5 (= Act1 16bit ) Actual value 1 as mapping

5402 FBA DATA IN 2 6 (= Act2 16bit ) Actual value 2 as mapping

5403 FBA DATA IN 3 106 Signal 106 POWER as mapping

5501 FBA DATA OUT 1 2 (= Ref1 16bi t) Reference 1 as mapping entry 2

5502 FBA DATA OUT 2 3 (= Ref2 16bi t) Reference 2 as mapping entry 3

5503 FBA DATA OUT 3 135 Signal 135 COMM VALUE 1 as

5127 FBA PAR

REFRESH

9904 MOTOR CTRL

MODE

1001 EXT1

COMMANDS

1002 EXT2

COMMANDS

1 = REFRESH Activates the fieldbus

2 = VECTOR: TORQ Selects the motor control mode.

10 = COMM Communication module as the

10 = COMM Communication module as the

1102 EXT1/EXT2 SEL 8 = COMM Communication module as the

1103 REF1 SELECT 8 = COMM Communication module as the

1106 REF2 SELECT 8 = COMM Communication module as the

Description

mode is used by Tx PDO1.

Transmission is triggered by the

event time.

Event time, that is, event time

elapses every 100 ms.

entry 2 in Tx PDO1

entry 3 in Tx PDO1

entry 4 in Tx PDO1

in Rx PDO1

in Rx PDO1

mapping entry 4 in Rx PDO1

configuration parameter

settings.

source for the start, stop and

direction commands in EXT1

mode

source for the start, stop and

direction commands in EXT2

mode

source for the control location

selection

source for reference 1

source for reference 2

Page 64

64 Start-up

Drive parameter Setting for ACS355

1601 RUN ENABLE 7 = COMM Communication module as the

1604 FAULT RESET

SEL

1)

Automatically detected

2)

Example

The start sequence for the parameter example above is given

below.

drives

8 = COMM Communication module as the

Description

source for the Run enable signal

source for the fault reset signal

Control word:

• Reset the fieldbus communication fault (if active).

• 47Eh (1150 decimal) –> READY TO SWITCH ON

• 47Fh (1151 decimal) –> OPERATING (Speed mode)

or

C7Fh (3199 decimal) –> OPERATING (Torque mode)

Starting up ACSM1 drives

1. Power up the drive.

2. Enable the communication between the adapter module and

the drive by setting parameter 50.01 FBA ENABLE to

ENABLE.

3. With parameter 50.02 COMM LOSS FUNC, select how the

drive reacts to a fieldbus communication break.

Note: This function monitors both communication between the

fieldbus master and adapter module and communication

between the adapter module and drive.

4. With parameter 50.03 COMM LOSS T OUT, define the time

between communication break detection and the selected

action.

Page 65

Start-up 65

5. Select application-specific values for parameters

50.04…50.11.

Examples of appropriate values are shown in the tables below.

6. Set the FCAN-01 configuration parameters in parameter group

51.

At minimum, set the required node address in parameter 51.02

NODE ID and the required bit rate in 51.03 BIT RATE, select

the source of the PDO configuration in 51.04 CONF LOC and

the communication profile in 51.05 PROFILE.

7. If group 51 is selected as the source for the PDO configuration,

select the application specific configuration for the PDOs with

parameters 51.07…51.24.

8. If group 51 is selected as the source for the PDO configuration,

define the process data transferred to and from the drive in the

FCAN-01 configuration parameter groups 52 and 53.

Note: If the PDO configuration is written from the PLC,

parameters 51.07…51.24 are not used and the parameter

groups 52 and 53 display the process data selected in the

PLC.

9. To validate the settings made in parameter groups 51, 52 and

53, set parameter 51.27 FBA PAR REFRESH to REFRESH.

10. Set the relevant drive control parameters to control the drive

according to the application.

See the parameter setting examples below.

Page 66

66 Start-up

Drive parameter Example setting

60.05 POS UNIT (Position unit) m

60.08 POS2INT SCALE 100

1000 / 100 = 10.00 m

60.05 POS UNIT

Physical value

60.08 POS2INT SCALE

Set point value

Parameter setting examples – ACSM1

Using position control with the CiA 402 Profile Position mode

This example shows how to configure a basic positioning

application for an ACSM1 motion control drive. The start/stop

commands and reference are according to the CiA 402 Profile

Position mode.

The parameter setting example results in the following PDO

configuration.

Note: Rx PDO1 and Tx PDO1 are enabled by default.

PDO Word 1 Word 2, 3 Length

Rx PDO1 6040h

Tx PDO1 6041h

Control word

Stat us wor d

The target position and actual value are defined as 32-bit integer

values; both are scaled as defined by drive parameter settings.

The target position (reference) and the position actual value are

scaled as follows:

607Ah

Target position

6064h

Position actual

value

48 bits

48 bits

Page 67

Start-up 67

The ACSM1 parameters and recommended parameter settings for

the CANopen fieldbus communication are listed in the following

table.

Drive parameter Setting for ACSM1