Page 1

DCS550

Quick Guide

DCS550 Drives (20 A to 1000 A)

Page 2

DCS550 Quick Guide

english Contents

DC Drives Worldwide Service Network .............................. 3

DCS550 Manuals ...............................................................4

DCS550 DC Drives ............................................................. 5

Brief instructions for CD and documents overview ............. 7

Notes on EMC .................................................................... 8

Standard function assignments for the terminals ...............10

Connection example .........................................................11

Fan power connection ...................................................... 13

Terminal locations on the converter ...................................14

Notes For North American Installations .............................15

Safety and operating instructions .....................................17

Installing the DCS550 PC tools on Your computer ............ 18

Commissioning .................................................................19

DCS550 Control Panel .....................................................20

Dimensions, drilling patterns and weights ........................ 77

Fault / Alarm list ............................................................... 80

Diagnosis messages.......................................... ...............86

Macro & Firmware structure ..............................................91

Declaration of conformity ................................................ 104

Declaration of Incorporation ........................................... 105

deutsch Inhalt

DC Drives Worldwide Service Network .............................. 3

DCS550 Manuals / DCS550 Handbücher ...........................4

DCS550 Gleichstromantriebe ........................................... 21

Kurzanweisung CD und Dokumentationsübersicht ..........23

EMV Filter ......................................................................... 24

Digitaler und analoger E-A/Anschluss von SDCS-CON-F .. 26

Anschlussbeispiel .............................................................27

Lüfterkühlung ...................................................................29

Klemmen- und Steckeranordnung des Stromrichters ........ 30

Sicherheits- und Anwendungshinweise ............................. 31

Installation der DCS550 Programme auf dem PC ............. 32

Inbetriebnahme ................................................................33

DCS550 Steuertafel .......................................................... 34

Abmessungen, Bohrbild und Gewichte ............................ 77

Fehler- / Alarmliste ........................................................... 80

Diagnosemeldungen.......................................... ............... 86

Makro & Firmware Struktur ............................................... 91

Declaration of conformity ................................................ 104

Declaration of Incorporation ........................................... 105

español Contenido

DC Drives Worldwide Service Network ............................... 3

DCS550 Manuals / Manuales de DCS550 ..........................4

Convertidores de CC DCS550 ......................................... 49

Instrucciones para el CD y de la documentación ..............51

Notas acerca de EMC .....................................................52

Asignaciones de funciones estándar para los terminales ... 54

Ejemplo de conexión ........................................................ 55

Conexión de alimentación del ventilador ..........................57

Ubicación de los terminales en el convertidor ...................58

Instrucciones de seguridad ............................................... 59

Cómo instalar las herramientas para PC del DCS550 ......60

Puesta en funcionamiento ...............................................61

Panel de control del DCS550 ........................................... 62

Dimensiones, patrones de taladrado y pesos....................77

Lista de errores / alarmas ................................................80

Mensajes de diagnóstico .................................................86

Estructura del macro & firmware ....................................... 91

Declaration of conformity ................................................ 104

Declaration of Incorporation ............................................ 105

français Sommaire

DC Drives Worldwide Service Network .............................. 3

DCS550 Manuals / Manuels du DCS550 ............................ 4

Variateurs à courant continu DCS550 ............................... 63

Documentation technique ................................................ 65

Compatibilité électromagnétique (CEM) ............................ 66

Raccordement standard des signaux d’E/S ...................... 68

Exemple de schéma de câblage ....................................... 69

Câblage du ventilateur ...................................................... 71

Emplacement des bornes sur le convertisseur .................. 72

Consignes de sécurité et d’exploitation............................. 73

Installation des outils logiciels du DCS550 sur votre PC .... 74

Mise en service ................................................................. 75

Micro-console DCS550 .................................................... 76

Dimensions, perçages et poids ........................................ 77

Liste des erreurs / alarmes ............................................... 80

Messages de diagnostic.......................................... ......... 86

Structure du logiciel macro & système .............................. 91

Declaration of conformity ................................................ 104

Declaration of Incorporation ........................................... 105

italiano Indice

DC Drives Worldwide Service Network .............................. 3

DCS550 Manuals / DCS550 Manuali .................................. 4

DCS550 DC Drives ........................................................... 35

Brevi istruzioni CD e documentazione Panoramica ...........37

Note sulle EMC ................................................................. 38

Assegnazione funzioni standard per i morsetti ..................40

Esempi schemi di collegamento........................................41

Ventole di raffreddamento ................................................. 43

Posizioni terminali sul convertitore ..................................... 44

Istruzioni per la sicurezza .................................................. 45

Installa i DCS550 PC tools sul Tuo computer .................... 46

Messa in servizio ..............................................................47

DCS550 Pannello di controllo ...........................................48

Dimensioni, schemi di foratura e pesi ............................... 77

Errore / Allarme di lista ..................................................... 80

Messaggi di diagnostica.......................................... ......... 86

Struttura macro & firmware ............................................... 91

Declaration of conformity ................................................ 104

Declaration of Incorporation ........................................... 105

2 3ADW000395R0100 DCS550 Quick guide edisf a2 3ADW000395R0100 DCS550 Quick guide edisf a

Page 3

ABB Drive Service EN

In order to offer the same after sales

service to our customer around the

world, ABB has created the DRIVE

SERVICE CONCEPT.

ABB's after sales service is globally

consistent due to common targets,

rules, and the way of operation. This

means for our customers:

Please visit the ABB drive service

homepage

www.abb.com/drivesservices

ABB Drive Service FR

Pour offrir la même qualité de service

à tous nos clients, ABB a créé DRIVE

SERVICE CONCEPT.

Dans le monde entier, les équipes de

service proposent les mêmes prestations aux mêmes conditions avec les

mêmes objectifs.

Pour en savoir plus, connectez-vous

sur ABB drive service homepage

www.abb.com/drivesservices

ABB Drive Service DE

Um jedem Kunden rund um die Welt

die gleiche Service Dienstleistung anbieten zu können, hat ABB das DRIVE

SERVICE CONCEPT entwickelt.

Durch die Definition von einheitlichen

Zielen, Regeln, und Arbeitsvorschriften kann ABB die Dienstleitungs

Produkte weltweit auf gleichwertig

hohem Qualitätsniveau anbieten. Für

unsere Kunden bedeuted dies:

Bitte besuchen Sie die ABB-Homepage Service für Antriebe

www.abb.com/drivesservices

ABB Drive Service IT

ABB ha creato il DRIVE SERVICE

CENCEPT, con lo scopo di offrire ai

nostri clienti lo stesso servizio post

vendita in tutto il mondo.

Attraverso la definizione di obbiettivi

comuni, ruoli e modo di operare, le

attività post vendita di ABB offrono

sevizi coerenti nella loro globalità. Per

i nostri clienti questo significa:

Vi invitiamo a visitare la homepage

ABB drive service

www.abb.com/drivesservices

ABB Drive Service ES

Para poder ofrecer el mismo servicio

posventa a nuestros clientes en todo

el mundo, ABB ha creado el CONCEPTO DE SERVICIO DE CONVERTIDORES.

El servicio posventa de ABB está

mundialmente consolidado gracias a

unos objetivos y normas comunes,

así como a su funcionamiento. Esto

significa para nuestros clientes:

Visiten el portal de convertidores de

ABB

www.abb.com/drivesservices

english

DC Drives Worldwide Service Network

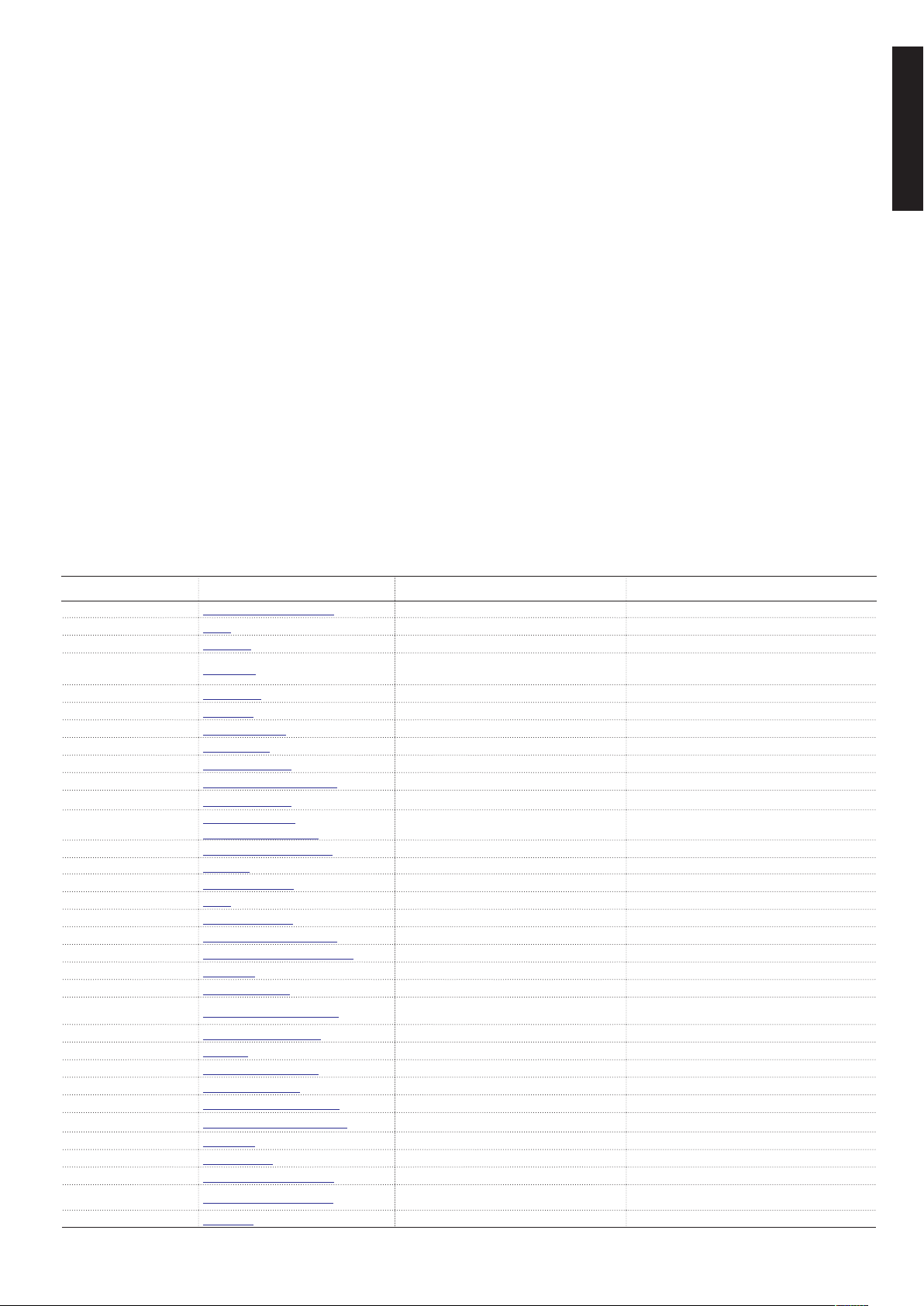

Country Local ABB Service Town Service Phone No.

Argentina Asea Brown Boveri S.A. BUENOS AIRES +54 (0) 12 29 55 00

Australia ABB NOTTING HILL +61 (0) 3 85 44 00 00

Austria ABB AG WIEN +43 1 60 10 90

Belgium ABB N.V. ZAVENTEM

Brazil ABB Ltda. OSASCO +55 (0) 11 70 84 91 11

Canada ABB Inc. SAINT-LAURENT +1800 865 7628

China ABB China Ltd BEIJING +86 40 08 10 88 85 - 24h service

Czech Republic ABB S.R.O. PRAHA +42 02 34 32 23 60

Finland ABB Oy Service KUUSANKOSKI +35 8 10 22 51 00

Finland ABB Oy Product Service HELSINKI +35 8 10 22 20 00

Finland ABB Oy Service NOKIA +35 8 10 22 51 40

France

ABB Automation

ABB Process Industry

MONTLUEL from abroad

France

Germany ABB Process Industries MANNHEIM +49 18 05 22 25 80

Greece ABB SA METAMORPHOSSIS +30 69 36 58 45 74

Ireland ABB Ireland Ltd. TALLAGHT +35 3 14 05 73 00

Italy ABB MILAN +39 02 90 34 73 91

Korea, Republic ABB Ltd., Korea CHONAN +82 (0) 4 15 29 22

Malaysia ABB Malaysia Sdn. Bhd. KUALA LUMPUR +60 3 56 28 42 65

Mexico ABB Sistemas S.A. DE C.V. TLALNEPANTLA +52 53 28 14 00

Netherlands ABB B.V. ROTTERDAM +31 1 04 07 88 66

New Zealand ABB Service ltd AUCKLAND +64 92 76 60 16

Poland ABB Centrum IT Sp.zo.o

WROCLAW

LODZ

Russia ABB Automation LLC MOSCOW +74 95 96 0

Switzerland ABB AG DÄTTWIL +41 5 85 86 87 86

Singapore ABB Industry Pte Ltd SINGAPORE +65 67 76 57 11

Slovakia ABB Elektro s.r.o. BANSKA BYSTRICA +42 19 05 58 12 78

South Africa ABB South Africa (Pty) Lt JOHANNESBURG +27 1 16 17 20 00

Spain ABB Automation Products BARCELONA +34 9 37 28 73 00

Taiwan ABB Ltd. TAIPEI 105 +88 62 25 77 60 90

Thailand ABB Limited SAMUTPRAKARN +66 27 09 33 46

Turkey ABB Elektirk Sanayi A.S ISTANBUL +90 2 16 36 52 90

USA ABB Industrial Products NEW BERLIN

Venezuela ABB S.A. CRCS +58 (0) 22 38 24 11 / 12

+32 27 18 64 86

+32 27 18 65 00 - 24h service

+33 1 34 40 25 81

+0810 02 00 00

+48 42 61 34 96 2

+48 42 29 93 91 39 5

+1 26 27 85 32 00

+1 262 435 7365

33ADW000395R0100 DCS550 Quick guide edisf a 33ADW000395R0100 DCS550 Quick guide edisf a

Page 4

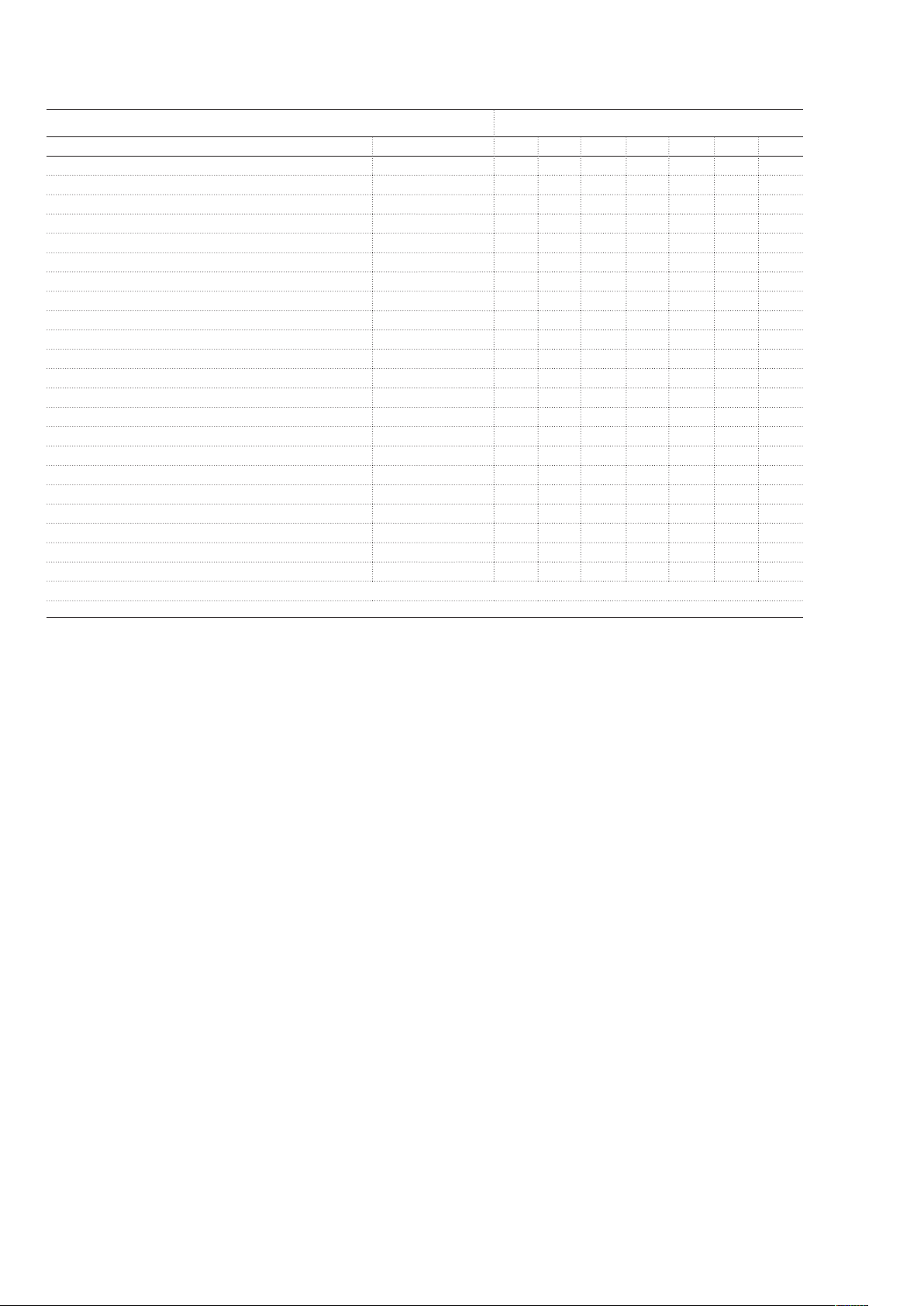

DCS550 Manuals

Language

Public. number E D I ES F CN RU

Quick Guide 3ADW000395 x x x x x

DCS550 Tools & Documentation CD 3ADW000377 x

DCS550 Modules

DCS550 Flyer 3ADW000374 x x

DCS550 Technical Catalog 3ADW000378 p

DCS550 Manual 3ADW000379 x

DCS550 Service Manual 3ADW000399 p

Installation according to EMC 3ADW000032 x

Technical Guide 3ADW000163 x

Extension Modules

RAIO-01 Analog IO Extension 3AFE64484567 x

RDIO-01 Digital IO Extension 3AFE64485733 x

Serial Communication

RPBA-01 PROFIBUS 3AFE64504215 x

RCAN-01 CANopen 3AFE64504231 x

RCNA-01 ControlNet 3AFE64506005 x

RDNA-01 DeviceNet 3AFE64504223 x

RMBA-01 MODBUS 3AFE64498851 x

RETA-01 Ethernet 3AFE64539736 x

x -> existing p -> planned

Status 05.2011

DCS550 Drive Manuals-List_d.doc

4 3ADW000395R0100 DCS550 Quick guide edisf a4 3ADW000395R0100 DCS550 Quick guide edisf a

Page 5

english

Standard Features

− compact

− highest power ability

− simple operation

− comfortable assistants, e.g. for autotuning or commissioning

3ADW000395R0100 DCS550 Quick guide edisf a

5

53ADW000395R0100 DCS550 Quick guide edisf a

Page 6

DCS550 DC Drives

Technical data

Mains supply volt. 230...525 V,

+/–10 %, 3~

Frequency 50...60 Hz, +/–5

Hz

Electronics supply 115...230 V,

–15 % / +10 %, 1~

DC Output current 20...1000 A

Overload capability 200 %

Ambient conditions

Ambient temperat. 0° ... +40° C

40° ... 50°C with

reduction

Storage temperat. –40° ... +55° C

Transport temper. –40° ... +70° C

Relative humidity 5 ... 95 %, not

condensing

(max. 50 % betw.

0°...5° C)

Pollution degree Class 2

Protection class IP 00

Altitude < 1,000 m height

above sea level:

nominal Current

> 1,000 m height

above sea level:

with reduction

I/O

Digital inputs: 8 standard, up to

14 optional

Digital outputs: 5 standard, up

to 9 optional

Analog inputs: 4 standard +/–

10 V; 0/2…10 V, up to 8 optional

+/ 20 mA; 0/4…20 mA

Analog outputs: 3 standard (1x

I

) +/-10 V; 0/2…10 V, up to 7

act

optional –20 mA; 0/4…20 mA

PC-Tools

DriveWindow Light: free of

charge with every converter,

Standard RS232 PC-connection

Approvals

(in preparation 12/2011)

Adaptive Programming

pre-defined drive-specific function

blocks, e.g.

• Free process controller (PIController)

• I/O- and digital Operations

With control panel or PC-Tool, no

need for additional hardware

Speed Feedback

EMF

Analog tacho

Encoder

Communication

Serial communication

• Ethernet • Profibus

• CANopen • DeviceNet

• ControlNet • EtherCat

• Modbus • ProfiNet

Industrial IT© enabled

Protections

Speed feedback monitoring •

Temperature • Overload • Over

speed • Motor stalled • Motor

over current • Motor over voltage

• Field over current • Minimum

field current • Zero speed •

Armature current ripple • Mains

over- and under voltage

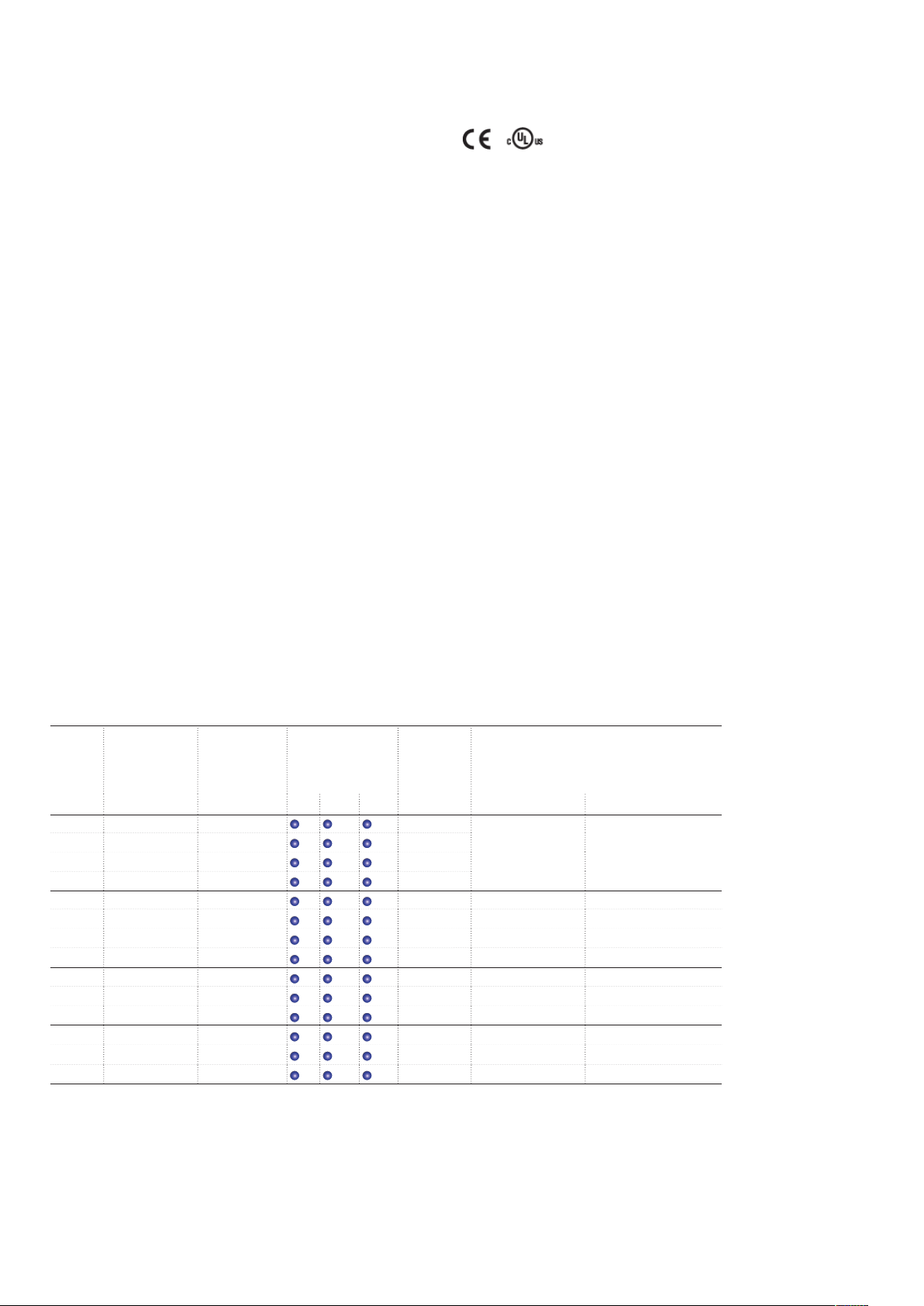

Current ratings, dimensions

Unit

size

F1 20 25 12 370 x 270 x 208 14.56 x 10.65 x 8.20

45 50

65 75

90 100

F2 135 150 18 370 x 270 x 264 14.56 x 10.65 x 10.40

270 300

F3 315 350 25 459 x 270 x 310 18.07 x 10,65 x 12,25

405 450

470 520

F4 610 680 35 644 x 270 x 345 25.35 x 10.65 x 13.60

740 820

900 1000

2-Q

rated Current

DCS550-S01

IDC[A] IDC[A] 230 400 525 [ADC] h x w x d [mm] h x w x d [inch]

180 200

225 250

4-Q

rated Current

DCS550-S02

Supply voltage

[V

]

AC

max. field

current

internal

Dimensions

6 3ADW000395R0100 DCS550 Quick guide edisf a6 3ADW000395R0100 DCS550 Quick guide edisf a

Page 7

Brief instructions for CD and documents overview

©

2

0

1

1

A

B

B

A

u

t

o

m

a

t

i

o

n

P

r

o

d

u

t

G

m

b

H

-

A

l

l

R

i

g

h

t

R

e

e

r

e

d

3ADW 000 377 R0201 / April 2011

System configuration

WINDOWS 98, NT, 2000, XP

Acrobat Reader 4.0 or higher

Internet Explorer 5.0 or higher

I

f

t

h

e

C

D

R

O

M

w

o

n

’

t

s

t

a

r

t

a

u

t

o

m

a

t

i

c

a

l

l

y

p

l

e

a

s

e

e

x

e

c

u

t

e

S

T

A

R

T

.

B

A

T

System confirmation

Win2000, WinXP

Before installation of PC tools

remove previous version by

CONTROL PANEL of your

PC

Read more details in

Quick Guide 3ADW000191

Content

This CD ROM provides

information about DCS550 and

contains PC tools:

DWL 2.93 for DC drives

+Commissioning Wizard 1.0

+DWL AP 2.2

FDT 2.2 Firmware

download kit

+ workspace

Firmware 1.1

DCS550

Ver.: 1.10

System confirmation

Win7, Win2000, WinXP

Before installation of PC tools

remove previous version by

CONTROL PANEL of your PC

We appreciate that you purchased an ABB DC drive power

converter and thank you for the trust you put in our products.

This brochure was put together to make sure that you continue to be satisfied with our product. It is intended to provide

you with a brief overview of the product's key data, EMC

notes, typical applications, start-up and trouble-shooting.

If you need more information about the product you are provided with a CD-ROM in addition to this brief documentation.

The CD-ROM is part of the delivery and features the following

contents:

Technical catalog (3ADW000378)

Comprehensive information to engineer complete DC drive

systems.

Manual (3ADW000379)

Detailed information, with all important particulars about the

individual components, like module dimensions, electronic

boards, fans and auxiliary components.

Information for mechanical and electrical installation are also

included.

Detailed information with all important issues about firmware

and setting of parameters. The manual includes information

for start-up and maintenance of the entire drive, in detailed

form.

This manual also includes Fault and Alarm codes and information for trouble shooting.

Service Manual (3ADW000399)

for maintenance and repair of the converters.

Additional information about applications and technical

accessories (e.g. Hardware extension or Field bus interfaces)

are handled by separate manuals.

See table DCS550 manuals.

System requirements to use the CD-ROM

c

− Operating system

WINDOWS 7, 2000, XP

s

s

s

v

− ACROBAT READER

In case the CD ROM does not

start automatically, please

double click on Setup.exe.

Further support

In addition we offer further support, since we can only be

satisfied when you, as our customer, are satisfied with us and

our products.

Internet

On the ABB homepage under

www.abb.com/dc

you'll find abundant information for

− DC products

− service support

− the latest updates

− tools

− downloads, etc.

Please don't hesitate to visit us.

Contacts

If you require any further information, please contact your

nearest ABB Drives office or send an email to:

DC-Drives@de.abb.com

Please give us your name, your company address and phone

number. We immediately put you in contact with our specialist.

english

3ADW000395R0100 DCS550 Quick guide edisf a

7

73ADW000395R0100 DCS550 Quick guide edisf a

Page 8

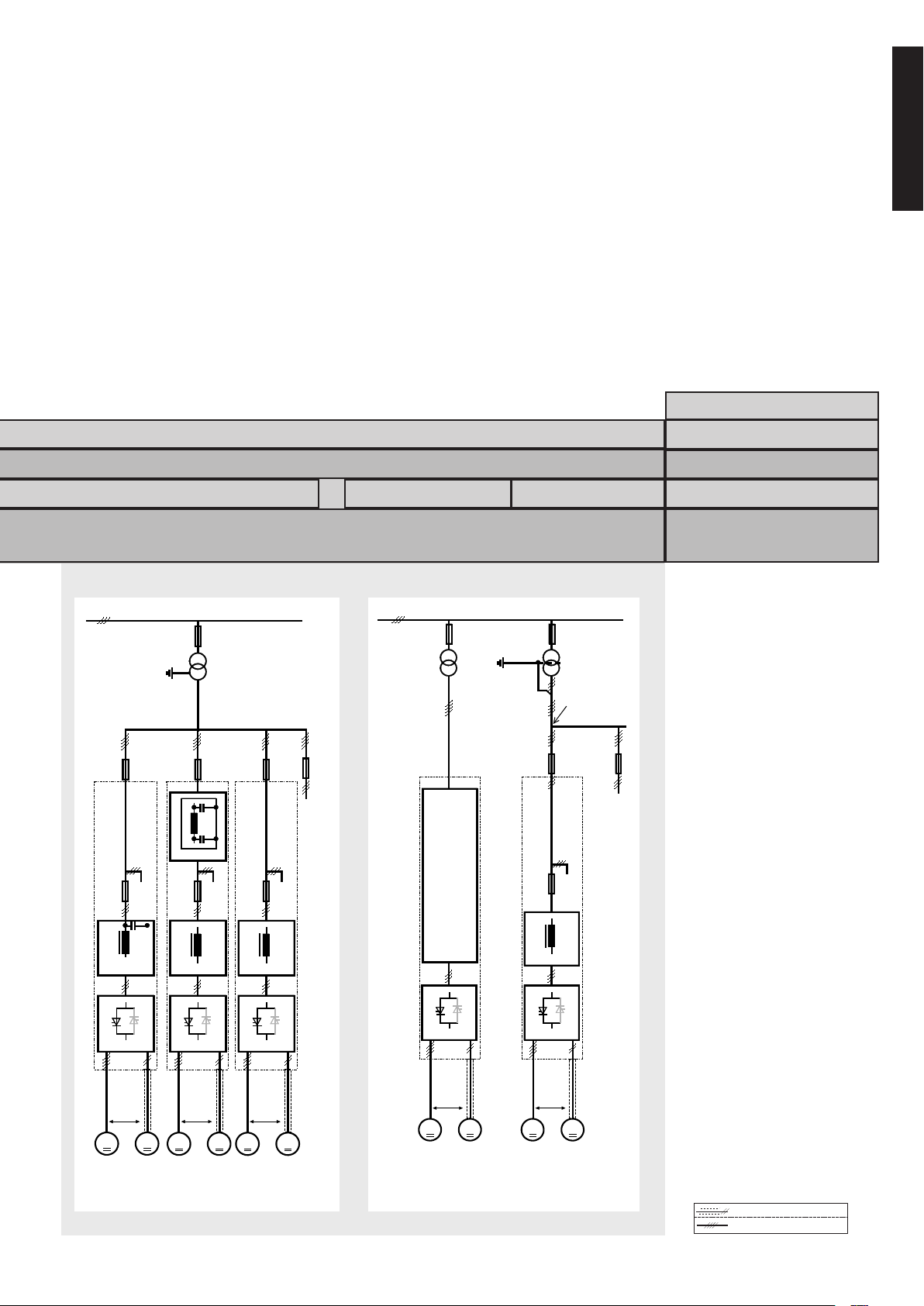

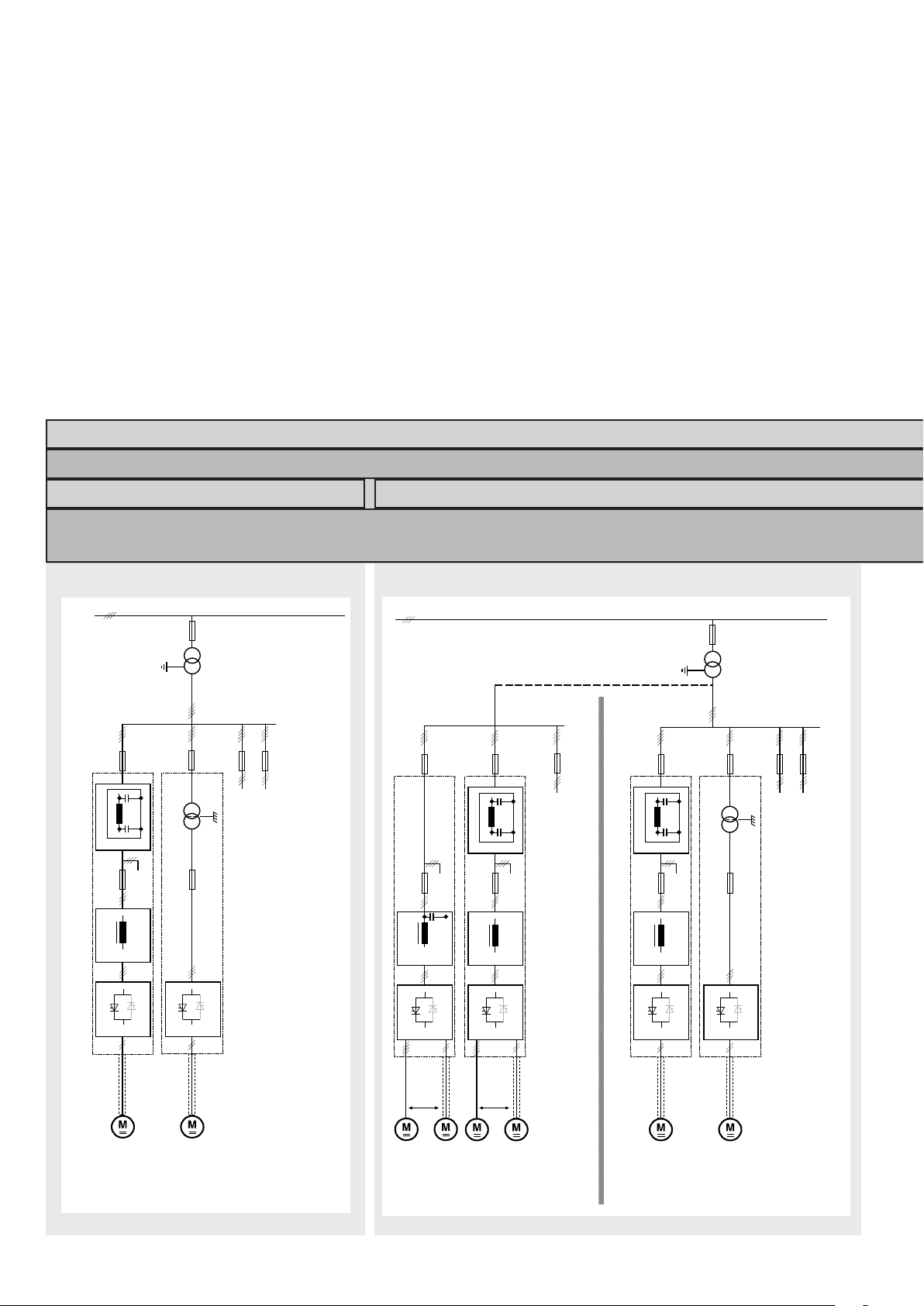

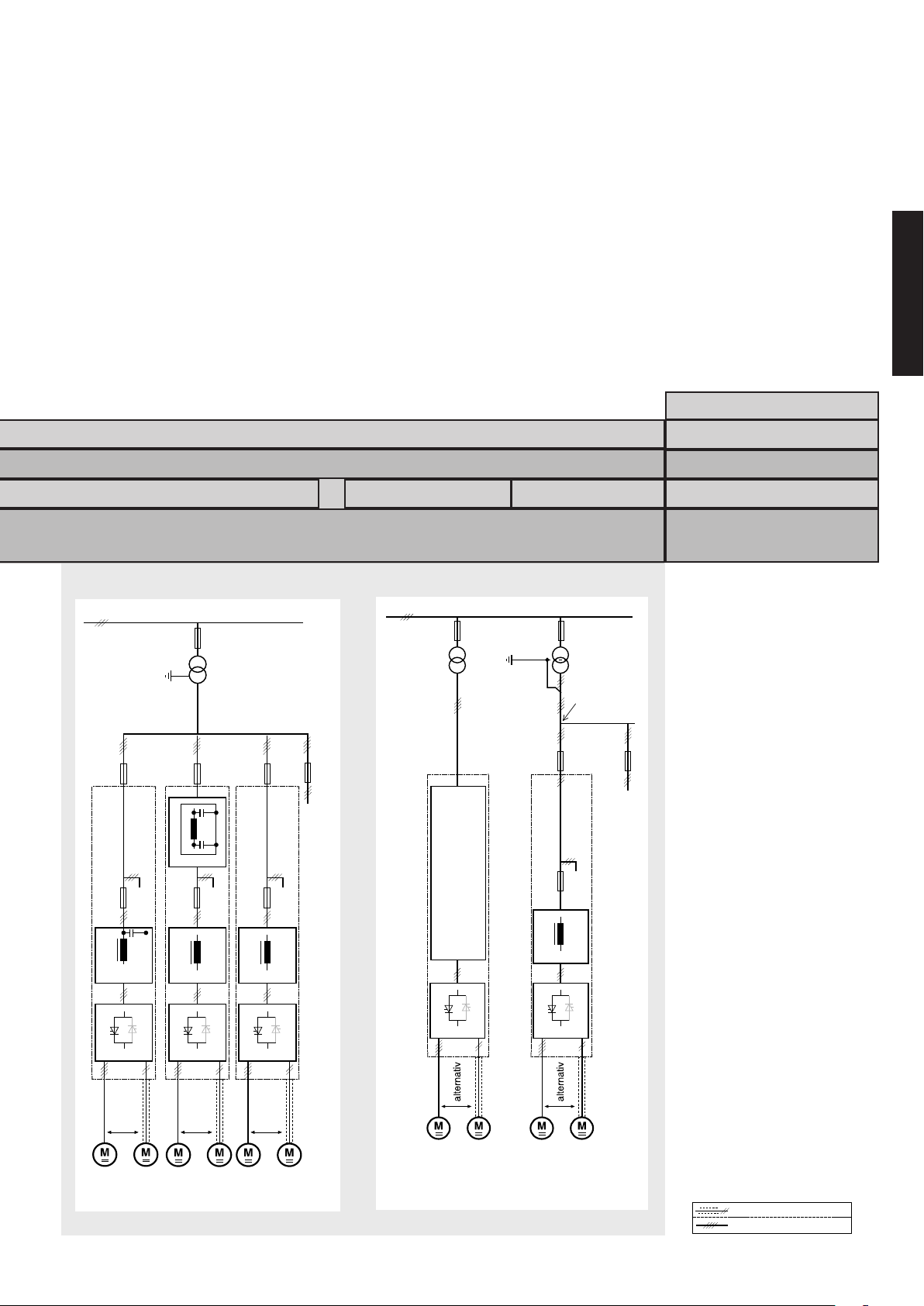

Notes on EMC

M

M

Mains filter

Converter

Line reactor

Supply transformer for a residential

area (rating normally

≤

1,2 MVA)

Earthed public 400-V

network with neutral

conductor

Medium-voltage network

Earthed

neutral

To other loads, e.g. drive systems

An isolating transformer

with an earthed screen

and earthed iron core

renders mains filter and

line reactor superfluous.

Operation at public

low-voltage network

together with other

loads of all kinds.

Residential area

To other loads which have to be protected from the system disturbances caused by

power converters (HF interference and commutation notches)

Converter

M

M

M

M

M

M

alternative

alternative

Line reactor +

Y-capacitor

Medium-voltage network

Supply transformer for a residential

area (rating normally

≤

1.2 MVA)

Earthed

neutral

Earthed public 400-V

network with neutral

conductor

To other loads, e.g. drive systems

Mains filter

Line reactor

Converter Converter

Mains filter

Line reactor

Converter Converter

An isolating transformer

with an earthed screen

and earthed iron core

renders mains filter and

line reactor superfluous.

Operation at public

low-voltage network

together with other

loads of all kinds.

To other loads, e.g. drive systems

To other loads which have to be protected from the system disturbances caused by

power converters (HF interference and commutation notches)

Earthed public 400-V

network with neutral

conductor

Operation at public

low-voltage network

together with other

loads of all kinds.

Light industry

Residential area

Commutaion notches < 20%

You will find further information in publication:

Technical Guide chapter:

EMC Compliant Installation

and Configuration for a

Power Drive System

The paragraphs below describe selection

of the electrical components in conformity

with the EMC Guideline.

The aim of the EMC Guideline is, as the

name implies, to achieve electromagnetic

compatibility with other products and

systems. The guideline ensures that the

emissions from the product concerned

are so low that they do not impair another

product‘s interference immunity.

In the context of the EMC Guideline, two

The EMC Guideline expects EMC to be taken

into account when a product is being developed; however, EMC cannot be designed in, it

can only be quantitatively measured.

Note on EMC conformity

The conformity procedure is the responsibility

of both the power converter‘s supplier and the

manufacturer of the machine or system concerned, in proportion to their share in expand-

ing the electrical equipment involved.

aspects must be borne in mind:

– the product‘s interference immunity

– the product‘s actual emissions

First environment (residential area with light industry) with PDS category C2 Second environment (industry) with PDS categories C3, C4

Not applied, since category C1 (general distribution sales channel) excluded Not applicable

satisfied satisfied

Not applicable

satisfied satisfied

8 3ADW000395R0100 DCS550 Quick guide edisf a8 3ADW000395R0100 DCS550 Quick guide edisf a

Page 9

For compliance with the protection ob-

MMMM

emv_clssif_b.dsf

Converter

transformer

Case-referenced EMC analysis

alternative

Converter

transformer

with earthed

iron core

(and earthed

screen where

appropriate)

alternative

I > 400 A

and/or

U > 500 V

Operation with separate power converter transformer. If there

are other loads at the same secondary winding, these must be

able to cope with the commutation gaps caused by the power

converter. In some cases, commutating reactors will be

required.

To other loads, e.g. drive systems

Converter Converter

Line reactor

Medium-voltage network

Industrial

zone

Legend

Unscreened cable with restriction

Screened cable

M

M

M

M

M

M

I

DC

< 100 A

I

DC

< 100 A

I

DC

>100 A

Supply transformer for a

residential area (rating

normally

≤

1.2 MVA)

Earthed 400-V network

with neutral conductor

;

3~

≤

400 A

Operation at low-voltage network together with

other loads of all kinds, apart from some kinds

of sensitive communication equipment.

To other loads, e.g. drive systems

Line reactor +

Y-capacitor

Line reactor

Converter Converter

Mains filter

Earthed

neutral

Medium-voltage network

Industrial zone

alternative

alternative

Line reactor

Converter

alternative

Commutation notches < 40%

jectives of the German EMC Act (EMVG)

in systems and machines, the following

EMC standards must be satisfied:

Product Standard EN 61800-3

EMC standard for drive systems (Pow-

erDriveSystem), interference immunity

and emissions in residential areas,

enterprise zones with light industry and

in industrial facilities.

This standard must be complied with in

the EU for satisfying the EMC requirements for systems and machines!

For emitted interference, the following apply:

EN 61000-6-3 Specialised basic standard for emissions in light industry

can be satisfied with special features (mains filters,

screened power cables) in the lower rating range *(EN 50081-1).

EN 61000-6-4 Specialised basic standard for emissions in industry *(EN 50081-2)

For interference immunity, the following apply:

EN 61000-6-1 Specialised basic standard for interference immunity in

residential areas *(EN 50082-1)

EN 61000-6-2 Specialised basic standard for interference immunity in

industry. If this standard is satisfied, then the EN 61000-6-1

standard is automatically satisfied as well *(EN 50082-2)

* The generic standards are given in brackets

Standards

EN 61800-3

EN 61000-6/3

english

PDS category C3

on customer's request

PDS category C4

satisfied

EN 61000-6/3

EN 61000-6-2

EN 61000-6-1

Classification

The following overview

utilises the terminology and

indicates the action required

in accordance with Product

Standard EN 61800-3.

For the DCS550 series,

the limit values for emitted

interference are complied

with, provided the measure

indicated is carried out. PDS

of category C2 (formerly

restricted distribution in first

environment) is intended to

be installed and commissioned only by a professional

(person or organization with

necessary skills in installing

and/or commissioning PDS

including their EMC aspects).

For power converters without

additional components, the

following warning applies:

This is a product of category

C2 under IEC 61800-3:2004.

In a domestic/residential

environment this product

may cause radio interference

in which case supplementary

mitigation measures my be

required.

The field supply is not depicted in this overview diagram.

For the field current cables,

the same rules apply as for

the armature-circuit cables.

3ADW000395R0100 DCS550 Quick guide edisf a

9

93ADW000395R0100 DCS550 Quick guide edisf a

Page 10

±90...±270 V

±

30...±90 V

±

8...±30 V

AI4

GND

GND

Power

Sense 0 V

Sense 5 V

AI3

AI1

I-act

GND

+10V

GND

-10V

DI1

DI3

DI4

DO4

DO1

3

4

5

6

9

X4:1

3

4

10

4

1

2

3

6

5

10

8

9

10

5

2

6

8

10

8

X1:1

X2:1

X3:1

X5:

SDCS-CON-F

B22_001_0_a.dsf

+

-

S2

3

4

250

S3

3

4

250

ATACH

+

-

+

-

+

-

+

-

GND

10

+

-

+

-

+

-

5V

S4

11

12

24V

K1

X96:1

t

230V

E

SDCS-PIN-F

1

3

4

6

S1

S1

1

3

S4

2

121

100nF

4

6

S4

5

121

100nF

7S48

121

100nF

10k

10k

10k

9

ChA

ChB

ChZ

ChA

ChB

ChZ

Firmware

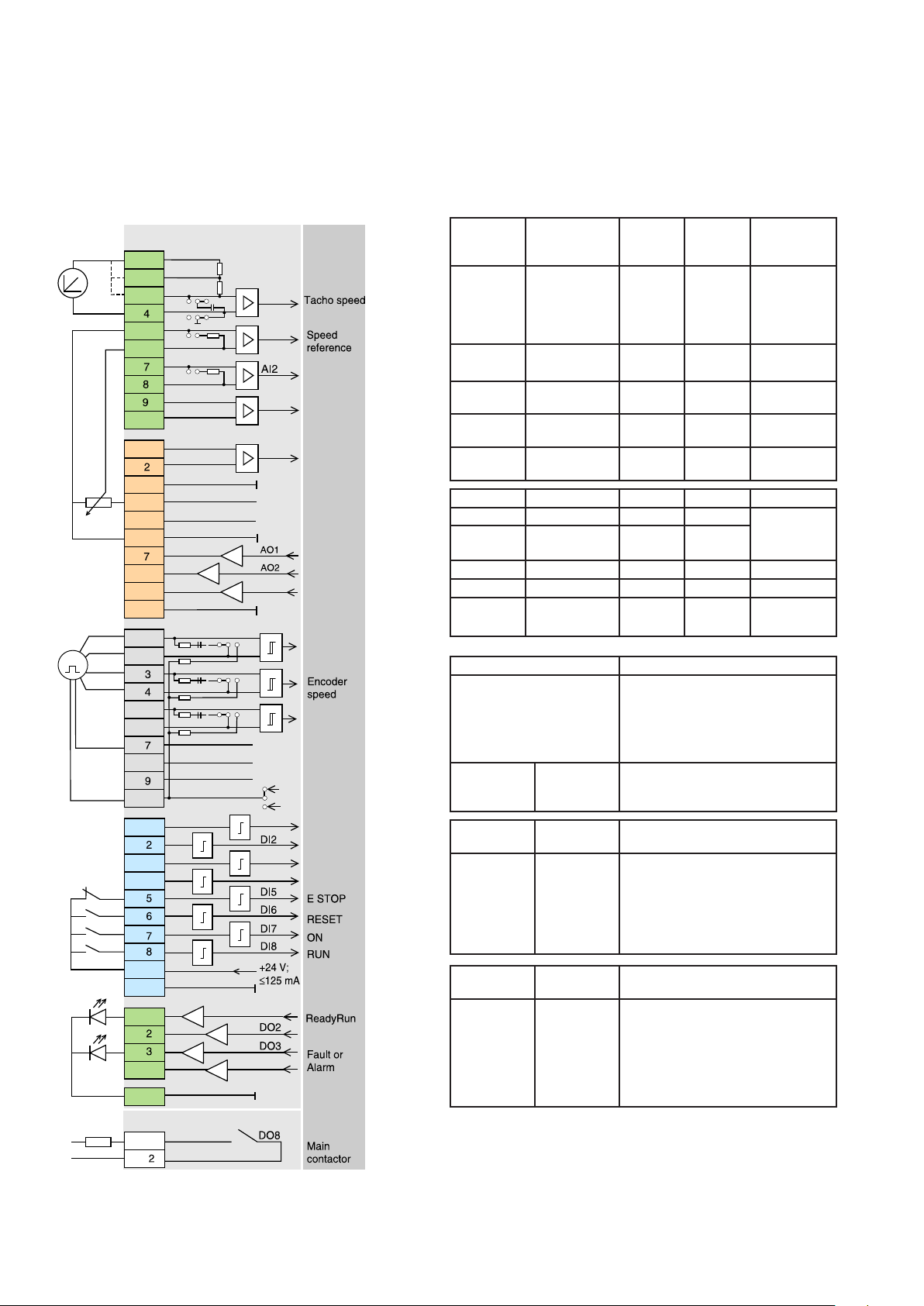

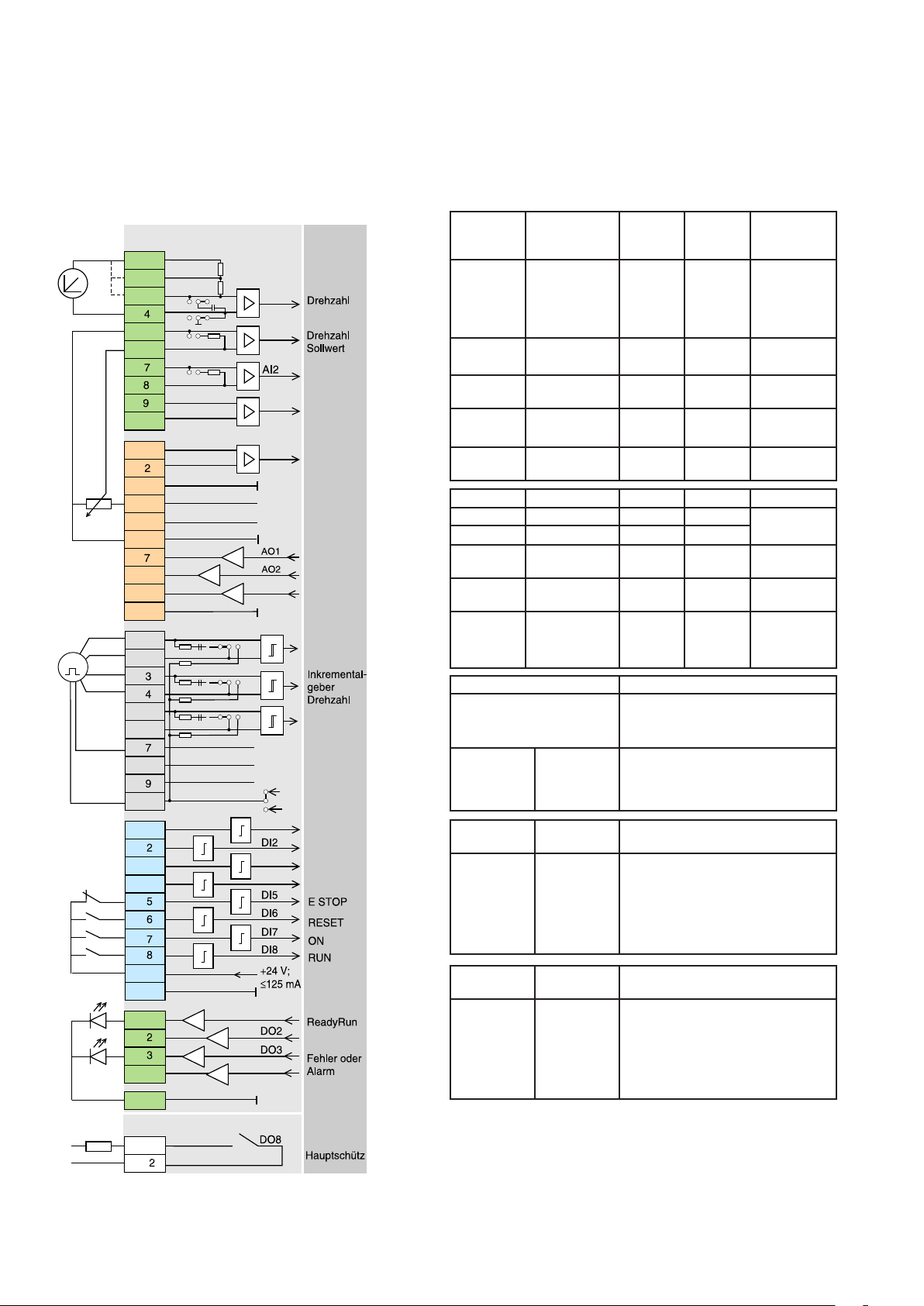

Standard function assignments for the terminals

Resolution

[bit]

15 + sign ±90...270 V

Input/output

values

Hardware

±30...90 V

ScalingbyCommon

mode

range

①

±15 V

Firmware

Remarks

±8...30 V

15 + sign -10...0...+10 V Firmware ±15 V

15 + sign -10...0...+10 V Firmware ±15 V

15 + sign -10...0...+10 V Firmware ±15 V

15 + sign -10...0...+10 V Firmware ±15V

Power

+10 V ≤ 5 mA

-10 V ≤ 5 mA

11 + sign -10...0...+10 V Firmware ≤ 5 mA

11 + sign -10...0...+10 V Firmware ≤ 5 mA

-10...0...+10 V Firmware+

≤ 5 mA

Hardware

for ext. use

e.g. refer. pot.

8 V -> min. of

325% of [99.03] or

230% of [4.05]

Encoder supply Remarks

5 V

24 V

≤ 250 mA

≤ 250 mA

Input value Signal

definition by

0...7.3 V

Firmware

7.5...50 V

Inputs not isolated

Impedance = 120 W, if selected

max. frequency ≤ 300 kHz

Sense lines for GND and supply

to correct voltage drops on cable

(only if 5 V encoder is in use).

Remarks

-> “0“ status

-> “1“ status

10 3ADW000395R0100 DCS550 Quick guide edisf a10 3ADW000395R0100 DCS550 Quick guide edisf a

Output value Signal

Remarks

definition by

50 * mA

22 V at no

load

Firmware

Current limit for all 7

outputs = 160 mA

Do not apply any reverse

voltages!

* short circuit protected

① gain can be varied in 15 steps between 1 and 4 by software

parameter

Page 11

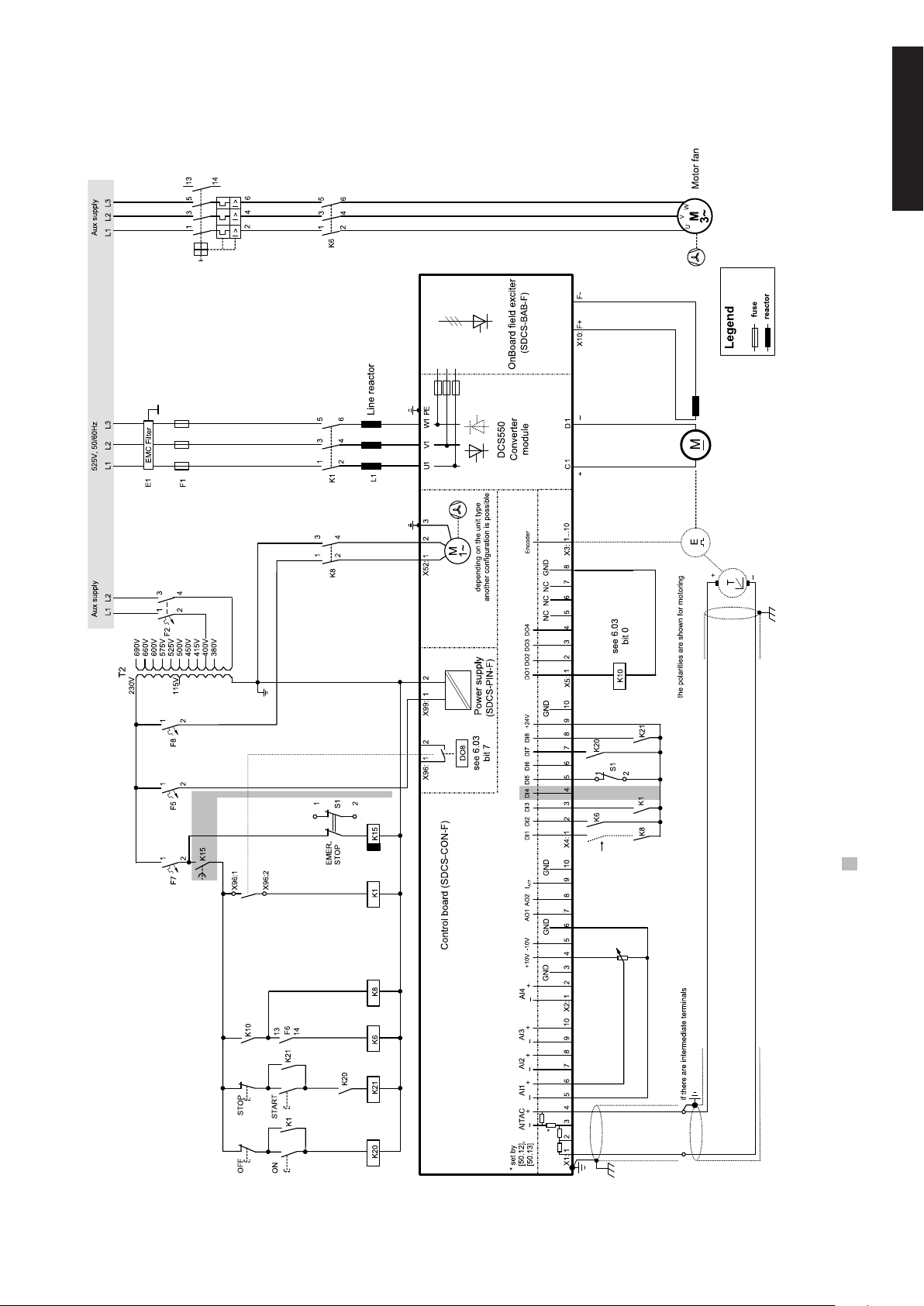

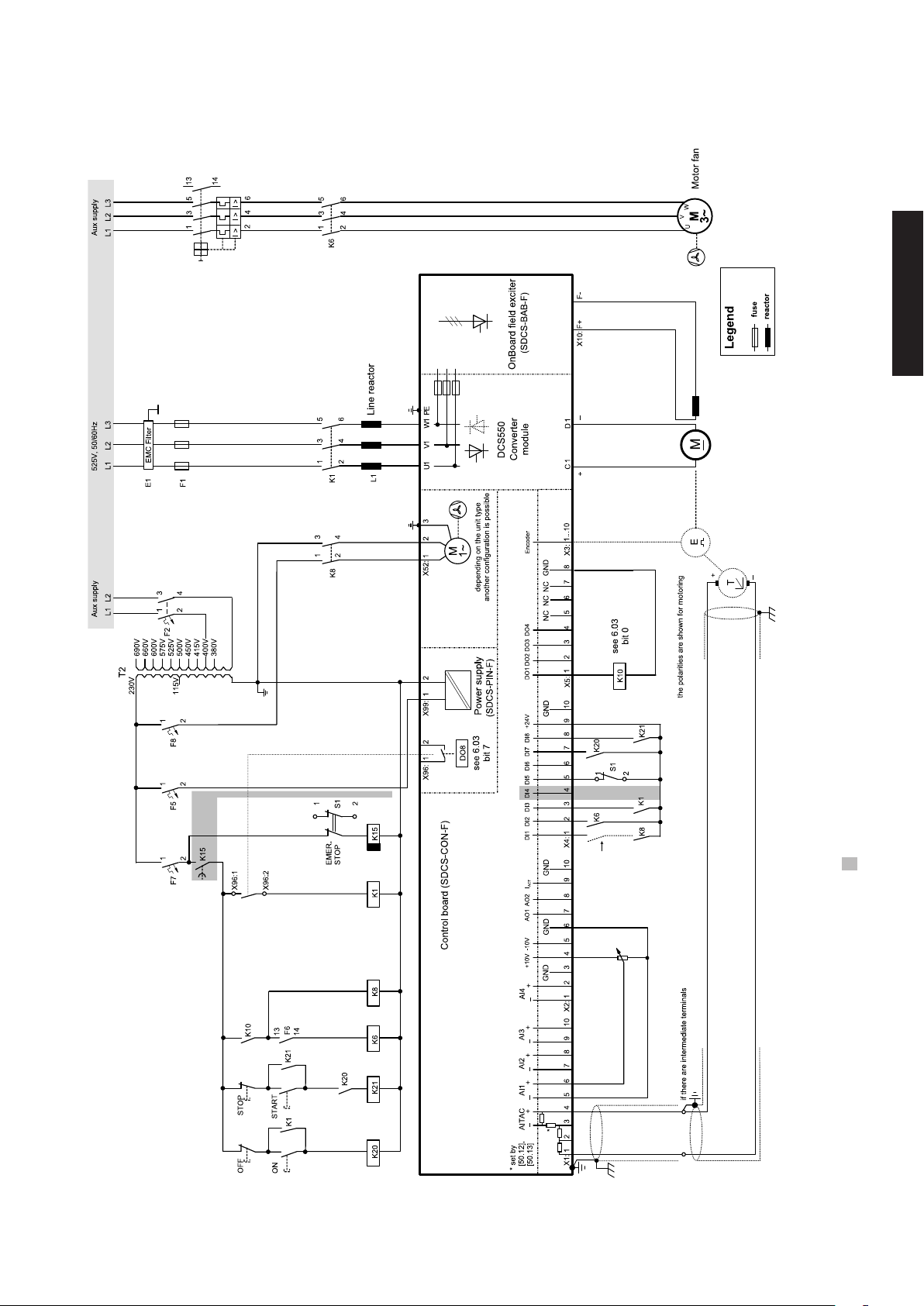

F6

DCS550_ans_1_c.dsf

Connection example

Converters F1...F4 drive configuration using ‘OnBoard‘ field exciter

Terminal selection according FACTORY macro (default)

english

3ADW000395R0100 DCS550 Quick guide edisf a

further information see the following page

11

113ADW000395R0100 DCS550 Quick guide edisf a

Page 12

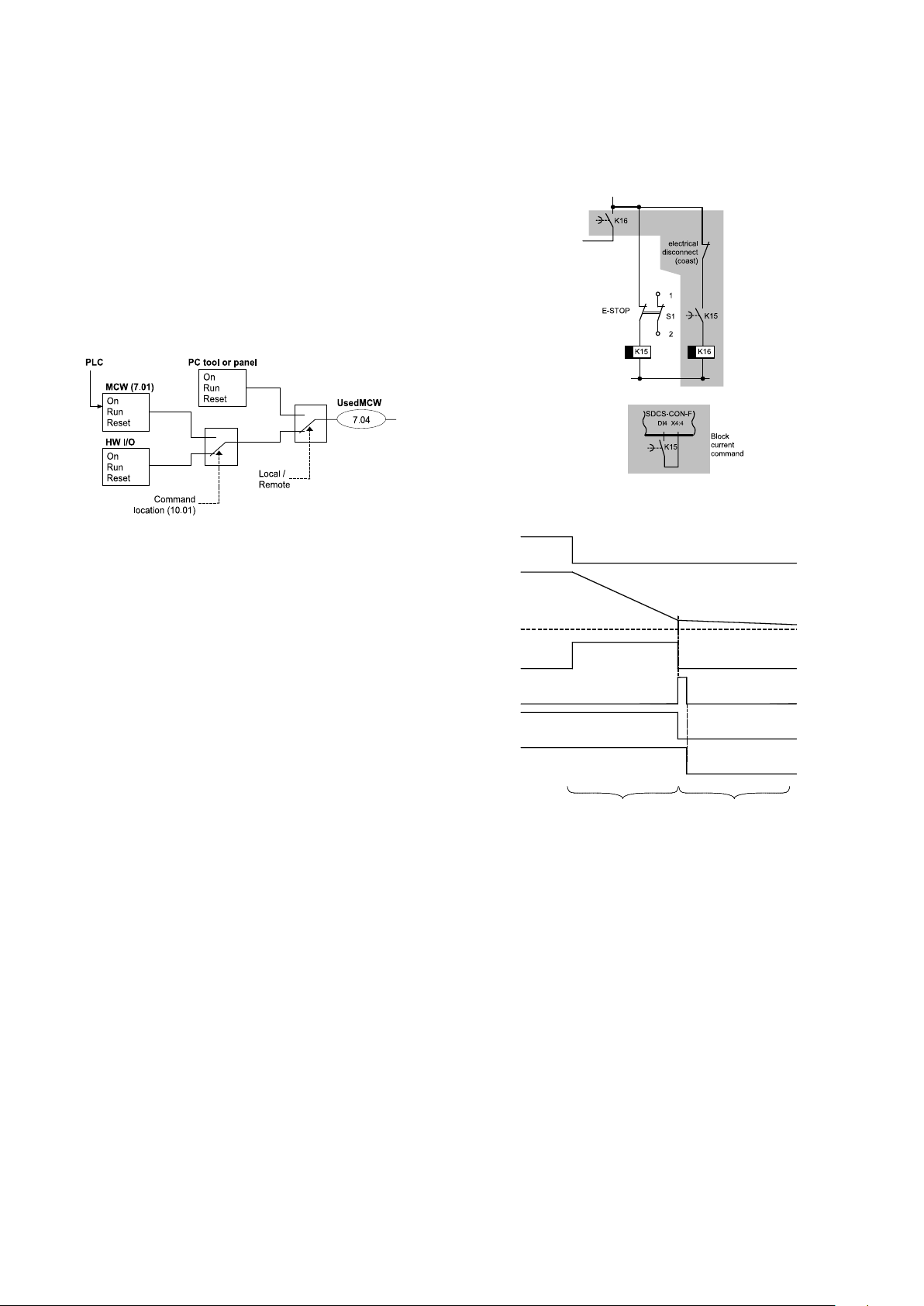

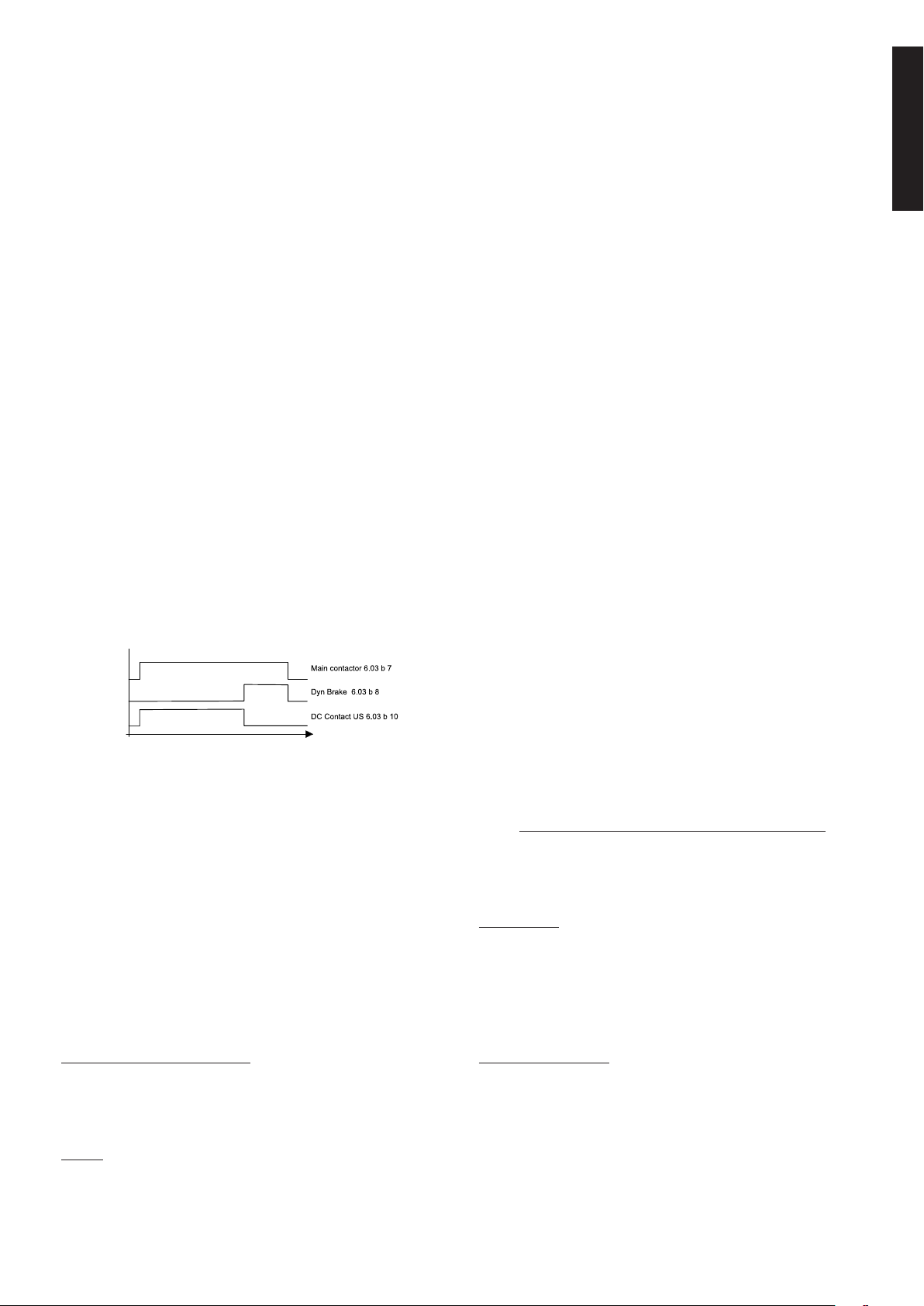

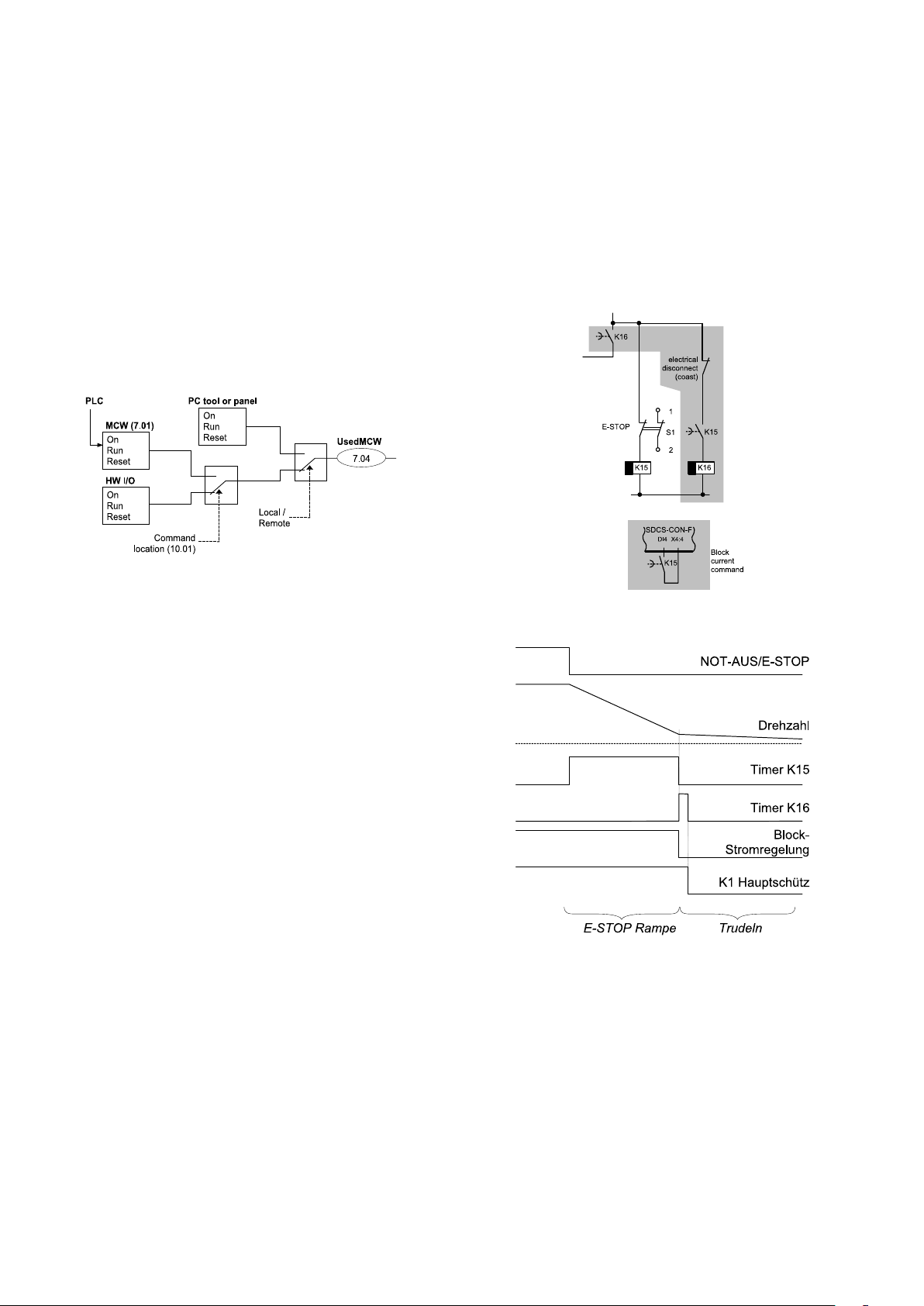

START, STOP and E-STOP control

gen_ctrl_cmd_c.dsf

Anschl_special_b.dsf

The relay logic can be split into three parts:

a: Generation of the ON/OFF and START/STOP command:

The commands represented by K20 and K21 (latching interface relay) can be e.g. generated by a PLC and transferred to

the terminals of the converter either by relays, using galvanic

isolation or directly via 24V signals.

These commands can be as well transferred via serial communication. Even a mixed solution can be realized by selecting different possibilities for the one or the other signal (see

parameter group 11).

b: Generation of control and monitoring signals:

The main contactor K1 for the armature circuit is controlled

by a dry contact (DO 8) located on the SDCS-PIN-F. Status

of fans and fans klixon can be monitored by means of fan ack

signals: MotFanAck (10.06).

If the drive has not finished the function within the K15 timer

setting, the drive must get the command to switch OFF the

current via K16. After K16 timer set has elapsed the main

contactor is opened independent of the drives status.

E-STOP

speed

Timer K15

c: OFF2, OFF3 Stop function:

Beside ON/OFF and START/STOP, the drive is equipped with

two additional stop functions, OFF2 and OFF3, according to

Profibus standard. OFF3 is a scalable stop function (rampstop, max torque stop, dynamic braking …) to perform stop

category 1. This function should be connected to the E-STOP

button without any time delay. In case of ramp stop selection

the, K 15 timer relay must be set longer than the EStopRamp

(22.04). For COAST selection, the drive opens the main contactor immediately.

OFF2 switches off DC current as fast as possible and prepares the drive for opening main contactor or drop down

mains supply. For a normal DC motor load the time to switch

OFF the DC current is below 20 ms. This function should be

connected to all signals and safety functions opening the main

contactor. This function is important for 4-quadrant drives. Do

not open main contactor during regenerative current.

The correct sequence is

1. switch off regenerative current

2. then open the main contactor

In case of the E-STOP is hit, the information is transferred to

the converter via digital input 5. In case of rampstop, or max

torque selection the converter will decelerate the motor and

then open main contactor.

Timer K16

Block current control

K1 main contactor

E-Stop ramp Coast

Stop-Mode_a.dsf

E-Stop reaction

12 3ADW000395R0100 DCS550 Quick guide edisf a12 3ADW000395R0100 DCS550 Quick guide edisf a

Page 13

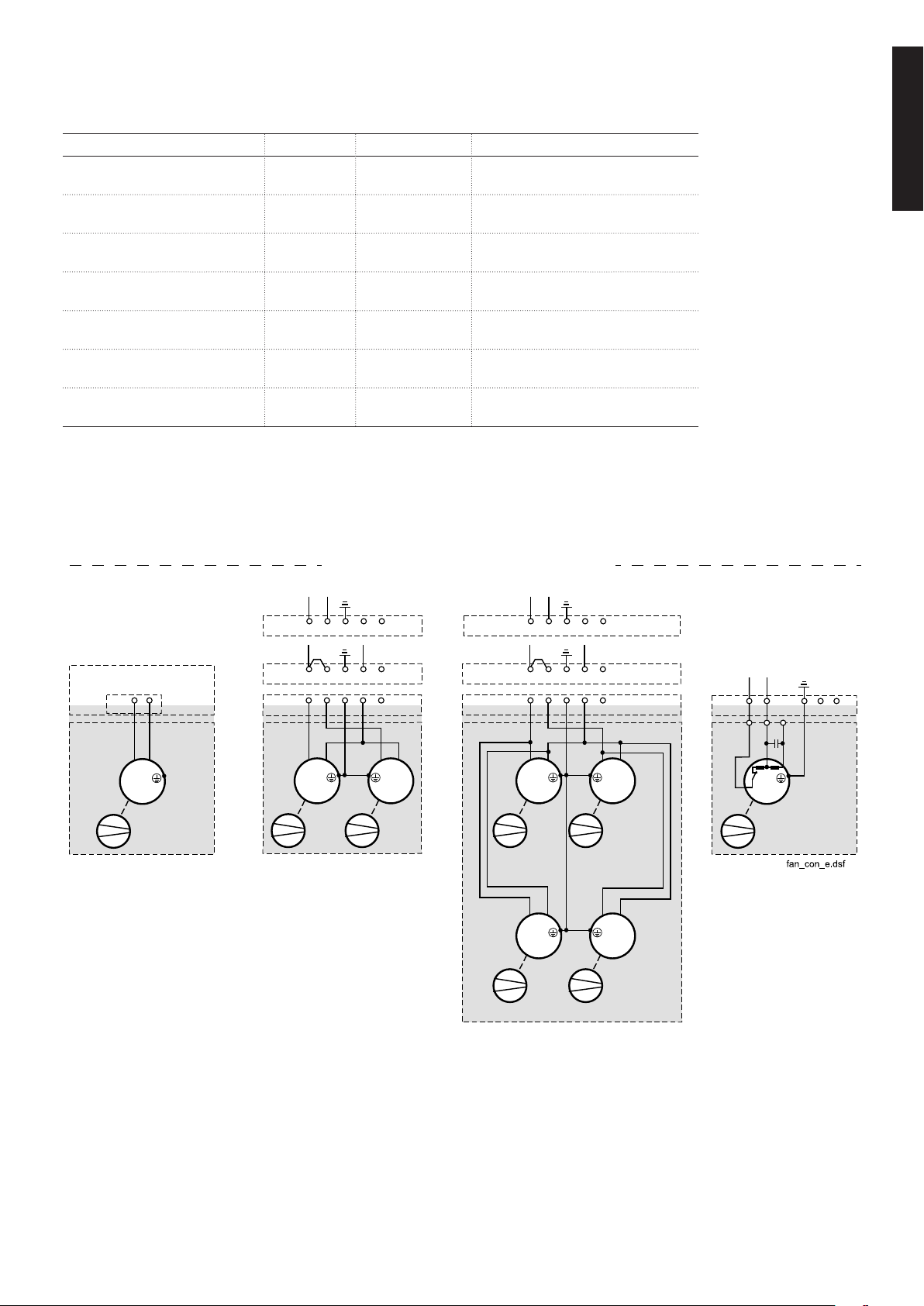

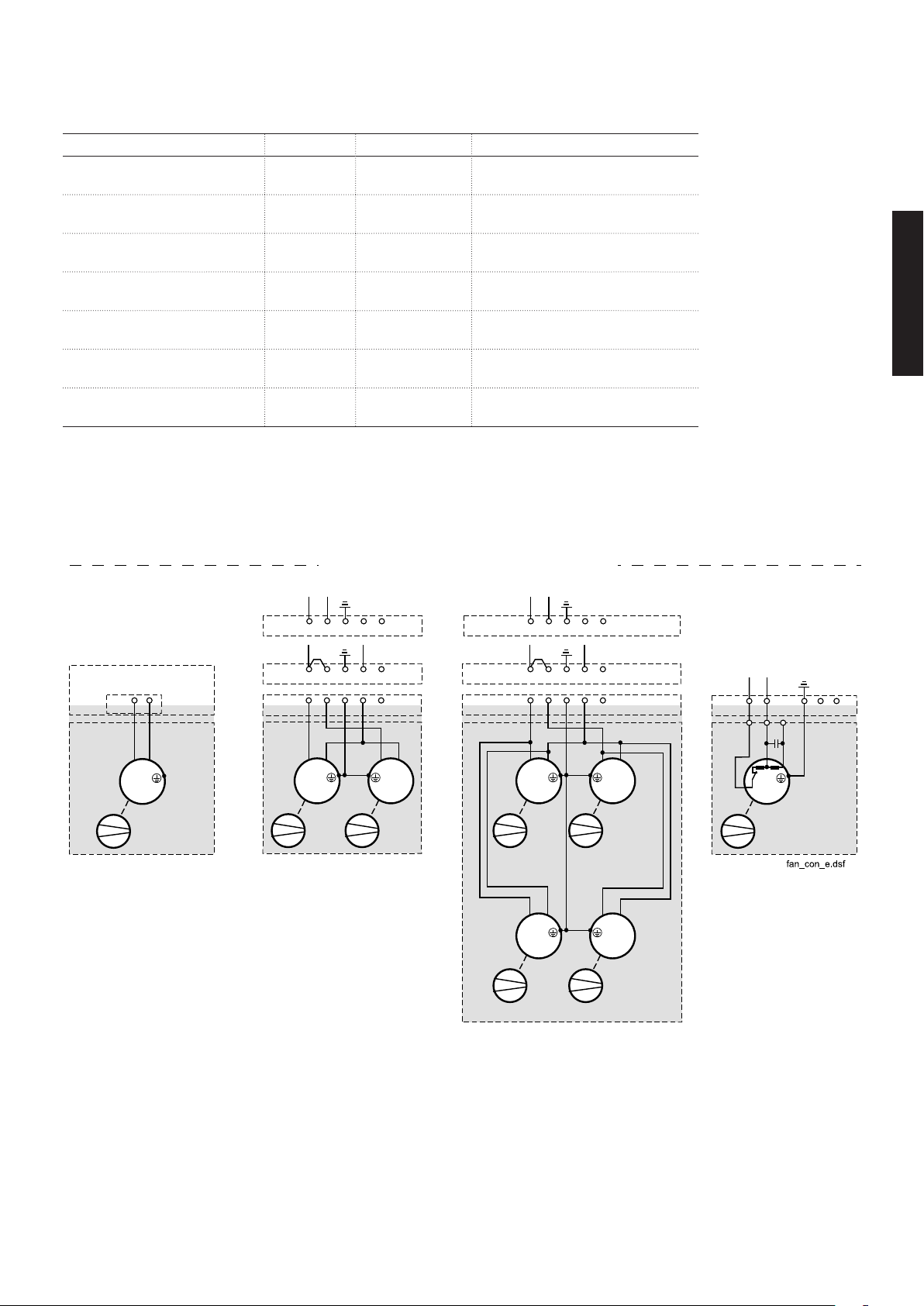

Fan power connection

1 2 3

X52:

4 5

L

N

230 V

AC

1 2 3

X52:

4 5

L

N

115 V

AC

M

~

1 2 3

X52:

M

~

4 5

M55 M56

M

~

1 2 3

X52:

M

~

4 5

M55 M56

M

~

M

~

M57 M58

M55

M

~

1 2 3 4 5

X52:

L

N

L

N

1 2 3

X52:

4 5

L

N

230 V

AC

1 2 3

X52:

4 5

L

N

115 V

AC

ϑ

only 230 V

AC

M55

M

~

X19:

SDCS-PIN-F

Configuration 4

F4

Configuration 3

F3

Configuration 2

F2, F3

Configuration 1

F1

Terminals are located on top of the converter housing

Fan assignment for DCS550

Converter type Model Configuration Fan voltage

DCS550-S01-0020, ...,

F1 - no fan, convection cooled

DCS550-S02-0025

DCS550-S01-0045, ...,

F1 1 1 x 3110KL-05W... (internal 24 V

DCS550-S02-0100

DCS550-S01-0135, ...,

F2 2 2 x 4715MS (115 / 230 V

DCS550-S02-0300

DCS550-S01-0315, ...,

F3 2 2 x 4715MS (115 / 230 V

DCS550-S02-0450

DCS550-S01-0470, ...,

DCS550-S02-0520

DCS550-S01-0610, ...,

F3 3 2 x 4715MS (115 / 230 V

2 x 3115FS (115 / 230 V

F4 4 1 x W2E200 (230 V

DCS550-S02-0820

DCS550-S01-0900, ...,

F4 4 1 x W2E250 (230 V

DCS550-S02-1000

Fan connection for DCS550

english

)

DC

)

AC

)

AC

)

AC

)

AC

)

AC

)

AC

3ADW000395R0100 DCS550 Quick guide edisf a

13

133ADW000395R0100 DCS550 Quick guide edisf a

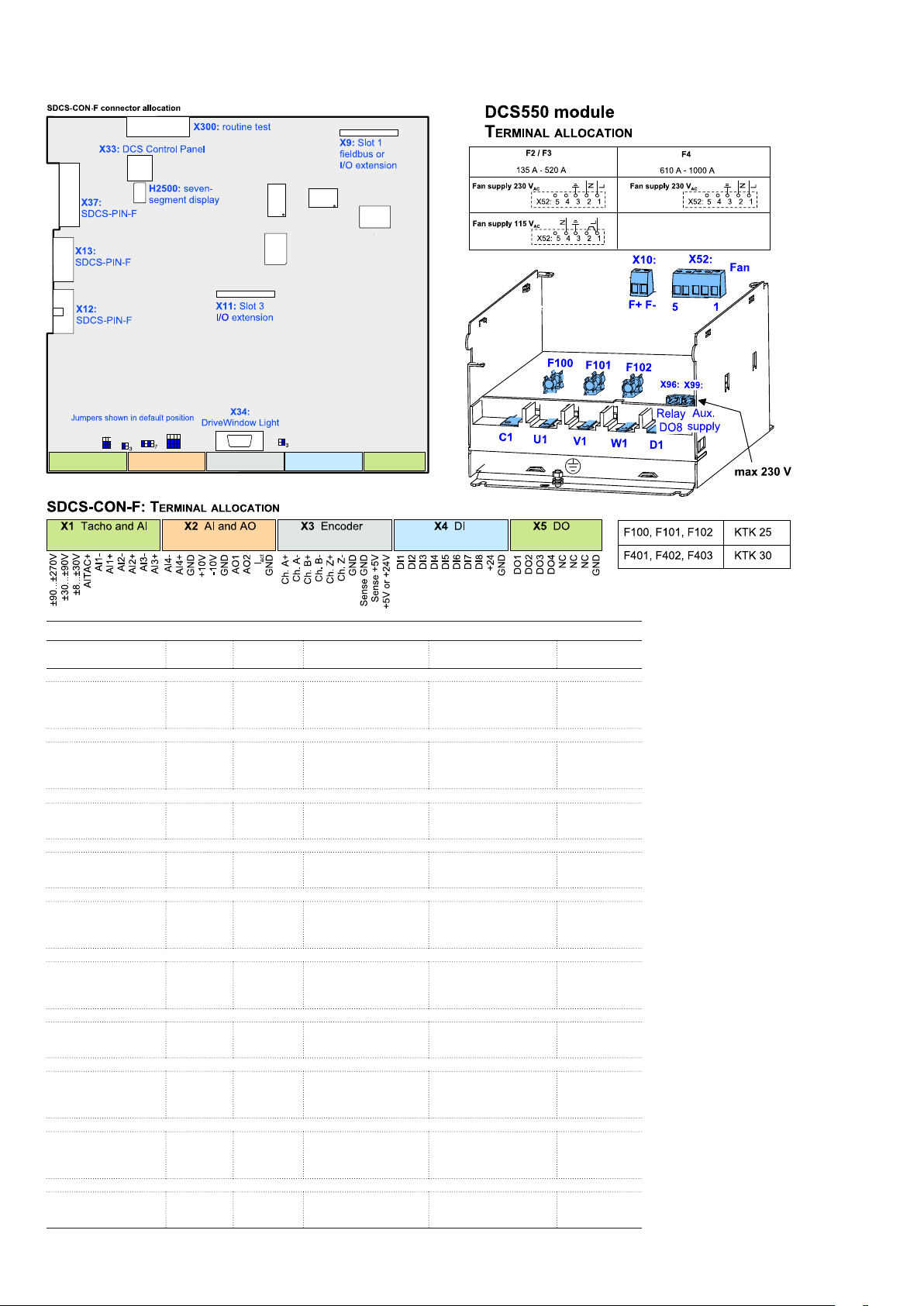

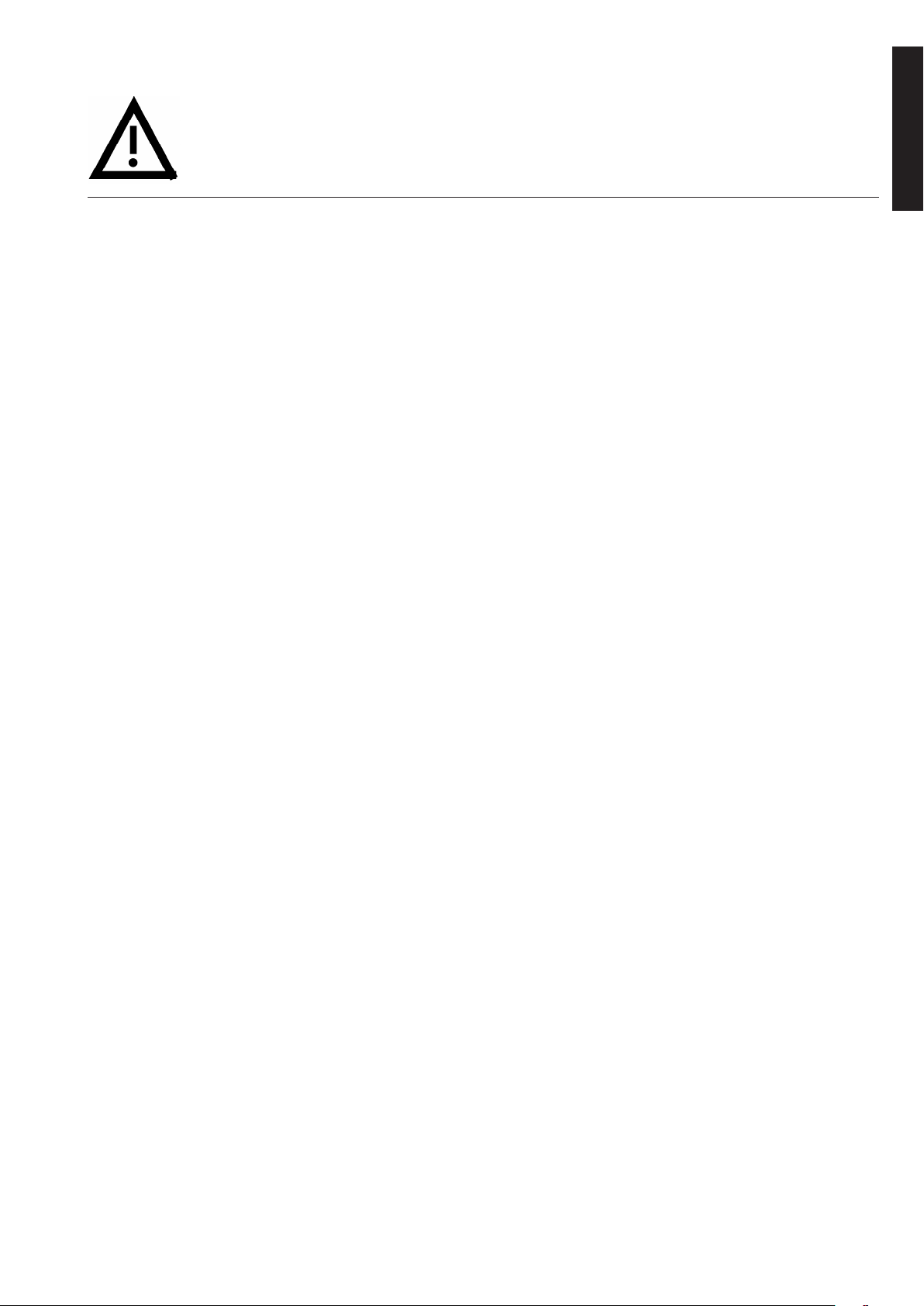

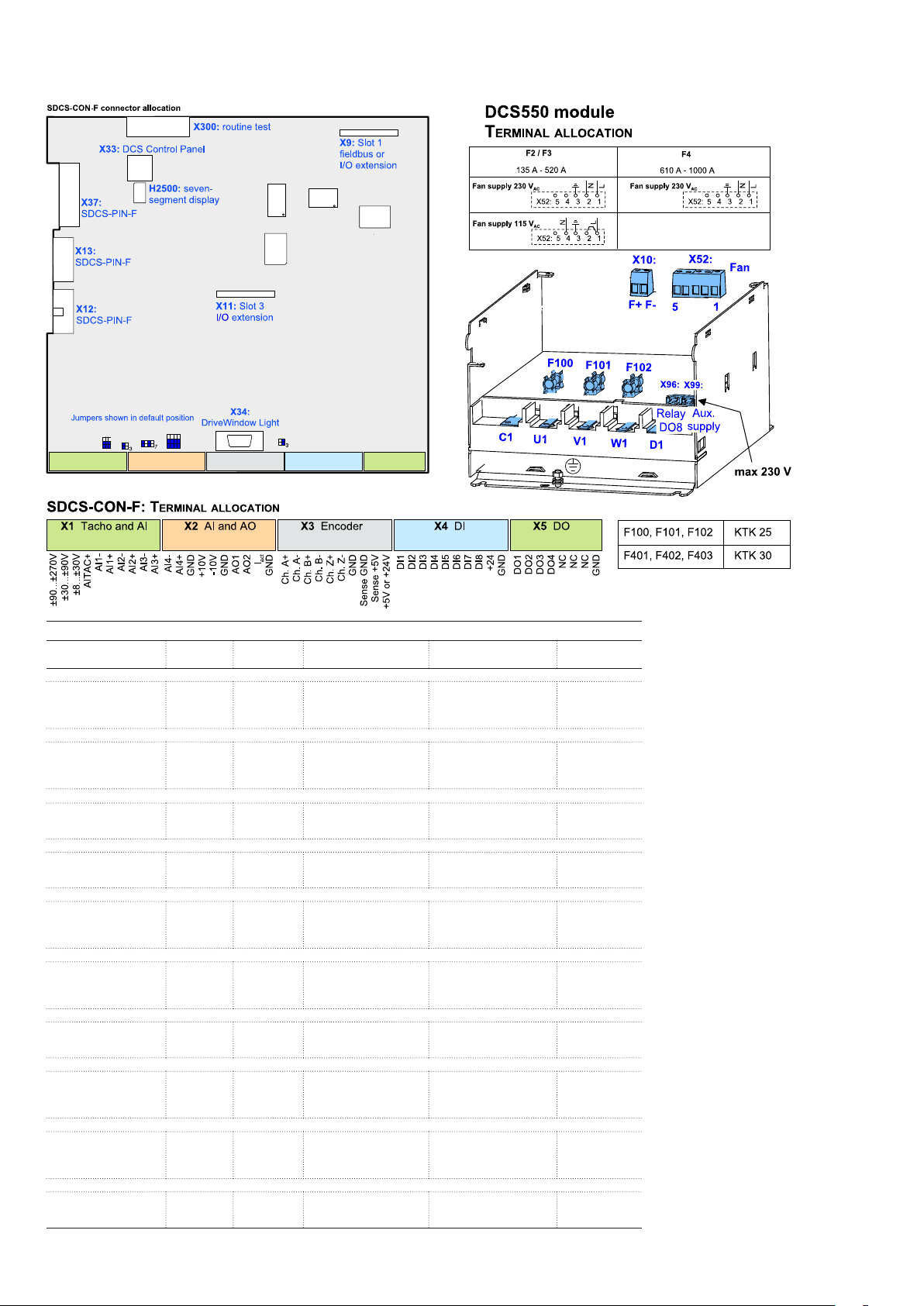

Page 14

Terminal locations on the converter

X2X1 X3 X4 X5

1 1 1 1 1

S5

15

6 9

S3

S2

S4

1

2

1

2

1

2

1

2

D2100

1

D2001

D2002

D1000

1 30

1

2

1

2

S1

1

42

1

2

3

10

11

12

1

82

1

42

1

2

3

7

8

9

DCS550 terminal alloc_c.dsf

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8

Macro finder

Macro name

Main

Contactor

ON / OFF

Start/Stop

Standard

AC Static

2-wire DC cont. US

DC Static

3-wire DC cont. US

DC Pulse

3-wire Standard

AC Pulse

Torque limit

AC Static

Manual / Const

AC Pulse

Hand / Auto

Hand / Mot Pot

Motor Pot

AC Static

AC Pulse

AC Static

Torque Ctrl

AC Static

14 3ADW000395R0100 DCS550 Quick guide edisf a14 3ADW000395R0100 DCS550 Quick guide edisf a

DI function

Jog1 --> DI1

Jog2 --> DI2

Ext Fault --> DI 3

Ext Alarm --> DI4

Jog1 --> DI1

Jog2 --> DI2

Ext Fault --> DI 3

Main Cont Ack --> DI4

Fix speed1 --> DI1

Ext Fault --> DI 3

Main Cont Ack --> DI4

Fix speed1 --> DI1

Ext Fault --> DI 3

Ext Alarm --> DI4

Jog1 --> DI1

Jog2 --> DI2

Ext Fault --> DI 3

Ext Alarm --> DI4

Jog1 --> DI1

Jog2 --> DI2

Direction --> DI 3

SpC - KP, KI --> DI4

Control select --> DI2

Reference select --> DI2

Direction select --> DI 3

Motor pot up --> DI1

Motor pot down --> DI2

Direction select --> DI 3

Reference select --> DI4

Direction select --> DI 1

Motor pot up --> DI2

Motor pot down --> DI3

Motor pot minimum --> DI4

OFF2 (coast stop) --> DI1

Torque select --> DI2

Ext Fault --> DI 3

Comment DI5 --> ESTOP

Hardware I/O control x

Hardware I/O control x

Hardware I/O control x

Hardware I/O control x

Hardware I/O control

+ Torque limit

Hardware I/O control

select gain

Hardware I/O control

or field bus control

Hardware I/O control

Reference hardware or Motor

potentiometer

Hardware I/O control

Reference Motor potentiometer

Hardware I/O control

Speed control or Torque

reference

DI6 --> Reset

x

x

x

x

x

x

Enabling a macro

Use the

[DCS550Wizard] 2. Macro assistant of DriveWindow Light or

Parameter browser, either

through the control panel,

DriveWindow, or DriveWindow

Light.

Use the following parameters:

ApplMacro (99.08) =

Macro selection

Applrestore (99.07) =

YES = execute selection

MacroSel (8.10) =

double check

NOTE

Functions and inputs defined by

macro can be changed later on

without restrictions.

NOTE

Macro diagrams see page 91 ...

Page 15

Notes For North American Installations

1. EMC conformity is not usually required in North America.

In most cases, the section “Notes on EMC” can be bypassed.

In this manual, you will see references to DIN, EN and VDE

standards. These are European standards and, generally, do

not apply to North America. It is, however, the responsibility of

the user to determine which standards need to be followed.

2. If using a DC contactor, you must connect an auxiliary

contact to a digital input of your choice and set para. Main-

ContAck accordingly. Set the following parameters:

MainContAck (10.21) = DI-1 (or any input you

choose for the DC cont.

auxiliary contact)

DO8BitNo (14.16) = 10

MainContCtrlMode (21.16)= DCcontact (3)

Set these parameters AFTER macros are loaded but BEFORE

the drive is commissioned.

Digital output 8 (DO-8) must be used to turn the DC contactor on and off.

DC contactor US:

DC contactor US K1.1 is a special designed contactor with 2x

NO contacts for C1 and D1 connection and 1x NC contact for

connection of Dynamic Brake resistor RB.

The contactor should be controlled by signal 6.03 Bit 10.

The acknowledge can be connected to parameter:

10.21 MainContAck

10.23 DCBreakAck

3. If using Dynamic Braking, the drive allows you to select

the stopping method under three different situations. Parameters 21.02, 21.03 and 21.04 select the stopping method for

loss of the OnOff, run command (StartStop, Jog1, Jog2, etc.),

and E-Stop input, respectively.

Each can be set to:

• RampStop • TorqueLimit

• CoastStop • DynBraking

In order to command the drive to perform a DB stop, one or

more of these parameters must be set to DynBraking. Most

users will want the drive to ramp stop when OnOff or a run

command (StartStop, Jog1, Jog2, etc.) input is cleared, and

dynamically brake when the E-Stop input is cleared. In that

case, use the following settings:

• Off1Mode (21.02) = RampStop

• StopMode (21.03) = RampStop

• E StopMode (21.04) = DynBraking

However, any case is allowed and the final decision is left to

the user.

Other parameters control stops during faults.

See:

LocalLossCtrl (30.27) ComLossCtrl (30.28)

FaultStopMode (30.30) SpeedFbFltMode (30.36)

If using EMF feedback with dynamic braking, set:

• DynBrakeDly (50.11) = t

Where: t = the time (sec) it normally takes the motor to

stop during dynamic braking

english

Overview of the Installation and Commissioning Process

Step 1:

Check converter for damage. Contact ABB Technical Support

if damage is found. In North America, call 1-800-435-7365

(1-800-HELP-365)

Step 2:

Select supporting hardware for the converter:

For specific recommendations for fuses, reactors, and contactors, see the DCS550 Manual or technical catalog.

Circuit breaker or disconnect:

Current rating = IDC * 0.816 * 1.25 (min)

= IDC * 0.816 * 2.50 (max)

Where: IDC = nominal DC motor current

Fuses:

AC Line Fuses: To properly protect the converter, semiconductor fuses on the incoming AC power line are required

in all cases.

DC Output Fuses: Fuses between the motor and the converter are required for all regenerative (4-Q) converters.

This is to protect the motor and converter if a commutation

fault should occur. NOTE: DC output fuses are the same type

and size as AC line fuses.

Line reactor:

All thyristor-based dc converters cause notching in the AC

line due to motor commutation. A properly sized line reactor

will mitigate the effect on the line. Unless the converter uses

a dedicated isolation transformer, each converter requires its

own line reactor.

AC or DC contactor:

A contactor is required to safely disconnect the motor from

the incoming power when the converter is off. The contactor can be installed between the line and the converter (an

AC contactor) or between the converter and the motor (a DC

contactor). Do not use both.

IMPORTANT: Other equipment may be necessary depending on application and local codes.

3ADW000395R0100 DCS550 Quick guide edisf a

15

153ADW000395R0100 DCS550 Quick guide edisf a

Page 16

Step 3:

Mount and wire the converter and supporting hardware inside

an industrial enclosure with adequate cooling (DCS550 modules have rating of NEMA type OPEN).

The following control and signal wiring is required:

− If using an AC contactor, we recommend wiring an auxiliary

contact to the digital input you have designated as Main-

ContAck (10.21) or Start/Stop (10.16).

− If using a DC contactor, you must wire an auxiliary contact

from the contactor to the digital input you have designated

as MainContAck (10.21).

− Wire 115 or 230 VAC 1-phase power to terminal block 99 for

converter control power.

− Wire 1-phase power to converter for cooling fans. See

table and wiring diagrams in this manual.

• F1 – F3 frames: 115/230 VAC selectable.

Fan terminal X52 is on top of the converter.

• F4 frame: use 230 VAC.

Fan terminal X52 is on top of the converter.

− Wire tachometer or encoder to terminal block X1 (tacho) or

X3 (encoder).

− Wire analog inputs (e.g., speed reference) and outputs

(e.g., meters for motor voltage, current) to terminal block

X1 and/or X2.

− Wire high speed serial interface if needed. (Requires optional fieldbus interface board.)

− The DCS550 allows you to choose the usage of each digital and analog input and output. The converter has factory

default settings which can be changed by loading a macro,

but some designations are universal. They include:

• Digital input 5: Estop

• Digital input 6: Fault reset

• Digital input 7: On/Off (maintained) or On-Start

(pulsed)

• *Digital input 8: Start/Stop (maintained) or

Off-Stop (pulsed)

• Digital output 8: Main Contactor On

(3 Amps max. at 115 – 230 VAC)

*except Hand/Auto macro

− Other signals may be required depending on your application (e.g., motor fan acknowledge input, Off2 input, fan-on

output, brake output).

− You will select the macro and / or choose the configuration

for digital and analog inputs and outputs in step 2 of the

commissioning process, or by updating group 10 and 14

parameters.

− Check all wire terminations (with continuity tester) before

proceeding to the next step.

Step 4:

Connect the drive system to incoming power and the motor to

the converter (both field and armature) as well as accessory

equipment (motor fan, thermal switch, brake, etc.).

− See hardware manual for typical cable size and tightening

torque recommendations.

− IMPORTANT: Be sure all safety equipment is properly

sized for your application

Step 5:

Apply control power to the converter.

− IMPORTANT: See section “Safety and Operating Instructions” in this manual before proceeding.

− Apply power to terminal block 99 and X52. The keypad

should light up and show the menu screen. The converter

fans should start to run (if converter has fans).

Step 6:

Commission the converter using DriveWindow Light

(preferred) or the control panel.

− IMPORTANT: See safety alerts and general instructions

in the section “Commissioning” before proceeding.

− Install the DCS550 PC tools on your computer. Instructions are in this manual. Use DriveWindow Light to commission your converter.

− If no PC is available, commission your drive using the control panel as follows:

• On the control panel, press the softkey to select

MENU.

• Using the down arrow, select ASSISTANTS.

Then press ENTER.

• Starting with “name plate data,” press SEL.

Change the value with the arrow keys.

Then press SAVE.

• Repeat above with other parameters.

Follow directions on the screen.

Configuring and Displaying analog and digital I/O

HINT: To see if the drive is responding to an “on” or “run” command, view signal 8.08.

Control Panel:

− Digital Status: View signal 8.05 (DI’s) or 8.06 (DO’s). Display is in hexadecimal.

− Configure digital inputs with Group 10.

− Analog Status: View signal 5.03 (AI1) or 5.11 (AO1). Display is in Volts.

− Configure analog speed ref. with Group 11.

DriveWindow Light:

− Connect to the DCS550 and go on line by clicking on File,

then New Online Drive.

− Click on Wizard, at left side of the screen.

− Click on Advanced.

− Check the box for “I/O assistant,” then click on Next.

− Click on “edit parameters” in the appropriate section (analog or digital inputs or outputs).

16 3ADW000395R0100 DCS550 Quick guide edisf a16 3ADW000395R0100 DCS550 Quick guide edisf a

Page 17

Safety and operating instructions

for drive converters DCS / DCF / DCR

(in conformity with the low-voltage directive 73/23/EEC)

english

1. General

In operation, drive converters, depending on their degree of

protection, may have live, uninsulated, and possibly also moving or rotating parts, as well as hot surfaces.

In case of inadmissible removal of the required covers, of

improper use, wrong installation or maloperation, there is the

danger of serious personal injury and damage to property.

For further information, see documentation.

All operations serving transport, installation and commissioning as well as maintenance are to be carried out by skilled

technical personnel (Observe IEC 364 or CENELEC HD 384

or DIN VDE 0100 and IEC 664 or DIN/VDE 0110 and national

accident prevention rules!).

For the purposes of these basic safety instructions, “skilled

technical personnel” means persons who are familiar with the

installation, mounting, commissioning and operation of the

product and have the qualifications needed for the performance of their functions.

2. Intended use

Drive converters are components designed for inclusion in

electrical installations or machinery and are to be mounted in

a cubicle or finger protected area.

In case of installation in machinery, commissioning of the drive

converter (i.e. the starting of normal operation) is prohibited

until the machinery has been proved to conform to the provisions of the directive 89/392/EEC (Machinery Safety Directive

- MSD). Account is to be taken of EN 60204.

Commissioning (i.e. the starting of normal opertion) is admissible only where conformity with the EMC directive (89/336/

EEC) has been established.

The drive converters meet the requirements of the low-voltage

directive 73/23/EEC. They are subject to the harmonized

standards of the series prEN 50178/DIN VDE 0160 in conjunction with EN 60439-1/ VDE 0660, part 500, and EN

60146/ VDE 0558.

The technical data as well as information concerning the supply conditions shall be taken from the rating plate and from

the documentation and shall be strictly observed.

3. Transport, storage

The instructions for transport, storage and proper use shall be

complied with.

4. Installation

The installation and cooling of the appliances shall be in accordance with the specifications in the pertinent documentation.

The drive converters shall be protected against excessive

strains. In particular, no components must be bent or isolating

distances altered in the course of transportation or handling.

No contact shall be made with electronic components and

contacts.

Drive converters contain electrostatic sensitive components

which are liable to damage through improper use. Electric

components must not be mechanically damaged or destroyed

(potential health risks).

5. Electrical connection

When working on live drive converters, the applicable national

accident prevention rules (e.g. VBG 4) must be complied with.

The electrical installation shall be carried out in accordance

with the relevant requirements (e.g. cross-sectional areas of

conductors, fusing, PE connection). For further information,

see documentation.

Instructions for the installation in accordance with EMC

requirements, like screening, earthing, location of filters and

wiring, are contained in the drive converter documentation.

They must always be complied with, also for drive converters

bearing a CE marking. Observance of the limit values required

by EMC law is the responsibility of the manufacturer of the

installation or machine.

6. Operation

Installations which include drive converters shall be equipped

with additional control and protective devices in accordance

with the relevant applicable safety requirements, e.g. Act

respecting technical equipment, accident prevention rules etc.

Changes to the drive converters by means of the operating

software are admissible.

After disconnection of the drive converter from the voltage

supply, live appliance parts and power terminals must not be

touched immediately because of possibly energized capacitors. In this respect, the corresponding signs and markings on

the drive converter must be respected.

During operation, all covers and doors shall be kept closed.

7. Maintenance and servicing

The manufacturer’s documentation shall be followed.

The climatic conditions shall be in conformity with prEN 50178.

Keep safety instructions in a safe place!

3ADW000395R0100 DCS550 Quick guide edisf a

17

173ADW000395R0100 DCS550 Quick guide edisf a

Page 18

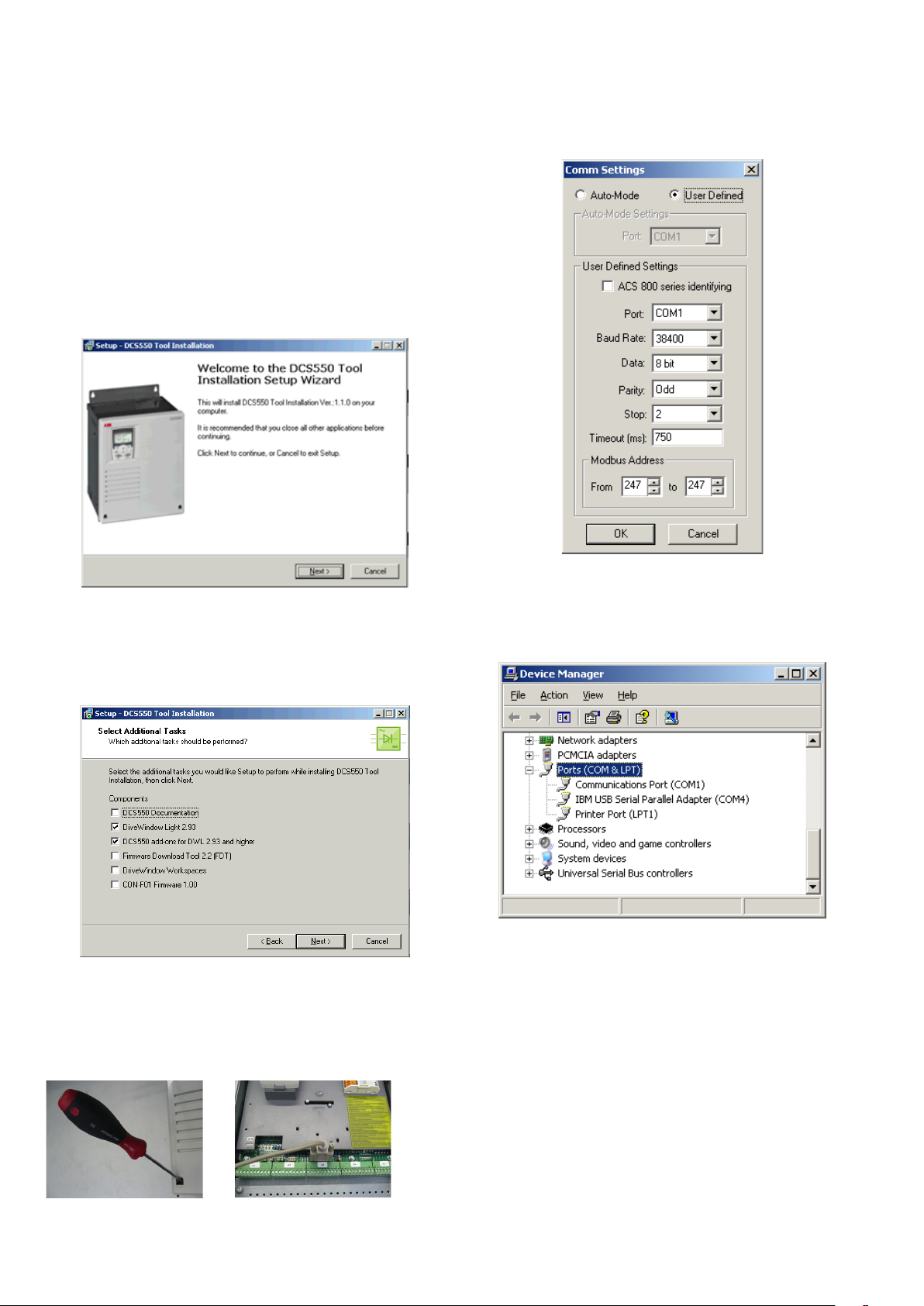

Installing the DCS550 PC tools on Your computer

After inserting the DCS550 CD all programs and documentation necessary to work with the DCS550 will be automatically

installed.

This includes:

1. DriveWindow Light for parameterization, commissioning

and service

2. Hitachi FDT 2.2 for firmware download

3. Installation CD of DCS550 Drive for e.g. DWL Wizard,

ABB documents

Attention:

If You do not want to install a certain program just skip it by

using Cancel at the beginning of the program’s wizard.

− Start DriveWindow Light PC tool

− Check the communication setting of your COM port

If the installation routine does not start automatically:

− Go to Start/Run and browse for setup.exe on the CD.

Now start the installation by confirming with OK

− Compact installation for DriveWindow Light + DCS550

add ons is reccomended

Steps to connect Drive to PC

− The documentation can be found under

C:\ABB\DCS550\Docu

− Remove design cover from the converter module

If You use ExpressCard to COM port interface or PCMCIA /

COM port double check the active COM enabled

Start => Settings => Control Panel => System => Hardware

=> Device Manager

− COM address of USB interface can change after the next

boot procedure or after disconnecting and reconnecting of

the USB interface.

Note:

ExpressCard / PCMCIA to COM port provide a stable and

faster drive interface.

Remove the DCS550 Control Panel

if present. Depress the locks to

remove the cover

Connect drive (X34) to your

PC COM port

18 3ADW000395R0100 DCS550 Quick guide edisf a18 3ADW000395R0100 DCS550 Quick guide edisf a

Utilize DriveWindow Light or DCS550 Panel Wizard continue

with chapter Commissioning in this manual.

Page 19

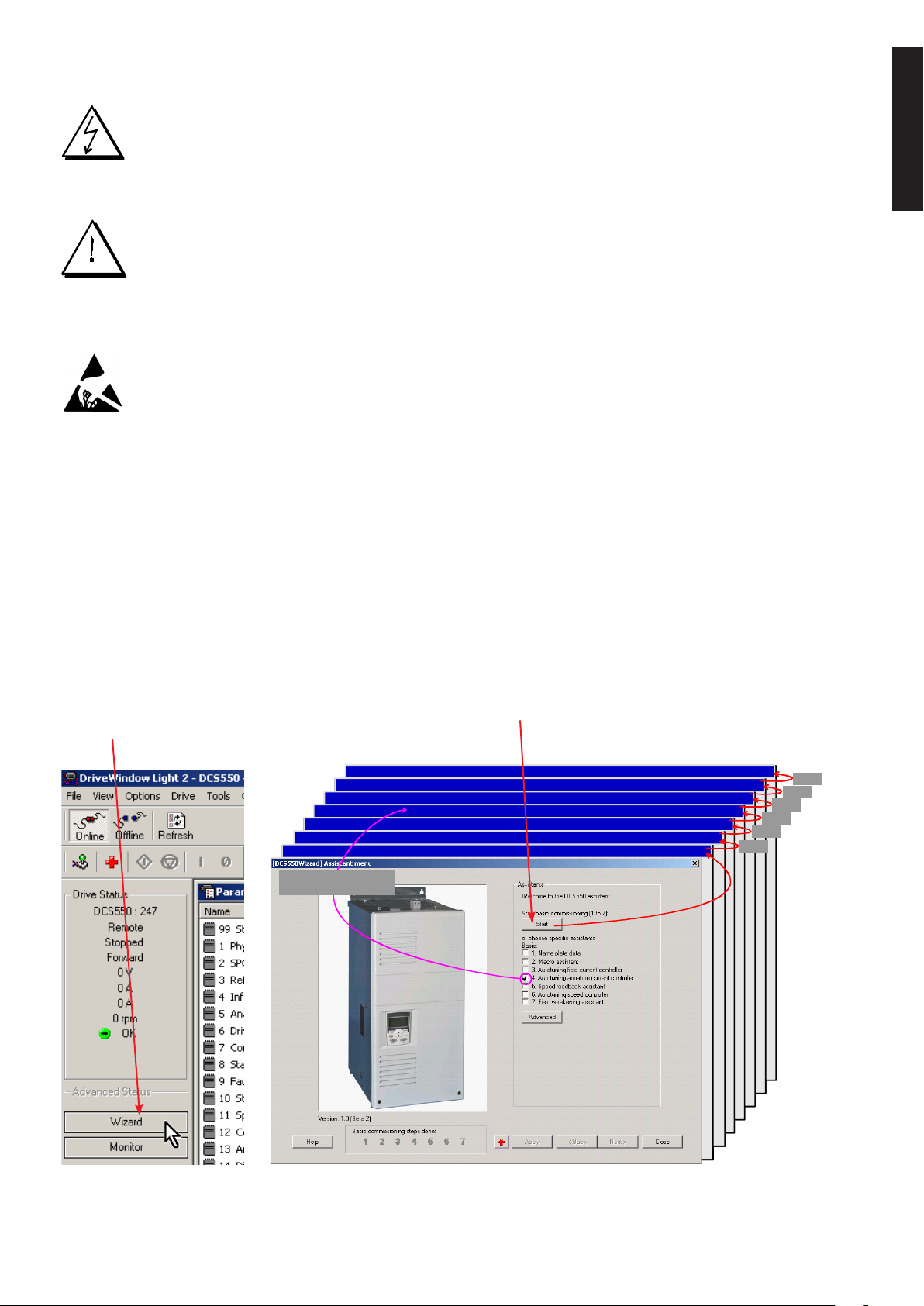

Commissioning

7. Field weakening assistant

6. Autotuning speed controller

5. Speed feedback assistant

4. Autotuning armature current controller

3. Autotuning field current controller

2. Macro assistant

1. Name plate data

Next

Next

Next

Next

Next

Next

Select specific

assistant & press Next

7. Field weakening assistant

6. Autotuning speed controller

5. Speed feedback assistant

4. Autotuning armature current controller

3. Autotuning field current controller

2. Macro assistant

1. Name plate data

Next

Next

Next

Next

Next

Next

Select specific

assistant & press Next

Danger! High voltage: this symbol warns of high

voltages which may result in injuries to persons

and/or damage to equipment. Where appropriate,

the text printed adjacent to this symbol describes

how risk of this kind may be avoided

General warning: this symbol warns of non-electrical risks and dangers which may result in

serious or even fatal injuries to persons and/or

damage to equipment. Where appropriate, the text

printed adjacent to this symbol describes how risk

of this kind may be avoided.

Warning of electrostatic discharge: this symbol

warns you against electrostatic discharges which

may damage to unit. Where appropriate, the text

printed adjacent to this symbol describes how risk

of this kind may be avoided.

NEC motor overload protection

The DCS550 provides a solid-state motor overload protection

in accordance with the NEC. The overload protection (e.g.

protection level in percent of full-load motor current) can be

adjusted by parameters in group 31 and group 99

The instructions can be found in chapter Motor thermal model

of the DCS550 Manual.

General instructions

− This short commissioning refers to chapter Connection

examples of this publication.

− Safety and operating instructions - chapter of this publica-

tion.

− Recommendations for motor and field voltages see Techni-

cal catalog.

− In accordance with DIN 57 100 Part 727 / VDE 0100 Part

727, precautions must be taken to enable the drive to be

shut down, e.g. in the event of danger. The unit’s digital

inputs or the control panel are not sufficient as the sole

measure for this purpose!

Preparations

− Check unit for any damage!

− Install unit and wire it up

− Supply voltage level / Rated value correct for electronics

and fan?

− Supply voltage level / Rated value correct for armaturecircuit converter?

− Supply voltage level / Rated value correct for field supply?

− Wiring / cross-sections, etc. correct?

− EMERGENCY STOP functioning properly?

− COAST STOP functioning properly?

english

Commissioning DriveWindow Light

Start the wizard in

DriveWindow Light

For basic commissioning press the Start button or select a specific assistant:

For more information about the wizard, parameters faults and alarms press the Help button!

3ADW000395R0100 DCS550 Quick guide edisf a

19

193ADW000395R0100 DCS550 Quick guide edisf a

Page 20

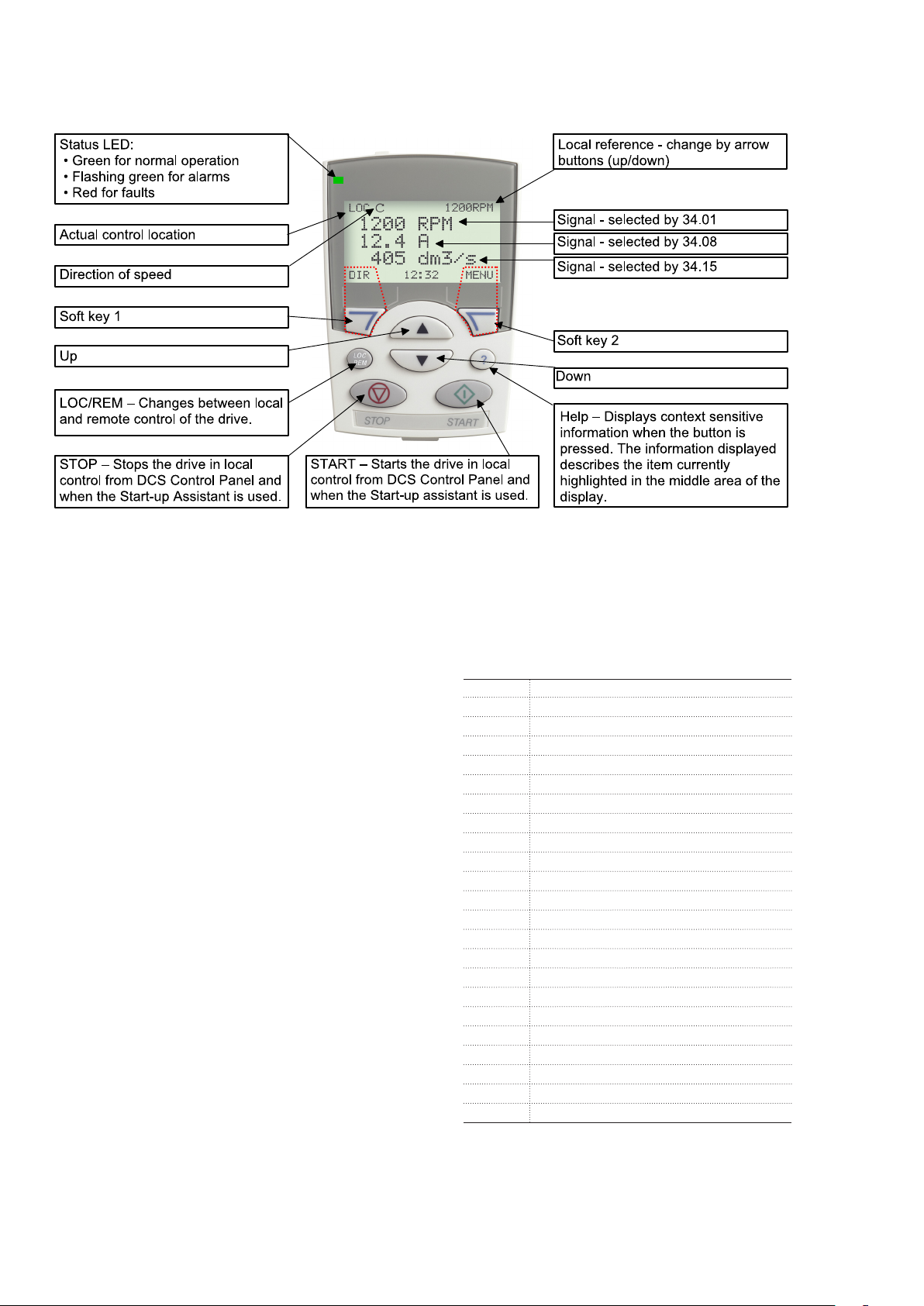

DCS550 Control Panel

DCS800 QG pan ov_c.dsf

The following table summarizes the button functions and displays of the DCS550 Control Panel

With USISel (16.09) it is possible to limit the amount of displayed parameters!

General display features

Parameters entered by assistant

Following modes are available in the MAIN MENU:

1. Parameters mode

2. Start-up assistants mode

a. Name plate data

b. Macro assistant

c. Autotuning field current controller

d. Autotuning armature current controller

e. Speed feedback assistant

(Tacho fine tuning not available)

f. Autotuning speed controller

g. Field weakening assistant

(only used when maximum speed is higher than base

speed)

3. Macros mode (currently not used)

4. Changed parameters mode (compare to default and

display changed parameters)

5. Fault logger mode (Display fault history)

6. Clock set mode

7. Parameter backup mode

• copy active parameter set from the drive into the

DCS550 Control Panel (only in local mode)

• copy parameter set from DCS550 Control Panel into

the drive (only in local mode)

8. I/O settings mode (currently not used)

99.02 Motor 1 nominal Voltage

99.03 Motor 1 nominal current

99.04 Motor 1 base speed

20.01 Motor 1 minimum speed

20.02 Motor 1 maximum speed

99.11 Motor 1 nominal field current

30.09 Armature over current level

30.16 Motor 1 over speed

99.10 Nominal mains voltage

99.12 Motor 1 used fex type

20.05 Torque maximum

20.06 Torque minimum

20.12 Motor 1 current limit bridge 1

20.13 Motor 1 current limit bridge 2

50.04 Motor 1 encoder pulse number, if selected

50.02 Motor 1 encoder measured mode, if selected

50.13 Motor 1 tacho volt, only DWL

50.12 Motor 1 tacho adapt, only DWL

20.03 Zero speed limit

22.01 Acceleration time 1

22.02 Deceleration time 1

30.12 Motor 1 field minimum trip

44.01 Field control mode

20 3ADW000395R0100 DCS550 Quick guide edisf a20 3ADW000395R0100 DCS550 Quick guide edisf a

Page 21

deutsch

Standard Features

− kompakt

− Höchste Leistungsfähigkeit

− Einfachste Bedienung

− Komfortable Assistenten, z. B. zur Inbetriebnahme oder Fehlersuche

3ADW000395R0100 DCS550 Quick guide edisf a

21

213ADW000395R0100 DCS550 Quick guide edisf a

Page 22

DCS550 Gleichstromantriebe

Technische Daten

Nennanschlusssp 230...525 V,

Frequenz 50 bis 60 Hz +/–5

Elektronikspg. 115...230 V,

–15 % / +10 %, 1~

DC Ausgangsstrom

Überlastbarkeit

Umgebungsgrenzwerte

Umgebungstemp. 0° ... +40° C

40° ... 50°C

Lagertemperatur –40° ... +55° C

Transporttemp. –40° ... +70° C

Relative Luftfeucht. 5 ... 95 %, nicht

(max. 50 % zw.

Verschmutzungsgrad

Schutzgrad IP 00

Betriebshöhe bis 1.000 m üNN

Über 1.000 m üNN

+/–10 %, 3~

Hz

20...1.000 A

200 %

Stromreduktion

kondensierend

0°...5° C)

Klasse 2

Nennstrom

Stromreduktion

Ein-/ Ausgänge

Digitale Eingänge: 8 Standard,

bis 14 optional

Digitale Ausgänge: 5 Standard,

bis 9 optional

Analoge Eingänge : 5 Standard

+/–10 V; 0/2…10 V, up

to 8 optional +/ 20 mA;

0/4…20 mA

Analog outputs: 3 standard (1x

I

) +/-10 V; 0/2…10 V, up to 7

act

optional –20 mA; 0/4…20 mA

PC-Tools

DriveWindow Light: kostenlos

mit jedem Antrieb, Standard

RS232 Verbindung

Zulassungen

(in Vorbereitung 12/2011)

Adaptive Programmierung

fertige antriebsspezifische Blöcke,

darunter

• Freier Prozessregler (PI-Regler)

• Ein/Ausgänge

Mit Bedien-Panel oder PC-Tool,

ohne zusätzliche Hardware

Drehzahlrückführung

EMK

Analoger Tachometer

Inkrementalgeber

Kommunikation

Verfügbare serielle Schnittstellen

• Ethernet • Profibus

• CANopen • DeviceNet

• ControlNet • EtherCat

• Modbus • ProfiNet

Industrial IT© enabled

Schutzfunktionen

• Überlast • Überdrehzahl •

Motor blockiert • Motorüberstrom

• Motorüberspannung

• Feldüberstrom •

Feldüberspannung •

Mindestfeldstrom • Drehzahl Null

• Ankerstromwelligkeit • Netz

Über- und Unterspannung

Nennstrom, Abmessungen

Bau-

größe

F1 20 25 12 370 x 270 x 208 14.56 x 10.65 x 8.20

45 50

65 75

90 100

F2 135 150 18 370 x 270 x 264 14.56 x 10.65 x 10.40

270 300

F3 315 350 25 459 x 270 x 310 18.07 x 10,65 x 12,25

405 450

470 520

F4 610 680 35 644 x 270 x 345 25.35 x 10.65 x 13.60

740 820

900 1000

2-Q

Dauerstrom

DCS550-S01

IDC[A] IDC[A] 230 400 525 [ADC] h x b x t [mm] h x b x t [inch]

180 200

225 250

4-Q

Dauerstrom

DCS550-S02

Versorgungs

spannung

[V

]

AC

max.

Feldstrom

intern

Abmessungens

22 3ADW000395R0100 DCS550 Quick guide edisf a22 3ADW000395R0100 DCS550 Quick guide edisf a

Page 23

Kurzanweisung CD und Dokumentationsübersicht

©

2

0

1

1

A

B

B

A

u

t

o

m

a

t

i

o

n

P

r

o

d

u

t

G

m

b

H

-

A

l

l

R

i

g

h

t

R

e

e

r

e

d

3ADW 000 377 R0201 / April 2011

System configuration

WINDOWS 98, NT, 2000, XP

Acrobat Reader 4.0 or higher

Internet Explorer 5.0 or higher

I

f

t

h

e

C

D

R

O

M

w

o

n

’

t

s

t

a

r

t

a

u

t

o

m

a

t

i

c

a

l

l

y

p

l

e

a

s

e

e

x

e

c

u

t

e

S

T

A

R

T

.

B

A

T

System confirmation

Win2000, WinXP

Before installation of PC tools

remove previous version by

CONTROL PANEL of your

PC

Read more details in

Quick Guide 3ADW000191

Content

This CD ROM provides

information about DCS550 and

contains PC tools:

DWL 2.93 for DC drives

+Commissioning Wizard 1.0

+DWL AP 2.2

FDT 2.2 Firmware

download kit

+ workspace

Firmware 1.1

DCS550

Ver.: 1.10

System confirmation

Win7, Win2000, WinXP

Before installation of PC tools

remove previous version by

CONTROL PANEL of your PC

Wir freuen uns, dass Sie einen ABB DC-Stromrichter erworben haben und bedanken uns für das Vertrauen, welches Sie

unseren Produkten entgegengebracht haben.

Damit Sie auch weiterhin mit unserem Produkt zufrieden sind,

haben wir diese Broschüre für Sie zusammengestellt. Sie soll

hauptsächlich dazu dienen, Ihnen einen kurzen Überblick über

das Produkt, EMV Hinweise, typische Anwendungen, Inbetriebnahme und Fehlersuche zu verschaffen.

Weitere Informationen zum Produkt finden Sie auf der beiliegenden CD-ROM. Die CD-ROM ist Teil der Lieferung und hat

folgende Bestandteile:

Technischer Katalog (3ADW000378)

Umfassende Information zur Planung kompletter DC-Stromrichter.

Handbuch (3ADW000379)

Detailinformation mit allen wichtigen Angaben zu den Einzelkomponenten, wie z.B. Modulabmaße, Elektronikkarten,

Lüfter und Zusatzkomponenten.

Informationen zur mechanischen und elektrischen Installation

sind ebenfalls enthalten.

Detailinformation mit allen wichtigen Angaben zur Firmware

und Einstellungen der Parameter. Dieses Handbuch enthält

alle notwendigen Informationen zur Inbetriebnahme.

Außerdem sind sowohl alle Fehler- und Alarmmeldungen aufgelistet als auch Informationen zur Fehlersuche.

Service Handbuch (3ADW000399)

Information zur Wartung und Reparatur der Stromrichter.

Weitere Informationen über Applikationen und technisches

Zubehör (z.B. Hardwareerweiterungen oder Feldbusadapter)

werden in separaten Handbüchern behandelt.

Siehe Tabelle DCS550 Manuals.

Systemvoraussetzungen für die Nutzung der CD ROM

c

− Betriebssystem

WINDOWS 7, 2000, XP

s

s

s

v

− ACROBAT READER

Falls die CD ROM nicht automatisch startet, klicken Sie bitte

doppelt auf Setup.exe.

Weitere Unterstützung

Wir bieten Ihnen darüber hinaus weitere Unterstützung an,

denn nur wenn Sie als Kunde mit uns und unseren Produkten

zufrieden sind, können auch wir zufrieden sein.

Internet

Auf der ABB Homepage unter

www.abb.com/dc

finden Sie viele Informationen zu

− DC Produkten

− Service

− neueste Updates

− Anwendersoftware

− Downloads etc.

Bitte zögern Sie nicht uns dort zu besuchen.

Kontakte

Benötigen Sie weitere Informationen, sprechen Sie bitte Ihr

nächstgelegenes ABB Drives Büro an oder schreiben Sie

eine E-Mail an:

DC-Drives@de.abb.com

deutsch

Geben Sie bitte Ihren Namen, Ihre Firmenadresse und Telefonnummer an und wir werden Ihnen umgehend den für Sie

zuständigen Ansprechpartner mitteilen.

3ADW000395R0100 DCS550 Quick guide edisf a

23

233ADW000395R0100 DCS550 Quick guide edisf a

Page 24

EMV Filter

Netzfilter

Stromrichter

Netzdrossel

Versorgungstransformator für

ein Wohngebiet

(Nennleistung

normalerweise≤ 1,2 MVA)

Geerdetes öffentliches

400 V-Netz mit NullLeiter

Mittelspannungsnetz

Geerdeter

Sternpunkt

Zu anderen Lasten, z.B. Antriebssystemen

Ein Trenntransformator

mit geerdetem Schirm

und geerdetem Eisenkern

macht das Netzfilter und

die Netzdrossel

überflüssig.

Betrieb am

öffentlichen Nieder-

spannungsnetz zu-

sammen mit anderen

Lasten aller Art.

Stromrichter

Wohngebiet

Zu anderen Lasten, die gegen die von Stromrichtern verursachten Netzstörungen

zu schützen sind (HF-Störungen und Kommutierungs

einbrüche)

alternativ

Netzdrossel

Geerdetes öffentliches

400 V-Netz mit NullLeiter

Versorgungstransf. für

ein Industriegebiet

(Nennleist. normalerweise≤ 1,2 MVA)

Geerdeter

Sternpunkt

Geerdetes öffentliches

400 V-Netz mit NullLeiter

Mittelspannungsnetz

alternativ

Netzdrossel +

Y-Kondensator

Leichtindustrie

Netzdrossel

Zu anderen Lasten, z.B. Antriebssystemen

Zu anderen Lasten, die gegen die von Stromrichtern verursachten Netzstörungen

zu schützen sind (HF-Störungen und Kommutierungs

einbrüche)

Zu anderen Lasten, z.B. Antriebssystemen

Wohngebiet

Ein Trenntransformator

mit geerdetem Schirm

und geerdetem Eisenkern

macht das Netzfilter und

die Netzdrossel

überflüssig.

Betrieb am

öffentlichen Nieder-

spannungsnetz zu-

sammen mit anderen

Lasten aller Art.

Betrieb am öffentlichen

Nieder-spannungsnetz zu-

sammen mit anderen

Lasten aller Art.

Kommutierungseibrüche < 20%

Weitere Informationen

hierzu siehe:

Technical Guide Kapitel:

EMC Compliant Installation

and Configuration for a

Power Drive System

Nachfolgend wird die Auswahl der elektrischen Komponenten entsprechend der

EMV-Richtlinie beschrieben.

Ziel der EMV-Richtlinie ist es, eine elektromagnetische Verträglichkeit mit anderen

Produkten und Systemen herzustellen. Die

Richtlinie stellt sicher, dass die von dem

Produkt abgestrahlten Emissionen so gering sind, dass sie die Störfestigkeit eines

anderen Produkts nicht beeinträchtigen.

Im Zusammenhang mit der EMV-Richtlinie

sind zwei Aspekte zu berücksichtigen:

Die EMV-Richtlinie verlangt, dass die EMV

bereits bei der Produktentwicklung berücksichtigt werden muss; jedoch kann die EMV nicht

mit eingeplant werden, sie kann nur quantitativ

gemessen werden.

Hinweis zur EMV

Das richtige Vorgehen liegt sowohl in der

Verantwortung der Stromrichterlieferanten wie

auch des Maschinen- oder Anlagenbauers

entsprechend ihrem Anteil an den elektrischen

Einrichtungen.

− die Störfestigkeit des Produkts

− die tatsächlichen Emissionen des

Produkts

Erste Umgebung (Wohngebiete mit Leichtindustrie) mit PDS Kategorie C2 Zweite Umgebung (Industrie) mit den PDS-Kategorien C3, C4

Nicht möglich, da Kategorie C1 (Vertriebskanäle für Produkte mit allgemeiner Erhältlichkeit) entfällt Entfäll

Erfüllt Erfüllt

Entfällt

Erfüllt Erfüllt

Stromrichter

Netzfilter

Stromrichter

Netzfilter

Stromrichter

Stromrichter

24 3ADW000395R0100 DCS550 Quick guide edisf a24 3ADW000395R0100 DCS550 Quick guide edisf a

Page 25

Um bei Maschinen und Anlagen die

Legende

ungeschirmtes Kabel mit

Einschränkung

abgeschirmtes Kabel

I

DC

< 100 A

I

DC

< 100 A

I

DC

>100 A

Netzdrossel

Netzfilter

Stromrichter

Versorgungstransf. für

ein Industriegebiet

(Nennleist. normalerweise≤ 1,2 MVA)

Geerdeter

Sternpunkt

Geerdetes 400 V-Netz mit

Null-Leiter; 3~ ≤ 400 A

Stromrichter

Mittelspannungsnetz

Zu anderen Lasten, z.B. Antriebssystemen

Netzdrossel +

Y-Kondensator

Industriegebiet

Betrieb am Niederspannungsnetz zusammen

mit anderen Lasten aller Art außer einige Arten

von em

pfindlichen Kommuni

kationsmitteln.

alternativ

alternativ

Kommutierungseibrüche < 40%

emv_clssif_c.dsf

Stromrichtertransformator

fallbezogene EMV-Analyse

Mittelspannungsnetz

Industriegebiet

Stromrichter

Stromrichtertransformator

mit geerdeter

Schirmwicklung

Netzdrossel

Stromrichter

I > 400 A

und/oder

U > 500 V

Betrieb mit separatem Stromrichter-transforma

tor. Wenn es an

dersel

ben Sekundärwicklung andere Lasten gibt, so müssen

diese die vom Stromrichter verursach

ten Kommutierungs

lücken

vertragen. In einigen Fällen sind Kommutierungsdrosseln

erforderlich.

Zu anderen Lasten, z.B. Antriebssystemen

Schutzvorgaben des deutschen EMVGesetzes (EMVG) erfüllen zu können,

müssen folgende EMV-Normen eingehalten werden:

Produktnorm EN 61800-3

EMC-Norm für Stromrichtersysteme

(PowerDriveSystem), Störfestigkeit und

Abstrahlungen in Wohn-, Gewerbegebieten mit Leichtindustrie und Industrieanlagen.

Diese Norm innerhalb der EU zur

Einhaltung der EMV-Anforderungen für

Maschinen und Anlagen erfüllt werden!

Normen für Störabstrahlungen:

EN 61000-6-3 Die spezielle Basisnorm für Abstrahlungen in der Leichtindustrie

kann mit speziellen Einrichtungen (Netzfiltern, geschirmten Kabeln)

im unteren Leistungsbereich erfüllt werden *(EN 50081-1).

EN 61000-6-4 Spezielle Basisnorm für Abstrahlungen in der Industrie

*(EN 50081-2)

Normen für Störfestigkeit::

EN 61000-6-1 Spezielle Basisnorm für Störfestigkeit in Wohngebieten

*(EN 50082-1)

EN 61000-6-2 Spezielle Basisnorm für Störfestigkeit in Industrieanlagen.

Wenn diese Norm erfüllt ist, ist auch automatisch die Norm

EN 61000-6-1 erfüllt *(EN 50082-2).

* Die alten Normen sind in Klammer n angegeben.

Standards

EN 61800-3

EN 61000-6/3

deutsch

PDS Kategorie C3

Auf Kundenwunsch Erfüllt

PDS Kategorie C4

EN 61000-6/3

EN 61000-6-2

EN 61000-6-1

Klassifizierung

In der folgenden Übersicht

werden die Maßnahmen dargestellt, die zur Einhaltung der

Produktnorm erforderlich sind.

EN 61800-3.

Bei der DCS550-Serie werden

die Grenzwerte für Störabstrahlungen eingehalten, wenn

die angegebenen Maßnahmen durchgeführt werden.

PDS der Kategorie C2 (früher

eingeschränkte Erhältlichkeit

in der Ersten Umgebung) ist

ausschließlich für die Installation und Inbetriebnahme durch

Fachpersonal (Person oder

Organisation mit dem erforderlichen Sachverstand bzw.

Inbetriebnahme des PDS einschließlich EMV-Maßnahmen)

vorgesehen.

Bei Stromrichtern ohne Zusatzkomponenten sind folgende

Warnhinweise zu beachten:

Es handelt sich um ein Produkt

der Kategorie C2 gemäß IEC

61800-3:2004. In Wohngebieten kann dieses Produkt

Funkstörungen verursachen.

In diesem Fall sind zusätzliche

Maßnahmen erforderlich.

Die Feldversorgung wird in dieser Übersicht nicht dargestellt.

Für Feldstromkabel gelten

dieselben Regeln wie für die

Ankerstromkreis.

3ADW000395R0100 DCS550 Quick guide edisf a

25

253ADW000395R0100 DCS550 Quick guide edisf a

Page 26

±90...±270 V

±

30...±90 V

±

8...±30 V

AI4

GND

GND

Power

Sense 0 V

Sense 5 V

AI3

AI1

I-act

GND

+10V

GND

-10V

DI1

DI3

DI4

DO4

DO1

3

4

5

6

9

X4:1

3

4

10

4

1

2

3

6

5

10

8

9

10

5

2

6

8

10

8

X1:1

X2:1

X3:1

X5:

SDCS-CON-F

B22_001_0_a.dsf

+

-

S2

3

4

250

S3

3

4

250

ATACH

+

-

+

-

+

-

+

-

GND

10

+

-

+

-

+

-

5V

S4