Electronic

7

Safety relays

Personnel safety and machine protection

Risk category according to EN 954-1

Classifi cation of a machine into categories to EN 954-1

Pursuant to the Machinery Directive 89/393/EEC, every machine must

comply with the relevant directives and standards. Measures must be taken to

keep the risk to persons below a tolerable extent.

In the fi rst step, the project planner performs a risk evaluation to

EN 1050 "Risk Assessment". This must take into consideration the machine's

ambient conditions for instance. Any overall risk must then be assessed. This risk

assessment must be conducted in such a form as to allow documentation of the

procedure and the results achieved. The risks, dangers and possible technical

measures to reduce risks and dangers must be stipulated in this risk assessment.

After stipulating the extent of the risk, the category on the basis of which the safety

circuits are to be designed is determined with the aid of EN 954-1 “Safety-Related

Components of Controls”.

This determined category defi nes the technical requirements applicable to the

design of the safety equipment.

7

There are fi ve categories (B, 1, 2, 3 and 4), whereby B (standing for basic

category) defi nes the lowest risk and, thus, also the minimum requirements

applicable to the controller.

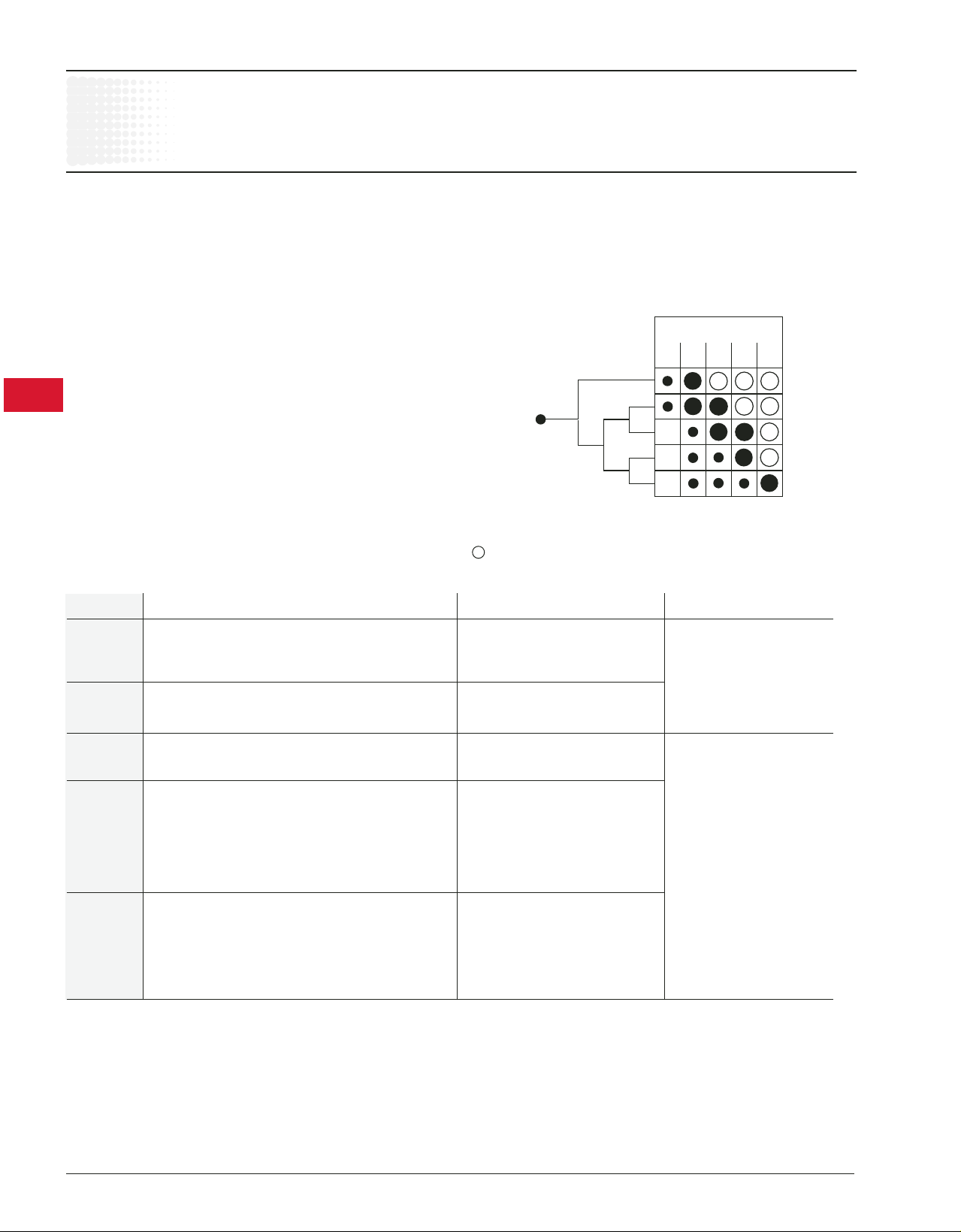

Possible selection of categories pursuant to EN 954-1

Starting point for the risk assessment of the safety-related component of the

controller.

S- Serious injuries

S1 Slight (normally reversible) injuries,

S2 Serious (normally irreversible) injuries,

including death

Safety

category 1 achieving safety

B The safety-related components of controls and/or their protection The occurrence of a fault may lead

devices and their components must be designed, constructed, to loss of the safety function.

selected, assembled and combined in compliance with the

applicable standards, such that they can withstand the anticipated Predominantly characterised

infl uences. by selection of componentsl

1 The requirements of B must be complied with. The occurrence of a fault may lead

Time-proven components and time-proven safety principles to loss of the safety function but the

must be applied. probability of occurrence is less than

in category B.

2 The requirements of B and the use of the time-proven safety principles • The occurrence of a fault may lead

must be complied with. to loss of the safety function between

The safety function must be checked at appropriate intervals the inspection intervals.

by the machine control.

• The loss of the safety function is

detected by the check/inspection.

3 The requirements of B and the use of the time-proven safety principles • If the single fault occurs, the safety

must be complied with. function is always retained.

Safety related components must be designed such that:

• a single fault in any of these components does not lead to loss • Certain faults but not all faults are

of the safety function and detected.

• the individual fault is detected, wherever feasible in an • An accumulation of undetected faults

appropriate manner. may lead to loss of the safety function.

Predominantly

characterised

4 The requirements of B and the use of the time-proven safety principles • If the faults occur, the safety function by the structure

must be complied with. is always retained.

Safety related components must be designed such that: • The faults are detected in good time to

• a single fault in any of these components does not lead to loss prevent loss of the safety function

of the safety function and

• the individual fault is detected at or before the next requirement

applicable to the safety function or, if this is not possible

an accumulation offaults may then not lead to loss of the

safety function.

This mandatory classifi cation runs likes a red thread from selection of the smallest limit switch through to the overall concept of the entire

machine, whereby it is necessary to grapple with the permanent confl ict between what is technically feasible and what is permitted on the basis

of “pure theory”.

Thus: Depending on application, not every technically feasible safety category is also permitted. For instance, in the case of contactless

protection devices (light barriers etc.) only categories 2 or 4 are permitted. By contrast, in the case of tread mats, categories B to 4 can be used,

depending on risk assessment, provided these categories can be reached at all owing to the design.

The 2-hand control C575 would technically also comply with the lower categories but it cannot be connected in categories 1-3.

Summary of requirements System behaviour 2

F- Frequency and/or duration of the risk exposure

F1 Rare to frequent and/or short duration of exposure

F1 Frequent to sustained and/or longduration of exposure

P- Options for risk avoidance

(Generally referred to the speed and frequency at which the

dangerous components moves and to the clearance from

the dangerous component).

P1 Possible under certain conditions

P2 Hardly possible

Categories

B12

S1

P1

F1

P2

S2

P1

F2

P2

B1-4 Categories for safety-related components of controls

● Preferred category

● Possible category requiring additional measures

Disproportionately extensive measures by comparison

with the risk

Principles for

3

4

1 The categories are not intended to be applied in any specifi c order or hierarchical arrangements with respect to the technical-safety requirements.

2 The risk assessment will indicate whether full or partial loss of the safety function(s) as the result of fault is acceptable.

7.38 Low Voltage Products & Systems

AC 1000 - 11/03

Selection table

Electronic

7

Safety relays

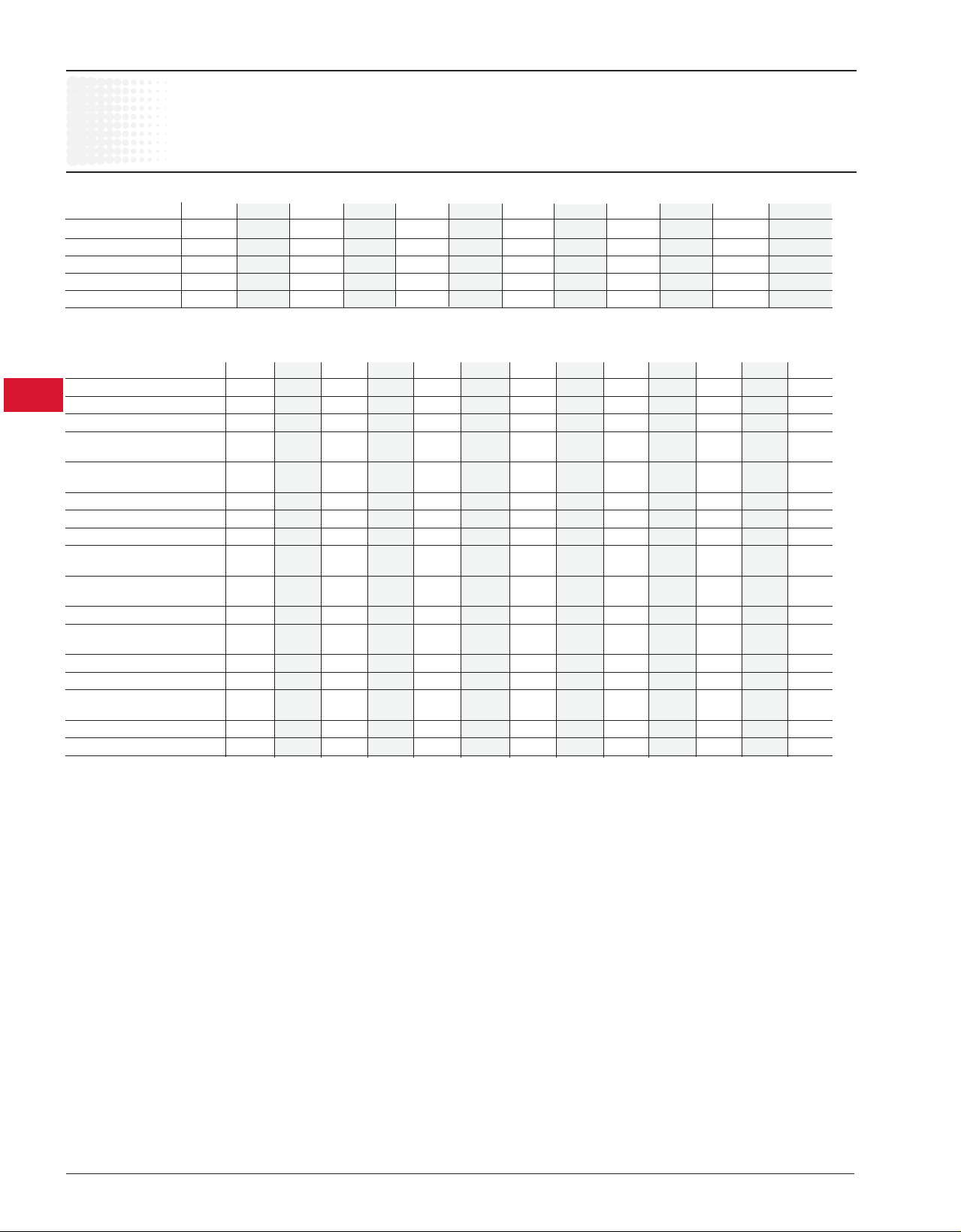

Selection table for ABB safety relays in accordance to risk category (EN 954-1):

Category C 570 C 571 C 572 C 573 C 574 C 575 C 576 C 577 C 578 C 6700 C 6701 C 6702

B

1 x x x x x x x x x x

2 x x x x x x x x x x

3 x

4 x

Selection table for ABB safety relays in accordance to device characteristics

Characteristics

suitable for device C 570 C 571 C 572 C 573 C 574 C 575 C 576 C 577 C 578 C 579 C 6700 C 6701 C 6702

EMERGENCY STOP yes yes yes yes yes — yes yes — 3 yes yes yes

7

Safety gate monitoring yes yes yes yes yes — yes yes — 3 yes yes yes

Tread mats — — — — — — — — — — — — Two-hand control — — — — — yes — — — — — — -

e.g. presses

Feedback loop for moni- yes yes yes yes yes yes yes yes — — yes yes yes

toring of external contactors

Single channel yes yes yes yes yes — — — — — yes yes yes

Two channel — yes yes yes — yes yes yes — — yes yes yes

Cross-short circuit monitoring — — yes — yes — yes yes — — — yes yes

24VDC at the EMERGENCY — — yes — — yes yes yes yes — yes yes yes

STOP limit switch

Operating voltage at the yes yes — yes yes — — — — — — — -

EMERG. STOP limit switch

No. of safety outputs 4 2 3 3 2 2 2 2 — 4 2 4 2 1

No. of time delayed — — — — 1 — — — — — — — 1

safety output contacts

No. of signalling contacts 2 — 2 1 2 2 — — — — — — 5 — 5

Enclosure width in mm 75 22.5 45 22.5 45 45 22.5 22.5 45 22.5 22.5 22.5 22.5

Monitoring overtravel — — — — — — — — yes — — —

e.g. presses

Auto-start yes yes yes yes yes — yes — — — yes yes yes

Controlled/monitored start — — yes — — — — yes — — yes yes yes

1

x x x x x x x x x

1

x x

1 x2

x x x x x x

1 Possible with additional external measures.

2 Applies only to undelayed contact. Category 3 applies to delayed contact.

3 Contact extension

4 Solid-state outputs requirements of safety in acc. to 954-1 only in combination with positively guided contactors.

5 Solid-state outputs could also be used as safe messaging outputs.

7.40 Low Voltage Products & Systems

AC 1000 - 11/03

Loading...

Loading...