ABB DPA Upscale RI 10, DPA Upscale RI 24, DPA Upscale RI 11, DPA Upscale RI 22, DPA Upscale RI 12 User Manual

...

DPA UPSCALE

TM

RI 10 - 80 kW

User Manual

Edition 18.06.2012

© Copyright 2015 ABB, All rights reserved.

04-3006_S0_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc

© Copyright ABB. All rights reserved.

Specification subjects to change

without notice.

Contact us

www.abb.com/ups

ups.sales@ch.abb.com

Section-0

04-3006_S0_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 2/8 ABB

Modifications reserved

GENERAL CONTENTS OF THE

Section-0

USER MANUAL DPA UPSCALE

TM

RI

0 SECTION-0:

0.1 FOREWORT

0.2 DPAUPSCALE RI SYSTEM DESCRIPTION

1 SECTION-1:

1.1 MECHANICAL CHARACTERISTICS DPA UPSCALE RI

1.2 SAFETY INSTRUCTIONS

1.2.1 GENERAL SAFETY INTRODUCTION

1.2.2 SYMBOLS, CONTROLS, AND INDICATORS

1.2.3 OPERATOR PRECAUTIONS

1.2.4 ENVIRONMENTAL CONSIDERATIONS

1.2.5 DECLARATION OF SAFETY CONFORMITY AND CE MARKING

1.2.6 INQUERIES

1.3 SYSTEM DESCRIPTION

1.3.1 GENERAL SYSTEM DESCRIPTION

1.3.2 DPA UPSCALE STTM BASIC SYSTEM CONFIGURATION

1.3.3 QUALITY STANDARDS AND UPS CLASSIFICATION CODE

1.3.4 SINGLE/PARALLEL-MODULES OPERATION

1.4 DELIVERY - TRANSPORT - STORAGE

1.4.1 INTRODUCTION

1.4.2 RECEIPT OF THE UPS AND VISUAL INSPECTION

1.4.3 UNPACKING

1.4.4 NAMEPLATE AND IDENTIFICATION

1.4.5 BATTERIES AND STORAGE

1.5 SITE PLANNING AND POSITIONING

1.5.1 PLANNING BEFORE THE INSTALLATION

1.5.2 POSITIONING OF UPS AND BATTERY CABINET

1.5.3 ASSEMBLING INSTRUCTION

1.6 ELECTRICAL INSTALLATION

1.6.1 PREPARATION FOR THE INPUT CABLING

1.6.2 INSTALLATION CHECKLIST

04-3006_S0_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 3/8 ABB

Modifications reserved

2 SECTION-2:

2.1 BLOCK DIAGRAM

2.1.1 WIRING AND BLOCK DIAGRAMS FOR ALL FRAMES AND MODULES

2.1.2 RECOMMENDED CABLE SECTIONS & FUSE RATINGS

2.1.3 BLOCK DIAGRAM DPA UPSCALE™

2.2 FRONT VIEW

2.2.1 FRONT VIEW OF DPA UPSCALE RI (RACK INDEPENDENT) ENCLOSURE

2.3 BATTERY CONNECTIONS

2.3.1 INTERNAL BATTERY MODULES

2.3.2 EXTERNAL BATTERY CABINET AND BATTERY CONNECTION

3 SECTION-3:

3.1 INTERFACING

3.1.1 CUSTOMER INTERFACE AND DRY PORTS (VOLT-FREE CONTACTS)

3.1.2 JD1 / RS232 COMPUTER INTERFACE

3.1.3 USB COMPUTER INTERFACE

Section-0

4 SECTION-4:

4.1 OPERATION

4.1.1 COMMISSIONING

4.1.2 CONTROL PANEL

4.1.3 DESCRIPTION OF THE LCD

4.1.4 OPERATING MODES

5 SECTION-5:

5.1 OPERATION–PROCEDURES

5.1.1 START-UP PROCEDURE

5.1.2 SHUTDOWN PROCEDURE

5.1.3 LOAD TRANSFER: FROM INVERTER OPERATION TO MAINTENANCE BYPASS

5.1.4 LOAD TRANSFER: FROM MAINTENANCE BYPASS TO INVERTER OPERATIONS

5.2 REPLACEMENT OF UPS-MODULE

5.2.1 REPLACEMENT OF UPS-MODULE IN SINGLE-MODULE SYSTEMS

5.2.2 REPLACEMENT OF UPS-MODULE IN REDUNDANT MULTI-MODULE SYSTEM

5.2.3 REPLACEMENT OF A MODULE IN CAPACITY MULTI-MODULE SYSTEM

04-3006_S0_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 4/8 ABB

Modifications reserved

6 SECTION-6:

6.1 MULTI-CABINET CONFIGURATION (NOT AVAILABLE)

7 SECTION-7:

7.1 MAINTENANCE

7.1.1 USER RESPONSIBILITIES

7.1.2 PREVENTATIVE MAINTENANCE

7.1.3 DEEP BATTERY TEST

7.1.4 BATTERY MAINTENANCE, DISPOSAL AND RECYCLING

8 SECTION-8:

8.1 TROUBLESHOOTING

8.1.1 ALARMS

8.1.2 MENU, COMMANDS, EVENT LOG, MEASUREMENTS,

8.1.3 FAULT IDENTIFICATION AND RECTIFICATION

Section-0

9 SECTION-9:

9.1 OPTIONS

9.1.1 INTRODUCTION

9.1.2 REMOTE SHUTDOWN (RSD)

9.1.3 GENERATOR ON FACILITIES (GEN ON)

9.1.4 WAVEMON SHUTDOWN AND MANAGEMENT SOFTWARE

9.1.5 SNMP CARD/ADAPTER FOR NETWORK MANAGEMENT /REMOTE MONITORING

04-3006_S0_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 5/8 ABB

Modifications reserved

10 SECTION-10: TECHNICAL DATA SHEET

10.1 DPA UPSCALE RI SYSTEM DESCRIPTION

10.2 TECHNICAL CHARACTERISTICS DPA UPSCALE RI

10.2.1 MECHANICAL CHARACTERISTICS DPA UPSCALE RI (RACK INDEPENDENT) SUBRACKS

10.3 INPUT CHARACTERISTICS

10.4 BATTERY CHARACTERISTICS

10.5 OUTPUT CHARACTERISTICS

10.5.1 GRAPH: AC – AC EFFICIENCY WITH LINIER LOAD @ COSPHI 1

10.5.2 GRAPH: OUTPUT POWER IN KW AND KVA VERSUS COSPHI

10.6 ENVIRONMENTAL CHARACTERISTICS

10.7 STANDARDS

10.8 COMMUNICATION

Section-0

10.8.1 POWER MANAGEMENT DISPLAY (PMD)

10.8.2 MIMIC DIAGRAM

10.8.3 DISPLAY

10.8.4 CUSTOMER INTERFACES TERMINALS X1…X2

10.8.5 CUSTOMER INPUTS DRY PORT S: TERMINAL BLOCK X2

10.8.6 CUSTOMER OUTPUTS DRY PORTS : TERMINAL BLOCKS X1

10.9 OPTIONS

10.9.1 SNMP CARD / WAVEMON MANAGEMENT SOFTWARE

10.10 BATTERY AUTONOMIES

10.10.1 EXAMPLES OF INTERNAL BATTERY AUTONOMY OF DPA UPSCALE RI 11, RI 12, RI 22, RI 24

10.11 INSTALLATION PLANNING

10.11.1 HEAT DISSIPATION PER MODULE WITH NON-LINEAR LOAD

10.12 WIRING AND BLOCK DIAGRAMS FOR ALL FRAMES AND MODULE

10.12.1 TERMINAL CONNECTIONS OVERVIEW

10.12.2 SINGLE FEED INPUT / CABLE SECTIONS

10.12.3 SINGLE FEED INPUT

10.12.4 DUAL FEED INPUT

10.12.5 DUAL FEED INPUT / CABLE SECTIONS

04-3006_S0_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 6/8 ABB

Modifications reserved

OPERATIONS INSIDE THE UPS MUST BE PERFORMED

BY A SERVICE ENGINEER FROM THE MANUFACTURER

OR FROM AN AGENT CERTIFIED BY THE

MANUFACTURER.

CAREFULLY READ THE USER MANUAL BEFORE

OPERATING OR WORKING ON THE UPS.

Section-0

0.1 FOREWORD

The UPS System operates with mains, battery or bypass power. It contains components that carry high

currents and voltages. The properly installed UPS System is grounded to earth and IP 20 rated against

electrical shock and foreign objects. Installation and service have to be done by the manufacturer’s

qualified technicians or their certified service partners.

This user manual contains guidelines to check delivery, installing and commissioning of the UPS and is

intended for people who plan the installation, install, commission and use or service the UPS. The

reader is expected to know the fundamentals of electricity, wiring, electrical components and electrical

schematic symbols

04-3006_S0_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 7/8 ABB

Modifications reserved

Section-0

0.2 DPA UPSCALE RI SYSTEM DESCRIPTION

In environments that demand zero downtime, continuous power protection availability is essential. In order to

respond to today’s dynamic IT and process-related environments that experience daily change through new server

technologies, migration and centralization, resilient and easily adaptable power protection concepts are required.

DPA UPScale is the foundation for continuous power protection availability of network-critical infrastructures in

enterprise data centers where business continuity has paramount importance and in process control environment

where manufacturing continuity is essential.

DPA UPScale’s is a third generation high-power-density (HPD), leading-edge double-conversion power protection

technology that has standardized on a modular component approach which helps speed deployment, improve

adaptability and increase system availability while reducing total cost of ownership.

DPA UPScale’s is a unique on-demand architecture that integrates the power rack, power distribution unit, back-up

battery rack and monitoring and management solutions to allow easy selection of optimized configurations.

DPA UPScale’s (Distributed Parallel Architecture) provides highest availability, unmatched flexibility and at the

same time lowest cost of ownership in IT environments.

This Technical Specification provides detailed technical information on the mechanical, electrical and

environmental performance of the DPA UPScale model types that can support to give answers to tender and enduser requirements. The DPA UPScale family was designed to respond to the most stringent safety, EMC and other

important UPS standards. DPA UPScale family is offered in two types of solutions:

DPA UPScale RI is a rack independent modular design offering 7-types of Rack Independent Subracks. Those can

accommodate DPA UPScale Rack based Modules for a wide range of power requirements:

DPA UPScale RI (rack independent) Subracks: DPA UPScale Modules types:

DPA UPScale RI 10 (20kW) UPScale M 10 (kW)

DPA UPScale RI 11 (20kW) UPScale M 20 (kW)

DPA UPScale RI 12 (20kW)

DPA UPScale RI 20 (40kW)

DPA UPScale RI 22 (40kW)

DPA UPScale RI 24 (40kW)

DPA UPScale RI 40 (80kW)

Key Features of DPA UPScale RI:

Highest Availability Near-zero down time

Modular, Decentralized Parallel Architecture (DPA)

High Power Density (up to 122kW / m2), Space-saving of expensive floor space

Small Footprint

Unity Output Power Factor No de-rating for loads with Unity PF

Full power for loads with unity PF

Highest Efficiency even with partial loads Energy cost saving during UPS-life-cycle

Efficiency = 94.5 - 95.5% for loads 25-100%

(depending on Module power and type of load)

Very low input current distortion THDi Gen-set power and installation cost saving

THDi = < 3@ 100 % load

04-3006_S0_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 8/8 ABB

Modifications reserved

CONTENTS SECTION-1

1.1 MECHANICAL CHARACTERISTICS DPA UPSCALE RI ................................................................. 2

1.2 SAFETY INSTRUCTIONS ................................................................................................................... 4

1.2.1 GENERAL SAFETY INTRODUCTION ........................................................................................ 4

1.2.2 SYMBOLS, CONTROLS, AND INDICATORS ............................................................................ 4

1.2.3 OPERATOR PRECAUTIONS ...................................................................................................... 5

1.2.4 ENVIRONMENTAL CONSIDERATIONS .................................................................................... 6

1.2.5 DECLARATION OF SAFETY CONFORMITY AND CE MARKING ............................................ 6

1.2.6 INQUIRIES ................................................................................................................................... 6

1.3 SYSTEM DESCRIPTION .................................................................................................................... 7

1.3.1 GENERAL SYSTEM DESCRIPTION .......................................................................................... 7

1.3.1.1 Feature : Unique “Safe-Swappable” Modules ..................................................................... 7

1.3.1.2 Feature : Advanced-Booster Technology ............................................................................ 7

1.3.1.3 Feature : Flexible Battery Management (FBM) ................................................................... 8

1.3.1.4 Feature : DPA Technology - Decentralized Parallel Architecture ....................................... 8

1.3.2 DPA UPSCALE™ RI BASIC SYSTEM CONFIGURATION ....................................................... 9

1.3.3 QUALITY STANDARDS AND UPS CLASSIFICATION CODE ................................................... 9

1.3.4 SINGLE/PARALLEL-MODULES OPERATION ......................................................................... 10

1.4 DELIVERY - TRANSPORT - STORAGE .......................................................................................... 11

1.4.1 INTRODUCTION ....................................................................................................................... 11

1.4.2 RECEIPT OF THE UPS AND VISUAL INSPECTION ............................................................... 11

1.4.3 UNPACKING .............................................................................................................................. 12

1.4.4 NAMEPLATE AND IDENTIFICATION ....................................................................................... 13

1.4.5 BATTERIES AND STORAGE .................................................................................................... 13

1.4.5.1 Storage of battery .............................................................................................................. 14

1.4.5.2 Storage of UPS .................................................................................................................. 14

1.5 SITE PLANNING AND POSITIONING ............................................................................................. 15

1.5.1 PLANNING BEFORE THE INSTALLATION .............................................................................. 15

1.5.2 POSITIONING OF UPS AND BATTERY CABINET .................................................................. 15

1.5.2.1 Final Transport ................................................................................................................... 15

1.5.2.2 Positioning ......................................................................................................................... 16

1.5.3 ASSEMBLING INSTRUCTIONS ............................................................................................... 17

1.5.3.1 Table of Weight .................................................................................................................. 17

1.5.3.2 Mechanical Drawing, Assembling and accessories DPA UPScale RI 10 ......................... 18

1.5.3.3 Mechanical Drawing, Assembling and accessories DPA UPScale RI 11 ......................... 22

1.5.3.4 Mechanical Drawing, Assembling and accessories DPA UPScale RI 12 ......................... 26

1.5.3.5 Mechanical Drawing, Assembling and accessories DPA UPScale RI 20 ......................... 30

1.5.3.6 Mechanical Drawing, Assembling and accessories DPA UPScale RI 22 ......................... 34

1.5.3.7 Mechanical Drawing, Assembling and accessories DPA UPScale RI 24 ......................... 38

1.5.3.8 Mechanical Drawing, Assembling and accessories DPA UPScale RI 40 ......................... 42

1.5.3.9 Air cooling flow DPA UPScale RI ....................................................................................... 46

1.6 ELECTRICAL INSTALLATION......................................................................................................... 48

1.6.1 PREPARATION FOR THE INPUT CABLING ........................................................................... 49

1.6.1.1 Mains supply and Earth connection ................................................................................... 49

1.6.1.2 Single Input Feed ............................................................................................................... 50

1.6.1.3 Dual Input Feed ................................................................................................................. 50

1.6.1.4 Preparation for the Output Cabling .................................................................................... 50

1.6.1.5 Connection of the Load ...................................................................................................... 51

1.6.2 INSTALLATION CHECKLIST .................................................................................................... 52

Section-1

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 1/52 ABB

Modifications reserved

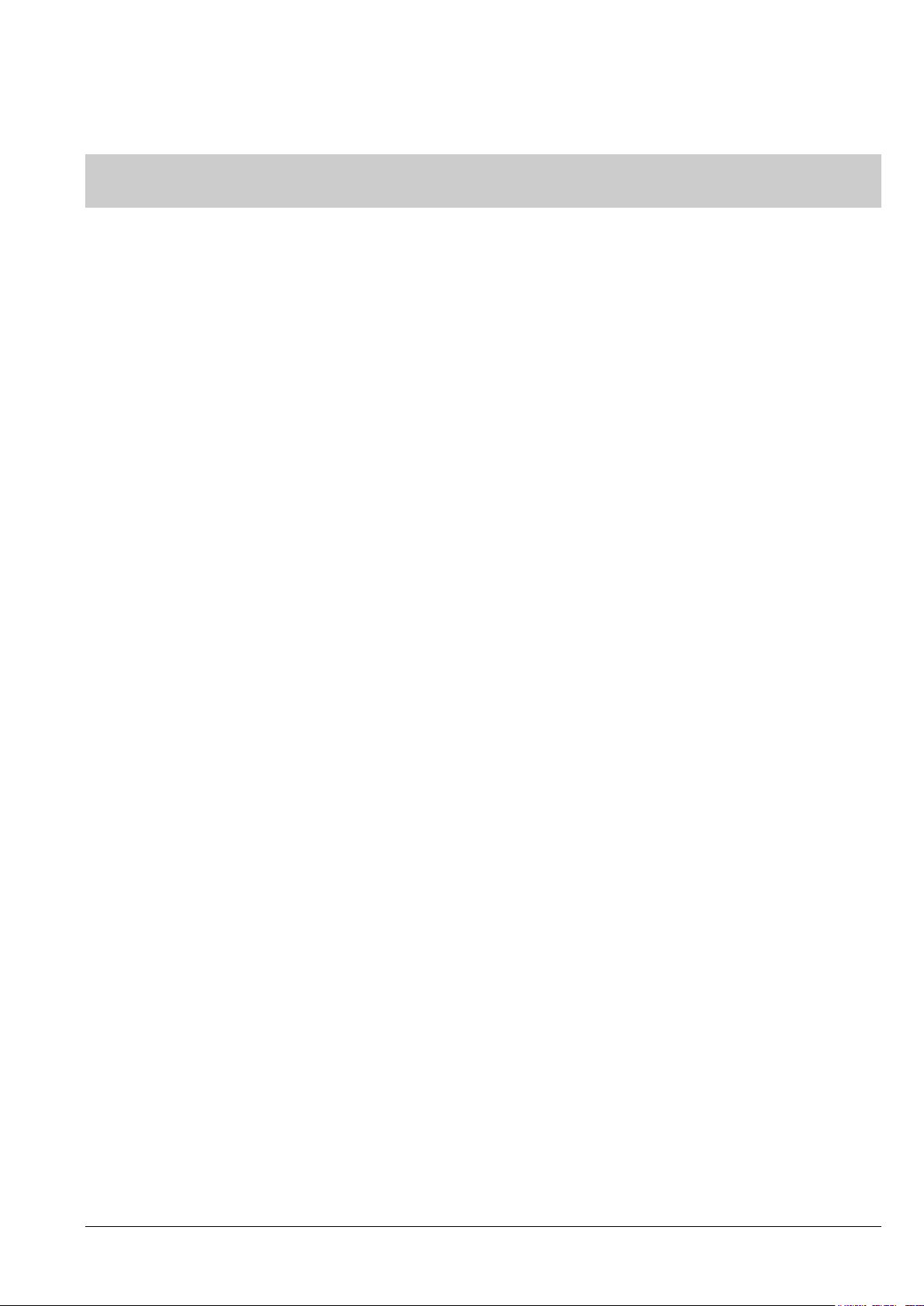

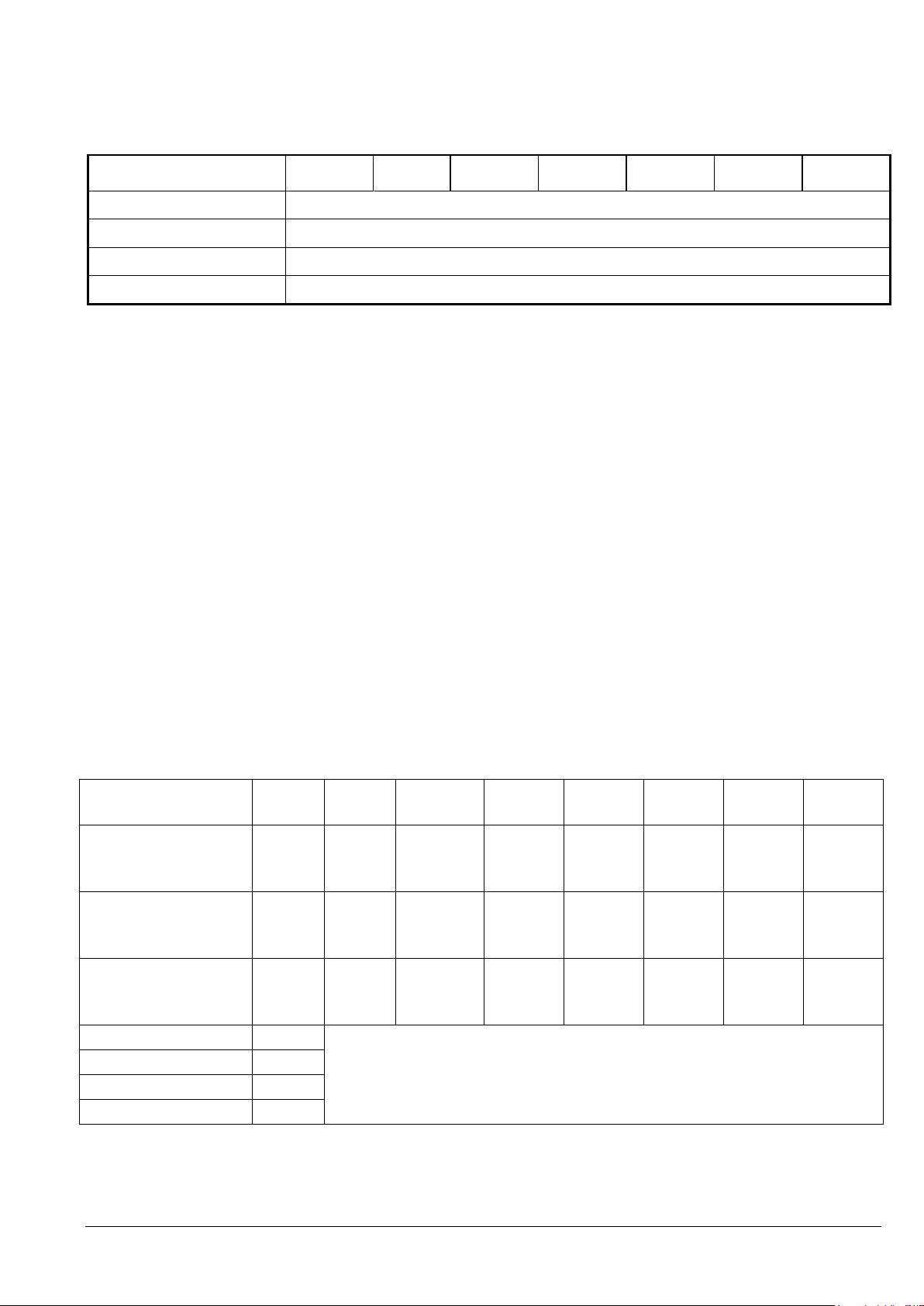

DPA UPScale RI

unit

UPScale RI 10

UPScale RI 11

UPScale RI 12

DPA UPScale RI Subrack

Configuration

accommodates:

Max.

1 module (10 or 20kW)

1 module (10 or 20kW)

with 40 x 7/9Ah batteries

1 module (10 or 20kW)

With 80 x 7/9Ah batteries

Max. Subrack connection

kW

20

20

20

Dimensions (WxHxD)

mm

448x310x565 (7 HU)

4821)x310x565 (7 HU)

448x487x735 (11 HU)

4821)x487x735 (11 HU)

448x665x735 (15 HU)

4821)x665x735 (15 HU)

Weight of Empty Frame

w/o modules and

w/o batteries

kg

20

40

56

Weight of Frame with

modules and w/o batteries

kg

39 up to 42

(with 1 Module)

59 up to 62

(with 1 Module)

75 up to 78

(with 1 Module)

DPA UPScale RI

unit

UPScale RI 20

UPScale RI 22

UPScale RI 24

DPA UPScale RI Subrack

Configuration

accommodates:

Max.

2 modules (10 or 20kW)

2 modules (10 or 20kW)

with 80 x 7/9Ah batteries

2 modules (10 or 20kW)

with 160 x 7/9Ah batteries

Max. Subrack connection

kW

40

40

40

Dimensions (WxHxD)

mm

448x440x565 (10 HU)

4821)x440x565(10 HU)

448x798x735 (18 HU)

4821)x798x735(18 HU)

448x1153x735 (26 HU)

4821)x1153x735(26 HU)

Weight of Empty Frame

w/o modules and

w/o batteries

kg

25

66

93

Weight of Frame with

modules and w/o batteries

kg

62 up to 68

(with 2 Modules)

103 up to 104

(with 2 Modules)

130 up to 136

(with 2 Modules)

1.1 MECHANICAL CHARACTERISTICS DPA UPSCALE RI

Section-1

Note : 1) 482 mm is the width including the wings in the front.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 2/52 ABB

Modifications reserved

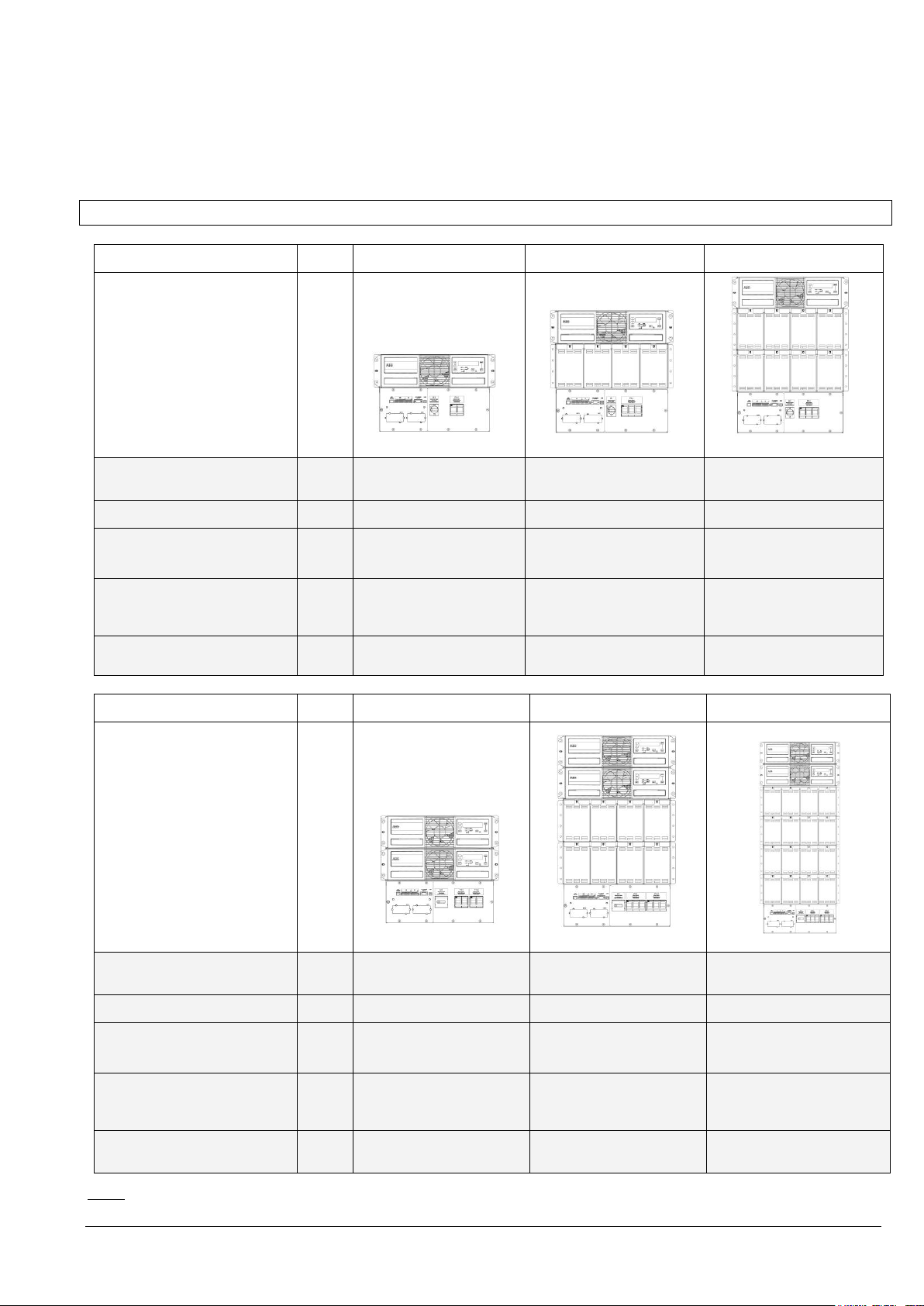

DPA UPScale RI

unit

UPScale RI 40

DPA UPScale RI Subrack

Configuration

accommodates:

Max.

4 modules (10 or 20kW)

Max. Subrack connection

kW

80

Dimensions (WxHxD)

mm

448x798x735 (18 HU)

4821)x798x735 (18 HU)

Weight of Empty Frame

w/o modules and

w/o batteries

kg

50

Weight of Frame with

modules and w/o batteries

kg

124 up to 136

(with 4 Modules)

Module type

unit

UPScale M 10

UPScale M 20

Module rated power

kW

10

20

Allowed nr. VRLA 12V

battery blocks

No.

202) - 50

302) - 50

Dimensions (WxHxD)

mm

4821) x 132 x 540 (3HU)

Weight

kg

18.6

21.5

Colors

Front : RAL 9005

Approximate3) audible

noise at 1m from front, of

one module only.

100% / 50% Load

dBA

553) / 493)

573) / 493)

Section-1

Notes:

1)

482 mm is the width including the wings in the front.

2)

Depending of the effective load in kW used by the module (see chapter 10.4 Battery Characteristics)

3)

These are approx. figures and of one module only. The audible noise depends also on the cabinet which host the

subracks.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 3/52 ABB

Modifications reserved

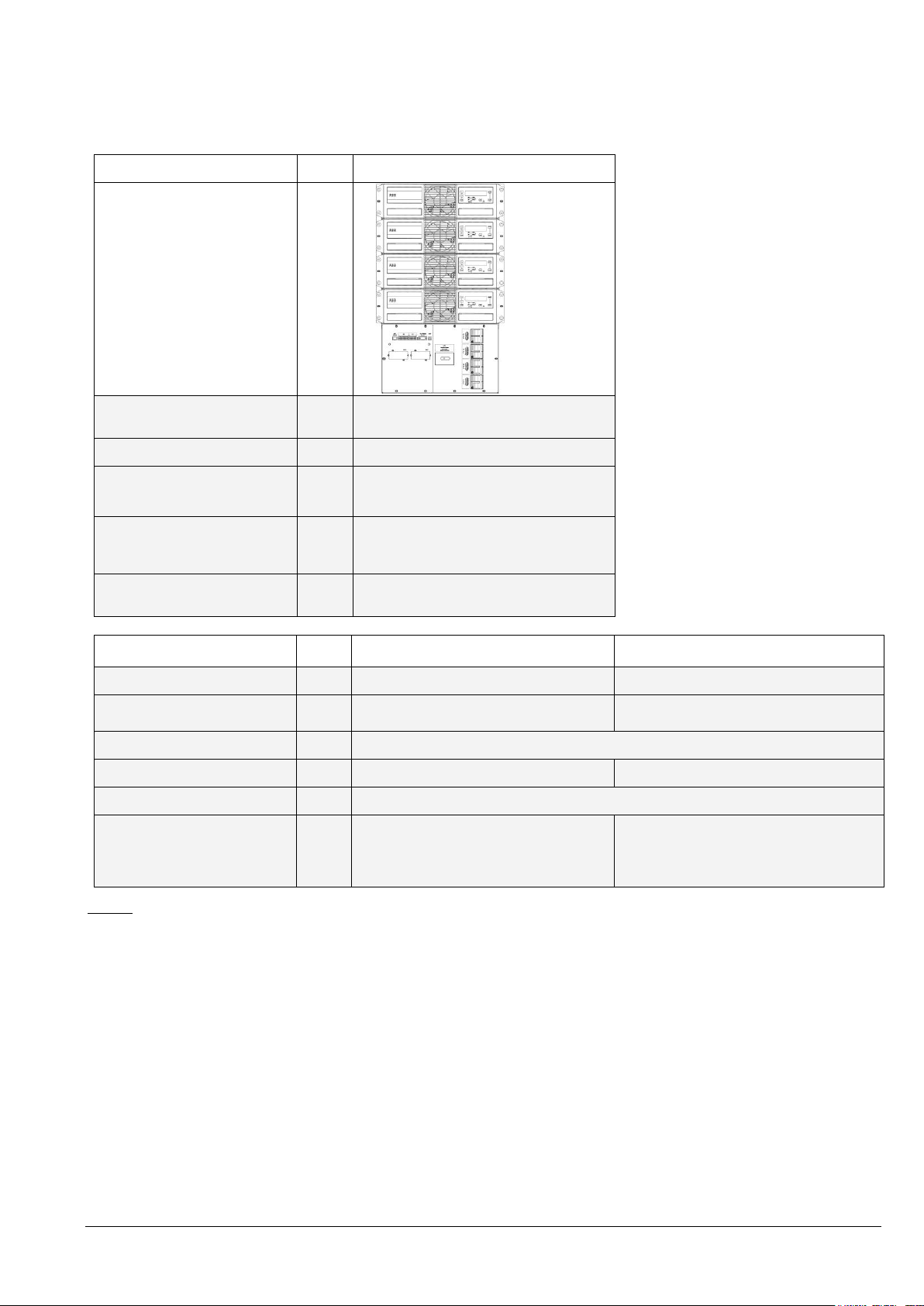

WARNING!

THERE IS DANGER OF AN ELECTRICAL IMPACT

NOTE!

READ THE INFORMATION, IN ORDER TO AVOID EQUIPMENT

DAMAGES

PROTECTIVE GROUNDING TERMINAL

A terminal which must be connected to earth ground prior to making any

other connection to the equipment.

A terminal to which or from which a direct current or voltage may be

applied or supplied.

This symbol indicates the word “phase”.

ON

The principal power switch is in the “ON” position

OFF

The principal power switch is in the “OFF” position.

C

St

CAUTION: REFER TO MANUAL

Refer to the Operator’s Manual for more information

DANGER: RISK OF ELECTRIC SHOCK

There is a risk of electric shock present, and you should observe

associated warnings. The UPS contains high voltages.

Section-1

1.2 SAFETY INSTRUCTIONS

1.2.1 GENERAL SAFETY INTRODUCTION

The UPS System operates with mains, battery or bypass power. It contains components that carry high currents

and voltages. The properly installed UPS System is grounded to earth and IP 20 rated against electrical shock and

foreign objects. Installation and service have to be done by the manufacturer’s qualified technicians or their certified

service partners.

This user manual contains guidelines to check delivery, installing and commissioning of the UPS and is intended

for people who plan the installation, install, commission and use or service the UPS. The reader is expected to

know the fundamentals of electricity, wiring, electrical components and electrical schematic symbols

1.2.2 SYMBOLS, CONTROLS, AND INDICATORS

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 4/52 ABB

Modifications reserved

WARNING!

IT IS PROHIBITED TO REMOVE ANY SCREWS FROM THE UPS SYSTEM OR

FROM THE BATTERY CABINET. THERE IS A DANGER OF ELECTRICAL SHOCK.

WARNING!

HIGH FAULT CURRENTS (LEAKAGE CURRENTS):

BEFORE CONNECTING THE MAINS YOU MUST ENSURE THAT THERE IS A

PROPER EARTH CONNECTION!

WARNING!

THE USER MUST DISPLAY A WARNING SHIELD ON ALL PRIMARY UPS

CIRCUIT BREAKERS. THE SERVICE PERSONNEL HAS TO BE INFORMED

ABOUT DANGEROUS VOLTAGES. THE WARNING PANELS MUST CONTAIN

THE FOLLOWING TEXT: “ BEFORE STARTING WITH THE MAINTENANCE

WORK ON THE CIRCUIT BREAKERS MAKE SURE THE UPS IS ISOLATED

Section-1

1.2.3 OPERATOR PRECAUTIONS

The only user operations permitted are:

Use of the LCD control panel (LCD Display) and of the Maintenance Bypass

Start up and shut down of the UPS of the user field (excluding the commissioning start up)

Operation of additional connectivity modules:

SNMP adapters and their software

Modem/GSM or Modem/Ethernet adapters and their software

The user must follow the precautions and only perform the described operations. Also in these measures the

operator of the UPS System must adhere to the instructions in this manual. Any deviations from the instructions

could be dangerous to the user or cause accidental load loss.

THE MANUFACTURER DOES NOT TAKE ANY RESPONSIBILITY FOR DAMAGES CAUSED THROUGH

WRONG MANIPULATIONS OF THE UPS SYSTEM.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 5/52 ABB

Modifications reserved

Product Standards

Standards

Safety Standard:

IEC/EN 62040-1:

IEC/EN 60950-1:

Electromagnetic Compatibility

Standard (EMC):

IEC/EN 62040-2:

IEC/EN 61000-6-2:

IEC/EN 61000-6-4:

IEC/EN 61000-4-2:

IEC/EN 61000-4-3:

IEC/EN 61000-4-4:

IEC/EN 61000-4-5:

IEC/EN 61000-4-6:

Performance Standard:

IEC/EN 62040-3:

Section-1

1.2.4 ENVIRONMENTAL CONSIDERATIONS

The UPS must be installed according to the recommendations in this manual. To operate the UPS at peak

efficiency, your installation site should meet the environmental parameters outlined in this manual. Excessive

amount of dust in the operating environment of UPS may cause damage or lead to malfunction. The UPS should be

always protected from the outside weather and sunshine. If you intend to operate the system at an altitude higher

than 1000 meters, contact your local sales or service office for important information about high altitude operation.

The operating environment must meet the weight, airflow, size and clearance requirements specified in the

technical datasheet.

Under no circumstances the UPS should be installed in an airtight room, in the presence of flammable gases, or in

an environment exceeding the specification.

The basic environmental requirements of the UPS system are:

Ambient Temperature Range: 0 to +40˚C (32 – 104˚F)

Recommended Operating Range: +20 to +25˚C (68 – 77˚F)

Maximum Relative Humidity: 95% (non-condensing)

The UPS cabinet uses forced air cooling to regulate internal component temperature. Air inlets are in the bottom

sides and front of the cabinet, and outlets in the rear of the cabinet. You must allow clearance in back of the

cabinet for proper air circulation. Refer to

Section 1, 1.5.2.2 POSITIONING for clearance requirements.

1.2.5 DECLARATION OF SAFETY CONFORMITY AND CE MARKING

The product has the CE marking in compliance with the following European directives:

Low Voltage Directive: 2006/95/EC

EMC Directive: 2004/108/EC

Declaration of conformity with UPS harmonized standards and directives EN 62040-1-1 (Safety) and EN 62040-2

(EMC) are available in the annex 1

1.2.6 INQUIRIES

Address inquiries about the UPS and battery cabinet to the local office or agent certified by the manufacturer.

Please note the type code and the serial number of the equipment and contact your nearest agent certified by the

manufacturer.

The Code and the serial no. are shown on the nameplate see

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 6/52 ABB

Section 1, 1.4.4 Nameplate and identification .

Modifications reserved

Section-1

1.3 SYSTEM DESCRIPTION

The product described in this manual is a transformerless Uninterruptible Power System (UPS). It is a true online,

continuous duty, double conversion, solid state, three-phase system, providing conditioned and uninterruptible AC

power to protect the customer’s load from all nine power failures.

1.3.1 GENERAL SYSTEM DESCRIPTION

The UPS’s are used to protect sensitive equipment and prevent loss of valuable electronic information, minimise

equipment downtime, and minimise the adverse effect on production equipment due to unexpected power

problems.

The UPS system continually monitors incoming electrical power and removes the surges, spikes, sags, and other

irregularities that are inherent in commercial utility power. Working with a building‘s electrical system, the UPS

system supplies clean, consistent power that sensitive electronic equipment requires for reliable operation. During

brownouts, blackouts, and other power interruptions, batteries provide emergency power to safeguard operation.

The UPS system is housed in single freestanding cabinets. The cabinets line up and match in style and colour, and

have safety shields behind the doors for hazardous voltage protection.

1.3.1.1 Feature : Unique “Safe-Swappable” Modules

The unique Safe-Swappable feature of the Modules indicates the ability to insert and extract the electronic/power

modules from a larger assembly while it is powered (hot). The safe-swappable design allows live powered modules

to be attached to and removed from a powered set without causing disturbance to the operation of the load and

without need to go to bypass.

1.3.1.2 Feature : Advanced-Booster Technology

Traditional input THD filters are no longer needed with this UPS product. The build-in advanced booster technology

of UPS modules provides perfect sinusoidal input power quality at 0.99 input power factor with harmonic content

less than 3% THD(i). This leads to more reliable total system operation and savings in generator and transformer

sizing as losses in the windings are minimised.

Due to the active front booster, regulating each individual phase, the UPS is comparable to a clean resistor load

(unity) from the mains perspective. Thus, the high input power factor provides minimised cabling and fusing costs

due to no reactive power consumption. The low harmonic currents are due to high input power factor and provide

the benefits:

No additional losses in wires and cables

No extra heating of transformers and generators with shortened service life

No over sizing of generators

No false circuit breaker tripping and malfunction

No erratic operation of computers, telecommunication, monitors, electronic test equipment etc.

No Resonance with power factor correction capacitors

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 7/52 ABB

Modifications reserved

Section-1

1.3.1.3 Feature : Flexible Battery Management (FBM)

The Flexible Battery Management (FBM) has been designed in all UPS products with the goal to avoid the

deterioration of battery age. The FBM – Key Features protect the battery from environmental negative impacts (high

temperature and false manipulations) and avoid deterioration of battery life by advanced management of battery

charging and preventive failure diagnostics. The implemented features result in benefits not only for the end user,

but also to the environment. The battery user will be required to replace his batteries less often. This translates into

financial and environmental benefits. Last but not least a well protected and managed battery is a healthy battery

and hence it enhance the overall availability of the UPS system.

The major benefits are:

AC-Ripple free battery charging due to DC-DC charger separated from the rectifier and inverter

Wide range of number of battery blocks (20-50 blocks of 12V; depending autonomy times and power)

UPS’S wide input voltage window tolerance extends the battery life due to less discharge cycles

Battery discharge protection caused by load jumps

Proactive battery protection from false manipulations and inadequate charging voltages

Proactive battery failure detection thanks to Advanced Battery Diagnosis (ABD) - Algorithm

User selectable battery tests

Optional temperature compensated charging to enhance battery life

Hence, the function of FBM system is to prolong the battery life considerably compared to traditional systems. In a

traditional online UPS the inverter also causes ripple-current to be fed to batteries causing corrosion.

1.3.1.4 Feature : DPA Technology - Decentralized Parallel Architecture

The UPS product features DPA paralleling technology that provides N+X redundancy without introducing a singlepoint-of-failure. The products utilizing the DPA technology are completely autonomous be means of individual

Power Units, Bypasses, CPU’s, Control Panels and separate battery configuration for each single module.

The DPA technology makes it more reliable than traditional paralleling techniques. A parallel UPS system means

the linking together of two or more UPS units in parallel so that in the unlikely event one fails the other can

automatically take up the load. Traditionally a parallel redundancy configuration is achieved by having a random or

fixed master-slave relationship among the UPS units. This master logic gives out individual commands to all the

slaves units. Unfortunately this can lead to a single-point-of-failure for the whole system because if the master logic

or communication to slaves fails, and causes the whole UPS system to be in trouble.

The DPA technology was developed as a Multi-Master logic concept with separated independent regulation and

logic buses to allow parallel capacity system and to maintain the highest system availability. An industry leading

paralleling technology in its own right, the DPA technology enables you to set up a parallel redundant system giving

you 100% conditioned power at all times. Its unique decentralized design eliminates the system level single point of

failure inherent in traditional parallel UPS, and exponentially increases the reliability of the overall system.

DPA UPScale RI technology allows up to six UPS modules to cover the same load in parallel and redundant

configuration. No vulnerable master logic is needed in this design. It provides automatic load sharing and module

level redundancy with nothing other than the power connecting to the DPA UPScale RITM version of UPS modules.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 8/52 ABB

Modifications reserved

DPA UPScale RI 10

DPA UPScale RI 11

DPA UPScale RI 12

DPA UPScale RI 20

DPA UPScale RI 22

DPA UPScale RI 24

DPA UPScale RI 40

Product Standards

Standards

Safety Standard:

IEC/EN 62040-1:

IEC/EN 60950-1:

Electromagnetic Compatibility

Standard (EMC):

IEC/EN 62040-2:

IEC/EN 61000-6-2:

IEC/EN 61000-6-4:

IEC/EN 61000-4-2:

IEC/EN 61000-4-3:

IEC/EN 61000-4-4:

IEC/EN 61000-4-5:

IEC/EN 61000-4-6:

Performance Standard:

IEC/EN 62040-3:

Section-1

1.3.2 DPA UPSCALE™ RI BASIC SYSTEM CONFIGURATION

The UPS system can be housed in a rack independent cabinet of 19”. The following basic UPS systems

configurations are available:

1.3.3 QUALITY STANDARDS AND UPS CLASSIFICATION CODE

The DPA UPScaleTM will provide your critical equipment with a steady and reliable power supply for many

years.The unique and modular UPS DPA UPScaleTM belongs to the newest generation of midrange 3-phase UPSSystems. High reliability, low operating cost and excellent electrical performance are only some of the highlights of

this innovative UPS solution.

The criteria and methods implemented for the design and manufacture correspond to the most stringent quality

standards.

The manufacturer is certified successfully in every areas according to the model of the International Standard

ISO 9001/EN 29001. The Certification of UPS with the operating performance according to the Norm

IEC 62 040-3 and VDE 0558 Part 530 is accomplished. With it the UPS has the Classification Code VFl-SS-111.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 9/52 ABB

Modifications reserved

Section-1

1.3.4 SINGLE/PARALLEL-MODULES OPERATION

The DPA UPScaleTM has unique paralleling features. We distinguish: Single or Parallel-Modules

A) Single-Module

DPA UPScale RI 10 DPA UPScale RI 11 DPA UPScale RI 12

If a configuration consists of one single Module it is defined as a Single-Module Configuration even being in

different cabinets like UPScale RI-10 , UPScale RI-11, UPScale RI-12, with a single Module.

B) Parallel-Module:

DPA UPScale RI 20 DPA UPScale RI 22 DPA UPScale RI 24 DPA UPScale RI 40

A Parallel-Module is a Module that is operating in parallel with other equivalent Modules, but still within the same

cabinet (e.g. DPA UPScale RI 24) using the DPA technology

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 10/52 ABB

Modifications reserved

NOTE!

IF THE UPS IS NOT IMMEDIATELY INSTALLED THE FOLLOWING GUIDELINES

MUST BE FOLLOWED:

TRANSPORT:

UPS CABINETS AND/OR BATTERY CABINET CAN FALL OVER. USE THE

SHIPPING BRACKETS ON THE REAR AND FRONT TO SECURE THE

CABINETS. DO NOT TILT THEM MORE THAN 10° FROM VERTICAL,

OTHERWISE CABINETS MAY TIP OVER.

POTENTIAL DANGERS:

- TILTING THE CABINET MIGHT DAMAGE THE SYSTEM AND THEREFORE

SHOULD NO LONGER BE CONNECTED TO THE MAINS.

- WEIGHT OF THE UPS SYSTEM COULD CAUSE SERIOUS INJURIES TO

PERSONS OR ANYTHING IN THE SURROUNDING AREA.

STORAGE:

- THE UPS SHOULD BE STORED IN THE ORIGINAL PACKING AND

SHIPPING CARTON

- THE RECOMMENDED STORING TEMPERATURE FOR THE UPS SYSTEM

AND BATTERIES IS BETWEEN +20 °C AND +25°C.

- THE UPS SYSTEM AND THE BATTERIE SETS MUST BE PROTECTED FROM

HUMIDITY < 95% (NON-CONDENSING)

NOTE!

VISIBLE TRANSPORT DAMAGES MUST BE CLAIMED TO THE CARRIER

IMMEDIATELY AFTER RECEIPT !!

OTHER CLAIM FOR SHIPPING DAMAGE MUST BE FILED IMMEDIATELY TOO

AND THE CARRIER MUST BE INFORMED WITHIN 7 DAYS OF RECEIPT OF THE

EQUIPMENT. THE PACKING MATERIALS SHOULD BE STORED FOR FURTHER

INVESTIGATION.

Section-1

1.4 DELIVERY - TRANSPORT - STORAGE

1.4.1 INTRODUCTION

This chapter contains all the necessary information for the correct unpacking, positioning, cabling and installation of

the UPS.

The UPS and accessories are delivered on a specifically designed pallet that is easy to move with a forklift or a

pallet jack. Keep the UPS always in upright position and do not drop the equipment. Do not either stack the pallets

because of high-energy batteries involved and the heavy weight

1.4.2 RECEIPT OF THE UPS AND VISUAL INSPECTION

Upon receiving the UPS, carefully examine the packing container and the UPS for any sign of physical damage.

The outside ’Tip&Tel’ ( "FRAGILE" and "ARROW") indicator should be intact if the equipment has been transported

in the upright position. In case of rupture or suspect inform immediately:

Ensure that the received UPS corresponds to the material indicated in the delivery note.

The packing container of the UPS protects it from mechanical and environmental damage. To increase its

protection the UPS is wrapped with a plastic sheet.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 11/52 ABB

The carrier and

The manufacturer

Modifications reserved

Bottom screws

Sides screws

!

KG

HEAVY !

3 1 1 2 4

Section-1

1.4.3 UNPACKING

Unpack the equipment by removing the packing and shipping materials. Make a visual inspection and check that

’Tip&Tel’ indicator ( "FRAGILE" and "ARROW") on the packing container is intact.

Perform the following steps to unpack the UPS equipment from the pallet and make sure that the floor surface is

solid and suitable for the wheeling and heavy weight:

(1) Cut wrappers and remove packing container by pulling it upwards;

(2) Remove the plastic cover from the UPS;

(3) Remove pallet from the UPS;

Retain the packaging materials for future shipment of the UPS;

Examine the UPS for any sign of damage. Notify your carrier or supplier immediately if damage is

apparent.

(4a) Open the UPS-door and make sure that all the UPS-Modules are appropriately fitted in their UPS Compartment and if the UPS system is provided

(4b) Without a UPS-module make sure that the empty UPS-compartment is correctly covered with the UPS compartment protection cover.

By unpacking the equipment from the wooden case remove all screws.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 12/52 ABB

Modifications reserved

TYPE

PRODUCT DESCRIPTION

DIMENSIONS

R1Uxxx

UPScale RI 10

Subrack (448x310x565mm)

R1Uxxx

UPScale RI 11

Subrack (448x487x735mm)

R1Uxxx

UPScale RI 12

Subrack (448x665x735mm)

R2Uxxx

UPScale RI 20

Subrack (448x440x565mm)

R2Uxxx

UPScale RI 22

Subrack (448x798x735mm)

R2Uxxx

UPScale RI 24

Subrack (448x1153x735mm)

R4Uxxx

UPScale RI 40

Subrack (448x798x735mm)

!

KG

HEAVY !

Section-1

1.4.4 NAMEPLATE AND IDENTIFICATION

The technical specifications of the Equipment are provided on the nameplate, which is situated at the front of the

UPS. Check if it corresponds to the purchased material mentioned in the delivery note.

1.4.5 BATTERIES AND STORAGE

The standard batteries of the UPS are sealed, maintenance-free batteries, sometimes mounted in an external

battery cabinet and will typically be connected when the UPS is commissioned.

The battery life depends very much on the ambient temperature. A temperature range between +20° and +25°C will

achieve the optimum battery life.

If the UPS is delivered without batteries, the manufacturer is not responsible for any damage or malfunctioning

caused to the UPS by incorrect wiring.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 13/52 ABB

Modifications reserved

WARNING!

SEALED BATTERIES MUST NEVER BE STORED IN A DISCHARGED OR

PARTIALLY DISCHARGED STATE.

EXTREME TEMPERATURE, UNDER- AND OVERCHARGE AND

OVERDISCHARGE WILL DESTROY BATTERIES!

NOTE!

THE UPS SYSTEM, THE BATTERY CABINET AND THE BATTERIES ARE HEAVY

AND MAY TIP DURING TRANSPORTATION CAUSING SERIOUS INJURY IF

UNPACKING INSTRUCTIONS ARE NOT CLOSELY FOLLOWED.

Section-1

1.4.5.1 Storage of battery

The battery life depends very much on the ambient temperature. It is therefore important to follow the storage

instructions/recommendation of the battery manufacturer. For long-term storage make sure that the battery is fully

recharged every 6 months. Before and after storing, charge the battery.

Always store the batteries in a dry, clean, cool environment in their original packaging. If the packing container is

removed protect the batteries from dust and humidity.

1.4.5.2 Storage of UPS

If you plan to store the UPS prior to use, keep the UPS unpacked in a dry, clean and cool storage room with an

ambient temperature between (-25 °C to +70°C) and humidity of less than 95% non-condensing.

If the packing container is removed protect the UPS from dust.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 14/52 ABB

Modifications reserved

!

KG

HEAVY !

Section-1

1.5 SITE PLANNING AND POSITIONING

1.5.1 PLANNING BEFORE THE INSTALLATION

The equipment must be installed and transported in a upright position. The equipment requires space to

bottom/front and back to enable cooling airflow. It is required to arrange ventilation of the UPS room.

All parts of the UPS for service and user access are accessible from the front and rear, making it a service-friendly

and maintenance-friendly UPS. Reserve enough space from the front (min. 600 mm)

The UPS should be located where:

Humidity (< 95 % non-condensing) and temperature (+20° and +25°C ) are within prescribed limits

Fire protection standards are respected

Cabling can be performed easily

Available front accessibility for service or periodic maintenance

Requested air cooling flow should be granted

The air conditioning system should have sufficient amount of air cooling needed to keep the max. room

temperature rise at desired level:

Dust or corrosive/explosive gases must be absent

The place is vibration free

Only front access is necessary for service and maintenance.

If the UPS will be installed in bayed enclosures, partition walls have to be installed as well.

An ambient temperature of +20 to 25 Celsius degrees is recommended to achieve a long life of the UPS and

batteries. The cooling air entering the UPS must not exceed +40 °C. Avoid high ambient temperature, moisture and

humidity. The floor material should be non-flammable and strong enough to support the heavy load.

1.5.2 POSITIONING OF UPS AND BATTERY CABINET

1.5.2.1 Final Transport

Check before transporting the surface loading and use a adequate forklift to move the equipment to the final

position.

Fig. 1.5.1 Floor surface must support loading

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 15/52 ABB

Modifications reserved

WARNING!

THE UPS CONTAINS HIGH DC VOLTAGES. A QUALIFIED PERSON MUST DO

THE CONNECTIONS BETWEEN THE UPS AND THE EXTERNAL BATTERY

CABINET(S). THE BATTERY CABINET IS CONNECTED ELECTRICALLY IN

PARALLEL WITH THE INTERNAL BATTERIES OF THE UPS.

WARNING!

IF AVAILABLE, THE INTERNAL BATTERY HAS TO BE DISCONNECTED

FIRST BECAUSE THE EXTERNAL

BATTERY TERMINALS ARE HAZARDOUS DUE TO THE PARALLEL

BATTERY STRING.

Section-1

1.5.2.2 Positioning

UPS: DPA UPScale RI is a rack independent design which is always mounted into a rack. The hosting rack must

have front and back opening for that air flow. The cold or ambient temp. air inlet is on the front; the hot air outlet is

on the back. Back clearance of min. 20 cm is required for hot air outlet.

External Battery: If external battery are needed it’s recommended to install external battery cabinet(s) next to the

UPS unit. The external battery can be placed on either side of the UPS unit, but it is recommended to install on left

hand side. External battery racks shall be sized to take the voltage drop in the cable into account. To obtain

support and help contact the local office or agent certified by the manufacturer.

Check before the installation that the battery voltage values in the ID card or in the Display settings of the UPS and

external battery cabinets are the same.

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 16/52 ABB

Modifications reserved

Subrack type

RI 10

RI 11

RI 12

RI 20

RI 22

RI 24

RI 40

Accessibility

Totally front accessibility for service and maintenance

Clearances

Back clearance of min. 20 cm required for hot air outlet. Cold air inlet is from front.

Positioning and mounting

see operating manual, Section 1 for details and mounting instructions.

Input and Output Cabling

From the bottom on the rear side.

UPScale RI

max. configuration

RI 10

RI 11

RI 12

RI 20

RI 22

RI 24

RI 40

Weight of empty frame

w/o modules and

w/o batteries

kg

20

40

56

25

66

93

50

Weight of empty frame

with modules and

w/o batteries

kg

39 - 42

59 - 62

75 - 78

44 - 47

104 -

110

131 -

137

124 -

136

Weight of empty frame

with modules and

with all batteries

kg

-

161 - 164

279 -

282

--

308 -

314

539 -

545

-

12V 7Ah battery block

2.5 kg

12V 9Ah battery block

2.55kg

UPS module M10

18.6 kg

UPS module M20

21.5 kg

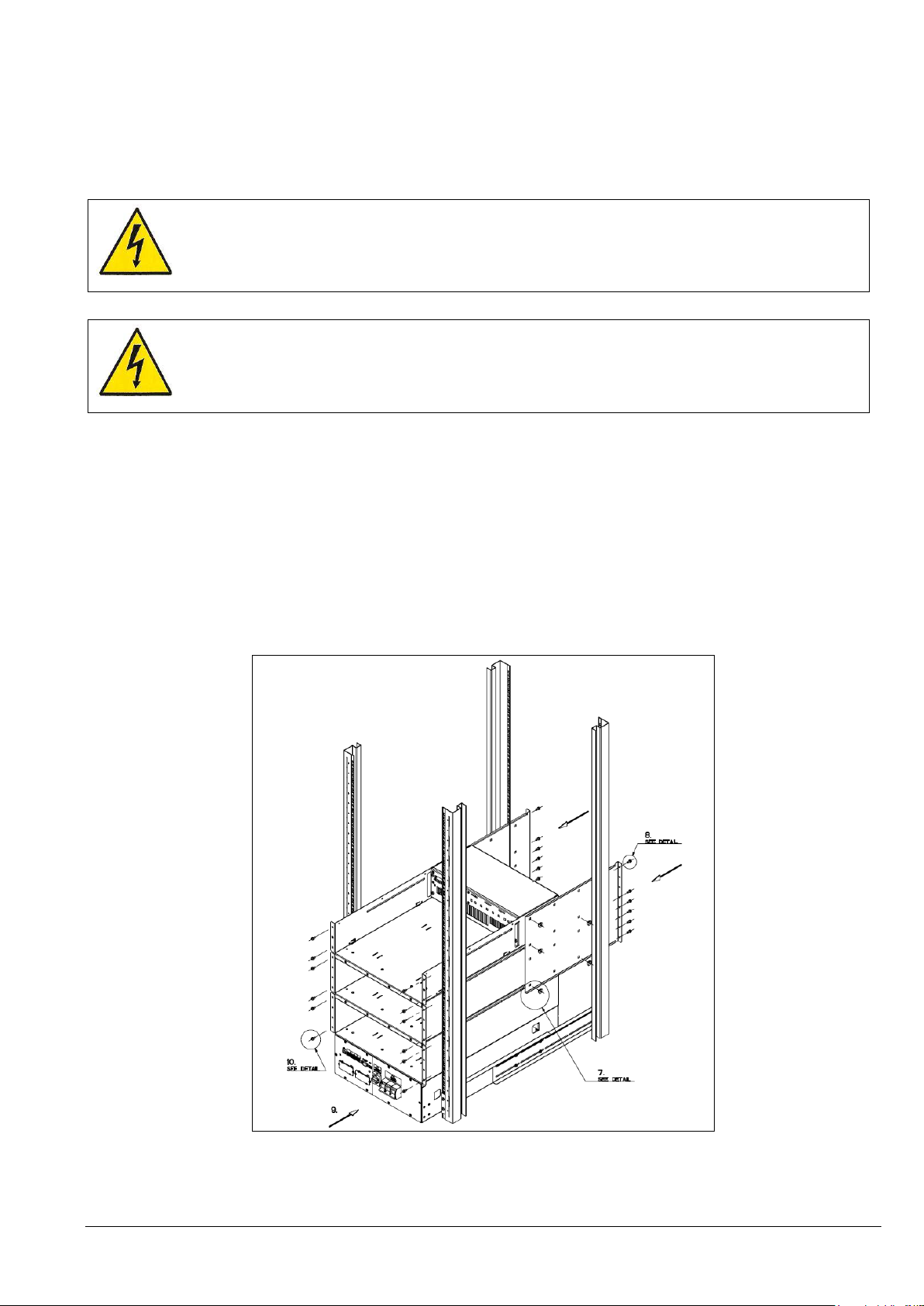

1.5.3 ASSEMBLING INSTRUCTIONS

Please make sure that the 19” Rack has a structure with minimum structure with four post system (see fig.

2.1 -2.7)

Please make sure that the four post system can hold the weight of the total UPS system. Refer to the table

below.

Position and air cooling flow at the 19” Rack. Please refer to the figures 4.1 and 4.2 to make sure the

required airflow and the right position is used.

The dimensions of the sub rack are shown in fig 1.1 – fig. 1.7

The terminal for input and output connection is at the rear side of the sub rack. The cable entry can be

made from rear or from bottom side. (see fig. 1.1 – 1.7)

For mounting the sub rack into your mains rack, you have to remove all the ups modules and the battery

treys from the sub rack.

Please use only the slides and brackets from the delivered accessories kit (see fig. 3.1 – 3.5)

Please follow the instruction drawing on fig. 2.1 – 2.7.

Note: for assembling the sub rack at a 19” rack you have to remove the UPS modules and the battery

shelves, while you need access for screw position (see Detail 12 on figure 2.1 – 2.7)

1.5.3.1 Table of Weight

Section-1

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 17/52 ABB

Modifications reserved

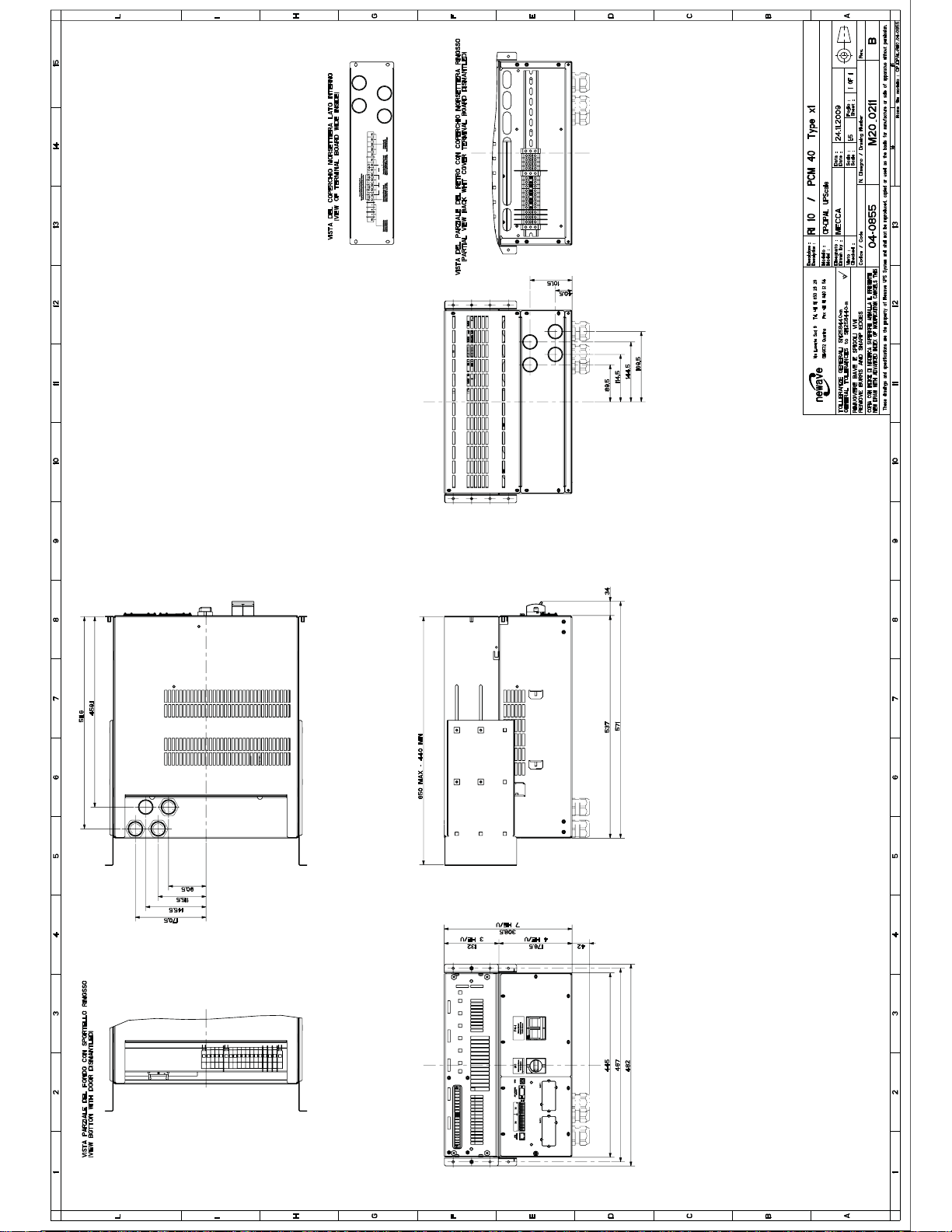

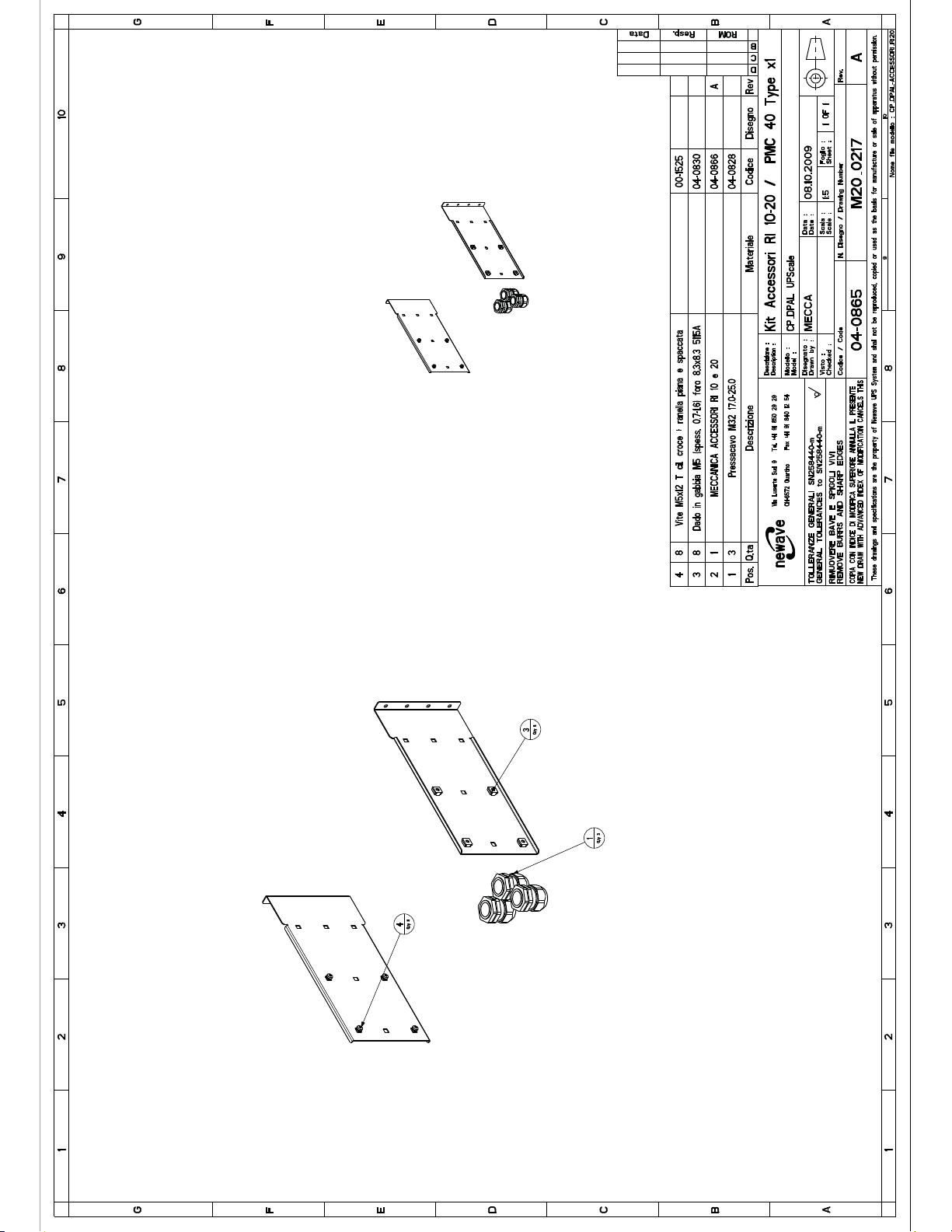

1.5.3.2 Mechanical Drawing, Assembling and accessories DPA UPScale RI 10

See drawings on the next pages:

Mechanical: fig.1.1_CP_DPAL-RI10_04-0855_PMC40_TYPE_X1.pdf

Assembling: fig.2.1_CP_DPAL-MONTAGGIO_RI10_PMC40_TYPE_X1

Accessories: fig.3.1_CP_DPAL-ACCESSORI_RI10-20_04-0865_TYPE_x1-x2

Section-1

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 18/52 ABB

Modifications reserved

1.5.3.3 Mechanical Drawing, Assembling and accessories DPA UPScale RI 11

See drawings on the next pages:

Mechanical: fig.1.3_CP_DPAL-RI11_04-0410_PMC40_TYPE1

Assembling: fig.2.3_CP_DPAL-MONTAGGIO_RI11_PMC40_TYPE1

Accessories: fig.3.2_CP_DPAL-ACCESSORI_RI11_04-0849_TYPE1

Section-1

04-3006_S1_OPM_ABB_DPA_UPSCALE_RI_10-80kW_EN_150316.doc Page 22/52 ABB

Modifications reserved

Loading...

Loading...