ABB DCS880 Hardware Manual

DCS880

Hardware manual

DCS880 Drives (20 ... 5200 A)

ABB

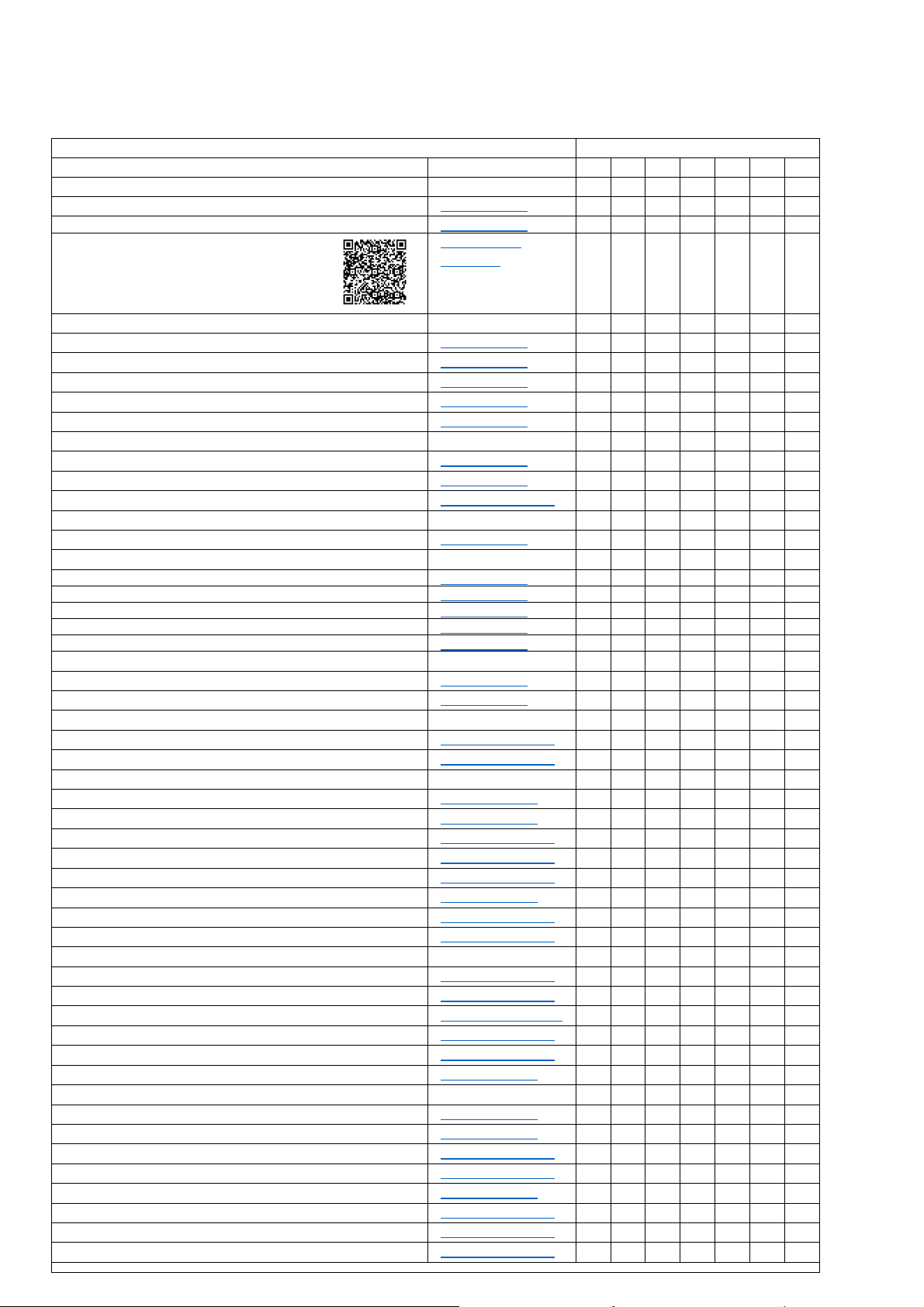

DCS880 Drive Manuals

Language

Publication number

General

DCS880 Quick guide

Safety instructions all languages

DCS880 Documentation pack

DCS880 Units

DCS880 Flyer

DCS880 Technical catalog

DCS880 Hardware manual

DCS880 Firmware manual

DCS880 Service manual

DCS880 Hardparallel manual

DCS880 12-pulse manual

Instructions for mounting the SDCS-CMA-2

ACS-AP-x assistant control panels user’s manual

Functional safety

Supplement for functional safety

Functional safety for enclosed converter

+Q957 Prevention of unexpected Start Up

+Q951 Emergency stop, category 0 with MC

+Q952 Emergency stop, category 1 with MC

+Q963 Emergency stop, category 0 without MC

+Q964 Emergency stop, category 1 without MC

Enclosed converter

Installation manual

DCS800-A + S880 Enclosed converters, flyer

Door mounting kits

DPMP-01 mounting platform for ACS-AP control panel

DPMP-02 mounting platform for ACS-AP control panel

Serial communication

FCAN-01 CANopen adapter module

FDNA-01 DeviceNet™ adapter module

FECA-01 EtherCAT adapter module

FENA-11/-21 Ethernet adapter module

FEPL-02 Ethernet POWERLINK adapter module

FPBA-01 PROFIBUS DP adapter module

FSCA-01 RS-485 adapter module

FDCO-01/02 DDCS communication modules

Tool and maintenance manuals and guides

Drive composer PC tool

Drive (IEC61131-3) application programming manual

Adaptive programming, Application guide

NETA-21 remote monitoring tool

NETA-21 remote monitoring tool guide

DDCS branching units NBDU-85, NBDU-95

Extension modules

FIO-11 Analog extension module

FIO-01 Digital extension modules

FAIO-01 Analog extension module

FDIO-01 Digital extension module

FEN-01 TTL encoder interface

FEN-31 HTL encoder interface

FEA-03 F series extension adapter

Ethernet tool network for ACS880 drives

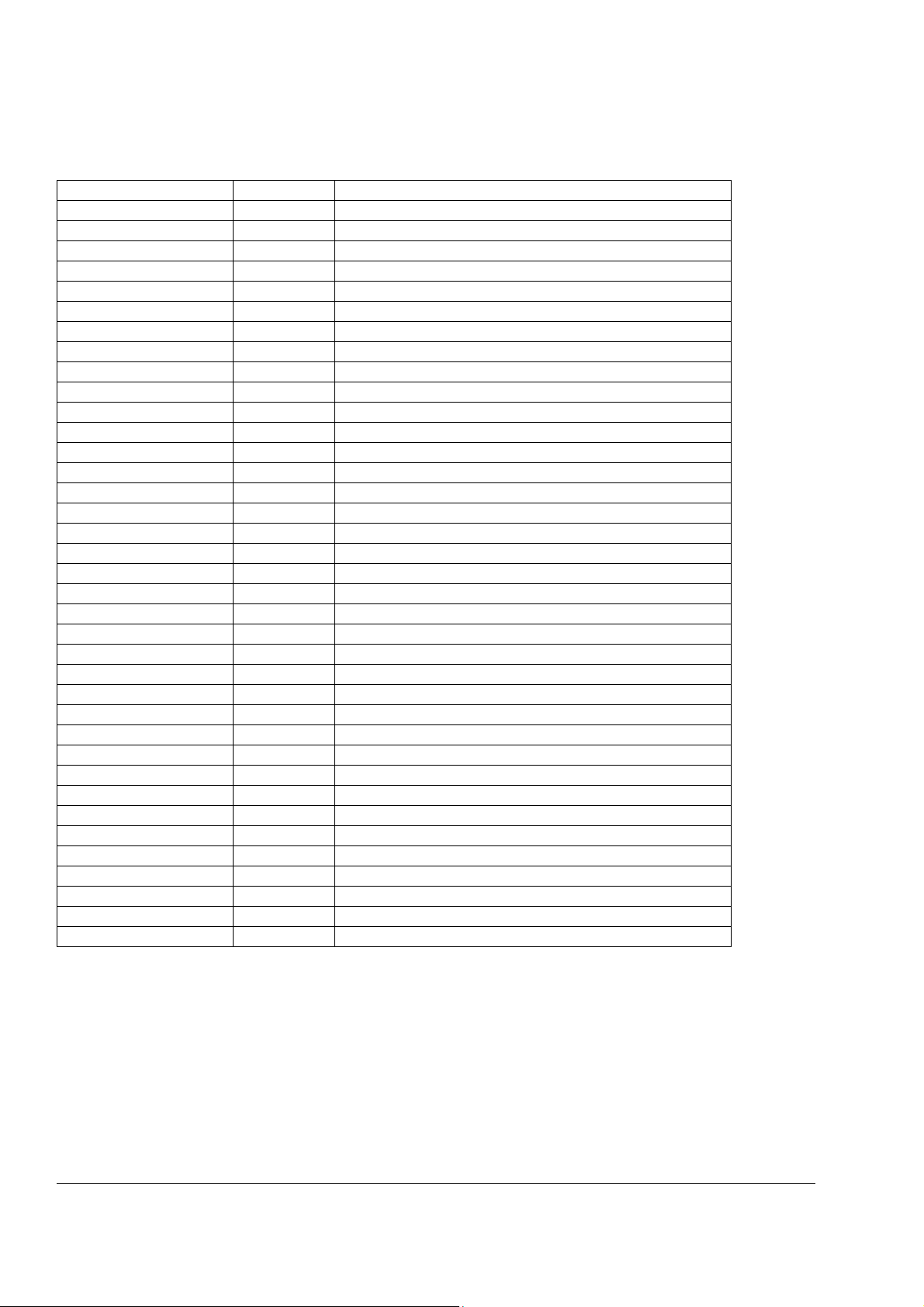

Status 10.2018 x → existing p → planned DCS880 Manuals list e g.docx

3ADW000480

3ADW000481 xxxxxxx

DCS880 CD

download

3ADW000475

3ADW000465

3ADW000462

3ADW000474

3ADW000488

3ADW000530

3ADW000533

3ADW000396

3AUA0000085685 x

3ADW000452 x

3ADW000504

3ADW000505

3ADW000506

3ADW000507

3ADW000508

3ADW000352

3ADW000523

3AUA0000100140

3AUA0000136205

3AFE68615500 xx

3AFE68573360

3AUA0000068940

3AUA0000093568

3AUA0000123527

3AFE68573271

3AUA0000109533

3AUA0000114058

3AUA0000094606

3AUA0000127808

3AXD50000028574

3AUA0000096939

3AUA0000096881

3BFE64285513

3AFE68784930 x

3AFE68784921

3AUA0000124968

3AUA0000124966

3AFE68784603

3AUA0000031044

3AUA0000115811

3AUA0000125635

E D I ES F CN RU

x

x

xx x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

xx

x

xx

xx

x

x

x

x

x

x

x

x

x

x

x

x

x

x

DCS880 Drives

20 ... 5200 A

Hardware manual

Code:

Effective:

Supersedes:

2019 ABB Automation Products GmbH. All rights reserved.

3ADW000462R0401 DCS880 Hardware manual e d

3ADW000462R0401 Rev D

01.2019

01.2018

4

Table of contents

DCS880 Drive Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of contents

Safety instructions

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

To which products this chapter applies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation and maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Printed circuit boards and fiber optic cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

The DCS880

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

The DCS880 converter modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Plus codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

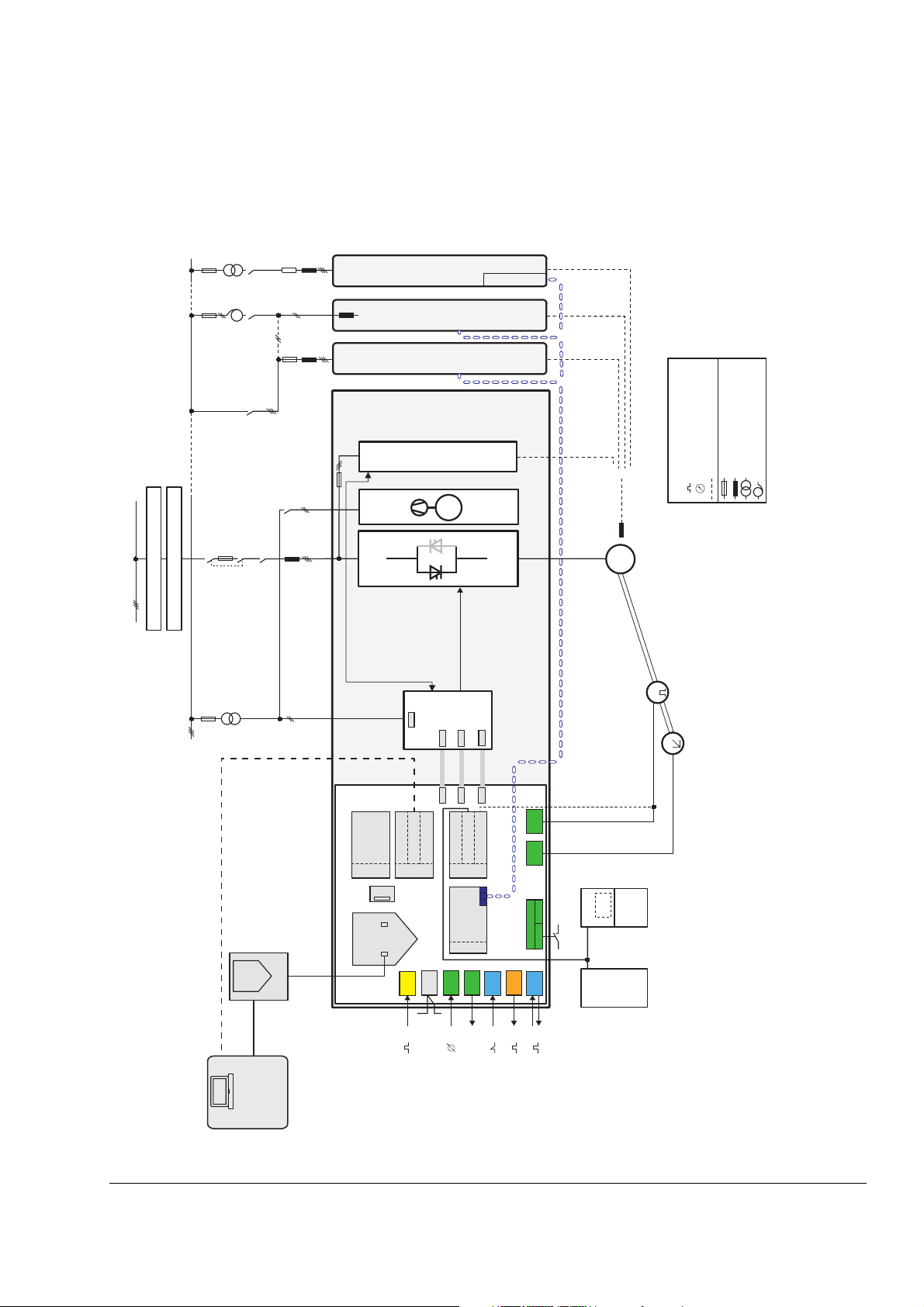

Main circuit and control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Armature converter DCS880 H1 ... H4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

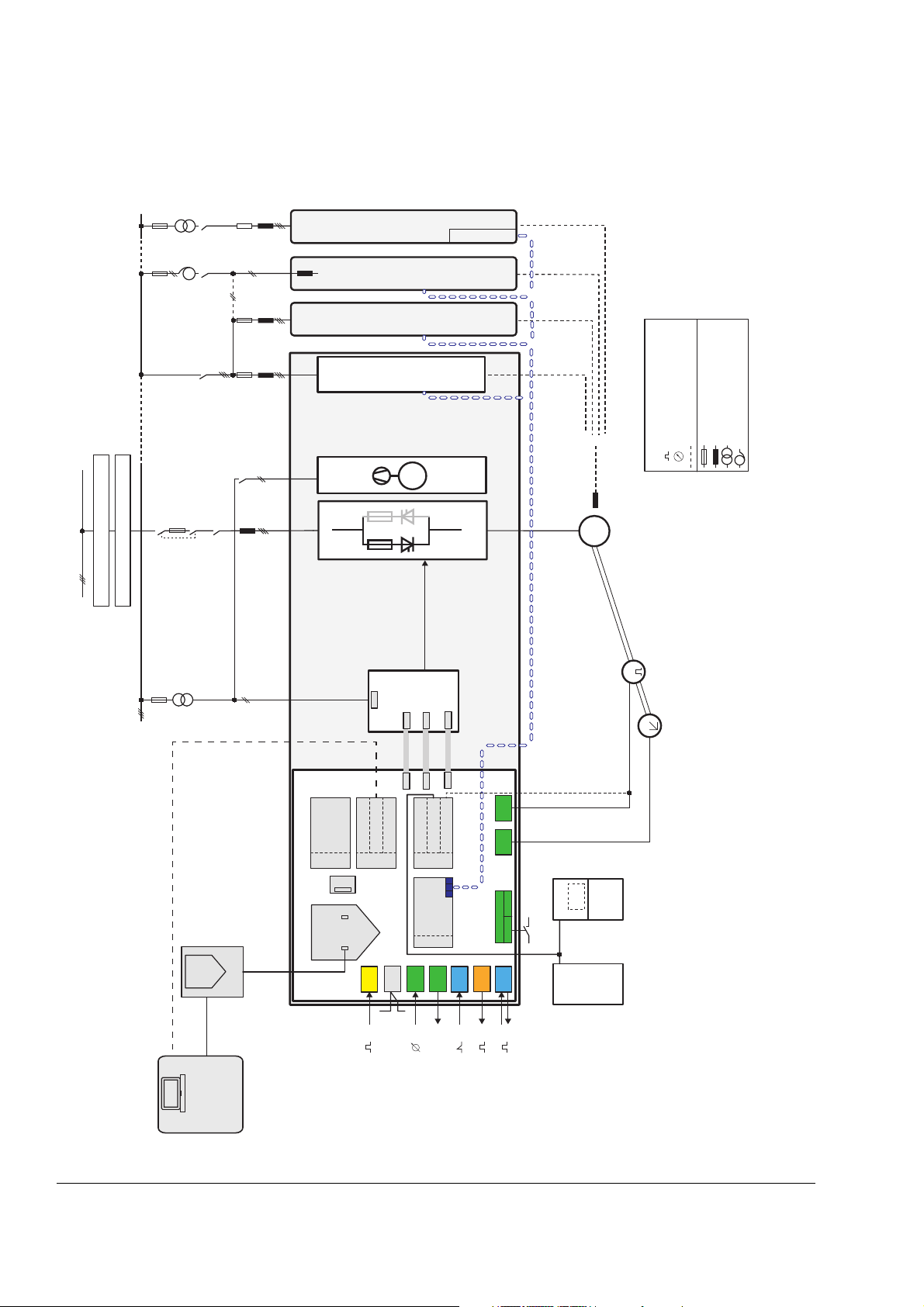

Armature converter DCS880 H5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

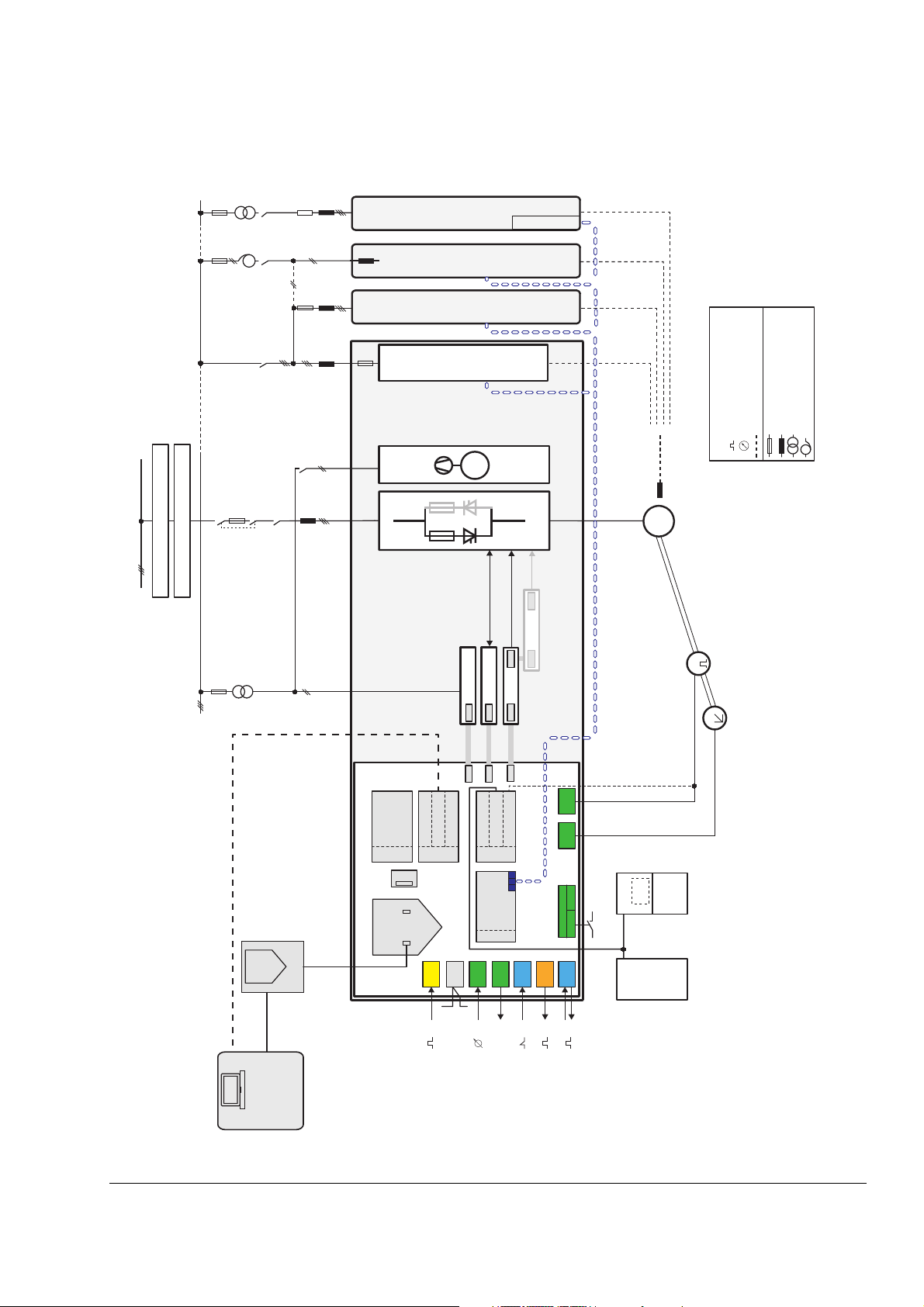

Armature converter DCS880 H6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

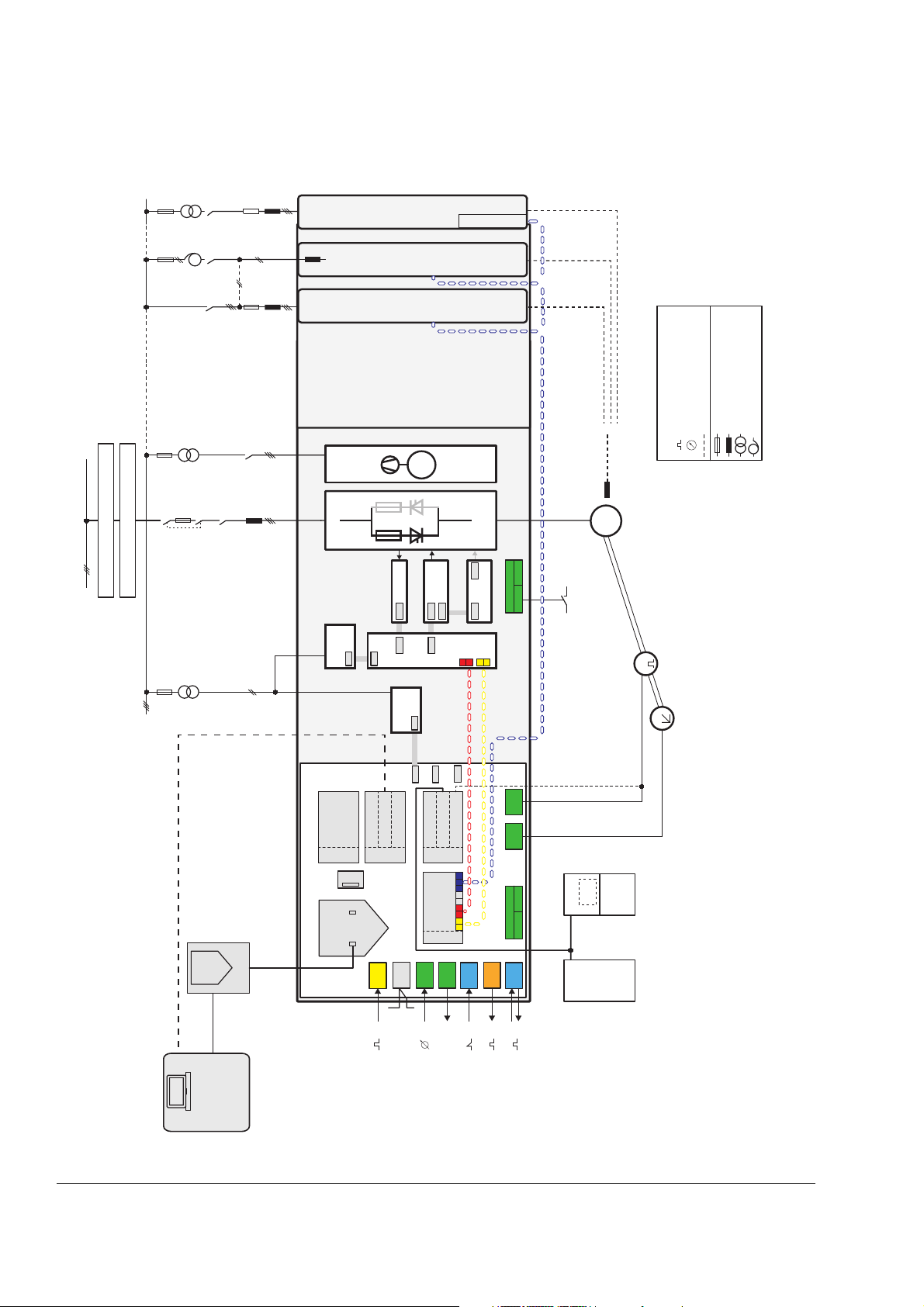

Armature converter DCS880 H7 and H8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mechanical installation

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Examining the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Necessary tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Moving the drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unpacking and examining the delivery (H1 … H3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unpacking and examining the delivery (H4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Unpacking and examining the delivery (H5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unpacking and examining the delivery (H6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Unpacking and examining the delivery (H7, H8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Delivery check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installing the drive (H1 … H3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing the drive (H4, H5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing the drive (H6 … H8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cabinet installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Preventing cooling air recirculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table of contents

3ADW000462R0401 DCS880 Hardware manual e d

Unit above another . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Terminal options for converter modules size H1 ... H4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connection of H4 converter module DC terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Terminal cover according to VBG 4 regulations (H1 ... H4 only) . . . . . . . . . . . . . . . . . . . . . . 32

Mounting the converter module H5 inside an enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mounting the H7 power unit inside an enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mounting the H8 power unit inside an enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Planning the electrical installation

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Line reactors (L1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Semiconductor fuses (F1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Semiconductor fuses (F1) and fuse holders for armature circuit . . . . . . . . . . . . . . . . . . . . . . 41

Fuses (F3.x) and fuse holders for field circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Single-phase autotransformer (T3) for field circuit (adapt voltage). . . . . . . . . . . . . . . . . . . . . 43

Line reactors for single- and 3-phase connection of field converters . . . . . . . . . . . . . . . . . . . 44

Auxiliary transformer (T2) for electronic system / fan supply . . . . . . . . . . . . . . . . . . . . . . . . . 44

EMC filters (E1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Converters size H1 ... H4 configuration using an OnBoard field exciter . . . . . . . . . . . . . . . . . . . . . 48

Converters size H5 configuration using FEX-425-Int field exciter . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Converters size H6 configuration using a FEX-425-Int field exciter. . . . . . . . . . . . . . . . . . . . . . . . . 50

Converters size H1 ... H6 configuration using external field exciters DCF803, DCF804 . . . . . . . . . 51

Converters size H7 and H8 configuration using external field exciters DCF803, DCF804 . . . . . . . 52

Converters size H1 ... H3 as large field exciter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Start, Stop and E-Stop control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Cooling fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Fan connection for DCS880 (H1 ... H4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Fan connection for DCS880 (H5 ... H8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Monitoring the DCS880 power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Implementing thermal overload and short-circuit protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Cross-sectional areas - Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connection of a motor temperature sensor to the drive I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5

Electrical installation

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Checking the insulation of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

IT (ungrounded) systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Connecting the power cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Location F-type adapters and interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

FEA-03 I/O extension adapter configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Pulse encoder connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Pulse encoder connection principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Connecting the signal and control cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

DCSLink wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table of contents

3ADW000462R0401 DCS880 Hardware manual e d

6

Connecting a control unit at H7 and H8 power units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Installation checklist

Maintenance

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Technical data

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Current ratings - IEC regenerative converters (S02). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Standard duty cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Current ratings - IEC non regenerative converters (S01) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Control board SDCS-CON-H01 (H1 ... H8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Recommended wire size - Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Control circuit terminal layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

XAI: Reference voltages and analog inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

XAO: Analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

XD2D: Drive-to-drive link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

RO1, RO2, RO3: Relay outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

XD24: Digital interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

XDIO: Digital inputs / outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

XDI: Digital inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

XENC: Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

XTAC: Analog tacho. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

XSMC: Mains contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

XSTO: Safe torque off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

X205 Memory unit connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Additional terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Ground isolation diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Jumpers and switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

DDCS Interface configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Ch0 DriveBus or module bus connection to Advant Controller (star). . . . . . . . . . . . . . . . . . . . 93

DDCS branching unit NDBU-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

DCSLink board SDCS-DSL-H1x (H1 ... H8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Daisy chain DPI-H01 kit (H1 ... H8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Power Interface board SDCS-PIN-H01 (H1 ... H5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Power supply board SDCS-POW-H01 (H6 ... H8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Field circuit interfaces SDCS-BAB-F01 and SDCS-BAB-F02 (H1 ... H4) . . . . . . . . . . . . . . . . . . . . 102

Measuring board SDCS-PIN-H51 (H6 ... H8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Firing pulse transformer board SDCS-PIN-H41 (H6 ... H8). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Optical power link board SDCS-OPL-H01 (H7, H8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Following connectors are available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

XSMC (X96): Mains contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Location of the SDCS-OPL-H01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table of contents

3ADW000462R0401 DCS880 Hardware manual e d

Connection between firing and control board for H6 ... H8. . . . . . . . . . . . . . . . . . . . . . . . . . 112

Galvanic isolation - T90, A92, F11, F90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

DC-DC transducer A92 (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Transformer T90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Dimensions and weights

Size H1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Size H2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Size H3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Size H4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Size H5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Size H6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Size H7

(+P906) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Size H8 lefthand (+P906). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Size H8 righthand (+P906). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Branch fuses installed inside converter sizes H5 ... H8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Accessories

7

DCF803-0016, FEX-425-Int and DCF803-0035. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Power part. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

DCSLink communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

RS232-Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

DCF803-0016 and DCF803-0035 configuration (H1 ... H8) . . . . . . . . . . . . . . . . . . . . . . . . . 134

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

FEX-425-Int configuration (H5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

FEX-425-Int configuration (H6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

DCF803-0050, DCF804-0050, DCF803-0060 and DCF804-0060. . . . . . . . . . . . . . . . . . . . . . . . . 138

Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Power part. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

DCSLink communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

RS232-Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

DCF803-0050 / 0060 and DCF804-0050 / 0060 configuration (e.g. 2 motors). . . . . . . . . . . 143

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

DCF505 / DCF506 Overvoltage Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Fuses and fuse holders IEC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Line reactors IEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Line reactors type ND01 ... ND17 (uk = 1 %) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Line reactors type ND401 ... ND413 (uk = 4 %) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Autotransformer (T3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Line reactor (L3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Auxiliary transformer (T2) for converter electronics and fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Supply transformer (T8) for cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

3ADW000462R0401 DCS880 Hardware manual e d

Table of contents

8

Other cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Recommended connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Optical cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Table of contents

3ADW000462R0401 DCS880 Hardware manual e d

Safety instructions

What this chapter contains

This chapter contains the safety instructions which you must follow when installing,

operating and servicing the drive. If ignored, physical injury or death may follow, or

damage may occur to the drive, the motor or driven equipment. Read the safety

instructions before you work on the unit.

To which products this chapter applies

The information is valid for the whole range of the product DCS880, the converter

modules DCS880-S0x size H1 ... H8, field exciter units DCF80x, etc. like the Rebuild

Kit DCS880-R00.

Use of warnings and notes

There are two types of safety instructions throughout this manual: warnings and

notes. Warnings caution you about conditions which can result in serious injury or

death and/or damage to the equipment and advice on how to avoid the danger.

Notes draw attention to a particular condition or fact, or give information on a

subject. The warning symbols are used as follows:

9

Dangerous voltage warning warns of high voltage which can cause

physical injury and/or damage to the equipment.

General danger warning warns about conditions, other than those

caused by electricity, which can result in physical injury or death and/or

damage to the equipment.

Electrostatic sensitive discharge warning warns of electrostatic

discharge which can damage the equipment.

3ADW000462R0401 DCS880 Hardware manual e d

Safety instructions

10

Installation and maintenance work

These warnings are intended for all who work on the drive, motor cable or motor.

Ignoring the instructions can cause physical injury or death and/or damage to the

equipment.

WARNING

Only qualified electricians are allowed to install and maintain the drive!

-

Never work on the drive, motor cable or motor when main power is applied.

-

Always ensure by measuring with a multimeter (impedance at least 1 MOhm)

that:

1. Voltage between drive input phases U1, V1 and W1 and the frame is

close to 0 V.

2. Voltage between terminals C+ and D- and the frame is close to 0 V.

Do not work on the control cables when power is applied to the drive or to the

external control circuits. Externally supplied control circuits may cause

dangerous voltages inside the drive even when the main power on the drive is

switched off.

Do not make any insulation resistance or voltage withstand tests on the drive or

drive modules.

Isolate the motor cables from the drive when testing the insulation resistance or

voltage withstand of the cables or the motor.

When reconnecting the motor cable, always check that the C+ and D- cables

are connected with the proper terminal.

Notes:

The motor cable terminals on the drive are at a dangerously high voltage when

the main power is on, regardless of whether the motor is running or not.

Depending on the external wiring, dangerous voltages (115 V, 220 V or 230 V)

may be present on the relay outputs of the drive system (e.g. XRO1 ... XRO3).

DCS880 with enclosure extension: Before working on the drive, isolate the

whole drive from the supply.

Safety instructions

3ADW000462R0401 DCS880 Hardware manual e d

Grounding

These instructions are intended for all who are responsible for the grounding of the

drive. Incorrect grounding can cause physical injury, death and/or equipment

malfunction and increase electromagnetic interference.

WARNING

Ground the drive, motor and adjoining equipment to ensure personnel safety in

all circumstances, and to reduce electromagnetic emission and pick-up.

Make sure that grounding conductors are adequately sized and marked as

required by safety regulations.

In a multiple-drive installation, connect each drive separately to protective

earth (PE ).

Minimize EMC emission and make a 360° high frequency grounding (e.g.

conductive sleeves) of screened cable entries at the cabinet lead-through

plate.

11

Do not install a drive equipped with an EMC filter to an ungrounded power

system or a high resistance-grounded (> 30 Ohms) power system.

Notes:

Power cable shields are suitable as equipment grounding conductors only

when adequately sized to meet safety regulations.

As the normal leakage current of the drive is higher than 3.5 mA

10 mA

This product can cause a DC current in the protective earthing conductor.

-

, a fixed protective earth connection is required.

DC

AC

or

Where a residual current-operated protective (RCD) or monitoring (RCM)

device is used for protection in case of direct or indirect contact, only an RCD

or RCM of Type B is allowed on the supply side of this product.

3ADW000462R0401 DCS880 Hardware manual e d

Safety instructions

12

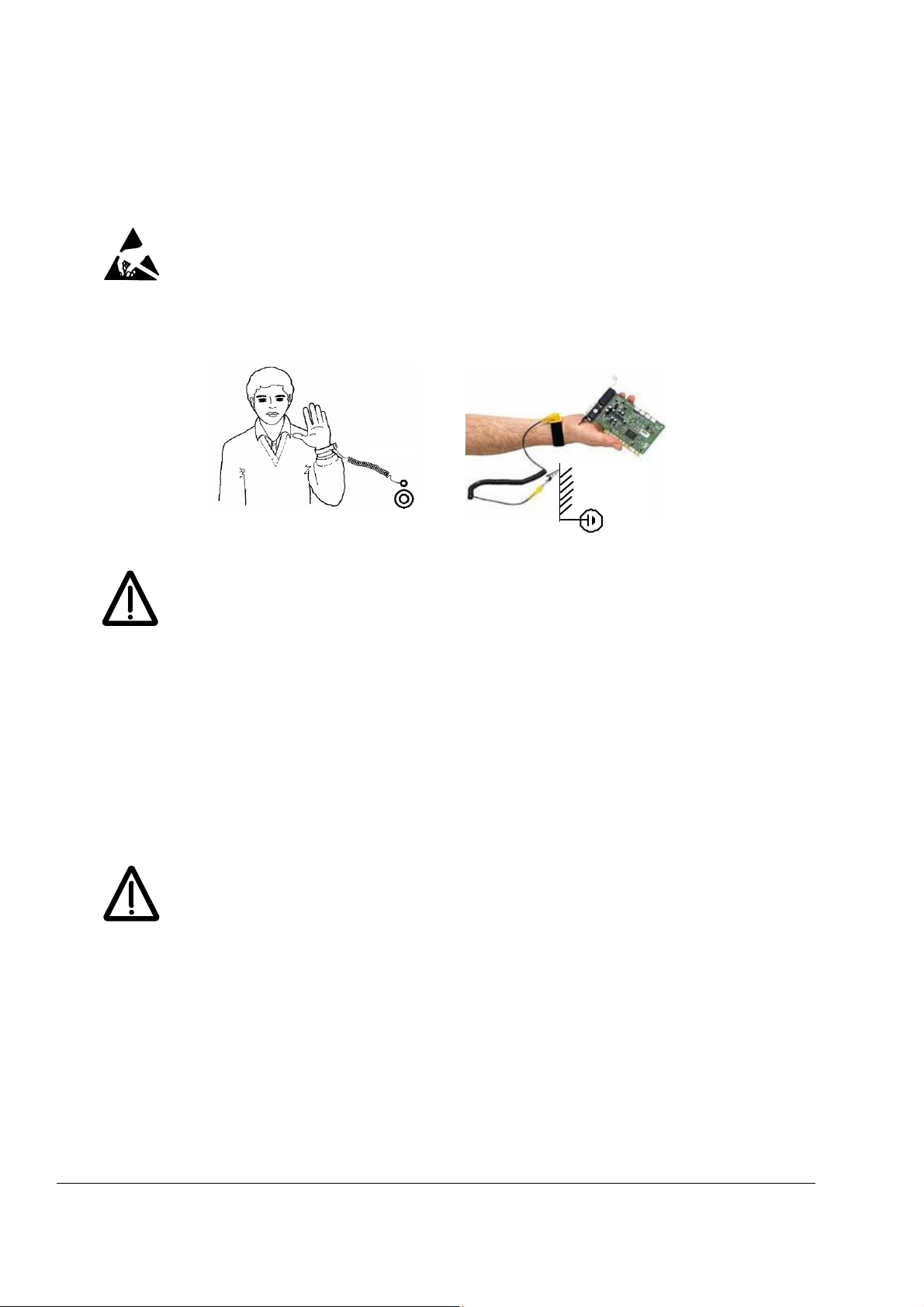

Printed circuit boards and fiber optic cables

These instructions are intended for all who handle the circuit boards and fiber optic

cables. Ignoring the following instructions can cause damage to the equipment.

WARNING

- The printed circuit boards contain components sensitive to electrostatic

discharge. Wear a grounding wrist band when handling the boards. Do not touch

the boards unnecessarily.

- Use grounding strip:

ABB order no.: 3ADV050035P0001

WARNING

- Handle the fiber optic cables with care.

- When unplugging optic cables, always grab the connector, not the cable itself.

- Do not touch the ends of the fibers with bare hands as the fiber is extremely

sensitive to dirt.

- The minimum allowed bend radius is 35 mm (1.38 in.).

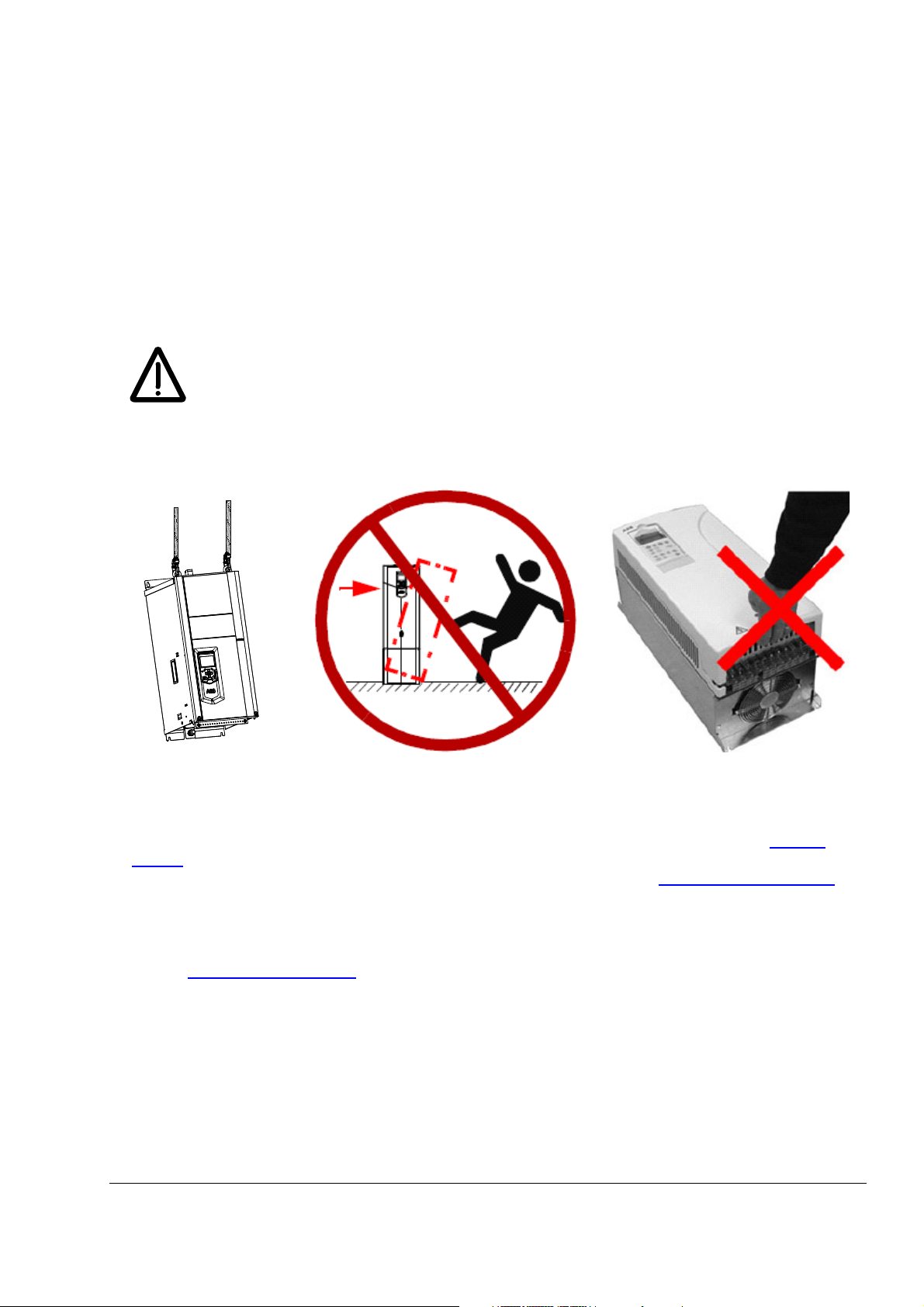

Mechanical installation

These notes are intended for all who install the drive. Handle the unit carefully to

avoid damage and injury.

WARNING

- DCS880 sizes H4 ... H8:

- The drive is heavy. Lift the drive by lifting lugs only.

- The drive’s center of gravity is high. Do not tilt the unit. The unit will overturn

from a tilt of about 6 degrees. An overturning drive can cause physical injury.

- Do not lift the unit by the front cover.

- Place units H4 … H6 only on their back.

- Make sure that dust from drilling does not enter the drive when installing.

Electrically conductive dust inside the unit may cause damage or lead to

malfunction.

- Ensure sufficient cooling.

- Do not fasten the drive by riveting or welding.

Safety instructions

3ADW000462R0401 DCS880 Hardware manual e d

Operation

13

These warnings are intended for all who plan the operation of the drive or operate

the drive. Ignoring the instructions can cause physical injury or death and/or damage

to the equipment.

WARNING

Before adjusting the drive and putting it into service, make sure that the motor

and all driven equipment are suitable for operation throughout the speed range

provided by the drive. The drive can be adjusted to operate the motor at

speeds above and below the base speed.

Do not control the motor with the disconnecting device (disconnecting mains);

instead, use the control panel keys and , or commands via the I/O

board of the drive.

Mains connection:

You can use a disconnect switch (with fuses) to disconnect the electrical

components of the drive from the mains for installation and maintenance work.

The type of disconnect switch used must be as per EN 60947-3, Class B, so as

to comply with EU regulations, or a circuit-breaker type which switches off the

load circuit by means of an auxiliary contact causing the breaker's main

contacts to open. The mains disconnect must be locked in its "OPEN" position

during any installation and maintenance work.

EMERGENCY STOP buttons must be installed at each control desk and at all

other control panels requiring an emergency stop function. Pressing the STOP

button on the control panel of the drive will neither cause an emergency stop of

the motor, nor will the drive be disconnected from any dangerous potential.

To avoid unintentional operating states, or to shut the unit down in case of any

imminent danger according to the standards in the safety instructions it is not

sufficient to merely shut down the drive via signals "RUN", "drive OFF" or

"Emergency Stop" respectively "control panel" or "PC tool".

Intended use:

The operating instructions cannot take into consideration every possible case

of configuration, operation or maintenance. Thus, they mainly give such advice

only, which is required by qualified personnel for normal operation of the

machines and devices in industrial installations.

If in special cases the electrical machines and devices are intended for use in

non-industrial installations - which may require stricter safety regulations (e.g.

protection against contact by children or similar) - these additional safety

measures for the installation must be provided by the customer during

assembly.

Note:

When the control location is not set to Local (Local not shown in the status row

of the display), the stop key on the control panel will not stop the drive. To stop

the drive using the control panel, press the Loc/Rem key and then the stop key

.

3ADW000462R0401 DCS880 Hardware manual e d

Safety instructions

14

Size H1 ... H5

20 ... 1190 A

Size H6

900 ... 2000 A

Size H7

1900 ... 3000 A

Size H8

2050 ... 5200 A

The DCS880

Chapter overview

This chapter describes briefly the operating principle and construction of the converter modules in short.

The DCS880 converter modules

The DCS880-S size H1 ... H8 are intended for controlling DC motors.

The DCS880

3ADW000462R0401 DCS880 Hardware manual e d

15

Type code

The type code contains information on the specification and configuration of the drive. The first digits from left show the basic configuration

(e.g. DCS880-S01-2000). The optional selections are given thereafter on the name plate by plus code. The main selections are described

below. Not all selections are available for all types.

The drive's basic type code: DCS880-aab-cccc-ddef + plus code

Product family DCS880

Product type: aa = S0

= R0

= E0

= A0

Bridge type: b= 1

= 2

Module type: cccc = Rated DC current (IP00)

Rated AC voltage: dd = 04

= 05

= 06

= 07

= 08

= 10

= 12

Power connection: e= X

= L

= R

Revision code: f= 01

Field exciter configuration: +0S163

+S164

Fan voltage:

Standard

Application programming: +S551 Memory unit including drive application programming license

SDCS-DSL-H10: +S521 1 DCSLink channel, 0 channels optical power link SDCS-DSL-H10 (H1 ... H4)

Current measurement: +S175 SDCS-CMA-2 (H6 ... H8)

Voltage measurement: +S185 SDCS-PIN-H51 configured for 20 V

Control panel: +0J404

+J428

+J429

The technical data and specifications are valid as of going to press. ABB reserves the right to make subsequent alterations.

Standard converter module

Rebuild kit

Panel solution

Enclosed converter

Single bridge (2-Q)

2 anti-parallel bridges (4-Q)

100 V

... 415 V

AC

100 VAC ... 500 VAC (IEC), 525 VAC (UL)

270 V

... 600 V

AC

315 VAC ... 690 V

360 VAC ... 800 V

450 VAC ... 990 V

540 VAC ... 1190 V

AC

AC

AC

AC

AC

AC

Standard H1 ... H7

Left side H8

Right side H8

st

generation

H1 ... H4 without OnBoard field exciter

H5 and H6 with internal field exciter, supply external

(H5 and H6: 25 A, Rebuild kit: 16 A / 25 A)

Size H4

Fan voltage: 230 V / 1-ph

... 100 VAC (H6 ... H8)

AC

Without control panel

daisy-chain option DPI-H01 kit

Bluetooth control panel ACS-AP-W

3ADW000462R0401 DCS880 Hardware manual e d

The DCS880

16

Plus codes

Option Option code Description

ACS-AP-I standard built-in

no ACS-AP-I 0J404 No Control Panel

ACS-AP-W +J429 Bluetooth panel

DPI-H01 +J428 daisy-chain option

FDNA-01 +K451 Fieldbus DeviceNet

FPBA-01 +K454 Fieldbus PROFIBUS

FCAN-01 +K457 Fieldbus CANOpen

FSCA-01 +K458 Fieldbus Modbus

FCNA-01 +K462 Fieldbus ControlNet

FECA-01 +K469 Fieldbus EtherCat

FEPL-02 +K470 Fieldbus Ethernet POWERLINK

FENA-11 +K473 Ethernet/IP, Modbus/TCP, Profinet

FENA-21 +K475 Ethernet/IP, Modbus/TCP, Profinet

FIO-11 +L500 Analog I/O Extension (3 AI, 1 AO, 2 DIO)

FIO-01 +L501 Digital I/O Extension (4 DIO, 2 RO)

FAIO-01 +L525 Analog I/O Extension (2 AI, 2 AO)

FDIO-01 +L526 Digital I/O Extension (3 DI, 2 RO)

FPTC-01 +L536 Thermistor protection module

FEN-01 +L517 TTL Encoder interface

FEN-21 +L516 Resolver Interface

FEN-31 +L502 HTL Encoder Interface

FDCO-01 +L503 DDCS communication 10/10 MBd

FDCO-02 +L508 DDCS communication 5/10 MBd

Application programming +S551 Memory unit including drive application programming license

no OnBoard field exciter 0S163 Excludes OnBoard field exciter (H1 ... H4)

SDCS-DSL-H10 +S521 1 DCSLink channel, 0 channels optical power link

FSO-21 +Q972 Functional Safety Option

FSE-31 +L521 Functional Safety Encoder

The DCS880

3ADW000462R0401 DCS880 Hardware manual e d

Main circuit and control

K1

T2

Q1

F2

F1

SB_880_008_H1-H8_e.ai

M

F3

T3

K3

L1

M

DCS880-S0x H1 ... H4

230 V (115 V)

L3

max. 500 V

F100 ... F102

PIN-H01

X99

K5

K1

Drive composer

entry / pro

ABB automation-

builder

XTAC XENC

XD2D

XSMC

MC

X51

X52

X53

STO

X205

XDIO

XRO

XDI

XSTO

2

3

3

326+1

XAO

XA1

DPI-H01

DSL-H10

DDCS

USB

Ethernet

XS13

XC12

X38

DPMP-01

FAIO

FIO

DCF803/804-0050/0060

DCF803-0035

DCF803-0016

SDCS-DSL-H1x

{

T

E

Lx

Fy

Kx

Fx

Tx

XS13

XC12

X38

analog input / output

alternative

Residual current detection

Slot1 Slot2

digital input / output

Legend

PC

Slot2 Slot3

X200

Slot1

AC800

TB810

CI810

CI858

NDBU95

Fieldbus

FENA

FIO, FAIO

F-module

FIO, FAIO

FDCO

FEN

FEA-03

fuse

line reactor

transformer

autotransformer

ACP-01

EMC filter

e

Aux. supply

twisted pair

single phase

or three-phase

Field

supply

OnBoard field exciter

DCS880-S0x as field exciter

c H1 ... H4, optional

d H4 only

e Maximum voltage see table Type code

c

d

100 ... 600 V, 50 / 60 Hz

Armature converter DCS880 H1 ... H4

400 V and 500 V (IEC) / 525 V (UL) units with OnBoard field exciter. 600 V units are always without OnBoard field exciter.

17

3ADW000462R0401 DCS880 Hardware manual e d

The DCS880

18

K1

T2

Q1

F2

F1

SB_880_008_H1-H8_e.ai

M

F3

T3

K3

L1

M

FEX-425-Int

L3L3

DCS880-S0x H5

PIN-H01

K5

230 V

X99

max. 500 V

K1

Drive composer

entry / pro

ABB automation-

builder

XTAC XENC

XD2D

XSMC

MC

X51

X52

X53

STO

X205

XDIO

XRO

XDI

XSTO

2

3

3

326+1

XAO

XA1

DPI-H01

DSL-H10

DDCS

USB

Ethernet

XS13

XC12

X38

DPMP-01

FAIO

FIO

DCF803/804-0050/0060

DCF803-0035

DCF803-0016

SDCS-DSL-H1x

{

T

E

Lx

Fy

Kx

Fx

Tx

XS13

XC12

X38

analog input / output

alternative

Residual current detection

Slot1 Slot2

digital input / output

Legend

PC

Slot2 Slot3

X200

Slot1

AC800

TB810

CI810

CI858

NDBU95

Fieldbus

FENA

FIO, FAIO

F-module

FIO, FAIO

FDCO

FEN

FEA-03

fuse

line reactor

transformer

autotransformer

ACP-01

EMC filter

e

Aux. supply

twisted pair

single phase

or three-phase

Field

supply

c optional (+S164)

e Maximum voltage see table Type code

c

F3.1

(F301 ... F303)

DCS880-S0x as field exciter

100 ... 525 V, 50 / 60 Hz

Armature converter DCS880 H5

H5 units with optional internal field exciter.

The DCS880

3ADW000462R0401 DCS880 Hardware manual e d

Armature converter DCS880 H6

K1

T2

Q1

F2

F1

SB_880_008_H1-H8_e.ai

M

F3

T3

K3

L1

M

L3

POW-H01

PIN-H51

PIN-H41

PIN-H41

DCS880-S0x H6

FEX-425-Int

L3

F3.1

(F301 -

F303)

XS23

XS13

XS23

K5

230 V

K1

Drive composer

entry / pro

ABB automation-

builder

XTAC XENC

XD2D

XSMC

MC

X51

X52

X53

STO

X205

XDIO

XRO

XDI

XSTO

2

3

3

326+1

XAO

XA1

DPI-H01

DSL-H10

DDCS

USB

Ethernet

XS13

XC12

X38

DPMP-01

FAIO

FIO

DCF803/804-0050/0060

DCF803-0035

DCF803-0016

SDCS-DSL-H1x

{

T

E

Lx

Fy

Kx

Fx

Tx

XS13

XC12

X38

analog input / output

alternative

Residual current detection

Slot1 Slot2

digital input / output

Legend

PC

Slot2 Slot3

X200

Slot1

AC800

TB810

CI810

CI858

NDBU95

Fieldbus

FENA

FIO, FAIO

F-module

FIO, FAIO

FDCO

FEN

FEA-03

fuse

line reactor

transformer

autotransformer

ACP-01

EMC filter

e

Aux. supply

twisted pair

single phase

or three-phase

Field

supply

c optional (+S164)

e Maximum voltage see table Type code

c

100 ... 690 V, 50 / 60 Hz

DCS880-S0x as field exciter

19

3ADW000462R0401 DCS880 Hardware manual e d

The DCS880

20

K1

T2

Q1

F2

F1

SB_880_008_H1-H8_e.ai

M

F3

T3

K3

L1

M

L3

POW-H01

OPL-H01

DCS880-S0x H7 and H8

XC12

XS13

X38

POW-H01

X38

X38

PIN-H41

XS13

XS23

PIN-H41

XS13 XS23

XC12

PIN-H51

T8

F8

K5

V2V1V12

V11

K1

XSMC

MC STO

Drive composer

entry / pro

ABB automation-

builder

XTAC XENC

XD2D

XSMC

MC

X51

X52

X53

STO

X205

XDIO

XRO

XDI

XSTO

2

3

3

326+1

XAO

XA1

DPI-H01

DSL-H12

DDCS

USB

Ethernet

XS13

XC12

X38

DPMP-01

FAIO

FIO

DCF803/804-0050/0060

DCF803-0035

DCF803-0016

SDCS-DSL-H1x

{

T

E

Lx

Fy

Kx

Fx

Tx

V2

V1

V12

V11

analog input / output

alternative

Residual current detection

Slot1 Slot2

digital input / output

Legend

PC

Slot2 Slot3

X200

Slot1

AC800

TB810

CI810

CI858

NDBU95

Fieldbus

FENA

FIO, FAIO

F-module

FIO, FAIO

FDCO

FEN

FEA-03

fuse

line reactor

transformer

autotransformer

ACP-01

EMC filter

e

Aux. supply

twisted pair

single phase

or three-phase

Field

supply

e Maximum voltage see table Type code

100 ... 1190 V, 50 / 60 Hz

DCS880-S0x as field exciter

Armature converter DCS880 H7 and H8

The DCS880

3ADW000462R0401 DCS880 Hardware manual e d

Mechanical installation

BG_880_011_H4_a.ai

Chapter overview

This chapter describes the mechanical installation of the DCS880.

Safety

WARNING

– DCS800 sizes H4 ... H8:

– The drive is heavy. Lift the drive by lifting lugs only.

– The drive’s center of gravity is high. Do not tilt the unit. The unit will overturn

from a tilt of about 6 degrees. An overturning drive can cause physical injury.

– Do not lift the unit by the front cover.

– Place units H4 … H6 only on their back.

21

Examining the installation site

The drive must be installed in an upright position with the cooling section against a wall.

Make sure that the installation site agrees with these requirements:

– The installation site has sufficient ventilation to prevent overheating of the drive. See chapter Current

ratings.

– The operation conditions of the drive agree with the specifications in chapter Environmental Conditions

– The wall is vertical, not flammable and strong enough to hold the weight of the drive.

– The material below the installation is not flammable.

– There is enough free space above, beside and below the drive for cooling air flow, service and

maintenance. There is enough free space in front of the drive for operation, service and maintenance. See

chapter Dimensions and weights

.

Necessary tools

– Drill and drill bits.

– Screwdriver and/or wrench with bits. Some drive covers have torx screws.

Moving the drive

Move the transport package by pallet truck to the installation site.

Mechanical installation

3ADW000462R0401 DCS880 Hardware manual e d

.

22

1

6

3

BG_DCS_001_verpackung_a.ai

2

4

4

5

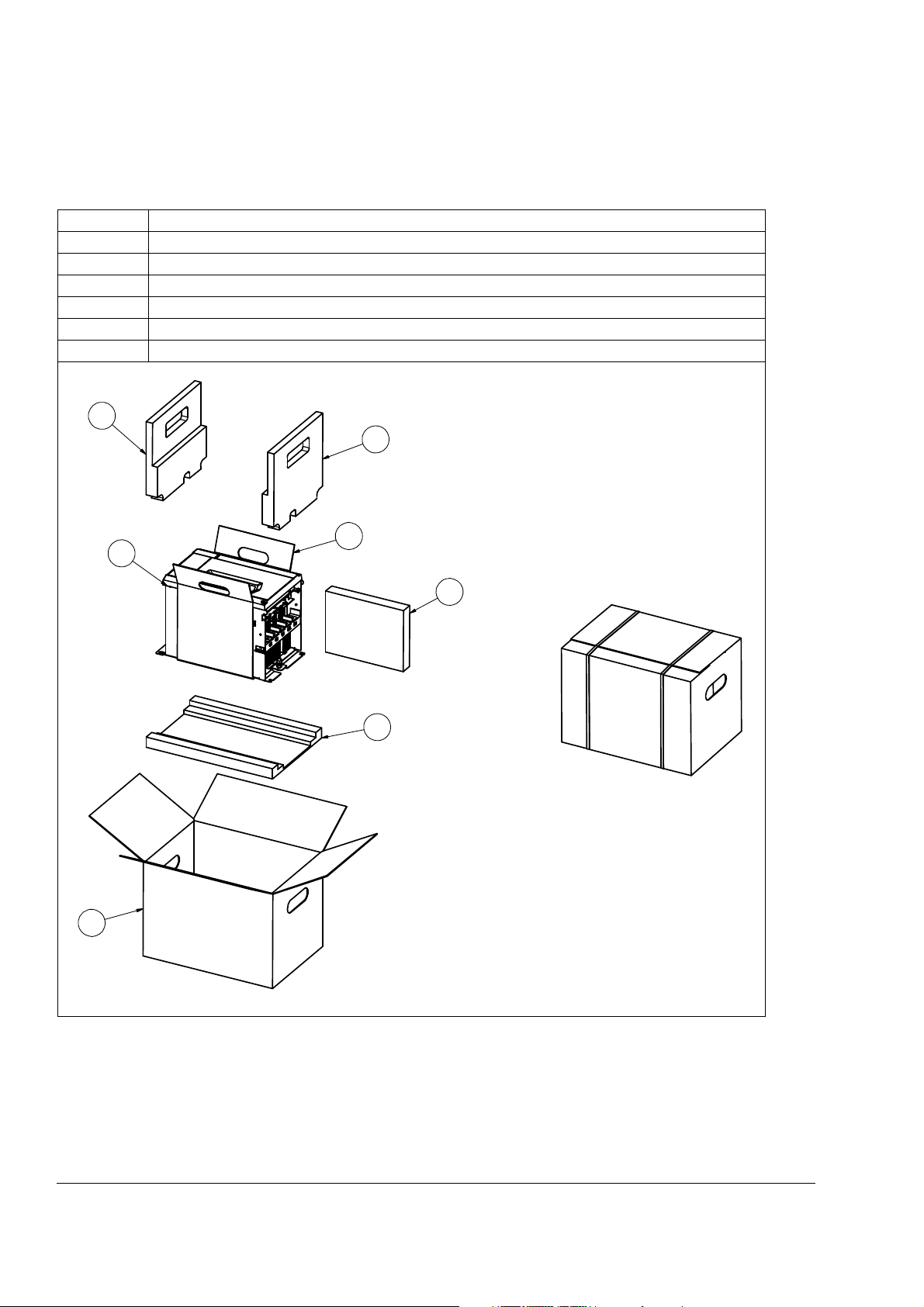

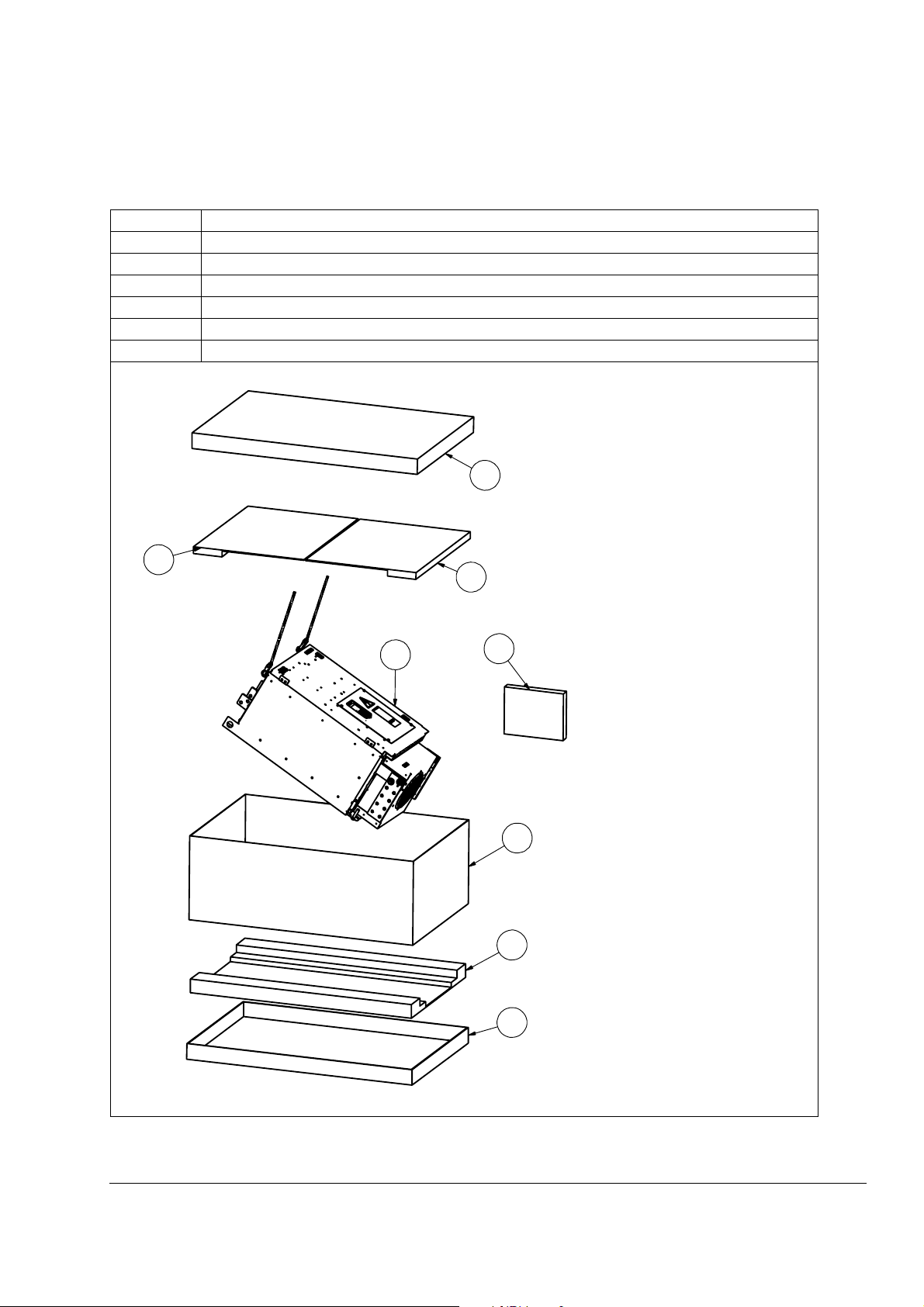

Unpacking and examining the delivery (H1 … H3)

This illustration shows the layout of the transport package. Examine that all items are present.

Item Description

1 Drive with factory installed options.

2 Cardboard box.

3 Shock damper.

4 Shock dampers.

5Tray.

6 Package containing documentation, plugs, mounting material, etc.

Mechanical installation

3ADW000462R0401 DCS880 Hardware manual e d

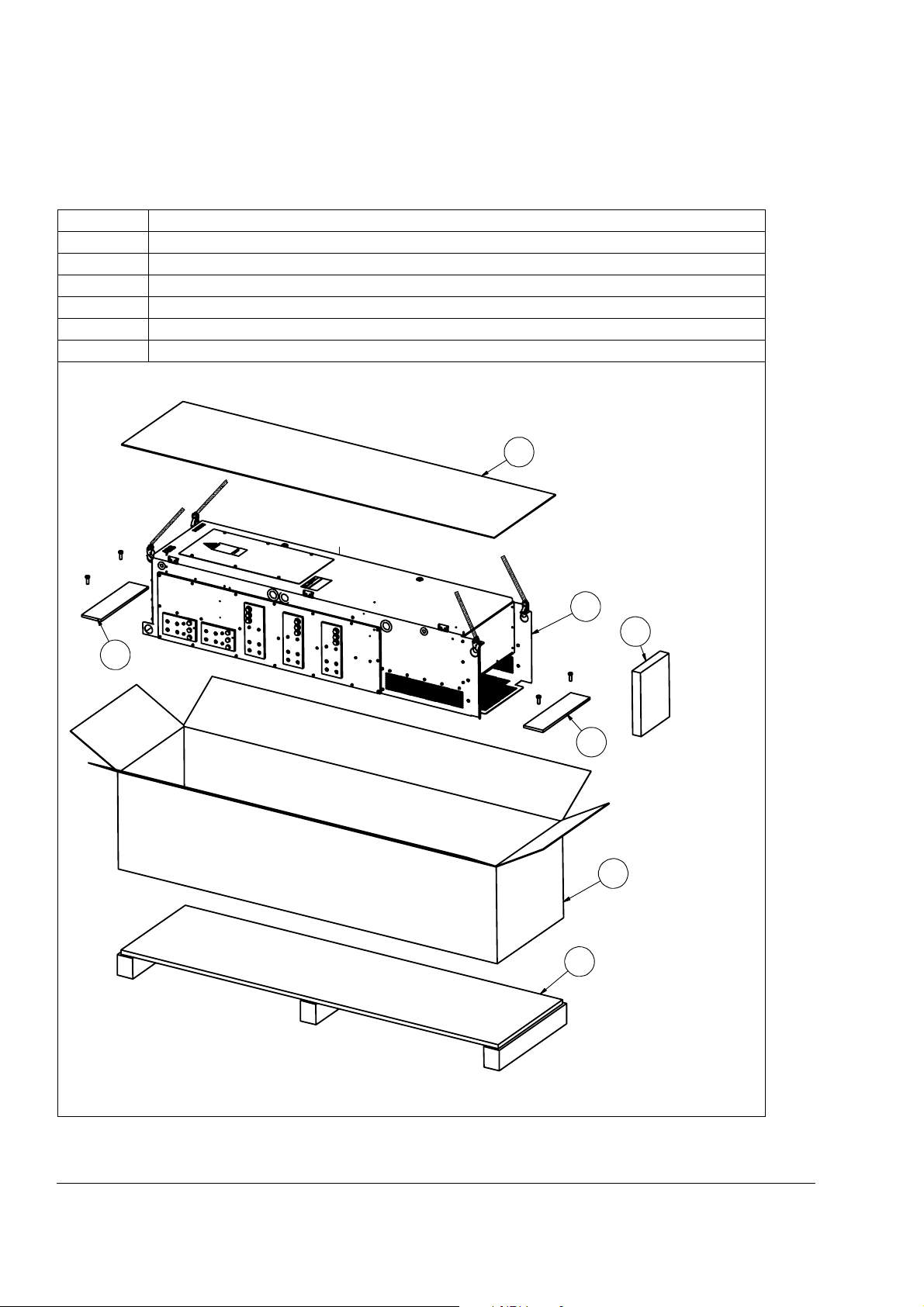

Unpacking and examining the delivery (H4)

BG_DCS_001_verpackung_a.ai

1

3

4

4

5

6

2

This illustration shows the layout of the transport package. Examine that all items are present.

Item Description

1 Drive with factory installed options.

2 Cardboard box.

3 Shock damper.

4 Shock dampers.

5 Shock damper.

6 Package containing documentation, plugs, mounting material, etc.

23

Mechanical installation

3ADW000462R0401 DCS880 Hardware manual e d

24

BG_DCS_001_verpackung_a.ai

A ( 1 : 2 )

A

2

3

4

1

3

1.a

1.b

1.c

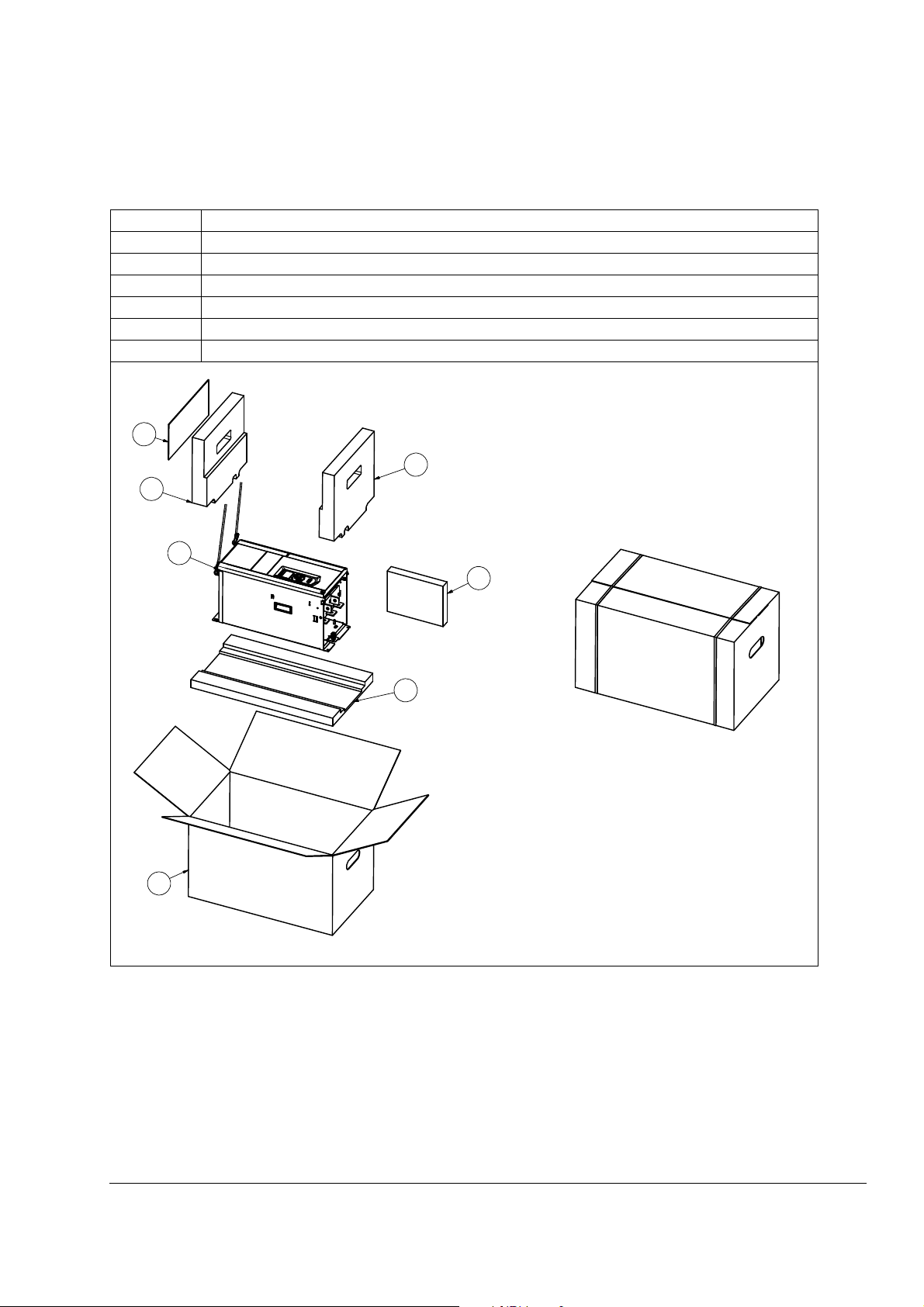

Unpacking and examining the delivery (H5)

This illustration shows the layout of the transport package. Examine that all items are present.

Item Description

1 Drive with factory installed options.

1.a Converter fan, remove before installation.

1.b Lifting lugs bracket.

1.c Lifting lugs bracket, attach before installation.

2 Cardboard box.

3 Shock dampers.

4 Package containing documentation, plugs, mounting material, etc.

Mechanical installation

3ADW000462R0401 DCS880 Hardware manual e d

Unpacking and examining the delivery (H6)

BG_DCS_001_verpackung_a.ai

1

2

3

4

4

5

5

6

This illustration shows the layout of the transport package. Examine that all items are present.

Item Description

1 Drive with factory installed options.

2 Cardboard box.

3 Shock damper.

4 Lower and upper cardboard box cover.

5 Shock dampers.

6 Package containing documentation, plugs, mounting material, etc.

25

3ADW000462R0401 DCS880 Hardware manual e d

Mechanical installation

26

BG_DCS_001_verpackung_a.ai

1

5

4

2

3

4

6

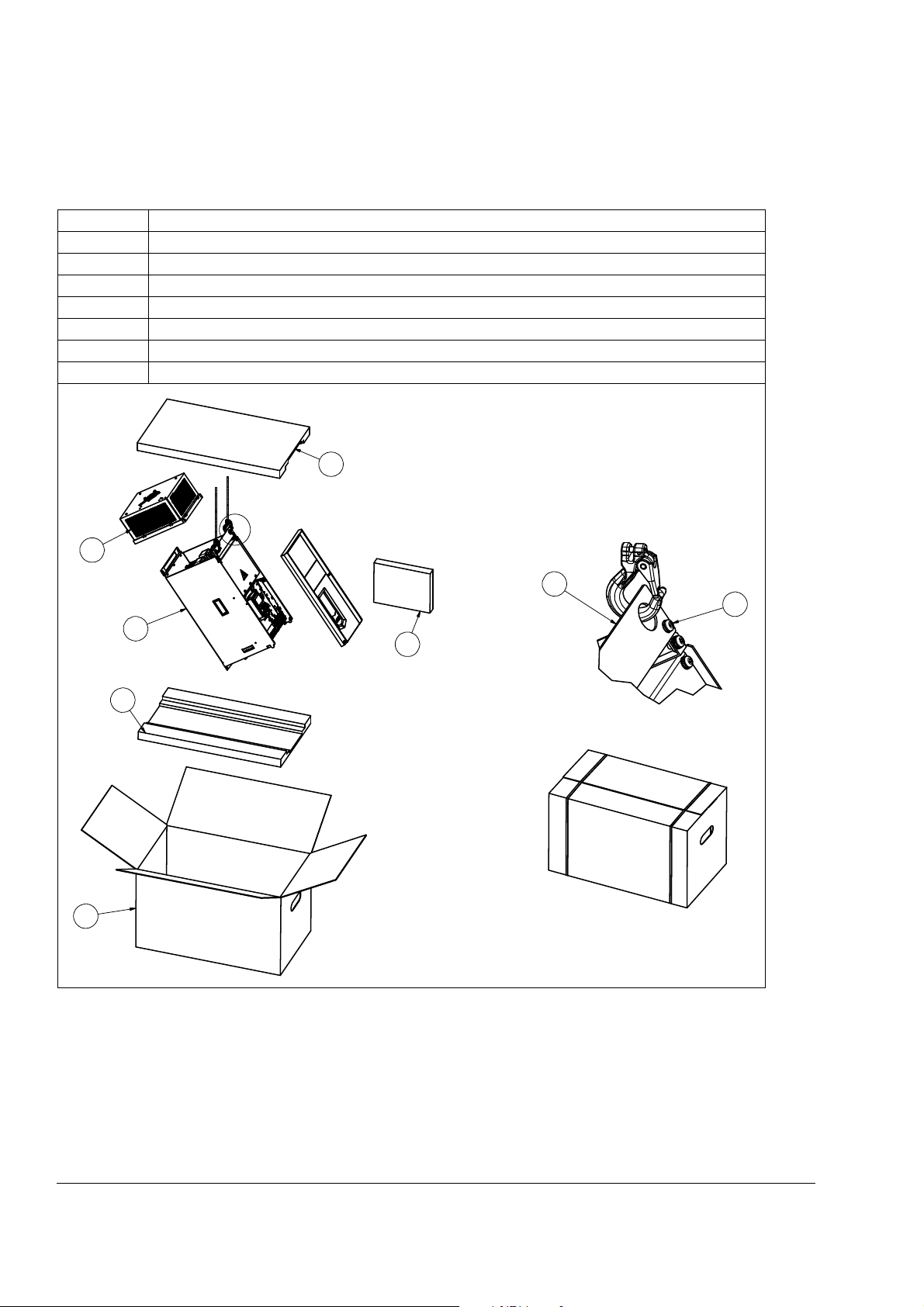

Unpacking and examining the delivery (H7, H8)

This illustration shows the layout of the transport package. Examine that all items are present.

Item Description

1 Drive with factory installed options.

2 Cardboard box.

3 Lower cardboard box cover.

4 Brackets to fasten the drive, remove before installation.

5 Shock damper.

6 Package containing documentation, plugs, mounting material, etc.

Mechanical installation

3ADW000462R0401 DCS880 Hardware manual e d

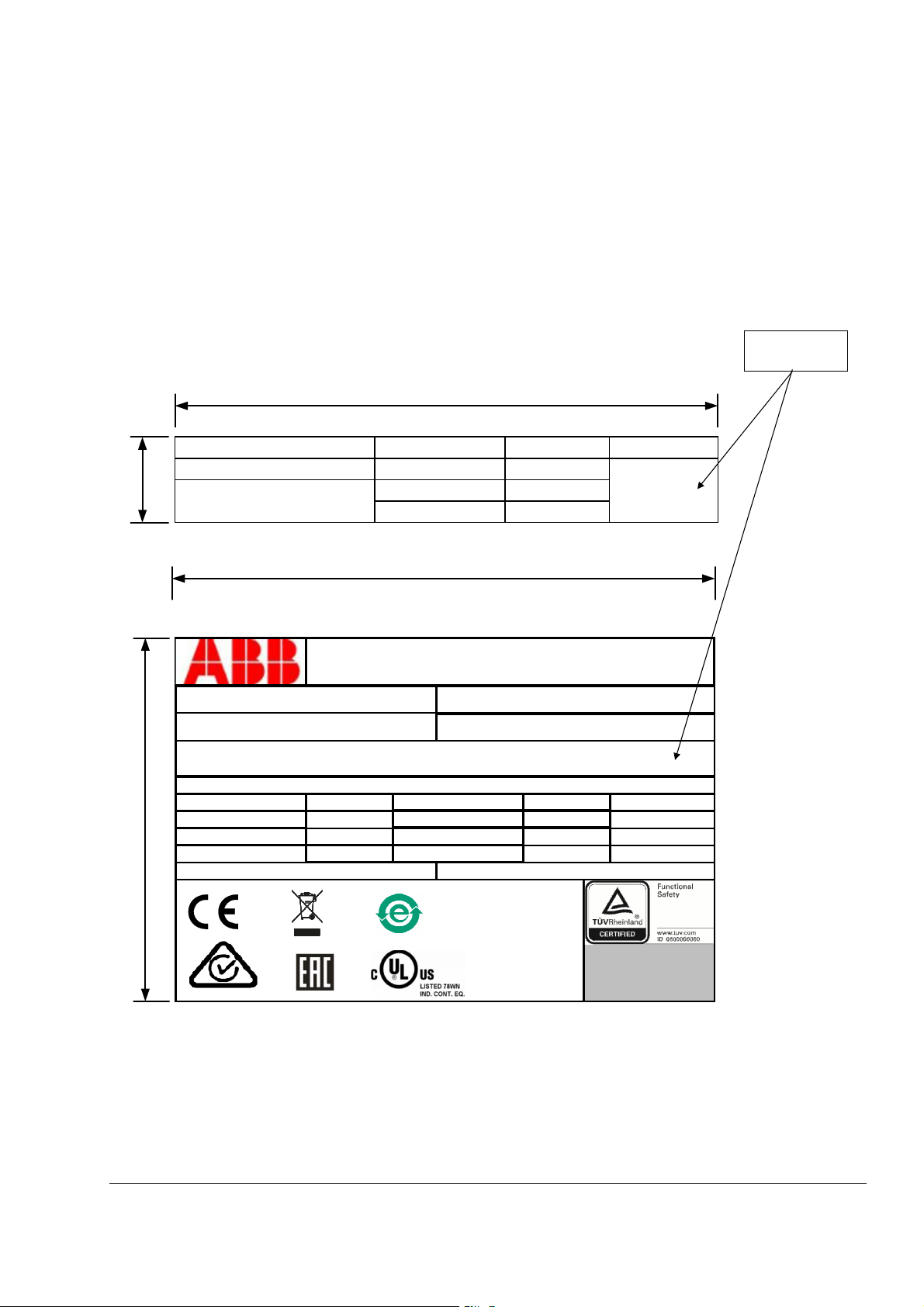

Delivery check

ϮϬϬϬ

ϭϮϱϬϬ

ƐƐĞŵďůĞĚŝŶWŽůĂŶĚ

Ƶ ƚŽŵ Ăƚŝ ŽŶ WƌŽ ĚƵĐ ƚƐ 'ŵ ď,

dLJƉĞ ^ϴϴ ϬͲ^ϬϮͲϬϬϱϬͲϬϱyϬ

hϭ

/

ϯΕϮϯϬͲϱϮ ϱshϮ

/

ϬͲϱϰϱs

/ϭϰϭ

/ϮϱϬ

^ĞƌEŽ ϭϭϭϭϭϭϭĂĂďďĐĐĐĐ

/Ĩ ϭͲϭϮ

h

&ĂŶ

/ ŶƚĞƌŶĂ ů

ĨϭϱϬϲϬ,nj

^ZϲϱŬ

ϴϱϬϬ

ϭϮϱϬϬ

ƵƚŽŵĂƚŝŽŶWƌŽĚƵĐƚƐ'ŵď,

tĂůůƐ ƚĂĚƚĞƌ ^ƚƌĂƘ Ğϱϵ

ϲϴϱϮϲ>Ă ĚĞ ŶďƵƌŐ' ĞƌŵĂŶ LJ

^ϴϴϬͲ^ϬϮͲϬϬϱϬͲϬϱyϬ ^ĞƌEŽ ϭϭϭϭϭϭϭĂĂďďĐĐĐĐ

^ĞƌEŽĂƌĐŽĚĞ

ĞƐŝŐ ŶĞĚď LJ ŝŶ'ĞƌŵĂŶ LJ ƐƐĞŵďůĞ ĚŝŶW ŽůĂŶĚ

hϭ

/

ϯΕϮϯϬͲϱϮ ϱs/ϭϰϭ

ĨϭϱϬϲϬ,nj

hϮ

/

ϬͲϱϰϱs

/ϮϱϬ

/ĨϭͲϭϮ

h&ĂŶ/ŶƚĞƌŶĂů ^ŝnjĞ,ϭ

ZĂƚĞĚ ŽŶǀĞƌƚĞƌ Ăƚ Ă

ŝƌĨ ůŽǁϱϳŵϹŚ /WϬϬ

hϭh>ϯΕϮϯϬͲϱϮ ϱs

hϮh>ϬͲϱϰϱs

h>ŽƉĞŶƚLJƉĞ

dĞŵƉϰϬΣ

h

Ƶdž

ϭϭϱsϮϯϬs

^ZϲϱŬ

)LHOGIRU3OXV

&RGHV

Check that there are no signs of damage. Before attempting installation and operation, check the

information on the nameplate of the converter module to verify that the unit is of the correct type.

The label includes an IEC rating, cULus, C-tick (N713) and CE markings, a type code and a serial

number, which allow individual identification of each unit. The remaining digits complete the serial

number so that there are no two units with the same serial number.

See an example nameplate below.

27

3ADW000462R0401 DCS880 Hardware manual e d

Mechanical installation

28

Ser. No. 0025421A17294264

1729 = Production year 2017 and week 29.

U1

U2

U1

U2

IEC

IEC

UL

UL

Rated input voltage according to IEC.

Rated output voltage according to IEC.

Rated input voltage according to UL.

Rated output voltage according to UL.

I1 Rated input current.

I2 Rated output current.

If Rated internal field exciter current.

f1 Rated frequency of mains voltage.

U

Fan

Rated fan voltage.

Airflow Rated cooling air flow.

U

Aux

Rated auxiliary voltage.

Size Unit size.

SCCR Short circuit current ratio.

IP: 00 Protection class according to ISO20653.

UL: open type Protection class according to UL.

Temp Max. permissible cooling air temperature.

Mechanical installation

3ADW000462R0401 DCS880 Hardware manual e d

29

BG_880_013_H3-Bef_a.ai

× 4

× 4

× 4

× 4

12 3

4

M6

5

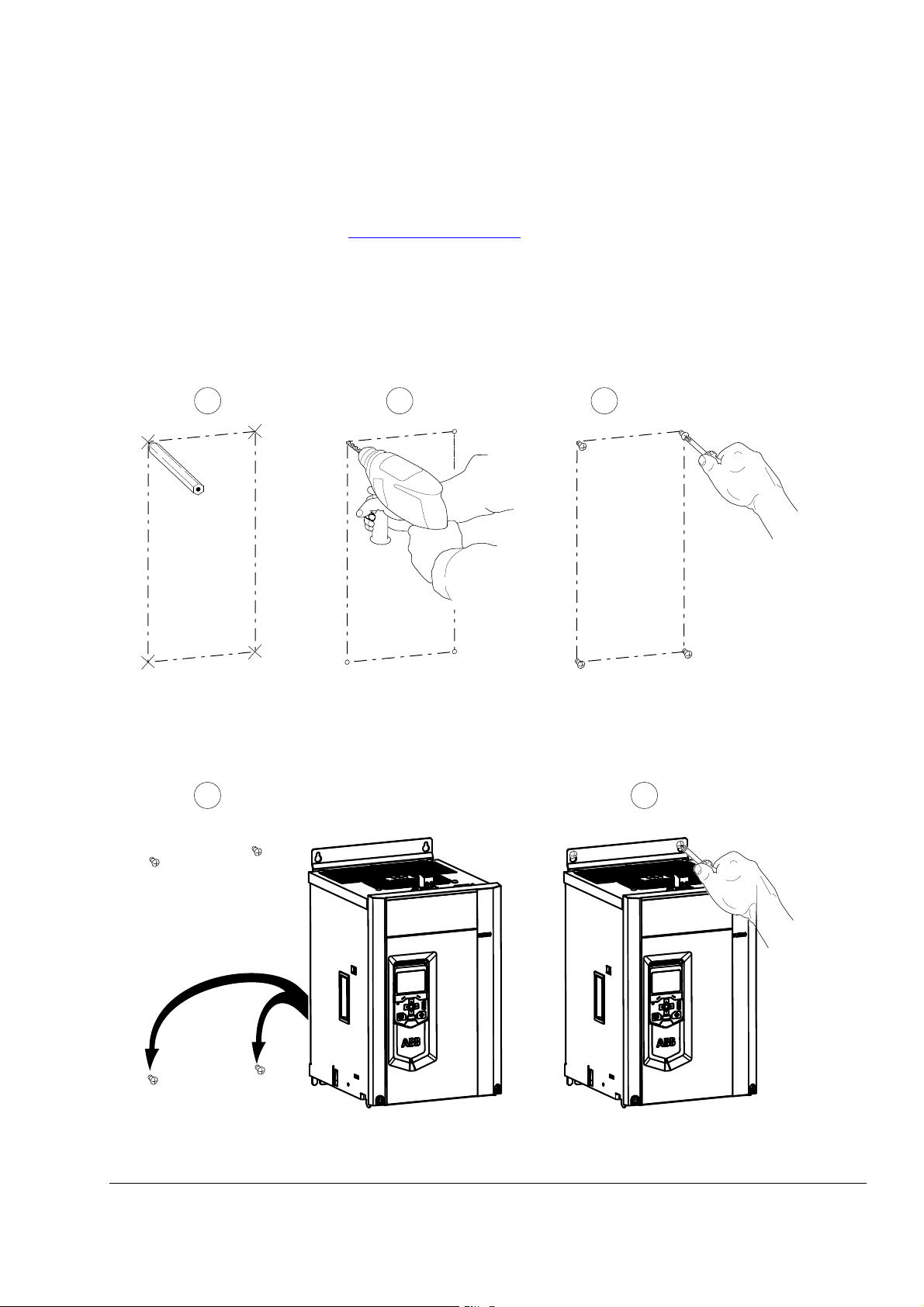

Installing the drive (H1 … H3)

This section tells you how to install the drive on wall without vibration dampers. The degree of protection is IEC:

IP00 and UL: open type.

1. See the dimensions in chapter Dimensions and weights.

2. Drill the mounting holes.

3. Insert wall plugs into the holes and start to screw bolts into the plugs. Drive the bolts deep enough into the

wall to make them carry the weight of the drive.

4. Position the drive onto the bolts on the wall.

5. Tighten the bolts securely in the wall.

Mark the locations for the four mounting holes.

3ADW000462R0401 DCS880 Hardware manual e d

Mechanical installation

30

BG_880_011_H4-Bef_a.ai

× 4

× 4

× 4

× 4

12 3

M6

4

5

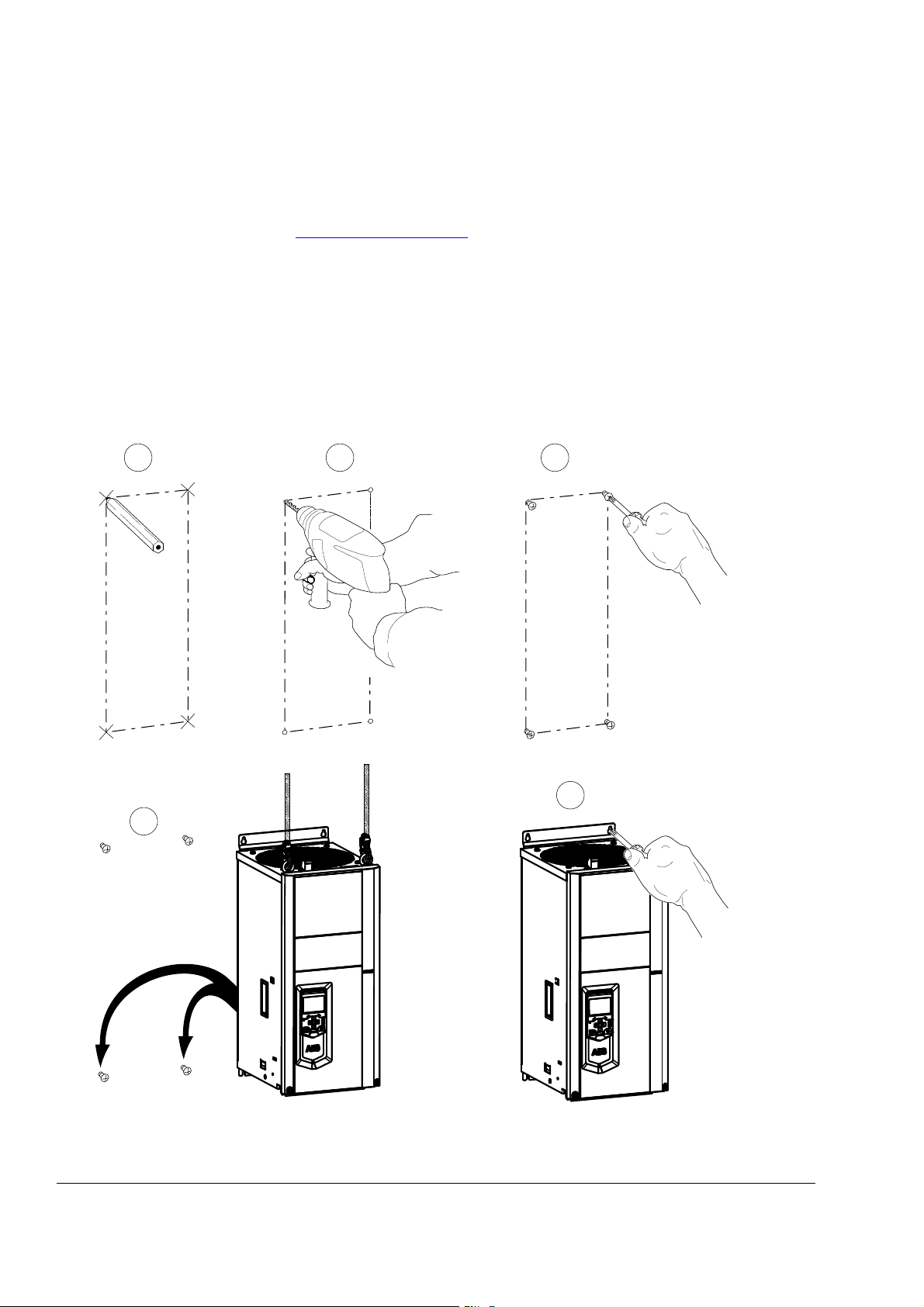

Installing the drive (H4, H5)

This section tells you how to install the drive on wall without vibration dampers. The degree of protection is IEC:

IP00 and UL: open type.

1. See the dimensions in chapter Dimensions and weights.

2. Drill the mounting holes.

3. Insert wall plugs into the holes and start to screw bolts into the plugs. Drive the bolts deep enough into the

wall to make them carry the weight of the drive.

4. Position the drive onto the bolts on the wall.

5. Tighten the bolts securely in the wall.

6. For H5 re-install the converter fan.

Mark the locations for the four mounting holes.

Mechanical installation

3ADW000462R0401 DCS880 Hardware manual e d

Loading...

Loading...