Page 1

—

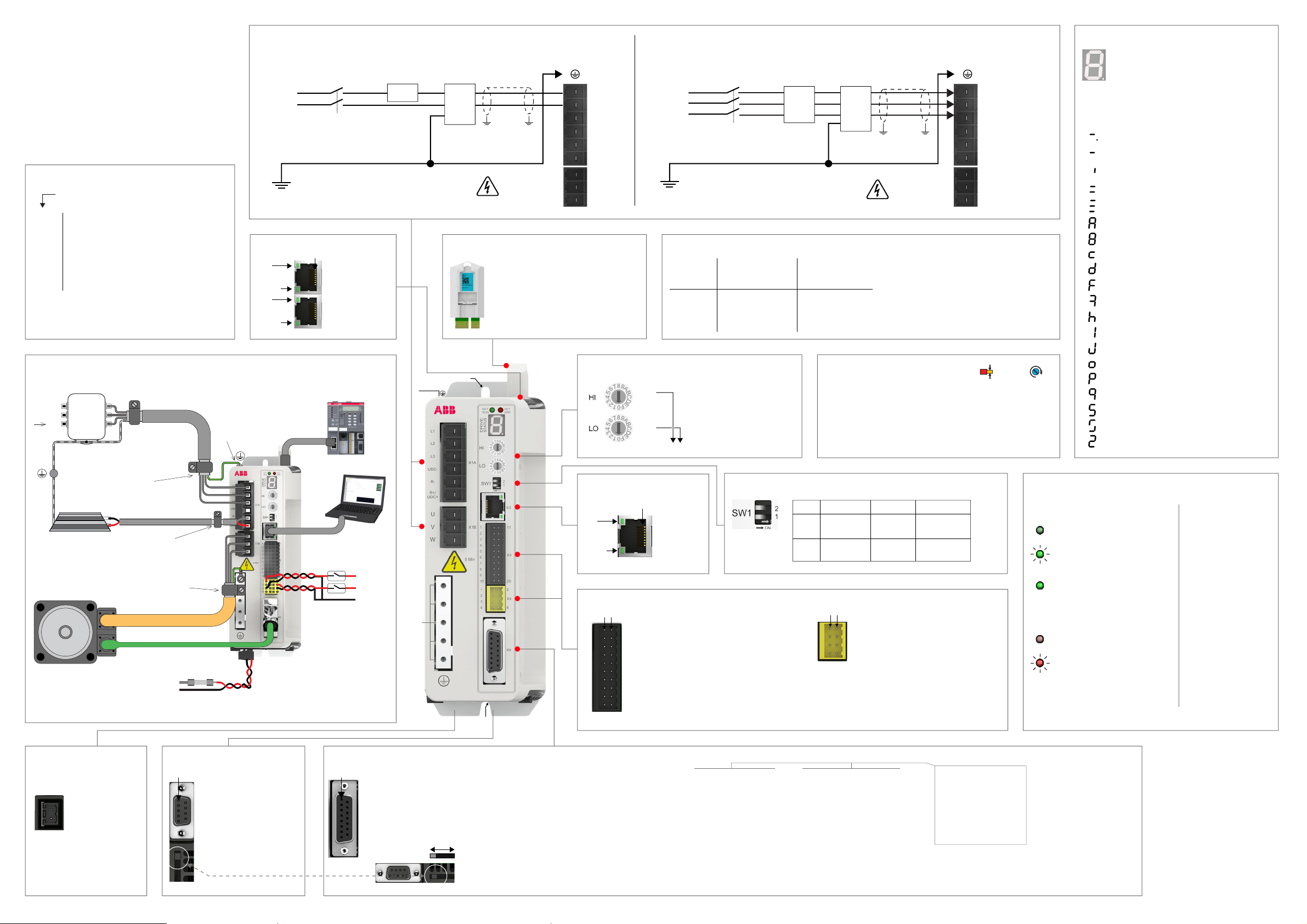

MicroFlex e190

Wall chart

ABB motion control products

Part numbers

MFE190 - 04UP - 03A0 - 2 + N8020

MFE190

Recommended system wiring

From

fuses

E190 = MicroFlex e190

04 = Construction / frame size

04

UP = Universal encoder, slave / CN, Programmable*

UP

Rated amps: 01A6 = 1.6 A, 03A0 = 3 A,

03A0

06A0 = 6 A, 09A0 = 9 A

Input voltage rating: 2 = 200...240 VAC ±10%

2

* Motion programming is enabled by fitting

memory unit MFE190-MU-OCU+N8020

(order code: 3AXD50000048603).

AC Power

L1

L1

L2

L2L1L2

Filter

L3

L3

Connect AC power

cable shield to metal

backplane using

conductive shield

clamps.

Optional regen resistor*

(Dynamic brake)

Shielded twisted pair, clamped to metal

backplane near drive using conductive

shield earth/ground clamp.

Connect motor power cable shield to earthing

strip using conductive shield clamps

Motor

Motor power U V W

Motor feedback

PE

Star

point

L3

AC power in

Regen

+24 V DC

0V

AC power PE

bonding point

provided on top

surface of drive.

2 A

fuse

Control circuit supply.

Use twisted pair cable.

X1A - Single phase 200...240 V AC ±10% input / X1B - Motor power out

AC power

supply

Line (L)

Neutral (N)

Earth/Ground together

Isolating switch

Incoming safety earth (PE)

E1 & E2 - Ethernet fieldbus

Link

Activity

Link

Activity

Pin1

Front

EtherCAT

Ethernet

Safety circuit: emergency

* Regeneration resistors:

If the application requires a

regeneration resistor, it

must have a resistance of at

least 39Ω and inductance of

less than 100 μH. ABB parts

are recommended:

RGJ139 (39Ω, 100 W)

RGJ160 (60Ω, 100 W)

RGJ260 (60Ω, 200 W)

RGJ360 (60Ω, 300 W)

1 TX+

E2

2 TX-

IN

3 RX+

4 (NC)

5 (NC)

6 RX-

E1

7 (NC)

OUT

8 (NC)

EtherCAT

master

Host PC

stop switch, relay etc.

+24 V STO1

+24 V STO2

0 V

STAR POINT

Mains filterFuseRoute L, N, and

Overall screened

WARNING

Memory unit

Screw:

M4 × 8 mm

Screws: M4 × 8 mm max.

Ø M5

Ø M5

PE

(top panel screw)

IPN+E

Hazardous

voltages on

X1A and X1B!

Stores firmware, parameters and Mint programs,

and defines drive features:

3AXD50000048603: MFE190-MU-OCU+N8020

CAUTION!

Do not insert or remove the memory unit while

the drive is powered.

X1A - Three phase 200...240 V AC ±10% input / X1B - Motor power out

L1

L2

L3

UDC-

R-

R+/UDC+

U

V

W

AC power

supply

Line (L1)

Line (L2)

Line (L3)

Earth/Ground together

Isolating switch

Incoming safety earth (PE)

Recommended power filters

Drive

continuous

current rating

1.6 A

3 A

6 A

9 A

1Ø AC power

ABB catalog

OFI-01 / OFI-02

OFI-01 / OFI-02

Ethernet fieldbus port configuration

HI

LO

Example: 0 0 = EtherCAT slave mode selected

E3 - Ethernet: host PC

Pin1

Link

Activity

Value Mode

00 EtherCAT slave mode

01-EF POWERLINK CN mode:

selected value is node ID

F0-FF Reserved

SW1 - DIP switches

1 TX+

2 TX-

3 RX+

4 (NC)

5 (NC)

6 RX-

7 (NC)

8 (NC)

X3 - Input / output

Pin 11Pin 1

1 Status- / DO0- 11 Status+ / DO0+

2 DO2- 12 DO2+

3 DO1- 13 DO1+

4 DI2- 14 DI2+

5 DI3- 15 DI3+

6 DI1- 16 DI1+

7 DI0- 17 DI0+

8 AGND 18 AO0

9 AI0- 19 AI0+

10 Shield 20 Shield

number

OFI-01

OFI-01

Fuses

STAR POINT

Mains filterRoute L1, L2, L3 and

Overall screened

IPN+E

(top panel screw)

Hazardous

voltages on

X1A and X1B!

WARNING

3Ø AC power

ABB catalog

number

OFI-03

OFI-03

JFI-02

JFI-02

IMPORTANT!

Compliant with EN61000-6-3 (Class B).

Foot-mount filter OFI-01 is designed for use

with any single-phase MicroFlex e190.

Mating connectors

X1A Dinkle EC762V-B3253206P-BK 0.2-6.0 / 30*-10 0.7 / 6.2

X1B Dinkle EC762V-B3253203P-BK 0.2-6.0 / 30*-10 0.7 / 6.2

X2 Phoenix MVSTBR 2,5HC/ 2-ST-5,08 0.2-2.5 / 24-12 0.6 / 5.3

X3 Weidmüller B2L 3.50/20/180 0.2-1.0 / 28-16 -/X3 Weidmüller B2L 3.50/8/180 0.2-1.0 / 28-16 -/-

* Minimum size for UL installations is 14 AWG.

Switch Purpose OFF ON

2 Firmware Normal Recovery

recovery operation mode

mode

1 Fix IP address Normal IP Fixed IP address

for host port configuration 192.168.0.1

X4 - Safe Torque Off (STO)

Pin 5Pin 1

1 STO1 5 STO1

2 STO2 6 STO2

3 SGND 7 SGND

4 24V out 8 24V out

The 24 V output is for

powering the STO inputs only.

See user manual for wiring.

PE

L1 AC Phase 1

L2 AC Phase 2

L3 AC Phase 3

UDC- DC -

R- Regen-

R+/UDC+ Regen+/DC+

U Motor U out

V Motor V out

W Motor W out

2

/ AWG N·m / lbf·in

mm

Drive status LED

The drive status display indicates general

MicroFlex e190 status information. When an error

occurs, the drive displays a sequence starting with

the symbol E, followed by the five digit error code.

If the initial symbol is b, call technical support.

The decimal point to the right of the number illuminates to

indicate that STO is activated (no torque). For a complete list

of error codes open Mint WorkBench, press F1, and locate

the error handling topics.

Drive disabled, and one or both STO inputs

are not powered

Drive disabled

Initialization error (check memory unit insertion) or

recovery mode.

Suspend active

Firmware loading

Hold To Analog (HTA) mode

Drive enabled, but idle

Cam move

Dwell

Flying shear

Follow move

Homing

Incremental move

Jog move

Offset move

Position move

Torque move

Stop input active

Velocity reference move

Spline move

Fieldbus status LEDs

NET RUN EtherCAT®

Off: INITIALISATION state

Blinking: PRE-OPERATIONAL state

1 flash: SAFE-OPERATIONAL state

2 flashes: 3 flashes: Device identification

Flickering: -

Continuous: OPERATIONAL state.

NET ERR EtherCAT®

Off: No errors or not powered.

Blinking: Invalid configuration

1 flash: Unhandled error. See

2 flashes: Sync manager watchdog.

Continuous: OPERATIONAL state.

(or not powered)

manual 3AXD50000037326

for details.

POWERLINK®

NOT ACTIVE state

(or not powered)

STOPPED state

PRE-OP1 state

PRE-OP2 state

READY TO OPERATE state

BASIC ETHERNET state

OPERATIONAL state

POWERLINK®

No errors or not powered.

-

-

-

An error has occurred.

X2 - 24 V control circuit

backup supply

Front

1 0 V

2 +24 V DC in

(Optional) A 24 V DC supply can be

provided to maintain the controlling

electronics if AC power is lost.

Continuous current - 1 A.

X7 Encoder in / out

Pin 1

1 CHA+ 6 CHA-

2 CHB+ 7 CHB-

3 CHZ+ 8 CHZ-

4 (NC) 9 +5 V out*

5 GND

† X7 can be configured as an

input (Enc 2) or output (Enc 0).

If X7 is configured as an input,

the extra incremental encoder

input on X8 cannot be used.

†

X8 - Feedback in (Enc 0)

Pin 1

Incremental encoders

1 CHA+ 9 CHA-

2 CHB+ 10 CHB-

3 CHZ+ 11 CHZ-

4 (NC) 12 +5.5 V out*

5 Hall U- 13 DGND

6 Hall U+ 14 Hall W-

7 Hall V- 15 Hall W+

8 Hall V+

EnDat 2.1

1 Data+ 9 Data-

2 Clock+ 10 Clock-

3 (NC) 11 (NC)

4 (NC) 12 +5.5 V out*

5 Sin- 13 DGND

6 Sin+ 14 (NC)

7 Cos-

8 Cos+

* X8 pin 12 provides a 5.5 V or 8-12 V supply for feedback devices that require power. The maximum

8 V5.5 V

combined current from all encoder supplies (X8 pin 12 and X7 pin 9) is 500 mA.

WARNING! The 8-12 V supply is provided for devices on X8 that require this voltage. Move the switch

towards the rear of the drive to select 8-12 V output. Selecting the wrong voltage could damage your

feedback device.

15 (NC)

SinCos

1 (NC) 9 (NC)

2 (NC) 10 (NC)

3 (NC) 11 (NC)

4 (NC) 12 +5.5 V out*

5 Sin- 13 DGND

6 Sin+ 14 (NC)

7 Cos- 15 (NC)

8 Cos+

BiSS, SSI or EnDat 2.2

1 Data+ 9 Data-

2 Clock+ 10 Clock-

3 (NC) 11 (NC)

4 (NC) 12 +5.5 V out*

5 (NC) 13 DGND

6 (NC) 14 (NC)

7 (NC) 15 (NC)

8 (NC)

* Max. combined current from X8 pin 12 and X7 pin 9 is 500 mA

Smart Abs

1 Data+ 9 Data-

2 (NC) 10 (NC)

3 (NC) 11 (NC)

4 (NC) 12 +5.5 V out*

5 (NC) 13 DGND

6 (NC) 14 (NC)

7 (NC) 15 (NC)

8 (NC)

An extra incremental encoder can be connected simultaneously with BiSS, SSI, EnDat 2.2, or Smart Abs.

Use OPT-MF-200 in conjunction with OPT-MF-201 Resolver Adapter to allow simultaneous connection of a

Use OPT-MF-200 Encoder Breakout for easy connection of both inputs.

resolver (Enc 0) and an incremental encoder (Enc 2).

Extra incremental encoder

1 (NC) 9 (NC)

2 (NC) 10 (NC)

3 (NC) 11 (NC)

4 (NC) 12 +5.5 V out*

5 CHA- 13 DGND

6 CHA+ 14 CHZ-

7 CHB- 15 CHZ+

8 CHB+

(Enc 2)

†

Hiperface

1 Data+ 9 Data-

2 (NC) 10 (NC)

3 (NC) 11 (NC)

4 (NC) 12 +8 V out*

5 Sin- 13 DGND

6 Sin+ 14 (NC)

7 Cos- 15 (NC)

8 Cos+

†

See note for X7.

3AXD50000037323

REV C (EN)

1/2

new.abb.com

The information in this document is

subject to change without notice.

ABB assumes no responsibility for any

errors that may appear in this document.

Page 2

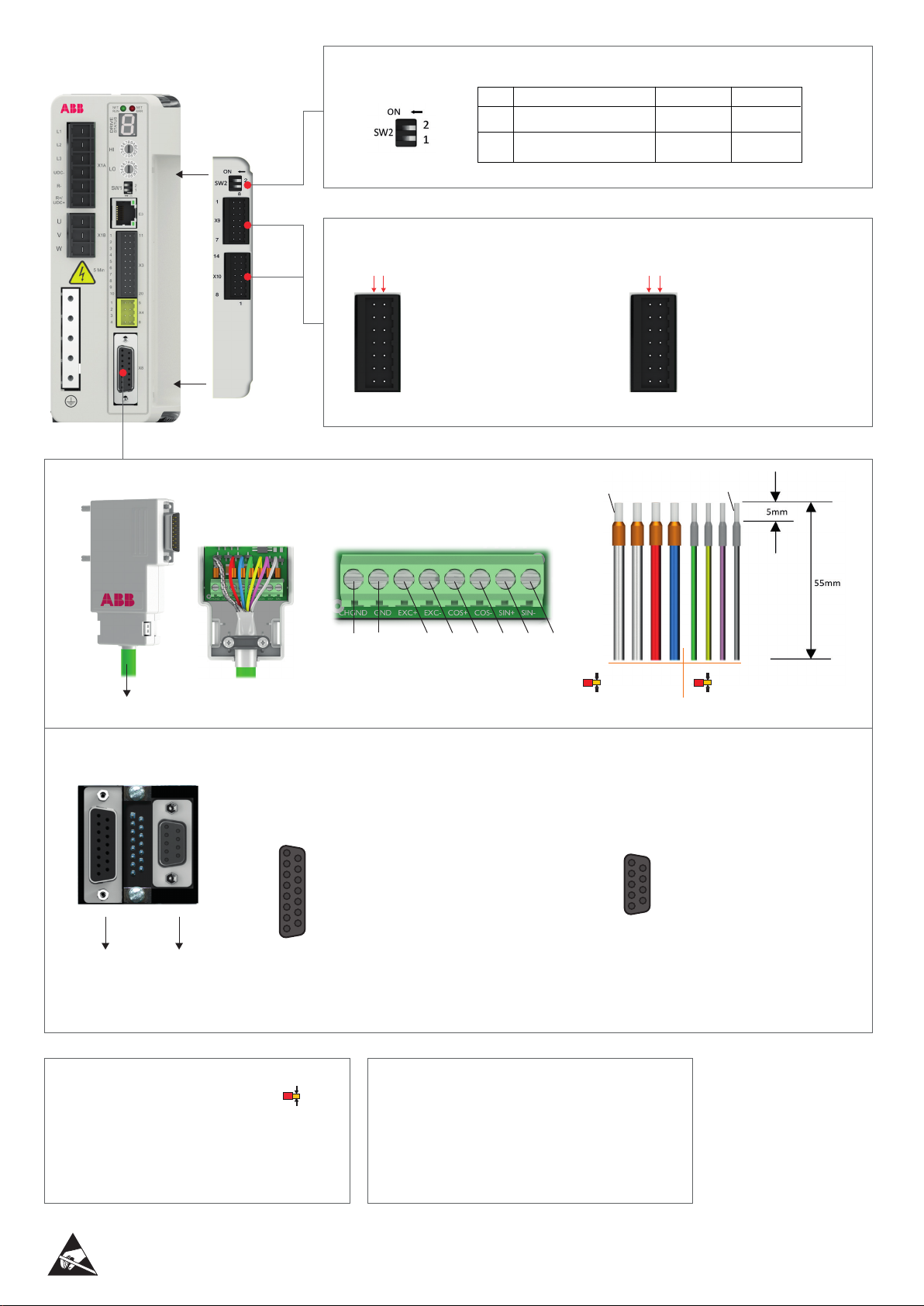

OPT-SIO-1 Option Card

MicroFlex e190 firmware build version that supports

the option card: Build 5900.4.0 and later.

SW2 - DIP switches

Switch Purpose ON OFF

2 RS422 RX terminator 120Ω No

1 RS422 TX terminator 120Ω No

or RS485 terminator

CAUTION!

Do not insert or remove the

option card while the drive is

powered.

X8 - OPT-MF-201 Resolver adapter

Resolver

Outer shield

X9 - Communication and Analog Input

Pin 8Pin 1

1 A/ TX+ 8 A/ TX+

2 B/ TX- 9 B/ TX-

3 Shield 10 Shield

4 RX+ 11 RX+

5 RX- 12 RX-

6 Shield 13 Shield

7 AIN1- 14 AIN1+

Outer shield SIN-

Inner shield

EXC+ EXC- COS+ COS- SIN+ SIN (REF+) (REF-)

X10 - Digital Input and Output

Pin 14 Pin 7

14 Shield

13 CREF1

12 DIN8

11 DIN9

10 USRV+

9 DOUT5

8 DOUT6

0.5 mm

(20AWG)

2

0.14 mm

(25AWG)

Ferrule Ferrule

7 DIN4

6 DIN5

5 DIN6

4 DIN7

3 CREF0

2 DOUT3

1 DOUT4

2

X8 - OPT-MF-200 Encoder breakout

X8A

1

2

3

4

5

X8A X8B

Motor feedback

X8A and X8B can be used together to connect a single motor

that has separate cables for encoder and Halls (e.g. a linear

motor). Use X8A for the encoder and X8B for the Halls.

Incremental

encoder

6

7

8

Mating connectors

2

mm

/ AWG

X9 X10 Weidmüller B2L 3.50/14/180

ANYTEK vw-3.50mm 14p

* Minimum size for UL installations is 14 AWG.

0.2-1.0 / 28-16

0.2-1.0 / 28-16

Incremental BiSS-B/SSI/ Smart Abs

EnDat 2.2

1 CHA+ Data+ Data+

2 CHB+ Clock+ (NC)

3 CHZ+ (NC) (NC)

4 (NC) (NC) (NC)

5 (NC) (NC) (NC)

9

10

11

12

13

14

15

6 (NC) (NC) (NC)

7 (NC) (NC) (NC)

8 (NC) (NC) (NC)

9 CHA- Data- Data10 CHB- Clock- (NC)

11 CHZ- (NC) (NC)

12 +5 V out +5 V out +5 V out

13 DGND DGND DGND

14 (NC) (NC) (NC)

15 (NC) (NC) (NC)

Shell Shield Shield Shield

X8B

1

2

3

4

5

Order Code

OPT-SIO-1 Option card

OPT-MF-200 Encoder breakout

OPT-MF-201 Resolver adapter

Recommended power filters Recommended regen resistors

OFI-01

3AXD50000046328

OFI-02

3AXD50000046327

OFI-03

3AXD50000032910

JFI-02

3ABD68711321

3AXD50000297450

3AXD50000032891

3AXD50000032892

3AXD50000032899

RGJ139

3AXD50000032900

RGJ160

3AXD50000032901

RGJ260

3AXD50000032902

RGJ360

Incremental Halls

1 CHA+ Hall U+

2 CHB+ Hall V+

3 CHZ+ Hall W+

4 (NC) (NC)

6

5 DGND DGND

7

8

6 CHA- Hall U-

9

7 CHB- Hall V8 CHZ- Hall W9 +5 V out +5 V out

Shell Shield Shield

3AXD50000037323

The information in this document is

subject to change without notice.

ABB assumes no responsibility for any

errors that may appear in this document.

REV C (EN)

2/2

new.abb.com

CAUTION

Electrical components can be damaged by static electricity. Before touching the card, be sure to discharge static electricity from your body and clothing by touching a grounded metal

surface. Alternatively, wear an earth strap while handling the card. Never work on the drive, motor cable or motor when input power is applied. To prevent equipment damage, be certain

that input and output signals are powered and referenced correctly. Do not remove the screw locks while the device is powered. See manual MicroFlex e190 for details.

Loading...

Loading...