ABB EXGP Installation Manual

ABB Instrumentation

EXGP

Oxygen Analyzer System

Installation Guide

EXGP Probe

ABB INSTRUMENTATION

✶

Note.

Clarification of an instruction or additional information.

Information.

Further reference for more detailed information or

technical details.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage,

it must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded

process system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual

for any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of

Technical Communications Department, ABB Instrumentation.

The Company

ABB Instrumentation is an established world force in the design and manufacture of

instrumentation for industrial process control, flow measurement, gas and liquid analysis and

environmental applications.

As a part of ABB, a world leader in process automation technology, we offer customers

application expertise, service and support worldwide.

We are committed to teamwork, high quality manufacturing, advanced technology and

unrivalled service and support.

The quality , accuracy and performance of the Company’s products result from over 100 years

experience, combined with a continuous program of innovative design and development to

incorporate the latest technology.

The NAMAS Calibration Laboratory No. 0255 is just one of the ten flow calibration plants

operated by the Company, and is indicative of ABB Instrumentation’s dedication to quality

and accuracy.

BS EN ISO 9001

St Neots, U.K. – Cert. No. Q5907

Stonehouse, U.K. – Cert. No. FM 21106

EN 29001 (ISO 9001)

Lenno, Italy – Cert. No. 9/90A

Use of Instructions

Warning.

An instruction that draws attention to the risk of injury or

death.

Caution.

An instruction that draws attention to the risk of damage to

the product, process or surroundings.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the

information given.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when operating in conditions of high pressure

and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures

must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data sheets (where applicable) may be

obtained from the Company address on the back cover, together with servicing and spares information.

0255

R

E

G

I

S

T

E

R

E

D

Stonehouse, U.K.

1

CONTENTS

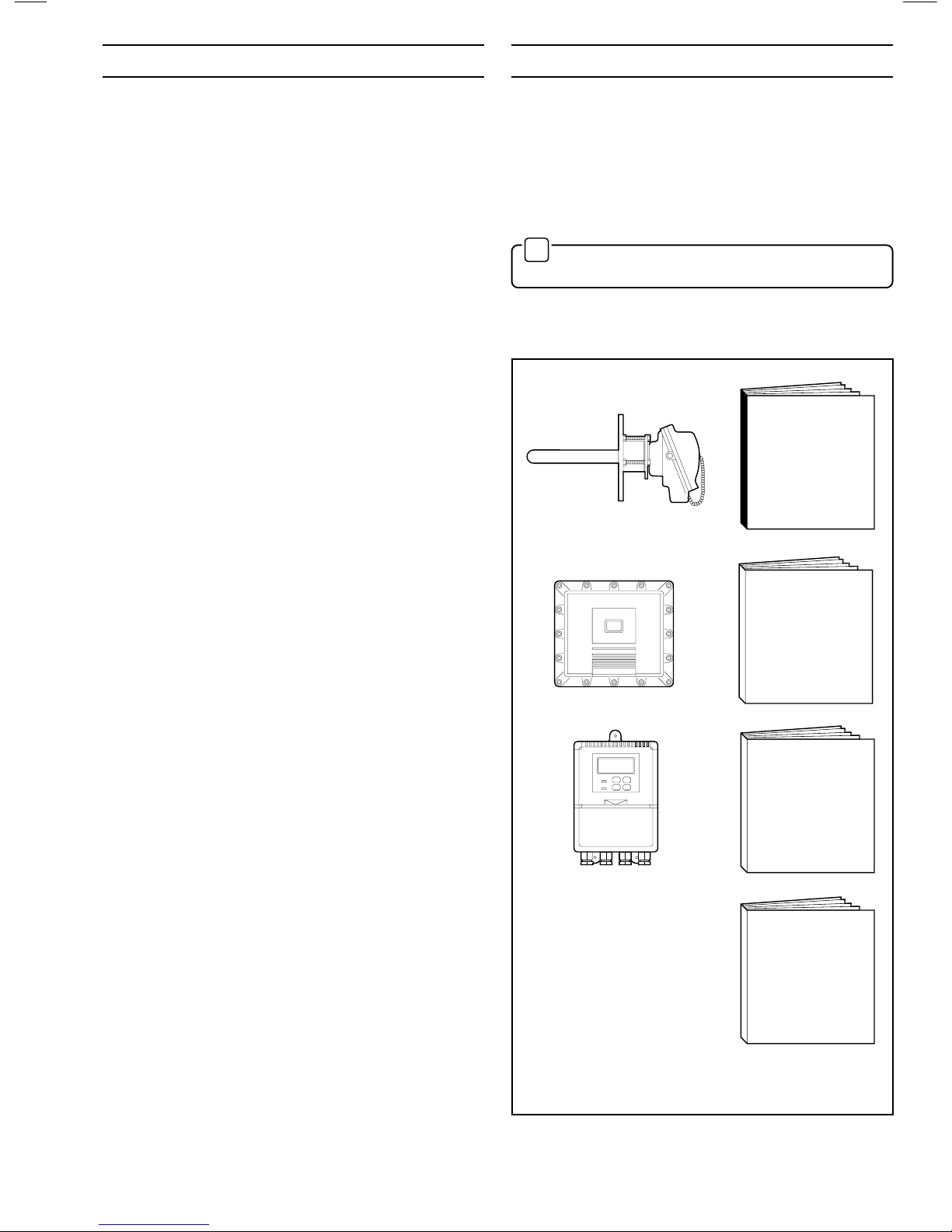

1.1 Documentation – Fig. 1.1

Documentation for the EXGP Oxygen Analyzer System is

shown in Fig. 1.1.

1.2 Certification

The EXGP Probe is classed as a 'Simple Apparatus' and may

therefore be installed in Zone 1 Hazardous Areas as an

intrinsically safe product.

✶

Note. A 'Simple Apparatus' is a device that does not

generate more than 1.2V, 0.1A, 20mJ and 25mW.

Documented evidence confirming the compliance of EXGP

Probes is available and is endorsed by BASEEFA.

Fig. 1.1 System Documentation

SPECIFICATION SHEET

Full Specification■

Part No.

SS/EXGP

PROBE

■

■

■

■

Part No.

IM/EXGP–PB

Product Identification

Mechanical Installation

Connections

Fault Finding

INTERFACE UNIT

Certification

Product Identification

Mechanical Installation

Electrical Installation

■

■

■

■

Part No.

IM/EXGP–INT

TRANSMITTER

Product Identification

Mechanical Installation

Electrical Connections

Controls & Displays

Operation

Programming

■

■

■

■

■

■

Part No.

IM/EXGP–4600

1 INTRODUCTION

1 INTRODUCTION ..........................................................1

1.1 Documentation ..................................................1

1.2 Certification .......................................................1

1.3 System Hardware..............................................2

2 PREPARATION ............................................................4

2.1 Unpacking .........................................................4

2.2 Checking the Code Number..............................4

2.3 Assembling the Probe .......................................5

3 INSTALLATION............................................................6

3.1 Siting..................................................................6

3.2 Mounting............................................................7

3.2.1 Mounting Configurations ..................... 8

4 CONNECTIONS ...........................................................9

4.1 Cable and Gland Specifications........................9

4.2 Access to Electrical Connections......................9

4.3 Electrical Connections ......................................9

4.4 Reference Air Connection .................................9

4.5 Routine Maintenance ........................................9

5 FAULT FINDING.........................................................10

5.1 In Situ Checking Using a Test Gas .................10

5.2 Comparison with Another O2 Probe ...............10

5.3 Returning the Probe

to the Manufacturer for Checking ...................10

5.4 Continuity Check .............................................10

APPENDIX...........................................................................11

A1 Principles of Operation....................................11

A2 Range of Operation.........................................11

2

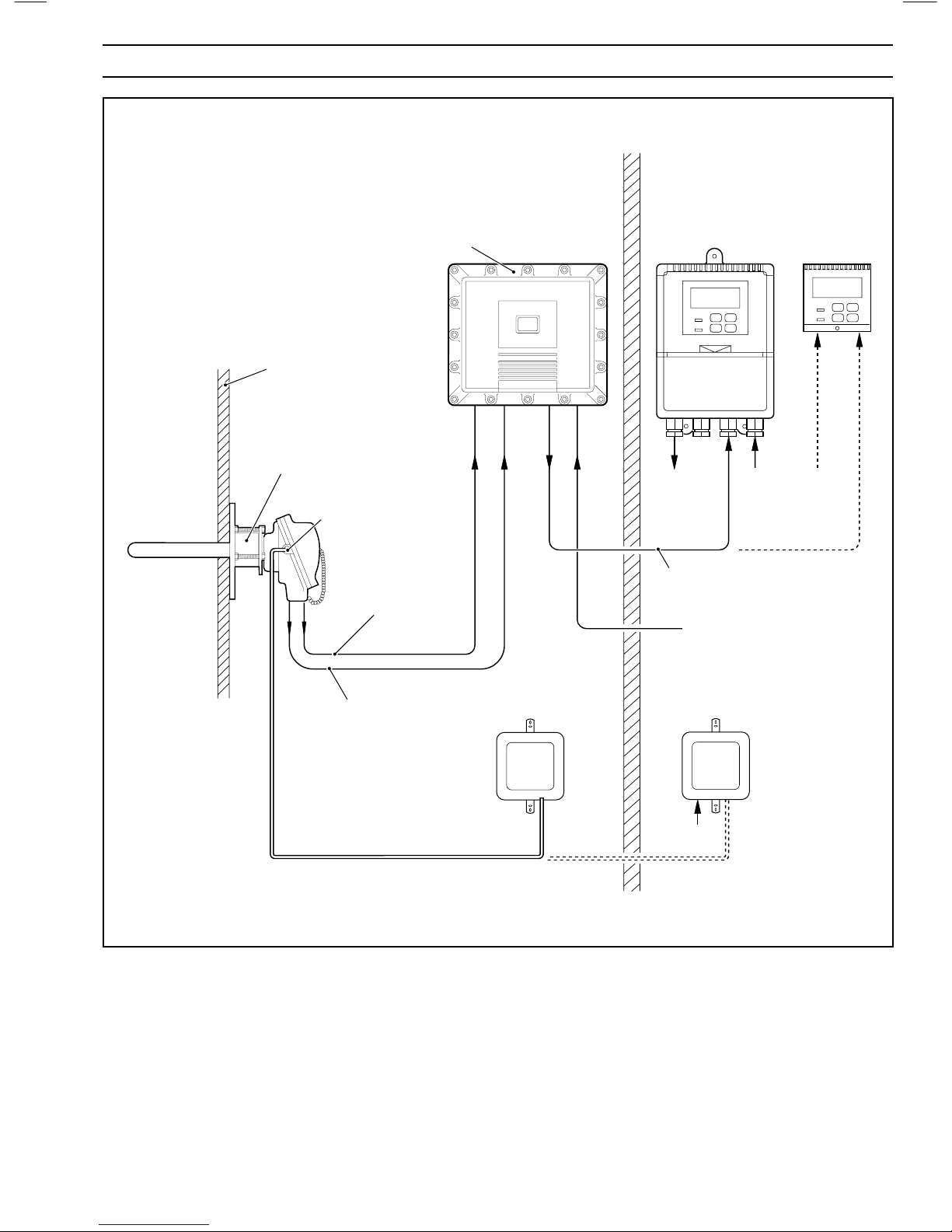

1.3 System Hardware – Fig. 1.2

The EXGP Oxygen Probe is an 'in situ' method of measuring

oxygen concentration designed for use in hazardous areas

(Zone 1). When used in conjunction with the EXGP Interface

Electronics Unit (also Zone 1 Certified), it enables signals to be

retransmitted up to 1km into a safe area.

The oxygen probe provides a mV signal that relates directly to

oxygen concentration in the range 0.25 to 25% O

2

, over a

process temperature range of 600°C to 1250°C. An integral 'R'

type thermocouple provides accurate continuous

measurement of the process temperature.

A calibration gas inlet port is provided to enable the probe to be

checked using test gas mixtures without removing it from the

process.

Reference air supplied at a rate of 100 to 1000cm

3

/hr (0.2 to

2ft

3

/hr) is required for accurate operation and can be provided

by a pump or regulator unit – see Fig. 1.2.

…1 INTRODUCTION

3

Mains Powered Pump

Unit (003000240)

NON HAZARDOUS AREAHAZARDOUS AREA

(Zone 1, Class IIB)

Process

600°C to 1400°C

(1250°C

continuous)

EXGP Probe

Simple Device Conforming

to BS5345 Part 4: 1977

Mains Supply

R Type Thermocouple

mV Signal

(0 to 1400°C)

Two 4 to 20mA Output Signals

(0 to 1400°C and 0.25 to 25%O2)

or

4680 Transmitter

Mains Supply

Flameproof Interface Electronics Unit

EExd. IIB T6 Conforming to BS5501 Part 5: 1977

Flue

4685 Transmitter

Retransmission

Output

Reference Air Line Entry

Regulated Reference Air

Unit (003000241)

Mains Supply

O2 mV Signal

(–20 to +180mV)

or

or

1 INTRODUCTION

Fig. 1.2 System Schematic

Loading...

Loading...