ABB DCS550 Manual REv e

DCS550

Manual

DCS550 Drives (20 A to 1000 A)

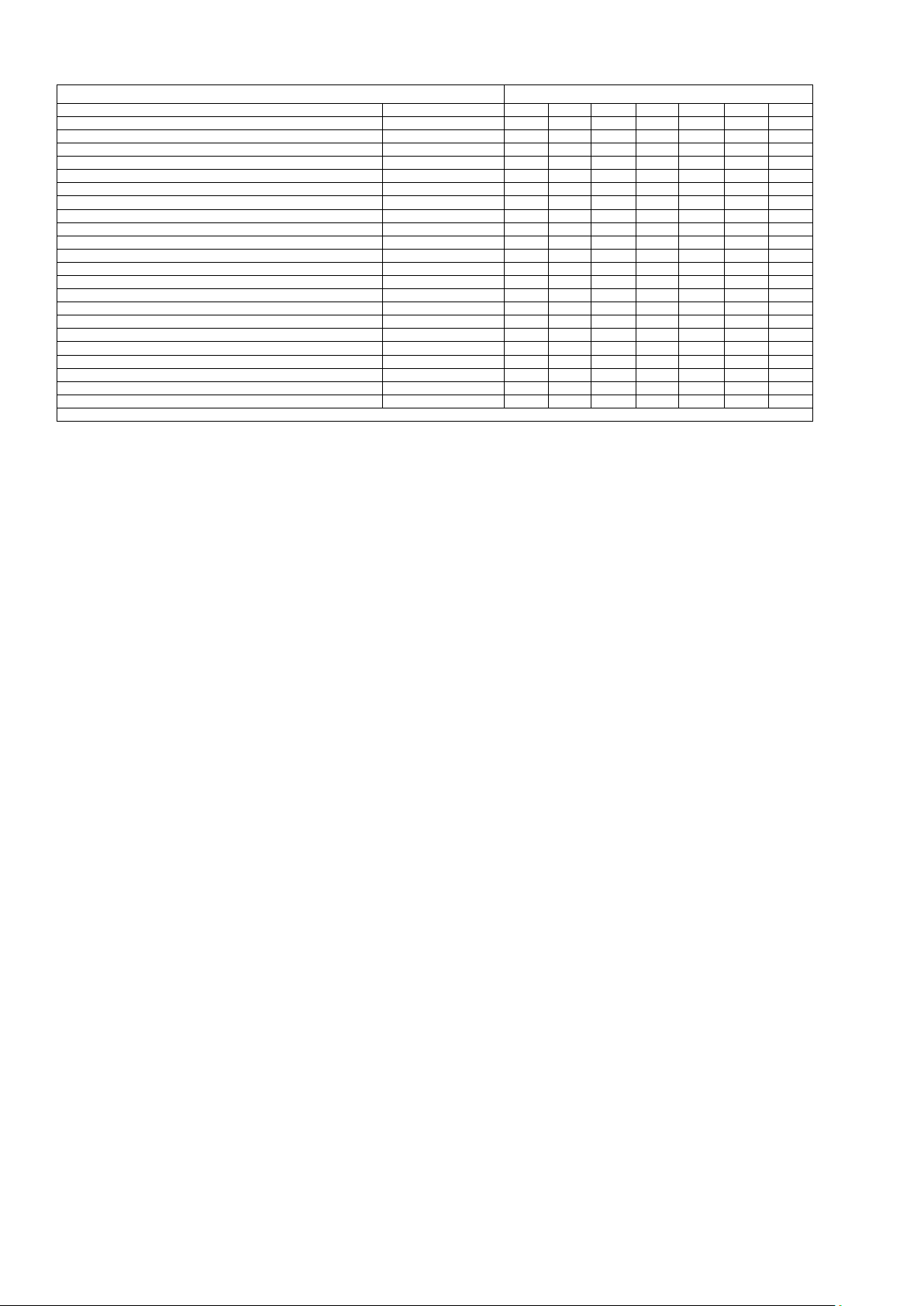

DCS550 Manuals

Public. number

E D I

ES F CN

RU

Quick Guide

3ADW000395

x x x x x

DCS550 Tools & Documentation CD

3ADW000377

x

DCS550 Modules

DCS550 Flyer

3ADW000374

x x x x

DCS550 Technical Catalog

3ADW000378

x x x

DCS550 Manual

3ADW000379

x x x x

DCS550 Service Manual

3ADW000399

x

Installation according to EMC

3ADW000032

x

Technical Guide

3ADW000163

x

Extension Modules

RAIO-01 Analog IO Extension

3AFE64484567

x

RDIO-01 Digital IO Extension

3AFE64485733

x

Serial Communication

RPBA-01 PROFIBUS

3AFE64504215

x

RCAN-01 CANopen

3AFE64504231

x

RCNA-01 ControlNet

3AFE64506005

x

RDNA-01 DeviceNet

3AFE64504223

x

RMBA-01 MODBUS

3AFE64498851

x

RETA-01 Ethernet

3AFE64539736

x

Status 11.2013

DCS550 Manuals list f.doc

Language

3ADW000379R0501 DCS550 Manual e e

Safety instructions

Dangerous voltage warning warns of high voltage, which can cause physical injury or death

and/or damage to the equipment.

General danger warning warns about conditions, other than those caused by electricity, which

can result in physical injury or death and/or damage to the equipment.

Electrostatic sensitive devices warning warn of electrostatic discharge, which can damage

the equipme

WARNING!

1.

•

•

•

•

•

Note:

•

•

•

system from the supply.

Chapter overview

This chapter contains the safety instructions you must follow when installing, operating and servicing the drive.

If ignored, physical injury or death may follow, or damage may occur to the drive, the motor or driven

equipment. Read the safety instructions before you work on the unit.

To which products this chapter applies

The information is valid for the whole range of the product DCS550.

Usage of warnings and notes

There are two types of safety instructions throughout this manual: warnings and notes. Warnings caution you

about conditions, which can result in serious injury or death and/or damage to the equipment, and advice on

how to avoid the danger. Notes draw attention to a particular condition or fact, or give information on a

subject. The warning symbols are used as follows:

3

nt.

Installation and main t enan ce wor k

These warnings are intended for all who work on the drive, motor cable or motor. Ignoring the instructions can

cause physical injury or death and/or damage to the equipment.

Only qualified electricians are allowed to install and maintain the drive!

Never work on the drive, motor cable or motor when main power is applied. Always ensure

by measuring with a multimeter (impedance at least 1 Mohm) that:

1. Voltage between drive input phases U1, V1 and W1 and the frame is close to 0 V.

2. Voltage between terminals C+ and D- and the frame is close to 0 V.

Do not work on the control cables when power is applied to the drive or to the external

control circuits. Externally supplied control circuits may cause dangerous voltages inside the

drive even when the main power on the drive is switched off.

Do not make any insulation resistance or voltage withstand tests on the drive or drive

modules.

Isolate the motor cables from the drive when testing the insulation resistance or voltage

withstand of the cables or the motor.

When reconnecting the motor cable, always check that the C+ and D- cables are connected

with the proper terminal.

The motor cable terminals on the drive are at a dangerously high voltage when the main

power is on, regardless of whether the motor is running or not.

Depending on the external wiring, dang er ous voltag es ( 115 V, 220 V or 230 V) may be

present on the relay outputs of the drive system (e.g. RDIO).

DCS550 with enclosure extension: Before working on the drive, isolate the whole drive

Safety instructions

4

3ADW000379R0501 DCS550 Manual e e

WARNING!

•

•

ed and marked as required by safety

•

•

Note:

WARNING!

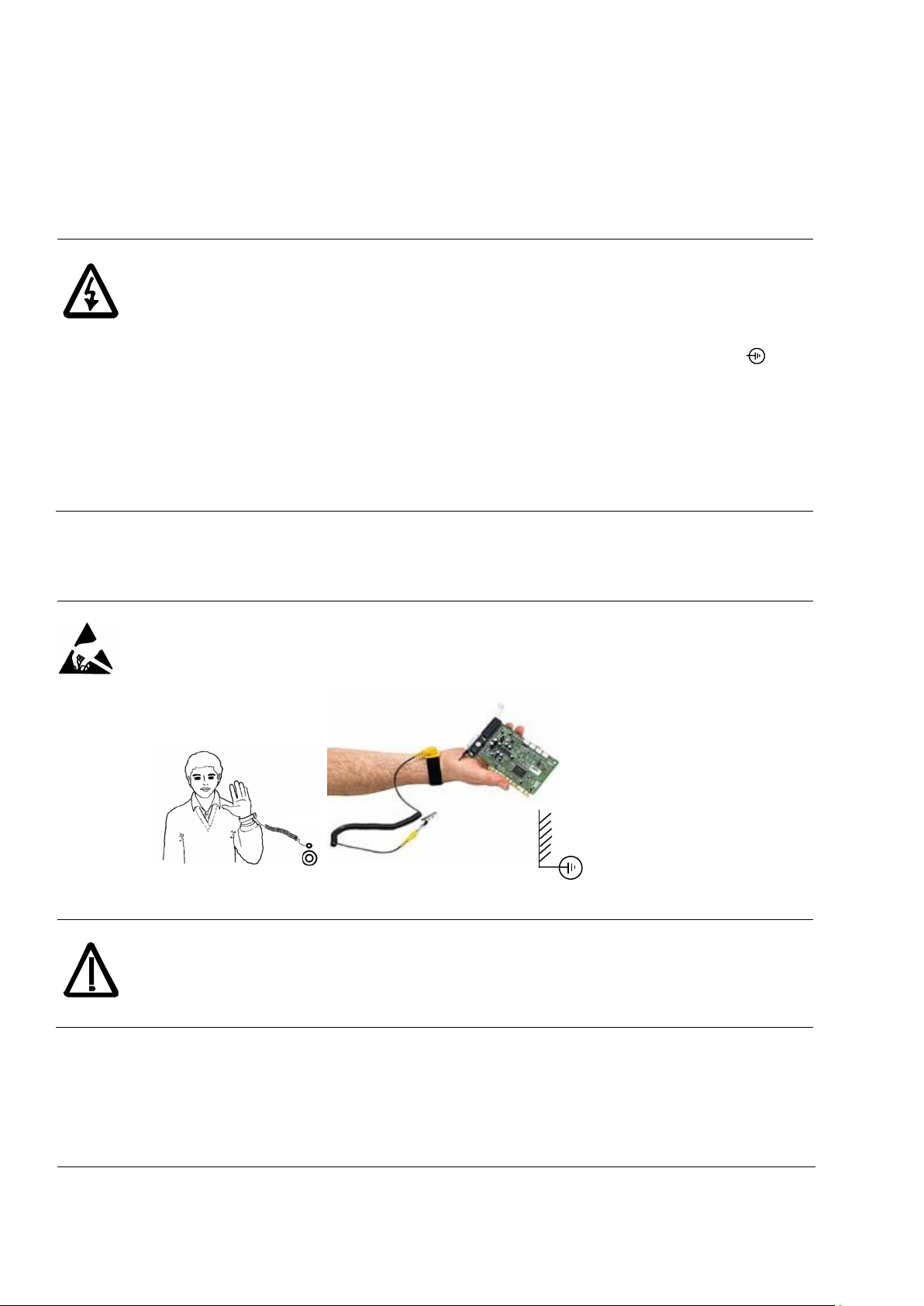

The printed circuit boards contain components sensitive to electrostatic discharge. Wear a

grounding

Use grounding strip:

ABB order no.: 3ADV050035P0001

WARNING!

Handle the fiber optic cables with care. When unplugging optic cables, always grab the

connector, not the cable itself. Do not touch the ends of the fibers with bare

is extremely sensitive

Grounding

These instructions are intended for all who are responsible for the grounding of the drive. Incorrect grounding

can cause physical injury, death and/or equipment malfunction and increase electromagnetic interference.

Ground the drive, motor and adjoining equipment to ensure personnel safety in all

circumstances, and to reduce electromagnetic emission and pick-up.

Make sure that grounding conductors are adequately siz

regulations.

In a multiple-drive installation, connect each drive separately to protective earth (PE ).

Minimize EMC emission and make a 360° high frequency grounding (e.g. conductive

sleeves) of screened cable entries at the cabinet lead-through plate.

Power cable shields are suitable as equipment grounding conductors only when adequately

sized to meet safety regulations.

As the normal leakage current of the drive is higher than 3.5 mAAC or 10 mADC (stated by EN

50178, 5.2.11.1), a fixed protective earth connection is required.

Printed circuit boards and fiber opti c cables

These instructions are intended for all who handle the circuit boards and fiber optic cables. Ignoring the

following instructions can cause damage to the equipment.

wristband when handling the boards. Do not touch the boards unn ec es sar ily.

to dirt. The minimum allowed bend radius is 35 mm (1.38 in.).

hands, as the fiber

Safety instructions

3ADW000379R0501 DCS550 Manual e e

Mechanical installation

WARNING!

WARNING!

Note:

These notes are intended for all who install the drive. Handle the unit carefully to avoid damage and injury.

DCS550 size F4: The drive is heavy. Do not lift it alone. Do not lift the unit by the front cover.

Place it only on its back.

Make sure that dust from drilling does not enter the drive when installing. Electrically

conductive dust inside the unit may cause damage or lead to malfunction.

Ensure sufficient cooling.

Do not fasten the drive by riveting or welding.

Operation

These warnings are intended for all who plan the operation of the drive or operate the drive. Ignoring the

instructions can cause physical injury or death and/or damage to the equipment.

Before adjusting the drive and putting it into service, make sure that the motor and all driven

equipment are suitable for operation throughout the speed range provided by the drive. The

drive can be adjusted to operate the motor at speeds above and below the base speed.

Do not control the motor with the disconnecting device (disconnecting mains); instead, use

5

the control panel keys

Mains connection

You can use a disconnect switch (with fuses) to disconnect the electrical components of the

drive from the mains for installation and maintenance work. The type of disconnect switch

used must be as per EN 60947-3, Class B, so as to comply with EU regulations, or a circuit-

breaker type which switches off the load circuit by means of an auxiliary contact causing the

breaker's main contacts to open. The mains disconnect must be locked in its "OPEN"

position during any installation and maintenance work.

EMERGENCY STOP buttons must be installed at each control desk and at all other control

panels requiring an emergency stop function. Pressing the STOP button on the control panel

of the drive will neither cause an emergency stop of the motor, nor will the drive be

disconnected from any dangerous potential.

To avoid unintentional operating states, or to shut the unit down in case of any imminent

danger according to the standards in the safety instructions it is not sufficient to merely shut

down the drive via signals "RUN", "drive OFF " or "Em ergency Stop" respectively "control

panel" or "PC tool".

Intended use

The operating instructions cannot take into consideration every possible case of

configuration, operation or maintenance. Thus, they mainly give such advice only, which is

required by qualified personnel for normal operation of the machines and devices in industrial

installations.

If in special cases the electrical machines and devices are intended for use in non-industrial

installations - which may require stricter safety regulations (e.g. protection against contact by

children or similar) - these additional safety measures for the installation must be provided by

the customer during assembly.

When the control location is not set to Local (L not shown in the status row of the display),

the stop key on the control panel will not stop the drive. To stop the drive using the control

and , or commands via the I/O board of the drive.

panel, press the LOC/REM key and then the stop key

.

Safety instructions

6

3ADW000379R0501 DCS550 Manual e e

Table of contents

DCS550 Manuals ................................................................................................................................................. 2

Safety instructions ................................................................................................................................................ 3

Table of contents ................................................................................................................................................. 6

Introduction .......................................................................................................................................................... 8

The DCS550 ........................................................................................................................................................ 9

General ...................................................................................................................................................... 9

Overview Main circuit and control ............................................................................................................ 11

Environmental Conditions ........................................................................................................................ 12

Type code ................................................................................................................................................ 13

Voltage and current ratings ..................................................................................................................... 14

Dimensions and weights .......................................................................................................................... 16

Mechanical installation ....................................................................................................................................... 19

Cabinet installation .................................................................................................................................. 20

Planning the electrical installation ...................................................................................................................... 21

Drive connection and wiring example ...................................................................................................... 22

Installation components ........................................................................................................................... 24

① Line reactors (L1) ................................................................................................................................ 24

② Semiconductor fuses (F1) ................................................................................................................... 25

③ EMC filters (E1) ................................................................................................................................... 25

④ Auxiliary transformer (T2) for converter electronics and fan ............................................................... 28

⑤ Start, Stop and E-stop control ............................................................................................................. 28

⑥ Cooling fans ........................................................................................................................................ 29

Cabling ..................................................................................................................................................... 30

Electrical ins ta ll a ti on .......................................................................................................................................... 34

Power connections .................................................................................................................................. 35

Drive interfaces ........................................................................................................................................ 37

Installation checklist ................................................................................................................................. 39

Electronic board details...................................................................................................................................... 40

Terminal locations.................................................................................................................................... 40

Table of used boards ............................................................................................................................... 41

Control board SDCS-CON-F ................................................................................................................... 42

Power Interfac e boar d SDC S-PIN-F........................................................................................................ 45

Integrated field exciters SDCS-BAB-F01 and SDCS-BAB-F02 .............................................................. 47

Accessories ........................................................................................................................................................ 50

① Line reactors (L1) ................................................................................................................................ 50

② Semiconductor fuses (F1) ................................................................................................................... 56

③ EMC filters (E1) ................................................................................................................................... 58

④ Auxiliary transformer (T2) for converter electronics and fans ............................................................. 58

Start-up .............................................................................................................................................................. 59

Commissioning ........................................................................................................................................ 59

Macros ..................................................................................................................................................... 63

Firmware description .......................................................................................................................................... 74

Table of contents

3ADW000379R0501 DCS550 Manual e e

Start / stop sequences.............................................................................................................................. 74

Excitation .................................................................................................................................................. 75

DC-breaker ............................................................................................................................................... 77

Dynamic braking ....................................................................................................................................... 78

Digital I/O configuration ............................................................................................................................ 80

Analog I/O configuration ........................................................................................................................... 84

Serial field bus communication ........................................................................................................................... 88

CANopen communication with fieldbus adapter RCAN-01 ...................................................................... 88

ControlNet communication with fieldbus adapter RCNA-01 .................................................................... 92

DeviceNet communication with fieldbus adapter RDNA-01 ..................................................................... 95

Ethernet/IP communication with fieldbus adapter RETA-01 .................................................................... 98

Modbus (RTU) communication with fieldbus adapter RMBA-01 ........................................................... 102

Modbus/TCP communication with fieldbus adapter RETA-01 ............................................................... 104

Profibus communication with fieldbus adapter RPBA-01 ....................................................................... 105

ProfiNet communication with fieldbus adapter RETA-02 ....................................................................... 109

Switch on sequence ............................................................................................................................... 110

Data set table ......................................................................................................................................... 110

AP (Adaptive Program) ..................................................................................................................................... 111

What is AP? ............................................................................................................................................ 111

DWL AP .................................................................................................................................................. 116

Function blocks ...................................................................................................................................... 120

7

Winder .............................................................................................................................................................. 132

Winder blocks ......................................................................................................................................... 132

Winder macros ....................................................................................................................................... 139

Signal and parameter list .................................................................................................................................. 153

Signal groups list .................................................................................................................................... 153

Parameter groups list ............................................................................................................................. 154

Signals .................................................................................................................................................... 156

Parameters ............................................................................................................................................. 181

DCS Control Panel ........................................................................................................................................... 270

Fault tracing ...................................................................................................................................................... 276

Converter protection ............................................................................................................................... 276

Motor protection ..................................................................................................................................... 279

Display of status, fault messages and error codes ................................................................................ 285

Fault signals (F) ...................................................................................................................................... 286

Alarm signals (A) .................................................................................................................................... 294

Notices ................................................................................................................................................... 301

Appendix A: Quick start-up diagrams ............................................................................................................... 302

Drive configuration with reduced components ....................................................................................... 302

I/O connections ...................................................................................................................................... 304

Appendix B: Firmware structure diagrams ....................................................................................................... 305

Appendix C: Index of signals and parameters ................................................................................................. 309

Table of contents

8

Introduction

Chapter overview

This chapter describes the purpose, contents and the intended use of this manual.

Before You Start

The purpose of this manual is to provide you with the information necessary to control and program the drive.

Study carefully the S afety i nstr uc tions

the drive. Read this manual before starting-up the drive.

Note:

This manual describes the standard DCS550 firmware.

What this manual contains

The Safety instructions ar e at the beginning of this manual.

Introduction

The DCS550

Mechanical installation

Planning the electrical installation

Electrical ins ta ll a ti on

Electronic b oard det ai ls

Accessories

Start-up

Firmware description

Serial field bus communication

AP (Adaptive Program)

Winder

Signal and parameter list

DCS Control Panel

Fault tracing

Appendix A: Quick start-up diagrams

Appendix B: Firmware structure diagrams

Appendix C: Index of signal and parameters

, the chapter you are currently reading, introduces you to this manual.

, this chapter describes the basic properties of the DCS550.

, this chapter describes the mechanical installation of the DCS550.

, this chapter describes the electrical installation of the DCS550.

, this chapter describes the electronics of the DCS550.

, this chapter describes the accessories for the DCS550.

, this chapter describes the basic start-up procedure of the DCS550.

, this chapter describes how to control the DCS550 with standard firmware.

, this chapter describes the communication capabilities of the DCS550.

, this chapter describes the basics of AP and instructs how to build an application.

, this chapter describes the winder and instructs how to use the winder blocks of the DCS550.

, this chapter contains all signals and parameters.

, this chapter describes the handling of the DCS Control Panel.

, this chapter describes the protections and fault tracing of the drive.

at the beginning of this manual before attempting any work on or with

, this chapter describes how to plan the electrical installation of the DCS550.

Introduction

3ADW000379R0501 DCS550 Manual e e

The DCS550

In order to offer the same after sales service to our customer around the

world, ABB has created the

sales service is globally consistent due to common targets, rules and the

way of operation.

drive service homepage at

Country

Local ABB Service

Town

Service Phone No.

Argentina

Asea Brown Boveri S.A.

BUENOS AIRES

+54 (0) 12 29 55 00

Australia

ABB

NOTTING HILL

+61 (0) 3 85 44 00 00

Austria

ABB AG

WIEN

+43 1 60 10 90

Belgium

ABB N.V.

ZAVENTEM

+32 27 18 64 86

+32 27 18 65 00 - 24h service

Brazil

ABB Ltda.

OSASCO

+55 (0) 11 70 84 91 11

Canada

ABB Inc.

SAINT

+1800 865 7628

China

ABB China Ltd

BEIJING

+86 40 08 10 88 85 - 24h service

Czech Republic

ABB S.R.O.

PRAHA

+42 02 34 32 23 60

Finland

ABB Oy Service

KUUSANKOSKI

+35 8 10 22 51 00

Finland

ABB Oy Product Service

HELSINKI

+35 8 10 22 20 00

Finland

ABB Oy Service

NOKIA

+35 8 10 22 51 40

France

ABB Automation

ABB Process Industry

MONTLUEL

from abroad France

+33 1 34 40 25 81

+0810 02 00 00

Germany

ABB Process Industries

MANNHEIM

+49 18 05 22 25 80

Greece

ABB SA

METAMORPHOSSIS

+30 69 36 58 45 74

Ireland

ABB Ireland Ltd.

TALLAGHT

+35 3 14 05 73 00

Italy

ABB

MILAN

+39 02 90 34 73 91

Korea, Republic

ABB Ltd., Korea

CHONAN

+82 (0) 4 15 29 22

Malaysia

ABB Malaysia Sdn. Bhd.

KUALA LUMPUR

+60 3 56 28 42 65

Mexico

ABB Sistemas S.A. DE C.V.

TLALNEPANTLA

+52 53 28 14 00

Netherlands

ABB B.V.

ROTTERDAM

+31 1 04 07 88 66

New Zealand

ABB Service ltd

AUCKLAND

+64 92 76 60 16

Poland

ABB Centrum IT Sp.zo.o

WROCLAW

LODZ

+48 42 61 34 96 2

+48 42 29 93 91 39 5

Russia

ABB Automation LLC

MOSCOW

+74 95 96 0

Switzerland

ABB AG

DÄTTWIL

+41 5 85 86 87 86

Singapore

ABB Industry Pte Ltd

SINGAPORE

+65 67 76 57 11

Slovakia

ABB Elektro s.r.o.

BANSKA BYSTRICA

+42 19 05 58 12 78

South Africa

ABB South Africa (Pty) Lt

JOHANNESBURG

+27 1 16 17 20 00

Spain

ABB Automation Products

BARCELONA

+34 9 37 28 73 00

Taiwan

ABB Ltd.

TAIPEI 105

+88 62 25 77 60 90

Thailand

ABB Limited

SAMUTPRAKARN

+66 27 09 33 46

Turkey

ABB Elektirk Sanayi A.S

ISTANBUL

+90 2 16 36 52 90

USA ABB Industrial Products

NEW BERLIN

+1 26 27 85 32 00

+1 262 435 7365

Venezuela

ABB S.A.

C

S

+58 (0) 22 38 24 11 / 12

Chapter overview

This chapter describes the basic properties of the DCS550.

General

ABB Drive Service

DRIVE SERVICE CONCEPT. ABB’s after

This means for our customers simply visit the ABB

www.abb.com/drivesservices.

DC drives worldwide Service Network

9

-LAURENT

RC

3ADW000379R0501 DCS550 Manual e e

The DCS550

10

Every DCS550 comes together with a DCS550

Tools CD. This CD contains the documentation

and PC tools for the DCS550.

DCS550 Tools CD

Documentation

The structure of the documentation is according to the following system:

− The DCS550 Technical Catalogue contains information to engineer complete DC drive systems.

− The DCS550 Manual contains information about

1. module dimensions, electronic boards, fans and auxiliary parts,

2. mechanical and electrical installation,

3. firmware and parameter settings

4. start-up and maintenance of the entire drive

5. fault, alarm codes and information for trouble shooting.

− The DCS800 / DCS550 Service Manual contains information for maintenance and repair of the converters.

− Additional information about technical accessories (e.g. hardware extension or fieldbus interfaces) are

handled by separate manuals. See chapter DCS550 Manuals

DCS550 PC tools

After inserting the DCS550 CD all programs and documentation necessary to work with the DCS550 can be

installed. This includes:

− DCS550 documentation,

− DriveWindow Light for parameterization, commissioning and service,

− plug ins for DriveWindow Light (DWL AP and the commissioning wizard)

− Hitachi FDT 2.2 for firmware download and

− DCS550 firmware.

.

The DCS550

3ADW000379R0501 DCS550 Manual e e

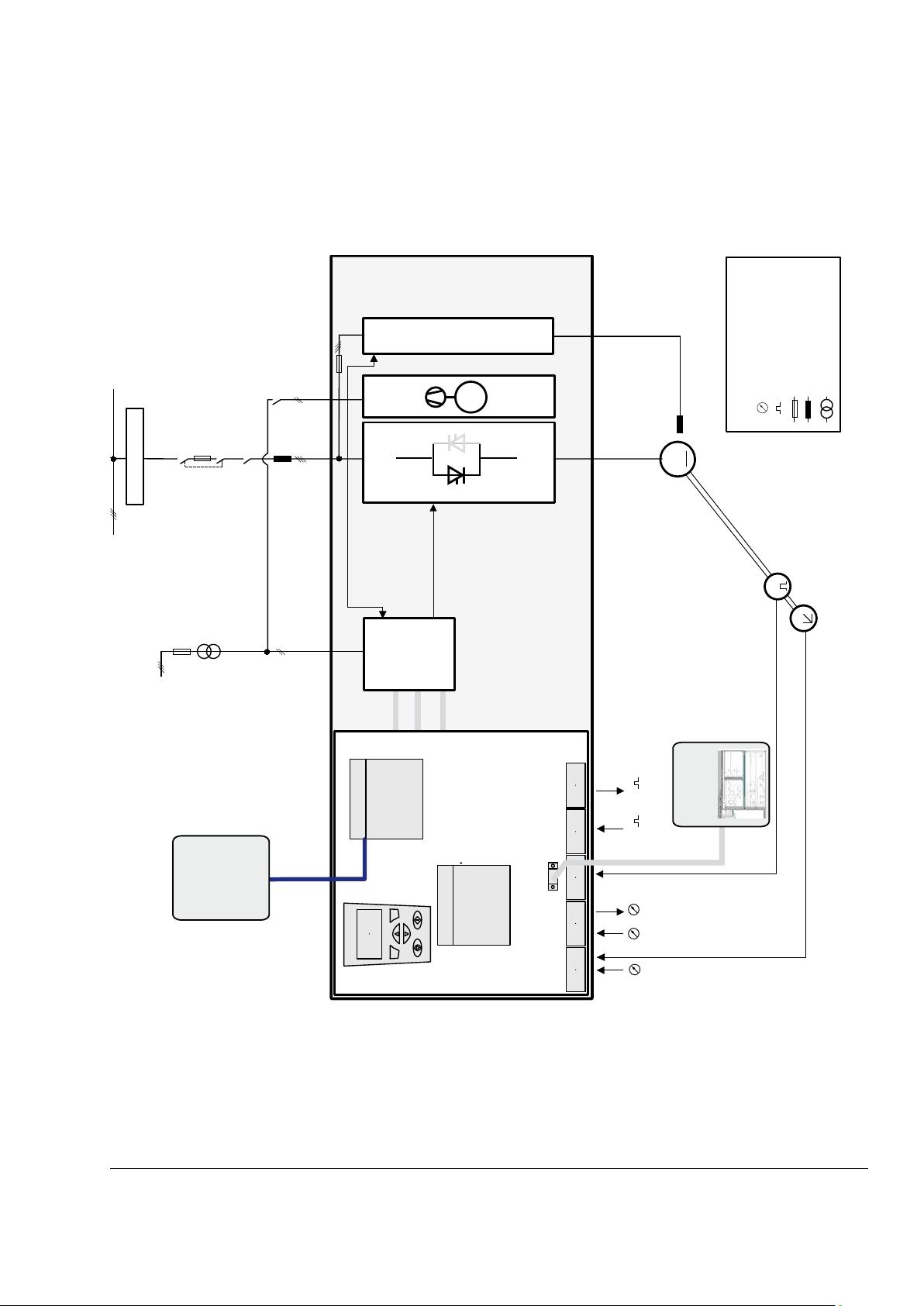

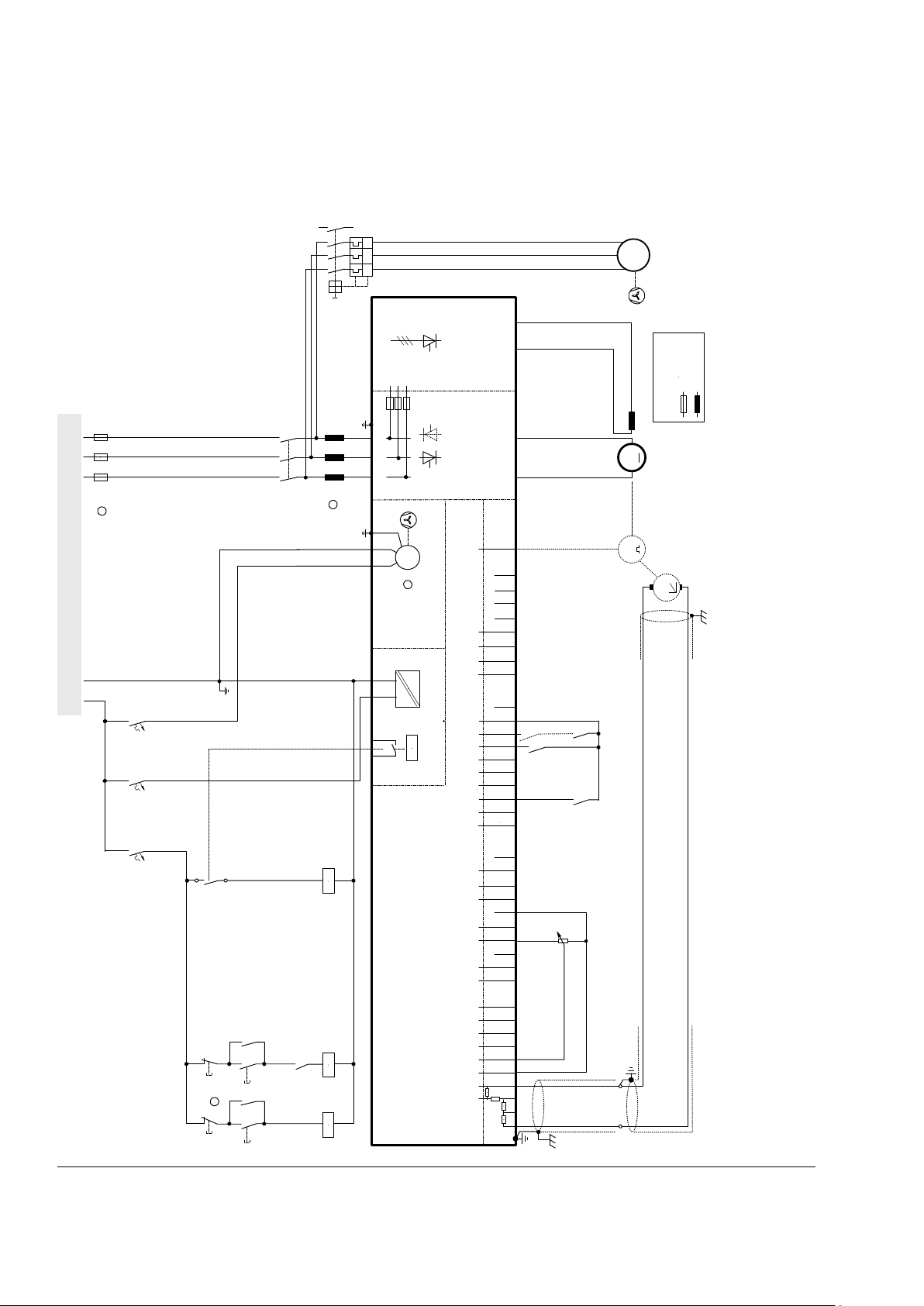

Overview Main circuit and contr ol

K1

T2

Q1

F2

M

F1

525V

525V

SB_550_001_a.ai

230 V / 115 V

L1

K5

(SDCS-BAB-F)

M

DCS550

SDCS-PIN-F

analog input / output

digital input / output

Legend

fuse

reactor

transformer

Slot 3

Slot 1

Fieldbusses,

adapters

R-type

OnBoard fieldexciter

EMC filter

DWL

PC with

8

4

7

3

E

T

SDCS-

CON-F

X1 X2 X3 X4 X5

X9

Panel

X33

X34

RS232

X11

E/A-Adapter R-Typ

PLC

1

DCS550 converter units F1 to F4 for 525 V with integrated field exciters.

11

3ADW000379R0501 DCS550 Manual e e

The DCS550

12

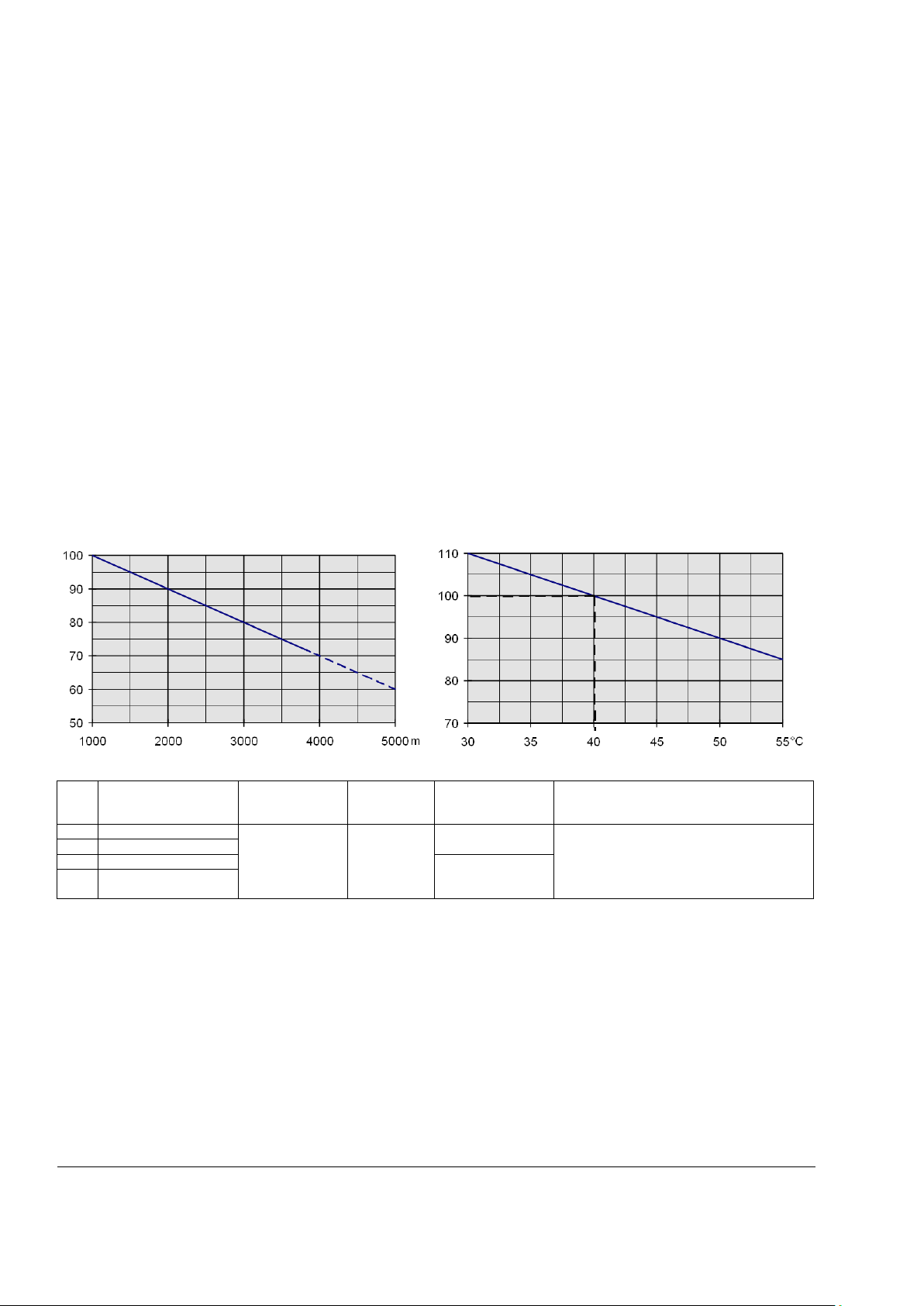

System connection

Environmental limit values

Voltage, 3-phase:

230 to 525 V acc. to IEC 60038

Permissible cooling air temperature

Voltage deviation:

±10 % continuous; ±15 % shorttime (0.5 to 30 cycles)

− with rated DC current (forced

ventilation):

0 to +40°C

Rated frequency:

50 Hz or 60 Hz

− with different DC current see

figure below:

+30 to +55°C

Static frequency deviation:

50 Hz ±2 %; 60 Hz ±2 %

Dynamic: frequency range:

50 Hz: ±5 Hz; 60 Hz: ± 5 Hz

− for options:

0 to +40°C

df/dt:

17 % / s

Relative humidity (at 5...+40°C):

5 to 95 %, no condensation

Note:

Special consideration must

regenerative mode.

Relative humidity (at 0...+5°C):

5 to 50 %, no condensation

Change of the ambient temp.

< 0.5°C / minute

Storage temperature:

-40 to +55°C

Degree of protection

Transport temperature:

-40 to +70°C

Converter modules and

options (line chokes, fuses,

field exciters, etc.):

IP 00 / NEMA TYPE OPEN

Pollution degree (IEC 60664-1,

IEC 60439-1):

2

Vibration class:

3M3

Site elevation

Paint finish

<1000 m above mean sea level:

100%, without current reduction

Converter modules:

Dark grey RAL 7012

>1000 m above mean sea level:

with current reduction, see figure

below

Effect of the site elevation above sea level on the converter’s load

capacity:

Effect of the ambient temperature on the converter module load

capacity:

Current reduction to (%)

Current reduction to (%) for converter modules

Size

Sound pressure level

LP (1 m distance)

Vibration

Shock

Transport in

original Package

Short circuit withstand rating

The DCS

capable of delivering not more than:

F1

55 dBA

1.5 mm, 2 - 9 Hz

0.5 g, 9

7 g / 22 ms

1.2 m

65 kA rms symmetrical ampere at a maximum

of 600 V

F2

55 dBA

F3

60 dBA

1.0 m

F4

66 - 70 dBA,

depending on fan

Environmental Conditi ons

The technical data contain the technical specifications of the drive, e.g. the ratings, sizes and technical

requirements, provisions for fulfilling the requirements for CE and other markings and warranty policy.

be taken for voltage deviation in

- 200 Hz

550 is suitable for use in a circuit

AC

The DCS550

3ADW000379R0501 DCS550 Manual e e

Regulatory Compliance

European Union Directive

Manufacturer's Assurance

Harmonized Standards

Machinery Directive

98/37/EEC

93/68/EEC

Declaration of Incorporation

EN 60204-1

[IEC 60204-1]

Low Voltage Directive

73/23/EEC

93/68/EEC

Declaration of Conformity

EN 61800-1

[IEC 61800

EN 60204

[IEC 60204-1]

EMC Directive

89/336/EEC

93/68/EEC

Declaration of Conformity

(

selection, cabling and EMC filters or dedic

transformer are followed.)

EN 61800-3

[IEC 61800-3]

in accordance with

3ADW000032

Rated supply voltage

Standards

up to 525 V

−

See UL Listing www.ul.com / certificate no. E196914

−

− or on request

The drive’s basic type code: DCS550-AAX-YYYY-ZZ-BB

Product family:

DCS550

Type:

AA

= S0

Standard converter modules IP00

Bridge type:

X

= 1

Single bridge (2-Q)

= 2

2 anti parallel bridges (4-Q)

Module type:

YYYY

=

Rated DC current

Rated AC voltage:

ZZ

= 05

230 VAC - 525 VAC

Fan voltage:

BB

= 00

Standard

F1:

F2, F3:

F4:

Additional informat ion:

CC

The converter modules are designed for use in industrial environments. In EEA countries, the components

fulfill the requirements of the EU directives, see table below.

13

If all installation instructions concerning cable

ated

North American Standards

In North America, the system components fulfill the requirements of the table below.

AC

Approval: cULus The spacings in the modules were evaluated to table 36.1 of

UL 508 C. Spacings also comply with table 6 and table 40 of C22.2 No. 14-05.

Type code

The type code contains information on the specifications and configuration of the drive.

Description see below:

-1]

-1

no fan 20 A / 25 A

24 VDC internal 45 A - 100 A

115 VAC / 230 VAC; single phase

230 VAC; single phase

The DCS550

3ADW000379R0501 DCS550 Manual e e

14

Mains voltage

Maximum DC voltage

Ideal DC voltage

DC voltage class

UVN [VAC]

U

d max 2-Q

[VDC]

U

d max 4-Q

[VDC]

Ud0 [VDC]

230

265

240

310

05

380

440

395

510

05

400

465

415

540

05

415

480

430

560

05

440

510

455

590

05

460

530

480

620

05

480

555

500

640

05

500

580

520

670

05

525

610

545

700

05

+

∗∗≤

%100

%100

35.1

TOL

UU

VNF

Size

IA, 2-Q

P

[kW] ①

IA, 4-Q

P

[kW] ①

Mains

IF

P

Air flow

Auxiliary

F1

20

12

25

13

230 - 525

1 - 12

0.11

no fan

115 VAC,

45

26

50

26

0.17

150

65

38

75

39

0.22

150

90

52

100

52

0.28

150

F2

135

79

150

78

1 - 18

0.38

300

180

104

200

104

0.56

300

225

131

250

131

0.73

300

270

157

300

157

0.88

300

F3

315

183

350

182

2 - 25

0.91

300

405

235

450

234

1.12

300

470

280

520

276

1.32

500

F4

610

354

680

354

2 - 35

1.76

950

740

429

820

426

2.14

950

900 ②

522

1000 ③

520

2.68

1900

Voltage and current ratings

The maximum available armature voltages have been calculated using the following assumptions:

− U

− Voltage tolerance ±10 %,

− Internal voltage drop approximately 1 %

If a deviation or a voltage drop has to be taken into account in compliance with IEC and VDE standards, the

output voltage and / or the output current must be reduced.

The maximum available field voltage can be calculated using following formula:

= rated mains voltage, 3-phase,

VN

, with:

U

= field voltage,

F

= mains voltage and

U

VN

TOL = tolerance of the mains voltage in %.

[A]

out

[A]

① Ratings for 500 VAC -10 %

② 900 A

③ 1000 A

for 35°C and 850 ADC for 40°C ambient temperature

DC

for 35°C and 950 ADC for 40°C ambient temperature

DC

out

[VAC]

-15 % / +10 %

[A]

loss

[kW]

[m3/h]

voltage

230 VAC,

230 V

DC

-15 % / +10 %

The DCS550

3ADW000379R0501 DCS550 Manual e e

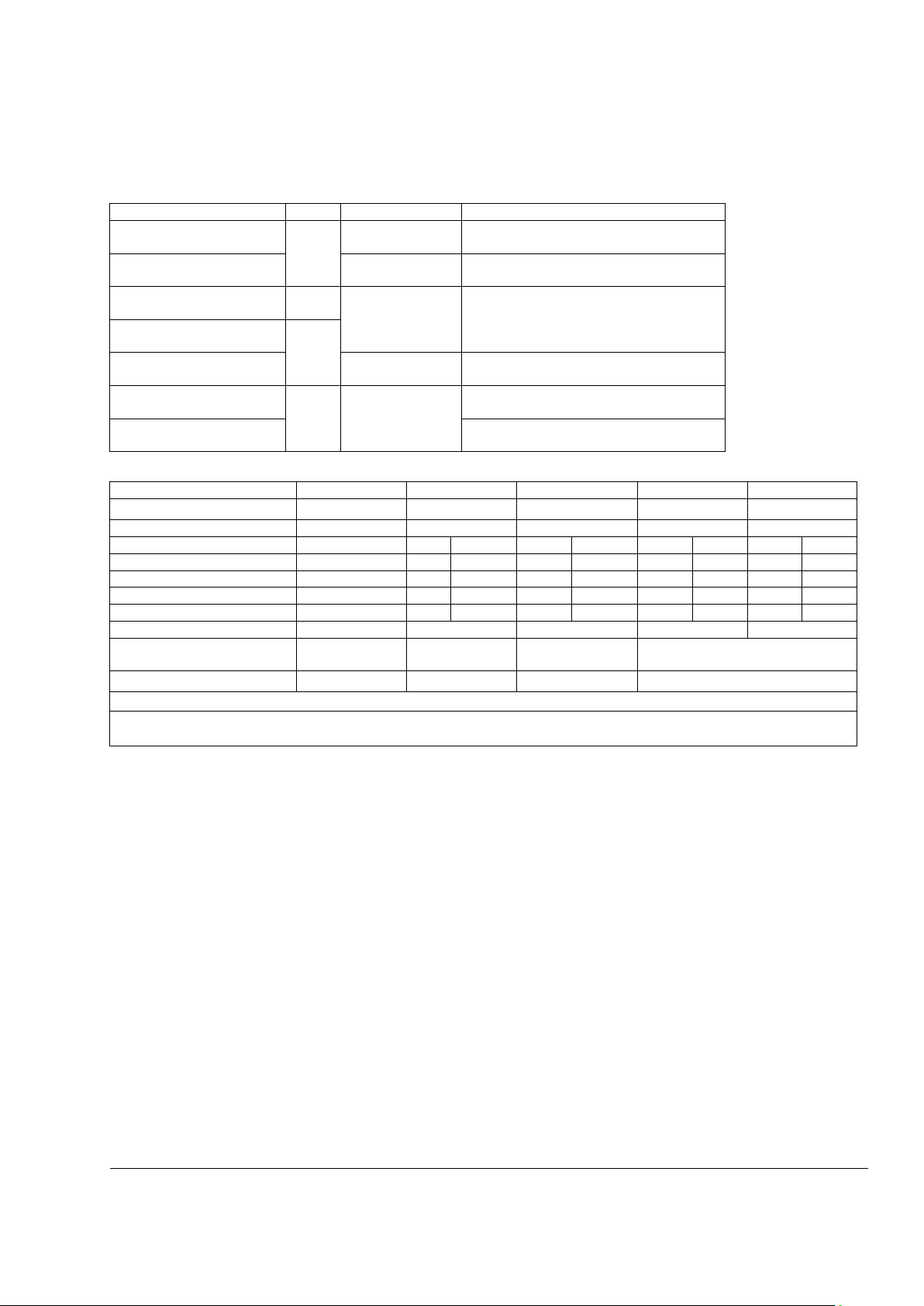

Current ratings - IEC non regenerative

Converter type (2

Internal field

current

continuous

15 min

60 s

15 min

120 s

15 min

10 s

525 V

[A]

[A]

[A]

[A]

DCS550-S01-0020-05

20

16

24

16

24

15

30

DCS550-S01-0045-05

45

36

54

35

52

31

62

DCS550-S01-0065-05

65

54

81

52

78

49

98

DCS550-S01-0090-05

90

76

114

74

111

73

146

DCS550-S01-0135-05

135

105

157

100

150

93

186

F2

1 - 18 A

DCS550-S01-0180-05

180

130

195

125

187

110

220

DCS550-S01-0225-05

225

170

255

165

247

148

296

DCS550-S01-0270-05

270

200

300

195

292

180

360

DCS550-S01-0315-05

315

240

360

235

352

215

430

F3

2 - 25 A

DCS550-S01-0405-05

405

310

465

300

450

270

540

DCS550-S01-0470-05

470

350

525

340

510

310

620

DCS550-S01-0610-05

610

455

682

435

652

425

850

F4

2 - 35 A

DCS550-S01-0740-05

740

570

855

540

810

525

1050

DCS550-S01-0900-05

900

680

1020

650

975

615

1230

Converter type (4

Internal field

current

continuous

100 %

15 min

150 %

60 s

100 %

15 min

150 %

120 s

100 %

15 min

200 %

10 s

525 V

[A]

[A]

[A]

[A]

DCS550-S02-0025-05

25

22

33

21

31

20

40

F1

1 -12 A

DCS550-S02-0050-05

50

38

57

37

55

33

66

DCS550-S02-0075-05

75

60

90

59

88

54

108

DCS550-S02-0100-05

100

85

127

83

124

80

160

DCS550-S02-0150-05

150

114

171

110

165

100

200

F2

1 - 18 A

DCS550-S02-0200-05

200

145

217

140

210

115

230

DCS550-S02-0250-05

250

185

277

180

270

165

330

DCS550-S02-0300-05

300

225

337

220

330

200

400

DCS550-S02-0350-05

350

275

412

265

397

245

490

F3

2 - 25 A

DCS550-S02-0450-05

450

350

525

340

510

310

620

DCS550-S02-0520-05

520

400

600

380

570

350

700

DCS550-S02-0680-05

680

525

787

510

765

475

950

F4

2 - 35 A

DCS550-S02-0820-05

820

630

945

610

915

565

1130

DCS550-S02-1000-05

1000

750

1125

725

1087

660

1320

See the current ratings including several standard duty cycles for the DCS550 with 50 Hz and 60 Hz supplies

below. The current ratings are based on an ambient temperature of maximum 40°C and an elevation of

maximum 1000 m above mean sea level:

-Q) I

I

DC I

100 %

I

DC II

150 %

100 %

I

DC III

150 %

100 %

Size

DC IV

200 %

F1 1 - 12 A

Note:

AC current I

= 0.82*IDC

AC

Current ratings - IEC regenerative

15

-Q) I

I

DC I

I

DC II

Note:

AC current I

= 0.82*IDC

AC

Sizing and standard duty cycles:

The ratings apply at ambient temperature of 40 °C (104 °F).

I

DC III

Size

DC IV

The DCS550

3ADW000379R0501 DCS550 Manual e e

16

Size

h * w * d [mm]

h * w * d [inch]

weight [kg]

weight [lbs]

F1

370*270*208

14.57*10.63*8.19

11

24

F2

370*270*264

14.57*10.63*10.39

16

35

F3

459*270*310

18.07*10.63*12.21

25

55

F4

644*270*345

25.35*10.63*13.58

38

84

Size F1:

Size F2:

Size F3:

Size F4:

DCS550-S01-0020

DCS550

DCS550

DCS550

DCS550

DCS550

DCS550

DCS550-S02-0100

DCS550-S01-0135

DCS550

DCS550

DCS550

DCS550

DCS550

DCS550

DCS550-S02-0300

DCS550-S01-0315

DCS550-S01-0610

DCS550

DCS550

DCS550

DCS550

DCS550

270

225

193.5

S

S

4 x 45 = 180

32.5

45

10

A

B

84.6

86

DCS550

S = 5 mm for size F1

S = 10 mm for size F2 - F3

Direction of air flow

Fan terminal

for Screw

Screw M6

Earthing

point H

D

E

F

G

C

43.5

20

10.5

9

8.7

T1

T1

Field terminal

Signal te

r

minals

P

o

w

er supply

ter

minals

Pow

er connection

MG_550_001_F1-F3_a-ai

Mounting Direction

Mini

mum top clear

ance

T1 = 150 mm

for si

ze F1

T1 = 250 mm

f

or siz

e F2 / F3

Minim

um bottom clear

ance

T2 = 100 mm

f

or siz

e F1

T2 = 150 mm

for si

ze F2 / F3

310

f

or si

z

e F1 / F2

400

f

or si

z

e F3

A

F1

F2

F3

370

370

459

350

350

437.5

165

-

242

208

264

310

79

121.5

147.5

110

163.5

205

157

212

255

M6

M10

M10

B C D E F G

H

Size

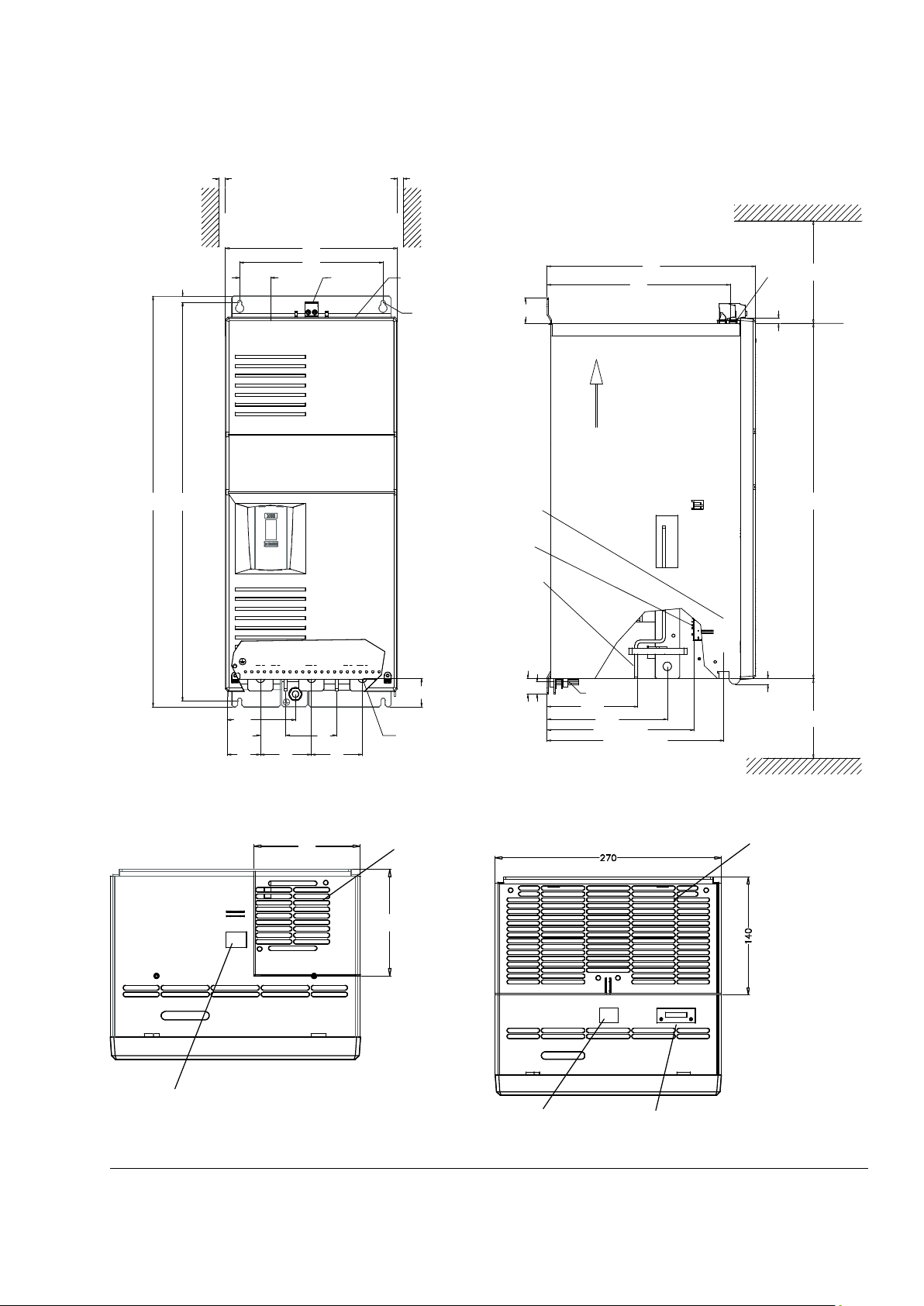

Dimensions and weights

See the dimensional drawings of the DCS550 below. The dimensions are in millimeters.

-S01-0045

-S01-0065

-S01-0090

-S02-0025

-S02-0050

-S02-0075

Size F1-F3:

-S01-0180

-S01-0225

-S01-0270

-S02-0150

-S02-0200

-S02-0250

DCS550-S01-0405

DCS550-S01-0470

DCS550-S02-0350

DCS550-S02-0450

DCS550-S02-0520

-S01-0740

-S01-0900

-S02-0680

-S02-0820

-S02-1000

The DCS550

3ADW000379R0501 DCS550 Manual e e

Size F4:

Top view, F1 45 A – 100 A

Top view, F2 135 A – 300 A

S

225

625

644

48.5

10

270

S

S = 10 mm

U1 V1 W1

D1

80

80

45

80

40

52

107

C1

DCS550

Power terminals: 40 x 5 mm

Fan terminal

for M6

Field terminals

for M12

298

345

42

8.7

250

577

150

9

25

20

147.5

195.5

240 (PIN-F01)

287.5 (CON-F01)

MG_550_002_F4_a.ai

Fan terminal

Minimum top clearanceMinimum bottom clearance

Direction of air flow

Earthing

point H

Earthing M12

Signal terminals

Power supply

terminals

Power connection

X10

115

115

MG_550_003_fans_a.ai

recommended

air exhaust duct

115 x 115 mm

Field terminals

X10 X52

MG_550_003_fans_a.ai

recommended

air exhaust duct

140 x 270 mm

Field terminals Fan terminal

17

Field-, fan terminals and cooling air duct sizes

The DCS550

3ADW000379R0501 DCS550 Manual e e

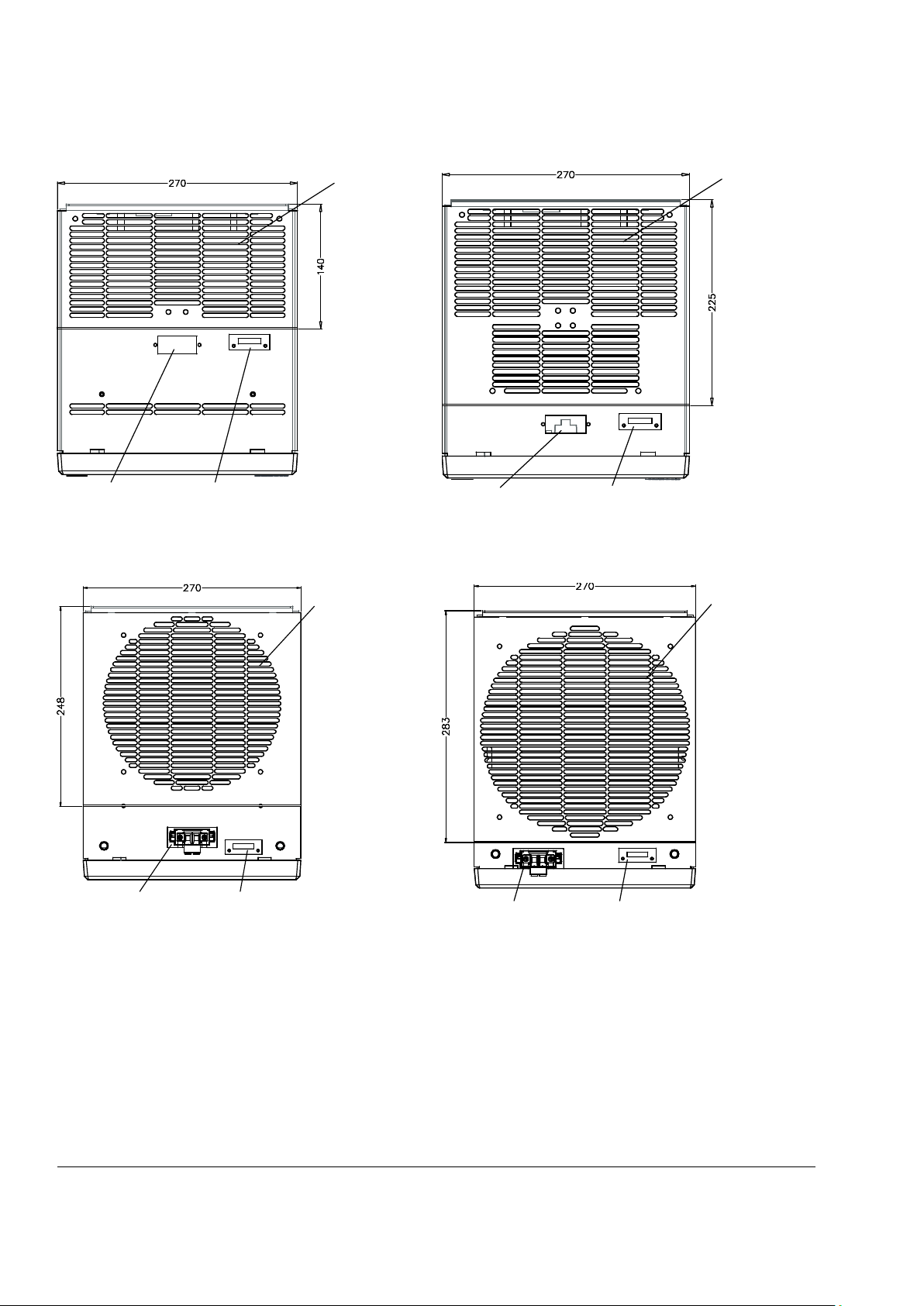

18

Top view, F3 315 A – 450 A

Top view, F3 470 A – 520 A

Top view, F4 610 A – 820 A

Top view, F4 900 A – 1000 A

X10 X52

recommended

air exhaust duct

140 x 270 mm

Field terminals F

an terminal

X10 X52

MG_550_003_fans_a.ai

recommended

air exhaust duct

225 x 270 mm

Field terminals Fan terminal

X10 X52

recommended

air exhaust duct

248 x 270 mm

Field terminals Fan terminal

X10 X52

MG_550_003_fans_a.ai

recommended

air exhaust duct

283 x 270 mm

Field terminals Fan terminal

The DCS550

3ADW000379R0501 DCS550 Manual e e

Mechanical installation

−

−

−

Attention:

Do

cover!

ABB Automation Products GmbH

U

1

U2

610 V

Made in Germany

Type: DCS550-S02-0075-05-00-00

I1

62 A

I2 75 A

Ser No: 0025421A10524264

f1

50/60 Hz

If

18 A

SCCR

65 kA

Fan

----

Rated input voltage

Rated output current

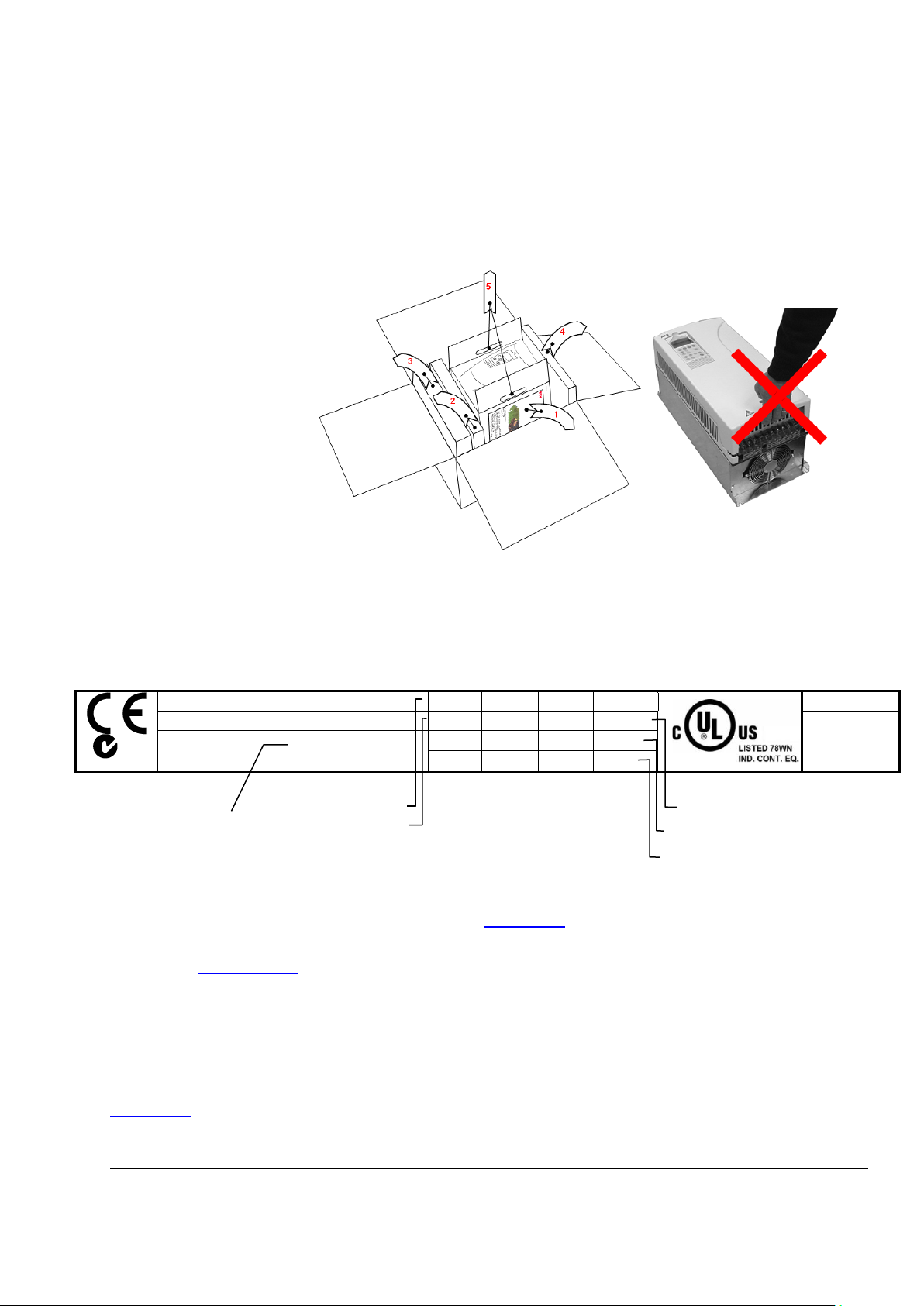

Chapter overview

This chapter describes the mechanical installation of the DCS550.

Unpacking the unit

Open the box,

take out shock dampers,

separate manual and

accessories.

not lift the drive by the

19

Delivery check

Check that there are no signs of damage. Before attempting installation and operation, check the information

on the nameplate of the converter module to verify that the unit is of the correct type. The label includes an

IEC rating, cULus, C-tick (N713) and CE markings, a type code and a serial number, which allow individual

identification of each unit. The remaining digits complete the serial number so that there are no two units with

the same serial number. See an example nameplate below.

3 ∼ 525 V

N713

Production year

2010 and week 52

Rated input current

Rated internal field exciter

current

Rated fan voltage

Before installation

Install the drive in an upright position with the cooling section facing a wall. Check the installation site

according to the requirements below. Refer to chapter Dimensions

Requirements for the installation site

See chapter Technic al dat a for the allowed operation conditions of the drive.

Wall

The wall should be as close to vertical as possible, of non-flammable material and strong enough to carry the

weight of the unit. Check that there is nothing on the wall to inhibit the installation.

Floor

The floor or material below the installation must be non-flammable.

Free space around the unit

Around the unit free space is required to enable cooling airflow, service and maintenance see chapter

Dimensions

.

for frame details.

Mechanical installation

3ADW000379R0501 DCS550 Manual e e

20

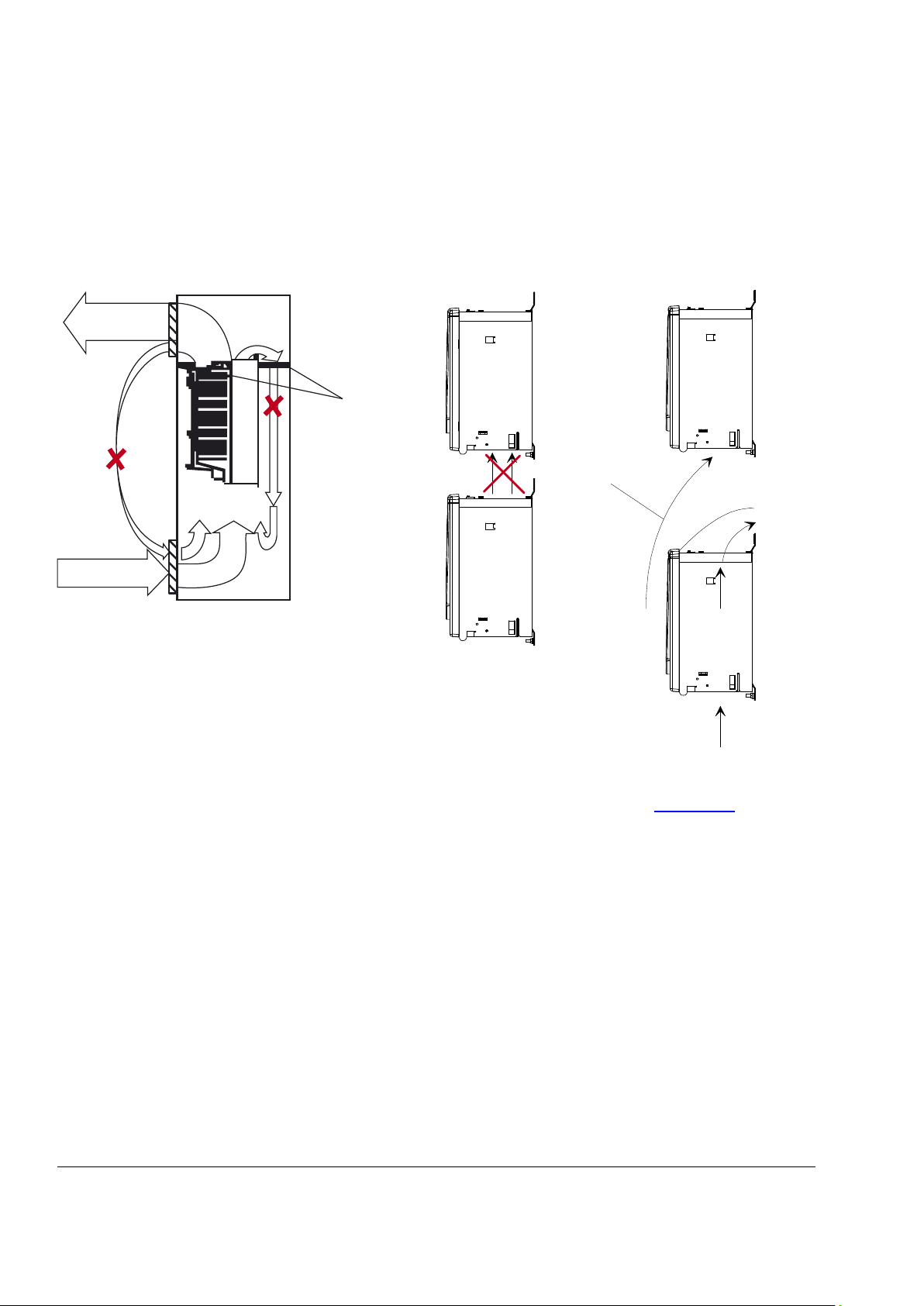

Preventing cooling air recirculation

Unit above another

Prevent air recirculation inside and outside the cabinet

Lead the exhaust cooling air away from the unit

above. Distances see chapter Dimensions.

BG_800_004_luft_a.ai

Hot area

Cool area

Main air flow in

Air ba

f

fle plates

Main air flow out

max.+40°C

BG_800_003_luft_a.ai

Air baffle plate

Airflow

Cabinet installation

The required distance between parallel units is five millimeters (0.2 in.) in installations without front cover. The

cooling air entering the unit must not exceed +40°C (+104°F).

Mechanical installation

3ADW000379R0501 DCS550 Manual e e

Planning the electrical installation

Chapter overview

This chapter contains the instructions that must be followed when selecting the motor, cables, protections,

cable routing and way of operation for the drive system. Always follow local regulations. This chapter applies

to all DCS550 converter modules.

Attention:

If the recommendations given by ABB are not followed, the drive may experience problems that the warranty

does not cover. See also Technical Guide.

21

Electrical installation

3ADW000379R0501 DCS550 Manual e e

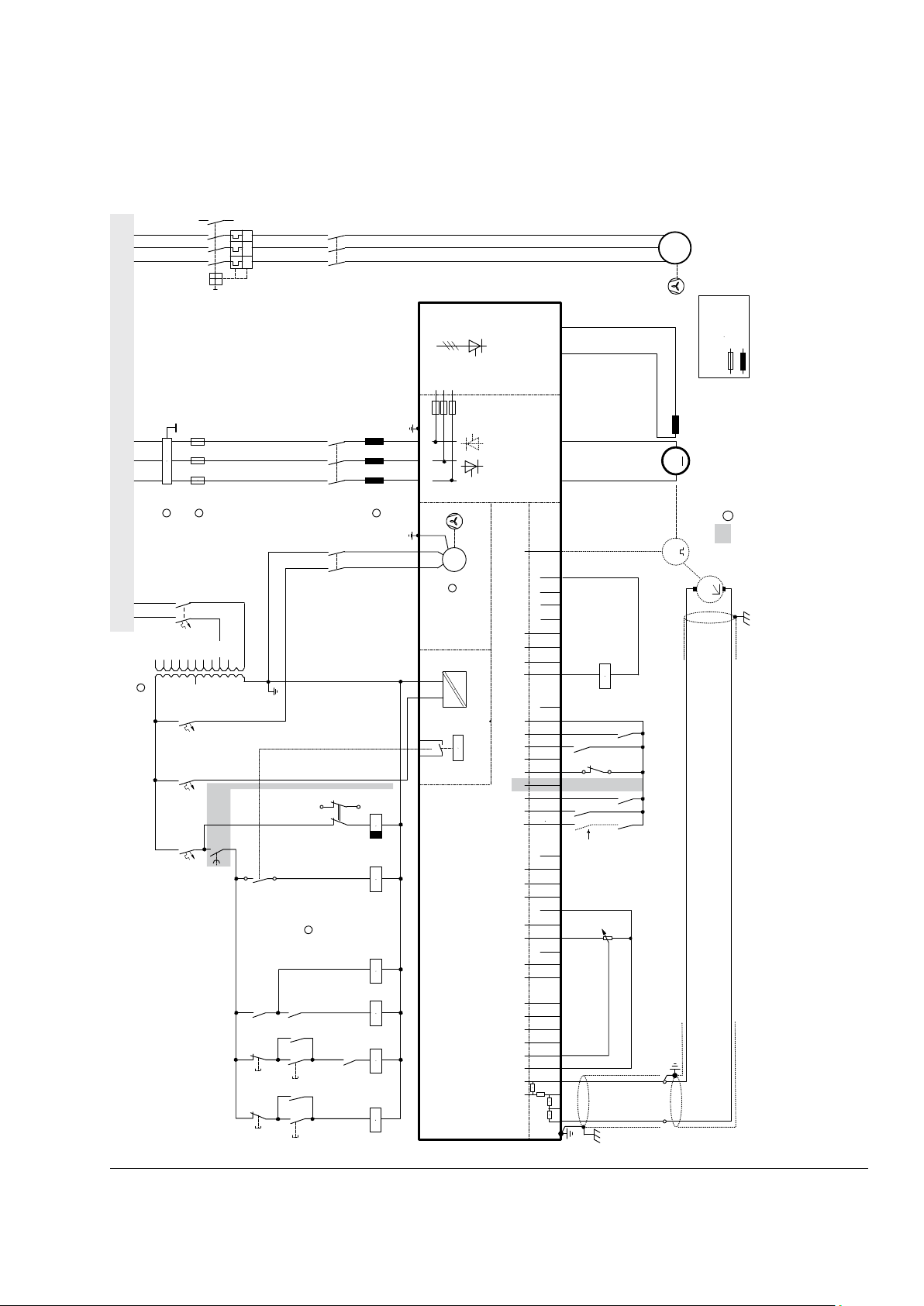

22

X96:

DO8

1 2 X52: 1 2 3

U1 W1V1 PE

K1

K20

K21K20 K1

X96:1

X96:2

L1 L2 L3

525V, 50/ 60Hz

F1

M

1~

K21

C 1 D 1

AITAC AI1

AI2 AI3

AI4

+10V -10V AO1 AO2 I

ACT

DI1 DI2 DI3 DI4 DI5 DI6 DI7 DI8 +24V DO1 D O2 DO3 DO4

_ _ _ _

_

+ + + +

+

Encoder

T

E

M

GND

GNDGNDGNDGND

NCNCNC

X1: 1 2 3 4 5 6 7 8 9 10 X2: 1 2 3 4 5 6 7 8 9 10 X4: 1 2 3 4 5 6 7 8 9 10

X5:

1 2 3 4 5 6 7 8 1...10

X3:

+

_

+

_

K1

K20

K21

F5

1

2

F8

1

2

F7

1

2

K1

1 3 5

2 4 6

L1

F+

F-

X10:

L1 N

2

1

4

3

6

5

F6

I > I > I >

13

14

U

V

W

M

3~

SF_550_004_ans_a.ai

*

2

1

6

5

X99: 1 2

DCS550

(SDCS-BAB-F)

(SDCS-PIN-F)

Control board (SDCS-CON-F)

Power supply

Converter

module

ON

OFF STOP

START

OnBoard f

ieldexciter

depending on the unit type

another configuration is possible

the polarities are shown for motor operation

if there are intermediate terminals

Aux. supply

* set by

[50.12],

[50.13]

Legend

fuse

reactor

see 6.03

bit 7

Drive connection and wiring example

The drive configuration with a reduced set of components gives the same control performance, but a lower

degree of monitoring functions.

Electrical installation

3ADW000379R0501 DCS550 Manual e e

X96:

DO8

1 2

X52:

1

2 3

U1

W1V1

PE

K1

F6

K20

K21K20 K1

X96:1

X96:2

L1 L2 L3

F1

M

1~

F2

3

4

1

2

T2

690V

660V

600V

575V

525V

500V

450V

415V

400V

380V

115V

230V

K15

K15

S1

1

2

K6 K8

K10

K21

C 1

D 1

AITAC AI1

AI2 AI3

AI4

+10V

-10V AO1 AO2 I

A

CT

DI1 D I2 DI3

DI4 DI5 DI6

DI7 D I8

+24V

DO1 DO2 DO3 DO4

_

_ _ _

_

+ + +

+

+

Encoder

T

E

M

GND

GNDGND

GND

GND

NC NC NC

X1: 1 2 3 4

5 6 7 8

9 10

X2

: 1

2 3

4 5

6 7 8 9 10 X4:

1 2 3 4

5 6

7

8 9

10

X5:

1 2 3 4 5 6

7 8 1...10

X3

:

+

_

+

_

K1

K20

K21

K6

K8

1

2

S1

K10

2

4 6

1

3 5

K6

F5

1

2

F8

1

2

F7

1

2

2

1

4

3

6

5

F6

I > I > I >

13

14

U

V

W

M

3~

K1

1 3 5

2 4 6

L1

1

2

3

4

K8

13

14

X10

: F+

F-

L1 L2 L1 L2 L3

SF_550_003_ans_a.ai

DCS550

*

(SDCS-PIN-F)

525V, 50/ 60Hz

EMC Filter

E1

see 6.03

bit 7

(SDCS-BAB-F)

see 6.03

bit 0

X99: 1 2

Control board (SDCS-CON-F)

Po

wer supply

Converter

module

ON

OFF

STOP

ST

ART

EMER.

STOP

OnBoard fielde

xciter

depending on the unit type

another configu

r

ation is possible

the polar

ities are shown f

or motoring

if there are inte

rmediate te

rminals

* set by

[50.12],

[50.13]

Leg

end

fuse

reactor

Line reactor

Motor

f

an

fu

rther inf

ormation see chapter

Start,Stop and E-stop control

Aux supply Aux supply

3

4

5

6

5

2

1

The drive configuration with a full set of components offers the highest degree of monitoring functions.

23

3ADW000379R0501 DCS550 Manual e e

Electrical installation

24

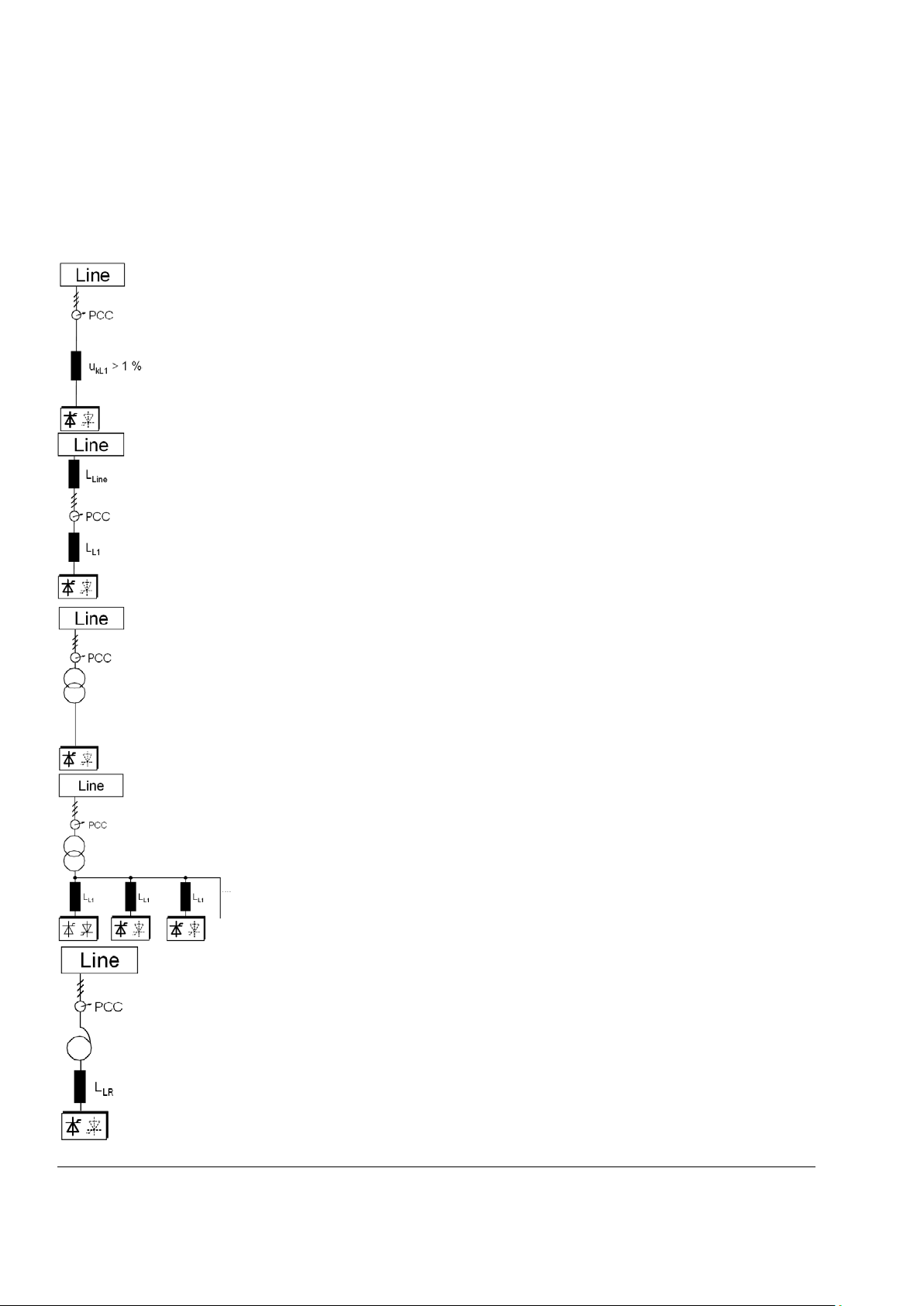

Configuration A

When using the power converter, a minimum of impedance is required to ensure proper

performance of the snubber circuit.

requiremen

should not exceed 10 % u

Configuration B

If special requirements have to be met at the PCC (standards like E

drives at the same line, etc), different criteria must be applied for selecting a line reactor. These

requirements are often defined as a voltage dip in percent of the nominal supply voltage. The

combined impedance of Z

ratio between the line impedance and the line reactor impedance determines the voltage dip at

the connecting point. In such

Example

Voltage dip = Z

Line

/ (Z

Line

+ ZL1) = 20 %. Detailed calculations see Technical Guide.

Configuration C

If an isolation transformer is used, it is possible to comply with certain connecting conditions per

Configuration B without using an additional line reactor. The condition described in Configuration

A will then likewise be satisfied, since the u

Configuration C1

When supplying

that each

Configuration D

In the case of high power converter

When using

because

Installation components

① Line reactors (L1)

When thyristor power converters operate, the line voltage is short-circuited during commutation from one

thyristor to the next. This operation causes voltage dips in the mains PCC (point of common coupling). For the

connection of a power converter system to the mains, one of the following configurations applies:

Use a line reactor to meet this minimum impedance

t. The value must therefore not drop below 1 % uk (relative impedance voltage). It

, due to considerable voltage drops at the converter outputs.

k

N 61 800-3, DC and AC

and ZL1 constitute the total series impedance of the installation. The

Line

cases, line chokes with an impedance around 4 % are often used.

calculation with ukLine = 1 % and ukL1 = 4 %:

is > 1 %.

k

2 or more converters by one transformer use conf iguration A or B. One can see

drive needs its own line reactor.

s, frequently a trans f ormer is used for voltage matching.

an autotransformer for this purpose, additionally install a commutating reactor,

the uk of commonly used autotransformers is too small.

Electrical installation

3ADW000379R0501 DCS550 Manual e e

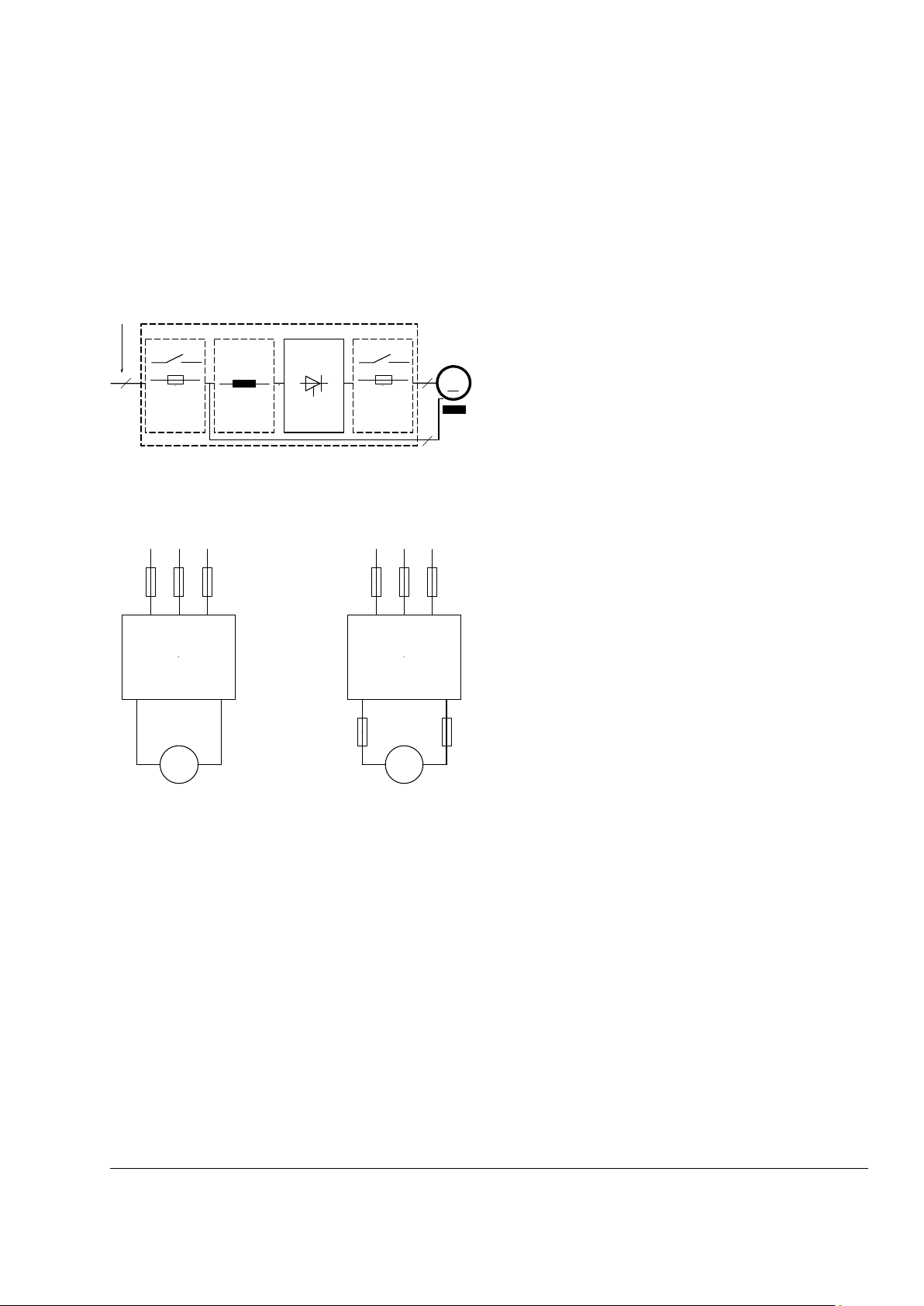

② Semiconductor fuses (F1)

The figure shows the arrangement of the switch-off

elements in the armature circuit. Further information

available

Never use standard fusing instead of semi-conductor

fusing in order to save money on the installation. In the

event of a

saved can cause the semiconductors or other devices to

explode and cause fires. Adequate pro

short circuit and earth fault, as depicted in the EN50178

standard, is possible only with appropriate

semiconductor fuses.

Use

protect the motor in case of a fault during regeneration.

DC fuses must be rated for the same current and voltage

as AC fuses, thus follows

M

.

.

.

.

.

.

3

2

2

SF_550_005_geräteschutz_a.ai

AC supply: public mains / plant's mains

Cabinet

M M

SF_800_009_fuses_a.ai

DCS converter

2-Q non-regen.

Semiconductor

fuses

Semiconductor

fuses

Semiconductor

fuses

4-Q resp.

2-Q regenerative

DCS converter

Aspects of fusing for the armature circuit of DC drives

Unit configuration

Protection elements such as fuses or overcurrent trip circuits are required in all cases to protect against

further damage. In some configurations, this will entail the following questions:

1. Where to place which protective element?

2. In the event of what faults will the element in question provide protection against damage?

in the Technical G uide .

Conclusion

25

is

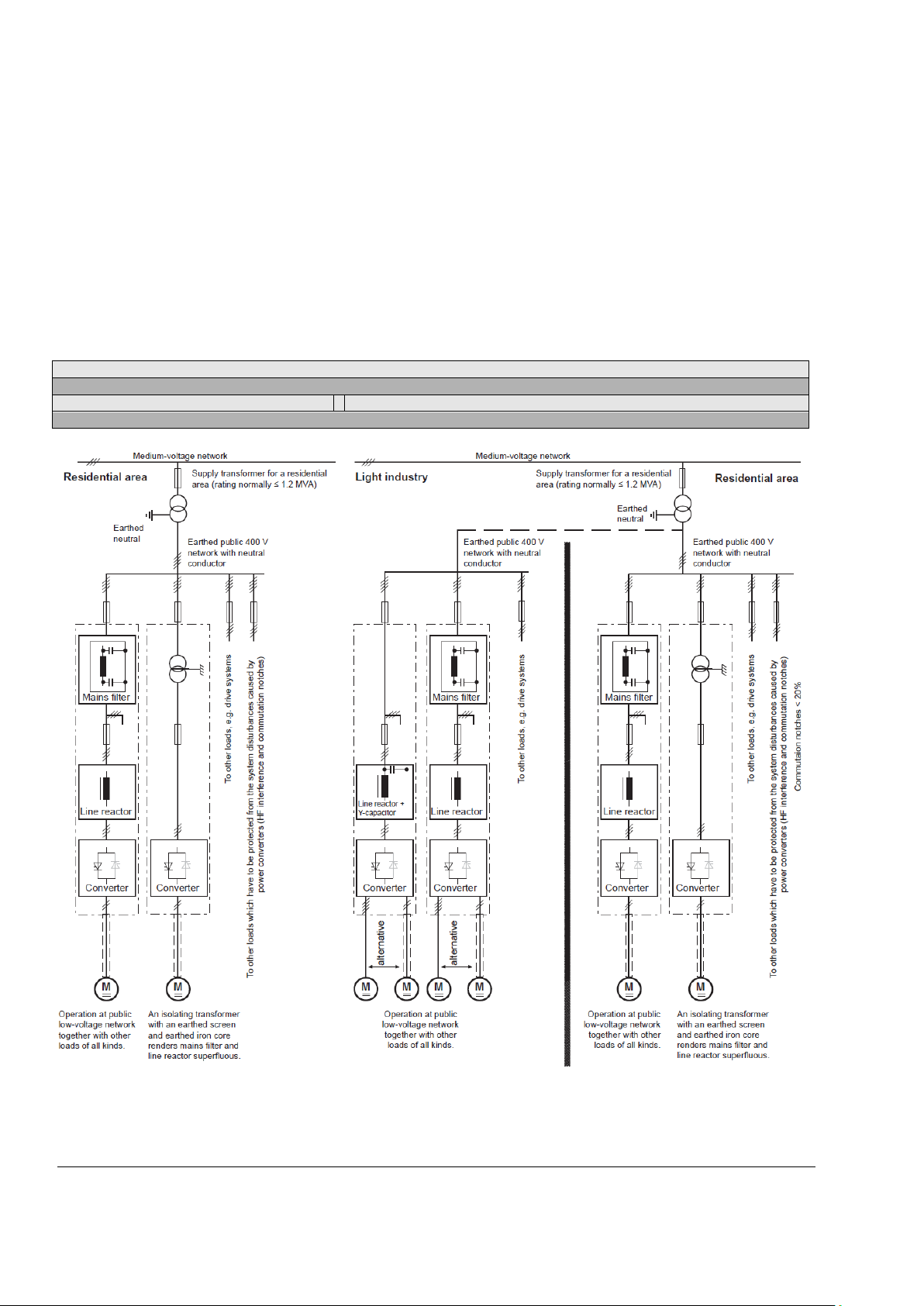

③ EMC filters (E1)

Filter in a grounded line (earthed TN or TT network)

The filters are suitable for grounded lines only, for example in public European 400 VAC lines. According to EN

61800-3 filters are not needed in insulated industrial networks with own supply transformers. Furthermore,

they could cause safety risks in such floating lines (IT networks). According to EN 61800-3 filters are not

needed in industrial zone (Second Environment) for DCS550 drives above 100 A

currents below 100 A

Three-phase filters

EMC filters are necessary to fulfill the standard for emitted interference if a converter shall be run at a public

low voltage line, in Europe for example with 400 V

offers suitable three-phase filters for 400 V

filters are available. Optimize the filters for the real motor currents:

Filter

= 0.8 * i

Mot max

− i

Lines with 500 V

sensitive electronics. Therefore, converters do not need EMC filters if they shall run with 500 V

, the filter requirement is identical to Light Industry (First Environment).

DC

; the factor 0.8 respects the current ripple.

and higher are not public. They are local networks inside factories, and they do not supply

AC

fault condition, the small amount of money

tection against

DC fuses (2 of them) for all regenerative drives to

DC fuses = AC fuses.

rated current. For rated

DC

. Such lines have a grounded neutral conductor. ABB

AC

. For 440 VAC public low voltage lines outside Europe 500 VAC

AC

and more.

AC

Electrical installation

3ADW000379R0501 DCS550 Manual e e

26

The paragraphs below describe selection of the

−

The EMC Guideline expects EMC to be taken into

First environment (residential area with light industry) with PDS category C2

Not applied, since category C1 (general distribution sal es c hanne l) ex cluded

Not applicable satisfied

satisfied

EMC filters

Further information

is available in the

Technical Guide.

electrical components in conformity with the

EMC Guideline. The aim of the EMC Guideline

is, as the name implies, to achieve

electromagnetic compatibility with other

products and systems. The guideline ensures

that the emissions from the product concerned

are so low that they do not impair another

product's interference immun it y .

In the context of the EMC Guideline, two

aspects must be borne in mind:

− the product's interference immunity and

the product's actua l emissions.

account when developing a product; however,

EMC cannot be designed in, it can only be

quantitatively measured.

Notes on EMC conformity:

The conformity procedure is the responsibility of

both the power converter' s sup plier and the

manufacturer of the machine or system

concerned, in proportion to their share in

expanding the electrical equipment involved.

Electrical installation

3ADW000379R0501 DCS550 Manual e e

For compliance with the protection

objectives of the German EMC Act

(EMVG) in systems and machines, the

following EMC standards must be satisfied:

Product Standard EN 61800

EMC

(

immunity and emissions in residential

areas, enterprise zones with light industry

and in industrial facilities. This standard

must be complied with in the EU for

sa

systems and machines!

For emitted interference, the following apply:

EN 61000

-6-3 Specialized basic standard for emissions in light industry

can be satisfied with special features (mains filters, screened

EN 61000

For interference immunity, the following apply:

EN 61000

EN 61000

* The old generic standards are given in brackets

Standards

Second environment (industry) with PDS categories C3, C4

EN 61800-3

Not applicable

EN 61000-6-3

satisfied

on customer's

request

satisfied

EN 61000-6-4

satisfied

EN 61000-6-2

EN 61000-6-1

Classification

The following overview

utilizes the terminology and

indicates the action required

in accordance with Product

Standard

EN 61800

For the DCS

limit values for emitted

interference are complied

with, provided the measure

indicated is carried

of category C2 (formerly

restricted distribution in first

environment) is intended to

be installed and

commissioned only by a

professional (person or

organization with necessary

skills in installing and/or

commissioning PDS

including their EMC asp

For power converters without

additional components, the

following warning applies:

This is a product of category

C2 under IEC 61800-3:2004.

In a domestic/residential

environment, this product

may cause radio interference

in which case supplementary

mitigation measures may be

required.

The field supply is not

depicted in this overview

diagram. For the field current

cables, the same rules apply

as for the armature

cables.

27

-3

standard for drive systems

PowerDriveSystem), interference

tisfying the EMC requirements for

power cables) in the lower rating range *(EN 50081-1).

-6-4 Specialized basic standard for emissions in industry *(EN

50081-2)

-6-1 Specialized basic standard for interference immunity in

residential areas *(EN 50082-1)

-6-2 Specialized basic standard for interference immunity in

industry. If this standard is satisfied, then the EN 61000-6-1

standard is automatically satisfied as well *(EN 50082-2).

-3

550 series, the

out. PDS

ects).

-circuit

Electrical installation

3ADW000379R0501 DCS550 Manual e e

28

The commands represented by K20 and K21

In case the E-stop push button is hit, the

setting, the drive must get the command to

the main contactor

is opened immediately, independent of the

K16

K15

K16

K15

DI4

K15

X6:9

SDCS-CON-4

S1

1

2

SF_CON4_001_E-stop_a.ai

E-Stop

electrical

disconnect

(coast)

Block

current

command

DZ_LIN_006_E-stop_b.ai

E-stop

Speed

Block current control

Main contactor K1

E-stop ramp Coast

Timer K15

Timer K16

④ Auxiliary transformer (T2) for converter electronics and fan

The converter module requires various auxiliary voltages, e.g. the module’s electronics and cooling fans

requires either a single-phase supply of 115 V

or 230 VAC. The auxiliary transformer (T2) is designed to

AC

supply the module’s electronics and cooling fans.

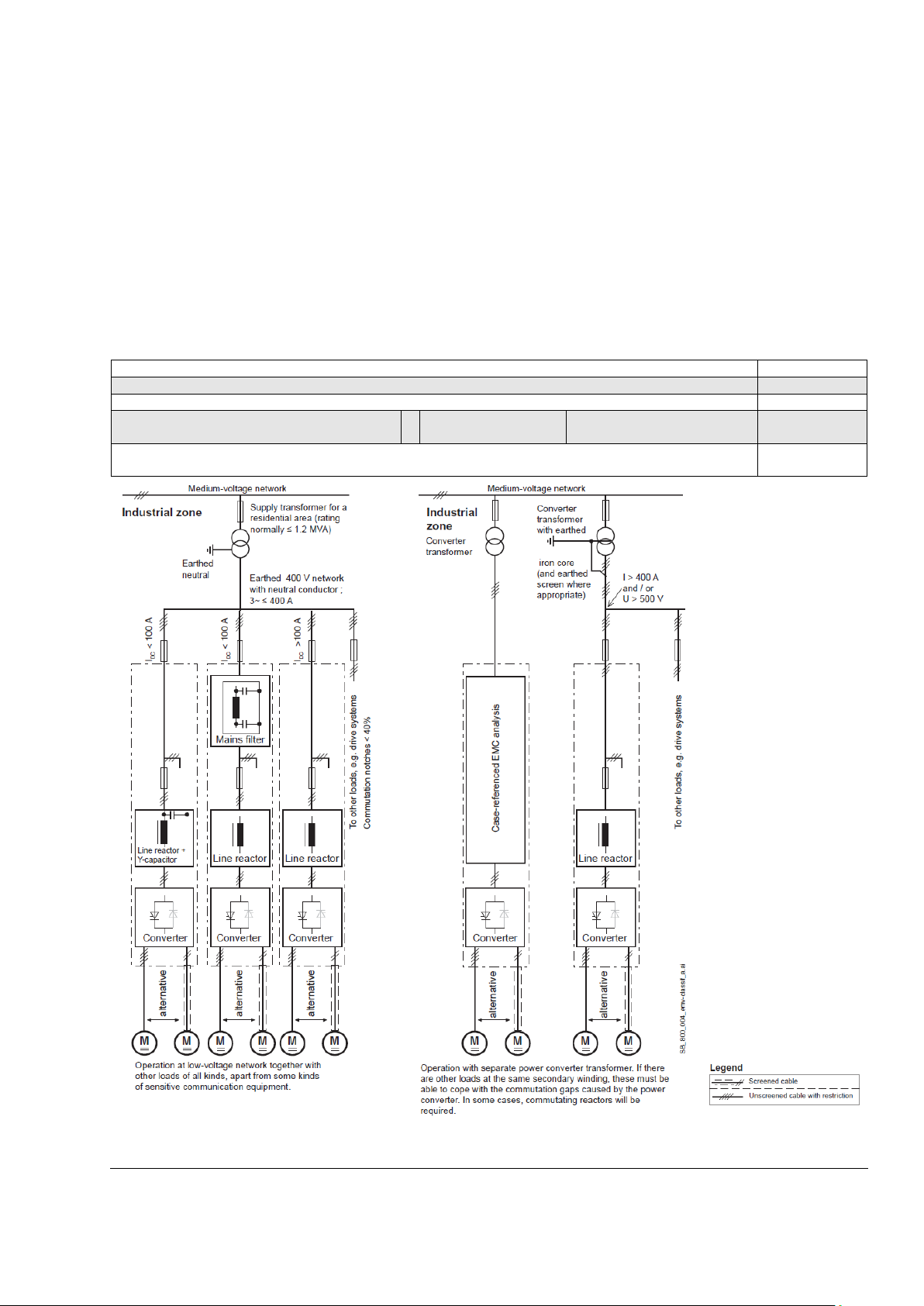

⑤ Start, Stop and E-stop control

The relay logic is splitted into three parts:

1. Generation of On / Off and Start / Stop commands:

(latching interface relay) can also be generated by

a PLC and transferred to the terminals of the

converter either by relays, using galv anic is ol ati on

or directly via 24 V signals. There is no need to

use hardwired signals. Transfer these commands

via serial communication. Even a mixed solution

can be realized by selecting different possibilities

for the one or the other signal (see parameter

group 11).

2. Generation of control and monitoring signals:

Control the main contactor K1 for the armature circuit by the dry contact of DO8 located on the

SDCS-PIN-F. The status of motor (K6) and converter (K8) fans can be monitored by means of MotFanAck

(10.06).

3. Off2 (Coast Stop) and Off3 (E-stop):

Beside On / Off and Start / Stop the drive is equipped with two additional stop functions Off2 (Coast Stop)

and Off3 (E-stop) according to Profibus standard. Off3 (E-stop) is scalable via E Stop Mo de (21.04) to

perform stop category 1. Connect this function to the E-stop push button without any time delay. In case of

E StopMode (21.04) = RampStop the K15 timer relay must be set longer than E StopRamp (22.04). For E

StopMode (21.04) = Coast the drive opens the main contactor immediately.

Off2 (Coast Stop) switches the DC current off as fast as possible and prepares the drive to open the main

contactor or drop the mains supply. For a normal DC motor load the time to force the DC current to zero is

below 20 ms. This function should be connected to all signals and safety functions opening the main

contactor. This function is important for 4-Q drives. Do not open main contactor during regenerative

current. The correct sequence is:

1. switch off regenerative current,

2. then open the main contactor.

information is transferred to the converter

via DI5. In case E StopMode (21.04) =

RampStop or TorqueLimit the converter

will decelerate the motor and then open

the main contactor. If the drive has not

finished the function within the K15 timer

switch off the current via K16. After the

K16 timer has elapsed,

drive’s status.

Electrical installation

3ADW000379R0501 DCS550 Manual e e

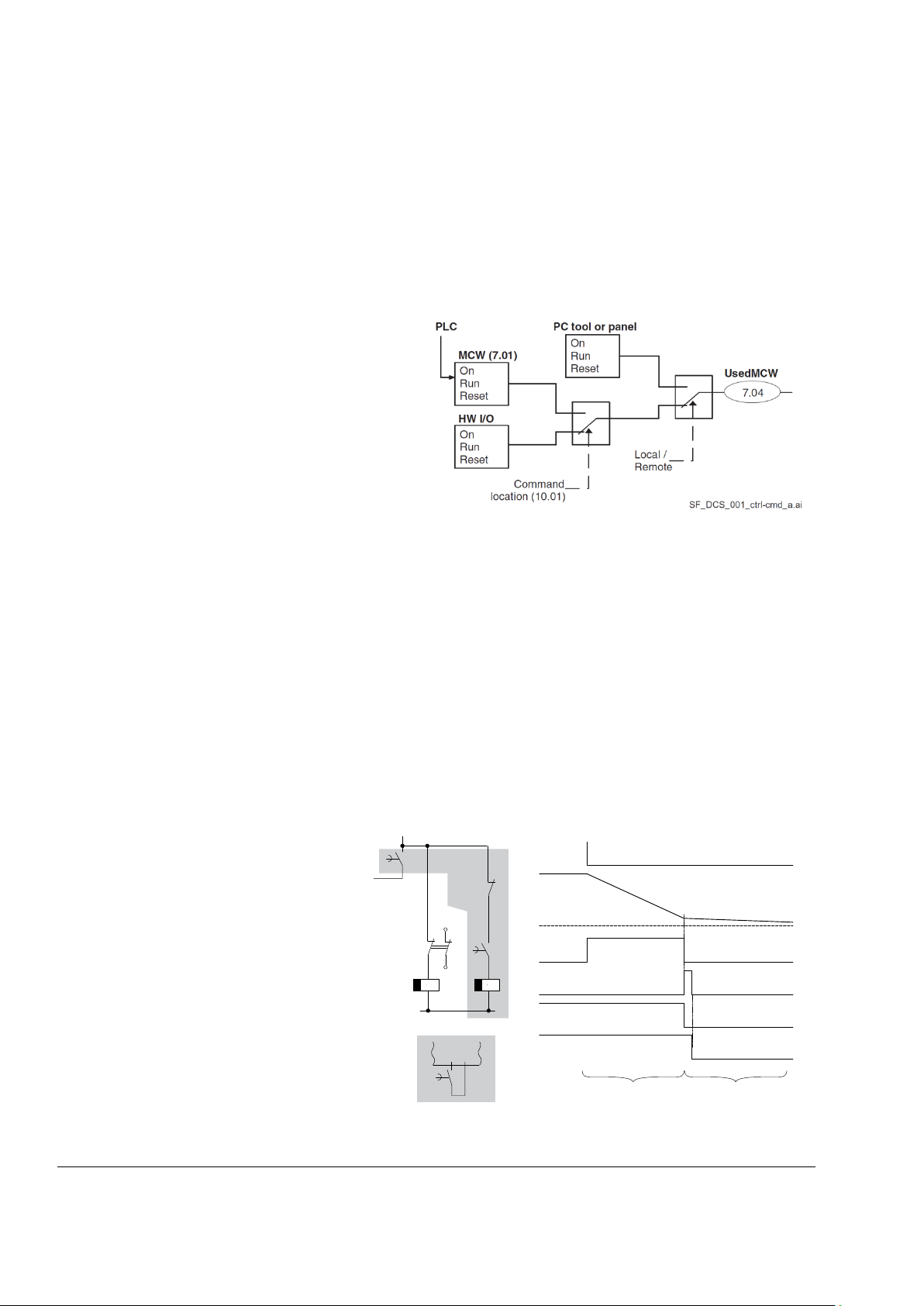

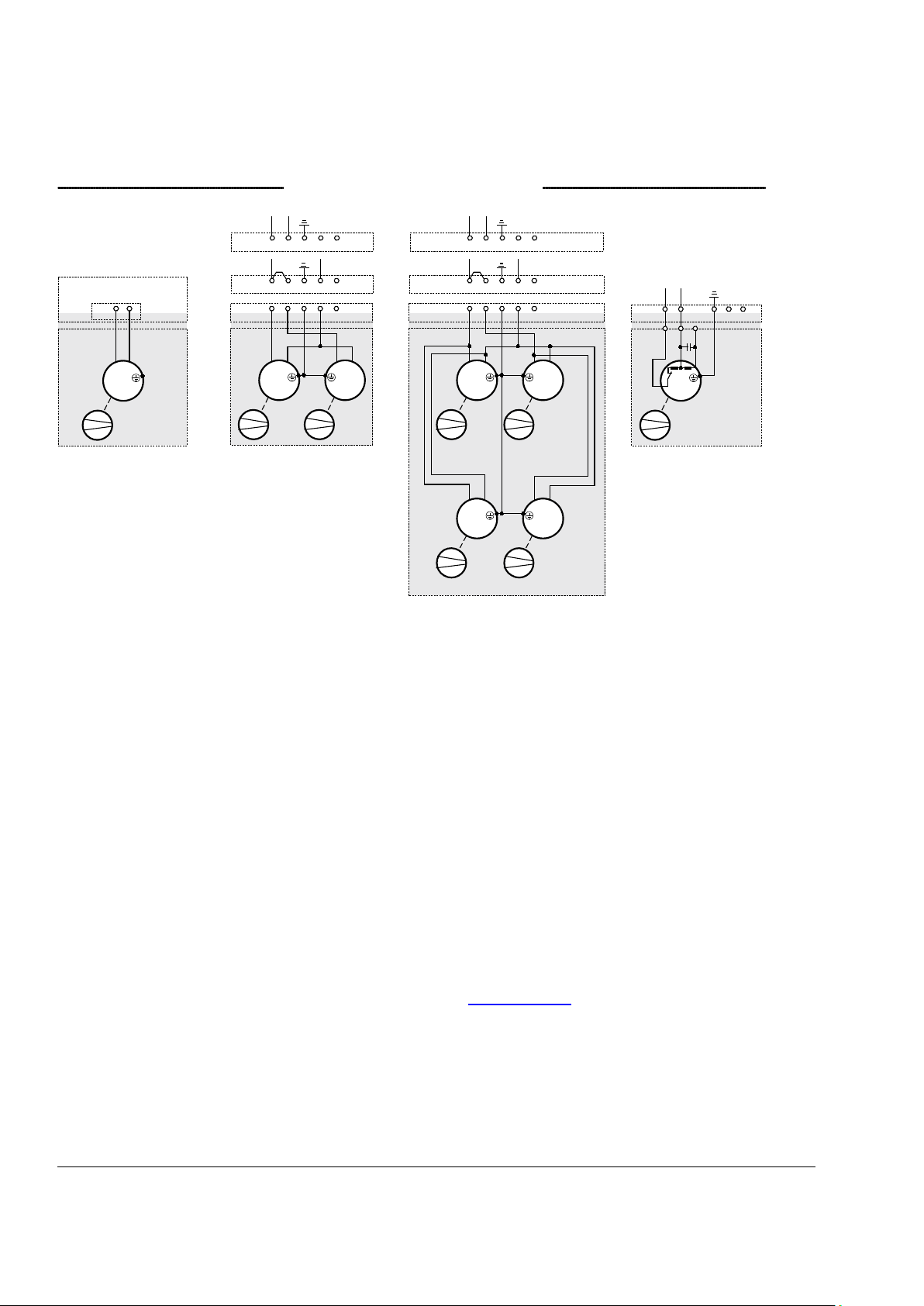

⑥ Cooling fans

Converter type

Size

Configuration

Fan type

DCS550-S01-0020, …,

DCS550-S02-0025

F1

-

No fan, convection cooled

DCS550-S01-0045, …,

DCS550-S02-0100

1

1 x 3110 KL-05W (internal 24 VDC)

DCS550-S01-0135, …,

DCS550-S02-0300

F2

2

2 x 4715 MS-12T (115 VAC / 230 VAC)

DCS550-S01-0315, …,

DCS550-S02-0450

F3

DCS550-S01-0470, …,

DCS550-S02-0520

3

2 x 4715 MS-12T (115 VAC / 230 VAC)

2 x 3115 FS-12T (115 V

/ 230 V

)

DCS550-S01-0610, …,

DCS550-S02-0820

F4

4

1 x W2E200 (230 VAC)

DCS550-S01-0900, …,

DCS550-S02-1000

1 x W2E250 (230 VAC)

Fan

3110 KL-05W

4715 MS-12T

3115 FS-12T

W2E200

W2E250

Rated voltage [VAC]

DC

115; 1~

115; 1~

230; 1~

230; 1~

Tolerance [%]

+15 / -50

± 10

± 10

+6 / -10

+6 / -10

Frequency [Hz]

-

50

60

50

60

50

60

50

60

Power consumption [W]

2.88

16

13

9.5

8.0

64

80

135

185

Current consumption [A]

0.12

0.2

0.17

0.075

0.060

0.29

0.35

0.59

0.82

Blocking current [A]

-

< 0.3

< 0.26

< 0.085

< 0.075

< 0.7

< 0.8

< 0.9

< 0.9

Air flow [m3/h] freely blowing

66

156

180

47.5

55

925

1030

1860

1975

Max. ambient temp. [°C]

< 70

< 60

< 70

< 70

< 60

Useful lifetime of grease

approximately

70,000 h / 25°

approximately

40,000 h / 60°

approximately

50,000 h / 20°

approximately 40,000 h / 60°

Protection

DC

Impedance

Internal temperature detector

①

②

permissible for the insulation class being involved.

Fan assignment for DCS550:

Fan data for DCS550:

24 V

29

①

Impedance ②

Internally connected

Increased losses due to increased current with a blocked rotor will not result in a winding temperature, higher than

Electrical installation

3ADW000379R0501 DCS550 Manual e e

30

1 2 3X52: 4 5

L

N

1 2 3

X52:

4 5

L

N

115V

AC

M

~

1 2 3

X52:

M

~

4 5

M55 M56

M

~

1 2 3

X52:

M

~

4 5

M55 M56

M

~

M

~

M57 M58

M55

M

~

1 2 3 4 5

X52:

L N

L

N

1 2 3

X52:

4 5

L

N

230V

AC

230V

AC

1 2 3X52: 4 5

L

N

115V

AC

J

M55

M

~

X19:

SDCS-PIN-F

F4F3F2, F3F1

SA_550_002_fan_a.ai

only 230 V

AC

Configuration 4Configuration 3Configuration 2Configuration 1

Terminals are located on top of the converter housing

Fan connection for DCS550:

Cabling

Thermal overload and short-circuit protection

The drive protects itself and the input and motor cables against thermal overload when the cables are

dimensioned according to the nominal current of the drive.

Power cables

Dimension the mains and motor cables according to local regulations. The cables must:

1. be able to carry the DCS550 load current,

2. be rated for at least 60°C (140°F),

3. fulfill short-circuit protection,

4. be rated according permissible touch voltage appearing under fault conditions (so that the fault point

voltage will not rise too high when an earth fault occurs) and

5. be screened according to safety regulations.

Mains cable (AC line cable) short-circuit protection

Always protect the input cable with fuses. Size the fuses according to local safety regulations, appropriate

input voltage and the rated current of the drive, see chapter Technical Data

High-speed semiconductor fuses provide short-circuit protection, but do not provide thermal overload

protection.

.

Electrical installation

3ADW000379R0501 DCS550 Manual e e

Loading...

Loading...